High-Performance Nanocellulose-Based Ionic Electroactive Soft Actuators

Abstract

1. Introduction

2. Experimental Section

2.1. Materials

2.2. Development of PEDOT/PSS-MFC-MWCNT Electrode Film

2.3. Fabrication of the PEDOT/PSS-MFC-MWCNT Actuator

2.4. Characterization

3. Results and Discussion

3.1. Scanning Electron Microscope

3.2. Thermogravimetric Analyzer

3.3. Fourier Transform Infrared Spectroscopy

3.4. X-ray Diffractometer

3.5. Tensile Testing

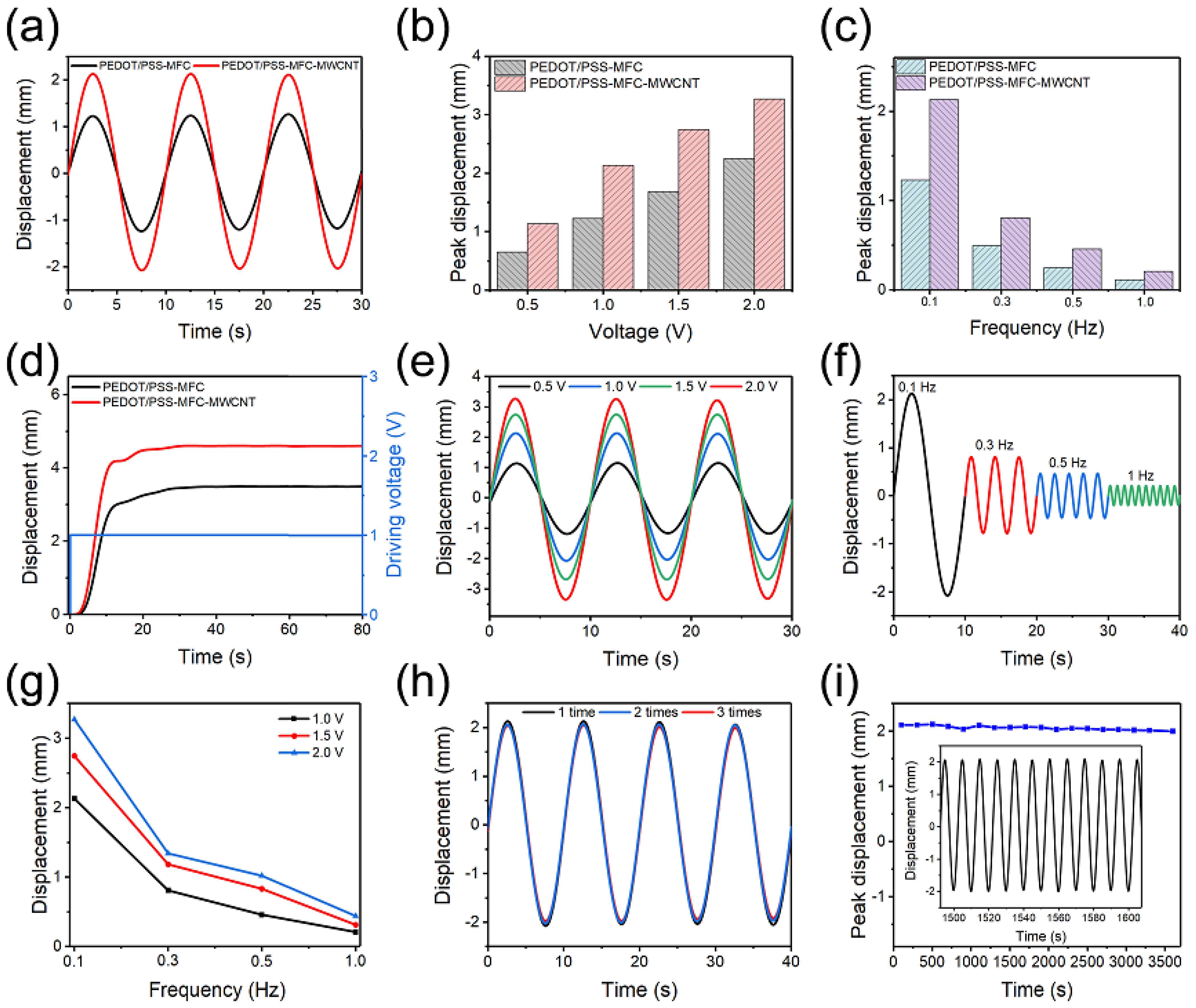

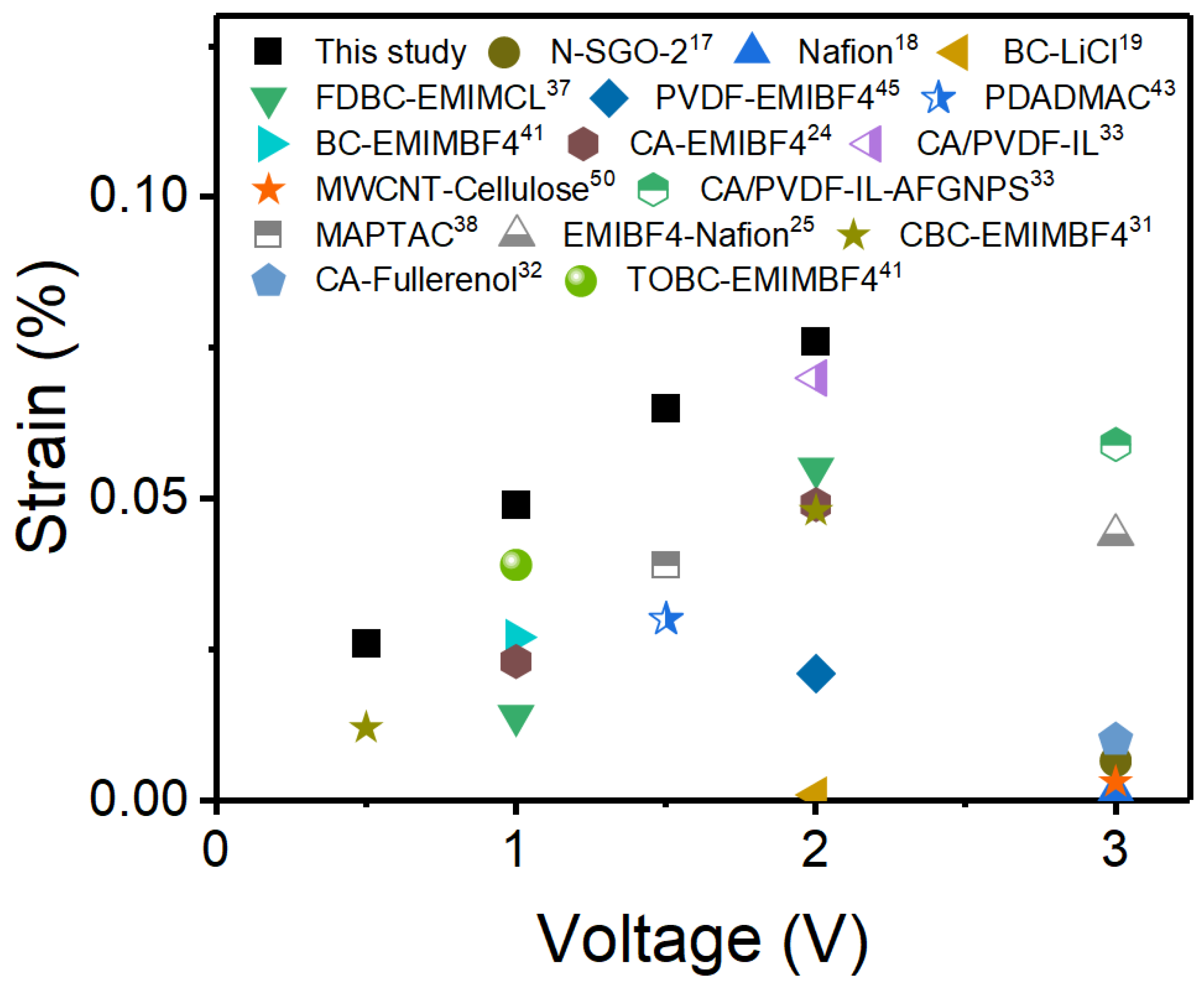

3.6. Electromechanical Characteristics

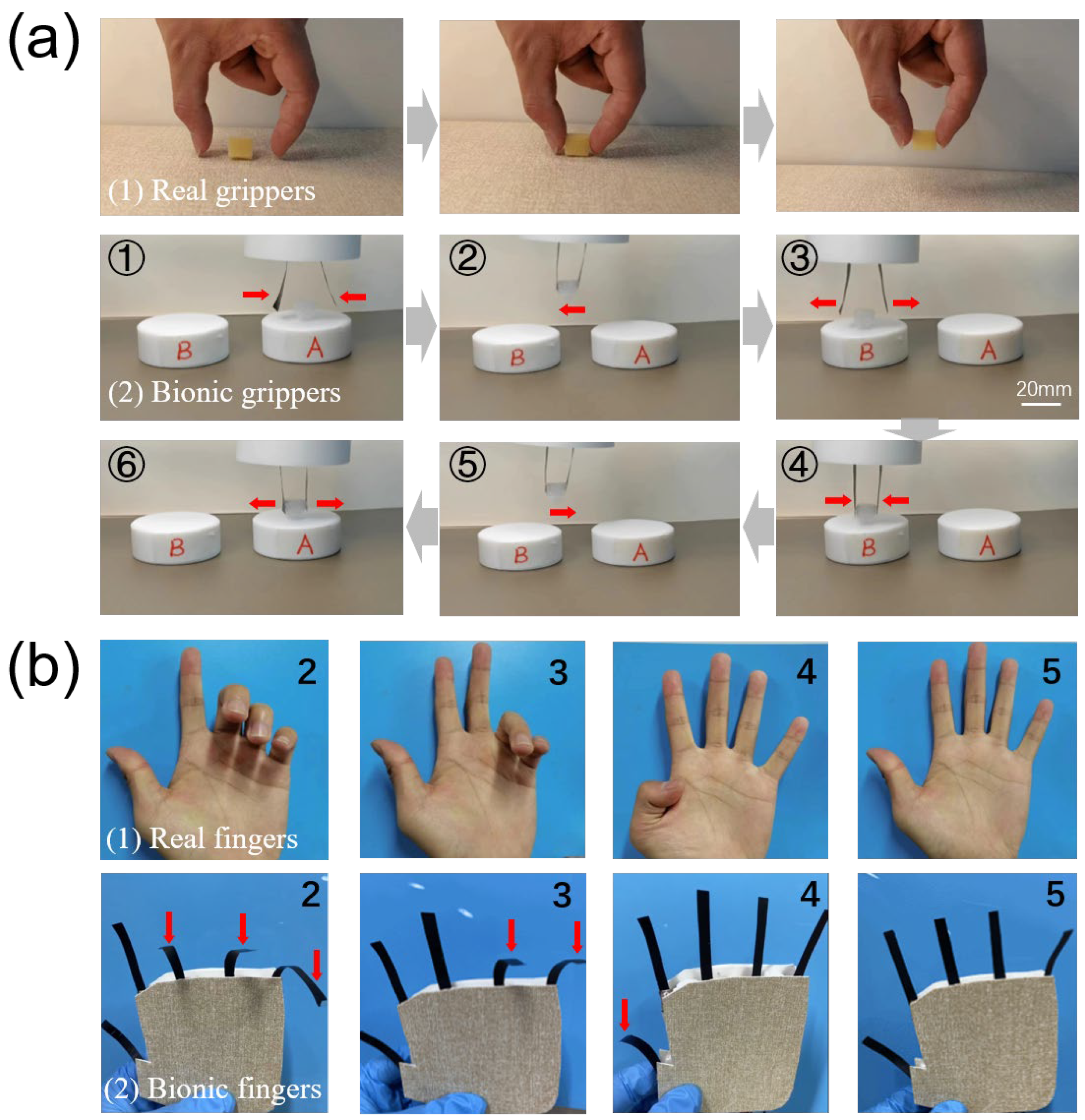

4. Applications

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nauber, R.; Goudu, S.; Goeckenjan, M.; Bornhauser, M.; Ribeiro, C.; Sanchez, M. Medical microrobots in reproductive medicine from the bench to the clinic. Nat. Commun. 2023, 14, 728. [Google Scholar] [CrossRef] [PubMed]

- Yoon, C. Advances in biomimetic stimuli responsive soft grippers. Nano Converg. 2019, 6, 20. [Google Scholar] [CrossRef] [PubMed]

- Zheng, M.; Wang, D.; Zhu, D.; Cao, S.; Wang, X.; Zhang, M. PiezoClimber: Versatile and self-transitional climbing soft robot with bioinspired highly directional footpads. Adv. Funct. Mater. 2024, 34, 2308384. [Google Scholar] [CrossRef]

- Chen, S.; Tan, Z.; Liao, P.; Li, Y.; Qu, Y.; Zhang, Q.; Yang, M.; Chan, K.; Zhang, L.; Man, K.; et al. Biodegradable microrobots for DNA vaccine delivery. Adv. Healthc. Mater. 2023, 12, 2202921. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Wang, Y.; Chen, H.; Law, J.; Pu, H.; Xie, S.; Duan, F.; Sun, Y.; Liu, N.; Yu, J. A magnetic multi-layer soft robot for on-demand targeted adhesion. Nat. Commun. 2024, 15, 644. [Google Scholar] [CrossRef] [PubMed]

- Xu, H.; Han, C.; Liu, X.; Li, Z.; Liu, J.; Sun, Z. A highly flexible and stretchable ionic artificial muscle. Sens. Actuator A Phys. 2021, 332, 113190. [Google Scholar] [CrossRef]

- Kyle, E.; Paul, A.; Olaf, D. Recent advances in the 3D printing of ionic electroactive polymers and core ionomeric materials. Polym. Chem. 2022, 13, 456. [Google Scholar]

- Aivazyan, V.; Kholodkova, E.; Khmelnitskiy, I.; Alekseev, N.; Adamovich, D.; Parfenovich, S.; Trushlyakova, V.; Broyko, A. Ionic electroactive actuators and sensors with hybrid polymer-metal electrodes. J. Struct. Chem. 2024, 65, 267–280. [Google Scholar] [CrossRef]

- Xu, Z.; Zhu, B.; Liu, X.; Lan, T.; Huang, Y.; Zhang, Y.; Wu, D. High-performance electroionic artificial muscles boosted by superior ion transport with Ti3C2Tx MXene Cellulose nanocomposites for advanced 3D-motion actuation. Chem. Eng. J. 2023, 477, 147246. [Google Scholar] [CrossRef]

- Wang, H.; Yang, L.; Tian, A.; Huang, B. Fractal recognition and contact characteristics of ionic electroactive polymer interface based on microstructure analysis. Tribol. Int. 2023, 186, 108650. [Google Scholar] [CrossRef]

- Aabloo, A.; Luca, V.; Pasquale, G.; Graziani, S.; Gugliuzzo, C.; Johanson, U.; Marino, C.; Pollicino, A.; Puglisi, R. A new class of ionic electroactive polymers based on green synthesis. Sens. Actuator A Phys. 2016, 249, 32–44. [Google Scholar] [CrossRef]

- Terui, A.; Takenaka, R.; Kawaguchi, D.; Mino, A.; Nakazawa, Y.; Endo, H.; Iga, K.; Washio, M.; Oshima, A. Development of ionic polymer metal composite actuator by EB graft-polymerization. Radiat. Phys. Chem. 2023, 213, 111258. [Google Scholar] [CrossRef]

- Biswal, D.; Moharana, B.; Mohapatra, T. Bending response optimization of an ionic polymer-metal composite actuator using orthogonal array method. Mater. Today Proc. 2022, 49, 1550–1555. [Google Scholar] [CrossRef]

- Mehraeen, S.; Sadeghi, S.; Cebeci, F.; Papila, M.; Gürsel, S. Polyvinylidene fluoride grafted poly(styrene sulfonic acid) as ionic polymer-metal composite actuator. Sens. Actuator A Phys. 2018, 279, 157–169. [Google Scholar] [CrossRef]

- Ikeda, T. Gold nanowire mesh electrode for electromechanical device. Sci. Rep. 2023, 13, 16669. [Google Scholar] [CrossRef] [PubMed]

- Yang, L.; Zhang, D.; Zhang, X.; Tian, A. Surface profile topography of ionic polymer metal composite based on fractal theory. Surf. 2021, 22, 100834. [Google Scholar] [CrossRef]

- Na, J.; Safari, M.; Moaven, S. Fabrication of SGO/Nafion-based IPMC soft actuators with sea anemone-like Pt electrodes and enhanced actuation performance. Carbon 2016, 100, 243. [Google Scholar]

- Yilmaz, O.C.; Sen, I.; Gurses, B.; Ozdemir, O.; Cetin, L.; Sarikanat, M.; Seki, Y.; Sever, K.; Altinkaya, E. The effect of gold electrode thicknesses on electromechanical performance of Nafion-based ionic polymer metal composite actuators. Compos. Part B. 2019, 165, 747. [Google Scholar] [CrossRef]

- Jeon, J.; Oh, I.; Kee, C.; Kim, S. Bacterial cellulose actuator with electrically driven bending deformation in hydrated condition. Sens. Actuators B Chem. 2010, 146, 307–313. [Google Scholar] [CrossRef]

- Yang, L.; Yang, Y.; Wang, H. Modeling and control of ionic polymer metal composite actuators: A review. Eur. Polym. J. 2023, 186, 111821. [Google Scholar] [CrossRef]

- Lee, S.; Hwang, L.; Lee, J.; Yang, T.; Jho, J.; Park, J. Multiday operable ionic polymer-metal composites prepared using a stacking method for practical actuator applications. Sens. Actuators B Chem. 2022, 372, 132616. [Google Scholar] [CrossRef]

- Wang, H.; Yang, L.; Yang, Y.; Zhang, D.; Tian, A. Highly flexible, large-deformation ionic polymer metal composites for artificial muscles: Fabrication, properties, applications, and prospects. Chem. Eng. J. 2023, 469, 143976. [Google Scholar] [CrossRef]

- Yu, F.; Ciou, J.; Chen, S.; Poh, W.; Chen, J.; Chen, J.; Haruethai, K.; Lv, J.; Gao, D.; Lee, P. Ionic covalent organic framework based electrolyte for fast-response ultra-low voltage electrochemical actuators. Nat. Commun. 2022, 13, 390. [Google Scholar] [CrossRef] [PubMed]

- Nan, M.; Wang, F.; Kim, S.; Li, H.; Jin, Z.; Bang, D.; Kim, C.; Park, J.; Choi, E. Ecofriendly high-performance ionic soft actuators based on graphene-mediated cellulose acetate. Sens. Actuators B Chem. 2019, 301, 127. [Google Scholar] [CrossRef]

- Kim, J.; Jeon, J.; Kim, H.; Lim, H.; Oh, I. Durable and water-floatable ionic polymer actuator with hydrophobic and asymmetrically laser-scribed reduced graphene oxide paper electrodes. ACS Nano. 2014, 8, 2986–2997. [Google Scholar] [CrossRef] [PubMed]

- Luqman, M.; Shaikh, H.; Anis, A.; Zahrani, A.; Hamidi, A.; Inamuddin, A. Platinum-coated silicotungstic acid-sulfonated polyvinyl alcohol-polyaniline based hybrid ionic polymer metal composite membrane for bending actuation applications. Sci. Rep. 2022, 12, 4467. [Google Scholar] [CrossRef] [PubMed]

- Gu, J.; Zhou, Z.; Zhu, Z.; Huang, G.; Zhang, Z. Mechanical stimulation of cells with electroactive polymer-based soft actuators. Eur. Phys. J. Spec. Top. 2023, 232, 2695–2708. [Google Scholar] [CrossRef]

- Li, H.; Fan, M.; Yue, Y.; He, Q.; Yu, M.; Chen, G. Displacement response of ionic polymer metal composite actuator to asymmetric square waves in air operating. Sens. Actuator A Phys. 2020, 311, 112069. [Google Scholar] [CrossRef]

- Horiuchi, T.; Sugino, T.; Asaka, K. Elliptical-like cross-section ionic polymer-metal composite actuator for catheter surgery. Sens. Actuator A Phys. 2017, 267, 235–241. [Google Scholar] [CrossRef]

- James, D.C.; Tucker, H.; Kwang, J.; Kam, K.L. 3D-Printing and machine learning control of soft ionic polymer-metal composite actuators. Sci. Rep. 2019, 9, 17482. [Google Scholar]

- Wang, F.; Jeon, J.; Park, S.; Kee, C.; Kim, S.; Oh, I. Soft biomolecule actuator based on a highly functionalized bacterial cellulose nano-fiber network with carboxylic acid groups. Soft Matter. 2016, 12, 246–254. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Vadahanambi, S.; Kim, C.; Oh, I. Electrospun fullerenol-cellulose biocompatible actuators. Biomacromolecules. 2011, 6, 2048–2054. [Google Scholar] [CrossRef] [PubMed]

- Nan, M.; Bang, D.; Zheng, S.; Go, G.; Bobby, D.; Kim, S.; Li, H.; Kim, C.; Hong, A.; Wang, F.; et al. High-performance biocompatible nanobiocomposite artificial muscles based on ammonia-functionalized graphene nanoplatelets–cellulose acetate combined with PVDF. Sens. Actuat. B-Chem. 2020, 323, 128709. [Google Scholar] [CrossRef]

- Li, H.; Luo, R.; Hu, J.; Yang, K.; Du, B.; Zhou, S.; Zhou, X. Self-assembled gel-assisted preparation of high-performance hydrophobic PDMS @ MWCNTs /PEDOT:PSS composite aerogels for wearable piezoresistive sensors. J. Mater. Sci. Technol. 2024, 182, 22–32. [Google Scholar] [CrossRef]

- Monika; Pradhan, P.; Amrute, V.; Chanda, A. Structural and optical study of conducting polymer PEDOT:PSS and its composite with GO. Mater. Today Proc. 2023, 7, 123. [Google Scholar] [CrossRef]

- Jeon, Y.; Ko, Y.; Lee, S.; Jeong, M.; Lee, K.; Kwon, G.; Kim, J.; You, J. PEDOT:PSS/regenerated cellulose composite microelectrode for high-performance micro-supercapacitor. Appl. Surf. Sci. 2023, 636, 157806. [Google Scholar] [CrossRef]

- Kim, S.; Jeon, J.; Kee, C.; Oh, I. Electro-active hybrid actuators based on freeze-dried bacterial cellulose and PEDOT:PSS. Smart Mater. Struct. 2013, 22, 085026. [Google Scholar] [CrossRef]

- Hara, Y.; Yamaguchi, Y. Development of a paper actuator with PEDOT:PSS thin-films as an electrode. Actuators 2014, 3, 285–292. [Google Scholar] [CrossRef]

- Li, Y.; Liu, W.; Gao, X.; Zou, T.; Deng, P.; Zhao, J.; Zhang, T.; Chen, Y.; He, L.; Shao, L.; et al. Carbon nanomaterials-PEDOT:PSS based electrochemical ionic soft actuators: Recent development in design and applications. Sens. Actuator A Phys. 2023, 354, 114277. [Google Scholar] [CrossRef]

- Wang, F.; Kong, Y.; Shen, F.; Wang, Y.; Wang, D.; Li, Q. High-performance microfibrillated cellulose-based low voltage electroactive ionic artificial muscles in bioinspired applications. Compos. Part. B-Eng. 2022, 228, 109436. [Google Scholar] [CrossRef]

- Kim, S.; Jeon, J.; Kim, H.; Kee, C.; Oh, I. High-fidelity bioelectronic muscular actuator based on graphene-mediated and TEMPO-oxidized bacterial cellulose. Adv. Funct. Mater. 2015, 25, 3560–3570. [Google Scholar] [CrossRef]

- Ma, X.; Zhang, M.; Zhang, J.; Wang, S.; Cao, S.; Li, Y.; Hu, G.; Kong, D. Highly permeable and ultrastretchable liquid metal micromesh for skin-attachable electronics. ACS Mater. Lett. 2022, 4, 634–641. [Google Scholar] [CrossRef]

- Wu, Y.; Minamikawa, H.; Nakazumi, T.; Hara, Y. Actuation properties of paper actuators fabricated using PEDOT/PSS electrode films. J. Oleo Sci. 2020, 69, 1331–1337. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Li, Y.; Ren, M.; Ni, Q.; Hu, J.; Li, K.; Li, R. Soft actuators based on piezoelectric composites for nanoscale self-bending. Compos. Struct. 2023, 320, 117218. [Google Scholar] [CrossRef]

- Lu, L.; Liu, J.; Hu, Y.; Zhang, Y.; Randriamahazaka, H.; Chen, W. Highly stable air working bimorph actuator based on a graphene nanosheet/carbon nanotube hybridelectrode. Adv. Mater. 2012, 24, 4317–4321. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, S.; Lee, B. Microfibrillated cellulose film with enhanced mechanical and water-resistant properties by glycerol and hot-pressing treatment. Cellulose 2021, 28, 5693–5705. [Google Scholar] [CrossRef]

- Li, H.; Kulachenko, A.; Mathew, A.; Stoltz, R.; Sevastyanova, O. Enhancing the strength and flexibility of microfibrillated cellulose films from lignin-rich kraft pulp. ACS Sustain. Chem. Eng. 2023, 11, 16793–16805. [Google Scholar] [CrossRef]

- Mustaffa, M.; Azis, R.; Abdullah, N.; Ismail, I.; Ibrahim, I. An investigation of microstructural, magnetic and microwave absorption properties of multi walled carbon nanotubes/Ni0.5Zn0.5Fe2O4. Sci. Rep. 2019, 9, 15523. [Google Scholar] [CrossRef] [PubMed]

- Areerob, Y.; Hamontree, C.; Sricharoen, P.; Limchoowong, N.; Nijpanich, S.; Nachaithong, T.; Oh, W.; Pattarith, K. Synthesis of novel MoWO4 with ZnO nanoflowers on multi-walled carbon nanotubes for counter electrode application in dye-sensitized solar cells. Sci. Rep. 2022, 12, 12490. [Google Scholar] [CrossRef] [PubMed]

- Yun, S.; Kim, J. Covalently bonded multi-walled carbon nanotubes-cellulose electro-active paper actuator. Sens. Actuator A Phys. 2009, 154, 73–78. [Google Scholar] [CrossRef]

- Wang, F.; Wang, L.; Wang, Y.; Wang, D. Highly bendable ionic electroactive polymer actuator based on carboxylated bacterial cellulose by doping with MWCNT. Appl. Phys. A. 2022, 128, 911. [Google Scholar] [CrossRef]

- Lertngim, A.; Phiriyawirut, M.; Wootthikanokkhan, J.; Yuwawech, K.; Sangkhun, W.; Kumnorkaew, P.; Muangnapoh, T. Preparation of surlyn films reinforced with cellulose nanofibres and feasibility of applying the transparent composite films for organic photovoltaic encapsulation. R. Soc. Open Sci. 2017, 4, 170972. [Google Scholar] [CrossRef] [PubMed]

- Aliabadi, M.; Chee, B.; Matos, M.; Cortese, Y.; Nugent, M.; Lima, T.; Magalhães, W.; Lima, G.; Firouzabadi, M. Microfibrillated cellulose films containing chitosan and tannic acid for wound healing applications. J. Mater. Sci. Mater. Med. 2021, 32, 67. [Google Scholar] [CrossRef] [PubMed]

- Du, H.; Zhang, M.; Liu, K.; Parit, M.; Jiang, Z.; Zhang, X.; Li, B.; Si, C. Conductive PEDOT:PSS/cellulose nanofibril paper electrodes for flexible supercapacitors with superior areal capacitance and cycling stability. Chem. Eng. J. 2022, 428, 131994. [Google Scholar] [CrossRef]

- Zhang, B.; Bu, X.; Wang, R.; Shi, J.; Chen, C.; Li, D. High mechanical properties of micro fibrillated cellulose/HDPE composites prepared with two different methods. Cellulose 2021, 28, 5449–5462. [Google Scholar] [CrossRef]

- Kozonoe, C.; Giudici, R.; Schmal, M. Ruthenium catalyst supported on multi-walled carbon nanotubes for CO oxidation. Mod. Res. Catal. 2021, 10, 73–91. [Google Scholar] [CrossRef]

| Ionic Membrane | Electrode | Fabrication Method | Thickness (mm) | Peak Displacement (mm) | Bending Strain (%) | Reference |

|---|---|---|---|---|---|---|

| Nafion | PEDOT/PSS-MFC-MWCNT | Hot-pressing | 0.105 | 3.3 | 0.076 (2 V, 0.1 Hz) | This study |

| Nafion | PEDOT/PSS-MFC-MWCNT | Hot-pressing | 0.105 | 2.8 | 0.065 (1.5 V, 0.1 Hz) | This study |

| Nafion | PEDOT/PSS-MFC-MWCNT | Hot-pressing | 0.105 | 2.1 | 0.049 (1.0 V, 0.1 Hz) | This study |

| Nafion | PEDOT/PSS-MFC-MWCNT | Hot-pressing | 0.105 | 1.1 | 0.026 (0.5 V, 0.1 Hz) | This study |

| N-SGO-2 | Pt | Plating | 0.130 | 0.1 | 0.0065 (3 V) | [17] |

| Nafion | Au | Thermal evaporation | 0.183 | 4.0 | 0.0016 (3 V, 0.25 Hz) | [18] |

| BC-LiCl | Au | Sputter coating | 0.04 | 0.1 | 0.0009 (2 V, 0.5 Hz) | [19] |

| CA-EMIMBF4 | PEDOT/PSS | Dip-coating | 0.15 | 0.7 | 0.023 (1 V, 0.1 Hz) | [24] |

| CA-EMIMBF4 | PEDOT/PSS | Dip-coating | 0.15 | 1.5 | 0.049 (2 V, 0.1 Hz) | [24] |

| EMIBF4 Nafion-117 | HLrGOP | Hot-pressing | 0.2 | 1.0 | 0.044 (3 V, 0.1 Hz) | [25] |

| CBC-EMIMBF4 | PEDOT/PSS | Dip-coating | 0.08 | 0.7 | 0.012 (0.5 V, 0.1 Hz) | [31] |

| CBC-EMIMBF4 | PEDOT/PSS | Dip-coating | 0.08 | 2.7 | 0.048 (2 V, 0.1 Hz) | [31] |

| CA-Fullerenol | Au | Deposition | 0.1 | 0.46 | 0.01 (3 V, 0.1 Hz) | [32] |

| CA/PVDF-IL | PEDOT/PSS | Dip-casting | 0.15 | 2.2 | 0.072 (2 V, 0.1 Hz) | [33] |

| CA/PVDF-IL-AFGNPS(0.15) | PEDOT/PSS | Dip-casting | 0.07 | 1.3 | 0.059 (3 V, 0.1 Hz) | [33] |

| FDBC-EMIMCl | PEDOT/PSS | Dip-coating | 1.4 | 0.1 | 0.014 (1 V, 0.1 Hz) | [37] |

| FDBC-EMIMCl | PEDOT/PSS | Dip-coating | 1.4 | 0.4 | 0.055 (2 V, 0.1 Hz) | [37] |

| MAPTAC | PEDOT/PSS | Spin-coating | 0.036 | 2.2 | 0.039 (1.5 V, 1 Hz) | [38] |

| BC-EMIMBF4 | PEDOT/PSS | Dip-casting | 0.15 | 0.8 | 0.027 (1 V, 0.1 Hz) | [41] |

| TOBC-EMIMBF4 | PEDOT/PSS | Dip-casting | 0.15 | 1.2 | 0.039 (1 V, 0.1 Hz) | [41] |

| PDADMAC | PEDOT/PSS | Spin-coating | 0.048 | 2.9 | 0.03 (1.5 V, 1 Hz) | [43] |

| PVDF- EMIBF4 | MWCNT | Hot-pressing | 0.13 | 0.5 | 0.021 (2 V, 0.1 Hz) | [45] |

| MWCNT-Cellulose | Au | Plating | 0.015 | 1.5 | 0.003 (3 V, 1 Hz) | [50] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Y.; Cui, Q.; Wang, F. High-Performance Nanocellulose-Based Ionic Electroactive Soft Actuators. Actuators 2024, 13, 200. https://doi.org/10.3390/act13060200

Wu Y, Cui Q, Wang F. High-Performance Nanocellulose-Based Ionic Electroactive Soft Actuators. Actuators. 2024; 13(6):200. https://doi.org/10.3390/act13060200

Chicago/Turabian StyleWu, Yujiao, Qiyuan Cui, and Fan Wang. 2024. "High-Performance Nanocellulose-Based Ionic Electroactive Soft Actuators" Actuators 13, no. 6: 200. https://doi.org/10.3390/act13060200

APA StyleWu, Y., Cui, Q., & Wang, F. (2024). High-Performance Nanocellulose-Based Ionic Electroactive Soft Actuators. Actuators, 13(6), 200. https://doi.org/10.3390/act13060200