Design of High-Speed Motor System for EV Based on 1200 V SiC-MOSFET Power Module

Abstract

1. Introduction

2. Motor System Design

2.1. High-Speed Motor Design

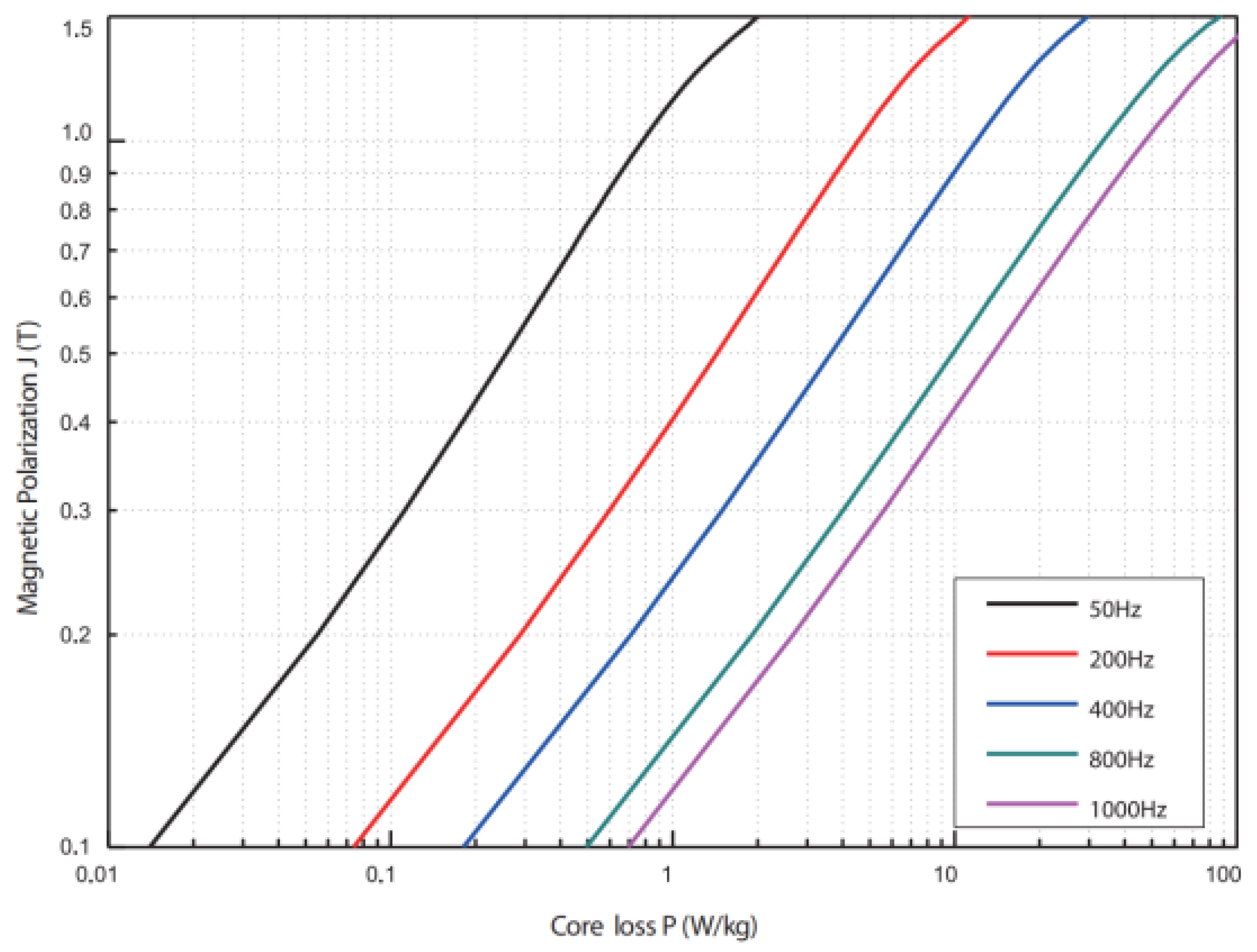

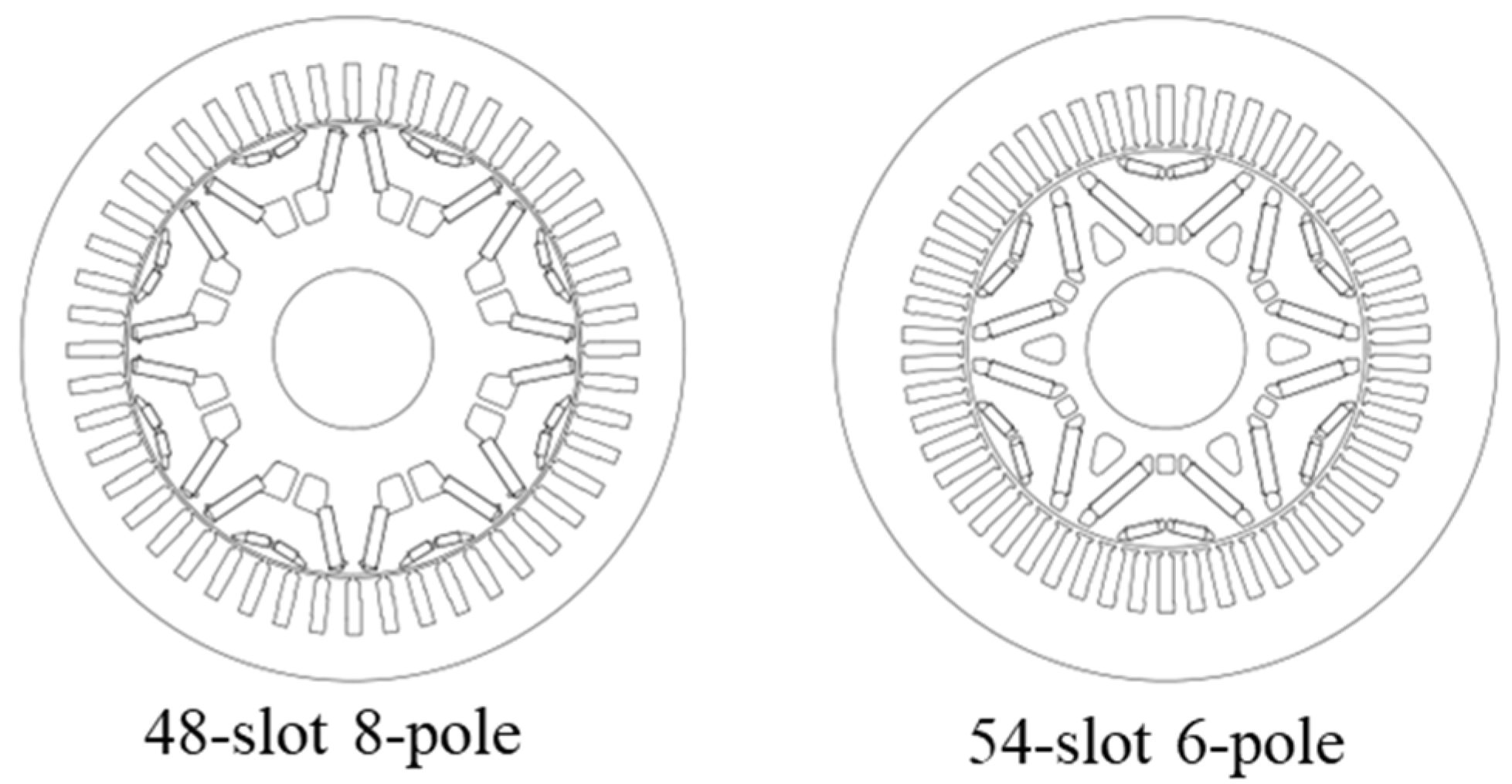

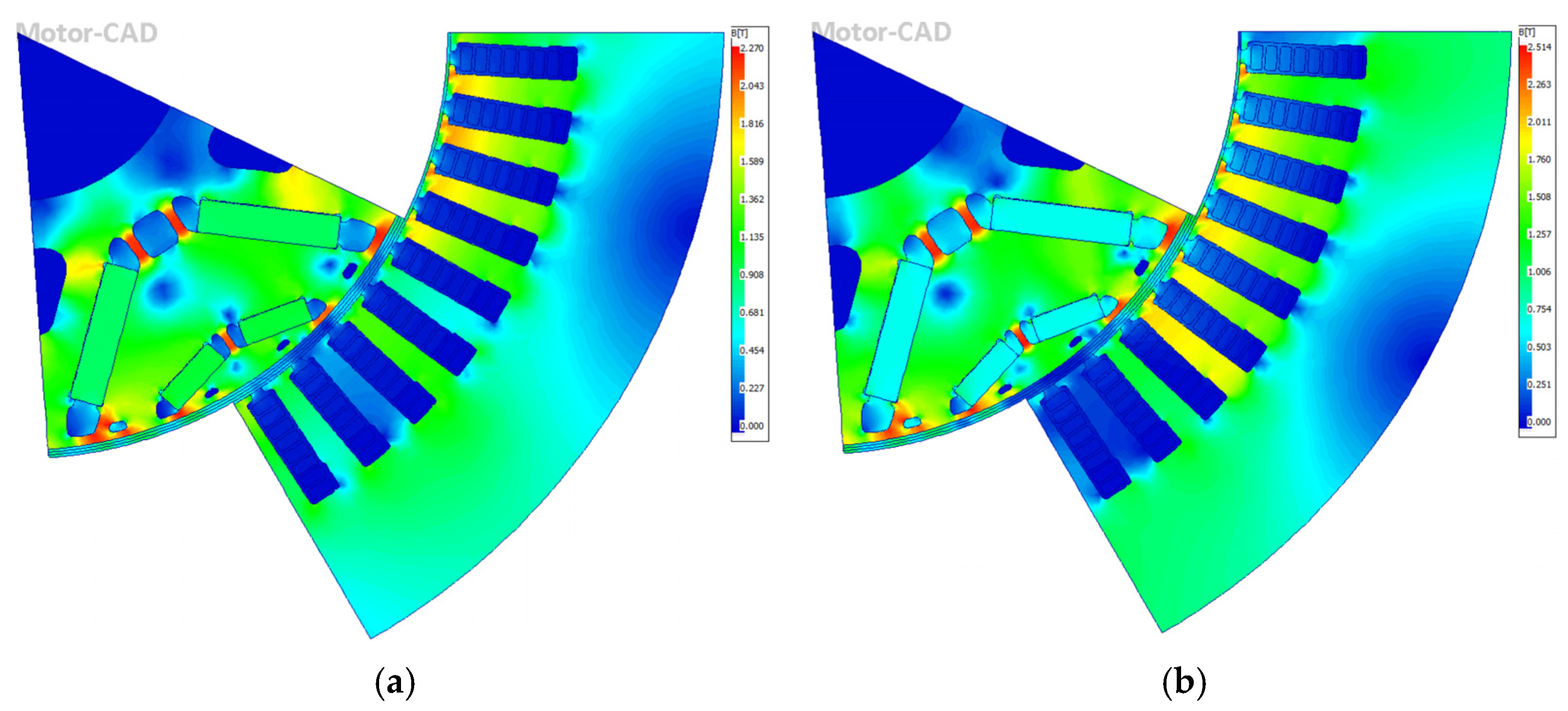

2.1.1. Iron Loss Optimization

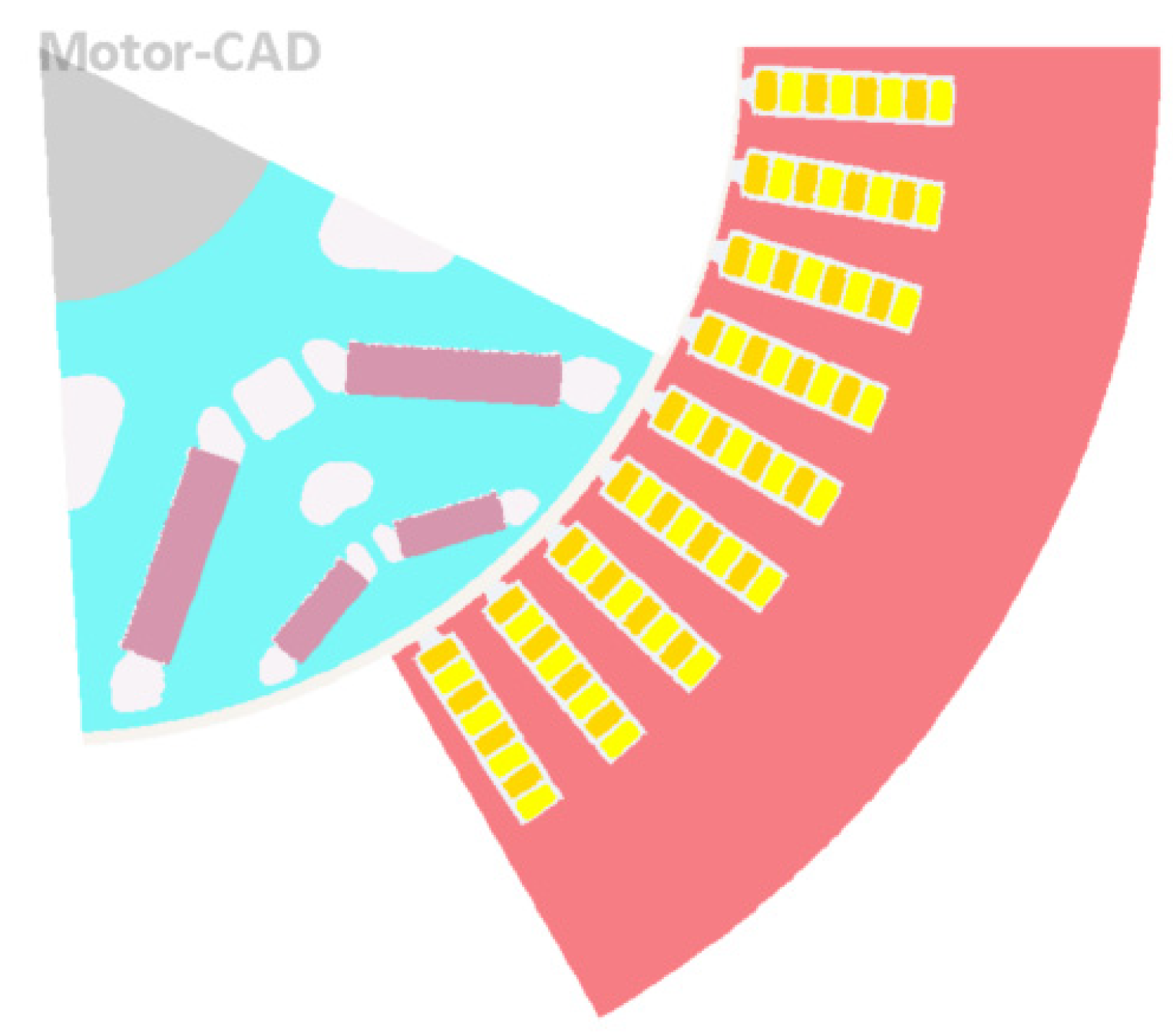

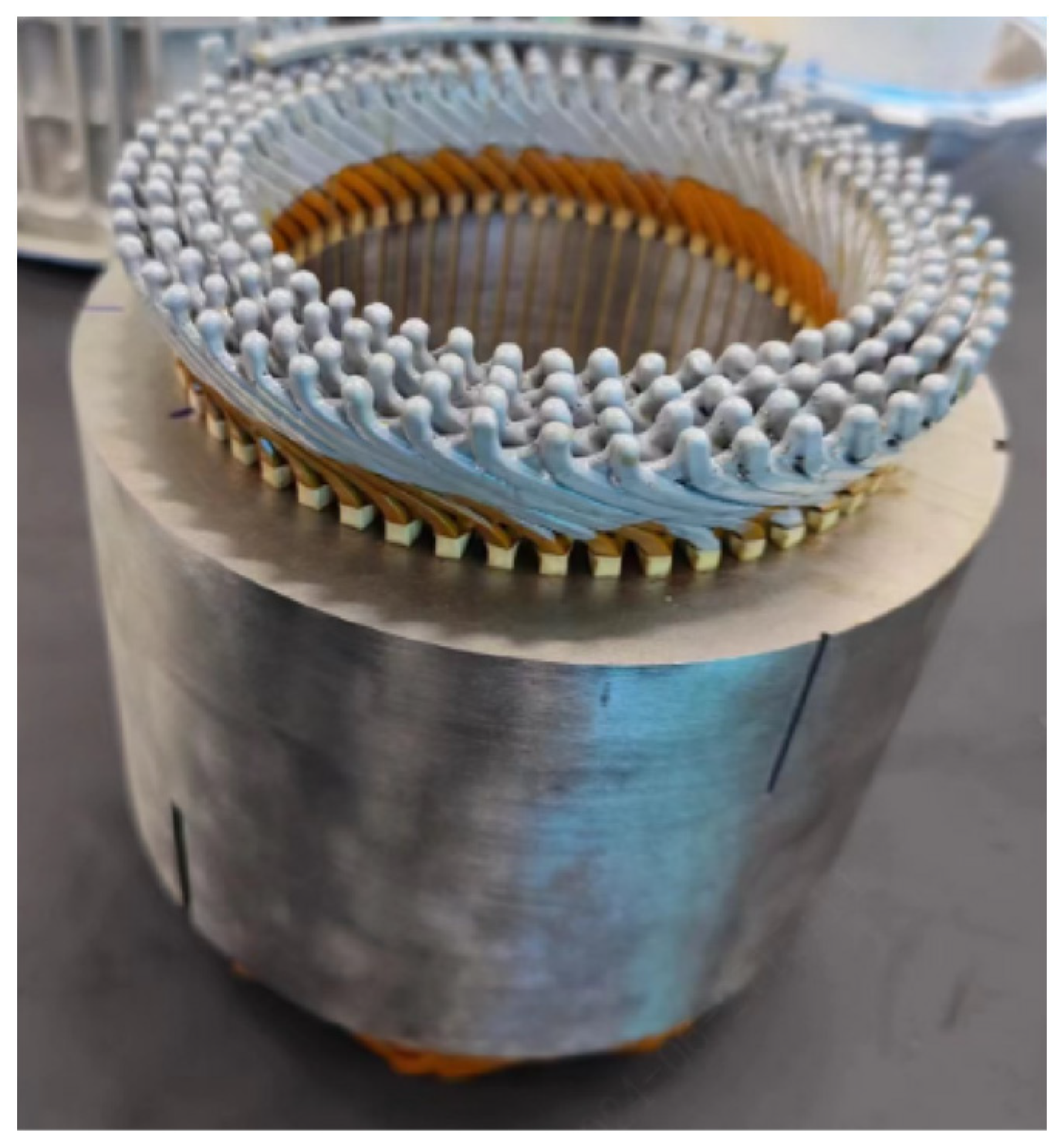

2.1.2. Copper Loss Optimization

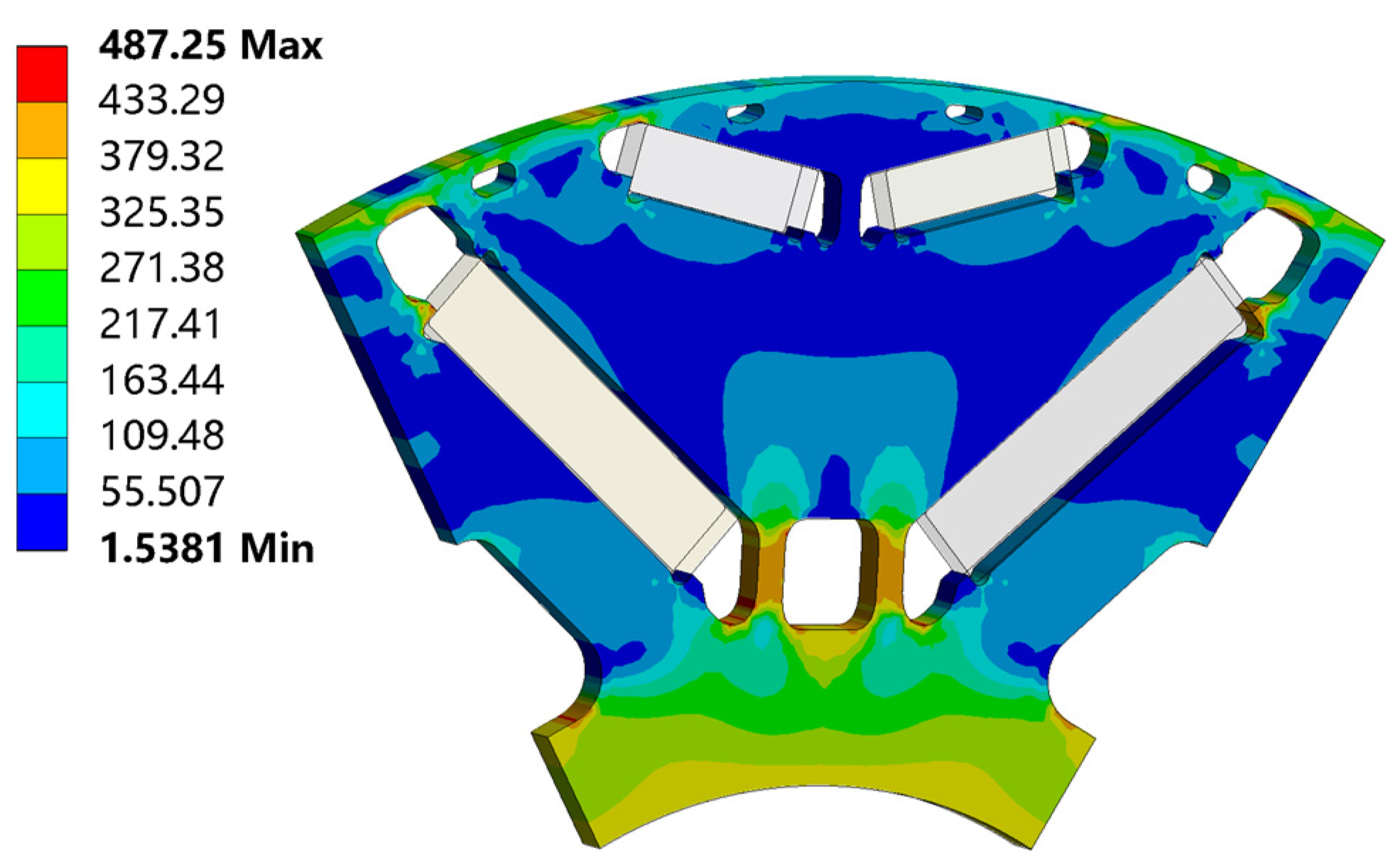

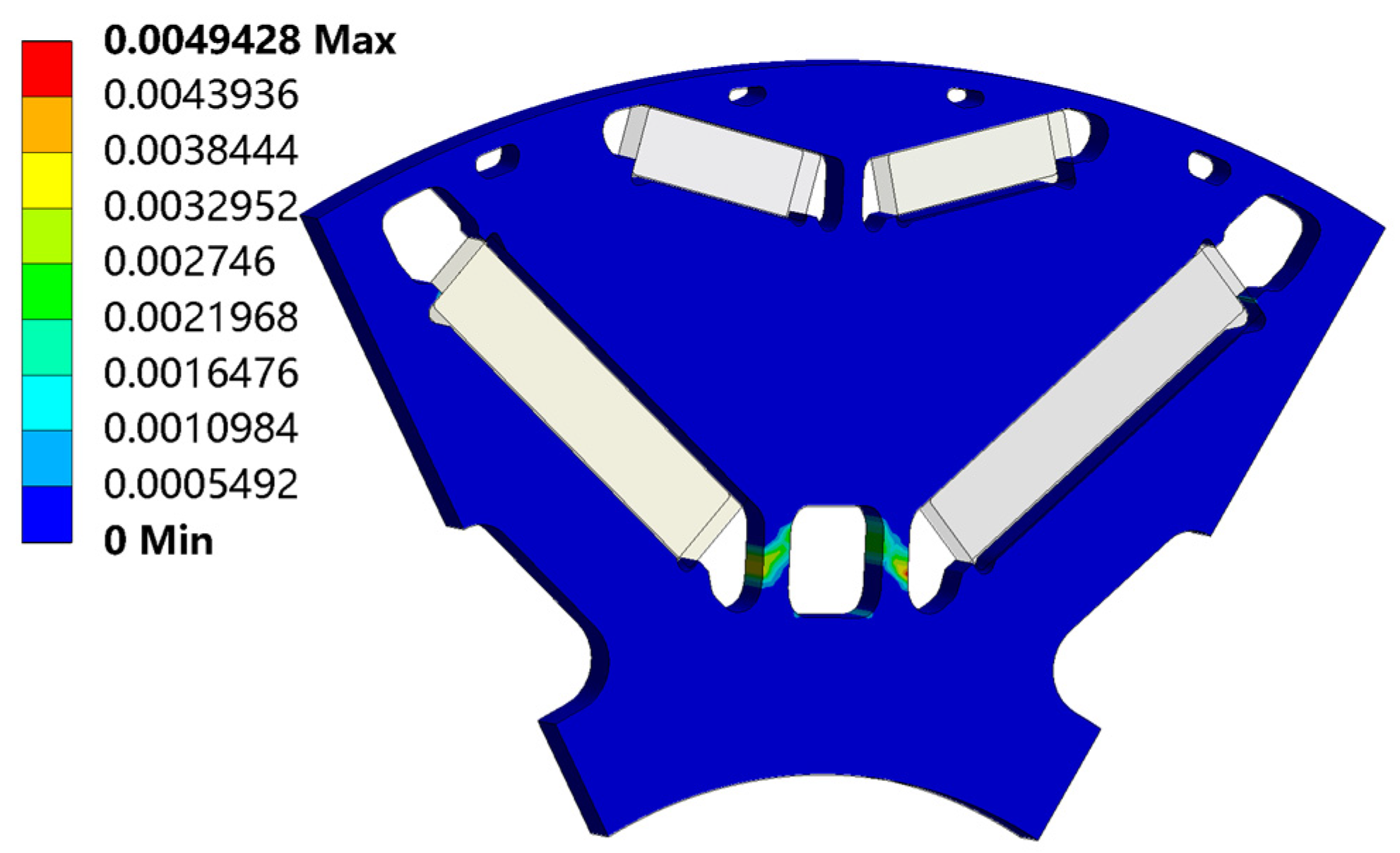

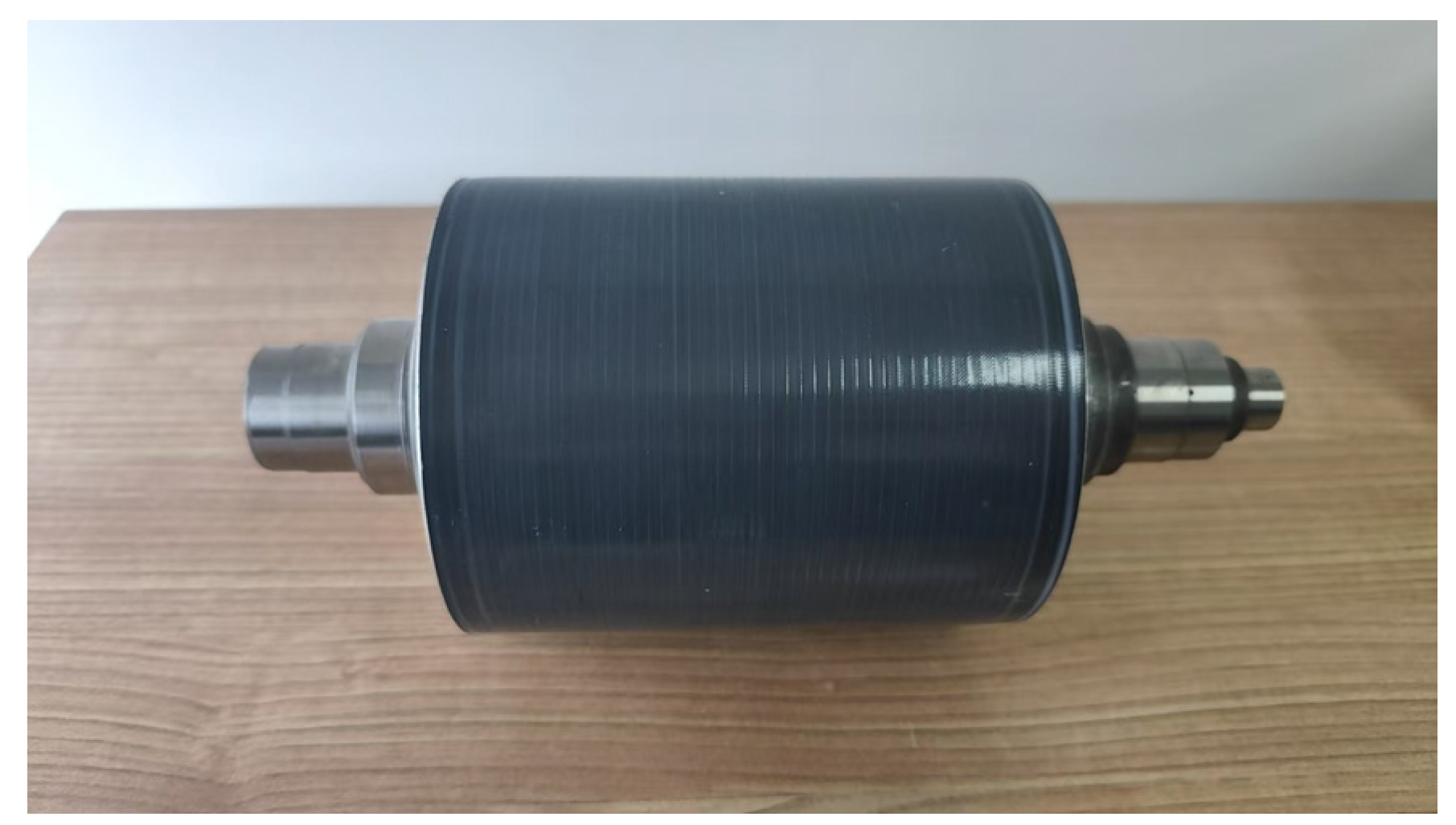

2.1.3. Structural Stress Optimization

2.1.4. Main Parameters Calculation

2.2. Controller Design

2.2.1. SiC-MOSFET

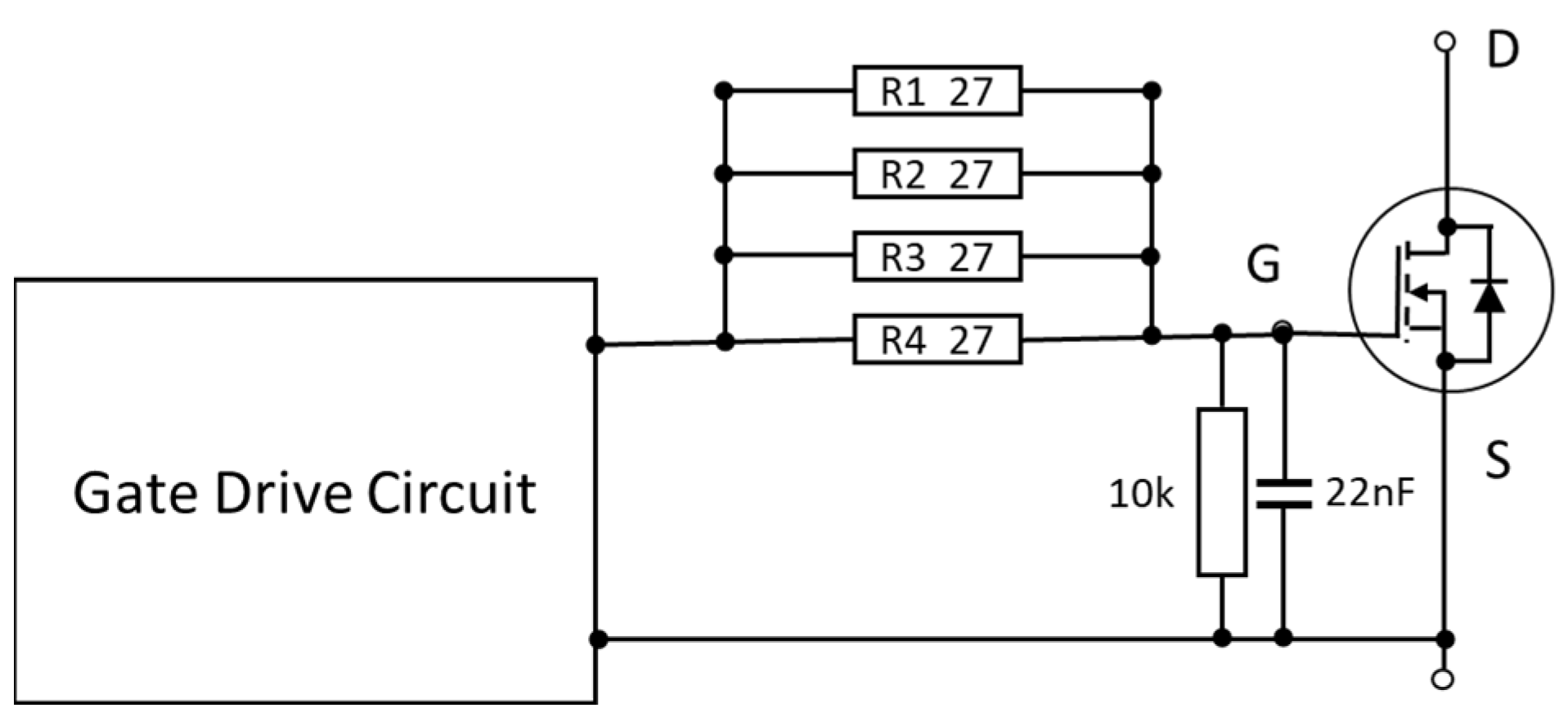

2.2.2. Drive Circuit

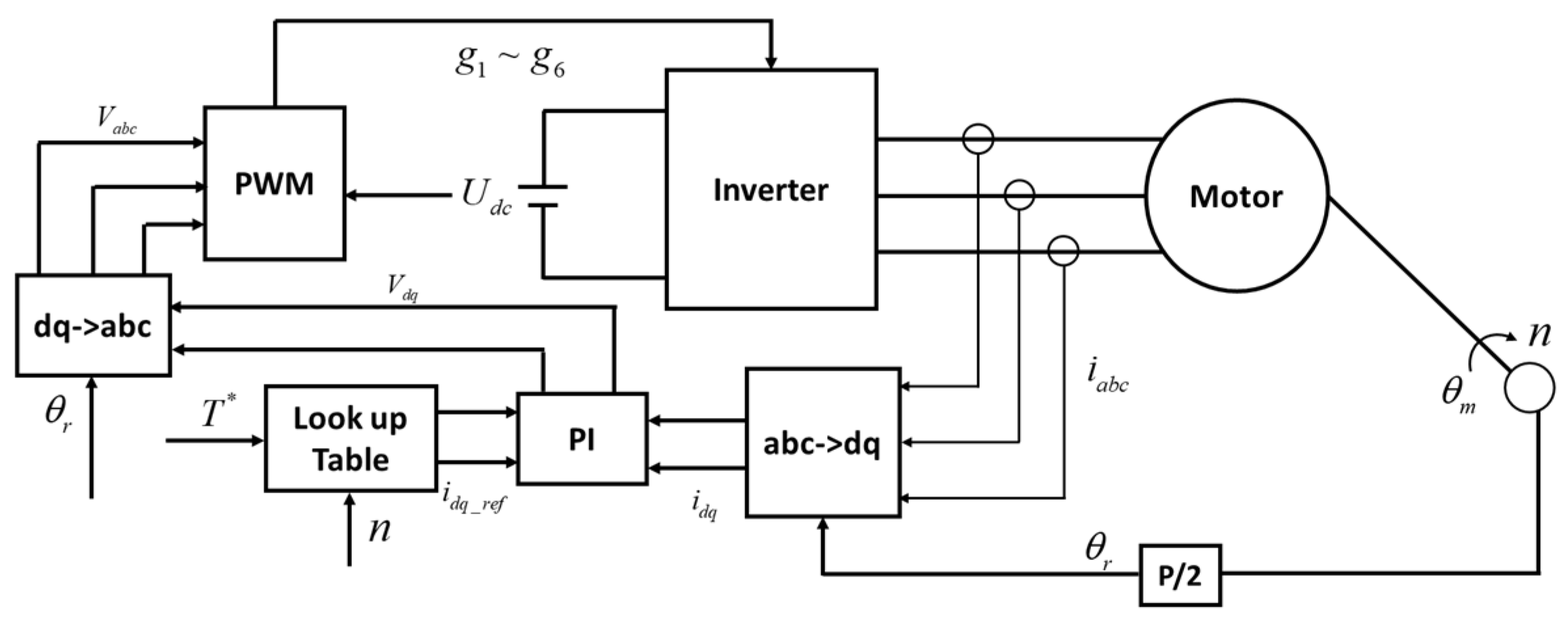

2.2.3. Control System

3. Simulation and Experimental Analysis

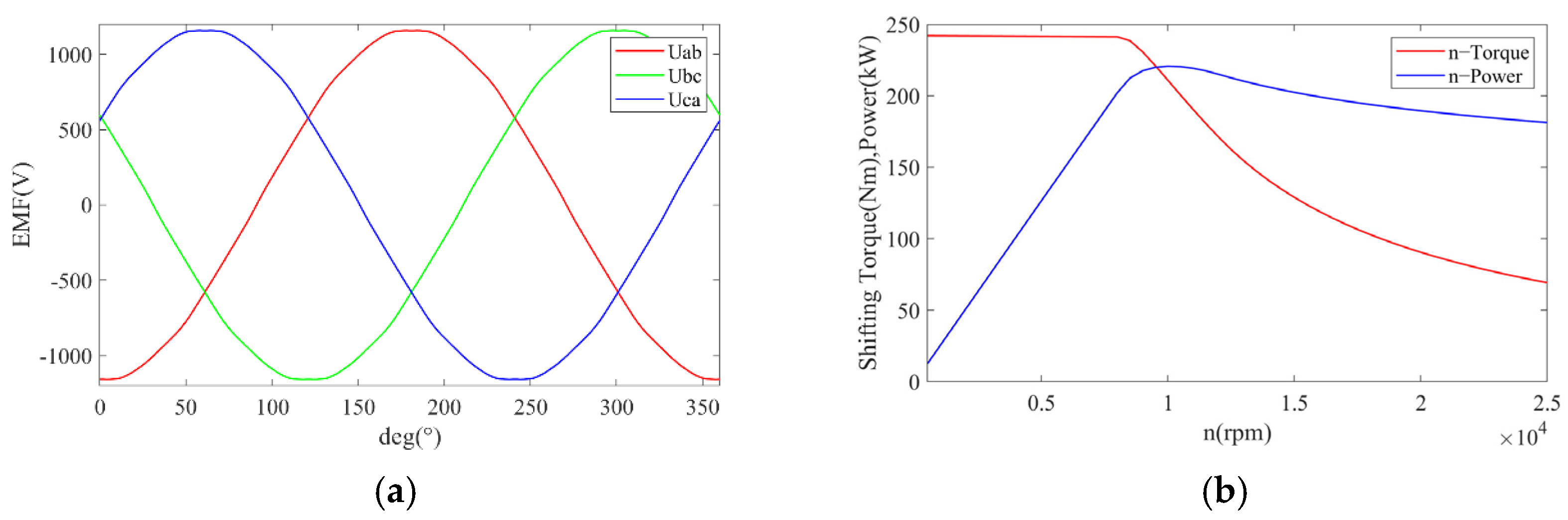

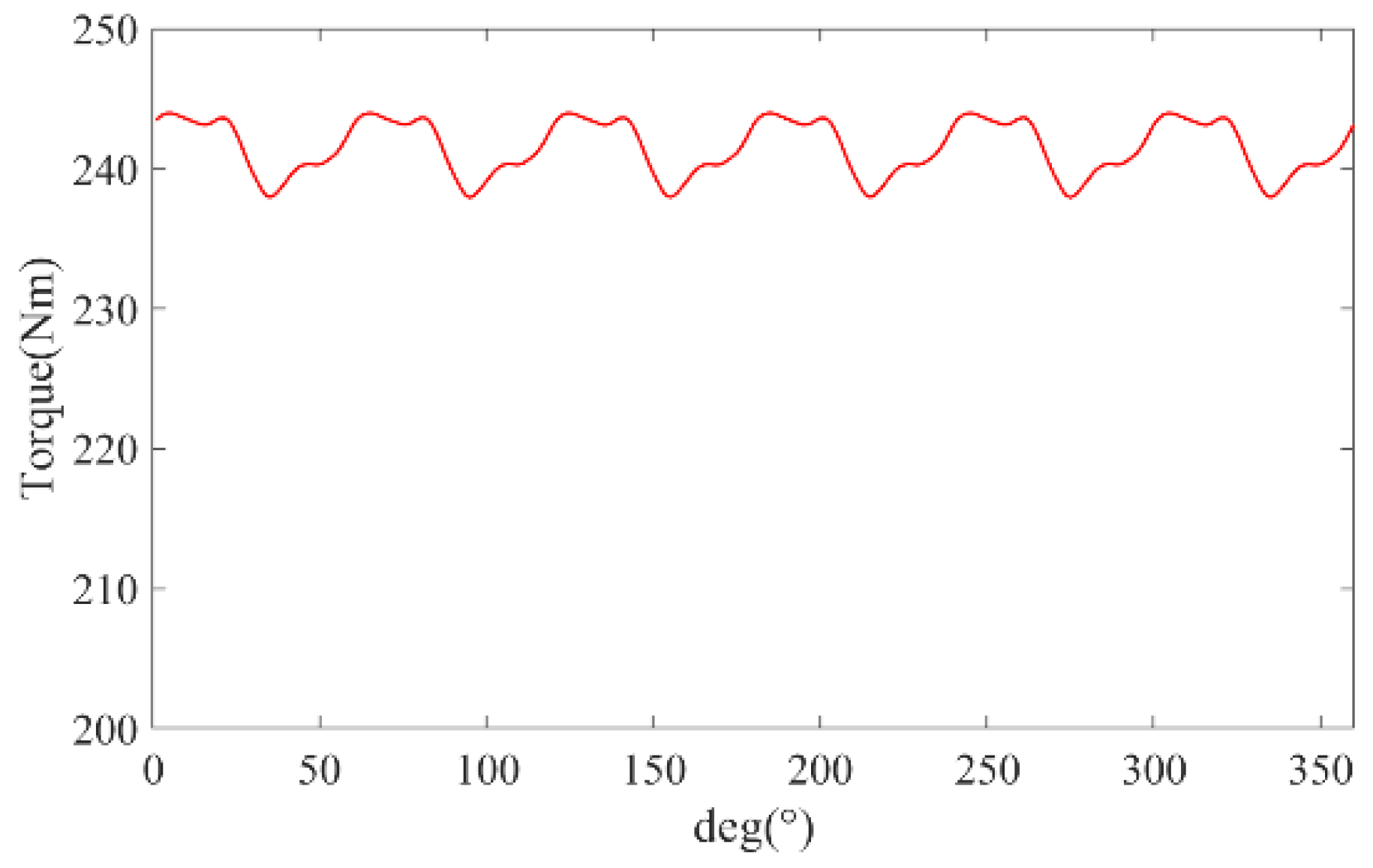

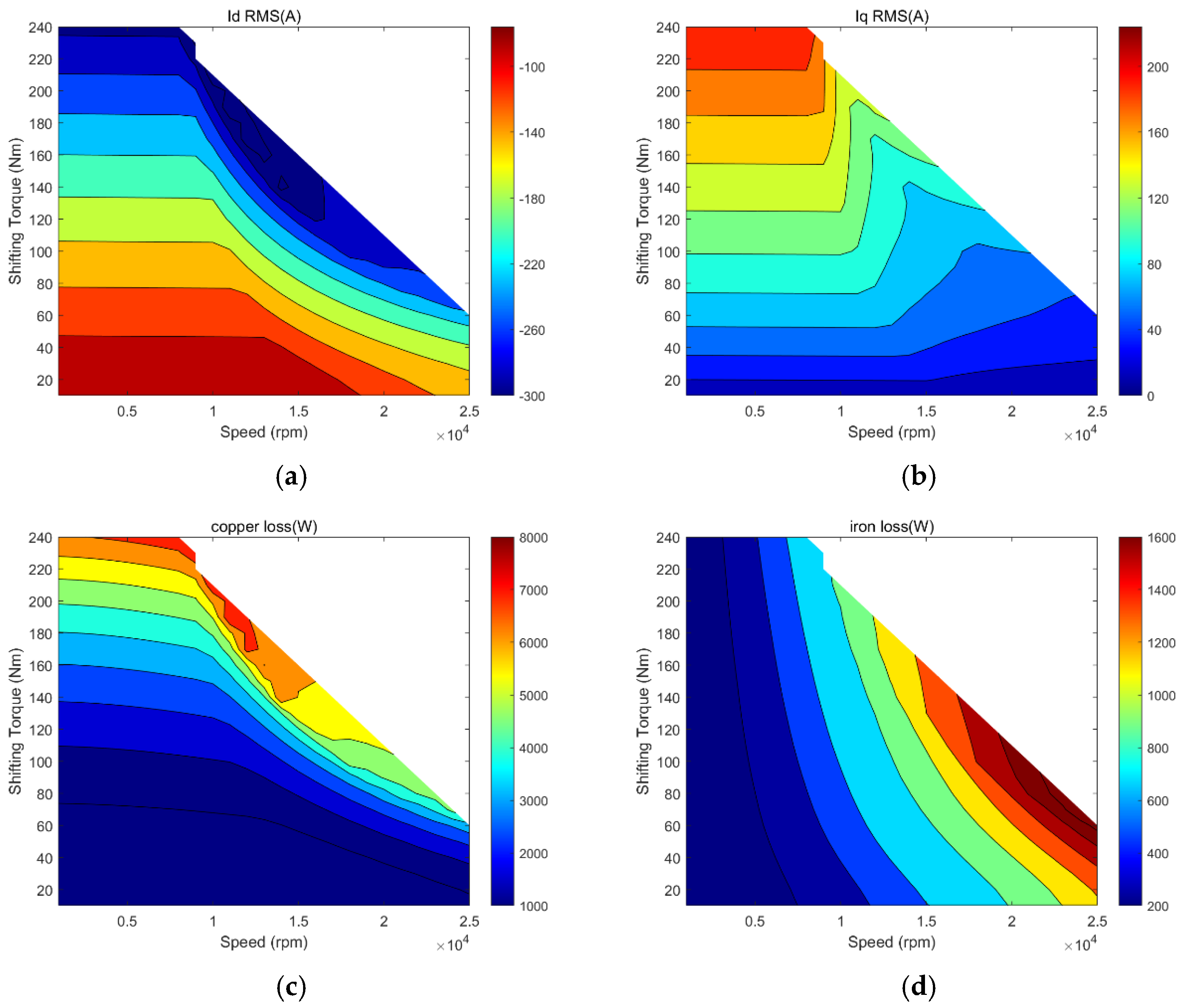

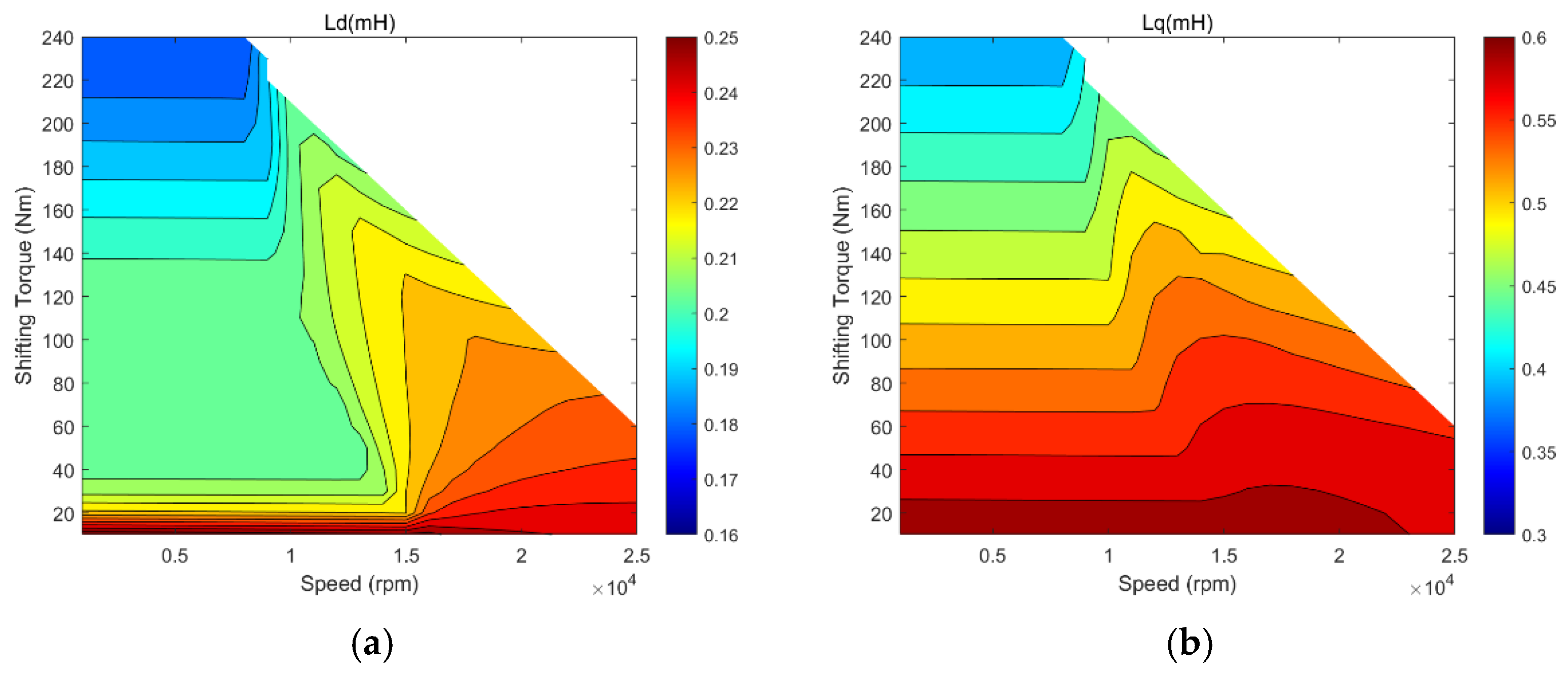

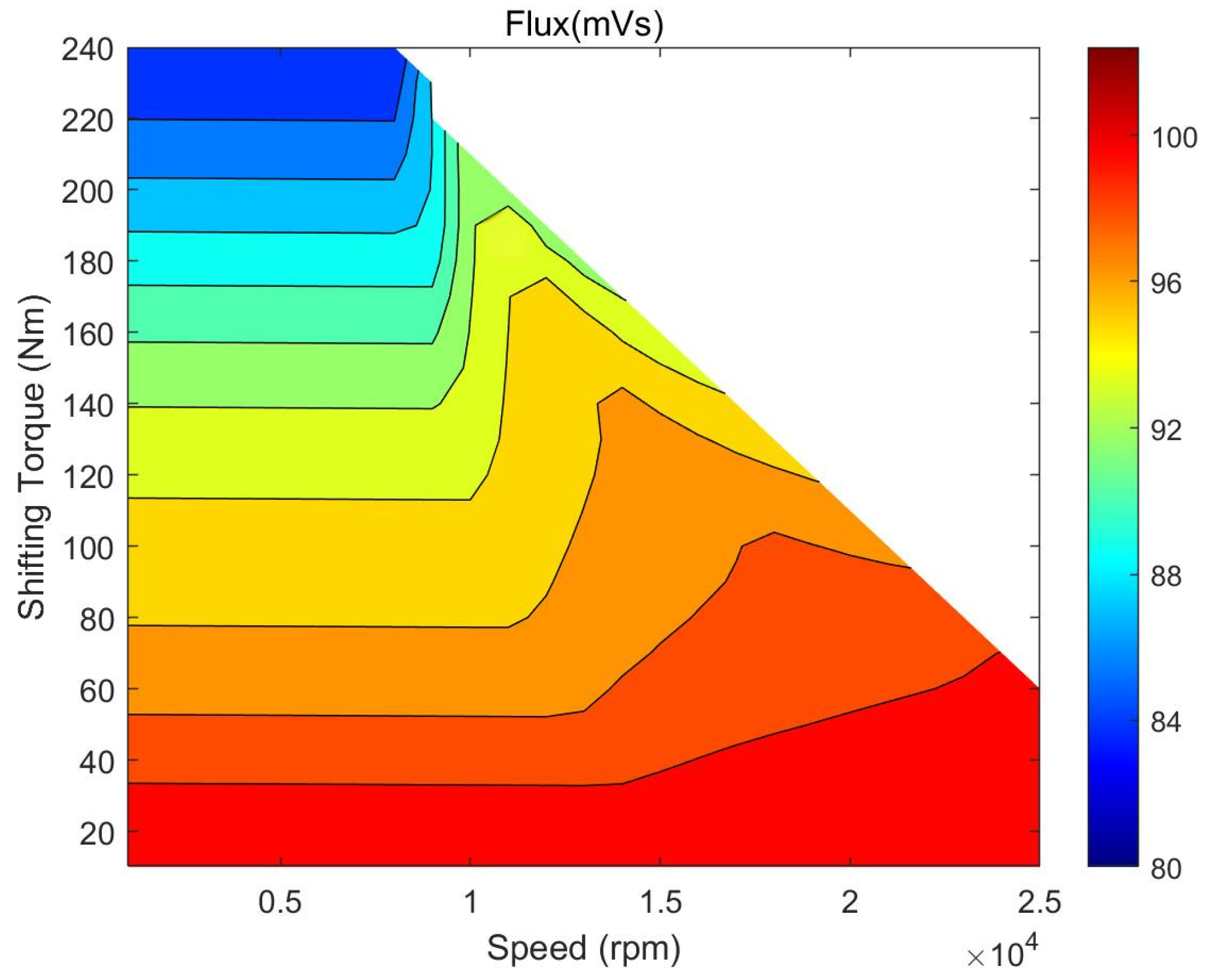

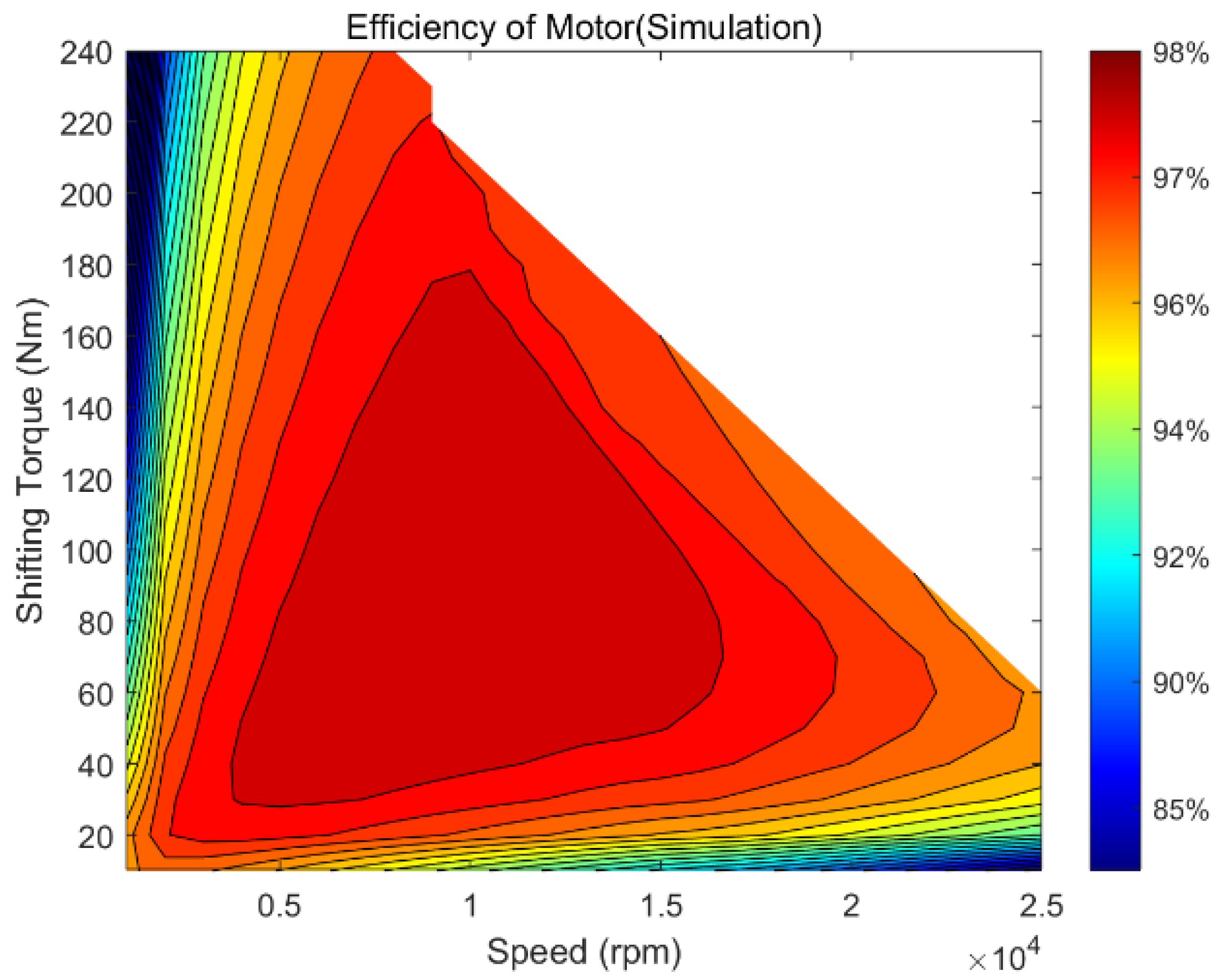

3.1. High-Speed Motor Simulation

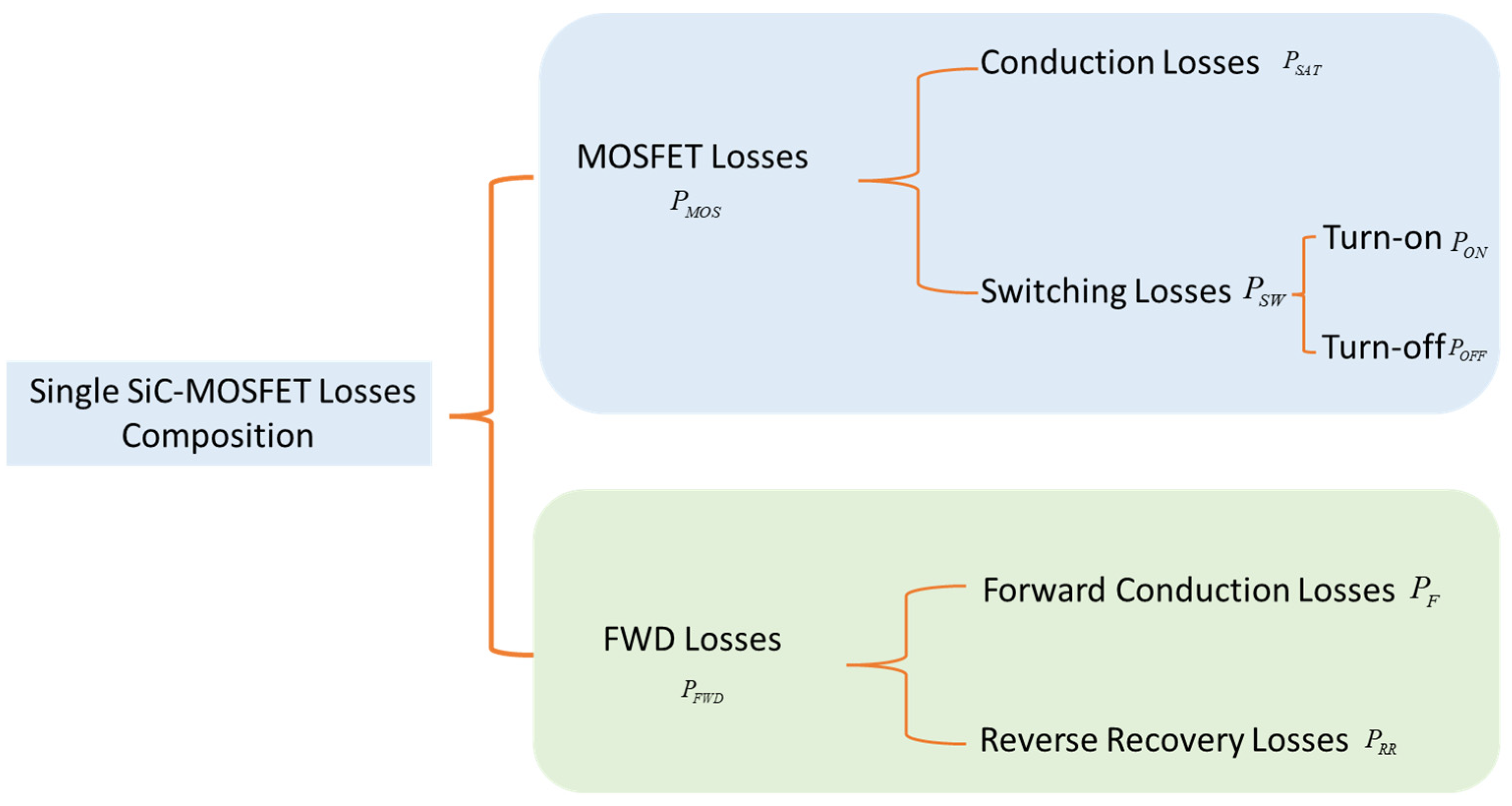

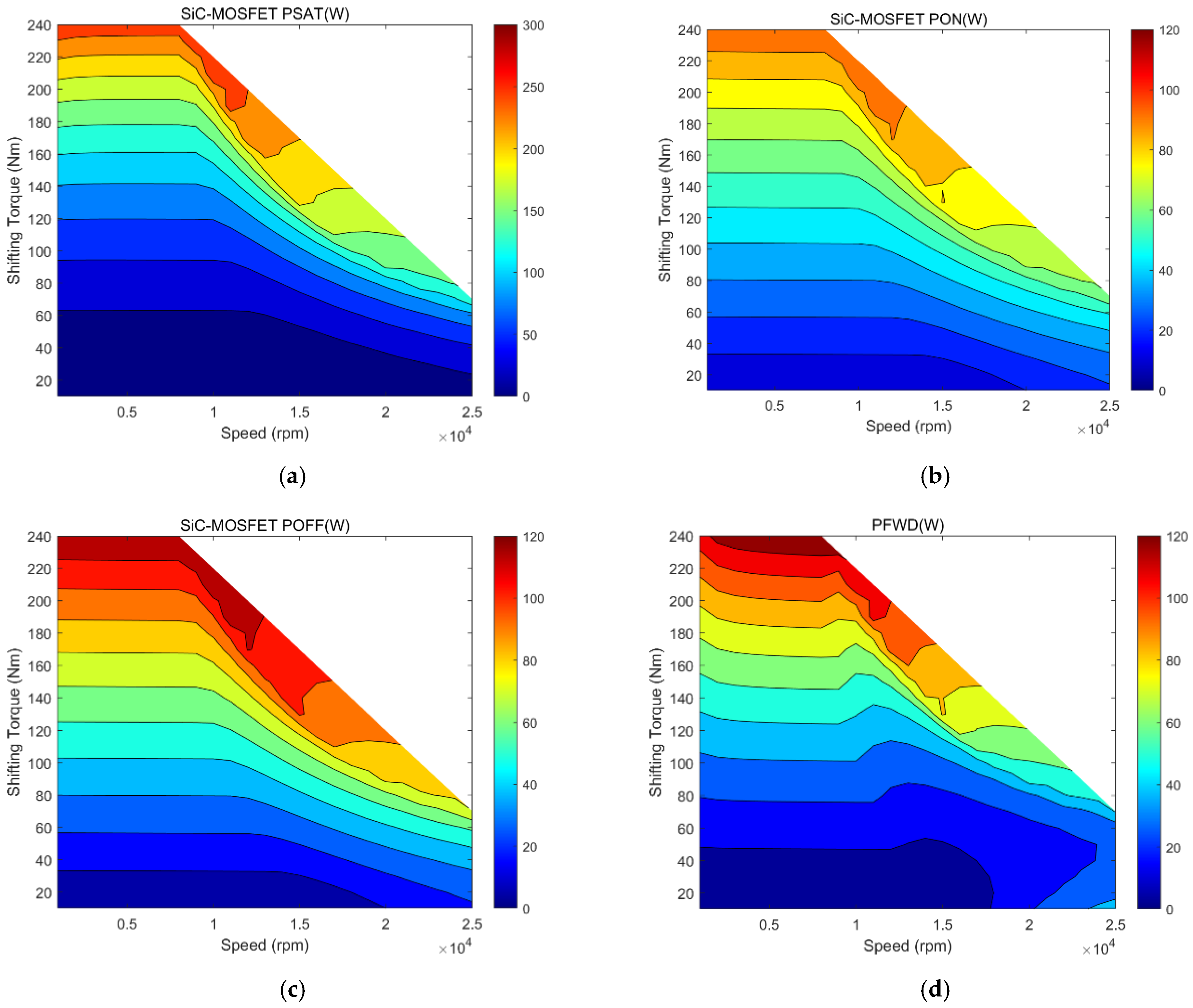

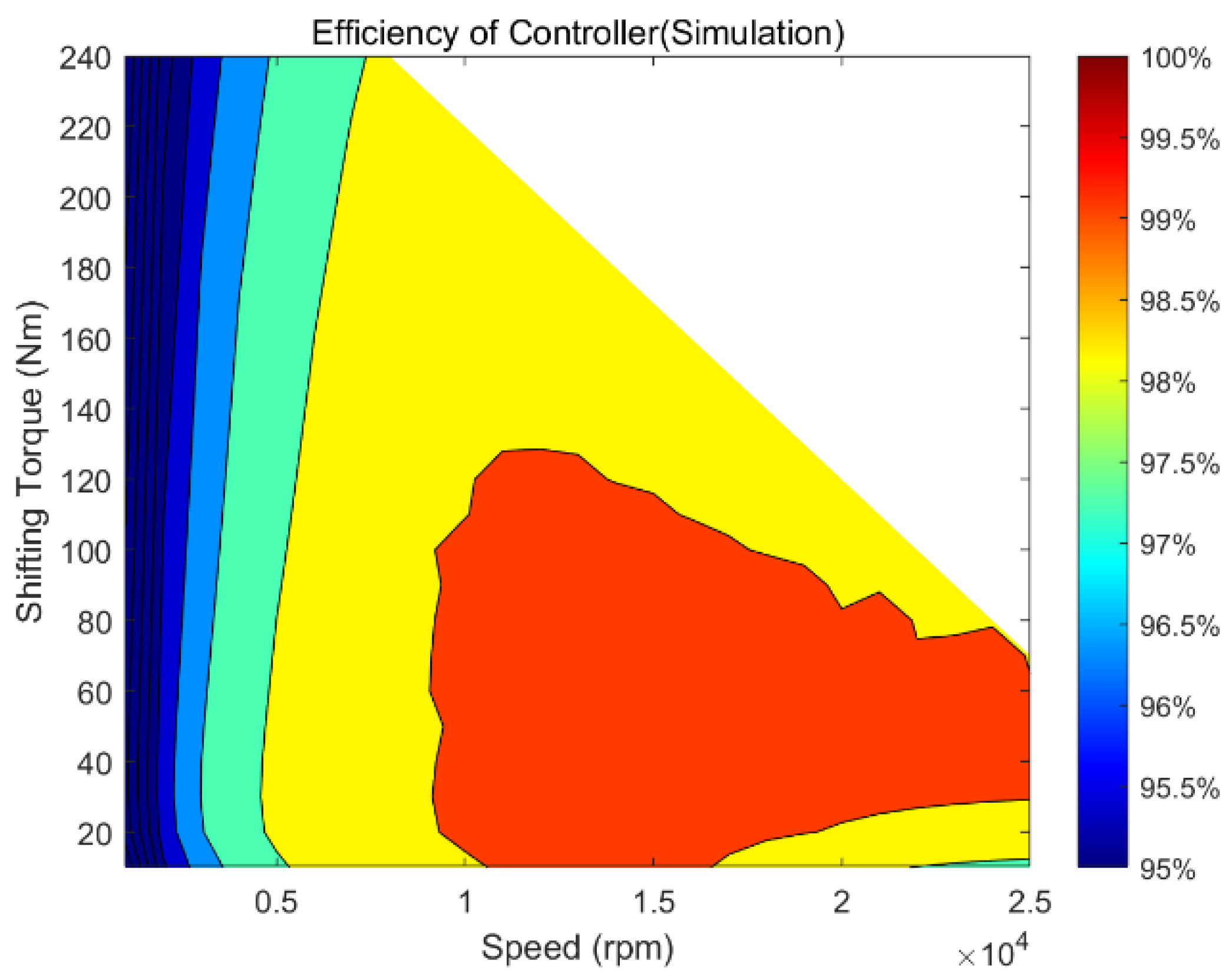

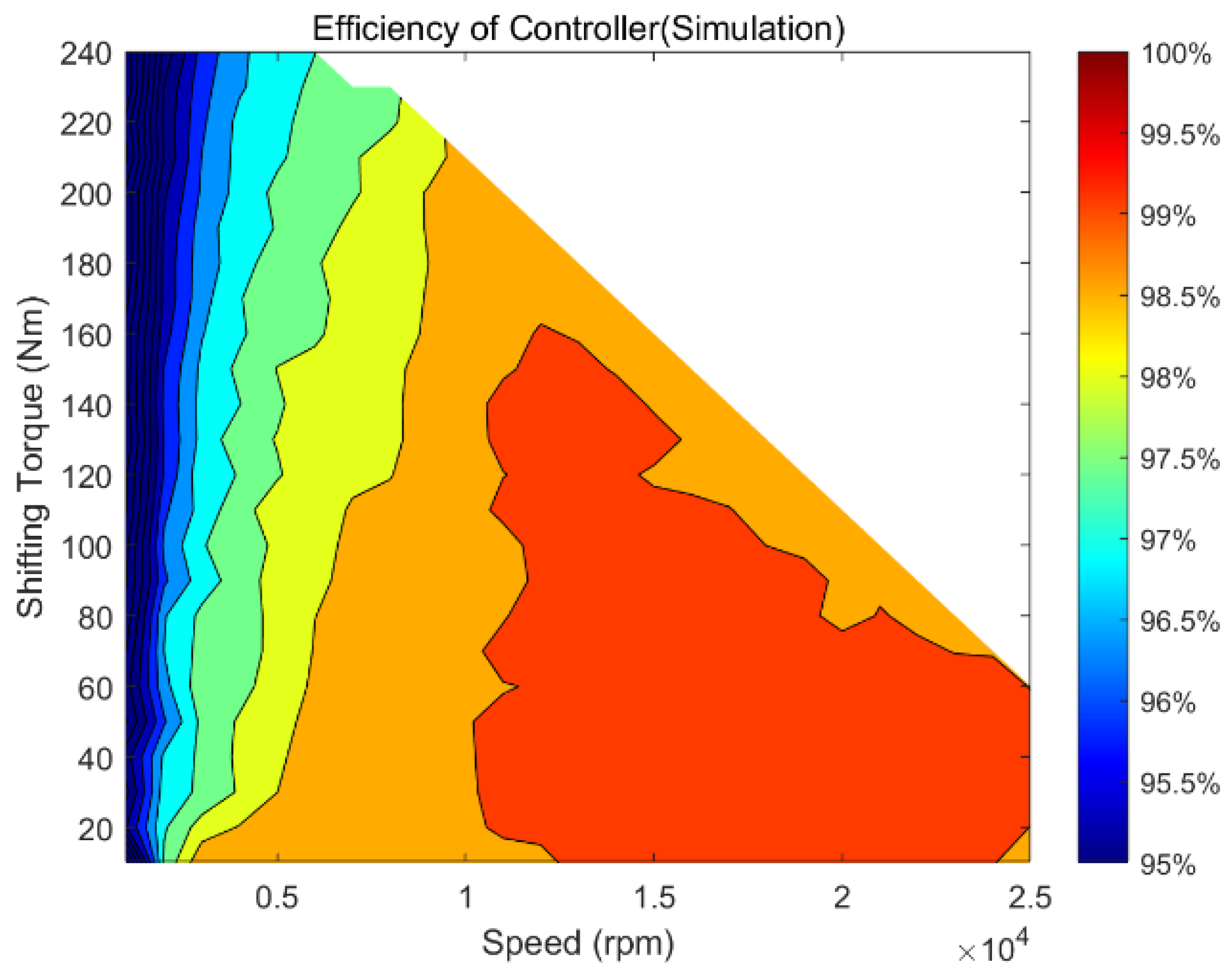

3.2. Power Module Efficiency Simulation

Components of Power Module Losses

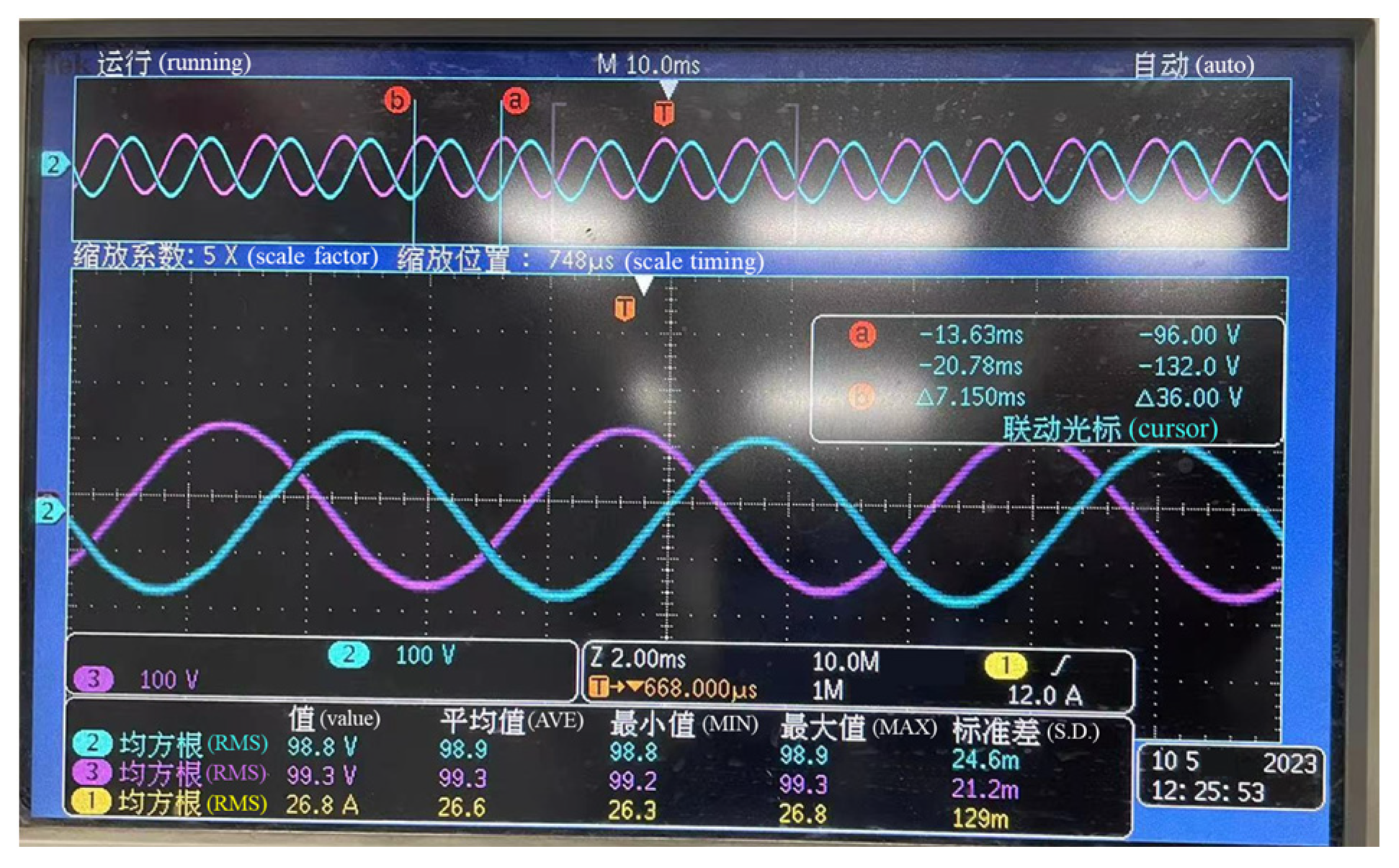

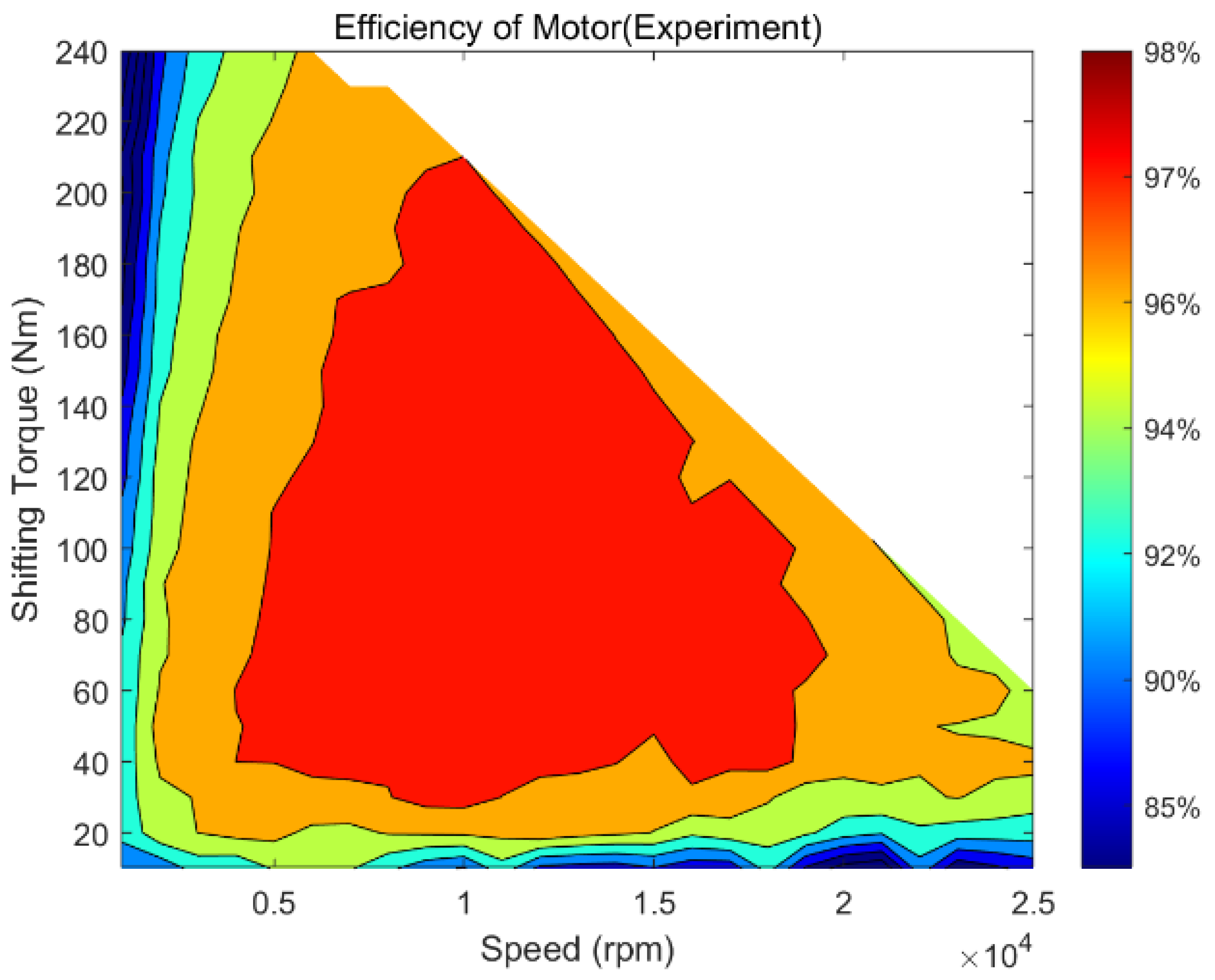

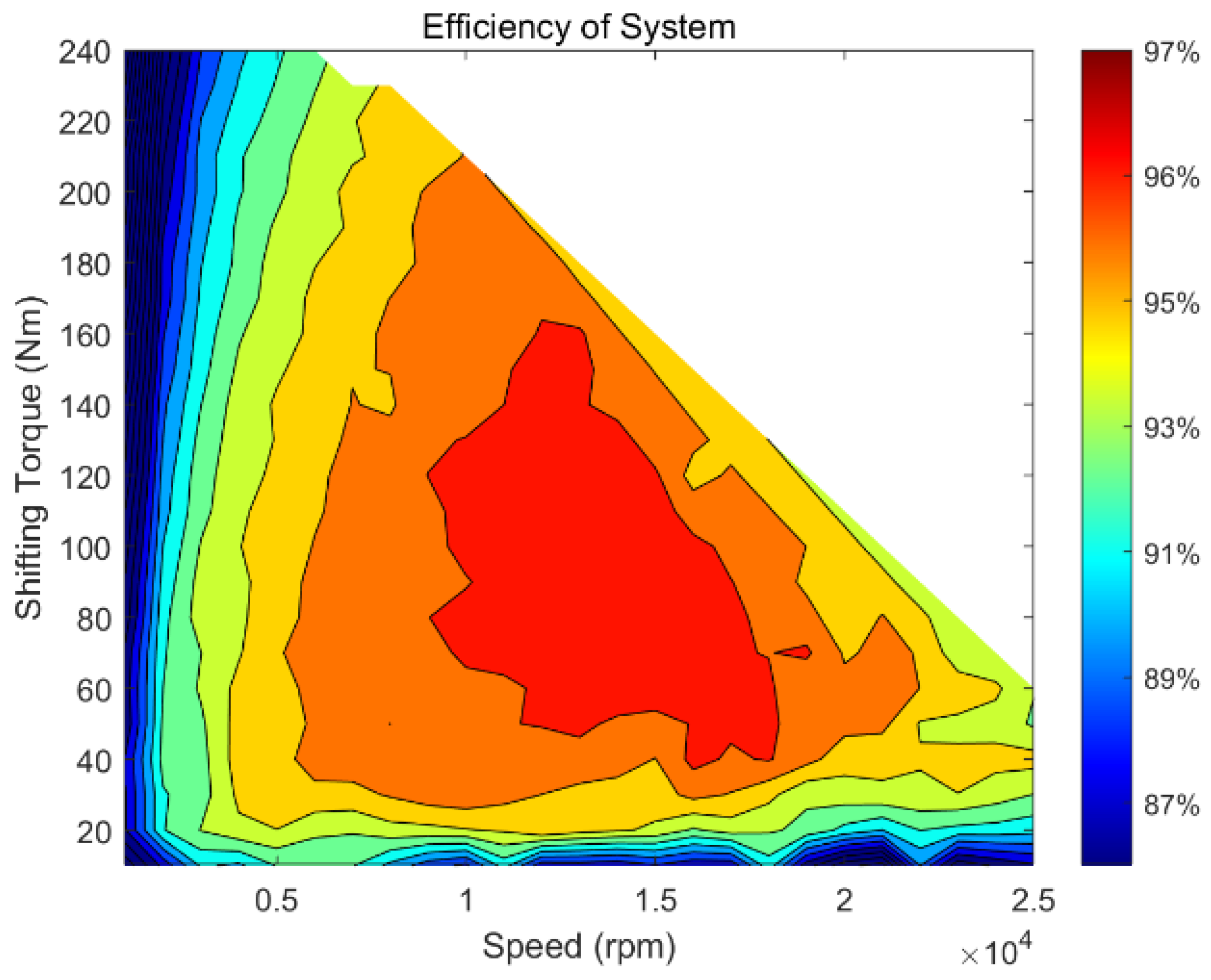

3.3. Analysis of the Motor System Experiment

4. Summary

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Abualnaeem, M.M.; Zulkifli, S.A.B.M.; Bin Yahaya, N.Z.; Soomro, H.A. Comparison of Power Loss in SiC-MOSFET and Si-IGBT Traction Inverter with Variable Switching Frequency for Electric Vehicle Application. In Proceedings of the 2024 IEEE Symposium on Industrial Electronics & Applications (ISIEA), Kuala Lumpur, Malaysia, 6–7 July 2024; pp. 1–6. [Google Scholar] [CrossRef]

- Zheng, H.; Wang, X.; Wang, X.; Ran, L.; Zhang, B. Using SiC MOSFETs to improve reliability of EV inverters. In Proceedings of the 2015 IEEE 3rd Workshop on Wide Bandgap Power Devices and Applications (WiPDA), Blacksburg, VA, USA, 2–4 November 2015; pp. 359–364. [Google Scholar] [CrossRef]

- Allca-Pekarovic, A.; Kollmeyer, P.J.; Mahvelatishamsabadi, P.; Mirfakhrai, T.; Naghshtabrizi, P.; Emadi, A. Comparison of IGBT and SiC Inverter Loss for 400V and 800V DC Bus Electric Vehicle Drivetrains. In Proceedings of the 2020 IEEE Energy Conversion Congress and Exposition (ECCE), Detroit, MI, USA, 11–15 October 2020; pp. 6338–6344. [Google Scholar] [CrossRef]

- Yu, Y.; Li, H.; Yu, Z.; Ding, L. Power Loss Analysis of Powertra in Inverter with SiC MOSFETs and Si IGBT for 400V and 800V Battery Voltage. In Proceedings of the 2024 IEEE 7th International Electrical and Energy Conference (CIEEC), Harbin, China, 10–12 May 2024; pp. 5064–5069. [Google Scholar] [CrossRef]

- Takatsuka, Y.; Hara, H.; Yamada, K.; Maemura, A.; Kume, T. A wide speed range high efficiency EV drive system using winding changeover technique and SiC devices. In Proceedings of the 2014 International Power Electronics Conference (IPEC-Hiroshima 2014—ECCE ASIA), Hiroshima, Japan, 18–21 May 2014; pp. 1898–1903. [Google Scholar] [CrossRef]

- Guo, Q.; Zhang, C.; Li, L.; Wang, M.; Wang, T. Efficiency optimization control of permanent magnet synchronous motor system with SiC MOSFETs for electric vehicles. In Proceedings of the 2017 20th International Conference on Electrical Machines and Systems (ICEMS), Sydney, NSW, Australia, 11–14 August 2017; pp. 1–5. [Google Scholar] [CrossRef]

- Dong, T.; Kwak, J.; Wei, L.; Castellazzi, A.; Nakamura, T. High Power-Density High-Efficiency Electric Drive Design with Halbach-Rotor PMSM and WBG-Based High-Frequency Inverter. In Proceedings of the 2021 24th International Conference on Electrical Machines and Systems (ICEMS), Gyeongju, Republic of Korea, 31 October–3 November 2021; pp. 1759–1762. [Google Scholar] [CrossRef]

- Ju, X.; Cheng, Y.; Ding, L.; Cui, S. Analysis and Design of Multi-Pole High-Speed IPMSM with SiC Based Inverters for EVs. In Proceedings of the 2020 International Conference on Electrical Machines (ICEM), Gothenburg, Sweden, 23–26 August 2020; pp. 1704–1710. [Google Scholar] [CrossRef]

- Hiroki, T.; Kohei, A. Performances comparison of PMSM and SRM for EV aiming for maximum speed of 50,000 min−1. In Proceedings of the 2024 IEEE Transportation Electrification Conference and Expo, Asia-Pacific (ITEC Asia-Pacific), Xi’an, China, 10–13 October 2024; pp. 623–627. [Google Scholar] [CrossRef]

- Bai, J.; Zhu, X.; Xiang, Z. Electromagnetic Vibration Improvement for a High-Speed Flat Wire PM Motor Based on Optimal Magnetic-Pole Boundary. IEEE Trans. Magn. 2024, 60, 8202006. [Google Scholar] [CrossRef]

- Yan, H.; Du, G.; Li, N.; Li, L.; Chen, Y.; Lei, G.; Zhu, J. Four Rotor Structures for High-Speed Interior Permanent Magnet Motor Considering Mechanical, Electromagnetic, and Thermal Performance. IEEE Trans. Transp. Electrif. 2025, 11, 2595–2608. [Google Scholar] [CrossRef]

- Ying, H.; Huang, S.; Xu, D. An high-speed low-noise rotor topology for EV/HEV PMSM. CES Trans. Electr. Mach. Syst. 2017, 1, 354–359. [Google Scholar] [CrossRef]

- Kumar, P.; Kumar, R.; Kumar, B.; Kumar, A. Design of a High Performance PMSM for Electric Vehicles. In Proceedings of the 2022 2nd International Conference on Emerging Frontiers in Electrical and Electronic Technologies (ICEFEET), Patna, India, 24–25 June 2022; pp. 1–5. [Google Scholar] [CrossRef]

- Ju, X.; Cheng, Y.; Yang, M.; Cui, S.; Sun, A.; Liu, X.; He, M. Voltage Stress Calculation and Measurement for Hairpin Winding of EV Traction Machines Driven by SiC MOSFET. IEEE Trans. Ind. Electron. 2022, 69, 8803–8814. [Google Scholar] [CrossRef]

- Allca-Pekarovic, A.; Kollmeyer, P.J.; Reimers, J.; Mahvelatishamsabadi, P.; Mirfakhrai, T.; Naghshtabrizi, P.; Emadi, A. Loss Modeling and Testing of 800-V DC Bus IGBT and SiC Traction Inverter Modules. IEEE Trans. Transp. Electrif. 2024, 10, 2923–2935. [Google Scholar] [CrossRef]

- 16 Hong, D.-K.; Woo, B.-C.; Lee, J.-Y.; Koo, D.-H. Ultra High Speed Motor Supported by Air Foil Bearings for Air Blower Cooling Fuel Cells. IEEE Trans. Magn. 2012, 48, 871–874. [Google Scholar] [CrossRef]

- Han, Y.; Lu, H.; Li, Y.; Chai, J. Analysis and Suppression of Shaft Voltage in SiC-Based Inverter for Electric Vehicle Applications. IEEE Trans. Power Electron. 2019, 34, 6276–6285. [Google Scholar] [CrossRef]

- Mei, L.; Xiao, W.; Cui, J.; Zhang, Q.; Liu, Z. Analytical Modeling and Pole–Slot Combination Selection Analysis of a Direct-Drive Drilling Permanent Magnet Synchronous Motor. Processes 2023, 11, 3222. [Google Scholar] [CrossRef]

- Jung, Y.-H.; Kim, K.-O.; Lim, M.-S. Performance Improvement of Rare-Earth Free High-Speed Multilayer IPMSM Using Dual-Phase Magnetic Material. IEEE Trans. Magn. 2023, 59, 8205105. [Google Scholar] [CrossRef]

- Cha, J.; Yoon, J.; Koo, J.; Uijong, B.; Sim, K.; Hahn, S. Loss Reduction and Operating Time Extension Using Segmented HTS Field Coil Bobbin for High-Speed Operation of EV Traction Motor. IEEE Trans. Appl. Supercond. 2024, 34, 5201705. [Google Scholar] [CrossRef]

- Song, X.; Han, B.; Zheng, S.; Chen, S. A Novel Sensorless Rotor Position Detection Method for High-Speed Surface PM Motors in a Wide Speed Range. IEEE Trans. Power Electron. 2018, 33, 7083–7093. [Google Scholar] [CrossRef]

- Muranaka, K.; Nakamura, T.; Okajima, S.; Ogasa, T.; Amemiya, N.; Itoh, Y. Experimental and Analytical Studies on Variable Speed Control of High-Temperature Superconducting Induction/Synchronous Motor. IEEE Trans. Appl. Supercond. 2016, 26, 5201205. [Google Scholar] [CrossRef]

- Mao, K.; Zheng, S.; Liu, G. Analysis and suppression of magnetically levitated rotor vibration influence for high-speed permanent magnet motor sensorless control. In Proceedings of the 2016 19th International Conference on Electrical Machines and Systems (ICEMS), Chiba, Japan, 13–16 November 2016; pp. 1–6. [Google Scholar]

- Li, Y.; Song, X.; Zhou, X.; Huang, Z.; Zheng, S. A Sensorless Commutation Error Correction Method for High-Speed BLDC Motors Based on Phase Current Integration. IEEE Trans. Ind. Inform. 2020, 16, 328–338. [Google Scholar] [CrossRef]

- Ok, S.; Xu, Z.; Lee, D.-H. A Sensorless Speed Control of High-Speed BLDC Motor Using Variable Slope SMO. IEEE Trans. Ind. Appl. 2024, 60, 3221–3228. [Google Scholar] [CrossRef]

- Song, Q.; Sun, P.; Wang, M. IPMSM Loss Reduction Control Under High-Speed Conditions for Electric Vehicles. IEEE J. Emerg. Sel. Top. Power Electron. 2024, 12, 2306–2316. [Google Scholar] [CrossRef]

- Hu, F.; Luo, D.; Luo, C.; Long, Z.; Wu, G. Cascaded Robust Fault-Tolerant Predictive Control for PMSM Drives. Energies 2018, 11, 3087. [Google Scholar] [CrossRef]

- Testing. CLTC Test Standard: A New Energy Vehicle Endurance Test Method Designed for the Chinese Market. [EB/OL]. 2024. Available online: https://www.auto-testing.net/baike/show-3383.html (accessed on 10 March 2025).

| Thicknesses of Carbon Fiber (mm) | Small V-Structure | Large V-Structure | ||

|---|---|---|---|---|

| Yield Speed (rpm) | Burst Speed (rpm) | Yield Speed (rpm) | Burst Speed (rpm) | |

| 0 | 30,150 | 32,250 | 23,890 | 224,850 |

| 0.3 | 32,250 | 34,750 | 25,700 | 26,950 |

| 0.6 | 34,200 | 35,550 | 26,000 | 27,700 |

| 0.8 | 34,350 | 35,850 | 27,150 | 28,150 |

| EMF (V) | 1014 | 1109 | 1158 |

| Peak torque (Nm) | 228 | 236 | 240 |

| Peak power (kW) | 211 | 216 | 221 |

| Maximum efficiency (%) | 97.42 | 97.49 | 97.53 |

| CLTC efficiency (%) | 94.81 | 94.91 | 94.85 |

| Rated point efficiency (%) | 97.29 | 97.39 | 97.43 |

| Parameters | Value | Parameters | Value |

|---|---|---|---|

| DC-link voltage (V) | 700 | Poles | 6 |

| Peak power (kW) | ≥200 | Stator slots | 54 |

| Peak torque (Nm) | ≥200 | Flat line layers | 8 |

| Cooling | Oil | Silicon steel | 20SW1200 |

| Magnet steel | 50 UH | Standard wire/mm | 3.565 × 1.635 |

| Rated phase current (RMS)/A | 156.7 | Stator outer diameter/mm | 200 |

| Maximum efficiency | 97.5% | Stator inner diameter/mm | 122.6 |

| Ripple torque | 3% (Peak torque) | Rotor outer diameter/mm | 119.4 |

| Power density | ≥6 kW/kg (without axis) | Rotor inner diameter/mm | 48 |

| Air gap length/mm | 1.6 | Maximum speed/rpm | 25,000 |

| Length/mm | 126 | / | / |

| Model | (V) | (V) | (A) |

| ZM600FB12W3 | 1200 | −5/18 | 450 |

| (Ω) | (V) | (J) | (J) |

| 3.2 m (85 °C) | 3.2 | 34 m (85 °C) | 60 m (85 °C) |

| Driving resistance Rg (Ω) | 6.75 |

| DC-link rated voltage (V) | 700 |

| Temperature (°C) | 150 |

| Driving voltage Vgs (V) | +18, −5 |

| Switching frequency | 10 kHz at all speed |

| Parameter | Value |

|---|---|

| Controller volume (L) | 5.03 |

| Motor weight (kg) | 87 |

| Motor assembly size (X × Y × Z) (mm) | 542 × 504 × 414.5 |

| Peak power of controller (kW) | 241.16 |

| Peak power of motor (kW) | >200 |

| Cost comparing with 400 V System (CNY) | SiC-MOSFET: +2000; |

| High-voltage bus capacitor: +200; | |

| High-voltage EMC: +200; | |

| Oil cooling: +55; | |

| Motor axis: +55; | |

| Motor assembly: +320; | |

| Material: −75; |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, K.; Gu, M.; Zheng, Y. Design of High-Speed Motor System for EV Based on 1200 V SiC-MOSFET Power Module. Actuators 2025, 14, 216. https://doi.org/10.3390/act14050216

Zhou K, Gu M, Zheng Y. Design of High-Speed Motor System for EV Based on 1200 V SiC-MOSFET Power Module. Actuators. 2025; 14(5):216. https://doi.org/10.3390/act14050216

Chicago/Turabian StyleZhou, Kun, Minglei Gu, and Yu Zheng. 2025. "Design of High-Speed Motor System for EV Based on 1200 V SiC-MOSFET Power Module" Actuators 14, no. 5: 216. https://doi.org/10.3390/act14050216

APA StyleZhou, K., Gu, M., & Zheng, Y. (2025). Design of High-Speed Motor System for EV Based on 1200 V SiC-MOSFET Power Module. Actuators, 14(5), 216. https://doi.org/10.3390/act14050216