Design and Optimization of a Permanent Magnet-Based Spring–Damper System

Abstract

1. Introduction

2. Modeling

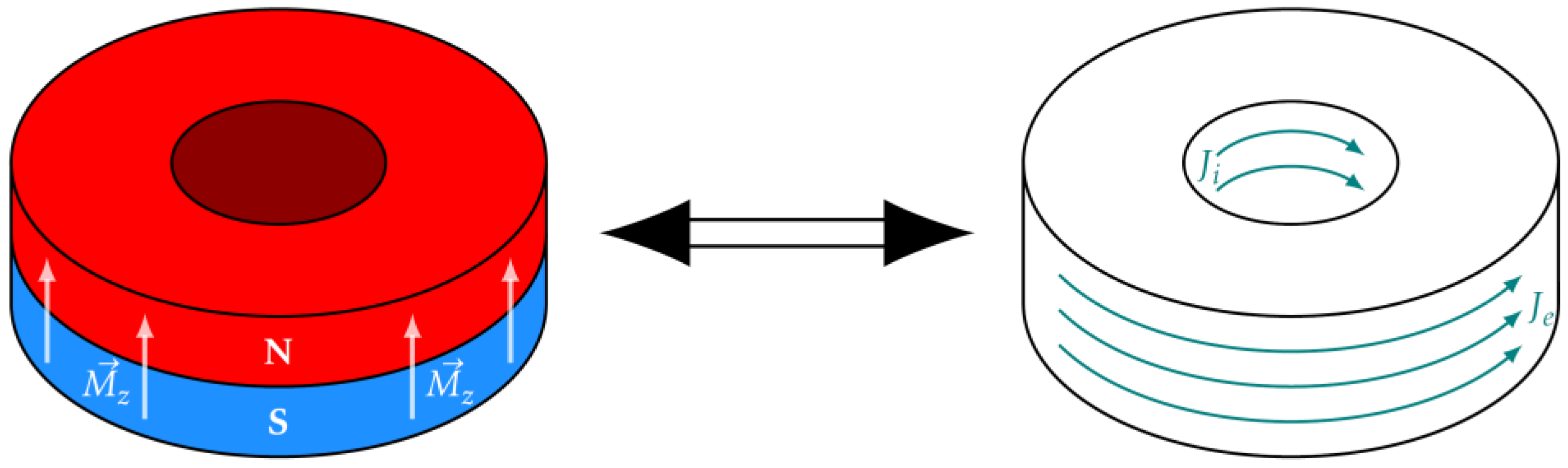

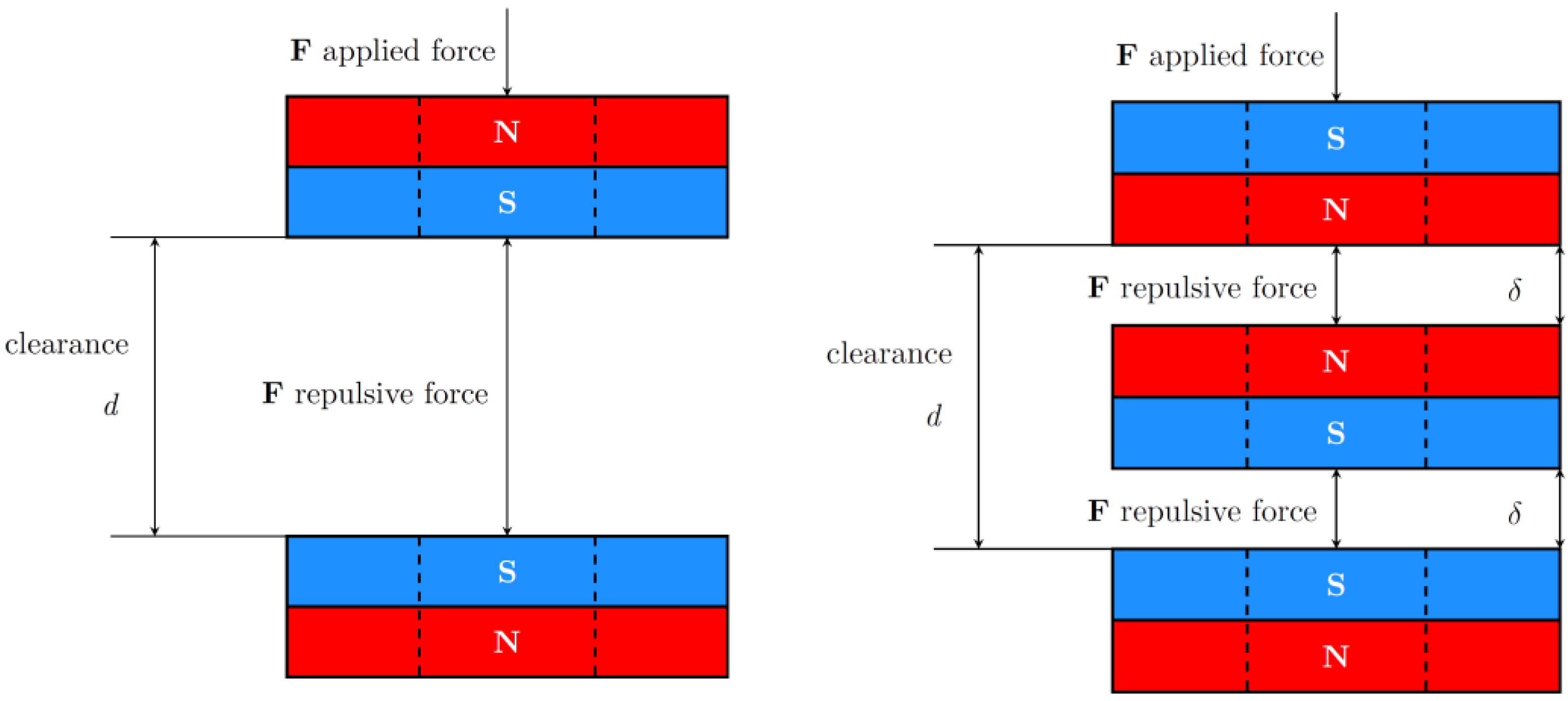

2.1. Analyzed Geometry

2.2. Model Development and Implementation

- (a)

- (b)

- Connecting the centers of near elements (red dots in the upper-right corner drawing of Figure 3) to form a 3D-structured grid (red segments);

- (c)

- Associate with each segment of the grid a new elementary volume highlighted in light red (upper-right corner of Figure 3); the current density in each new volume has the same direction as the segment; intersections of new elementary volumes (up to three) mean that the current density has more than one component;

- (d)

- Writing of Ohm’s law: the pointwise version of Ohm’s law is written in every new elementary volume of the conductive regions, and it is integrated along the current direction and averaged on the cross-section;

- (e)

- Arrangement in an electric network: as a result of point (b), a set of equations is obtained that can be seen as the voltage–current equation of a branch that is a series connection of a resistor, an inductor coupled with other inductors, and a voltage generator controlled by the currents in other elementary volumes;

- (f)

- Writing of the governing electro-mechanical equations: mesh analysis is adopted to write the governing equation of the electric network, while Newton’s law is written for the mechanical analysis.

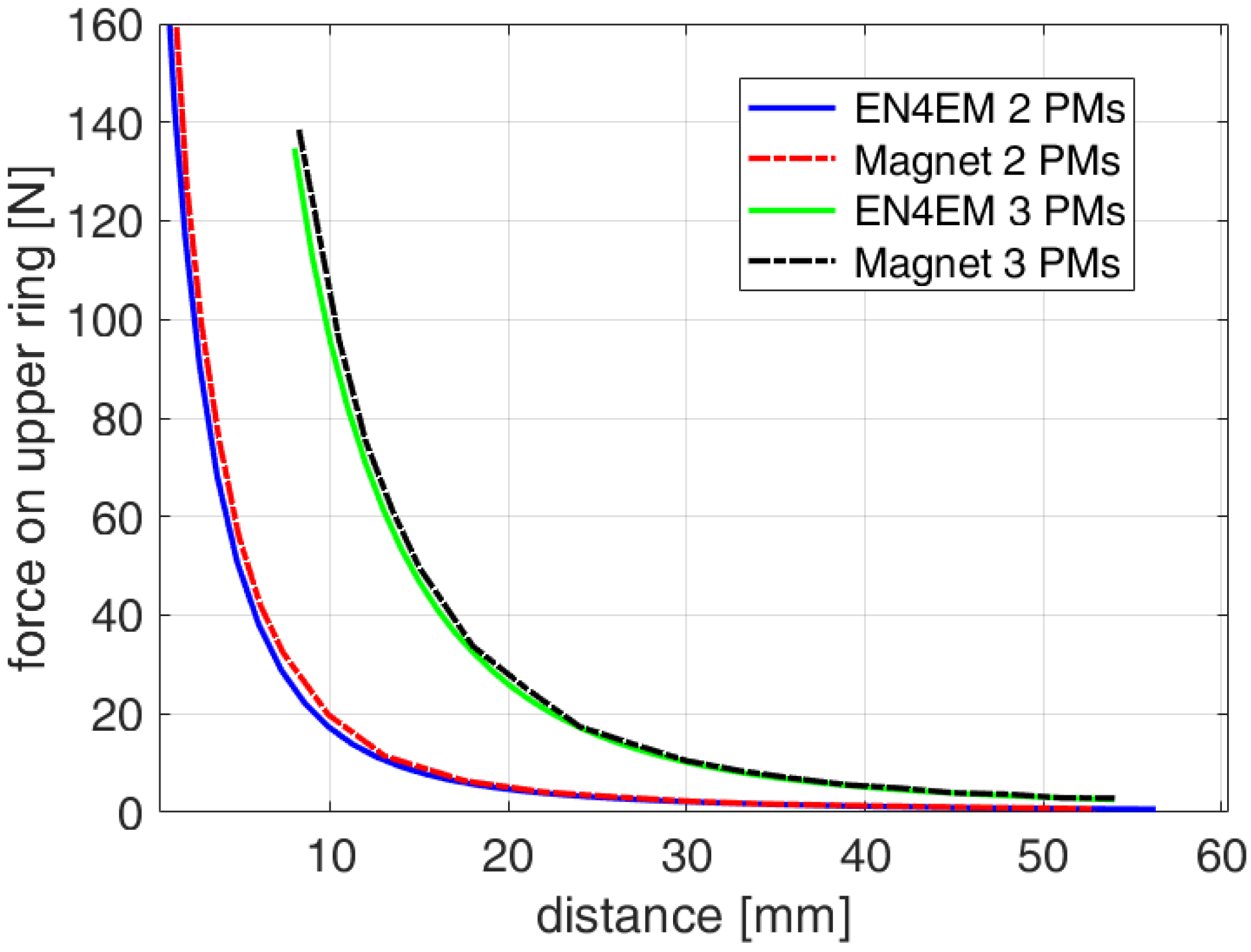

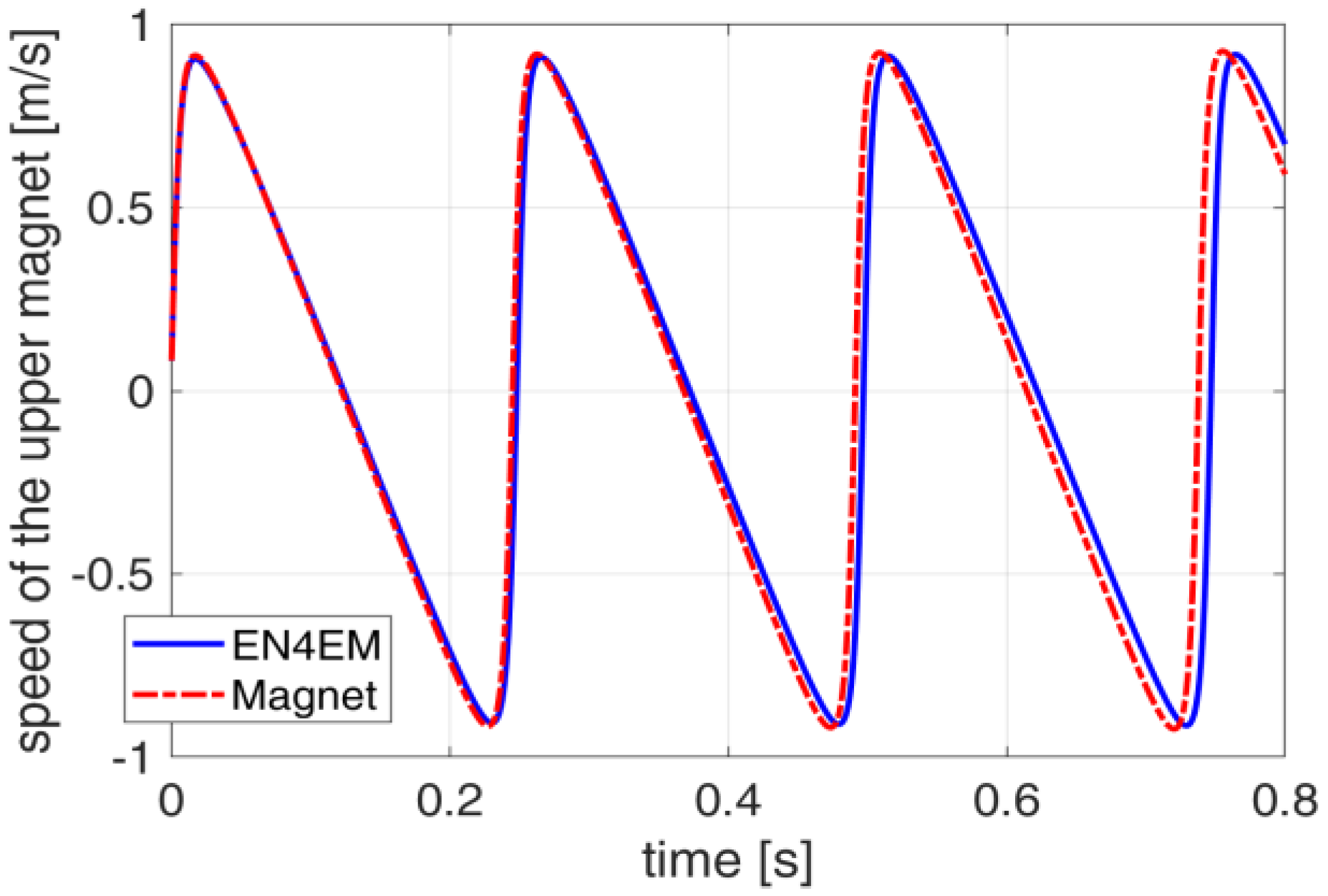

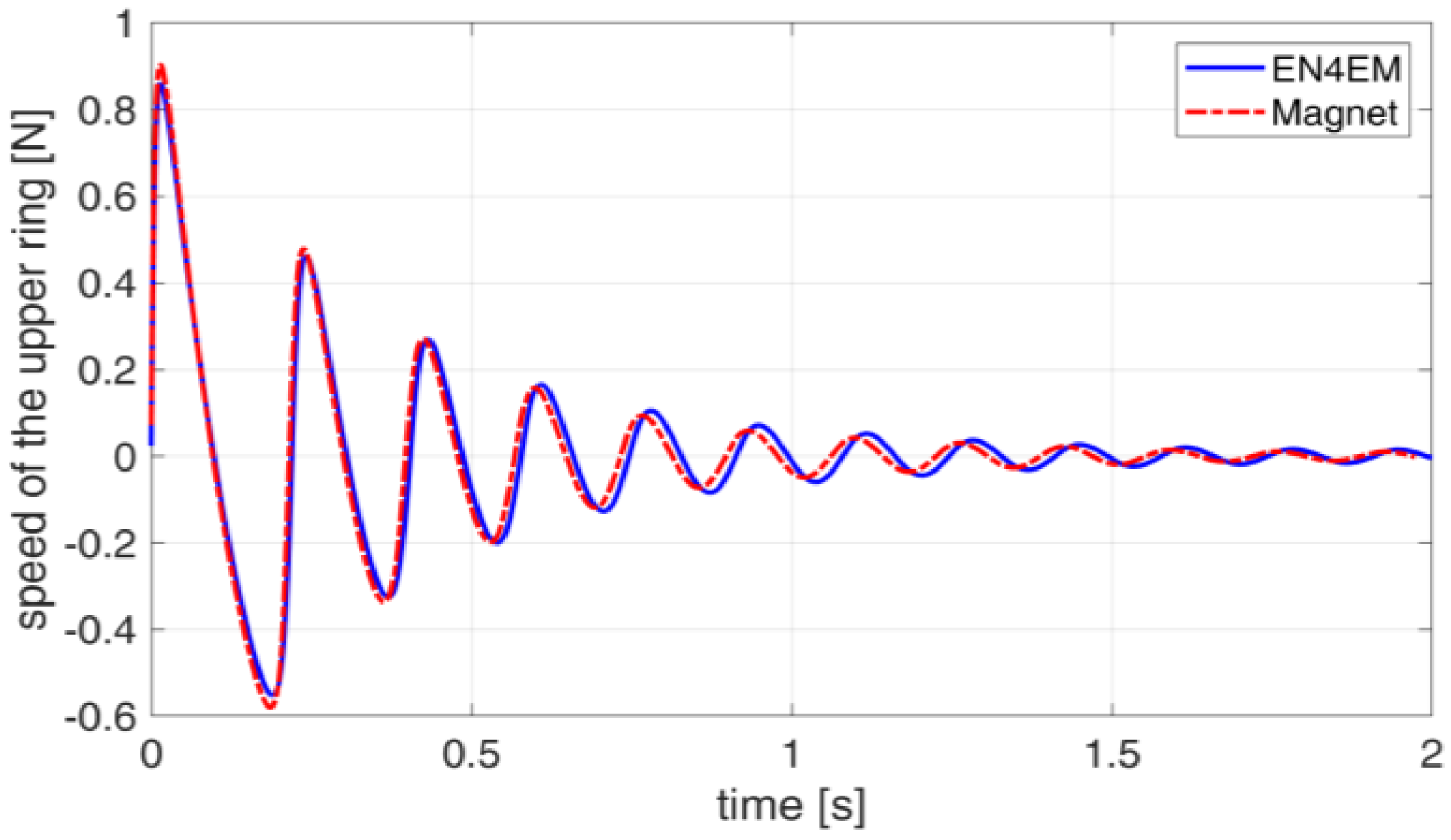

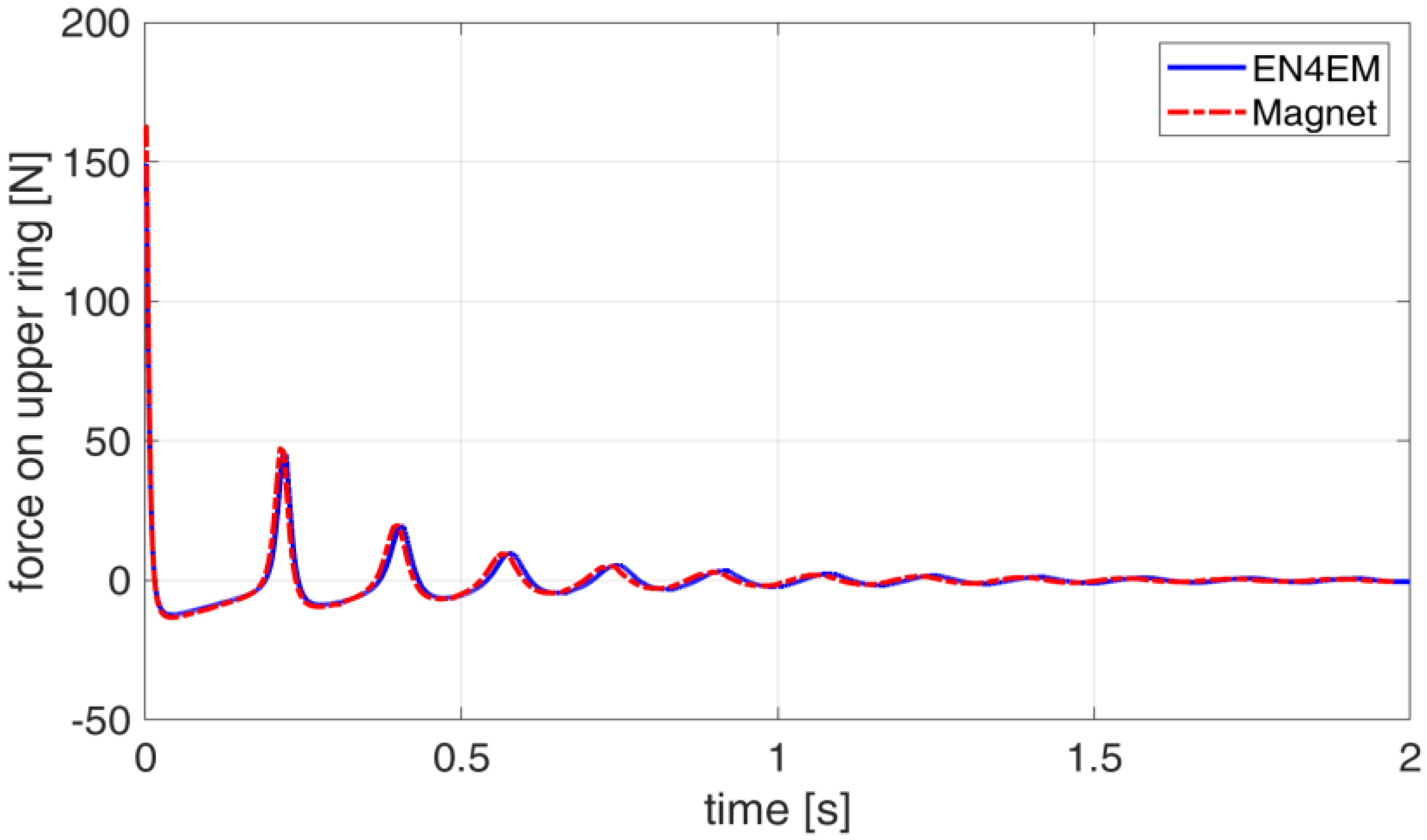

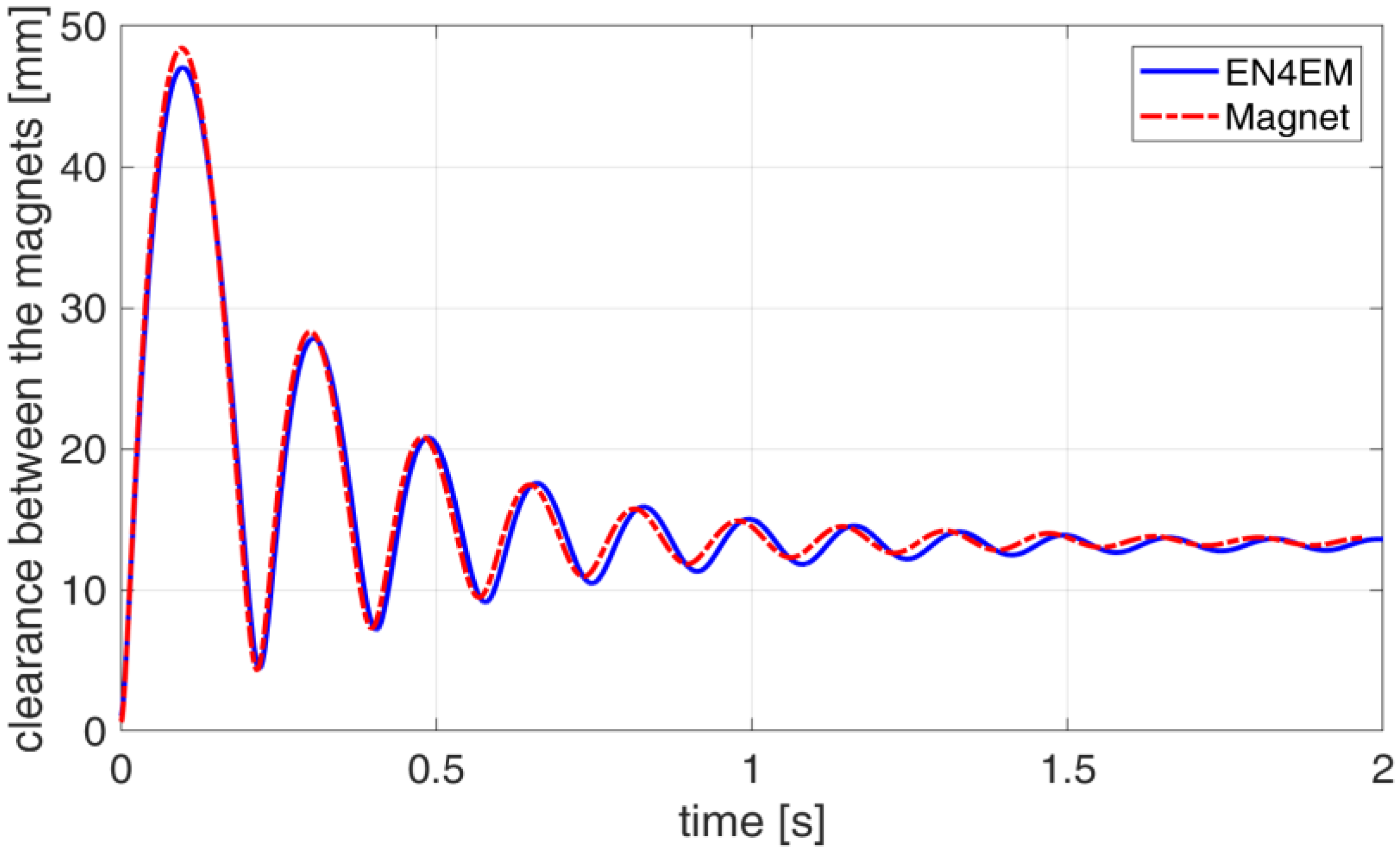

2.3. Validation of the Model

3. Optimization Procedure

3.1. Cost Function

3.2. Optimization Technique

- Initialization of the SOM: definition of a set of centroids belonging to the space of solutions;

- Evaluation of the cost function in all of the defined centroids;

- Evaluation of the fitness function: the winner centroid is the one with the minimum associated fitness function;

- Perturbation of all the centroids: the values of the centroids are perturbated to find any local minima of the associated fitness function;

- The process restarts by updating the values of the centroids considering the winner centroid found in the last step, and the local minima observed perturbating the previous centroids.

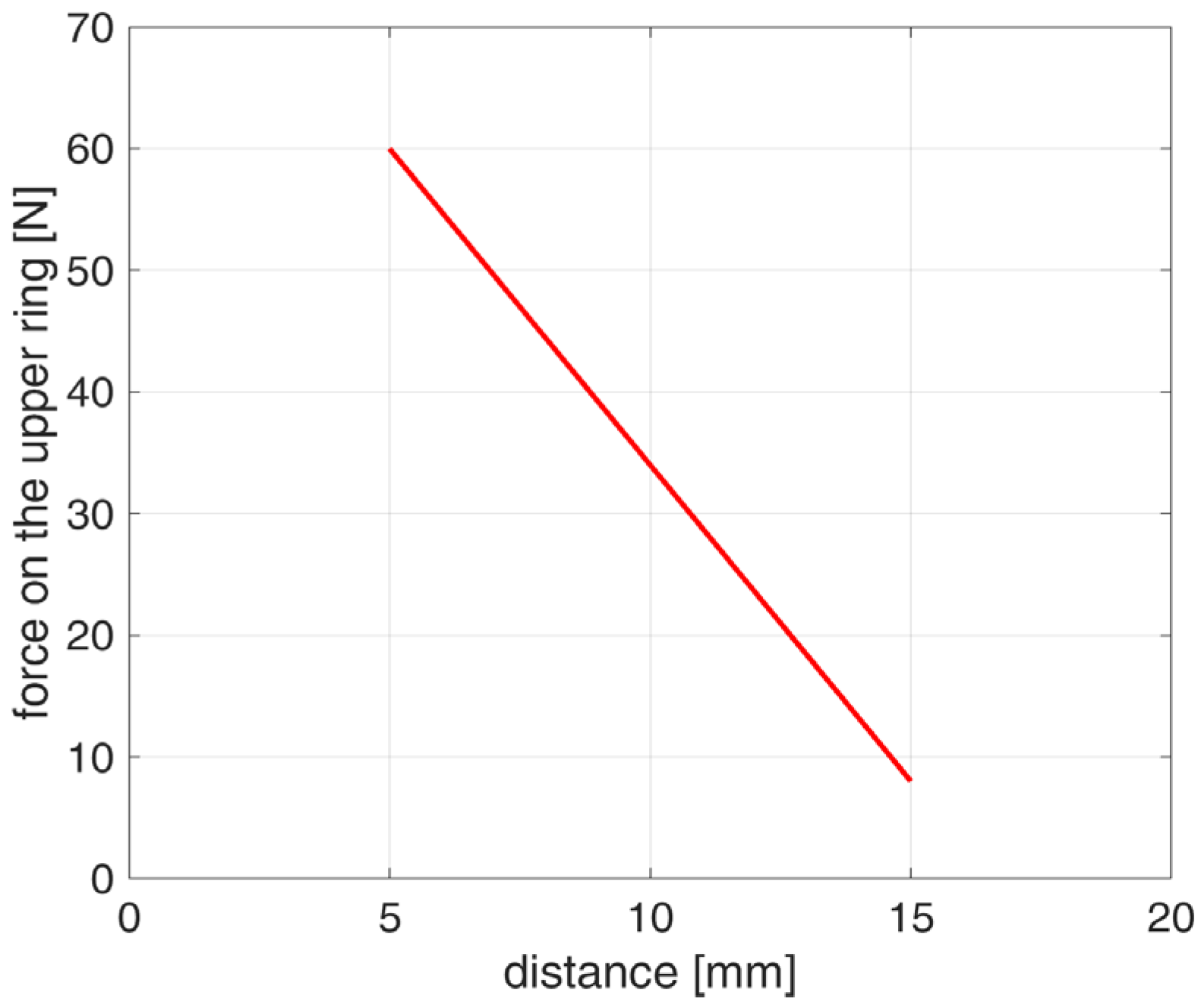

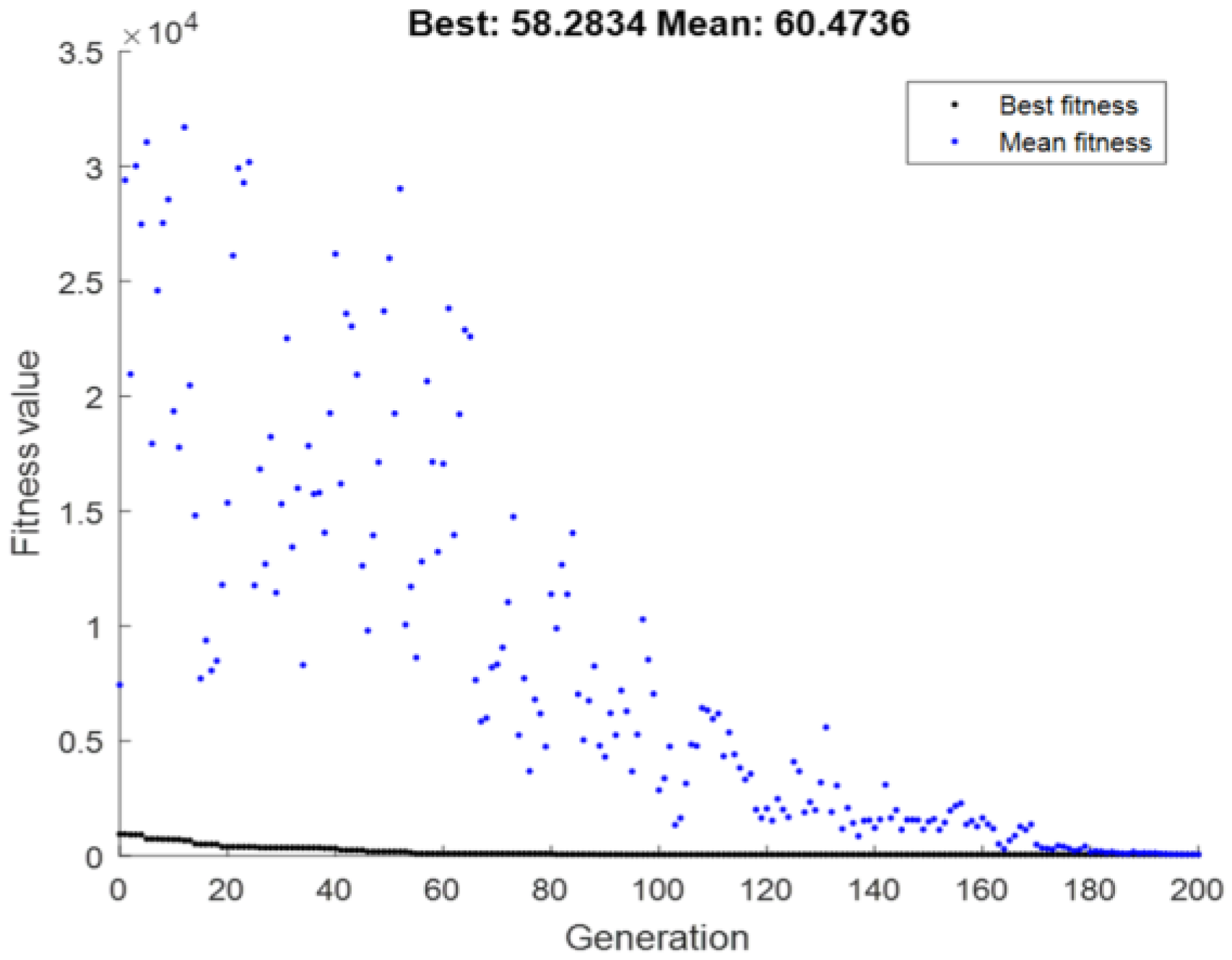

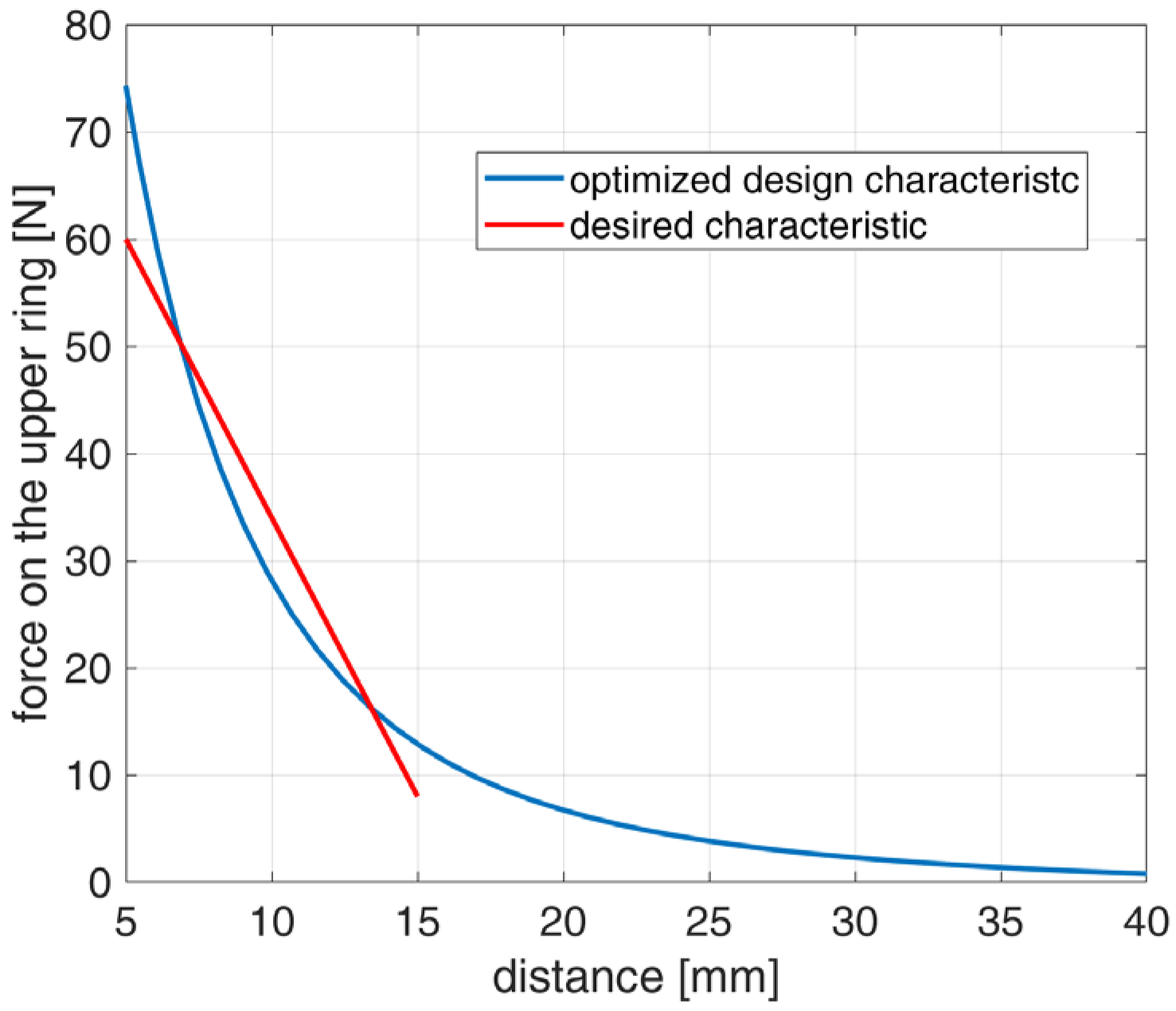

3.3. Optimized Result

- The global optimum improves by a quantity smaller than a given tolerance for a fixed number of iterations;

- The number of iterations performed overtakes a maximum value.

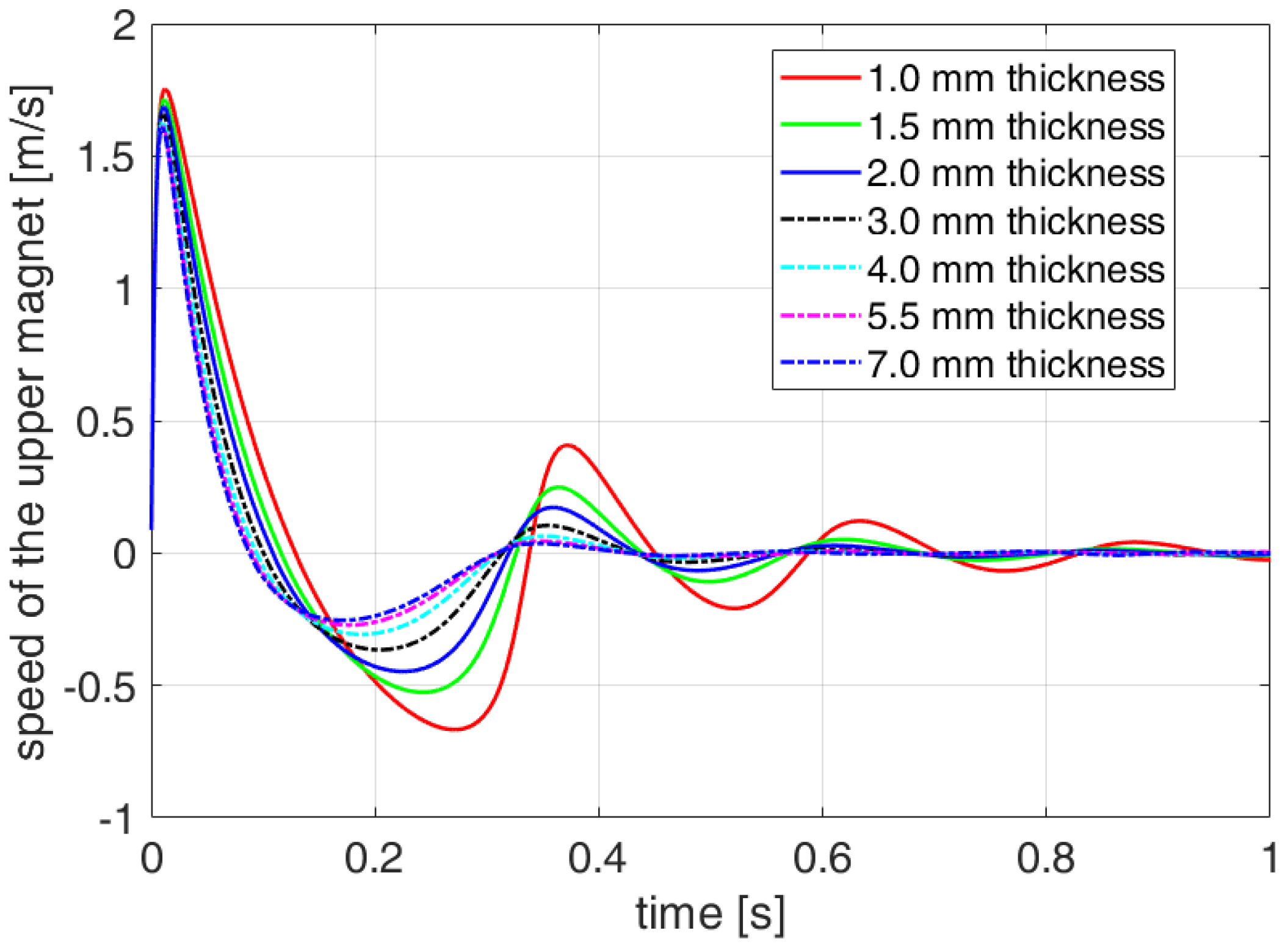

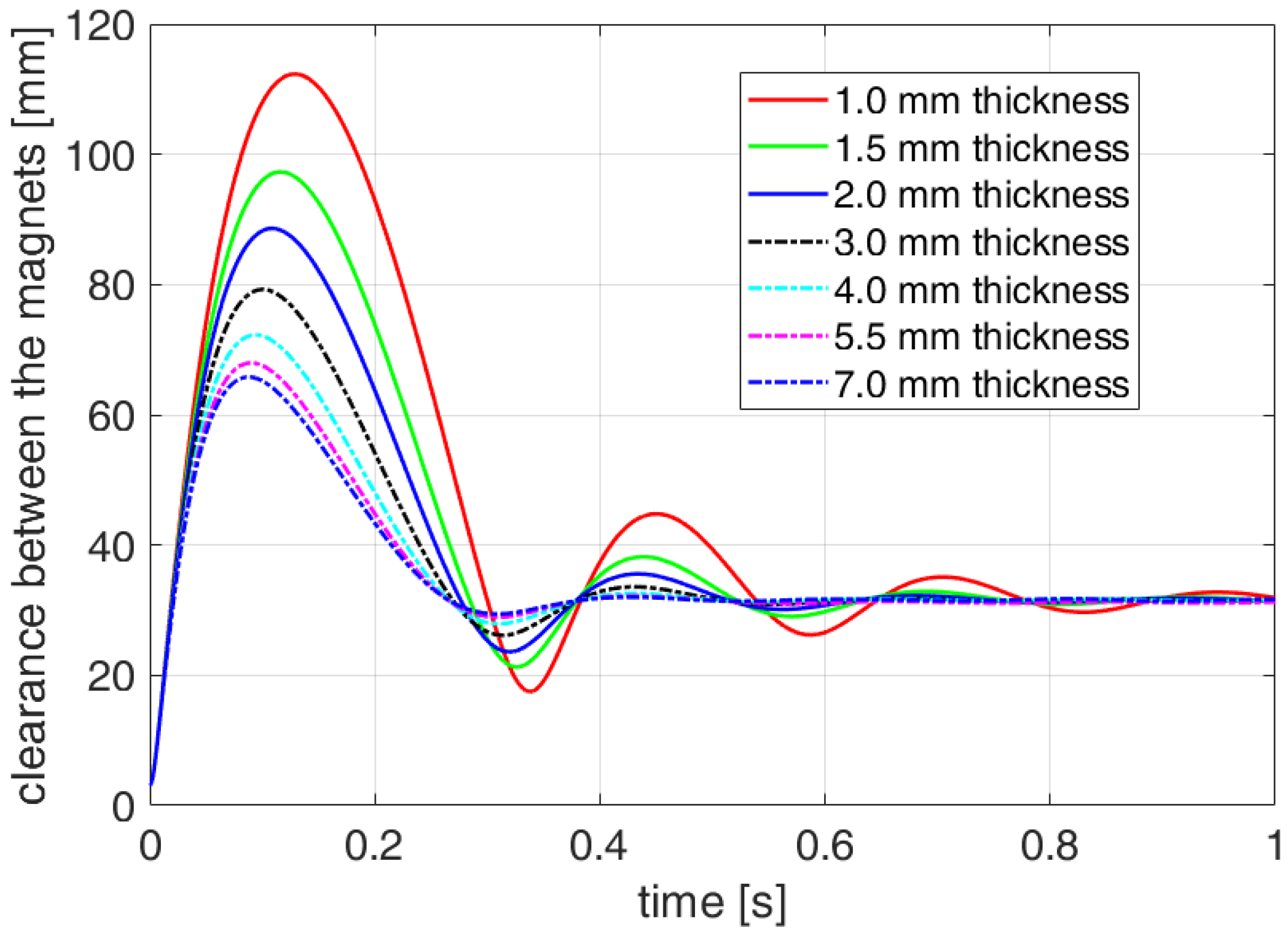

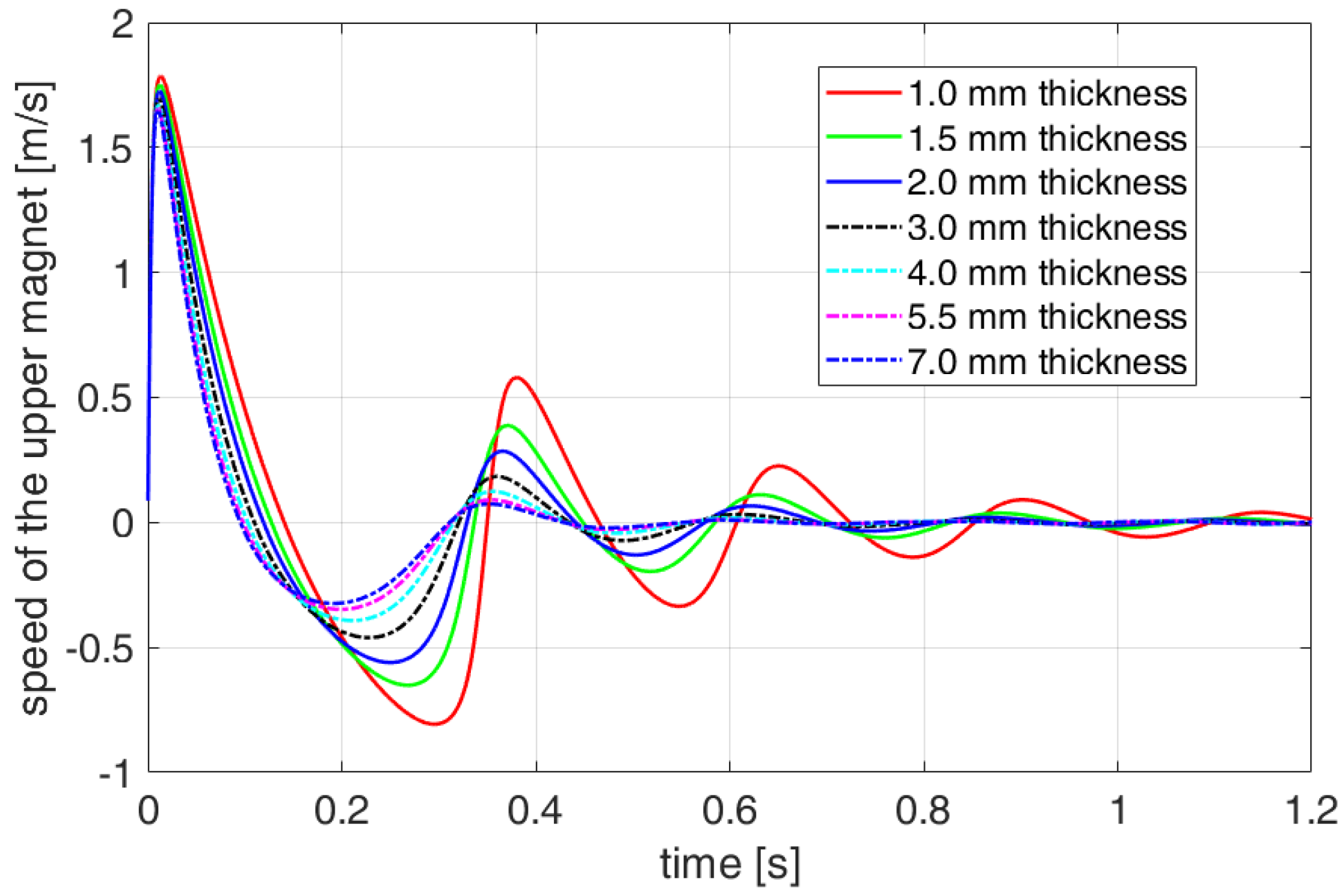

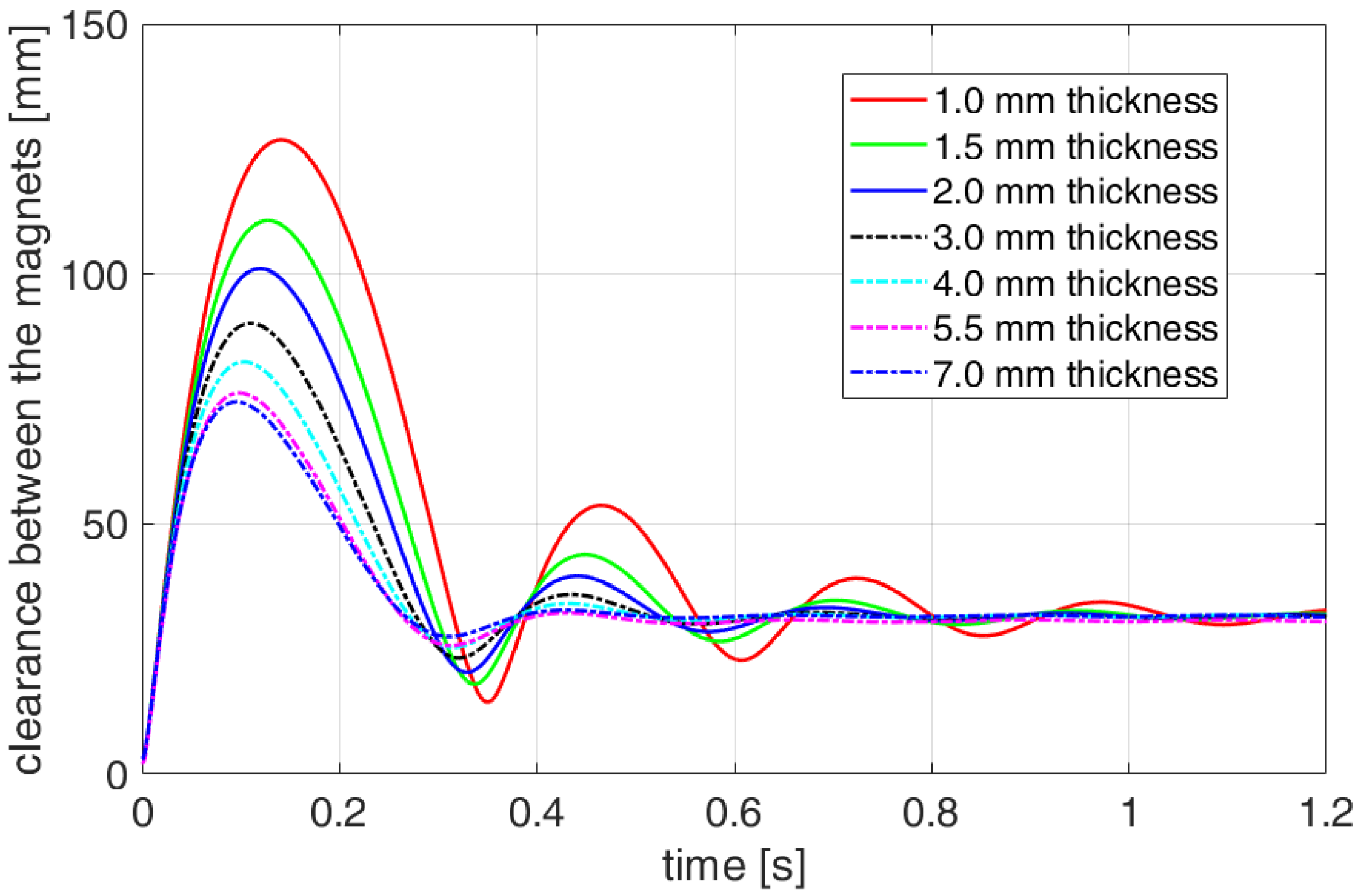

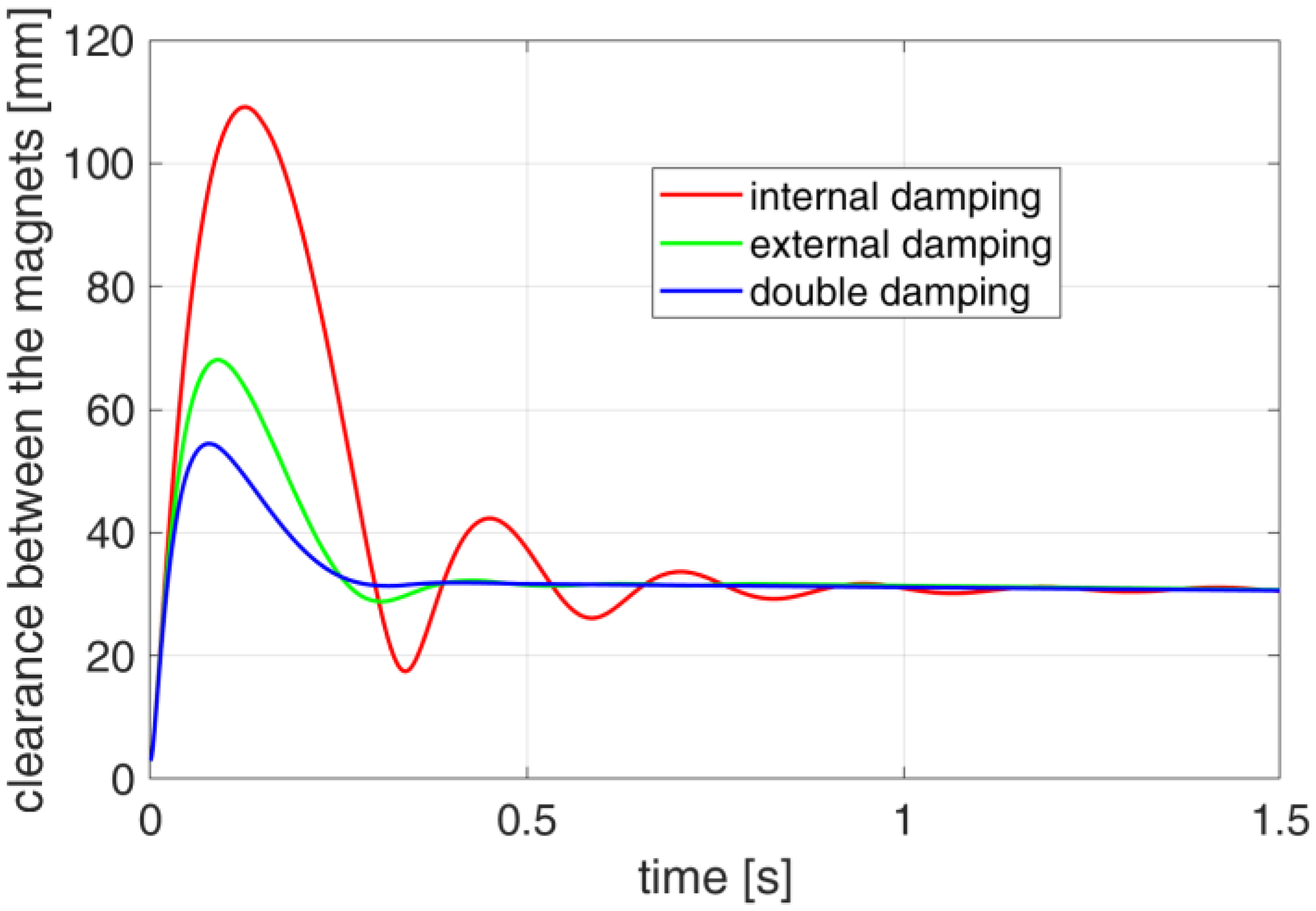

4. Eddy Current Damping

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Qian, K.-X.; Zeng, P.; Ru, W.-M.; Yuan, H.-Y. Novel magnetic spring and magnetic bearing. IEEE Trans. Magn. 2003, 39, 559–561. [Google Scholar] [CrossRef]

- Robertson, W.; Cazzolato, B.; Zander, A. A Multipole Array Magnetic Spring. IEEE Trans. Magn. 2005, 41, 3826–3828. [Google Scholar] [CrossRef]

- Xu, D.; Yu, Q.; Zhou, J.; Bishop, S.R. Theoretical and experimental analyses of a nonlinear magnetic vibration isolator with quasi-zero-stiffness characteristic. J. Sound Vib. 2013, 332, 3377–3389. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, B.; Li, J.; Wang, Y. Model and Experimental Research on an Electromagnetic Vibration-Powered Generator with Annular Permanent Magnet Spring. IEEE Trans. Appl. Supercond. 2012, 22, 5201504. [Google Scholar] [CrossRef]

- Diez-Jimenez, E.; Montero, R.S.; Muñoz, M.M. Towards Miniaturization of Magnetic Gears: Torque Performance Assessment. Micromachines 2017, 9, 16. [Google Scholar] [CrossRef] [PubMed]

- Paden, B.; Groom, N.; Antaki, J.F. Design Formulas for Permanent-Magnet Bearings. J. Mech. Des. 2003, 125, 734–738. [Google Scholar] [CrossRef]

- Poltschak, F.; Ebetshuber, P. Design of Integrated Magnetic Springs for Linear Oscillatory Actuators. IEEE Trans. Ind. Appl. 2018, 54, 2185–2192. [Google Scholar] [CrossRef]

- Perez-Diaz, J.L.; Diez-Jimenez, E.; Valiente-Blanco, I.; Cristache, C.; Alvarez-Valenzuela, M.-A.; Sanchez-Garcia-Casarrubios, J.; Ferdeghini, C.; Canepa, F.; Hornig, W.; Carbone, G.; et al. Performance of Magnetic-Superconductor Non-Contact Harmonic Drive for Cryogenic Space Applications. Machines 2015, 3, 138–156. [Google Scholar] [CrossRef]

- Furlani, E.P. A formula for the levitation force between magnetic disks. IEEE Trans. Magn. 1993, 29, 4165–4169. [Google Scholar] [CrossRef]

- Vokoun, D.; Beleggia, M.; Heller, L.; Šittner, P. Magnetostatic interactions and forces between cylindrical permanent magnets. J. Magn. Magn. Mater. 2009, 321, 3758–3763. [Google Scholar] [CrossRef]

- Robertson, W.; Cazzolato, B.; Zander, A. A Simplified Force Equation for Coaxial Cylindrical Magnets and Thin Coils. IEEE Trans. Magn. 2011, 47, 2045–2049. [Google Scholar] [CrossRef]

- Bonisoli, E.; Vigliani, A. Identification techniques applied to a passive elasto-magnetic suspension. Mech. Syst. Signal Process. 2007, 21, 1479–1488. [Google Scholar] [CrossRef]

- Barmada, S.; Raugi, M.; Tucci, M. An evolutionary algorithm for global optimization based on self-organizing maps. Eng. Optim. 2016, 48, 1740–1758. [Google Scholar] [CrossRef]

- Tucci, M.; Sani, L.; Di Dio, V. Optimization of a novel magneto-rheological device with permanent magnets. Prog. Electromagn. Res. M 2017, 62, 175–188. [Google Scholar] [CrossRef]

- Musolino, A.; Raugi, M.; Rizzo, R.; Tucci, M. Force optimization of a double-sided tubular linear induction motor. IEEE Trans. Magn. 2014, 50, 1–11. [Google Scholar] [CrossRef]

- Musolino, A.; Raugi, M.; Rizzo, R.; Tucci, M. Optimal design of EMALS based on a double-sided tubular linear induction motor. IEEE Trans. Plasma Sci. 2015, 43, 1326–1331. [Google Scholar] [CrossRef]

- Williams, C.B.; Yates, R.B. Analysis of a micro-electric generator for microsystems. Sens. Actuators A Phys. 1996, 52, 8–11. [Google Scholar] [CrossRef]

- Carneiro, P.; Soares dos Santos, M.P.; Rodrigues, A.; Ferreira, J.A.; Simões, J.A.; Marques, A.T.; Kholkin, A.L. Electromagnetic energy harvesting using magnetic levitation architectures: A review. Appl. Energy 2020, 260, 114191. [Google Scholar] [CrossRef]

- Tonoli, A.; Amati, N. Dynamic modeling and experimental validation of eddy current dampers and couplers. J. Vib. Acoust. 2008, 130, 021011. [Google Scholar] [CrossRef]

- Yao, H.; Wang, T.; Wen, B.; Qiu, B. A tunable dynamic vibration absorber for unbalanced rotor system. J. Mech. Sci. Technol. 2018, 32, 1519–1528. [Google Scholar] [CrossRef]

- Diez-Jimenez, E.; Alén-Cordero, C.; Alcover-Sánchez, R.; Corral-Abad, E. Modelling and test of an integrated magnetic spring-eddy current damper for space applications. Actuators 2021, 10, 8. [Google Scholar] [CrossRef]

- Bae, J.S.; Hwang, J.H.; Roh, J.H.; Yi, M.S. Development of an electromagnetic shock absorber. Int. J. Appl. Electromagn. Mech. 2015, 49, 157–167. [Google Scholar] [CrossRef]

- Zhu, X.; Jing, X.; Cheng, L. Magnetorheological fluid dampers: A review on structure design and analysis. J. Intell. Mater. Syst. Struct. 2012, 23, 839–873. [Google Scholar] [CrossRef]

- Wang, D.H.; Liao, W.H. Magnetorheological fluid dampers: A review of parametric modelling. Smart Mater. Struct. 2011, 20, 023001. [Google Scholar] [CrossRef]

- Zhang, X.; Xia, X.; Xiang, Z.; You, Y.; Li, B. An online active balancing method using magnetorheological effect of magnetic fluid. J. Vib. Acoust. 2019, 141, 011008. [Google Scholar] [CrossRef]

- Valiente-Blanco, I.; Cristache, C.; Sanchez-Garcia-Casarrubios, J.; Rodriguez-Celis, F.; Perez-Diaz, J.L. Mechanical impedance matching using a magnetic linear gear. Shock Vib. 2017, 2017, 7679390. [Google Scholar] [CrossRef]

- Perez-Diaz, J.L.; Valiente-Blanco, I.; Cristache, C.; Sanchez-García-Casarubios, J.; Rodriguez, F.; Esnoz, J.; Diez-Jimenez, E. A novel high temperature eddy current damper with enhanced performance by means of impedance matching. Smart Mater. Struct. 2019, 28, 025034. [Google Scholar] [CrossRef]

- Ebrahimi, B.; Khamesee, M.B.; Golnaraghi, F. Eddy current damper feasibility in automobile suspension: Modeling, simulation and testing. Smart Mater. Struct. 2008, 18, 015017. [Google Scholar] [CrossRef]

- Tripodi, E.; Musolino, A.; Rizzo, R.; Raugi, M. A new predictor–corrector approach for the numerical integration of coupled electromechanical equations. Int. Jour. Numer. Methods Eng. 2016, 105, 261–285. [Google Scholar] [CrossRef]

- Musolino, A.; Raugi, M.; Rizzo, R.; Sani, L.; Di Dio, V. Electromechanical Numerical Analysis of an Air-Core Pulsed Alternator via Equivalent Network Formulation. IEEE Trans. Plasma Sci. 2017, 45, 1429–1435. [Google Scholar] [CrossRef]

- Musolino, A.; Rizzo, R.; Sani, L.; Tripodi, E. Null-flux coils in permanent magnets bearings. IEEE Trans. Plasma Sci. 2017, 45, 1545–1552. [Google Scholar] [CrossRef]

- Azzerboni, B.; Cardelli, E.; Tellini, A. Computation of the magnetic field in massive conductor systems. IEEE Trans. Magn. 1989, 25, 4462–4473. [Google Scholar] [CrossRef]

- Azzerboni, B.; Cardelli, E.; Raugi, M.; Tellini, A.; Tina, G. Analytic expressions for magnetic field from finite curved conductors. IEEE Trans. Magn. 1991, 27, 750–757. [Google Scholar] [CrossRef]

- Musolino, A. Numerical analysis of a rail launcher with a multilayered armature. IEEE Trans. Plasma Sci. 2011, 39, 788–793. [Google Scholar] [CrossRef]

- Consolo, V.; Musolino, A.; Rizzo, R.; Sani, L. Numerical 3D simulation of a full system air core compulsator-electromagnetic rail launcher. Appl. Sci. 2020, 10, 5903. [Google Scholar] [CrossRef]

- Di Dio, V.; Sani, L. Coupled electromechanical analysis of a permanent-magnet bearing. Appl. Comput. Electromagn. Soc. J. 2017, 32, 736–741. [Google Scholar]

- Musolino, A.; Raugi, M.; Rizzo, R.; Tripodi, E. Stabilization of a permanent-magnet MAGLEV system via null-flux coils. IEEE Trans. Plasma Sci. 2015, 43, 1242–1247. [Google Scholar] [CrossRef]

- Available online: https://plm.sw.siemens.com/en-US/simcenter/electromagnetics-simulation/magnet/ (accessed on 16 June 2023).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gori, N.; Simonelli, C.; Musolino, A.; Rizzo, R.; Díez Jiménez, E.; Sani, L. Design and Optimization of a Permanent Magnet-Based Spring–Damper System. Actuators 2023, 12, 291. https://doi.org/10.3390/act12070291

Gori N, Simonelli C, Musolino A, Rizzo R, Díez Jiménez E, Sani L. Design and Optimization of a Permanent Magnet-Based Spring–Damper System. Actuators. 2023; 12(7):291. https://doi.org/10.3390/act12070291

Chicago/Turabian StyleGori, Nicolò, Claudia Simonelli, Antonino Musolino, Rocco Rizzo, Efren Díez Jiménez, and Luca Sani. 2023. "Design and Optimization of a Permanent Magnet-Based Spring–Damper System" Actuators 12, no. 7: 291. https://doi.org/10.3390/act12070291

APA StyleGori, N., Simonelli, C., Musolino, A., Rizzo, R., Díez Jiménez, E., & Sani, L. (2023). Design and Optimization of a Permanent Magnet-Based Spring–Damper System. Actuators, 12(7), 291. https://doi.org/10.3390/act12070291