Comparative Study of Analytical Model Predictive Control and State Feedback Control for Active Vibration Suppression of Two-Mass Drive

Abstract

1. Introduction

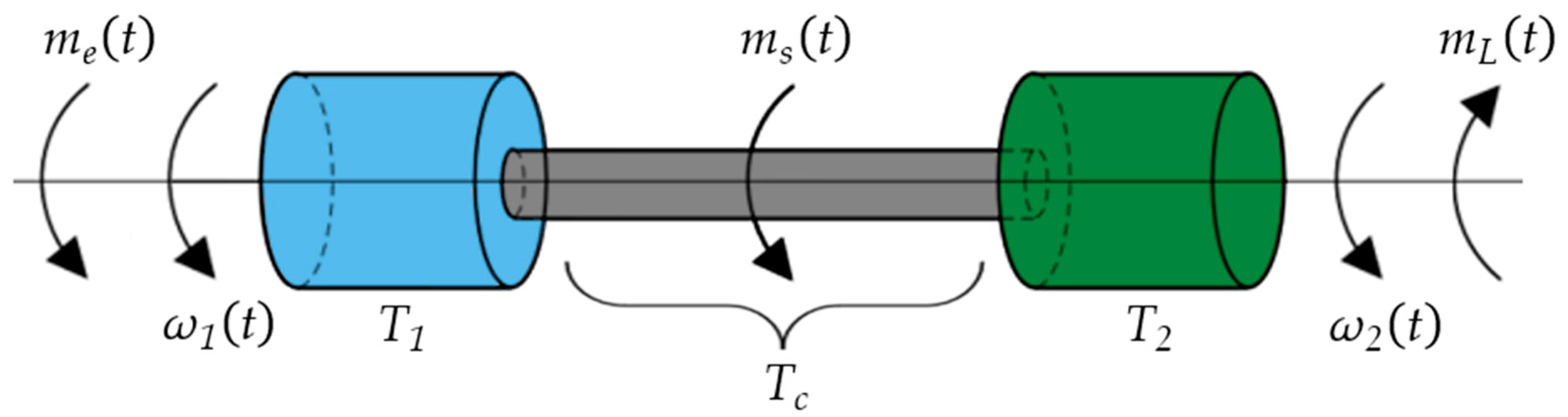

2. The Mathematical Model of the Two-Mass Motor Drive

3. Proposed Control Methods

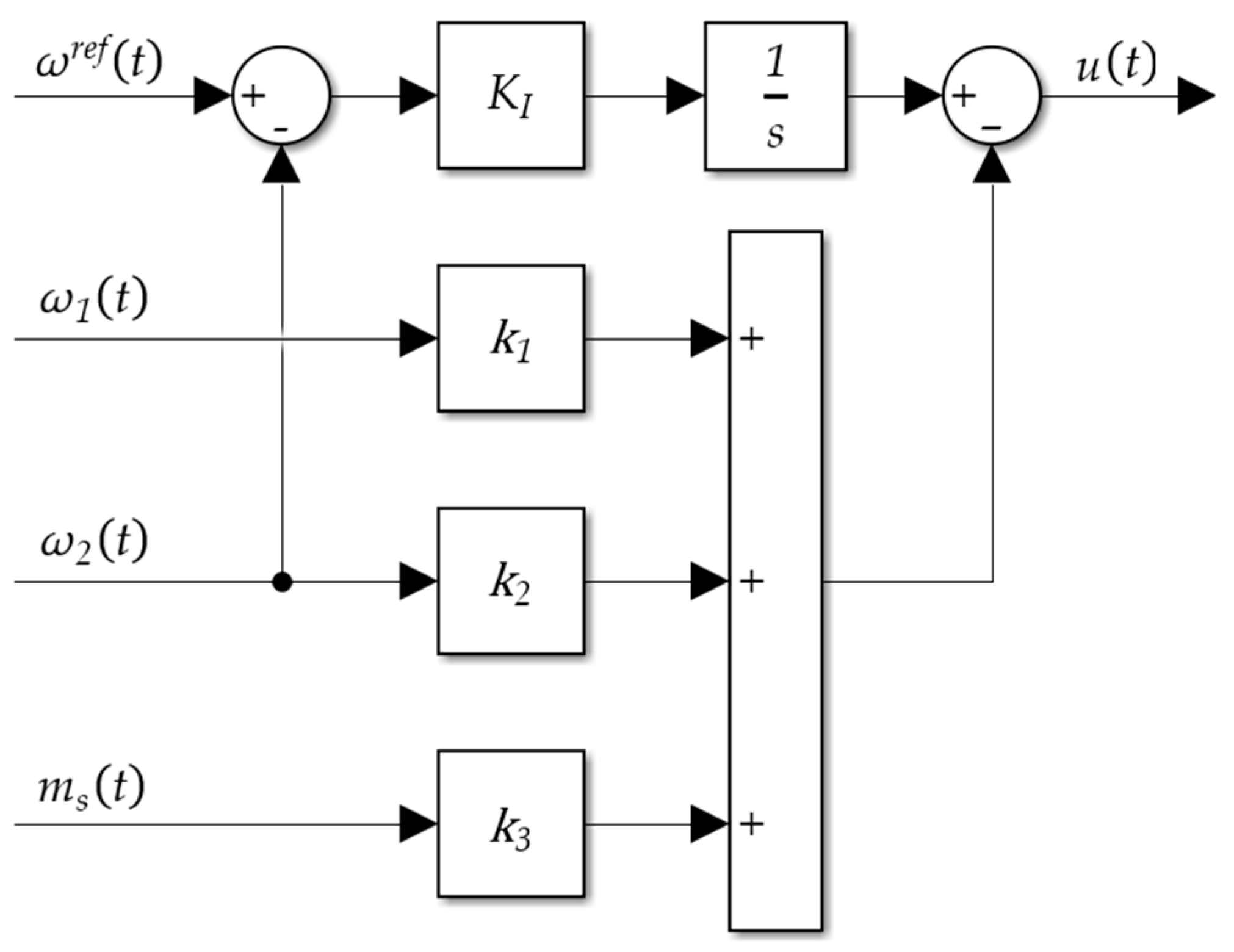

3.1. State Feedback Control (SFC)

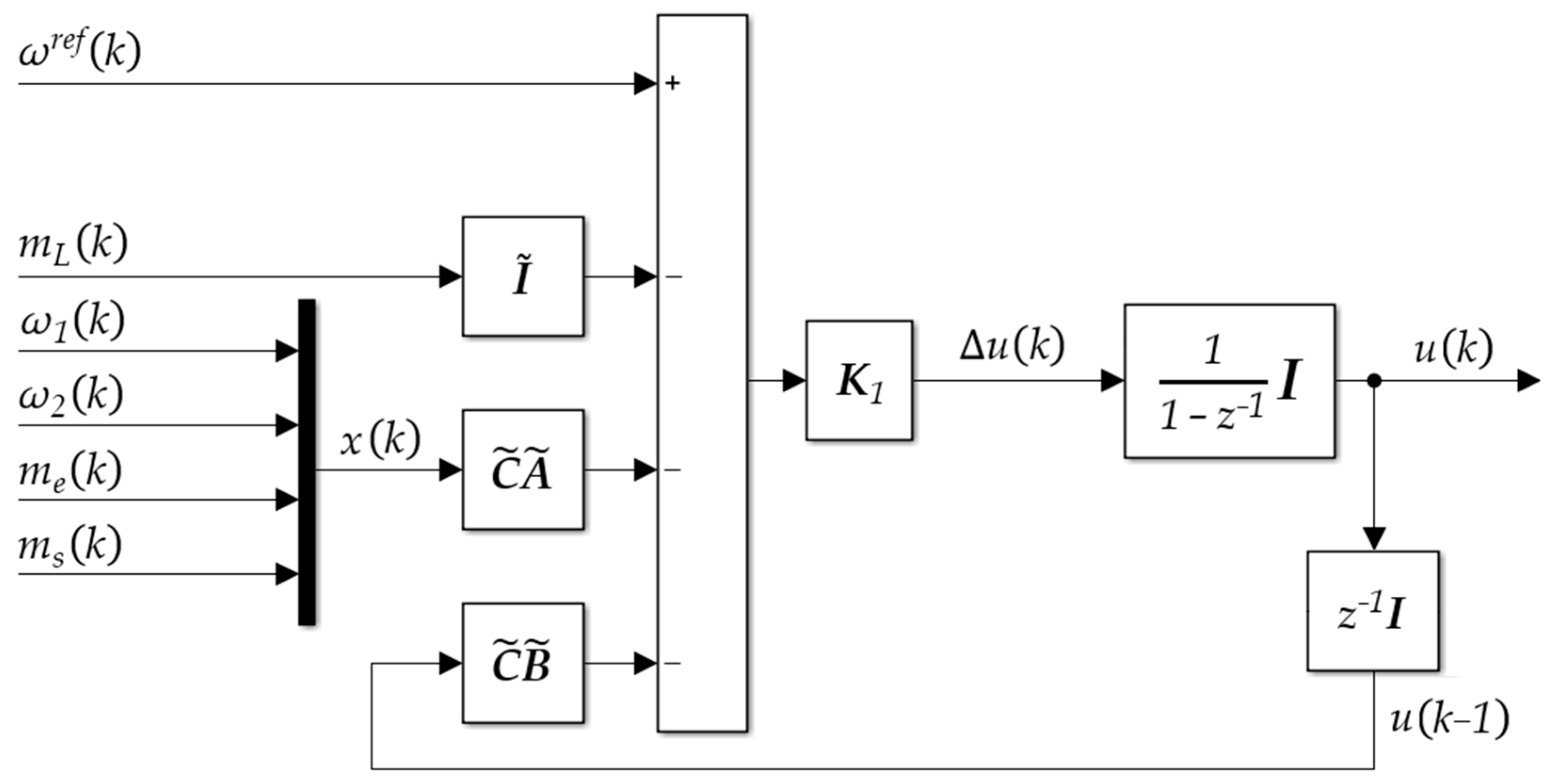

3.2. Analytical Model Predictive Control (aMPC)

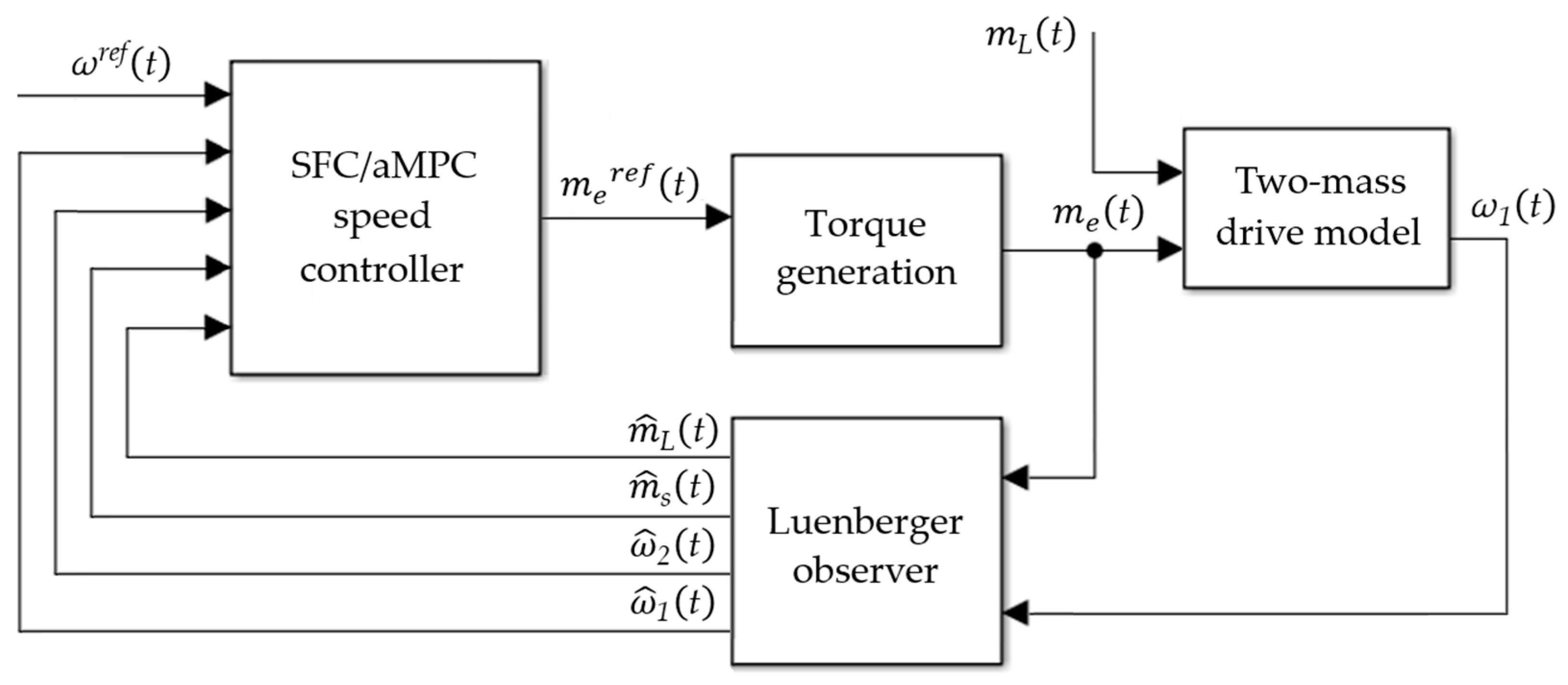

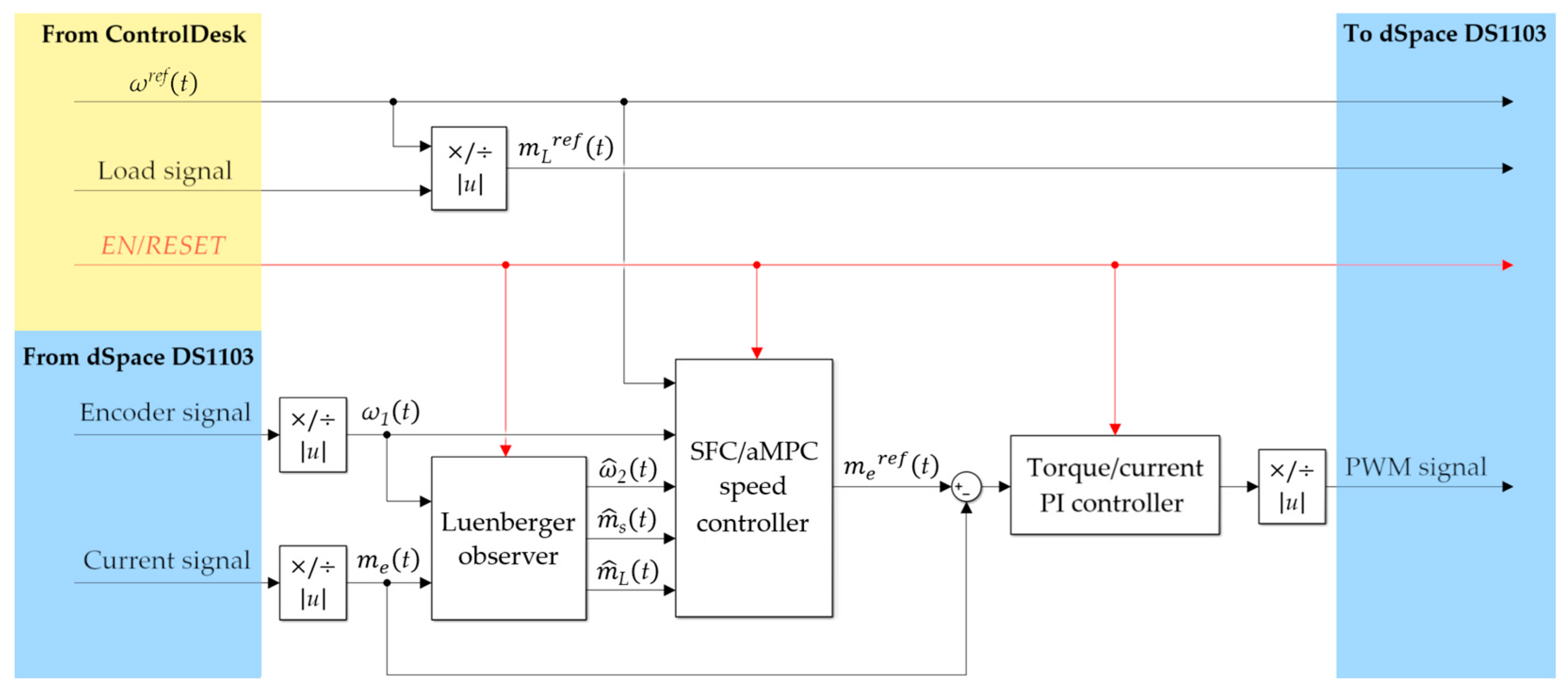

4. Control Structure

4.1. Proposed Cascade Control Structure

4.2. Control Quality Evaluation

5. Simulation Study

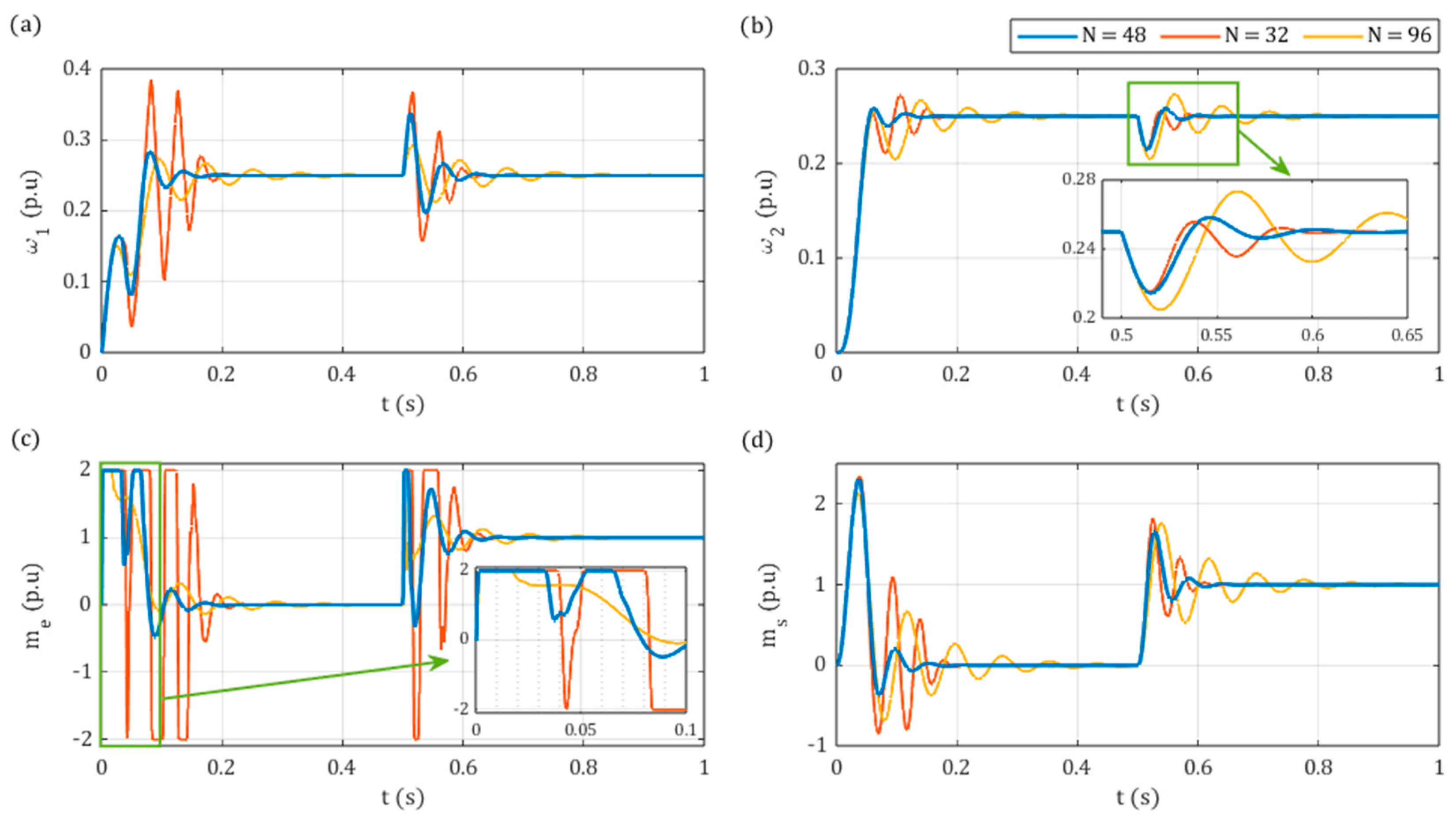

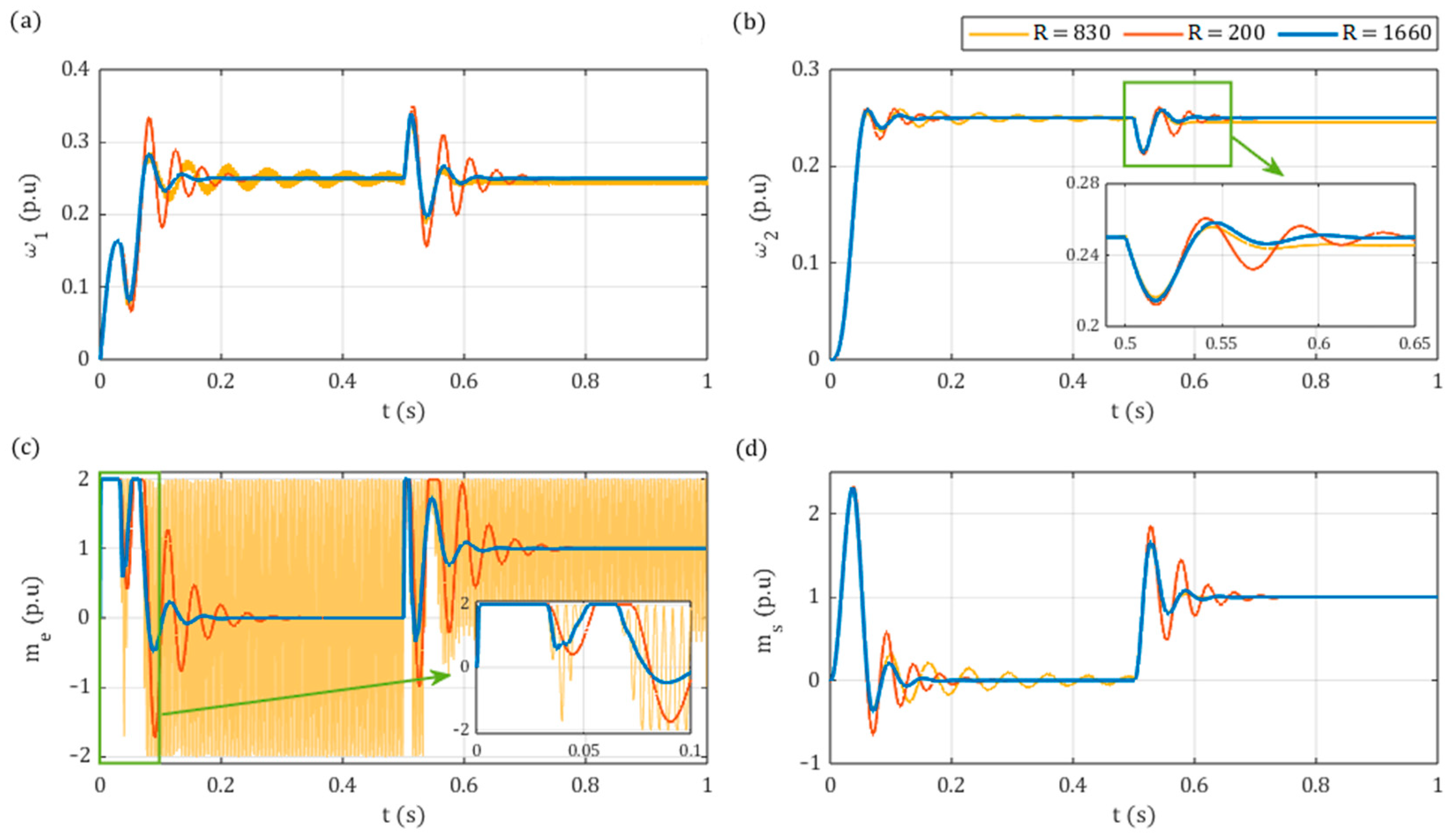

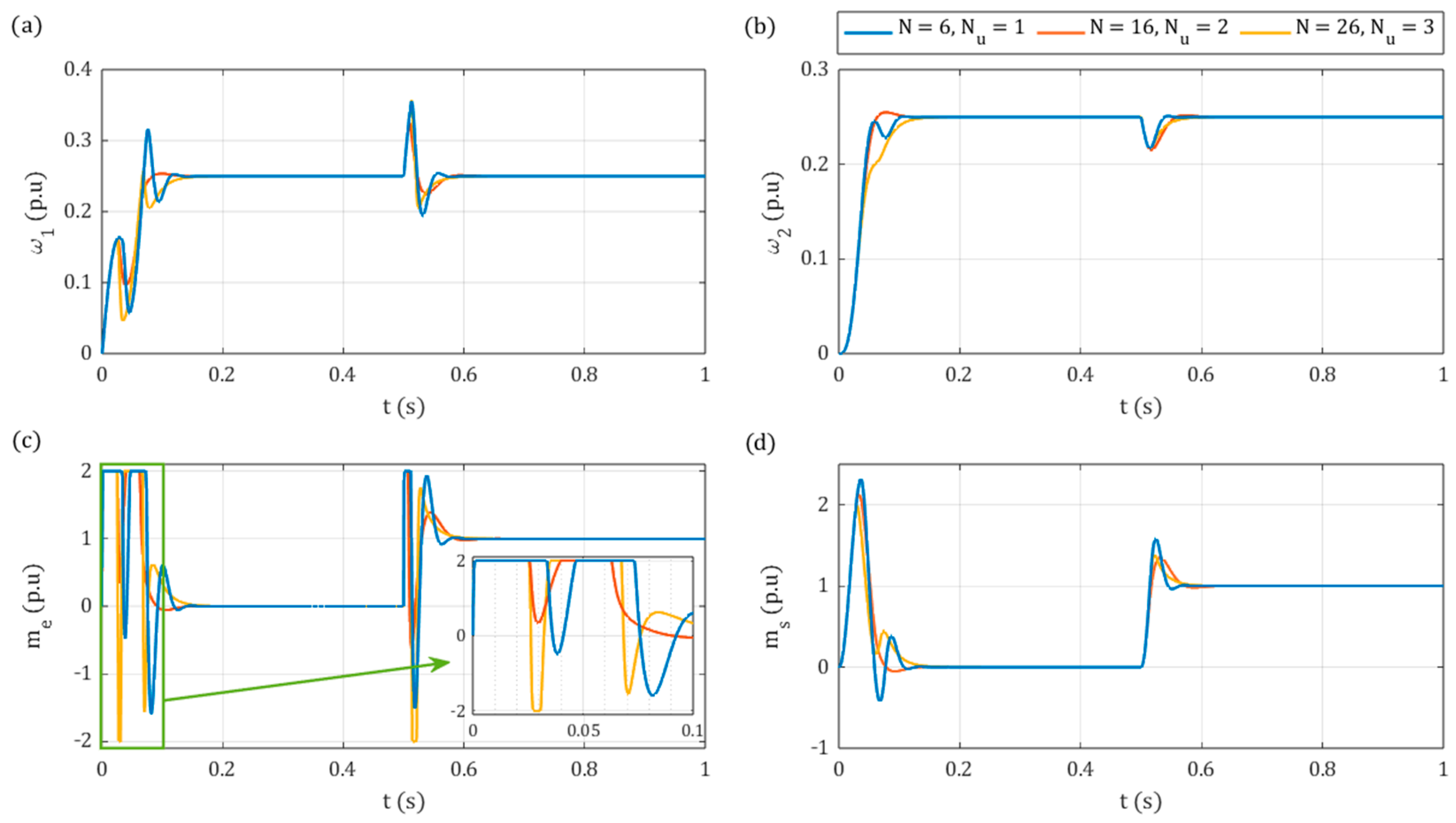

5.1. Analytical Model Predictive Control (aMPC) Tests

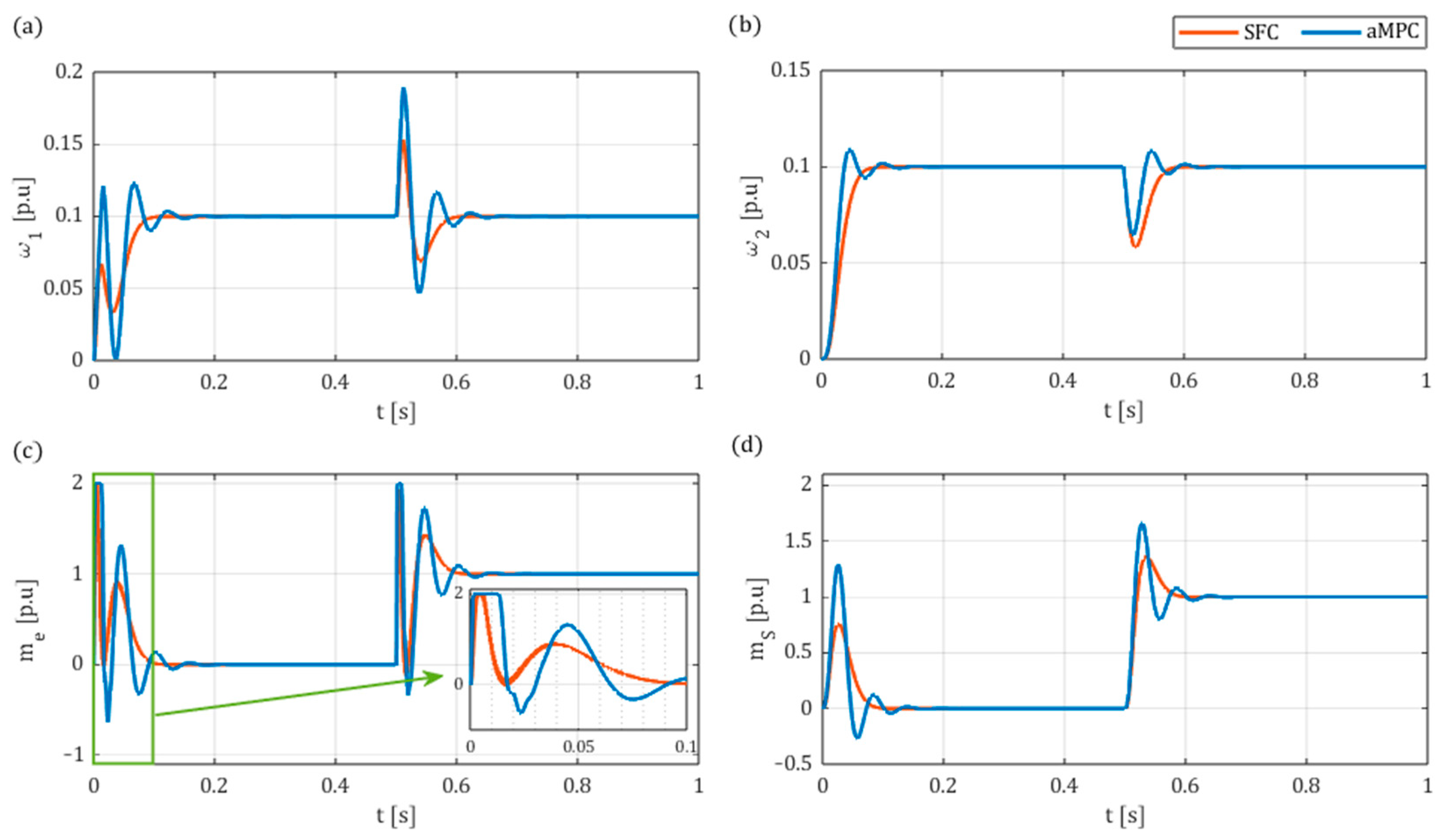

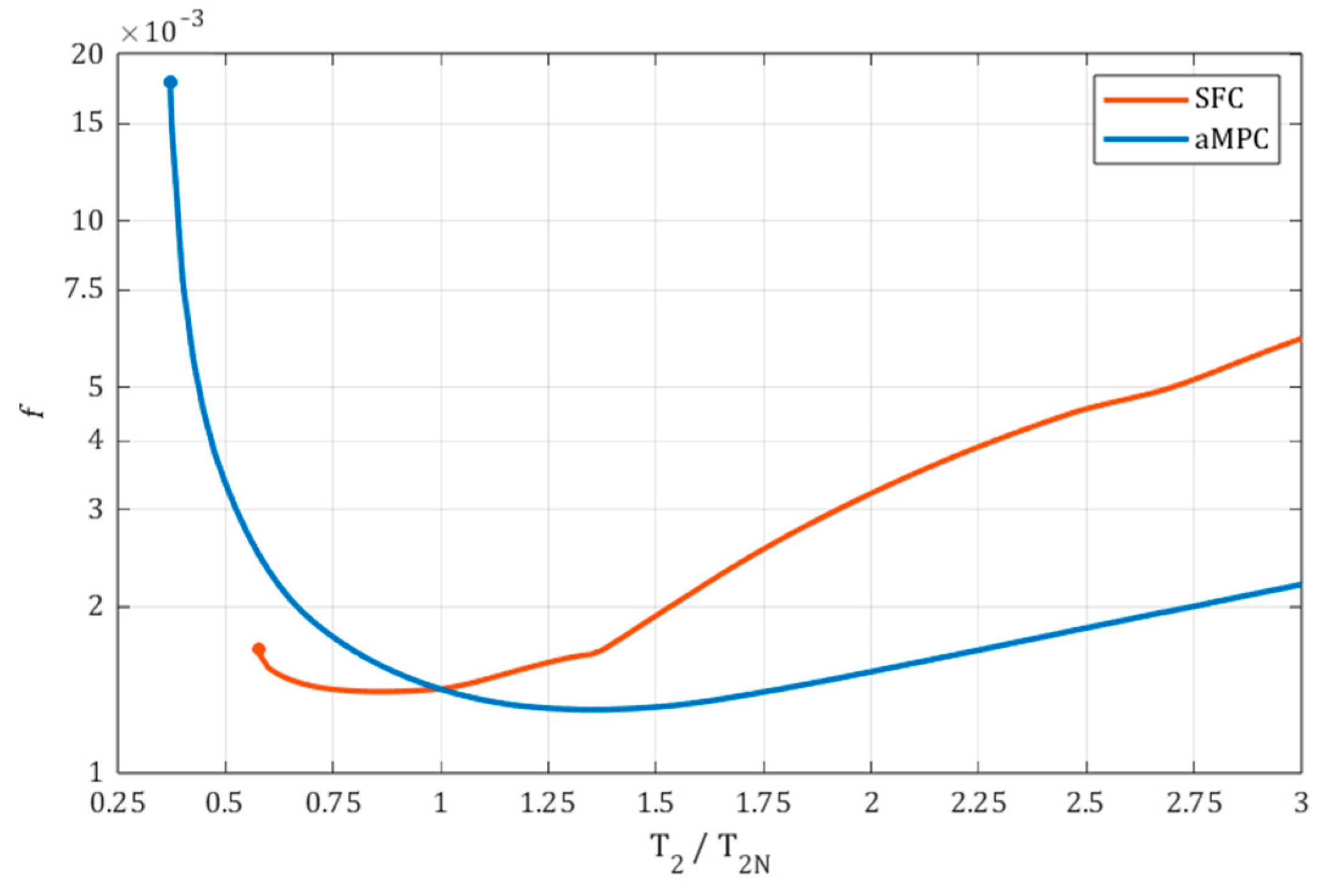

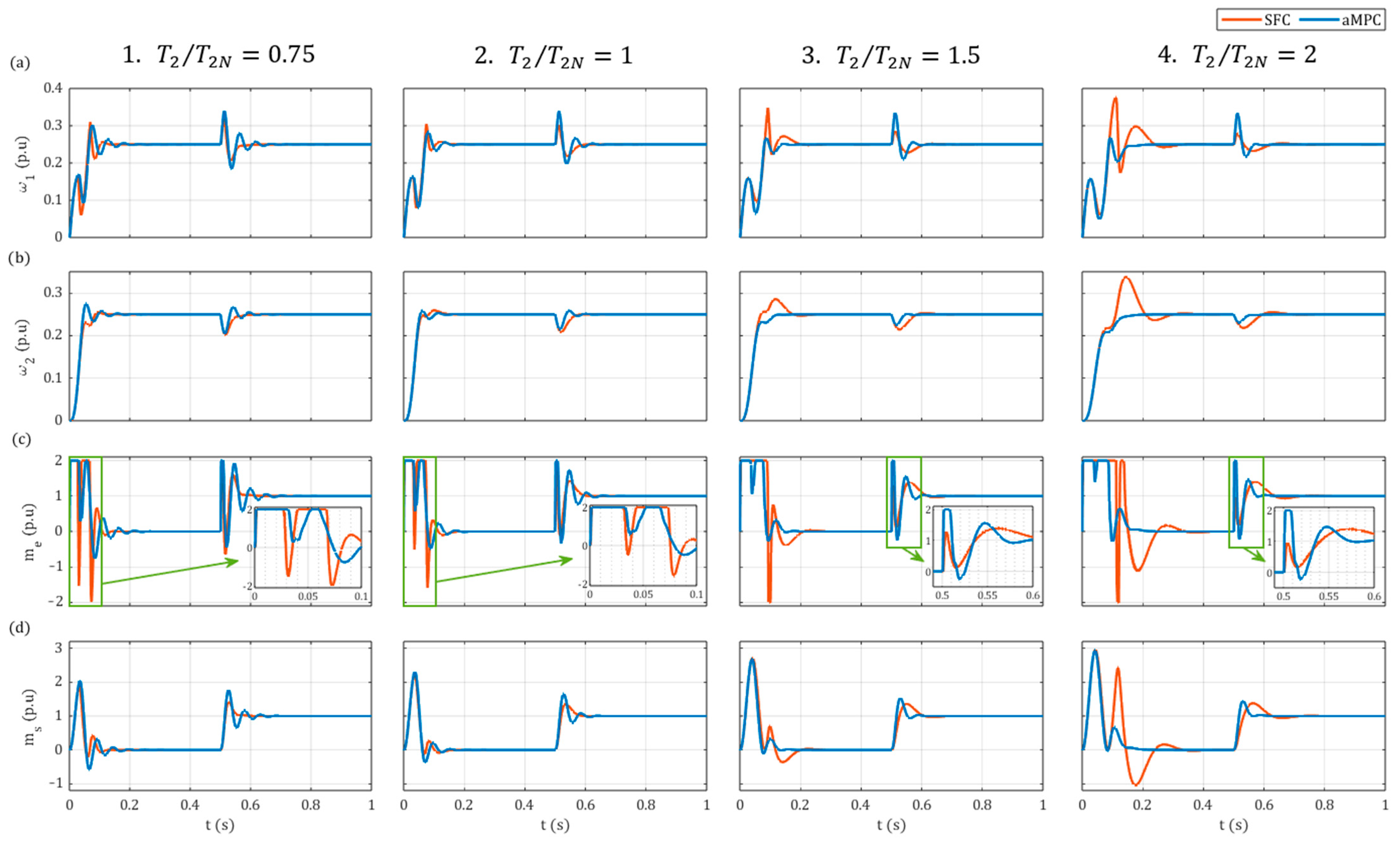

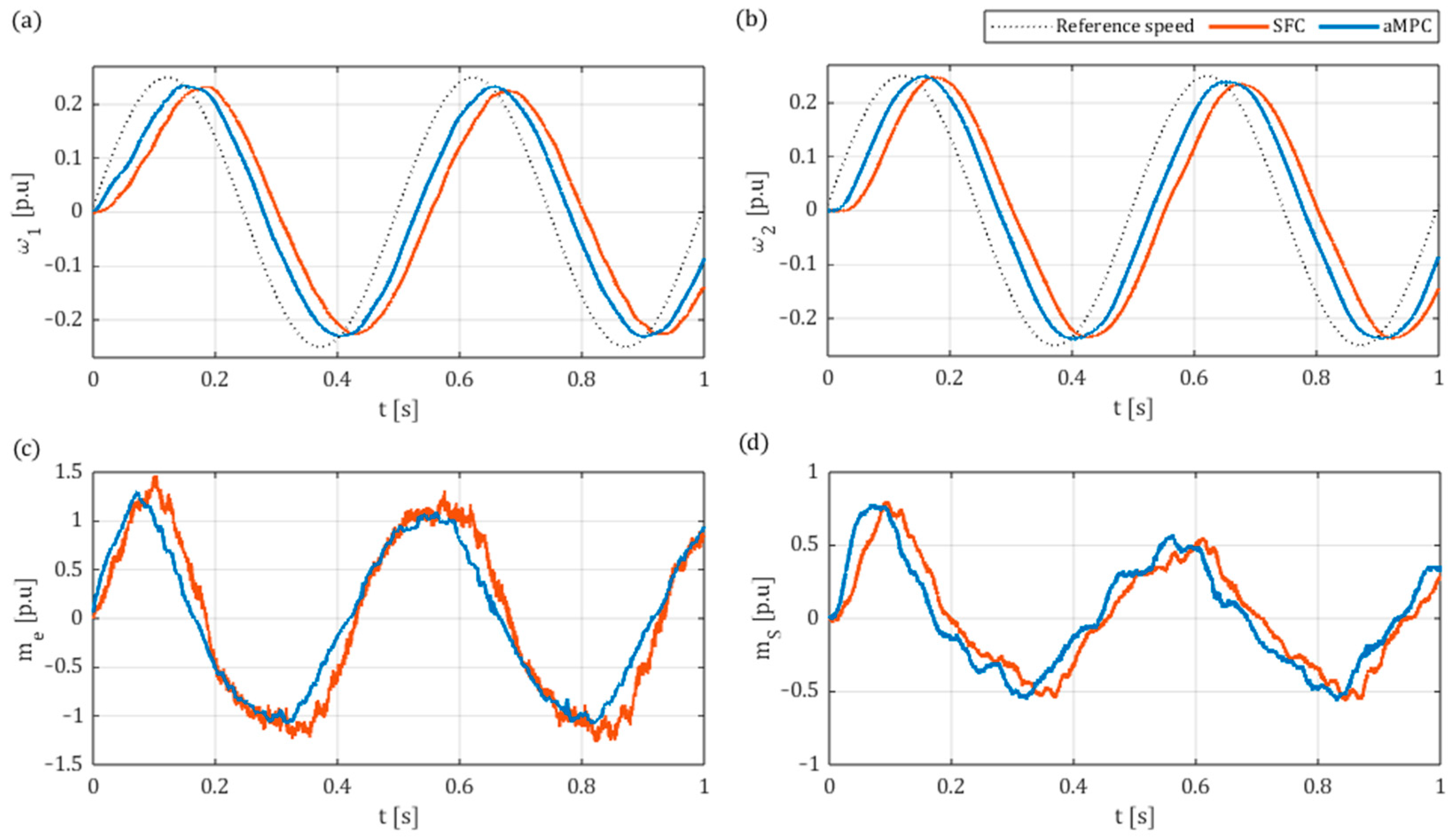

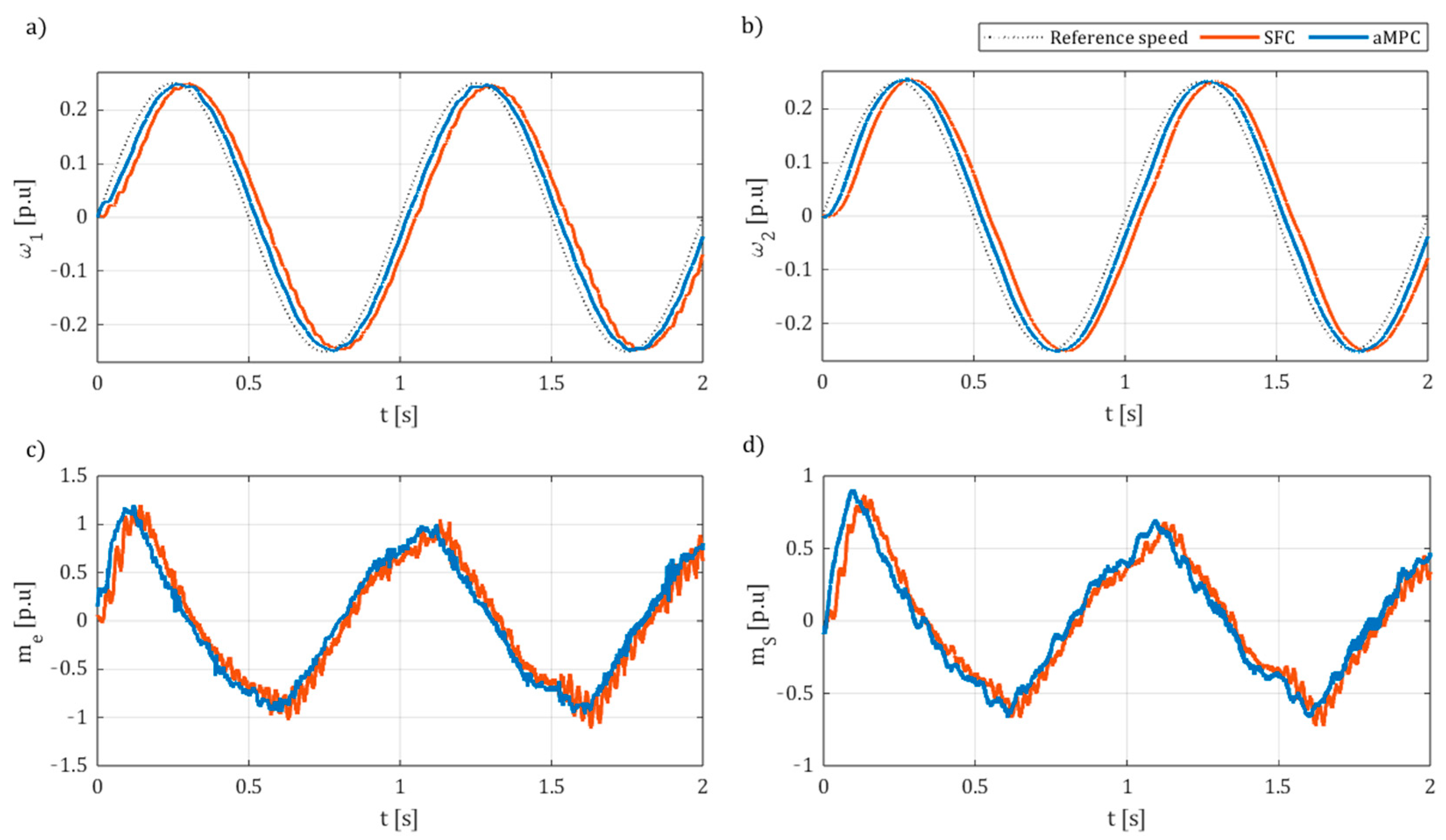

5.2. Comparative Study

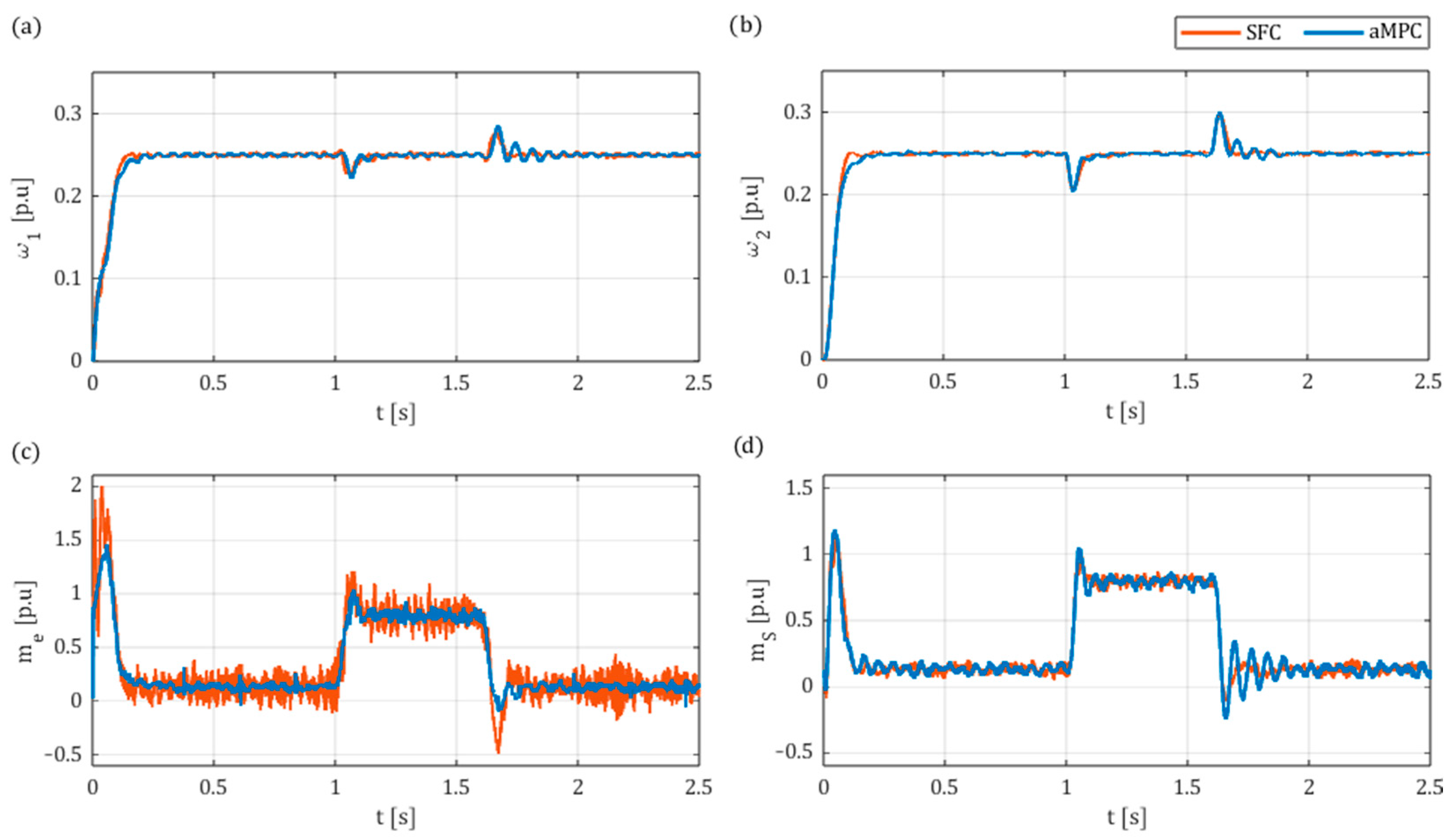

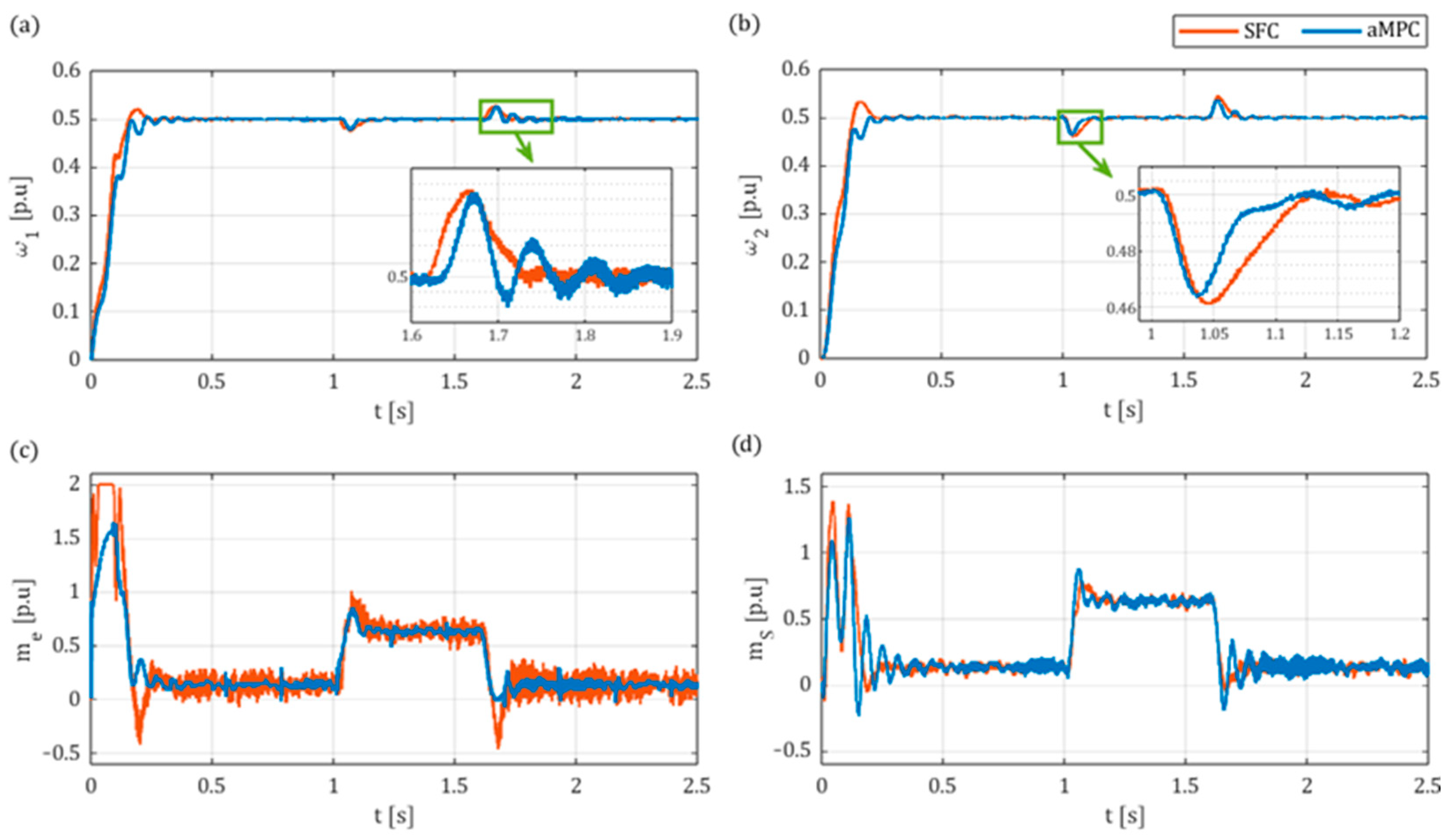

6. Experimental Results

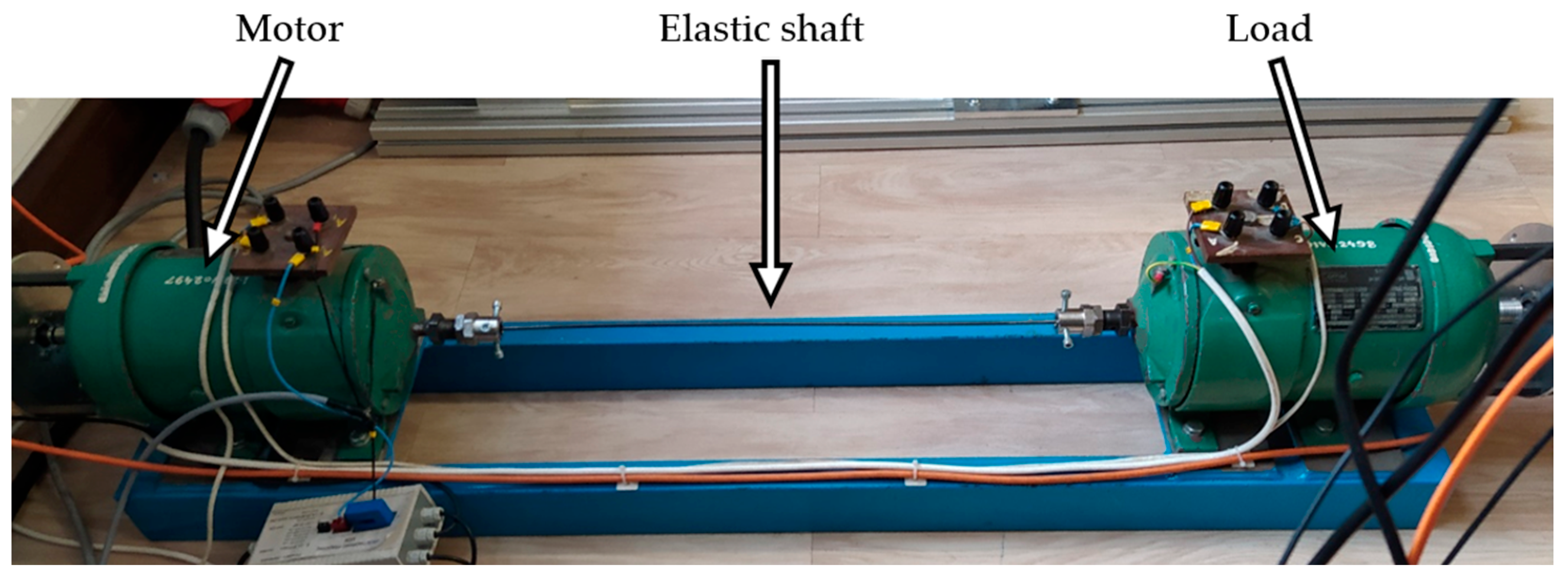

6.1. Laboratory Setup

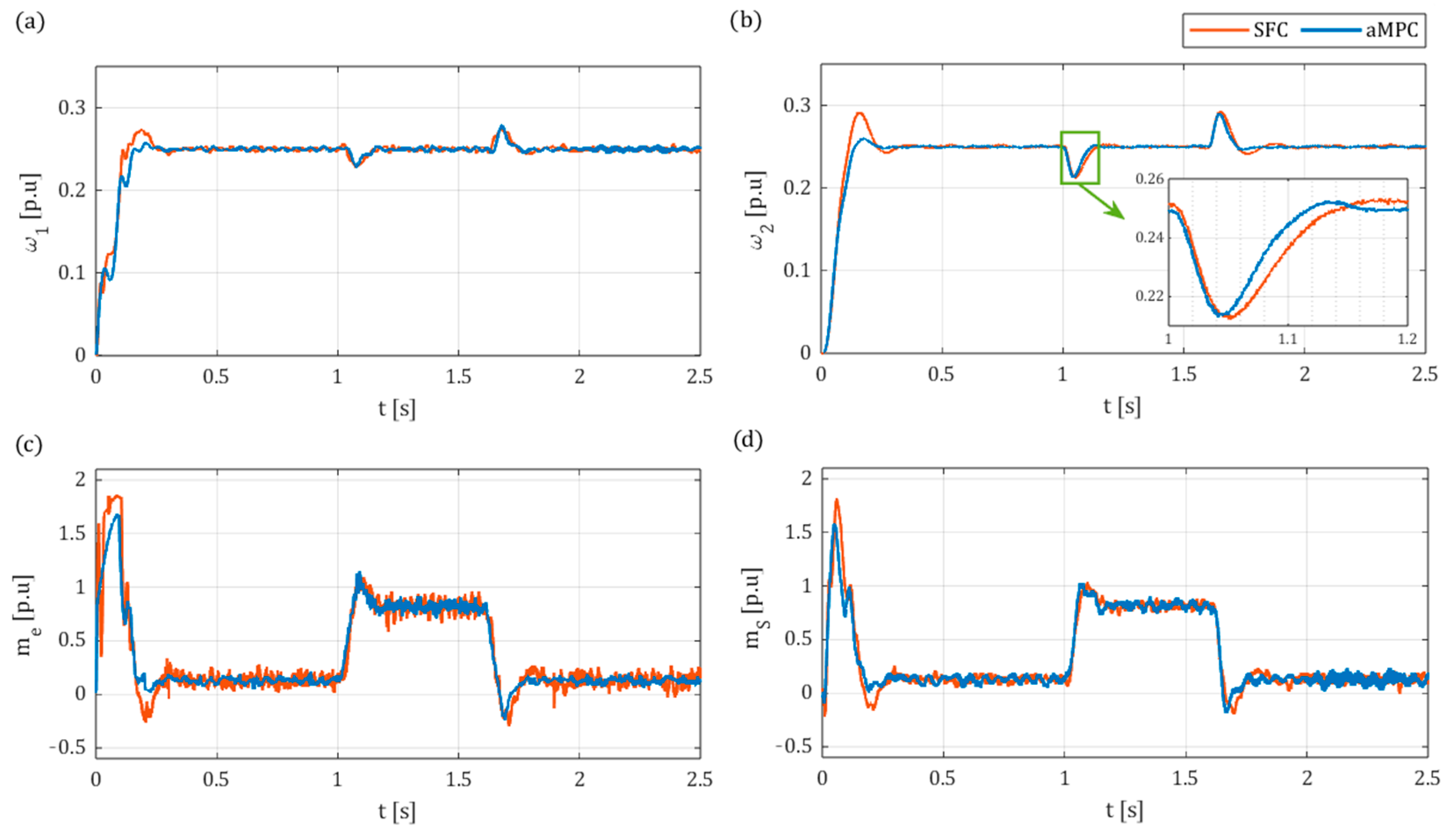

6.2. Results

7. Discussion and Conclusions

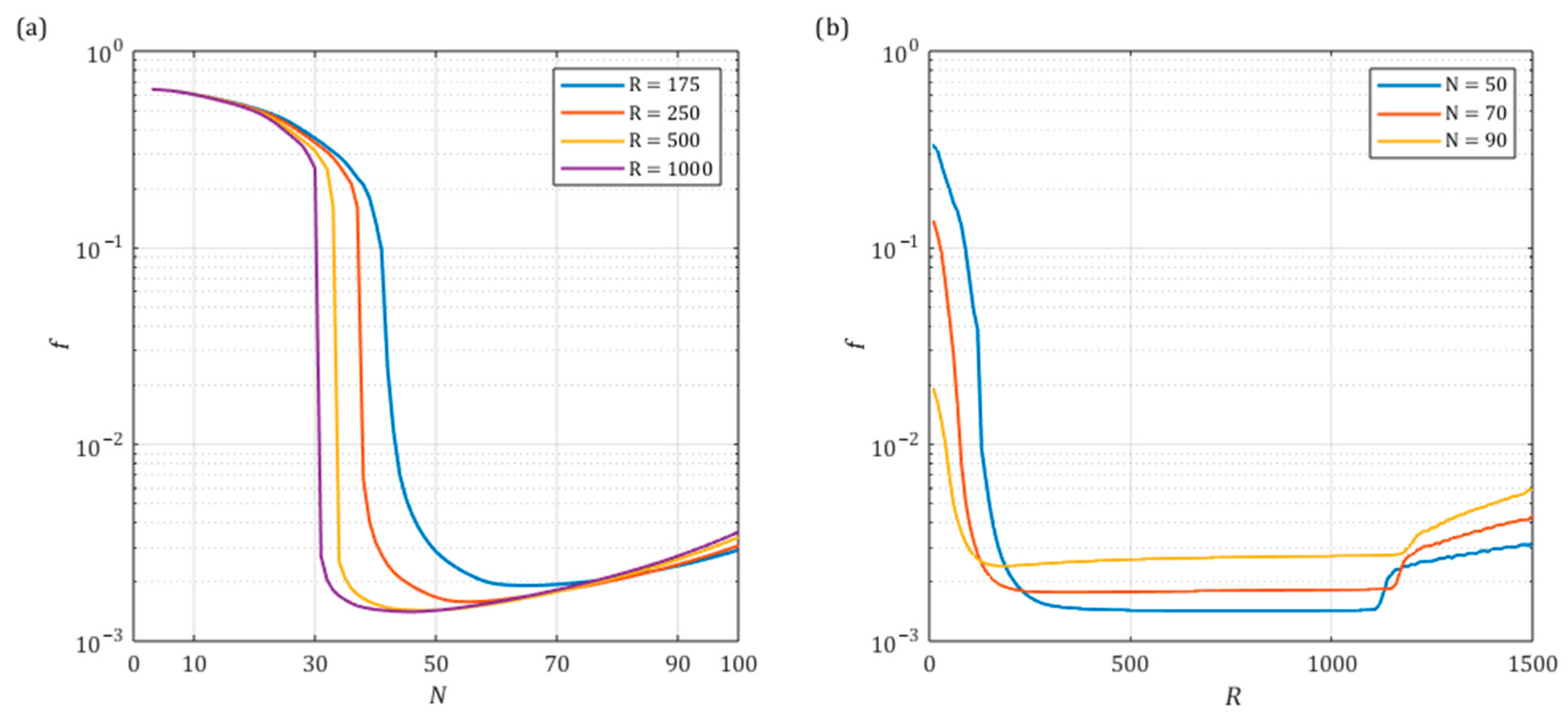

- It has been demonstrated that the dynamics of the aMPC controller depend on four parameters simultaneously—namely sampling time prediction horizon , control horizon , and gain coefficient . In this regard, it is recommended that the sampling time is selected first in accordance with the capabilities and physical limitations of the considered system. Furthermore, it was explained that extending the control horizon substantially increases the computational complexity of the controller, and only the first control signal is applied to the object. Therefore, its value should remain at .

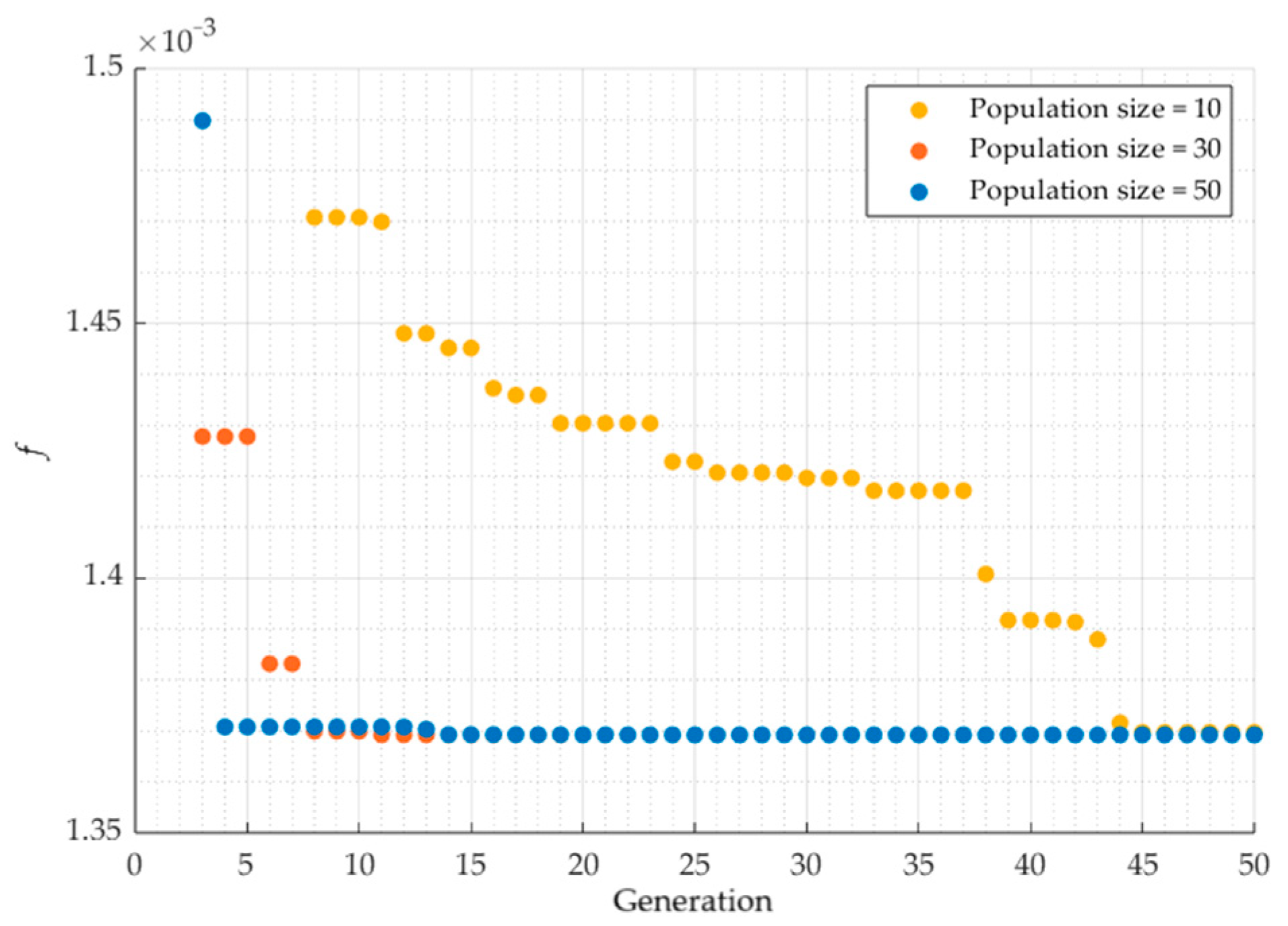

- This leaves two remaining parameters, whose impact on the performance of the controller was presented in the article. Additionally, a performance function, , was proposed, which may be used as the minimised objective function for automated tuning, in this case, with the implementation of GA.

- In the simulation results, a comparison between the aMPC and SFC systems indicated that the proposed aMPC system may display better dynamics and higher robustness to changes of load time constant over a wide range, ensuring better performance for high ratios and remaining stable for very low ratios.

- The developed predictive controller was also able to be successfully implemented online in the laboratory setup. Valid results were obtained for similar controller parameters to those of the simulation model automatically optimised by the GA, confirming its applicability in the tuning process. The main advantage of the proposed system in comparison to conventional SFC is the ability to reach similarly high or even better dynamics with much smoother electromagnetic torque transients. Additionally, the superior robustness and better dynamics of aMPC were showcased for higher load inertia. However, the accurate estimation of the state variables, including the load torque, is imperative for the effective operation of aMPC. In this instance, it was observed that the employment of a classical Luenberger observer resulted in oscillations of the state variables during the load torque switching on and off.

- As the performance of the proposed solution relies on the quality of state variable estimation, further studies could include a comparison of the performance of aMPC for different methods of estimation presented in the literature. Additionally, the present study does not undertake a comparison between the performance and robustness of the proposed aMPC and other predictive control approaches, such as the explicit MPC. This aspect could be considered for future work to further contextualise the proposed solution within the broader landscape of predictive control methods.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Algorithm A1 aMPC matrix calculation | |

| 1. | Matrix preallocation |

| 2. | |

| 3. | Matrix |

| 4. | for |

| 5. | |

| 6. | end |

| 7. | Matrix |

| 8. | for |

| 9. | 1 (1 —state-space system output matrix) |

| 10. | end |

| 11. | Matrix |

| 12. | |

| 13. | for |

| 14. | |

| 15. | end |

| 16. | Matrix |

| 17. | for |

| 18. | |

| 19. | end |

| 20. | Dynamic matrix |

| 21. | |

| 22. | Controller output matrix |

| 23. | |

References

- Yakub, M.F.M.; Qadir, A.; Aminudin, B.A. Comparative Study on Control Method for Two-Mass Systems. Int. J. Adv. Sci. Eng. Inf. Technol. 2012, 2, 261–266. [Google Scholar] [CrossRef][Green Version]

- Shao, N.; Zhou, Q.; Shao, C.; Zhao, Y. Adaptive Control of Robot Series Elastic Drive Joint Based on Optimized Radial Basis Function Neural Network. Int. J. Soc. Robot. 2021, 13, 1823–1832. [Google Scholar] [CrossRef]

- Jin, X.; Wang, J.; He, X.; Yan, Z.; Xu, L.; Wei, C. Improving Vibration Performance of Electric Vehicles Based on In-Wheel Motor-Active Suspension System via Robust Finite Frequency Control. IEEE Trans. Intell. Transp. Syst. 2023, 24, 1631–1643. [Google Scholar] [CrossRef]

- Zhang, G. Comparison of control schemes for two-inertia system. In Proceedings of the IEEE 1999 International Conference on Power Electronics and Drive Systems PEDS’99, Hong Kong, China, 27–29 July 1999. [Google Scholar] [CrossRef]

- Goubej, M. Fundamental performance limitations in PID controlled elastic two-mass systems. In Proceedings of the 2016 IEEE International Conference on Advanced Intelligent Mechatronics (AIM), Banff, Canada, 12–15 July 2016. [Google Scholar] [CrossRef]

- Szabat, K.; Orłowska-Kowalska, T. Vibration Suppression in a Two-Mass Drive System Using PI Speed Controller and Additional Feedbacks—Comparative Study. IEEE Trans. Ind. Electron. 2007, 54, 1193–1206. [Google Scholar] [CrossRef]

- Zhang, G.; Furusho, J. Speed control of two-inertia system by PI/PID control. IEEE Trans. Ind. Electron. 2000, 47, 603–609. [Google Scholar] [CrossRef]

- Li, X.; Shang, D.; Li, H.; Li, F. Resonant Suppression Method Based on PI control for Serial Manipulator Servo Drive System. Sci. Prog. 2020, 103, 36850420950130. [Google Scholar] [CrossRef]

- Kahsay, A.H.; Derugo, P.; Szabat, K.; Katsura, S. Design of Disturbance Observer-Based Robust Speed Control Structure for Two-Mass Drive System with the Help of Birch Optimization Algorithm. Energies 2025, 18, 1914. [Google Scholar] [CrossRef]

- Wróbel, K.; Śleszycki, K. Robust states controller for two mass system. Przegląd Elektrotechniczny 2023, 99, 9–12. [Google Scholar] [CrossRef]

- Szczepański, R.; Kamiński, M.; Tarczewski, T. Auto-Tuning Process of State Feedback Speed Controller Applied for Two-Mass System. Energies 2020, 13, 3067. [Google Scholar] [CrossRef]

- Wang, C.; Wang, T.; Chen, G.; Pan, J. Automatic Detection and Self-Adjustment Compensation for Mechanical Oscillations and Disturbances in Servo Systems. IEEE Trans. Syst. Man Cybern. Syst. 2024, 54, 1180–1190. [Google Scholar] [CrossRef]

- Serkies, P.; Szabat, K. Effective damping of the torsional vibrations of the drive system with an elastic joint based on the forced dynamic control algorithms. J. Vib. Control. 2019, 25, 2225–2236. [Google Scholar] [CrossRef]

- Sariyildiz, E.; Yu, H.; Nozaki, T.; Murakami, T. Robust vibration control of two-mass resonant systems in state space. In Proceedings of the 2016 IEEE 14th International Workshop on Advanced Motion Control (AMC), Auckland, New Zealand, 22–24 April 2016. [Google Scholar] [CrossRef]

- Vittek, J.; Ryvkin, S. Decomposed Sliding Mode Control of the Drive with Interior Permanent Magnet Synchronous Motor and Flexible Coupling. Math. Probl. Eng. 2013, 2013, 680376. [Google Scholar] [CrossRef]

- Wang, C.; Liu, F.; Xu, J.; Pan, J. A SMC-Based Accurate and Robust Load Speed Control Method for Elastic Servo System. IEEE Trans. Ind. Electron. 2024, 71, 2300–2308. [Google Scholar] [CrossRef]

- Lukichev, D.V.; Demidova, G.L. PID-type fuzzy adaptive control for two-mass servo-drive system: Design, simulation and experiment. In Proceedings of the 2016 IX International Conference on Power Drives Systems (ICPDS), Perm, Russia, 3–7 October 2016. [Google Scholar] [CrossRef]

- Vukojičić, S.; Ristić, L.; Kvaščev, G. Comparation between PI and Model Predictive Control of Two Mass Resonant Mechanical System. In Proceedings of the 7th International Conference on Environment Friendly Energies and Applications (EFEA), Bagatelle Moka MU, Mauritius, 13–16 December 2022. [Google Scholar] [CrossRef]

- Kaczmarczyk, G.; Stanislawski, R.; Kamiński, M. Deep-Learning Techniques Applied for State-Variables Estimation of Two-Mass System. Energies 2025, 18, 568. [Google Scholar] [CrossRef]

- Thomsen, S.; Hoffmann, N.; Fuchs, F.W. Comparative study of conventional PI-control, PI-based state space control and model based predictive control for drive systems with elastic coupling. In Proceedings of the 2010 IEEE Energy Conversion Congress and Exposition, Atlanta, GA, USA, 12–16 September 2010. [Google Scholar] [CrossRef]

- Serkies, P.; Szabat, K. Application of the MPC to the Position Control of the Two-Mass Drive System. IEEE Trans. Ind. Electron. 2013, 60, 3679–3688. [Google Scholar] [CrossRef]

- Wang, C.; Yang, M.; Zheng, W.; Long, J.; Xu, D. Vibration Suppression with Shaft Torque Limitation Using Explicit MPC-PI Switching Control in Elastic Drive Systems. IEEE Trans. Ind. Electron. 2015, 62, 6855–6867. [Google Scholar] [CrossRef]

- Fuentes, E.J.; Silva, C.A.; Yuz, J.I. Predictive Speed Control of a Two-Mass System Driven by a Permanent Magnet Synchronous Motor. IEEE Trans. Ind. Electron. 2012, 59, 2840–2848. [Google Scholar] [CrossRef]

- Kouro, S.; Perez, M.A.; Rodriguez, J.; Llor, A.M.; Young, H.A. Model Predictive Control: MPC’s Role in the Evolution of Power Electronics. IEEE Ind. Electron. Mag. 2015, 9, 8–21. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Nguyen, T.H.; Jeon, J.W. Explicit Model Predictive Speed Control for Permanent Magnet Synchronous Motor with Torque Ripple Minimization. IEEE Access 2023, 11, 134199–134210. [Google Scholar] [CrossRef]

- Wróbel, K.; Szabat, K.; Serkies, P. Long-horizon model predictive control of induction motor drive. Arch. Electr. Eng. 2019, 68, 569–593. [Google Scholar] [CrossRef]

- Karg, B.; Lucia, S. Efficient Representation and Approximation of Model Predictive Control Laws via Deep Learning. IEEE Trans. Cybern. 2020, 50, 3866–3878. [Google Scholar] [CrossRef] [PubMed]

- Abu-Ali, M.; Berkel, F.; Manderla, M.; Reimann, S.; Kennel, R.; Abdelrahem, M. Deep Learning-Based Long-Horizon MPC: Robust, High Performing, and Computationally Efficient Control for PMSM Drives. IEEE Trans. Power Electron. 2022, 37, 12486–12501. [Google Scholar] [CrossRef]

- Chaber, P.; Ławryńczuk, M. Fast Analytical Model Predictive Controllers and Their Implementation for STM32 ARM Microcontroller. IEEE Trans. Ind. Inform. 2019, 15, 4580–4590. [Google Scholar] [CrossRef]

| Nominal Parameter | Notation | Value |

|---|---|---|

| Power | 500 W | |

| Voltage | 220 V | |

| Armature current | 3.15 A | |

| Field current | 0.254 A | |

| Speed | 1450 rpm | |

| Moment of inertia | 0.044 | |

| Armature circuit resistance | 8.05 | |

| Armature circuit inductance | 0.8 H | |

| Moment of inertia | 0.044 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gorla, A.; Serkies, P. Comparative Study of Analytical Model Predictive Control and State Feedback Control for Active Vibration Suppression of Two-Mass Drive. Actuators 2025, 14, 254. https://doi.org/10.3390/act14050254

Gorla A, Serkies P. Comparative Study of Analytical Model Predictive Control and State Feedback Control for Active Vibration Suppression of Two-Mass Drive. Actuators. 2025; 14(5):254. https://doi.org/10.3390/act14050254

Chicago/Turabian StyleGorla, Adam, and Piotr Serkies. 2025. "Comparative Study of Analytical Model Predictive Control and State Feedback Control for Active Vibration Suppression of Two-Mass Drive" Actuators 14, no. 5: 254. https://doi.org/10.3390/act14050254

APA StyleGorla, A., & Serkies, P. (2025). Comparative Study of Analytical Model Predictive Control and State Feedback Control for Active Vibration Suppression of Two-Mass Drive. Actuators, 14(5), 254. https://doi.org/10.3390/act14050254