Dual-Layer Flexible Capacitance Sensor with Wide Range and High Sensitivity

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Fabrication Procedures of the Sensor

2.3. Characterization and Pressure Sensing Testing

3. Results and Discussion

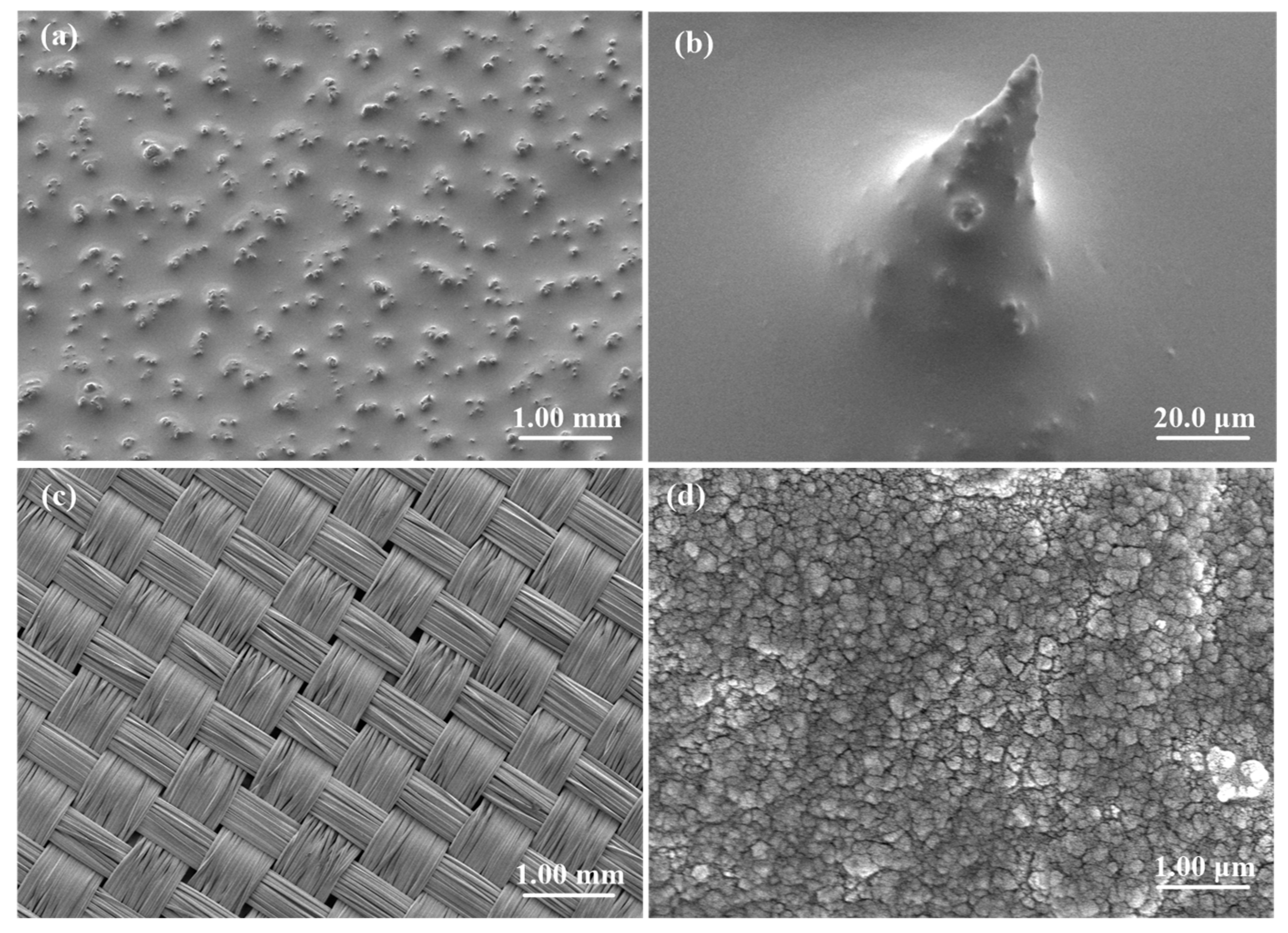

3.1. Characterization

3.2. Pressure Sensing Testing

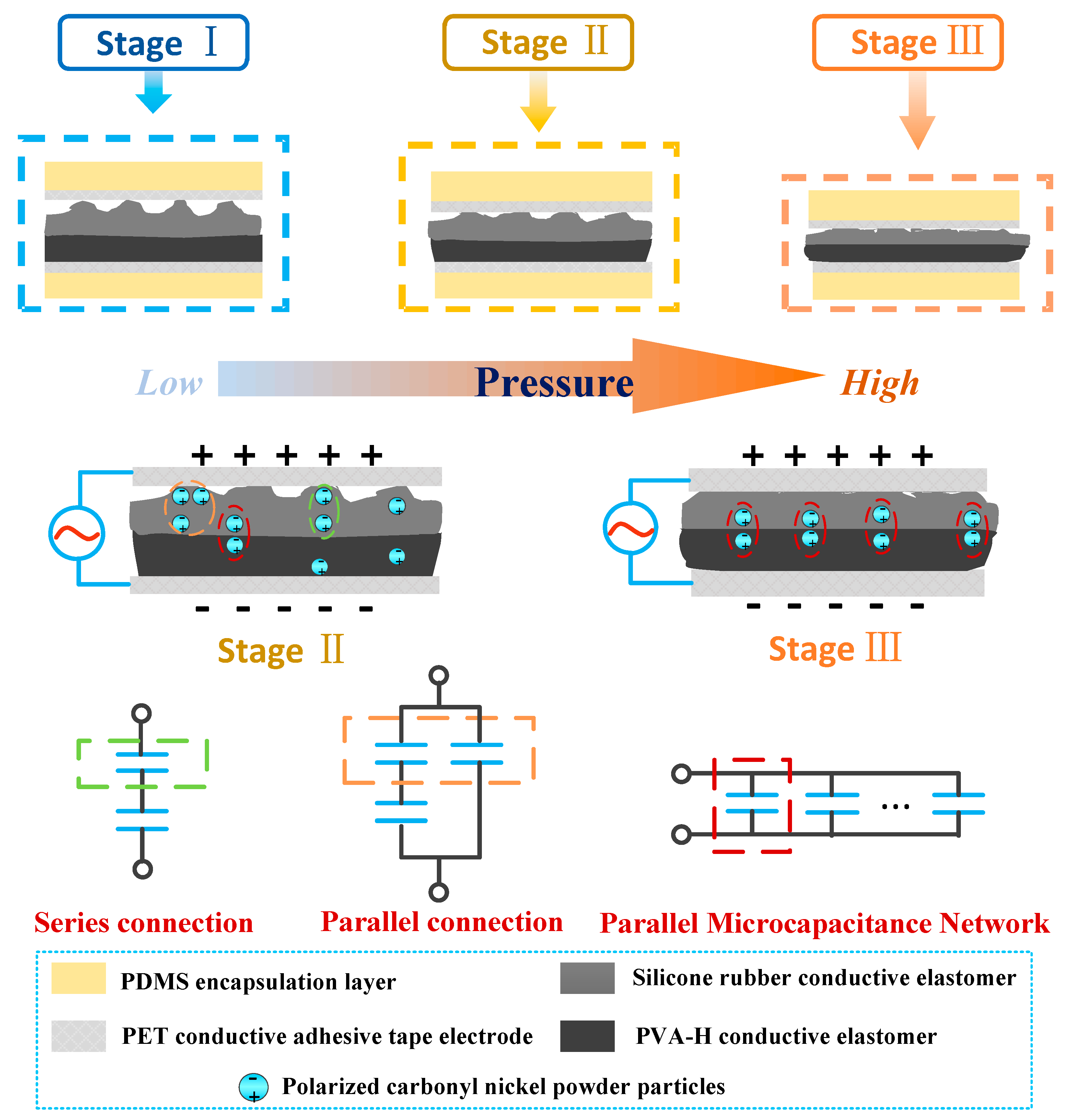

3.3. Pressure Sensing Mechanism

3.4. Demonstration of Multifunctional Applications

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wen, N.; Zhang, L.; Jiang, D.; Wu, Z.; Li, B.; Sun, C.; Guo, Z. Emerging flexible sensors based on nanomaterials: Recent status and applications. J. Mater. Chem. A 2020, 8, 25499–25527. [Google Scholar] [CrossRef]

- Peng, Y.; Sakai, Y.; Funabora, Y.; Yokoe, K.; Aoyama, T.; Doki, S. Funabot-Sleeve: A Wearable Device Employing McKibben Artificial Muscles for Haptic Sensation in the Forearm. IEEE Robot. Autom. Lett. 2025, 10, 1944–1951. [Google Scholar] [CrossRef]

- Mao, Z.; Naoki, H.; Shingo, M. Flexible electrohydrodynamic fluid-driven valveless water pump via immiscible interface. Cyborg Bionic Syst. 2024, 5, 91. [Google Scholar] [CrossRef] [PubMed]

- Zhi, C.; Shi, S.; Si, Y.; Fei, B.; Huang, H.; Hu, J. Recent progress of wearable piezoelectric pressure sensors based on nanofibers, yarns, and their fabrics via electrospinning. Adv. Mater. Technol. 2023, 8, 2201161. [Google Scholar] [CrossRef]

- Song, D.; Chen, X.; Wang, M.; Wu, Z.; Xiao, X. 3D-printed flexible sensors for food monitoring. Chem. Eng. J. 2023, 474, 146011. [Google Scholar] [CrossRef]

- Zazoum, B.; Batoo, K.M.; Khan, M.A.A. Recent advances in flexible sensors and their applications. Sensors 2022, 22, 4653. [Google Scholar] [CrossRef]

- Peng, Y.; Yang, X.; Li, D.; Ma, Z.; Liu, Z.; Bai, X.; Mao, Z. Predicting flow status of a flexible rectifier using cognitive computing. Expert Syst. Appl. 2025, 264, 125878. [Google Scholar] [CrossRef]

- Bai, X.; Peng, Y.; Li, D.; Liu, Z.; Mao, Z. Novel soft robotic finger model driven by electrohydrodynamic (EHD) pump. J. Zhejiang Univ. Sci. A 2024, 25, 596–604. [Google Scholar] [CrossRef]

- Mao, Z.; Bai, X.; Peng, Y.; Shen, Y. Design, modeling, and characteristics of ring-shaped robot actuated by functional fluid. J. Intell. Mater. Syst. Struct. 2024, 35, 1459–1470. [Google Scholar] [CrossRef]

- Niu, H.; Yin, F.; Kim, E.S.; Wang, W.; Yoon, D.Y.; Wang, C.; Liang, J.; Li, Y.; Kim, N.Y. Advances in flexible sensors for intelligent perception system enhanced by artificial intelligence. InfoMat 2023, 5, e12412. [Google Scholar] [CrossRef]

- Yuan, H.; Zhang, Q.; Zhou, T.; Wu, W.; Li, H.; Yin, Z.; Ma, J.; Jiao, T. Progress and challenges in flexible capacitive pressure sensors: Microstructure designs and applications. Chem. Eng. J. 2024, 485, 149926. [Google Scholar] [CrossRef]

- Mao, Z.; Kobayashi, R.; Nabae, H.; Suzumori, K. Multimodal strain sensing system for shape recognition of tensegrity structures by combining traditional regression and deep learning approaches. IEEE Robot. Autom. Lett. 2024, 9, 10050–10056. [Google Scholar] [CrossRef]

- Zhang, C.; Chen, J.; Li, J.; Peng, Y.; Mao, Z. Large language models for human–robot interaction: A review. Biomim. Intell. Robot. 2023, 3, 100131. [Google Scholar] [CrossRef]

- Yan, J.; Ma, Y.; Jia, G.; Zhao, S.; Yue, Y.; Cheng, F.; Zhang, C.; Cao, M.; Xiong, Y.; Shen, P.; et al. Bionic MXene based hybrid film design for an ultrasensitive piezoresistive pressure sensor. Chem. Eng. J. 2022, 431, 133458. [Google Scholar] [CrossRef]

- Hong, S.H.; Chen, T.; Wang, G.; Popovic, S.M.; Filleter, T.; Naguib, H.E. Room temperature self-healing polysiloxane networks for highly sensitive piezoresistive pressure sensor with micro-dome structures. Chem. Eng. J. 2023, 471, 144429. [Google Scholar] [CrossRef]

- Li, W.; Jin, X.; Zheng, Y.; Chang, X.; Wang, W.; Lin, T.; Zheng, F.; Onyilagha, O.; Zhu, Z. A porous and air gap elastomeric dielectric layer for wearable capacitive pressure sensor with high sensitivity and a wide detection range. J. Mater. Chem. C 2020, 8, 11468–11476. [Google Scholar] [CrossRef]

- Hwang, J.; Kim, Y.; Yang, H.; Oh, J.H. Fabrication of hierarchically porous structured PDMS composites and their application as a flexible capacitive pressure sensor. Compos. Part B Eng. 2021, 211, 108607. [Google Scholar] [CrossRef]

- Wang, C.; Hu, Y.; Liu, Y.; Shan, Y.; Qu, X.; Xue, J.; He, T.; Cheng, S.; Zhou, H.; Liu, W.; et al. Tissue-adhesive piezoelectric soft sensor for in vivo blood pressure monitoring during surgical operation. Adv. Funct. Mater. 2023, 33, 2303696. [Google Scholar] [CrossRef]

- Kim, D.B.; Han, J.; Sung, S.M.; Kim, M.S.; Choi, B.K.; Park, S.J.; Hong, H.R.; Choi, H.J.; Kim, B.K.; Park, C.H.; et al. Weave-pattern-dependent fabric piezoelectric pressure sensors based on polyvinylidene fluoride nanofibers electrospun with 50 nozzles. npj Flex. Electron. 2022, 6, 69. [Google Scholar] [CrossRef]

- Lei, H.; Cao, K.; Chen, Y.; Liang, Z.; Wen, Z.; Jiang, L.; Sun, X. 3D-printed endoplasmic reticulum rGO microstructure based self-powered triboelectric pressure sensor. Chem. Eng. J. 2022, 445, 136821. [Google Scholar] [CrossRef]

- Yang, P.; Shi, Y.; Li, S.; Tao, X.; Liu, Z.; Wang, X.; Wang, Z.L.; Chen, X. Monitoring the degree of comfort of shoes in-motion using triboelectric pressure sensors with an ultrawide detection range. ACS Nano 2022, 16, 4654–4665. [Google Scholar] [CrossRef] [PubMed]

- Yang, C.R.; Wang, L.J.; Tseng, S.F. Arrayed porous polydimethylsiloxane/barium titanate microstructures for high-sensitivity flexible capacitive pressure sensors. Ceram. Int. 2022, 48, 13144–13153. [Google Scholar] [CrossRef]

- Mao, Z.; Peng, Y.; Hu, C.; Ding, R.; Yamada, Y.; Maeda, S. Soft computing-based predictive modeling of flexible electrohydrodynamic pumps. Biomim. Intell. Robot. 2023, 3, 100114. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, T.; Hu, X. Robust active disturbance rejection control for modular fluidic soft actuators. Int. J. Hydromechatronics 2024, 7, 293–309. [Google Scholar] [CrossRef]

- Fan, B.; Zhao, H.; Meng, L. Obstacle detection for intelligent robots based on the fusion of 2D lidar and depth camera. Int. J. Hydromechatronics 2024, 7, 67–88. [Google Scholar] [CrossRef]

- Liu, E.; Cai, Z.; Ye, Y.; Zhou, M.; Liao, H.; Yi, Y. An overview of flexible sensors: Development, application, and challenges. Sensors 2023, 23, 817. [Google Scholar] [CrossRef]

- Zhao, D.; Jia, W.; Feng, X.; Yang, H.; Xie, Y.; Shang, J.; Wang, P.; Guo, Y.; Li, R.W. Flexible Sensors Based on Conductive Polymer Composites. Sensors 2024, 24, 4664. [Google Scholar] [CrossRef]

- Zhao, Y.; Shen, T.; Zhang, M.; Yin, R.; Zheng, Y.; Liu, H.; Sun, H.; Liu, C.; Shen, C. Advancing the pressure sensing performance of conductive CNT/PDMS composite film by constructing a hierarchical-structured surface. Nano Mater. Sci. 2023, 5, 343–350. [Google Scholar] [CrossRef]

- Yang, C.R.; Lin, M.F.; Huang, C.K.; Huang, W.C.; Tseng, S.F.; Chiang, H.H. Highly sensitive and wearable capacitive pressure sensors based on PVDF/BaTiO3 composite fibers on PDMS microcylindrical structures. Measurement 2022, 202, 111817. [Google Scholar] [CrossRef]

- Khong Duc, C.; Hoang, V.P.; Tien Nguyen, D.; Thanh Dao, T. A low-cost, flexible pressure capacitor sensor using polyurethane for wireless vehicle detection. Polymers 2019, 11, 1247. [Google Scholar] [CrossRef]

- Li, R.; Dong, K.; Panahi-Sarmad, M.; Li, S.; Xiao, X. Three-dimensional printing of a flexible capacitive pressure sensor array in the assembly network of carbon fiber electrodes and interlayer of a porous polyurethane dielectric. ACS Appl. Electron. Mater. 2021, 3, 3999–4008. [Google Scholar] [CrossRef]

- Lim, B.; Yoon, J. High-Load Capable Soft Tactile Sensors: Incorporating Magnetorheological Elastomer for Accurate Contact Detection and Classification of Asymmetric Mechanical Components. Adv. Intell. Syst. 2024, 7, 2400275. [Google Scholar] [CrossRef]

- Song, M.; Yu, H.; Zhu, J.; Ouyang, Z.; Abdalkarim, S.Y.H.; Tam, K.C.; Li, Y. Constructing stimuli-free self-healing, robust and ultrasensitive biocompatible hydrogel sensors with conductive cellulose nanocrystals. Chem. Eng. J. 2020, 398, 125547. [Google Scholar] [CrossRef]

- Ji, B.; Zhou, Q.; Wu, J.; Gao, Y.; Wen, W.; Zhou, B. Synergistic optimization toward the sensitivity and linearity of flexible pressure sensor via double conductive layer and porous microdome array. ACS Appl. Mater. Interfaces 2020, 12, 31021–31035. [Google Scholar] [CrossRef]

- Someya, T.; Bao, Z.; Malliaras, G.G. The rise of plastic bioelectronics. Nature 2016, 540, 379–385. [Google Scholar] [CrossRef]

- Lei, Z.; Wang, Q.; Sun, S.; Zhu, W.; Wu, P. A bioinspired mineral hydrogel as a self-healable, mechanically adaptable ionic skin for highly sensitive pressure sensing. Adv. Mater. 2017, 29, 1700321. [Google Scholar] [CrossRef]

- Jing, X.; Li, H.; Mi, H.Y.; Liu, Y.J.; Feng, P.Y.; Tan, Y.M.; Turng, L.S. Highly transparent, stretchable, and rapid self-healing polyvinyl alcohol/cellulose nanofibril hydrogel sensors for sensitive pressure sensing and human motion detection. Sens. Actuators B Chem. 2019, 295, 159–167. [Google Scholar] [CrossRef]

- Wang, Z.; Si, Y.; Zhao, C.; Yu, D.; Wang, W.; Sun, G. Flexible and washable poly (ionic liquid) nanofibrous membrane with moisture proof pressure sensing for real-life wearable electronics. ACS Appl. Mater. Interfaces 2019, 11, 27200–27209. [Google Scholar] [CrossRef]

- Fan, L.; Liu, Y.; Yang, X.; Sun, H. A novel capacitive sensor featuring surface microstructure and hydrogels for measuring full pressure with high-sensitivity. Sens. Actuators A Phys. 2024, 370, 115228. [Google Scholar] [CrossRef]

- Wang, Y.; Tebyetekerwa, M.; Liu, Y.; Wang, M.; Zhu, J.; Xu, J.; Zhang, C.; Liu, T. Extremely stretchable and healable ionic conductive hydrogels fabricated by surface competitive coordination for human-motion detection. Chem. Eng. J. 2021, 420, 127637. [Google Scholar] [CrossRef]

- Xiong, Y.; Shen, Y.; Tian, L.; Hu, Y.; Zhu, P.; Sun, R.; Wong, C.P. A flexible, ultra-highly sensitive and stable capacitive pressure sensor with convex microarrays for motion and health monitoring. Nano Energy 2020, 70, 104436. [Google Scholar] [CrossRef]

- Bai, N.; Wang, L.; Xue, Y.; Wang, Y.; Hou, X.; Li, G.; Zhang, Y.; Cai, M.; Zhao, L.; Guan, F.; et al. Graded interlocks for iontronic pressure sensors with high sensitivity and high linearity over a broad range. Acs Nano 2022, 16, 4338–4347. [Google Scholar] [CrossRef] [PubMed]

- Fan, Y.; Liao, C.; Liao, G.; Tan, R.; Xie, L. Capacitive pressure-sensitive composites using nickel–silicone rubber: Experiments and modeling. Smart Mater. Struct. 2017, 26, 075003. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, S.; Chen, Y.; Ling, H.; Zhao, L.; Luo, G.; Wang, X.; Hartel, M.C.; Liu, H.; Xue, Y.; et al. Gelatin methacryloyl-based tactile sensors for medical wearables. Adv. Funct. Mater. 2020, 30, 2003601. [Google Scholar] [CrossRef]

- Huang, L.; Wang, H.; Zhan, D.; Fang, F. Flexible capacitive pressure sensor based on laser–induced graphene and polydimethylsiloxane foam. IEEE Sens. J. 2021, 21, 12048–12056. [Google Scholar] [CrossRef]

- Guo, Z.; Zhang, H.; Xie, W.; Liu, W. Structurally Designed Hydrogel-based Pressure Sensors for Wearable Sensing. IEEE Sens. J. 2024, 24, 20394–20401. [Google Scholar] [CrossRef]

- Choong, C.L.; Shim, M.B.; Lee, B.S.; Jeon, S.; Ko, D.S.; Kang, T.H.; Bae, J.; Lee, S.H.; Byun, K.; Im, J.; et al. Highly stretchable resistive pressure sensors using a conductive elastomeric composite on a micropyramid array. Adv. Mater. 2014, 26, 3451–3458. [Google Scholar] [CrossRef]

- Liu, M.; Pu, X.; Jiang, C.; Liu, T.; Huang, X.; Chen, L.; Du, C.; Sun, J.; Hu, W.; Wang, Z.L. Large-area all-textile pressure sensors for monitoring human motion and physiological signals. Adv. Mater. 2017, 29, 1703700. [Google Scholar] [CrossRef]

- Yu, P.; Li, X.; Li, H.; Fan, Y.; Cao, J.; Wang, H.; Guo, Z.; Zhao, X.; Wang, Z.; Zhu, G. All-fabric ultrathin capacitive sensor with high pressure sensitivity and broad detection range for electronic skin. ACS Appl. Mater. Interfaces 2021, 13, 24062–24069. [Google Scholar] [CrossRef]

- Fu, M.; Zhang, J.; Jin, Y.; Zhao, Y.; Huang, S.; Guo, C.F. A highly sensitive, reliable, and high-temperature-resistant flexible pressure sensor based on ceramic nanofibers. Adv. Sci. 2020, 7, 2000258. [Google Scholar] [CrossRef]

- Pruvost, M.; Smit, W.J.; Monteux, C.; Poulin, P.; Colin, A. Polymeric foams for flexible and highly sensitive low-pressure capacitive sensors. npj Flex. Electron. 2019, 3, 7. [Google Scholar] [CrossRef]

- Jian, M.; Xia, K.; Wang, Q.; Yin, Z.; Wang, H.; Wang, C.; Xie, H.; Zhang, M.; Zhang, Y. Flexible and highly sensitive pressure sensors based on bionic hierarchical structures. Adv. Funct. Mater. 2017, 27, 1606066. [Google Scholar] [CrossRef]

- Duan, Z.; Jiang, Y.; Huang, Q.; Yuan, Z.; Zhao, Q.; Wang, S.; Zhang, Y.; Tai, H. A do-it-yourself approach to achieving a flexible pressure sensor using daily use materials. J. Mater. Chem. C 2021, 9, 13659–13667. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fu, B.; Wang, Z.; Chen, K.; Mao, Z.; Wang, H.; Ju, B.; Peng, Y. Dual-Layer Flexible Capacitance Sensor with Wide Range and High Sensitivity. Actuators 2025, 14, 251. https://doi.org/10.3390/act14050251

Fu B, Wang Z, Chen K, Mao Z, Wang H, Ju B, Peng Y. Dual-Layer Flexible Capacitance Sensor with Wide Range and High Sensitivity. Actuators. 2025; 14(5):251. https://doi.org/10.3390/act14050251

Chicago/Turabian StyleFu, Benyuan, Zipei Wang, Kun Chen, Zebing Mao, Hao Wang, Benxiang Ju, and Yanhong Peng. 2025. "Dual-Layer Flexible Capacitance Sensor with Wide Range and High Sensitivity" Actuators 14, no. 5: 251. https://doi.org/10.3390/act14050251

APA StyleFu, B., Wang, Z., Chen, K., Mao, Z., Wang, H., Ju, B., & Peng, Y. (2025). Dual-Layer Flexible Capacitance Sensor with Wide Range and High Sensitivity. Actuators, 14(5), 251. https://doi.org/10.3390/act14050251