Ramp Start and Speed Control of Self-Driving Commercial Vehicles under Ramp and Vehicle Load Uncertainty

Abstract

1. Introduction

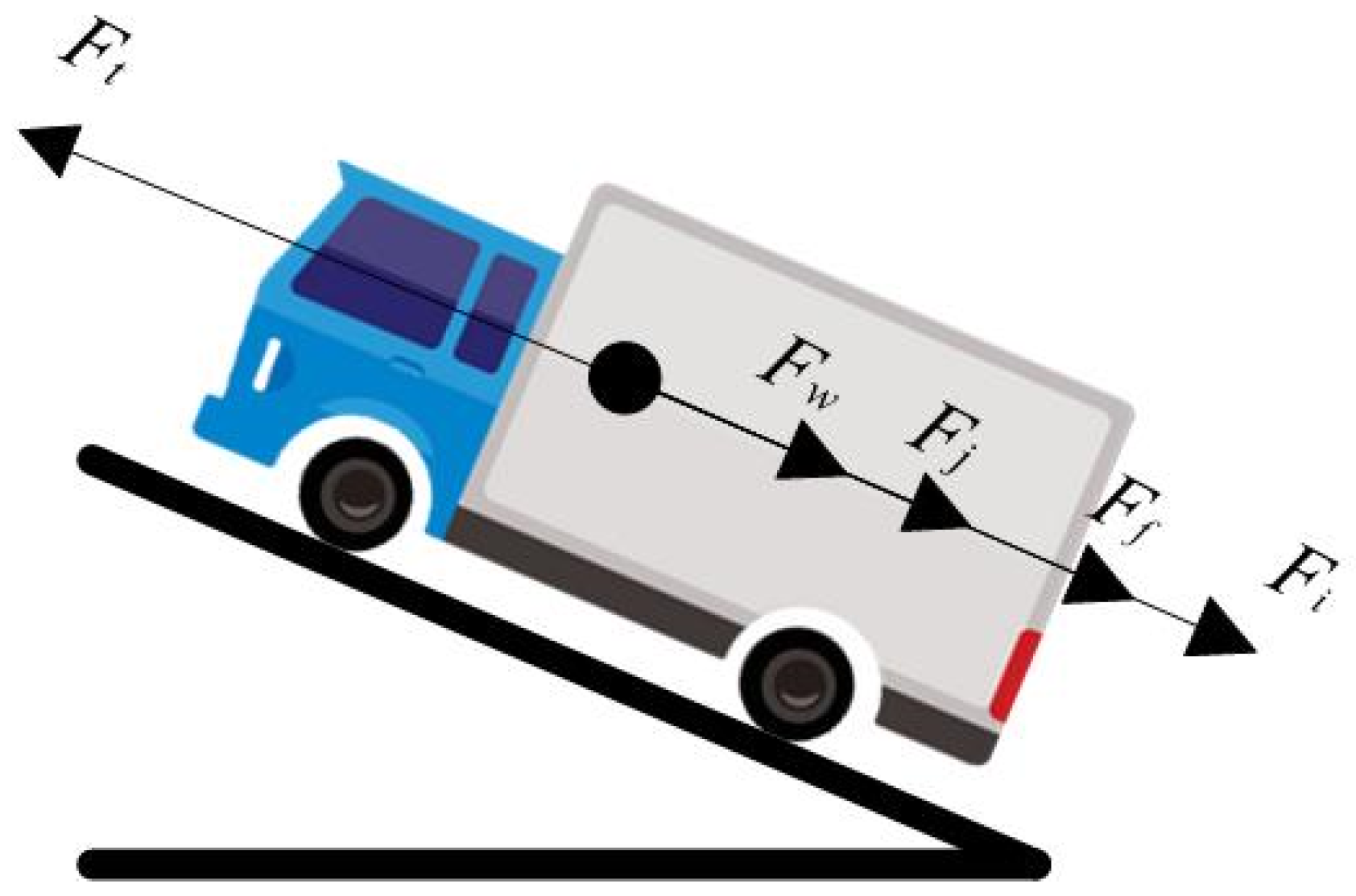

2. Vehicle Model

3. Materials and Methods

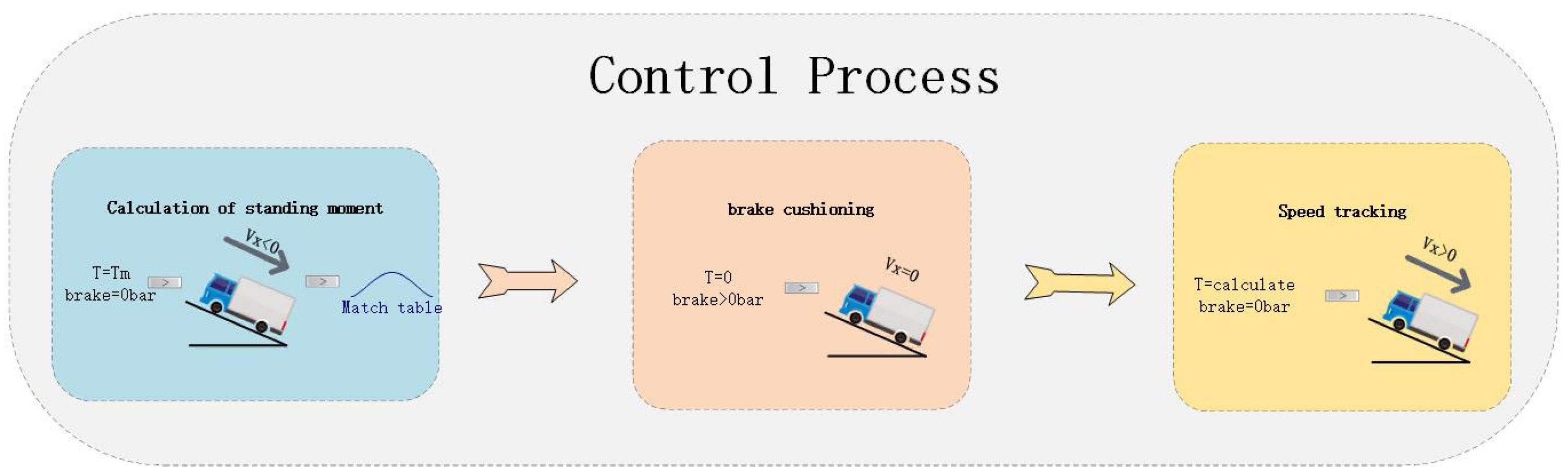

3.1. Ramp Start Process Analysis

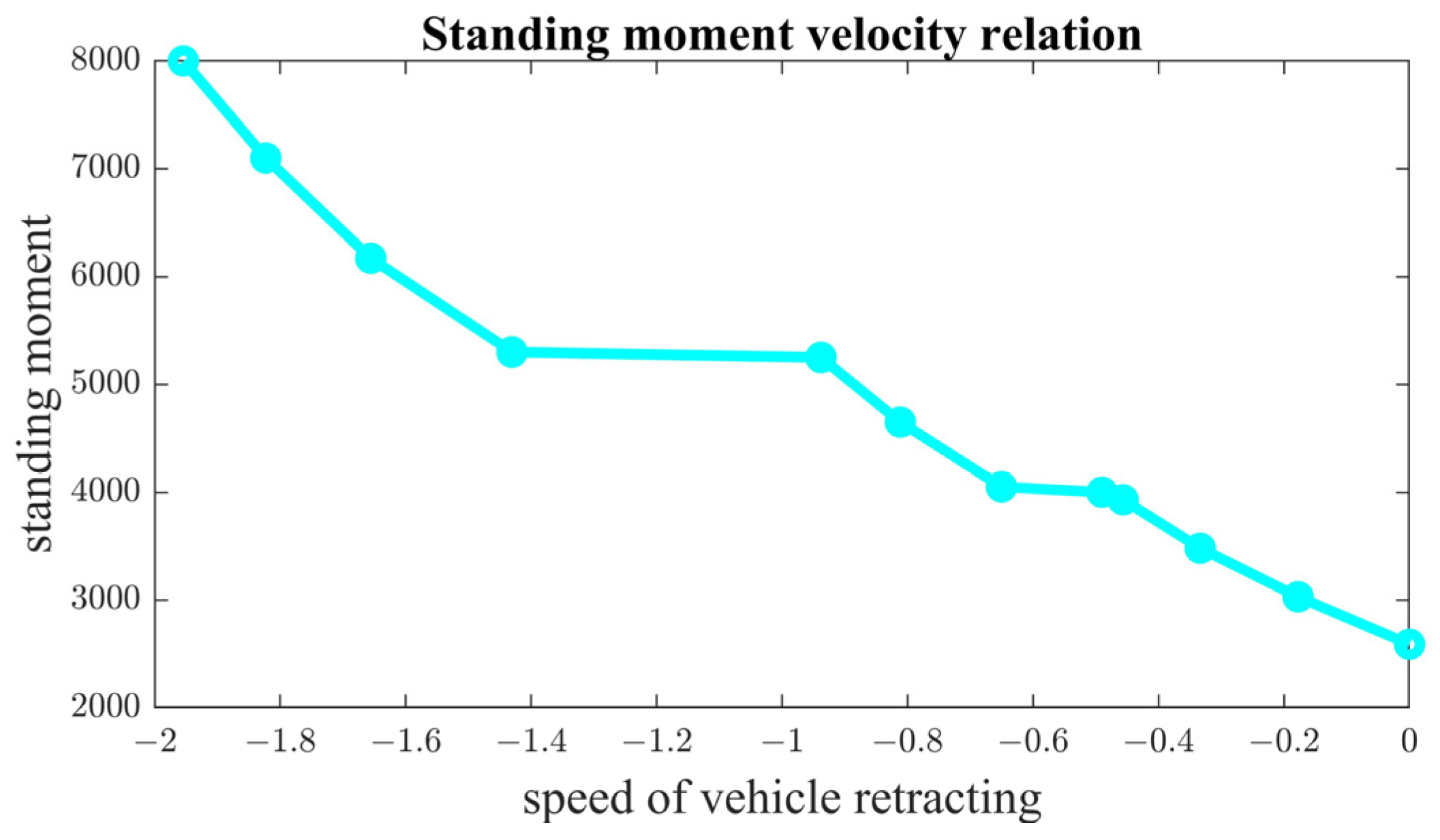

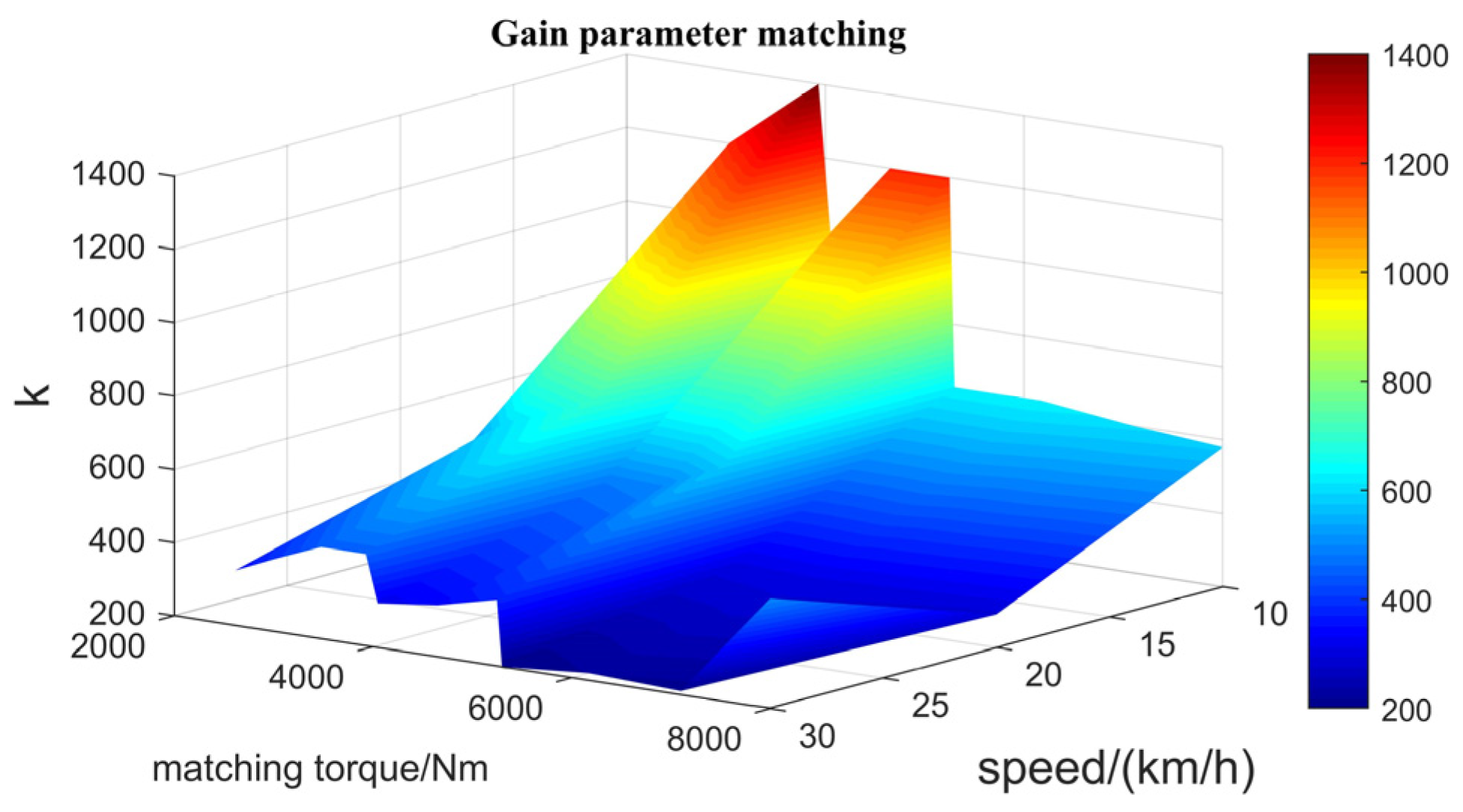

3.2. Matching of Hill-Starting Moments during Hill Starts

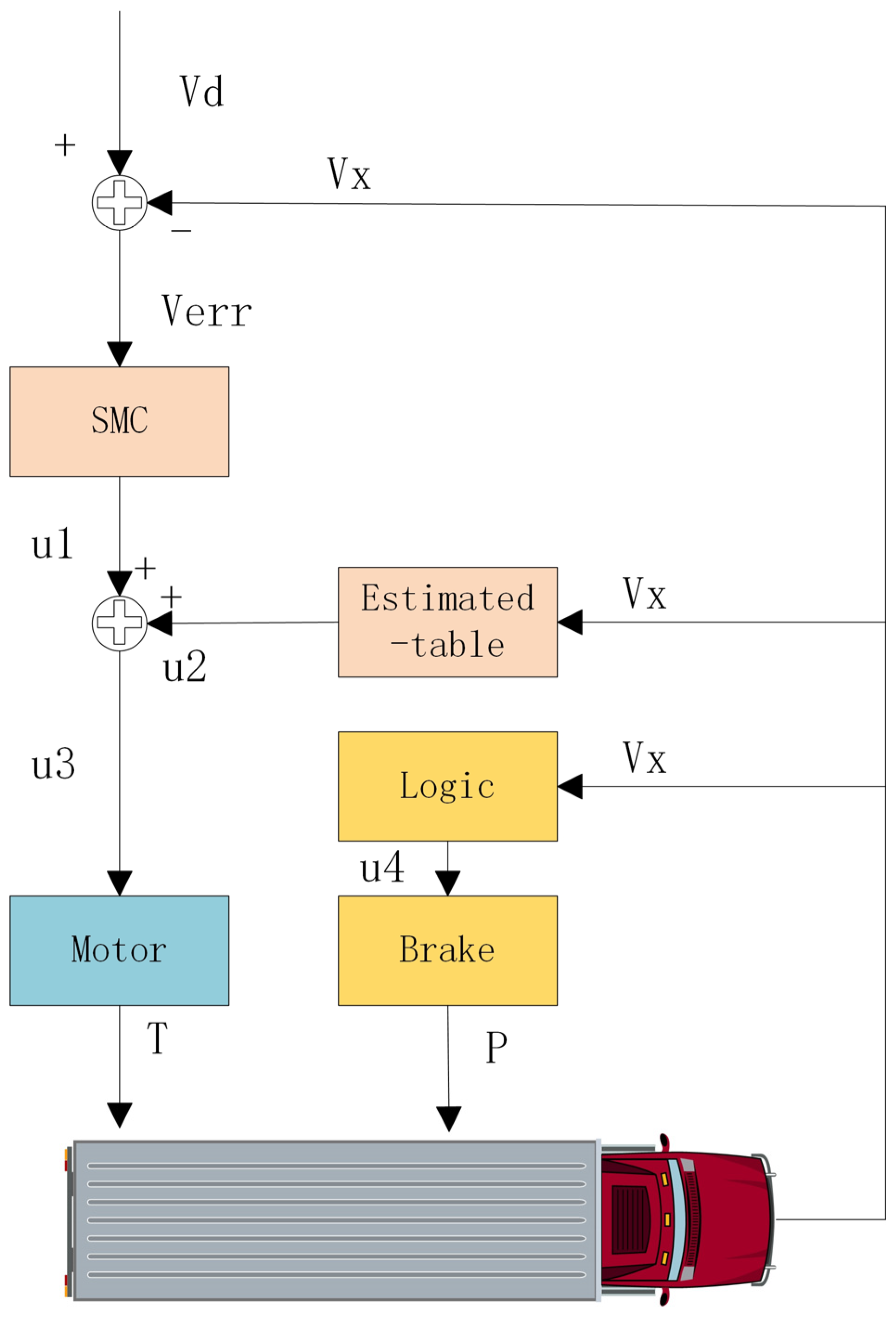

3.3. Sliding Mode Variable Structure Controller

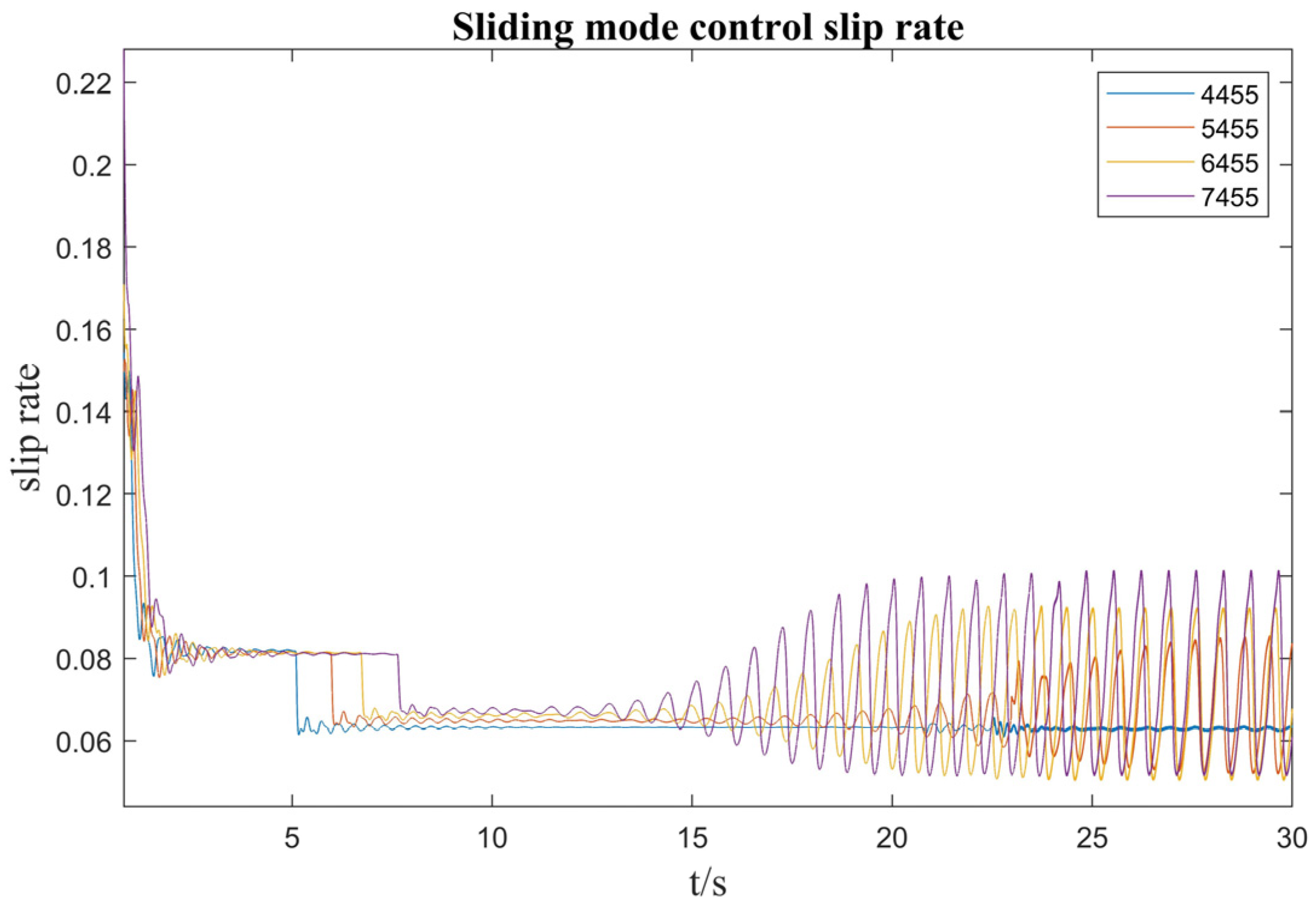

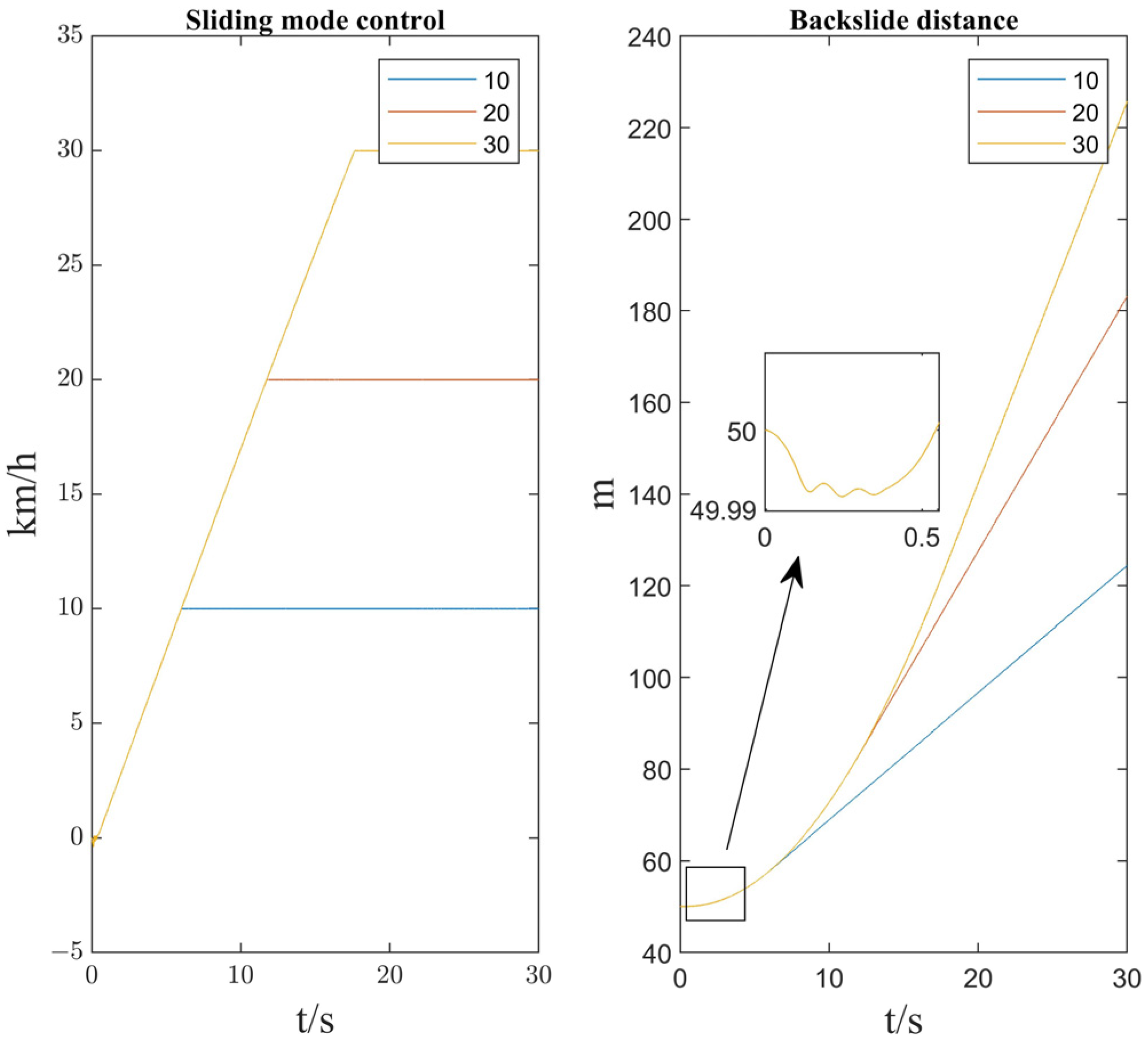

3.4. Sliding Mode Control Based on Rear Slip Speed Matching the Standing Hill Moment

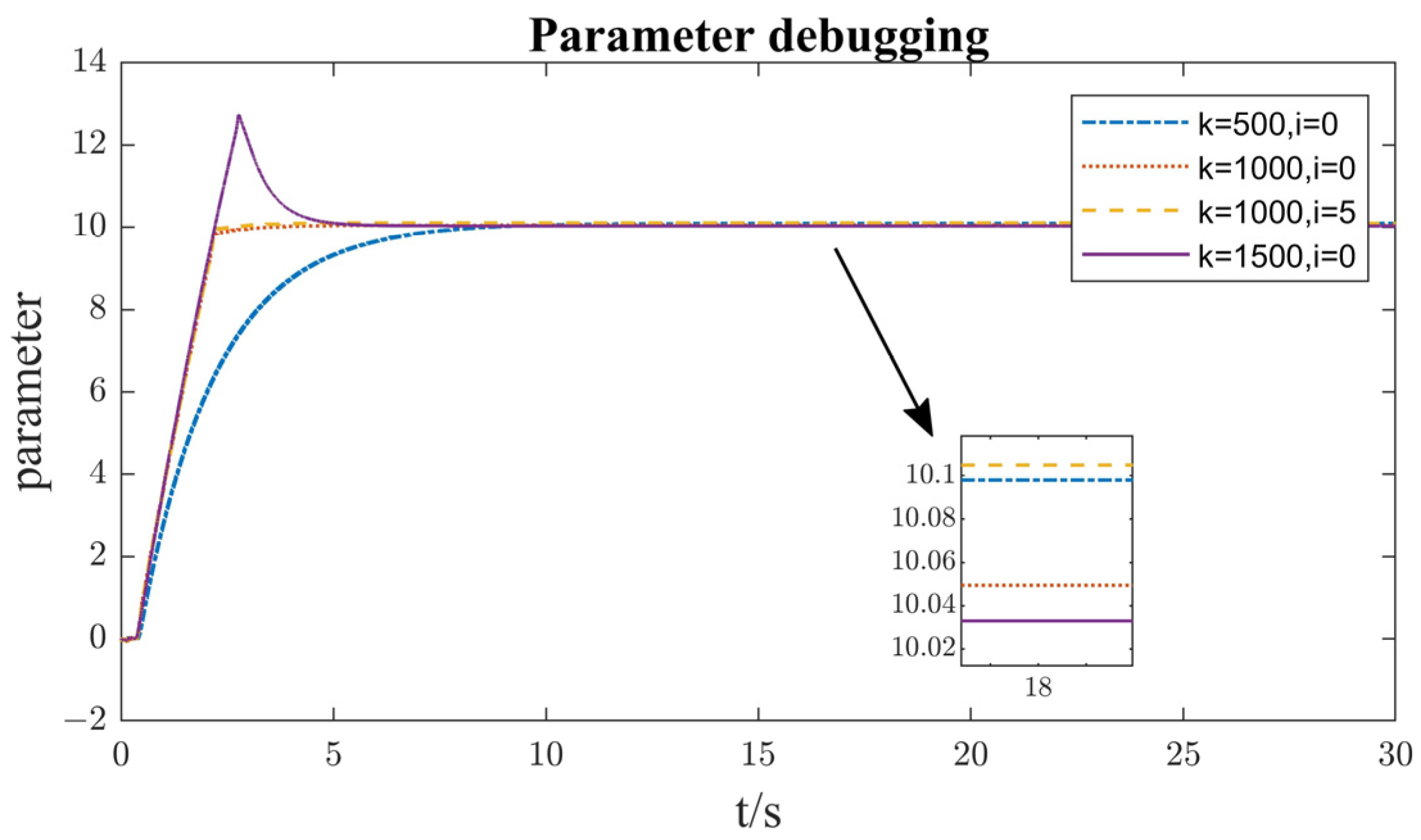

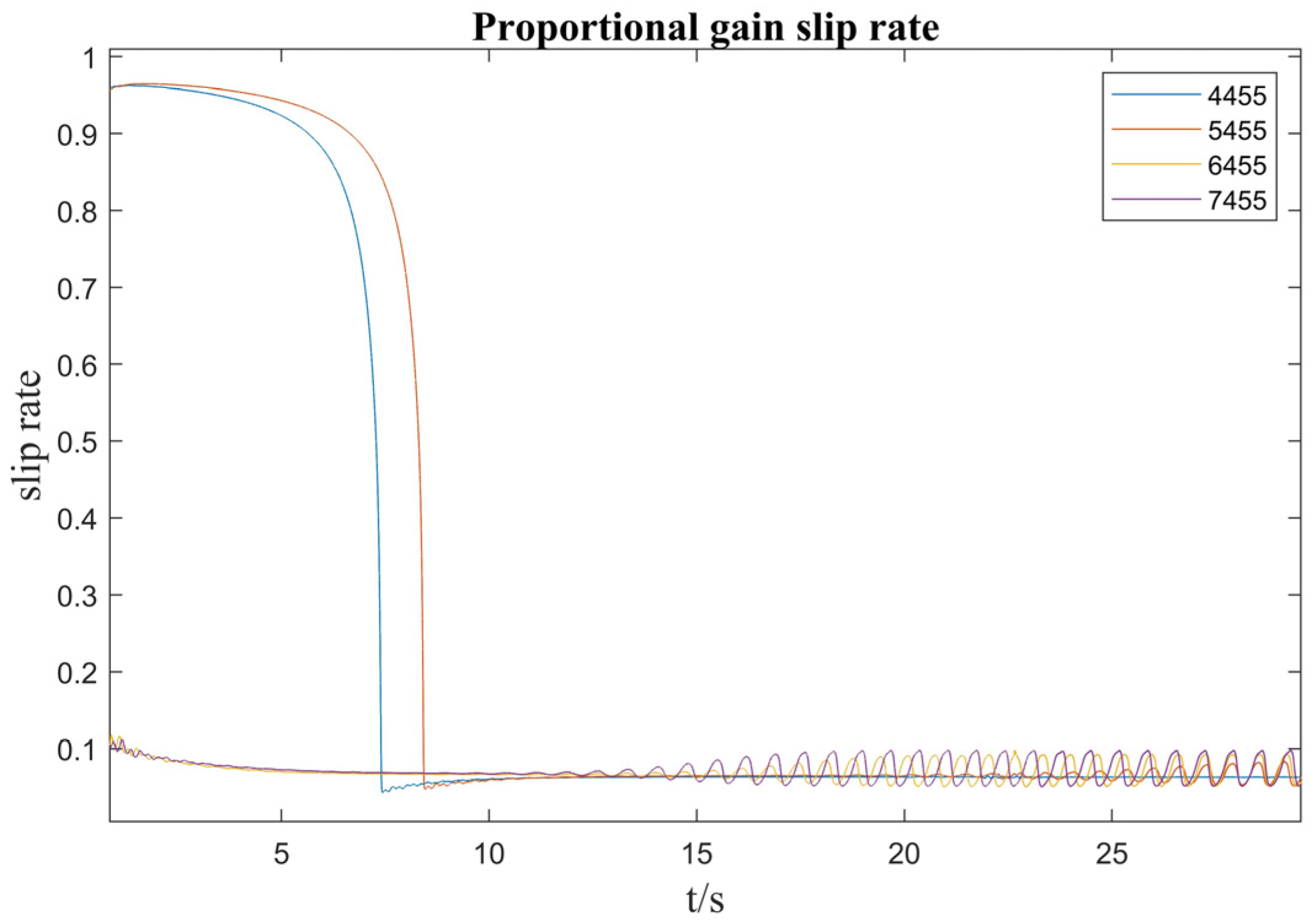

3.5. Proportional Gain Control Based on Rear Slippage Velocity-Matched Standing Moment

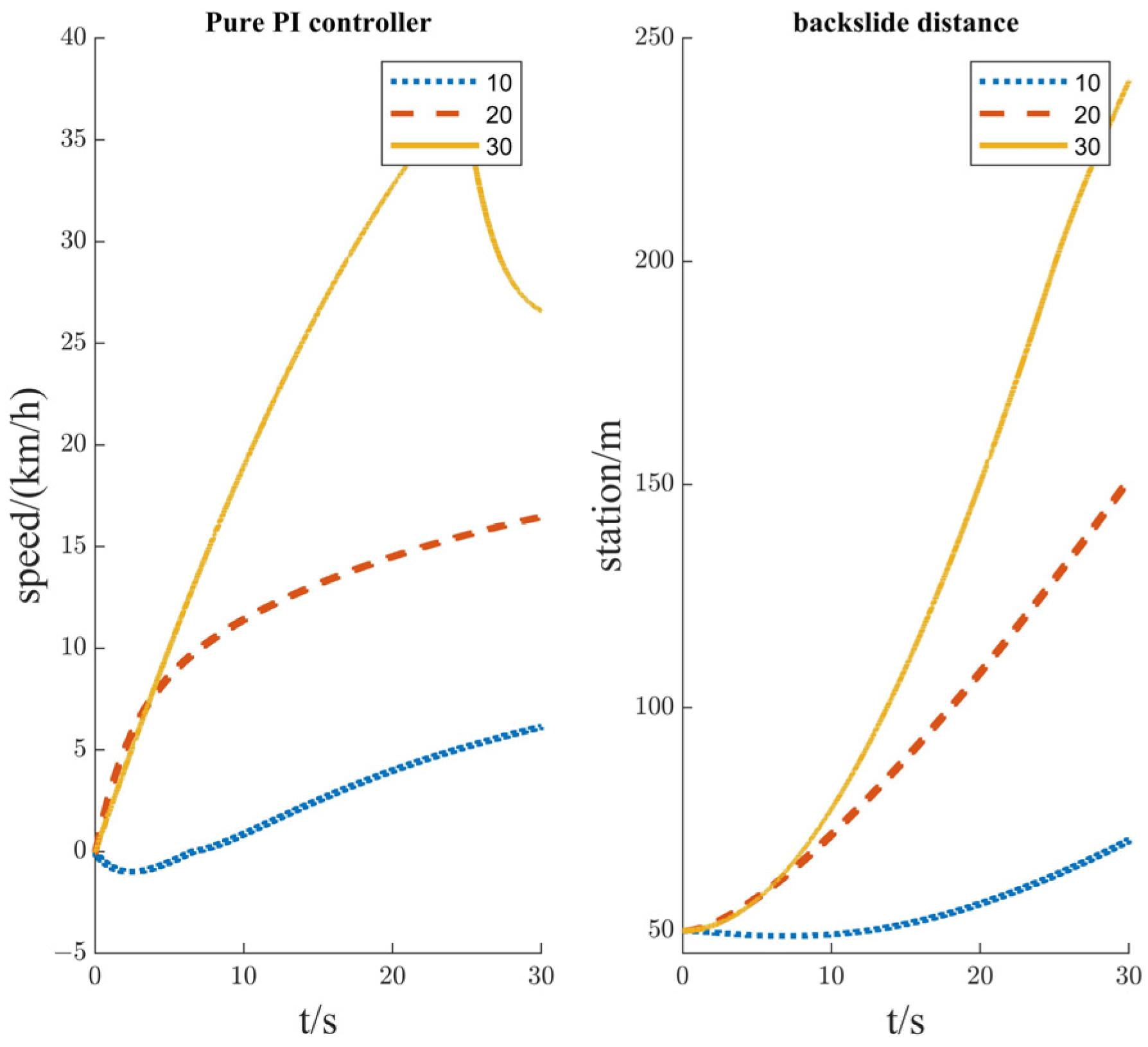

3.6. Pure PI Controller

4. Discussion

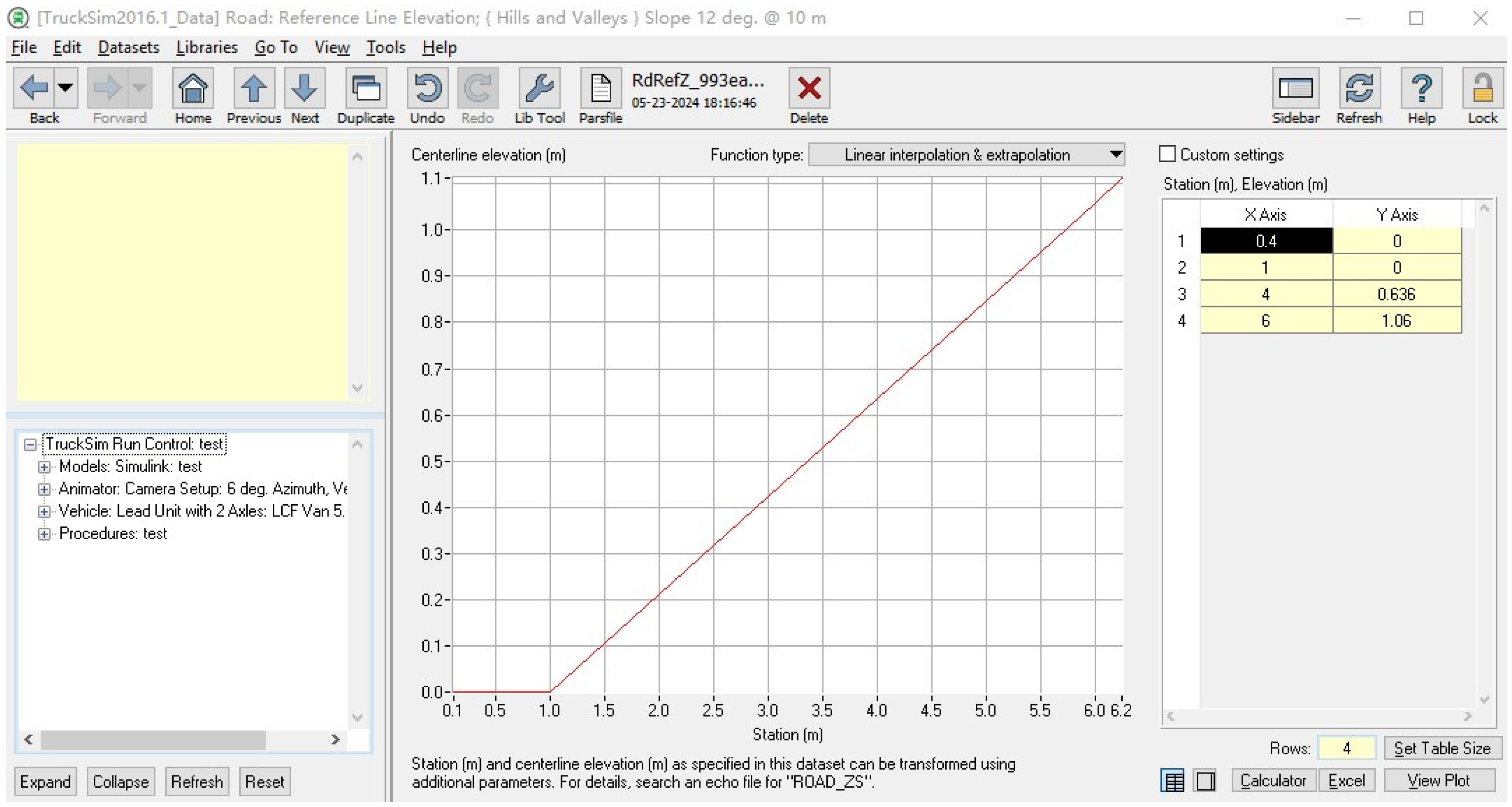

4.1. Simulation Environment Setup

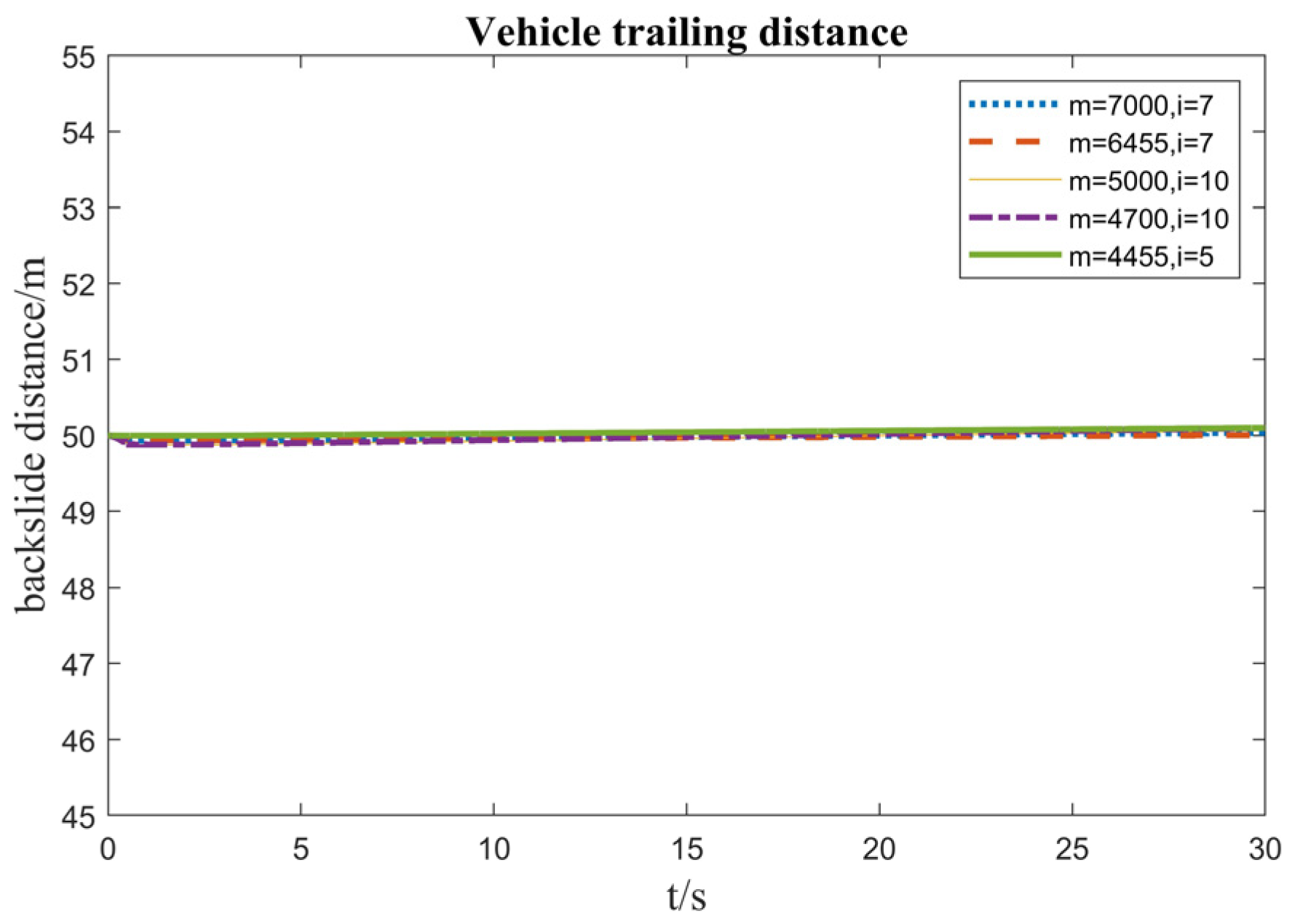

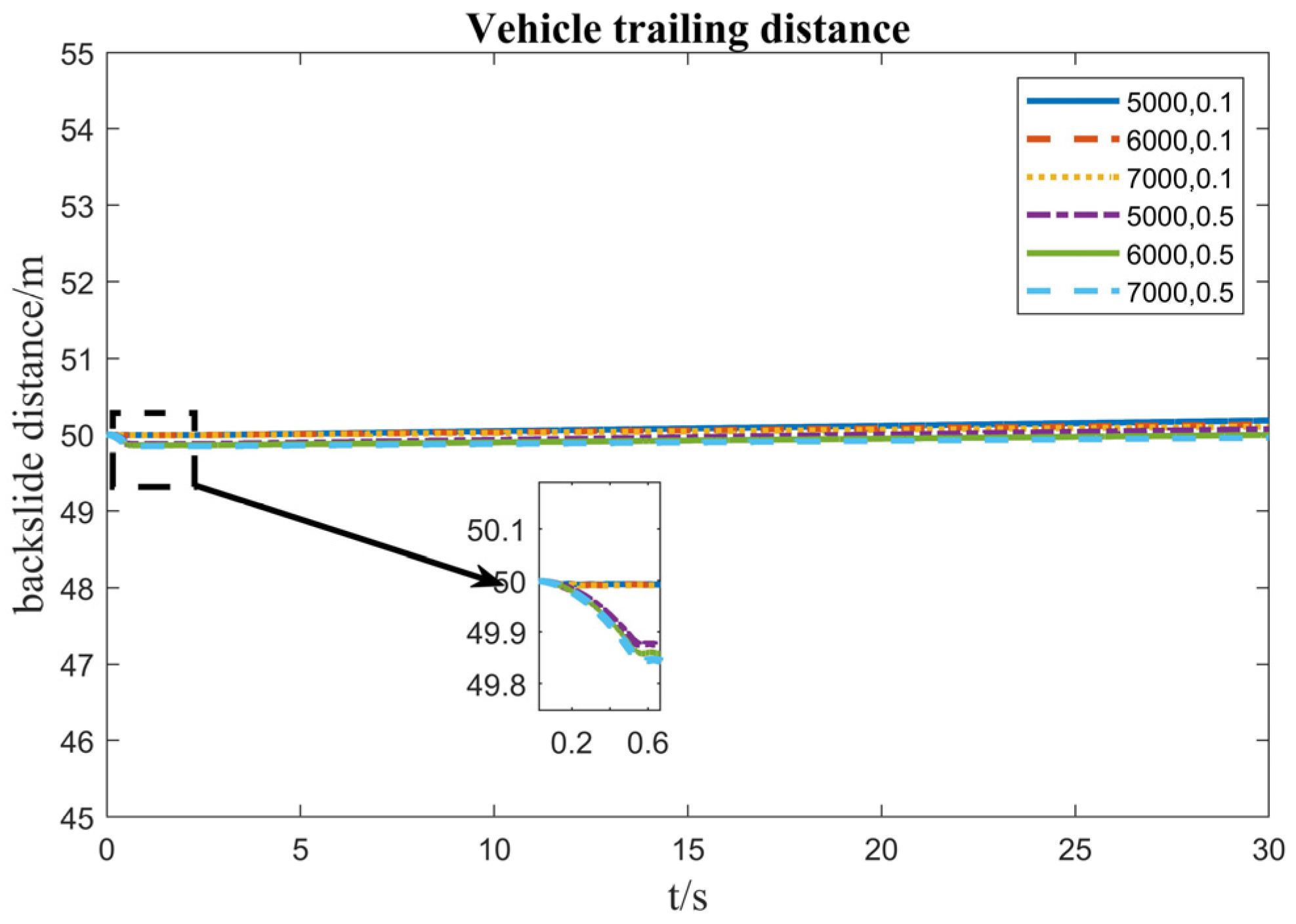

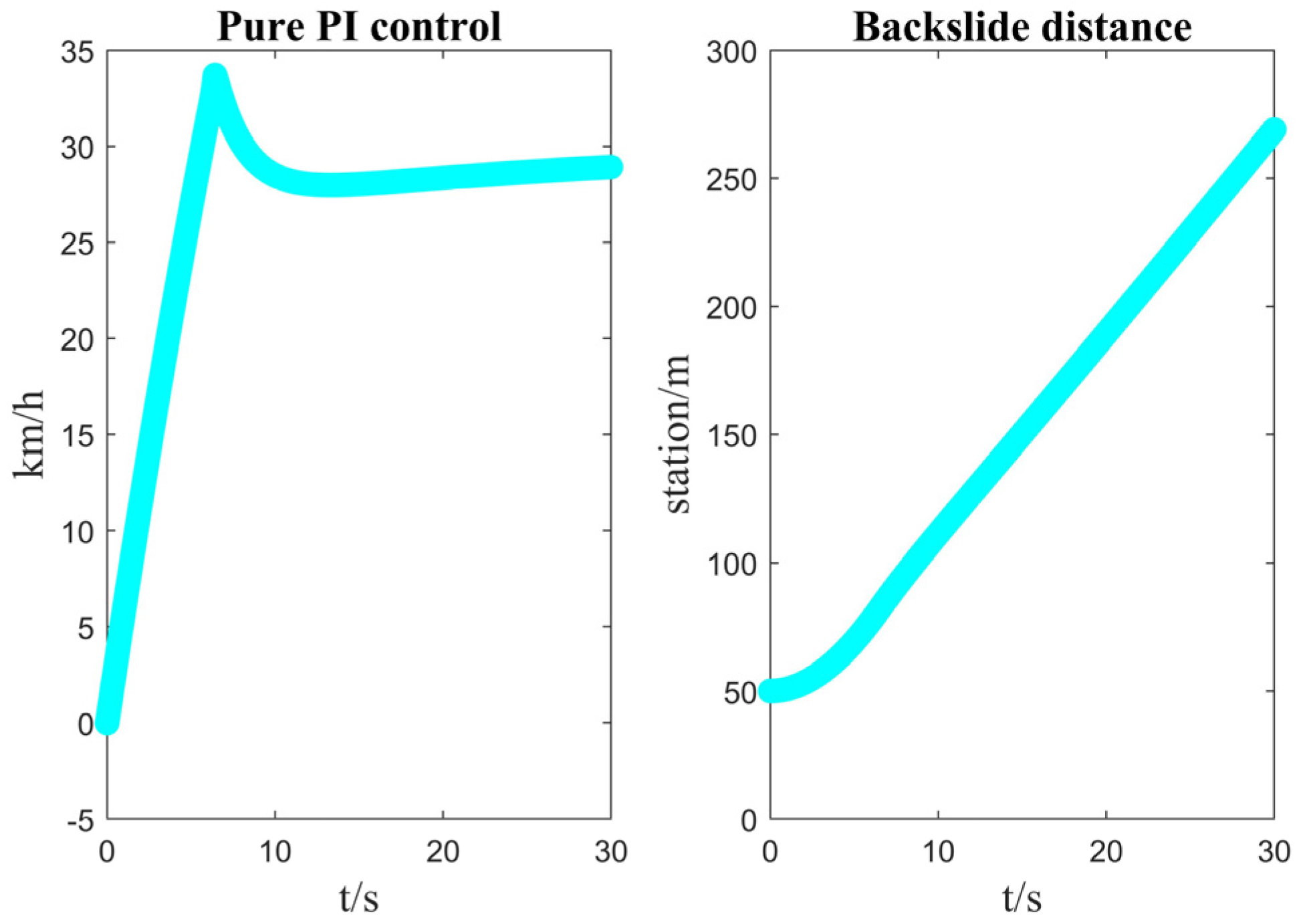

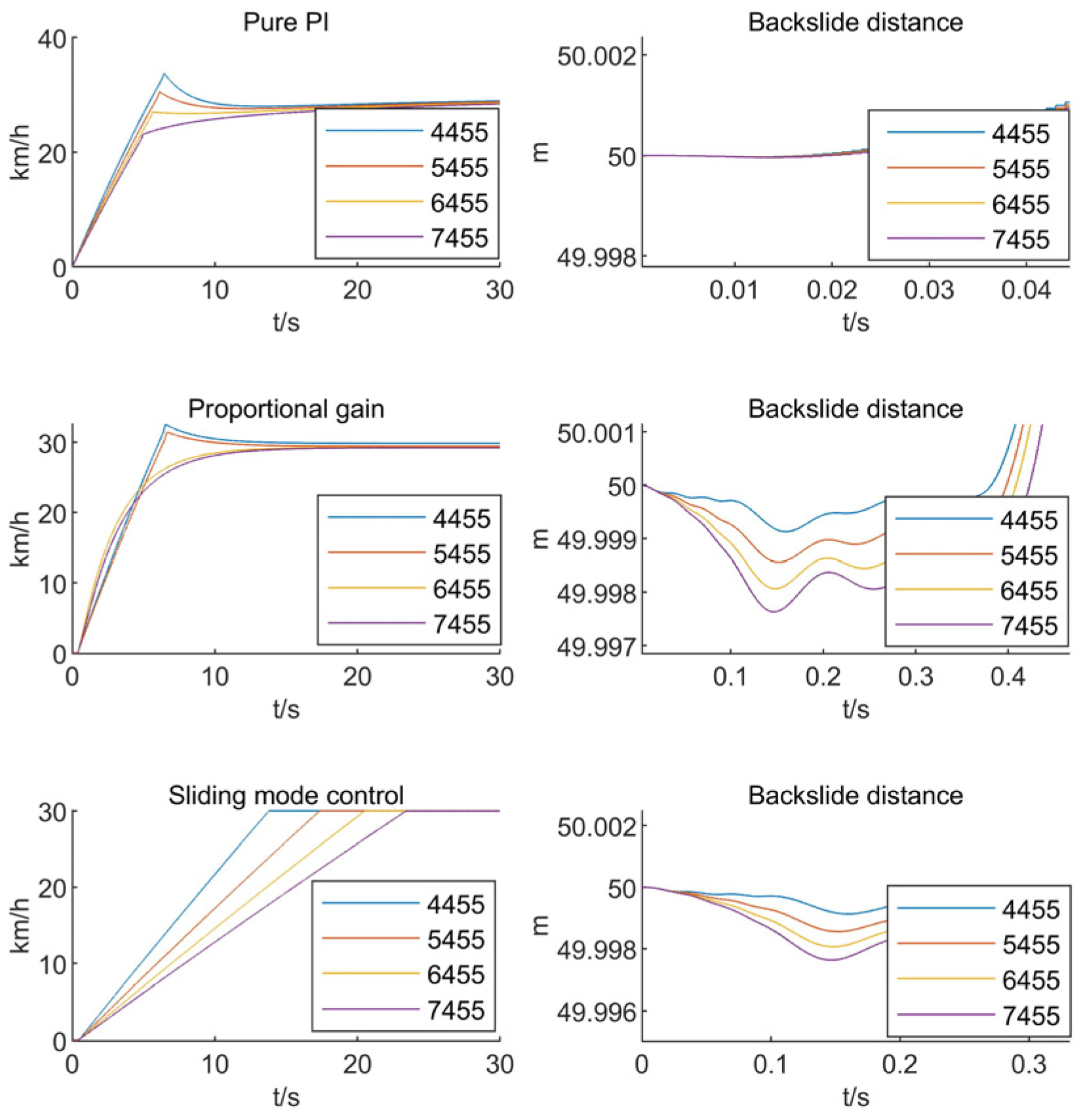

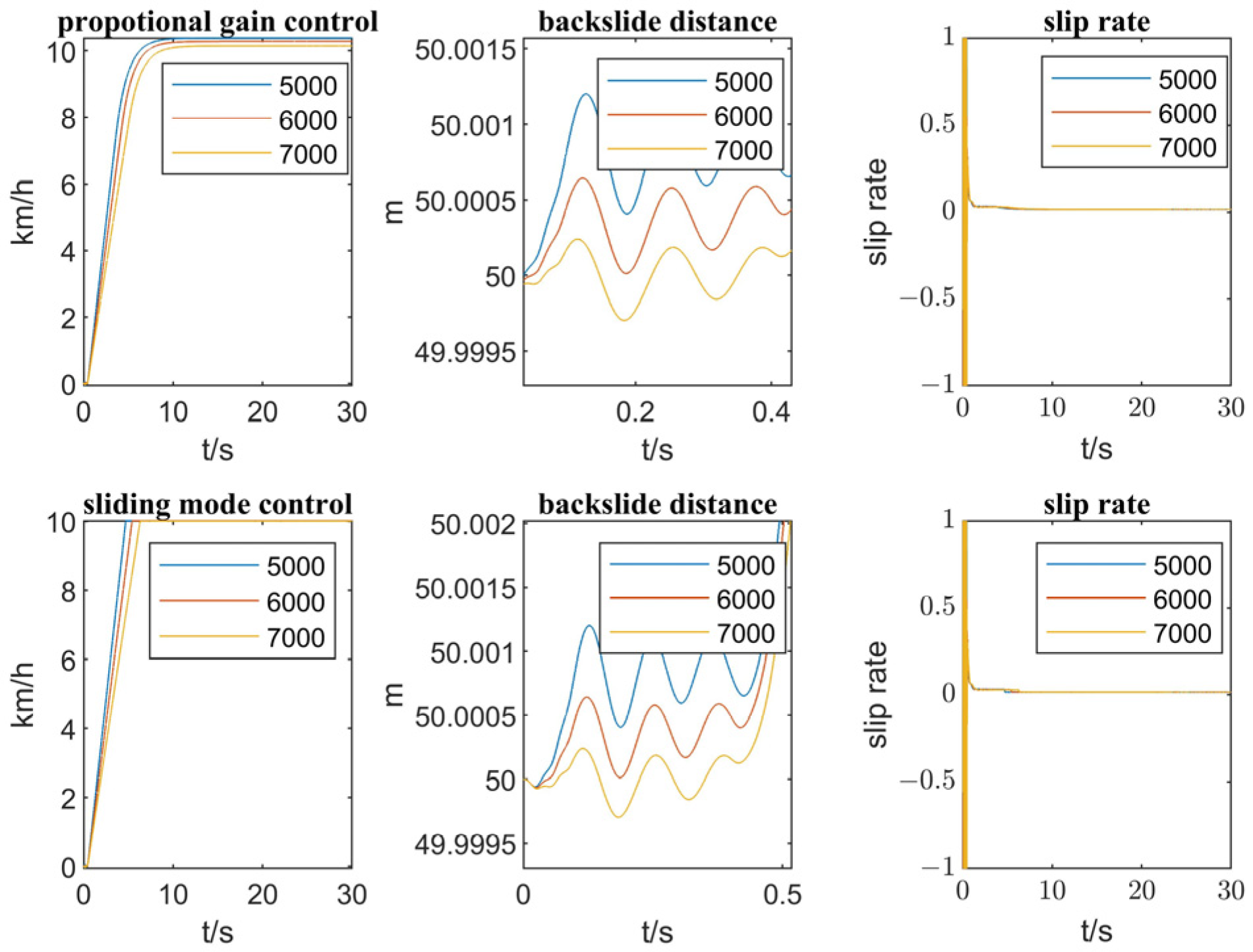

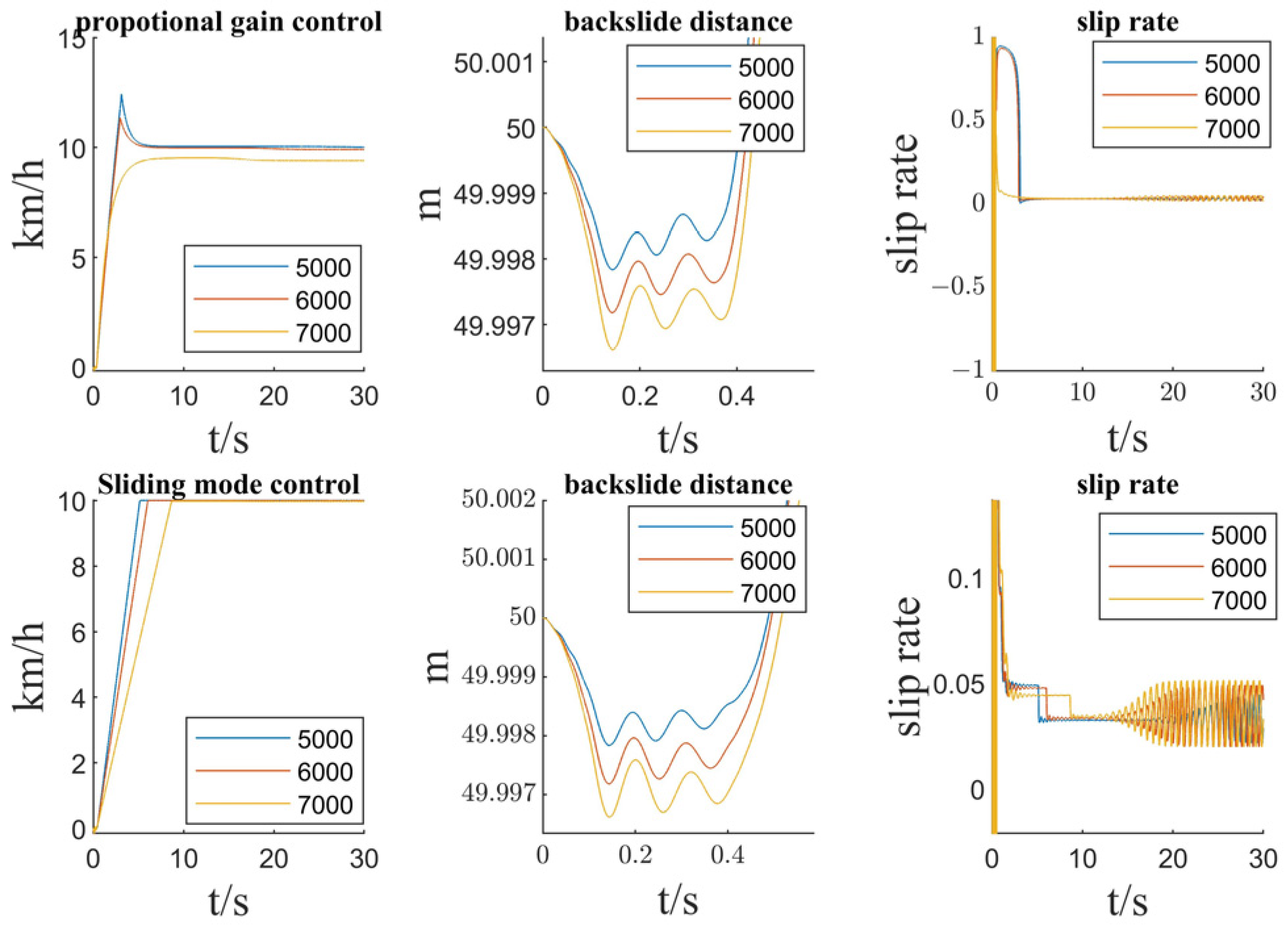

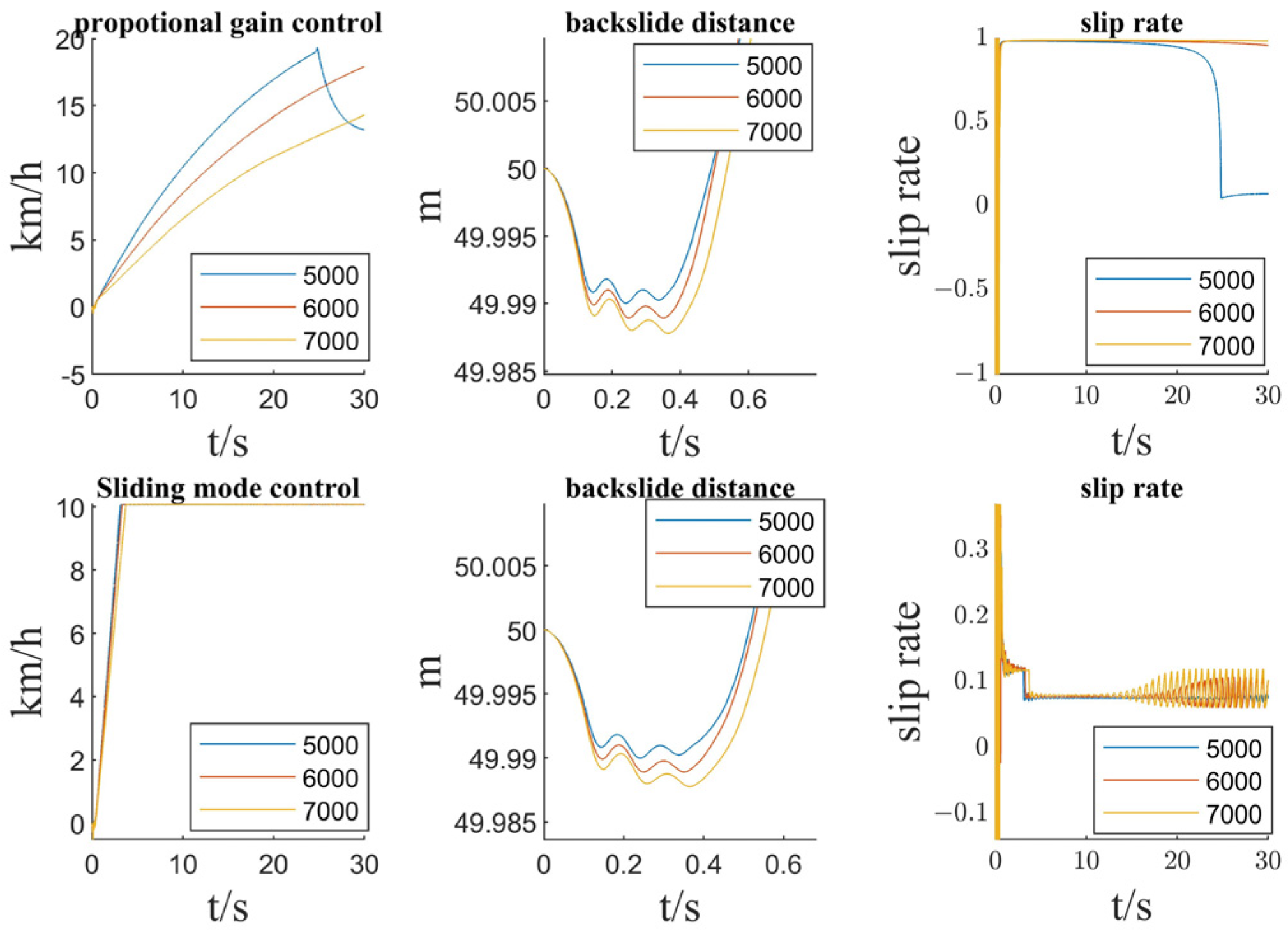

4.2. Comparison of Calibration Slope Quality Algorithms

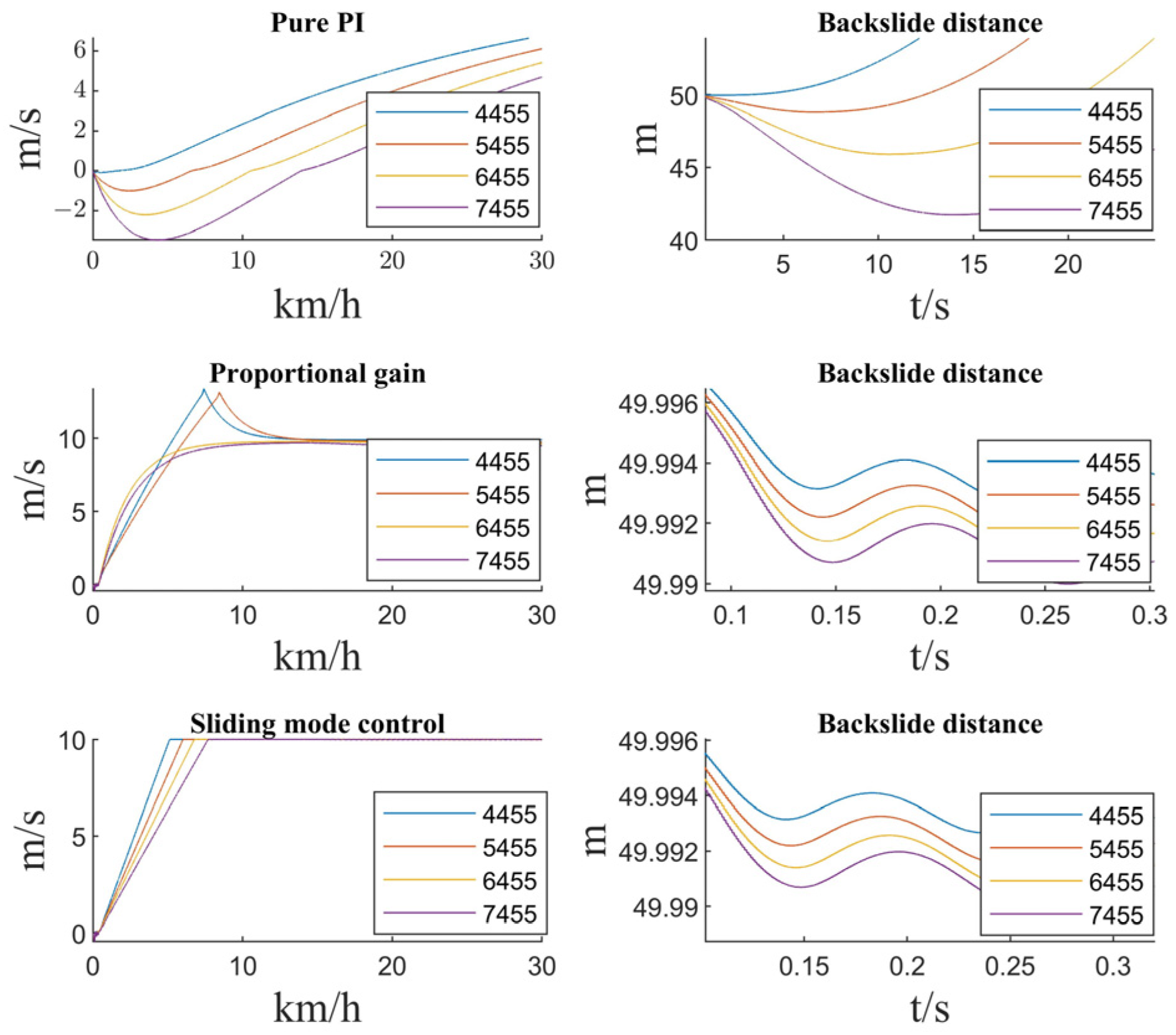

4.3. Comparison of Uncalibrated Slope Quality Algorithms

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Balasubramanian, B. Sensor-less hill-assist using traction control in electric LCV. In Proceedings of the IEEE International Transportation Electrification Conference, Chennai, India, 27–29 August 2015; IEEE: New York, NY, USA, 2015; pp. 1–7. [Google Scholar]

- Ramani, S.; Ramani, S.; Balasubramaniam, R. Standalone Hill Drive Away Assist; SAE Technical Paper 2023-01-1867; SAE International: Warrendale, PA, USA, 2023. [Google Scholar]

- Delvecchio, D.; Savaresi, S.M.; Spelta, C.; Dozio, S.; Mandrioli, L.; Cantoni, C. A Control System for Hill Start Assistance for Commercial Vehicles. In Proceedings of the 2nd Annual Dynamic Systems and Control Conference (DSCC 2009)/Bath/ASME Symposium on Fluid Power and Motion Control, Hollywood, CA, USA, 12–14 October 2009. [Google Scholar]

- Huang, Y.; Wang, H.; Khajepour, A.; He, H.; Ji, J. Model predictive control power management strategies for HEVs: A review. J. Power Sources 2017, 341, 91–106. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, H.; Khajepour, A.; Li, B.; Ji, J.; Zhao, K.; Hu, C. A review of power management strategies and component sizing methods for hybrid vehicles. Renew. Sustain. Energy Rev. 2018, 96, 132–144. [Google Scholar] [CrossRef]

- Subramanian, S.; Thangavel, P.; MI, F.S.; Sornam, K.; Rambhaji, G.P.; Velusamy, R. Development and Testing of a Control Algorithm to Assist Drive-Off in the Gradient—A Rapid Control Prototyping Approach; SAE International: Warrendale, PA, USA, 2015. [Google Scholar]

- Zhang, X.; Göhlich, D.; Li, J. Energy-efficient toque allocation design of traction and regenerative braking for distributed drive electric vehicles. IEEE Trans. Veh. Technol. 2018, 67, 285–295. [Google Scholar] [CrossRef]

- Park, J.; Jang, I.G.; Hwang, S.H. Torque Distribution Algorithm for an Independently Driven Electric Vehicle Using a Fuzzy Control Method: Driving Stability and Efficiency. Energies 2018, 11, 3479. [Google Scholar] [CrossRef]

- Xiong, L.; Teng, G.W.; Yu, Z.P.; Zhang, W.X.; Feng, Y. Novel stability control strategy for distributed drive electric vehicle based on driver operation intention. Int. J. Automot. Technol. 2016, 17, 651–663. [Google Scholar] [CrossRef]

- Shi, K.; Yuan, X.; Liu, L. Model predictive controller-based multi-model control system for longitudinal stability of distributed drive electric vehicle. ISA Trans. 2018, 72, 44–55. [Google Scholar] [CrossRef]

- Nair, A.; Sreedharan, R.P.; Rajesh, M. Intelligent motion control of bots using hill hold assistance mechanism. In Proceedings of the Conference: 2017 International Conference on Smart Technologies for Smart Nation (SmartTechCon), Bengaluru, India, 17–19 August 2017; pp. 618–621. [Google Scholar]

- Ishak, M.R.; Belhocine, A.; Taib, J.M.; Omar, W.Z. Brake torque analysis of fully mechanical parking brake system: Theoretical and experimental approach. Measurement 2016, 94, 487–497. [Google Scholar] [CrossRef]

- Sharma, A.; Gangwar, H.K.; Dabhole, D.; Pathak, S.B.; Dwivedi, V.; Nigam, A. Hill Start Assistance Developed for Buses Equipped with AMT. In Proceedings of the SAE 2016 World Congress and Exhibition, Detroit, MI, USA, 12–14 April 2016. [Google Scholar]

- Paul, M.; Baidya, K.; Deepak, R. Electro-Magnetic Parking Brake System for Electric Vehicles. In Proceedings of the Symposium on International Automotive Technology 2019, Pune, India, 16–18 January 2019. [Google Scholar]

- Iyer, R.; Awade, Y.; Doshi, P.; Dabhade, A.; Jadhav, V. Safety and Comfort for All: An Affordable HillHold and Automated Parking Brake System; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2019. [Google Scholar]

- Song, M.; Wang, H.; Liu, H.; Peng, P.; Wang, X.; Pi, D.; Yang, C.; He, G. Double layer control for AMT clutch in commercial vehicle starting: Design and experiment. J. Mech. Eng. 2019, 65, 9. [Google Scholar] [CrossRef]

- Peng, P.; Wang, H.; Pi, D.; Wang, E.; Yin, G. Two-layer mass-adaptive hill start assist control method for commercial vehicles. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2020, 234, 438–448. [Google Scholar] [CrossRef]

- Zhao, X.; Liu, C.-Z.; Li, L.; Zhang, Z.; Cheng, S.; Wang, X.-Y. Cooperative Control of Clutch and Hydraulic Control Unit. IEEE Trans. Ind. Electron. 2018, 66, 7209–7218. [Google Scholar] [CrossRef]

- Sun, X.; Zhang, H.; Cai, Y.; Wang, S.; Chen, L. Hybrid modeling and predictive control of intelligent vehicle longitudinal velocity considering nonlinear tire dynamics. Nonlinear Dyn. 2019, 97, 1051–1066. [Google Scholar] [CrossRef]

- Wu, L.; Wang, H.; Pi, D.; Wang, E.; Wang, X. Hill-start of Distributed Drive Electric Vehicle Based on Pneumatic Electronic Parking Brake System. IEEE Access 2020, 8, 64382–64398. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, D.; Fang, H.; Yu, Y.; Hu, Y.; Zhang, P.; Luo, W. Ramp Start and Speed Control of Self-Driving Commercial Vehicles under Ramp and Vehicle Load Uncertainty. Actuators 2024, 13, 201. https://doi.org/10.3390/act13060201

Zeng D, Fang H, Yu Y, Hu Y, Zhang P, Luo W. Ramp Start and Speed Control of Self-Driving Commercial Vehicles under Ramp and Vehicle Load Uncertainty. Actuators. 2024; 13(6):201. https://doi.org/10.3390/act13060201

Chicago/Turabian StyleZeng, Dequan, Huafu Fang, Yinquan Yu, Yiming Hu, Peizhi Zhang, and Wei Luo. 2024. "Ramp Start and Speed Control of Self-Driving Commercial Vehicles under Ramp and Vehicle Load Uncertainty" Actuators 13, no. 6: 201. https://doi.org/10.3390/act13060201

APA StyleZeng, D., Fang, H., Yu, Y., Hu, Y., Zhang, P., & Luo, W. (2024). Ramp Start and Speed Control of Self-Driving Commercial Vehicles under Ramp and Vehicle Load Uncertainty. Actuators, 13(6), 201. https://doi.org/10.3390/act13060201