1. Introduction

Pneumatic servo systems, which utilize air as a power source, provide economical and safe alternatives to hydraulic equipment. These systems are characterized by their emission-free operation and minimal maintenance requirements, making them particularly advantageous across various applications. Their compact design allows for substantial output capabilities, leading to widespread adoption as actuators in industrial robotics. Additionally, the inherent compressibility of air offers significant benefits, such as effective shock absorption and the mitigation of reaction forces, positioning these systems as promising solutions for rehabilitation devices and other equipment involving human interaction [

1,

2].

Despite these advantages, pneumatic servo systems exhibit nonlinear characteristics arising from delays in air-pressure response, friction between pistons and cylinders, and pressure variations due to temperature changes. These nonlinearities present challenges in achieving precise control and stability.

To address these issues, many control methods have been proposed. L. Zhao, et al. presented an active disturbance rejection position control scheme for a magnetic, rodless cylinder in servo systems without pressure states. The method effectively reduced the overshot using a tracking differentiator. Meanwhile, nonlinearity is estimated using a designed extended-state observer [

3]. W. Deng, et al. proposed a recursive robust integral of the sign of the error (RISE) control method for mechanical servo systems with mismatched uncertainties. In controller development, two auxiliary error signals are introduced into the recursive backstepping design framework, and then RISE feedbacks are synthesized to eliminate the matched and mismatched uncertainties simultaneously [

4]. Active disturbance rejection control (ADRC) is a possibility-based online estimating disturbance rejection control method. It is attractive for use in various applications. S. Gu et al. proposed a variable-gain active disturbance rejection control (VGADRC) method to solve the trajectory-tracking problem of delta parallel manipulators with disturbances [

5]. The method employs a variable gain-tracking differentiator (VGTD), a variable-gain extended-state observer (VGESO), and a variable-gain controller (VGC), and it incorporates error-based variable gains to improve control performance. A novel event-triggered finite-time variable gain ADRC strategy is proposed for master-slave teleoperated parallel manipulators by Gu et al. [

6]. It integrates error-based variable gains and event-triggered mechanisms to enhance control performance and reduce communication burden, with stability analysis, steady-state performance evaluation, and avoidance of the Zeno phenomenon validated through simulations and experiments. Zhang et al. proposed a novel tuning method for ADRC to extend its application to high-order electro-hydraulic servo systems by decomposing ADRC into a pre-filter

and a controller

in the frequency domain, with parameter tuning based on quantitative feedback theory, demonstrating superior performance compared to traditional bandwidth tuning methods through simulations and experimental validation [

7]. G. Herbst et al. employed a tuning implementation in a discrete-time domain for three different error-based ADRC applications [

8]. In the paper, it is shown that these are almost one-to-one counterparts of existing output-based implementations, to the point where transfer functions and coefficients can be reused in unaltered form. A finite-time trajectory-tracking control strategy for a rodless pneumatic cylinder system with disturbances was developed using an inner-outer loop framework by L. Zhao, et al. [

9] In the framework, a generalized, nonlinear, extended state observer and an inner loop controller compensate for matched disturbances, while a super-twisting extended state observer and an outer loop controller address unmatched disturbances, ensuring finite-time stability, which was validated with experimental results. Similarly, H. Sun et al. proposed a novel position-tracking control strategy for high-pressure pneumatic servo systems integrating extended state observers (ESOs) and sliding mode control (SMC) within a command-filtered backstepping framework to compensate for matched and mismatched disturbances, enhance robustness, and mitigate high switching gains, with system stability ensured via Lyapunov theory and validated through numerical simulations, demonstrating an improved response speed and tracking accuracy [

10].

Furthermore, with the rapid advancement of artificial intelligence, many methods with intelligent algorithms have also been developed in recent years. Their applications attract more and more attention [

11,

12,

13]. J. Li et al. proposed an intelligent control method using IMC control combined with NN [

11]. The IMC ensured the great minimization of disturbance, offering stability and robustness properties in the method. NN was applied to achieve a suitable control parameter to deal with the non-linear elements of the plant. A hybrid electric–pneumatic actuator was analyzed theoretically and tested experimentally by F. Jiang et al. [

12]. A BP neural network model for pneumatic system inflation and deflation was developed by selecting appropriate state parameters, and a prediction algorithm was proposed to predict the output force of the system for a period of time during the process of inflation (deflation). The prediction of output force variation provides an effective method for the dynamic modeling of complex pneumatic systems. Y. Chen et al. proposed an adaptive, robust neural network controller (ARNNC) synthesized for a single-rod pneumatic actuator to achieve high tracking accuracy without the bounds of the parameters and disturbances being known [

13]. The ARNNC control framework integrates adaptive control, robust control, and neural network control intelligently. The effectiveness of the proposed ARNNC was confirmed by a high tracking accuracy.

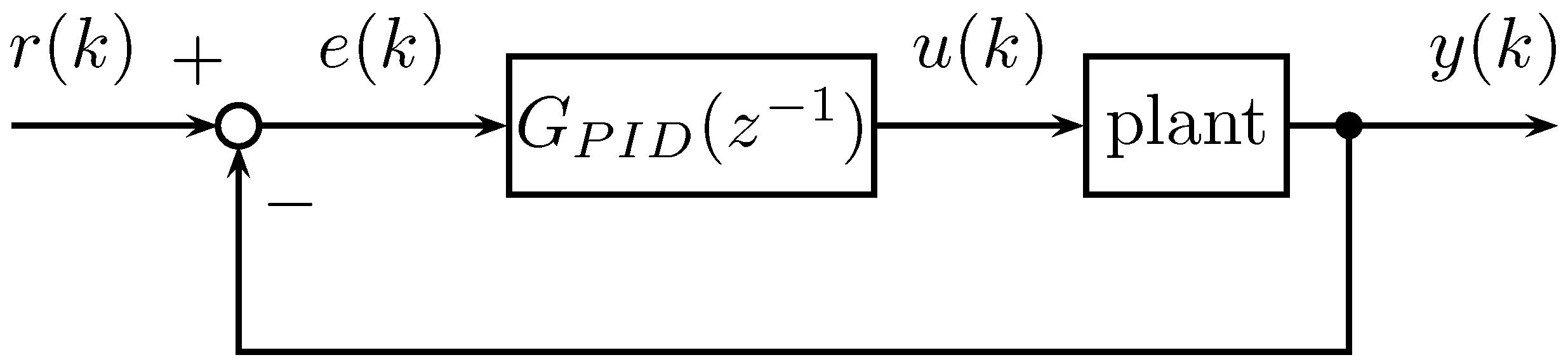

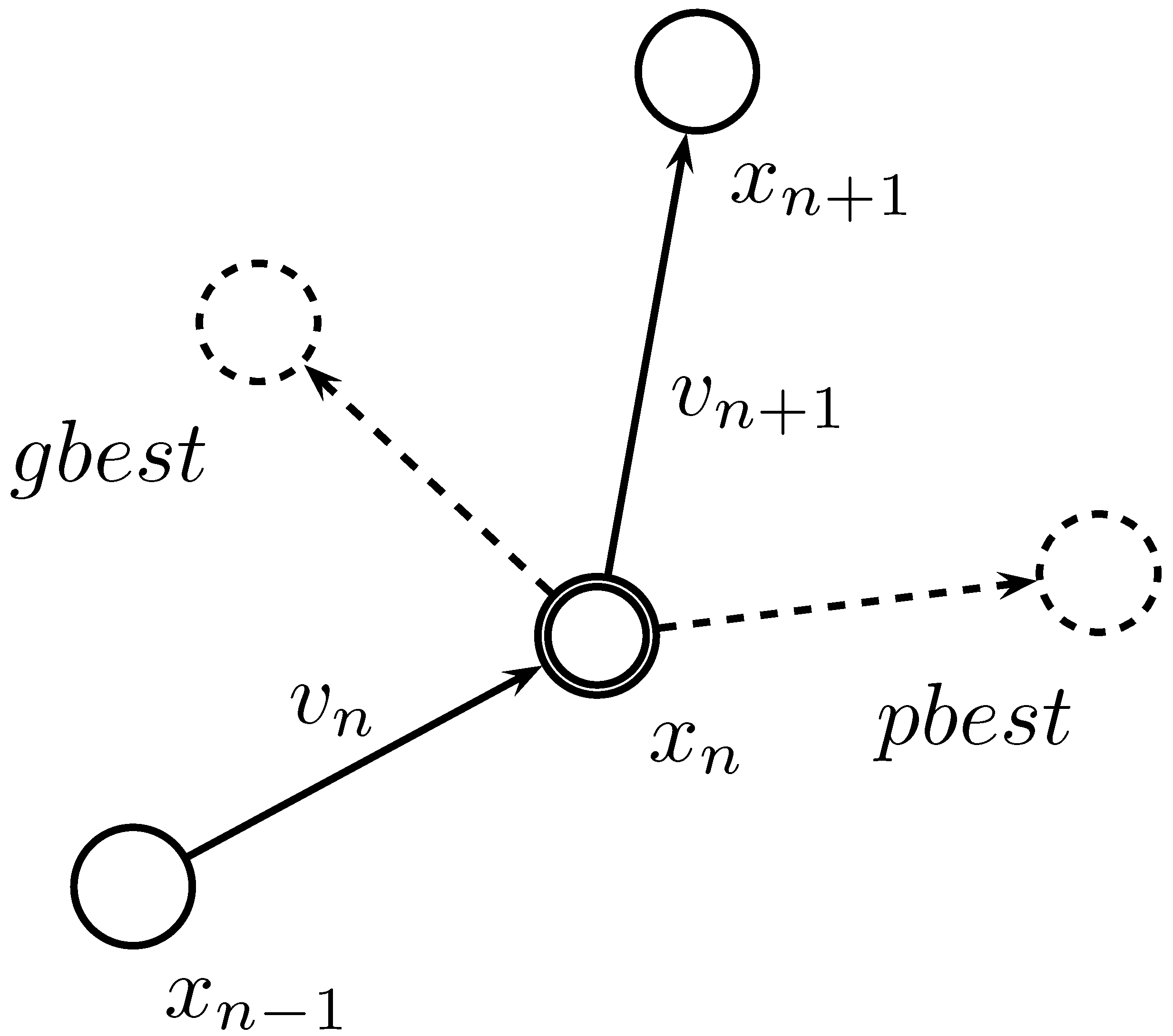

According to our previous research, the integration of proportional–integral–derivative (PID) control with neural networks (NNs) has proven effective in the intelligent control of plants with nonlinear elements [

14]. NNs, which mathematically model the functionalities of the human brain, excel in processing and separating nonlinear data. Traditional NN approaches often rely on back propagation (BP) to update connection weights. However, this method requires differential information, complicating the computation process. In contrast, particle swarm optimization (PSO) utilizes only the numerical values of evaluation functions for optimization. This approach enables the resolution of complex nonlinear optimization problems without the need for continuity or differential information. PSO is an optimization method developed by J. Kennedy and R. Eberhart in 1995 [

15,

16]. It is a multiple-dimensional optimization method based on the collective search behavior of flocks of birds and schools of fish. The algorithm involves numerous particles moving through a dimensional space to search for solutions that optimize the objective function. Notable features of PSO include its ability to search for solutions rapidly compared to traditional heuristic methods, its applicability to continuous problems without requiring derivative information of the objective function, and the presence of several parameters that significantly influence its search capabilities [

12,

17]. By employing PSO algorithms, methods of training NNs in various scenarios have been confirmed. C. Lin et al. designed an evolutionary neural fuzzy network using the functional-link-based neural fuzzy network (FLNFN) and a new evolutionary learning algorithm [

18]. The evolutionary learning algorithm is based on a hybrid of cooperative PSO and a cultural algorithm. The proposed FLNFN model uses functional-link neural networks as the consequent part of the fuzzy rules. Finally, the proposed functional link-based neural fuzzy network with cultural cooperative PSO (FLNFN-CCPSO) is adopted in several predictive applications. J. Chen et al. proposed a satisfactory and efficient algorithm for training an artificial NN in supervised learning using the method of PSO combined with the Cuckoo Search (CS) algorithm [

19]. The proposed hybrid algorithm is employed as a new training method for feedforward neural networks (FNNs). To investigate the performance of the proposed algorithm, two benchmark problems are used, and the results are compared with those obtained from FNNs trained with original PSO and CS algorithms. The experimental results show that the proposed hybrid algorithm outperforms both PSO and CS in training FNNs. S. Mirjalili et al. proposed a hybrid of PSO and the gravitational search algorithm (GSA) to achieve a faster searching speed [

20]. In their work, GSA and PSOGSA are employed as new training methods for feedforward neural networks (FNNs) in order to investigate the efficiencies of these algorithms in reducing the problems of trapping in local minima and the slow convergence rate of current evolutionary learning algorithms. The experimental results of the proposed method show that PSOGSA outperforms both PSO and GSA for training FNNs in terms of converging speed and avoiding local minima. It has also been proven that an FNN trained with PSOGSA achieves better accuracy than one trained with GSA.

Recent advancements have focused on optimized particle swarm optimization (OPSO), which introduces a meta-optimization layer to PSO, where a higher-level “super-swarm” optimizes the parameters of subordinate swarms. This hierarchical structure allows the subordinate swarms to handle the optimization task while the super-swarm adjusts their parameters, improving overall performance. This concept has been effectively applied to the training of neural networks, leading to substantial reductions in training time and improvements in prediction accuracy [

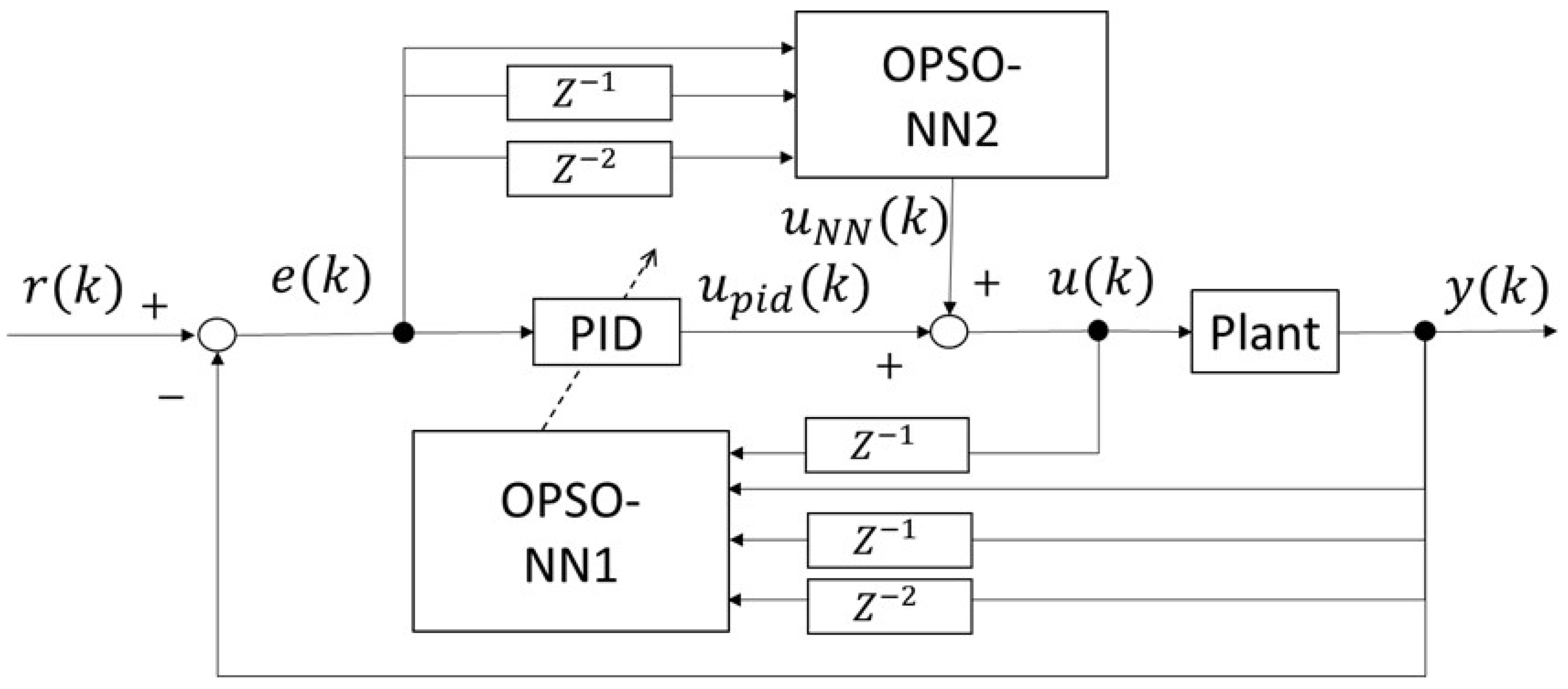

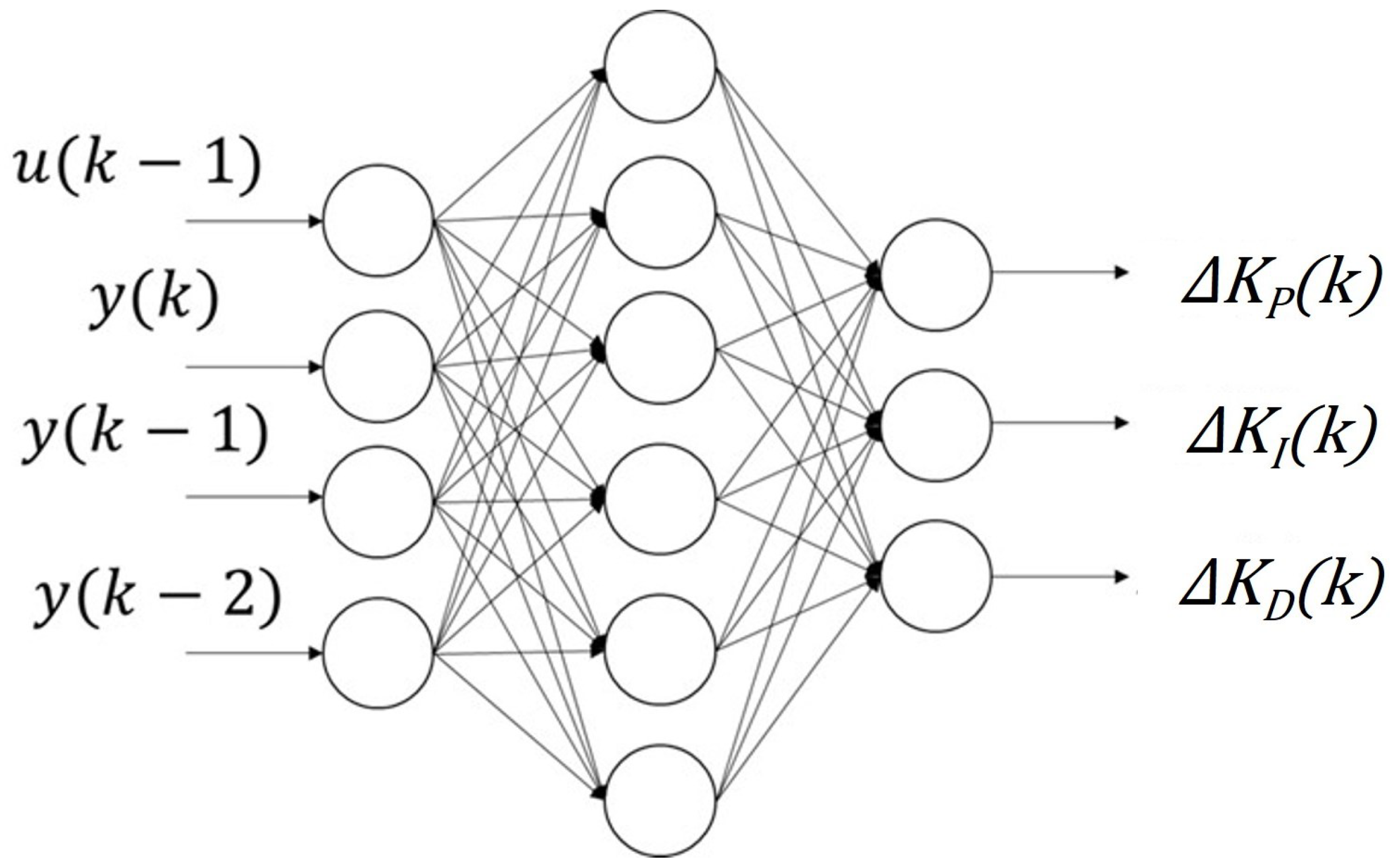

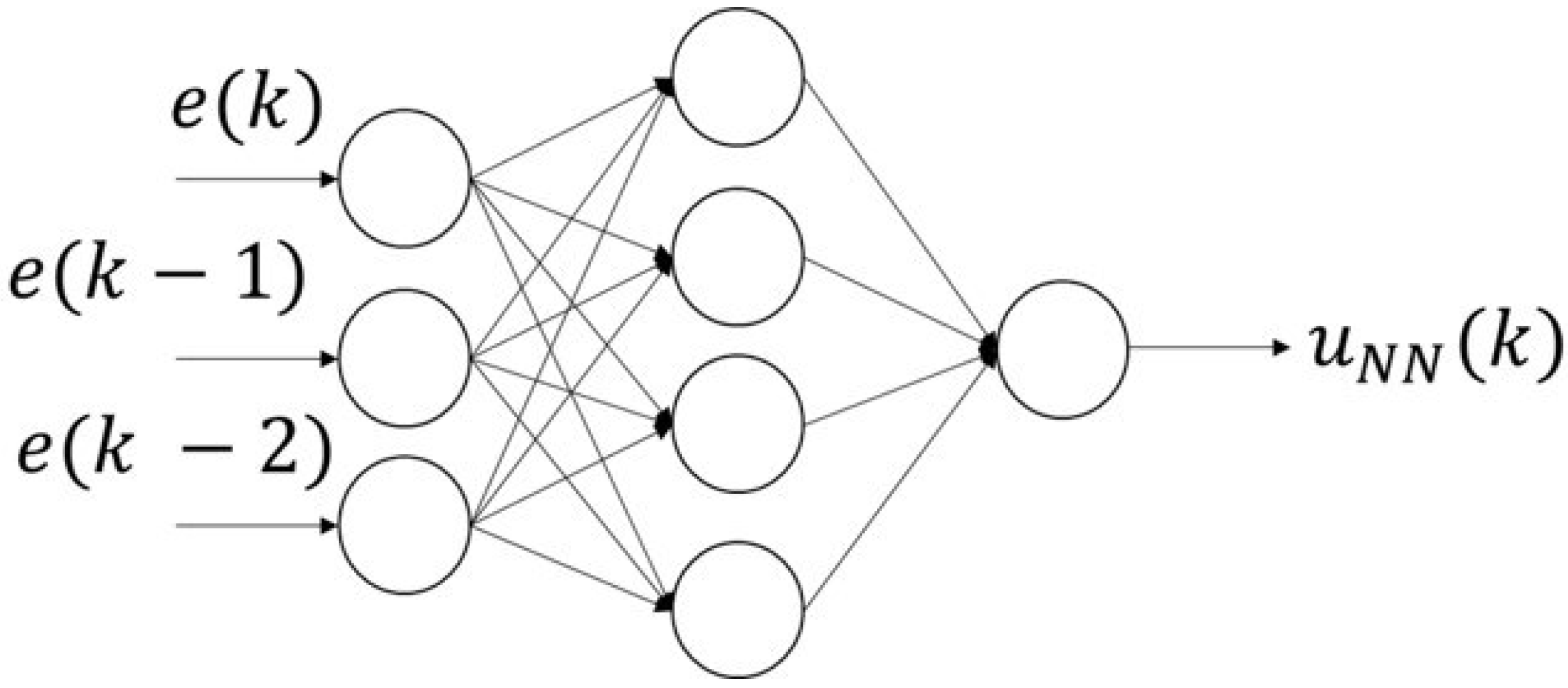

21]. In this study, we propose a variable-gain PID control strategy employing an optimized particle swarm optimization (OPSO)-type NN to update connection weights, referred to as OPSO-NN. Compared to traditional PSO, OPSO demonstrates faster convergence and requires fewer tuning parameters. This research specifically aims to enhance the accuracy and responsiveness of position control in pneumatic servo systems using OPSO-NN-based PID tuning.

The structure of this paper is organized as follows:

Section 2 outlines the pneumatic servo systems utilized in this study.

Section 3 provides an overview of fixed-gain PID control, the architecture of NNs, the principles of PSO, and variable-gain PID control using OPSO-type NNs.

Section 4 details the experimental procedures conducted to assess the proposed method’s effectiveness and discusses the resulting data. The

Section 5 concludes the paper by synthesizing the key findings and implications of the research.

2. Pneumatic Servo System

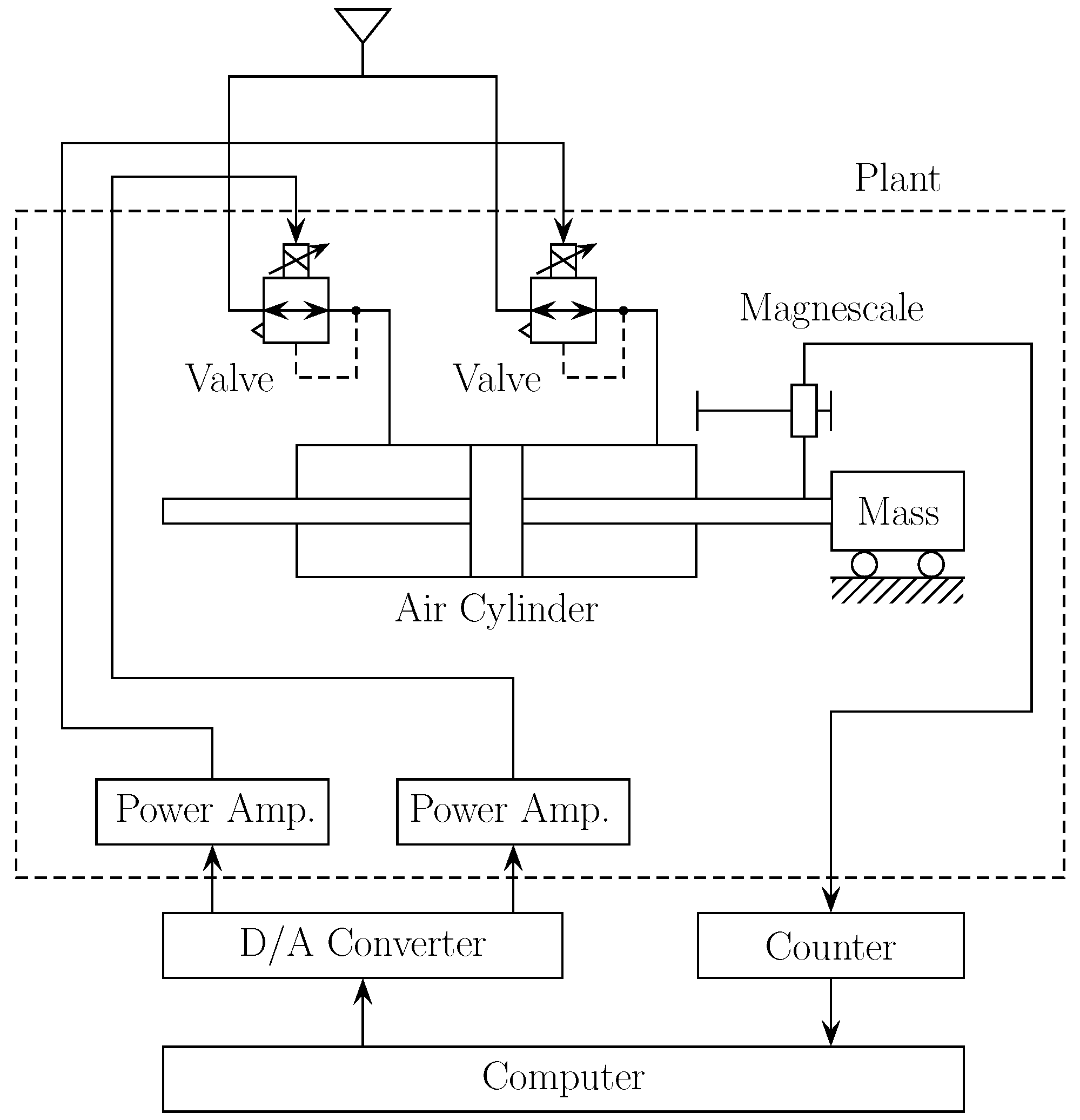

The system configuration of the horizontal pneumatic servo system used in this study is shown in

Figure 1. The parameters of pneumatic servo system are shown in

Table 1.

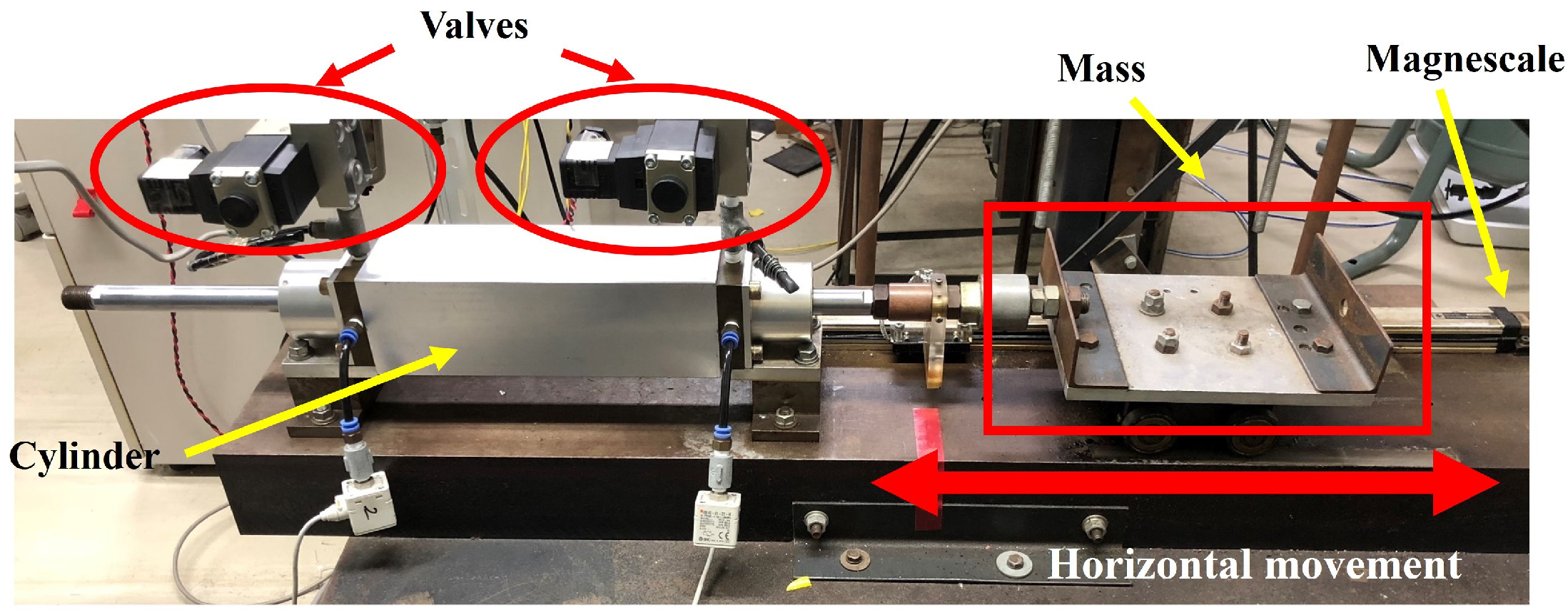

The primary actuator is the cylinder installed horizontally in the servo system. The pneumatic cylinder converts compressed air into linear motion. It is essential for generating the necessary force to move the attached mass, allowing for precise control over its position horizontally. The appearance of the experimental apparatus is illustrated in

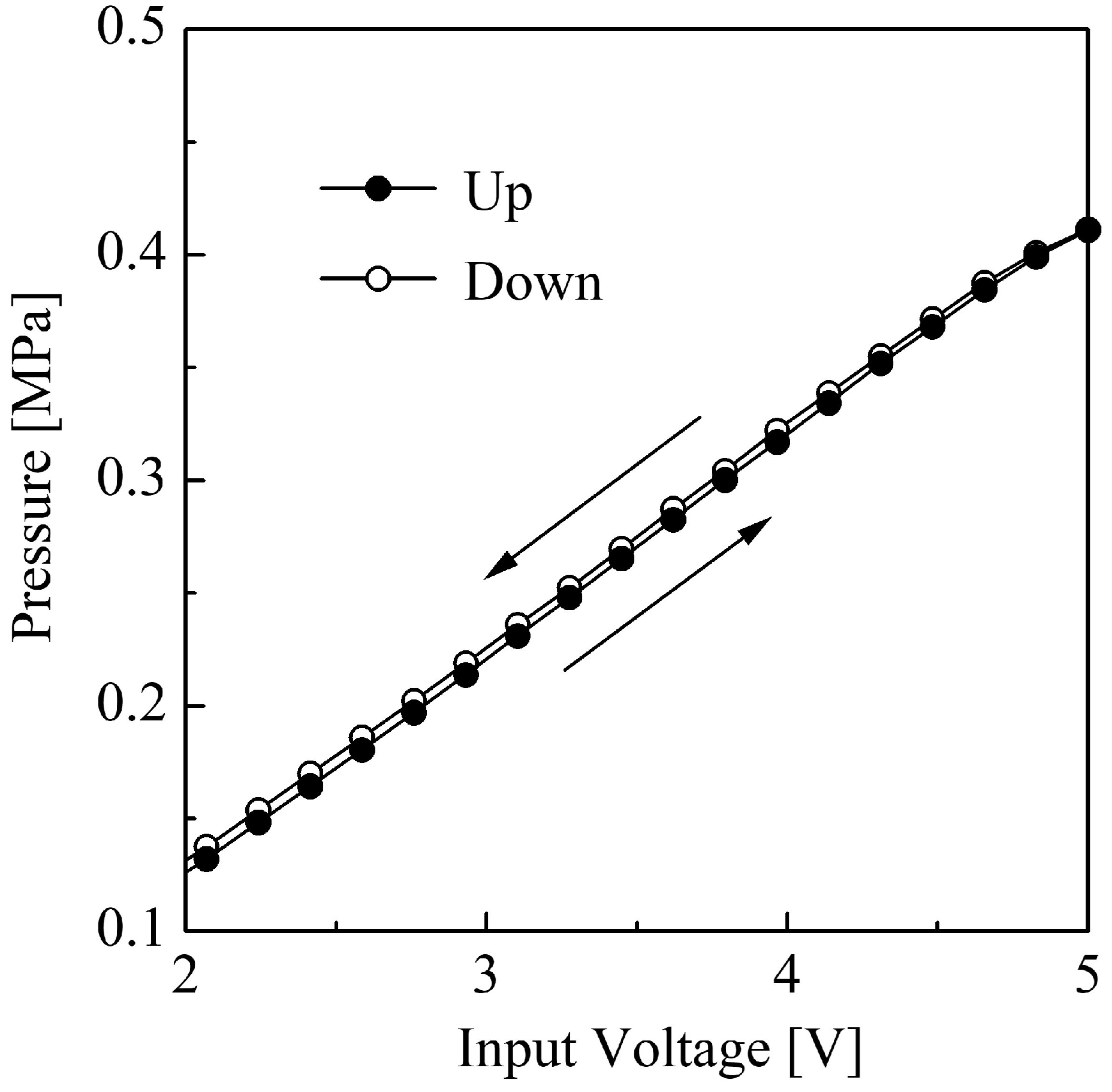

Figure 2. Two three-way electro-pneumatic proportional pressure control valves are applied in the system. These valves regulate the airflow to the cylinder, enabling the pressure and direction of the pneumatic force applied to the mass. Offering an effective control signal to valves is crucial for achieving the desired response characteristics of the system. To obtain precision position control of the pneumatic servo system, the supply pressure for controlling the valves is expressed as

and

. The specific pressure characteristics are shown in

Figure 3. A magnescale is employed in this servo system for the accurate position detection of the moving mass. The data obtained from the magnescale are sent via the counter board to the computer, ensuring that the servo system can maintain precise positioning. The computer processes the input data from the counter and magnescale, executes the control algorithms, and sends control commands to the D/A converter for real-time actuation. The power amplifiers boost the control signals sent from the computer through the D/A converter, ensuring that adequate power is supplied to the actuator for control operation.

Figure 3 illustrates the input–output characteristics of the control valve, including the amplifier. The position detection of the cylinder is conducted using a magnescale sensor (Sony Magnescale SR50-50A: effective length 500 mm). The signal from the magnescale is converted into a pulse signal corresponding to the displacement by a detector circuit (Sony Magnescale MD30-1G5C). Subsequently, the signal is counted via a counter board (Interface Inc. 6201E) and input into a computer as a digital signal. The resolution of position detection on the computer is 5 µm. The control signal for the control valve is output from the computer to a D/A converter (Interface Inc. 3346A) as a digital signal. The D/A converter uses two channels; if one channel’s output is positive, the other’s is negative, thus outputting opposite control signals. These control signals are converted to analog through the D/A converter and drive the pneumatic cylinder via the power amplifier and control valve. Since the pneumatic servo system includes nonlinear elements, it is practically impossible to make a complete control model. Therefore, we consider the plant with the input–output characteristics shown in

Figure 3 as the target for control. In this case, a dead time of 0.04 s is included in the control input to account for operational delays and computation time.

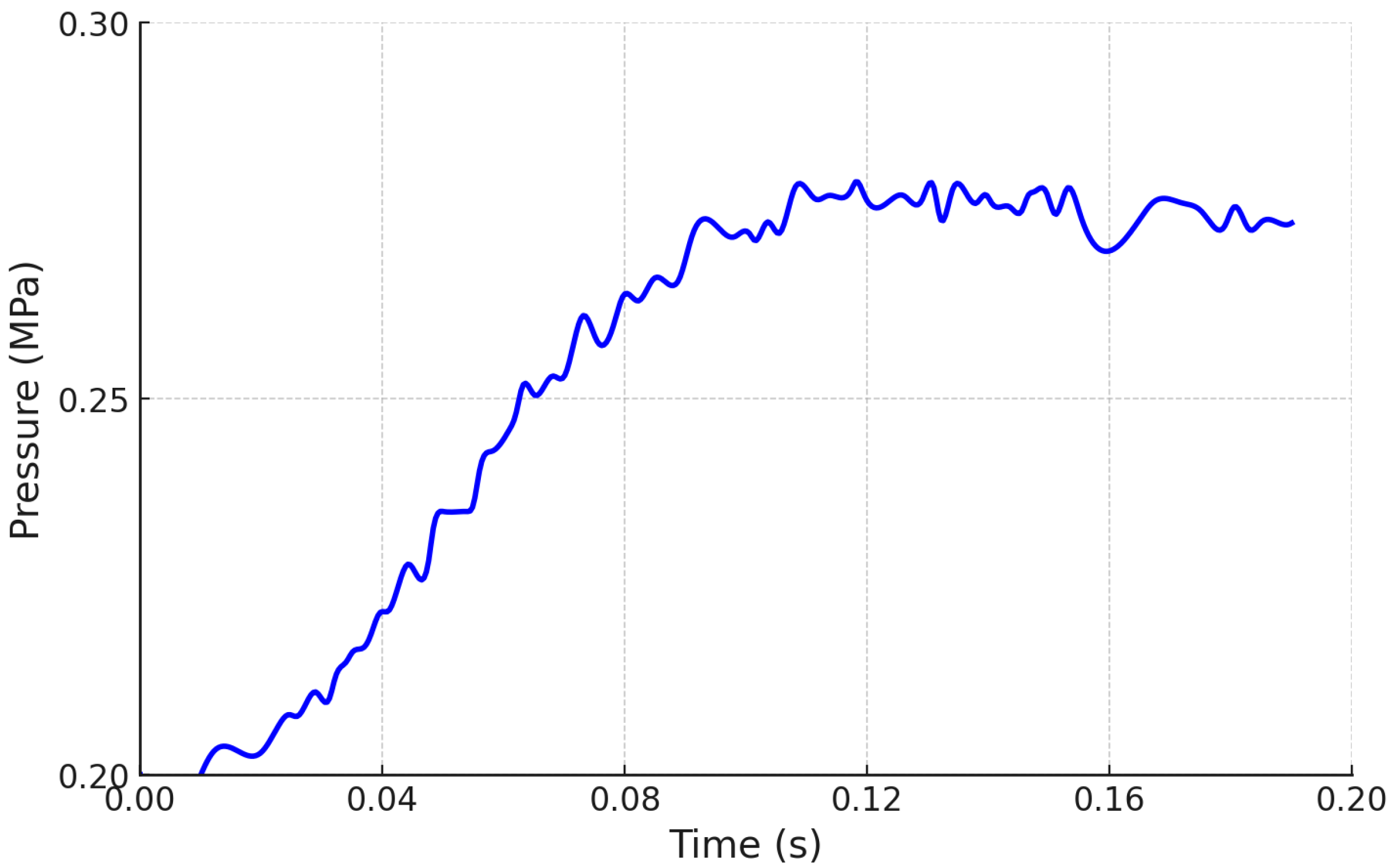

Figure 4 illustrates the pressure response within the cylinder when a step input voltage is applied to the power amplifier of an electro-pneumatic proportional pressure-control valve. This measurement was obtained by fixing one end of the cylinder and changing the input voltage from 5 V to 6 V (corresponding to a change in the secondary pressure from

MPa to

MPa). From the figure, it is evident that the relationship between the applied voltage and the cylinder pressure can be approximated by a first-order lag system with dead time. Here, a dead time of 40 ms was incorporated into the control input, taking into account the computational time of 30 ms for the operational delay [

22].

5. Conclusions

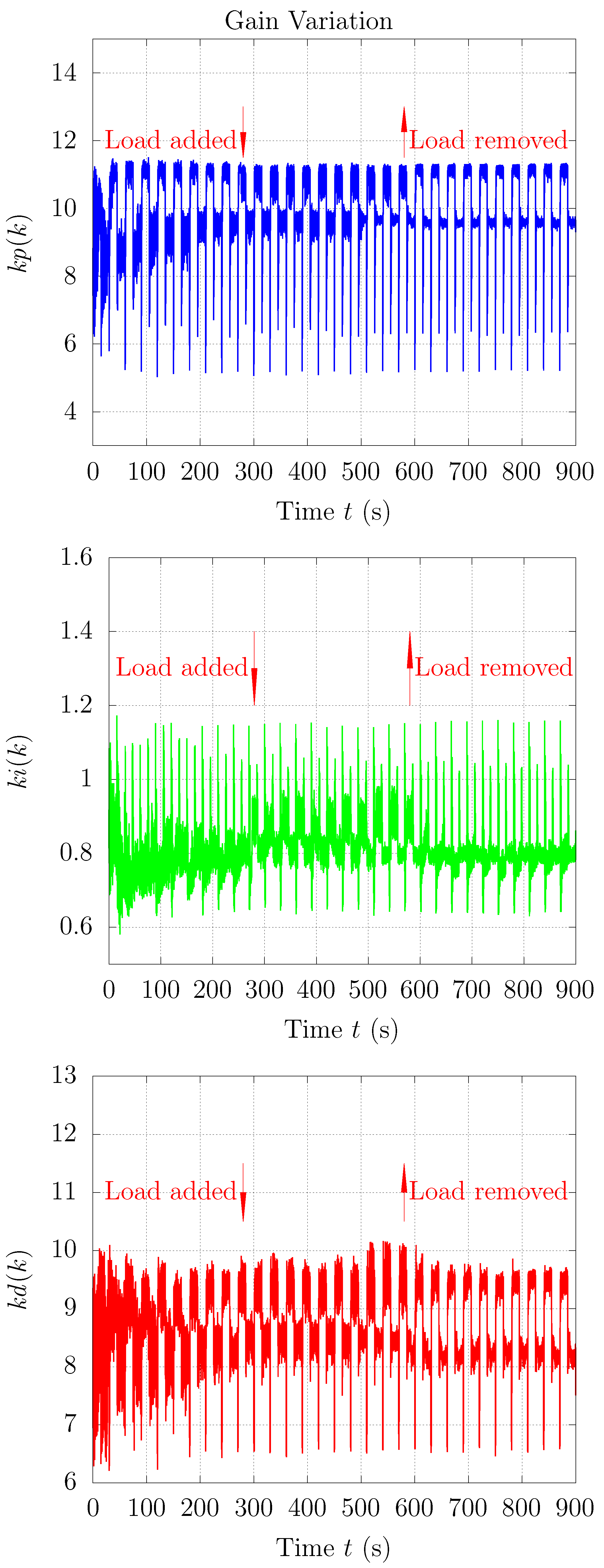

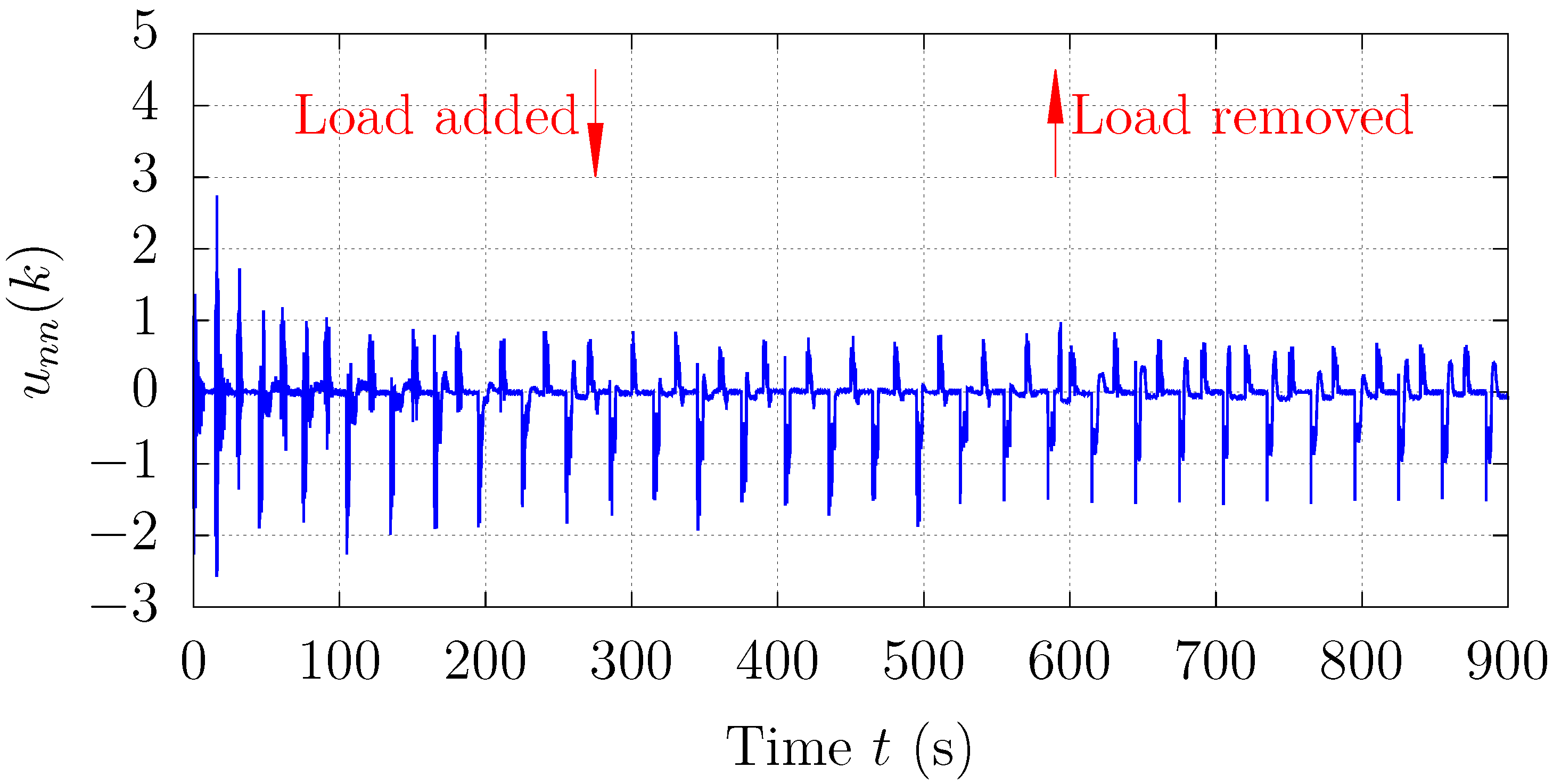

In this study, an advanced variable-gain PID control method for pneumatic servo systems, utilizing an optimized particle swarm optimization-type neural network to address the system’s inherent nonlinearities, was implemented. By integrating two OPSO-type NNs, the controller demonstrated improved accuracy and adaptability in tuning PID gains dynamically, which resulted in enhanced control performance.

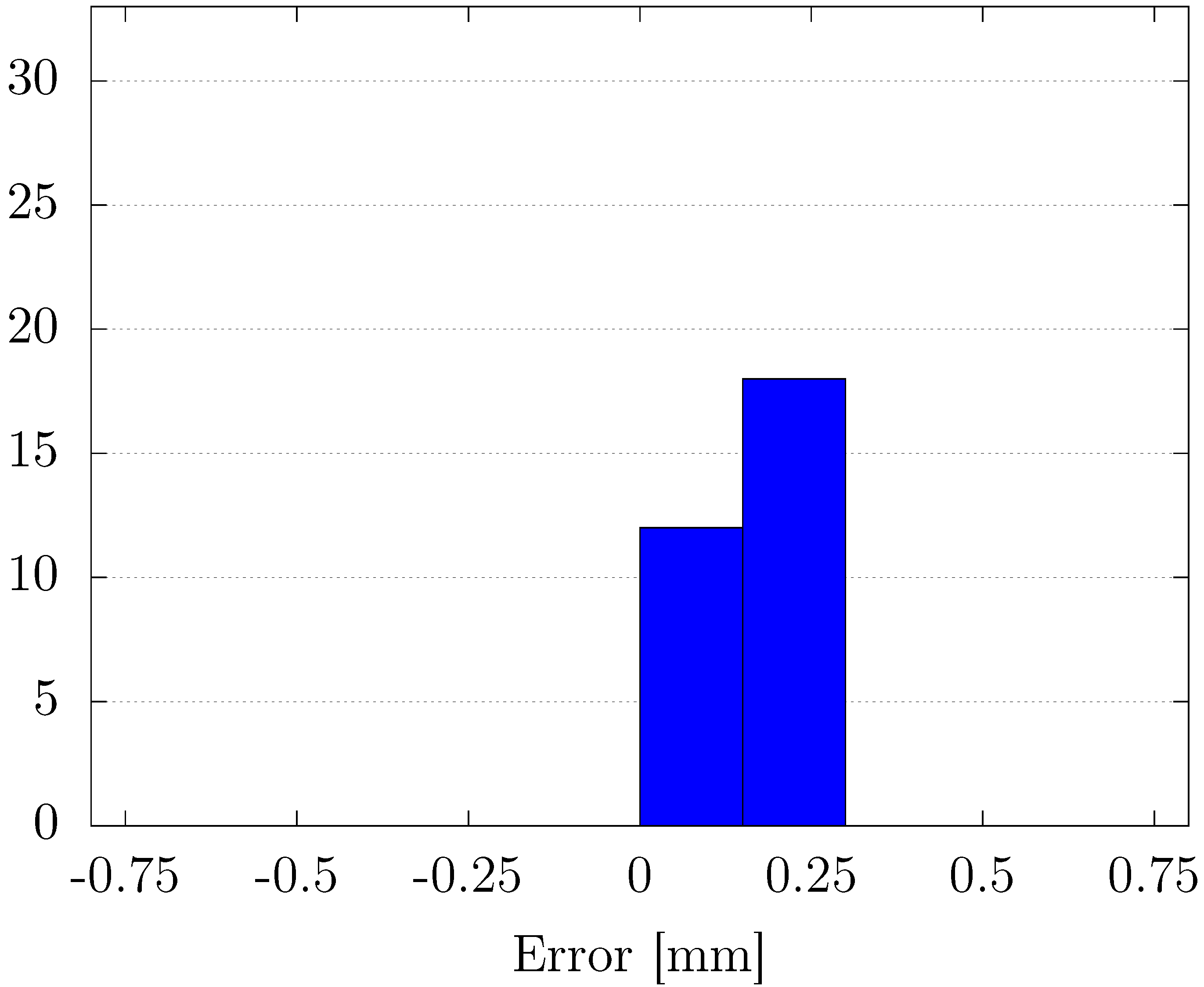

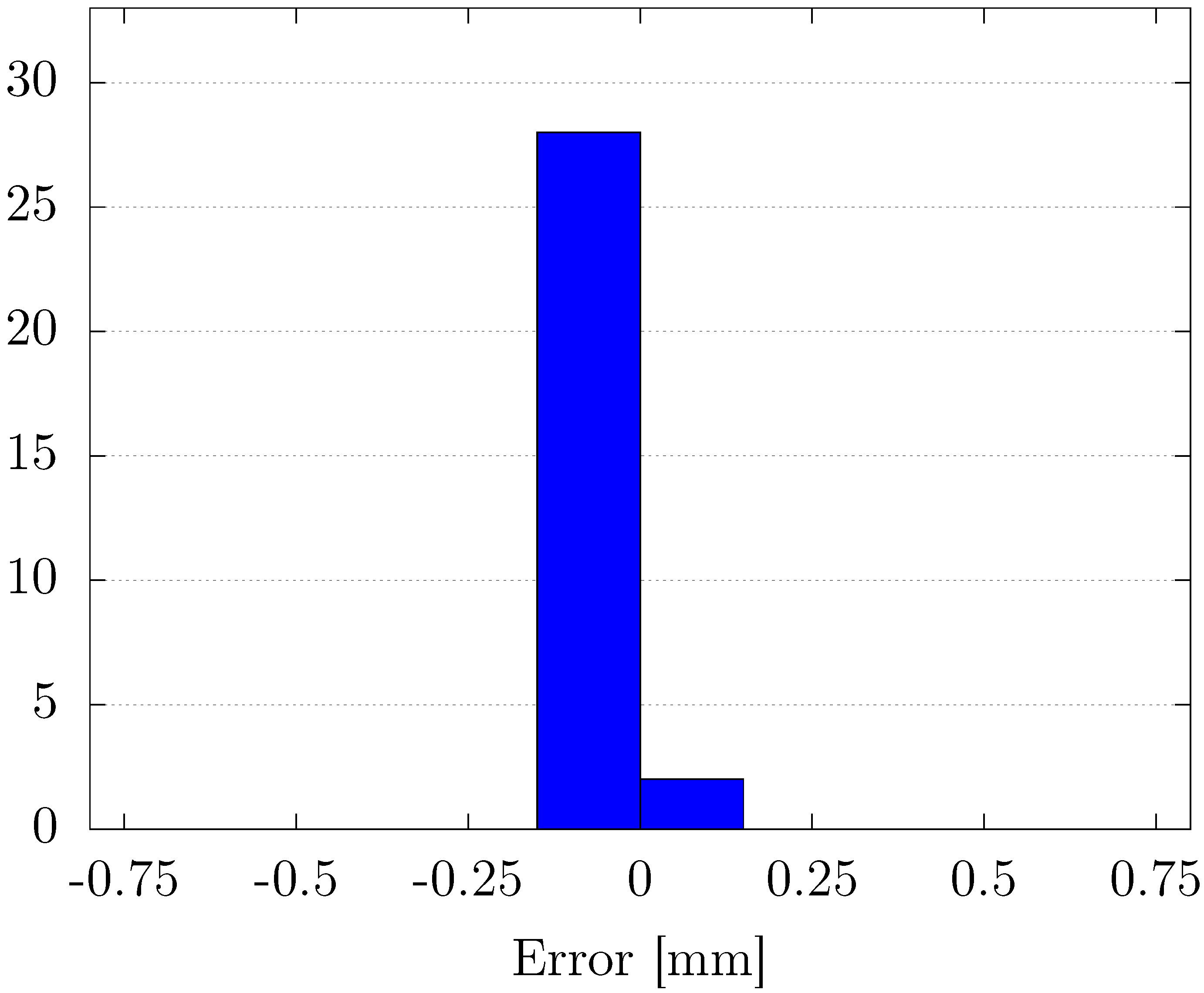

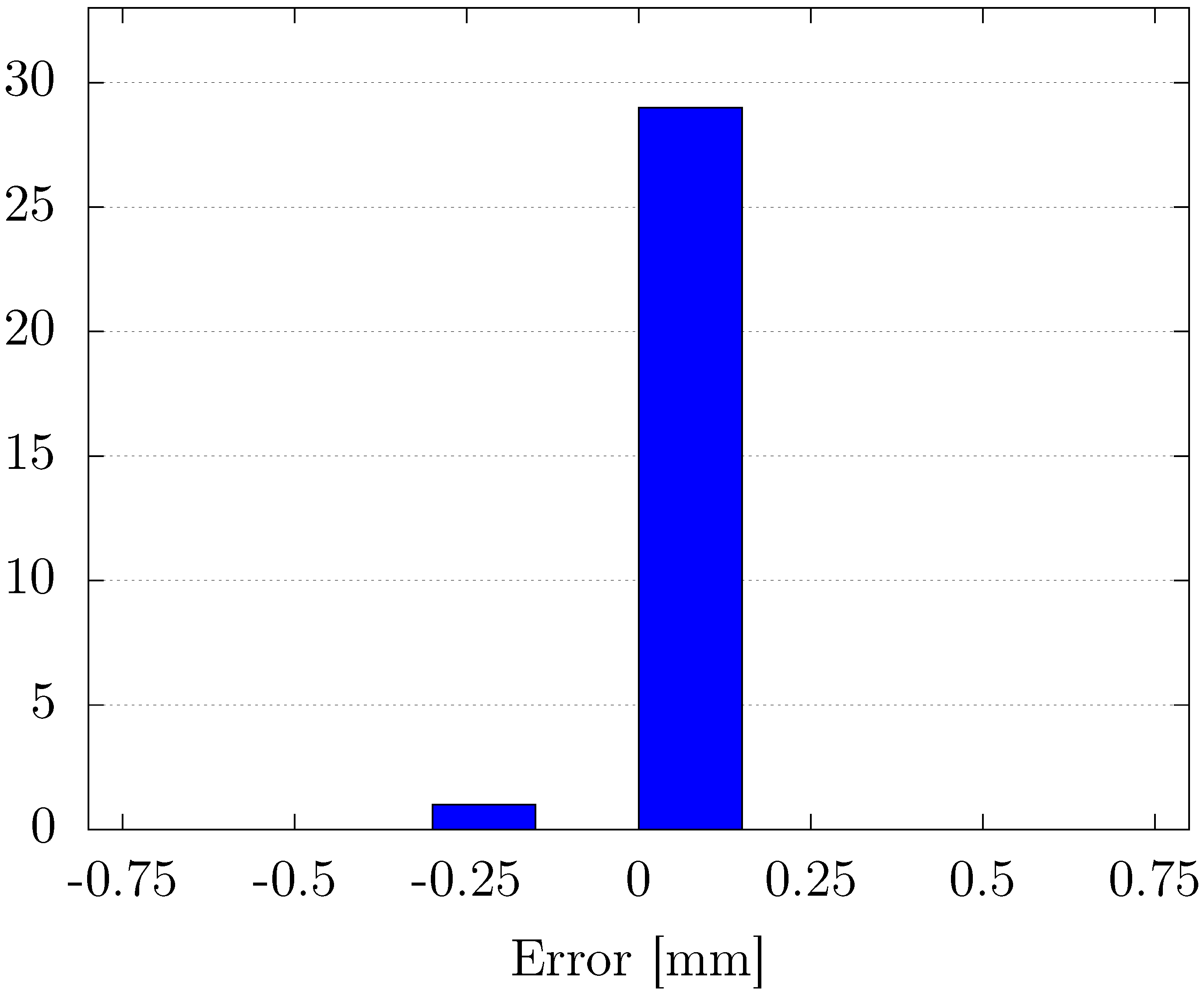

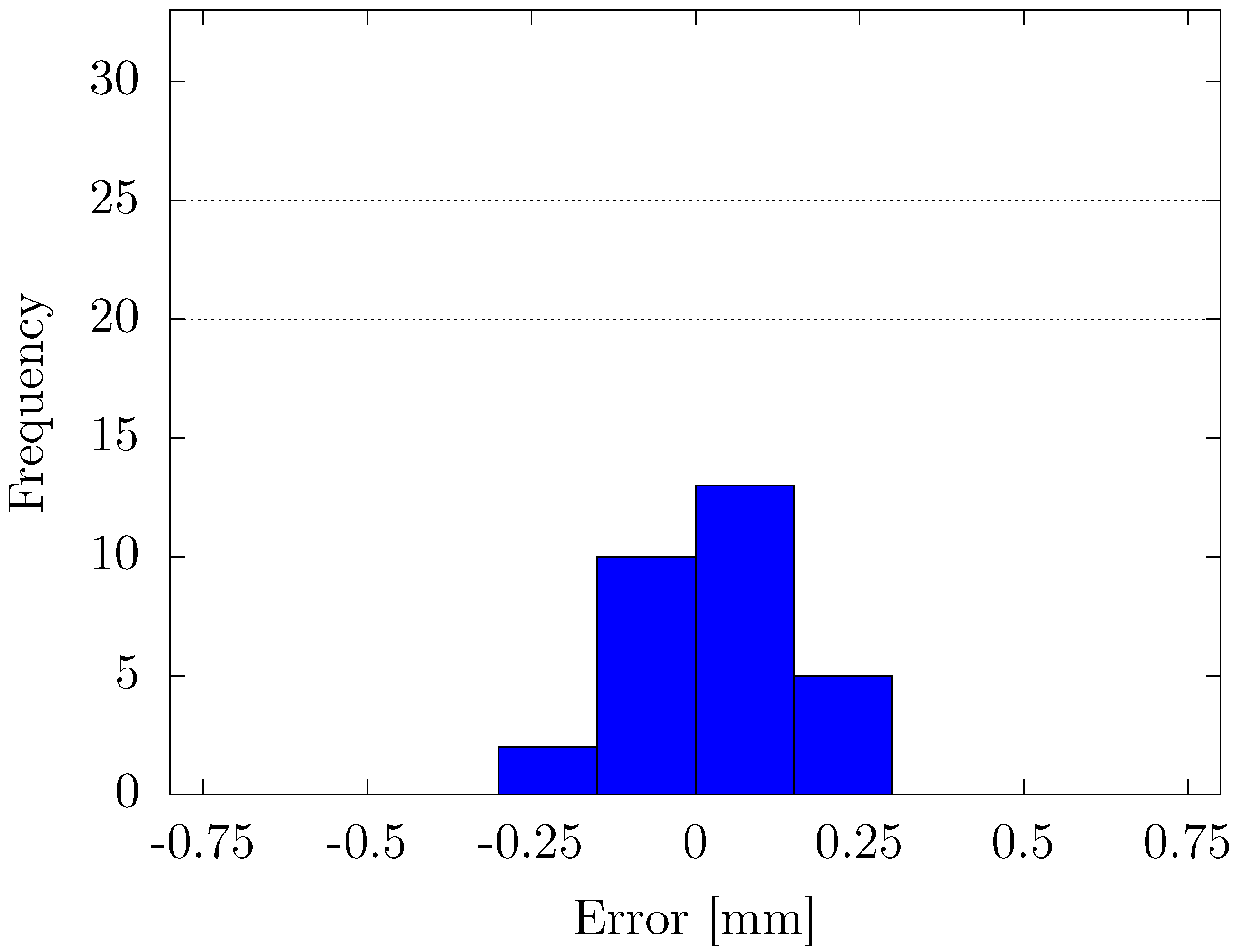

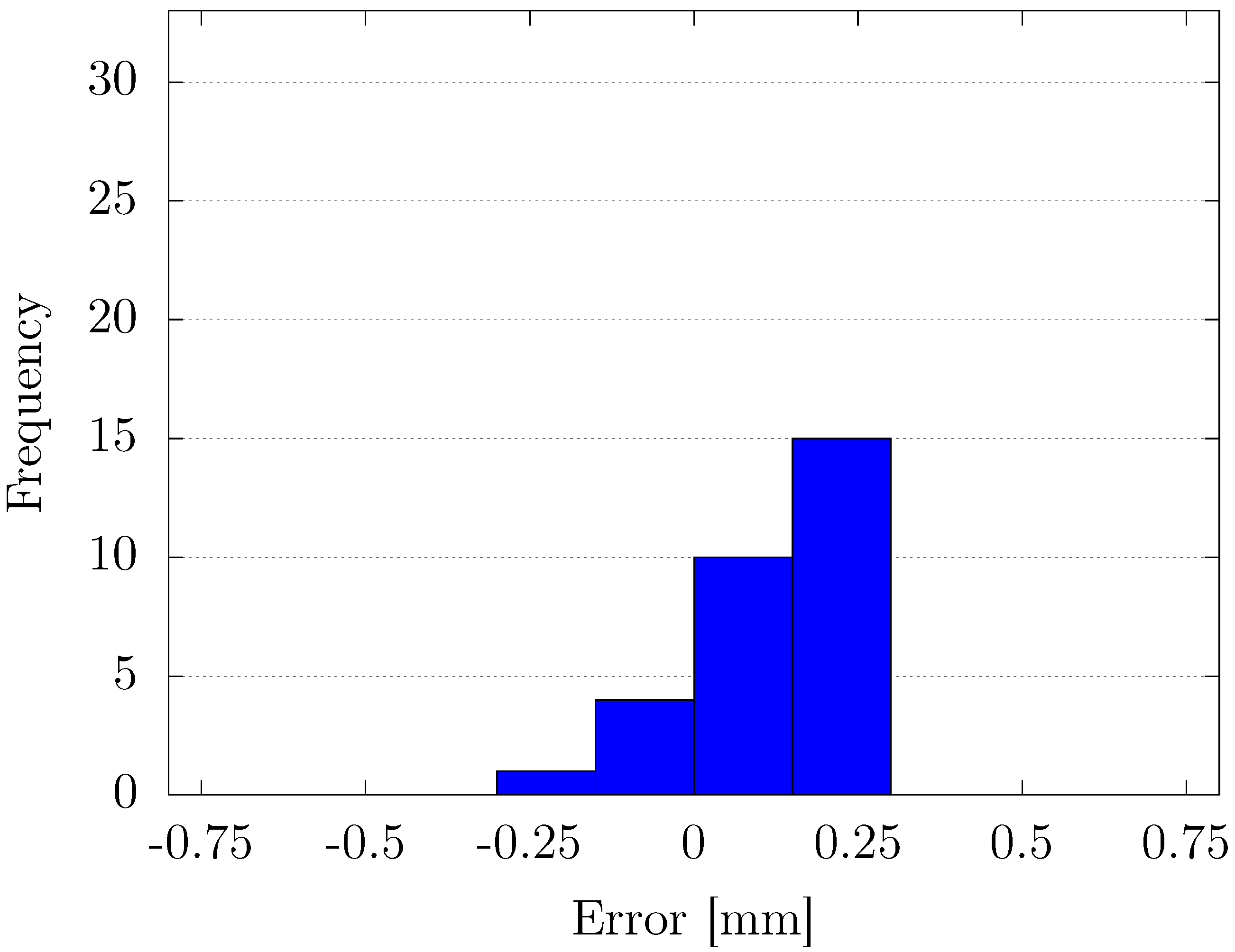

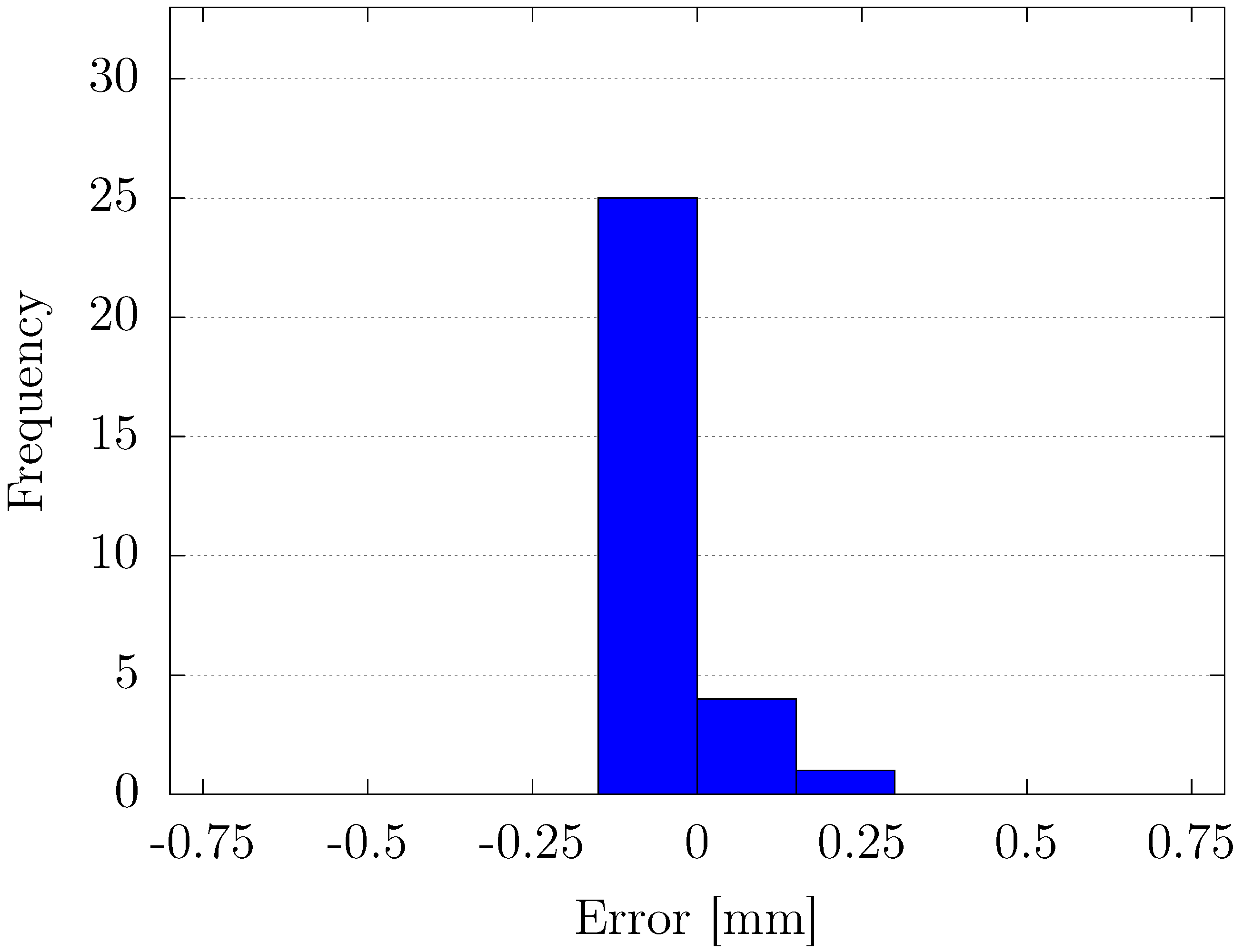

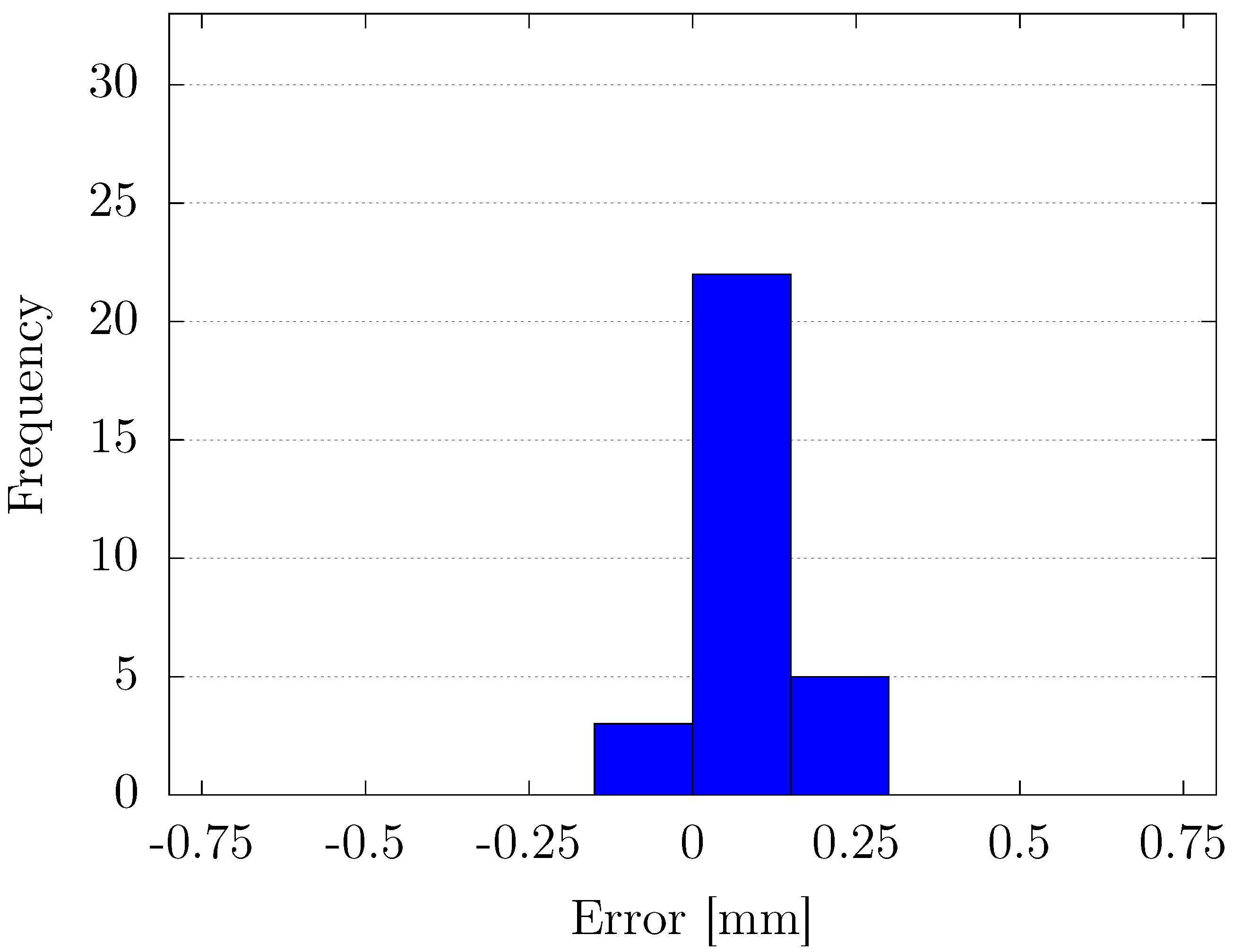

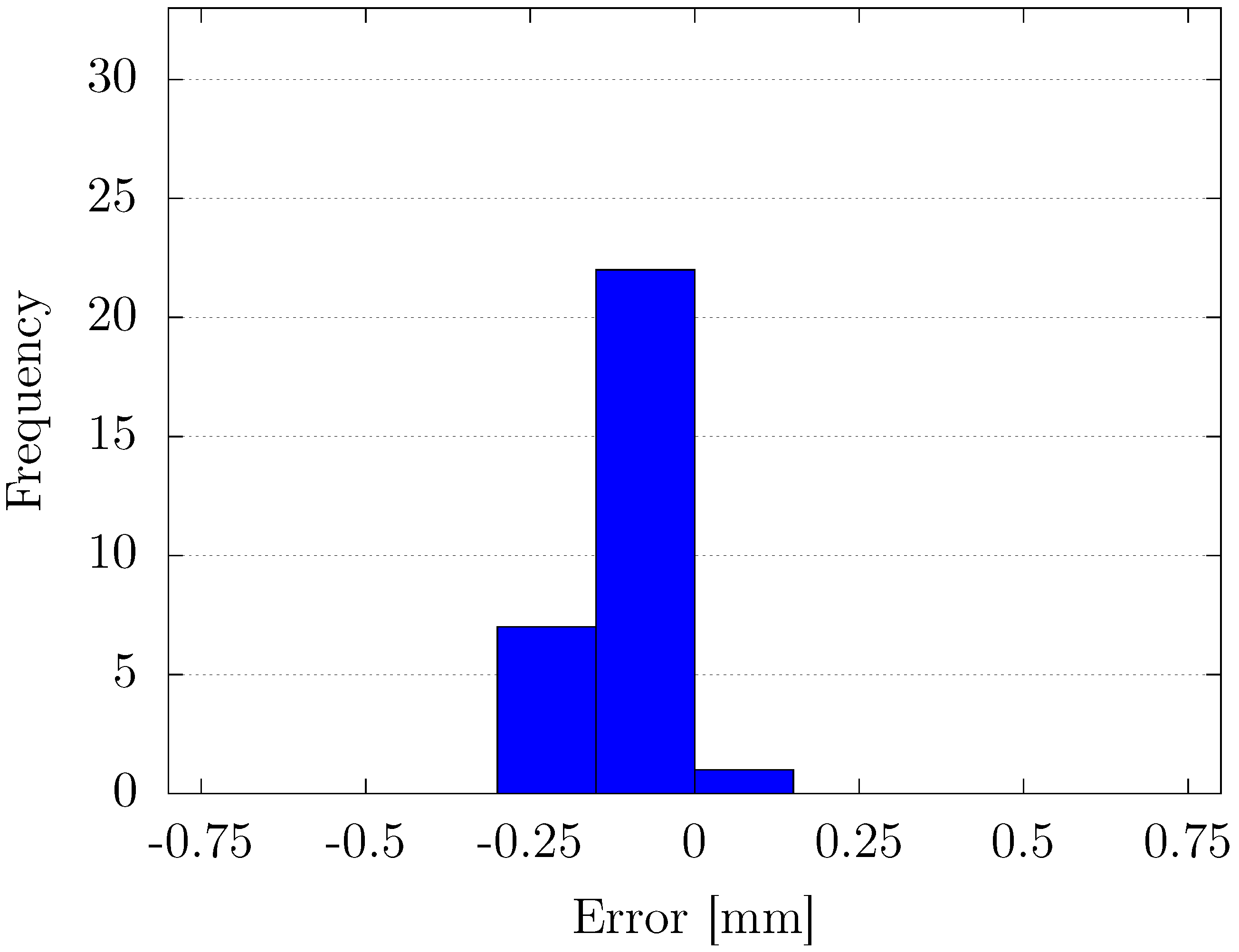

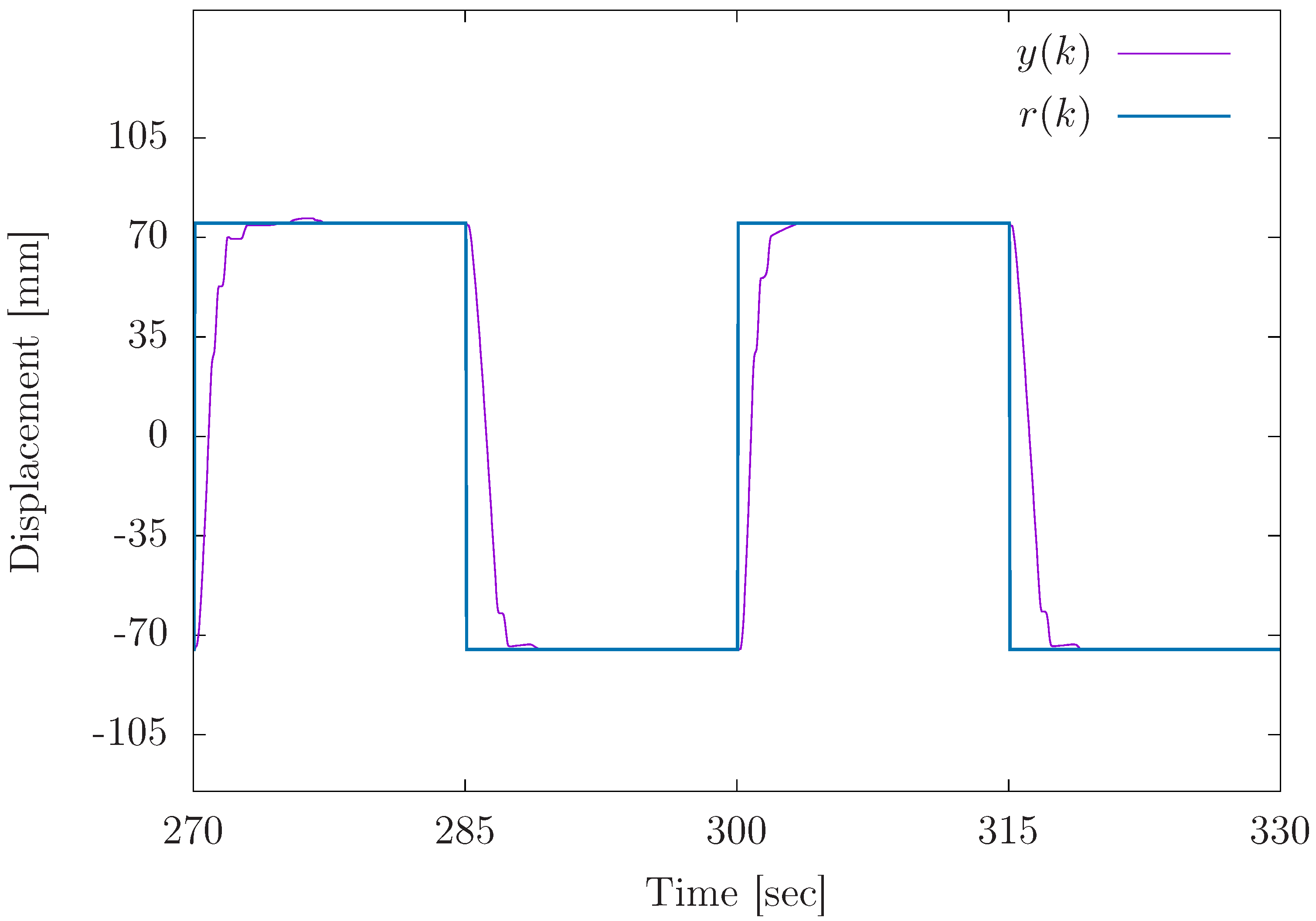

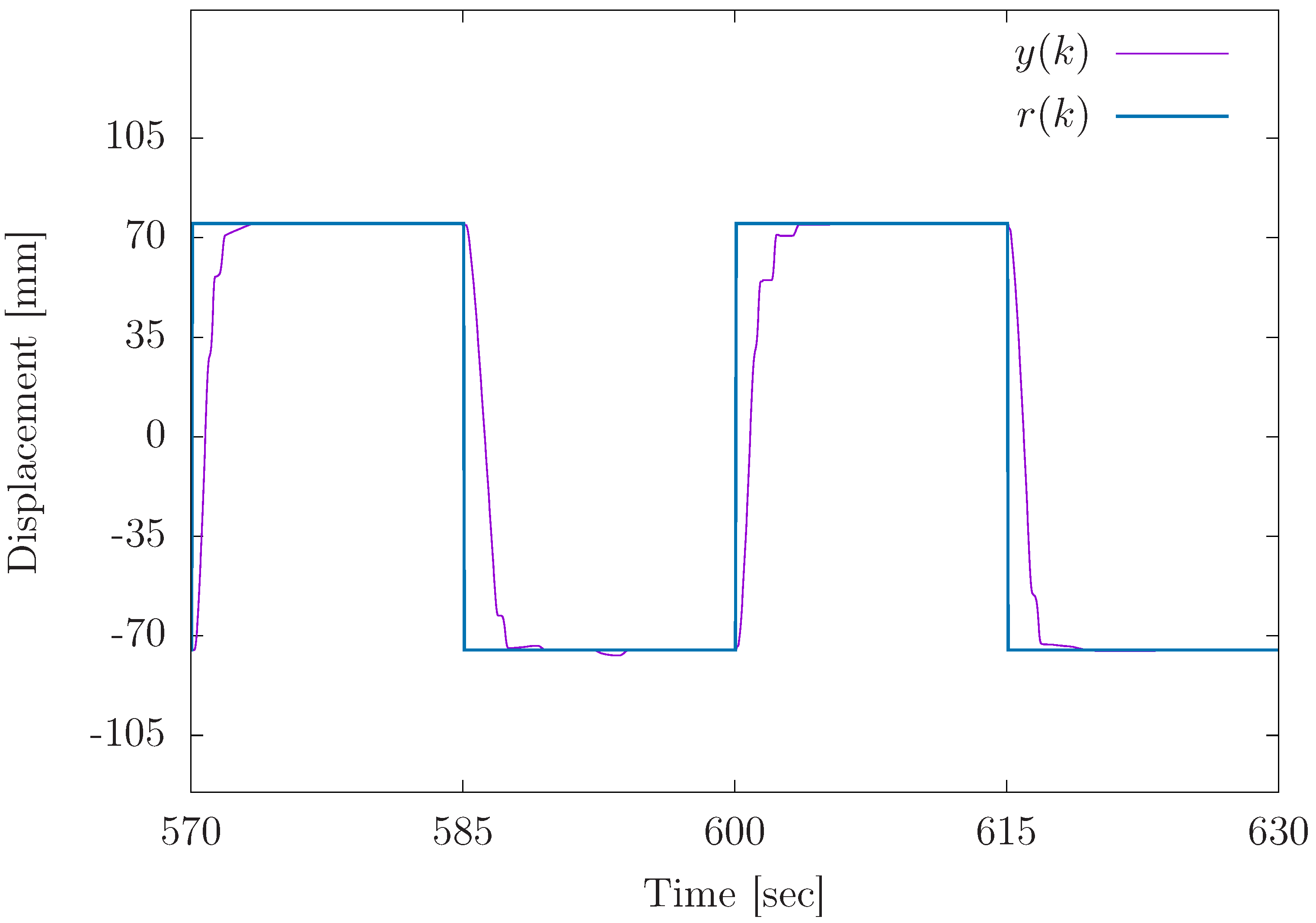

Through experimental validation, we confirmed that the proposed method outperformed conventional fixed-gain PID control in terms of position-tracking accuracy, transient response, and steady-state error reduction. Specifically, the proposed controller achieved faster settling times and minimized overshoot, particularly in response to abrupt changes in the reference signal. Additionally, the steady-state error analysis revealed that the variable-gain control method consistently provided more precise results, with errors concentrated in narrower ranges at both positive and negative displacement targets. Despite its effectiveness, some variability in steady-state performance was noted, indicating areas for future improvement, particularly in fine-tuning the inertia coefficient of the sub-swarm to further optimize control precision. Compared to traditional fixed-gain PID methods, our OPSO-NN method uniquely integrates hierarchical swarm optimization into real-time PID tuning, significantly enhancing system adaptability and control precision.

Future work will explore these improvements and extend the method’s validation under higher load conditions. The results of this study highlight the potential of the OPSO-NN method as a robust and adaptable control strategy, offering significant advantages over traditional PID control approaches for complex systems like pneumatic servo mechanisms.