Strain Characteristics of PLZT-Based Ceramics for Actuator Applications

Abstract

1. Introduction

2. Processing and Properties of PLZT-Based Ceramics

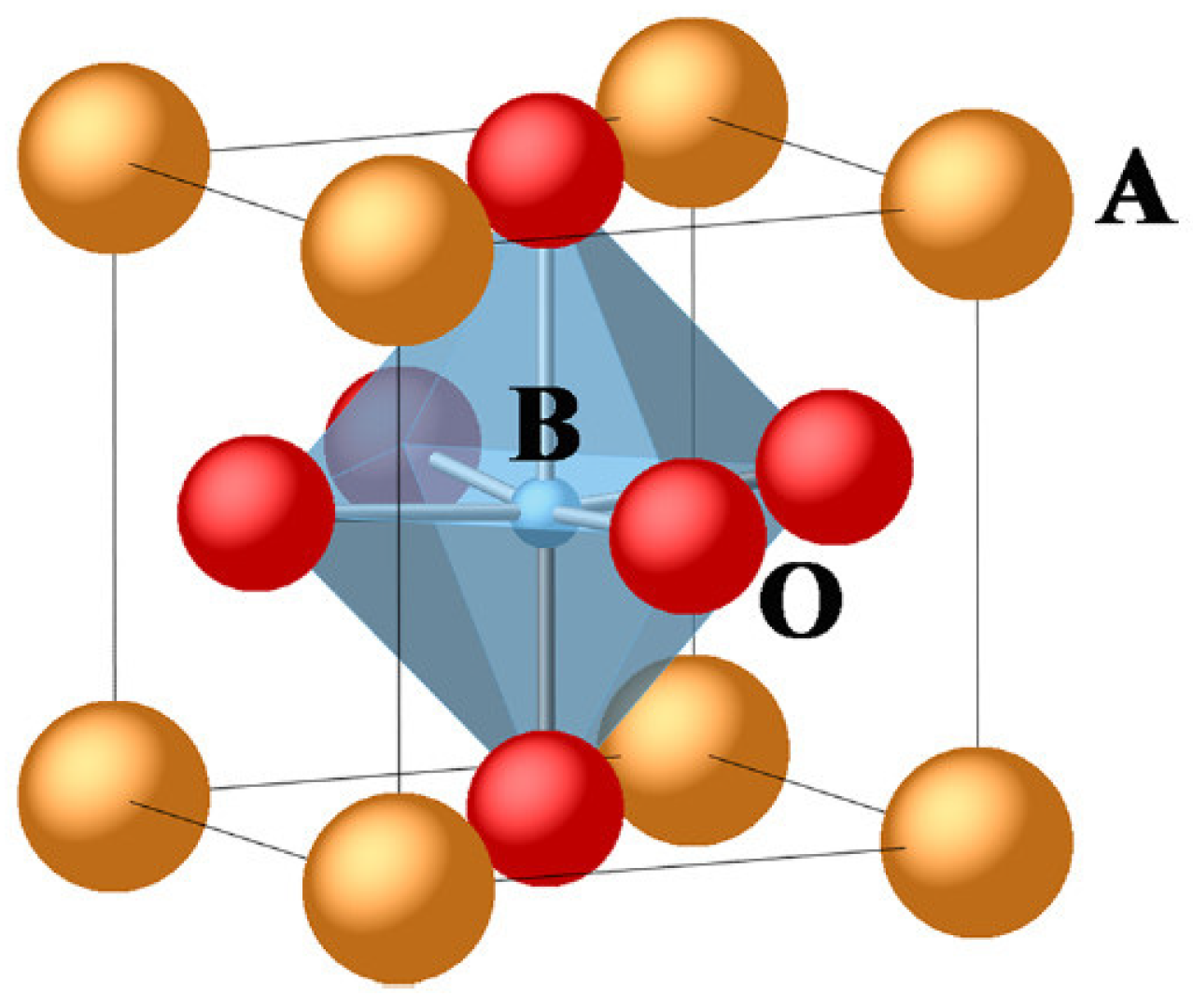

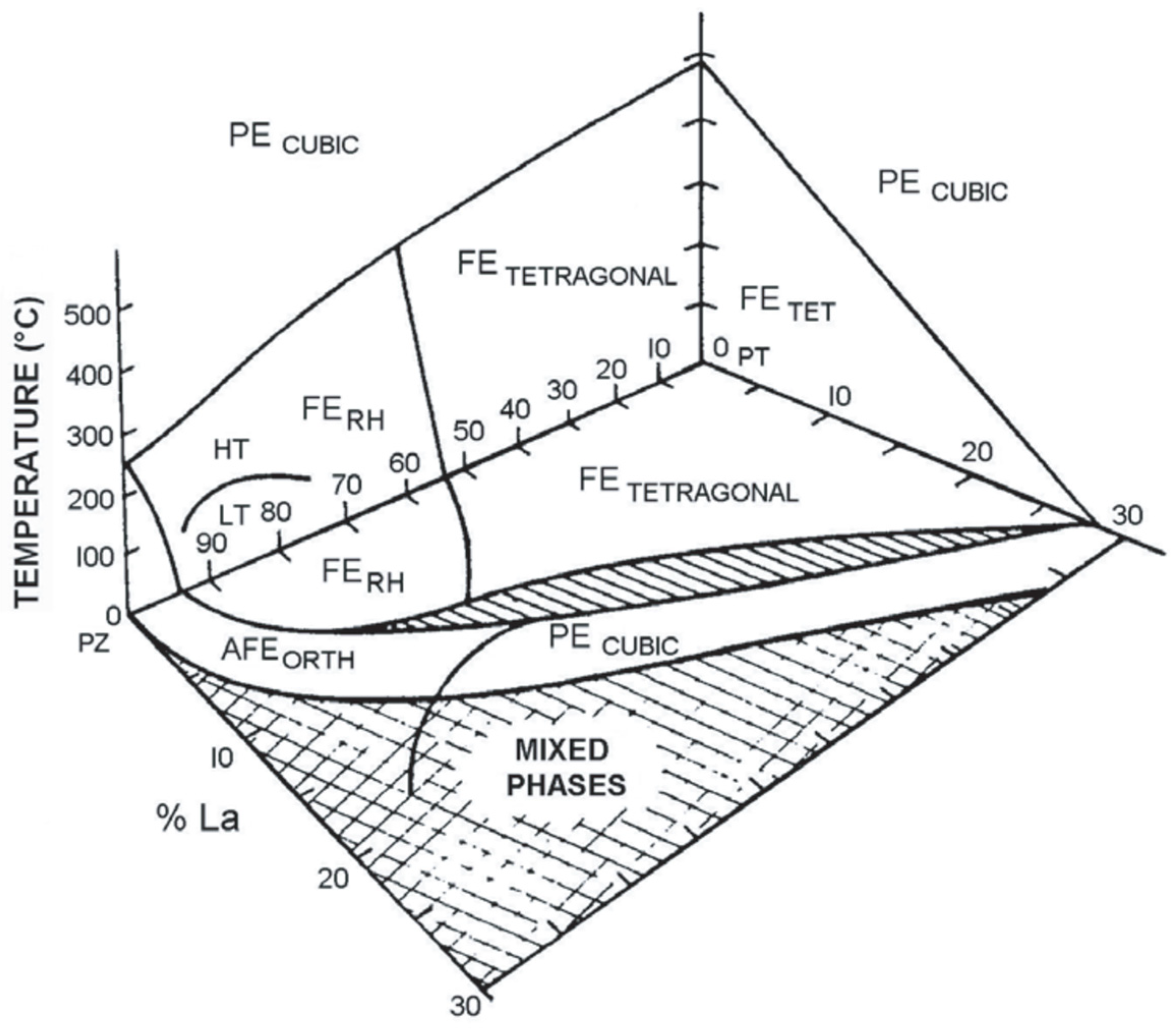

2.1. PLZT Ceramics

2.2. Grain Boundary Complexions and Pore Structure

2.3. Tailoring Microstructure and Properties of PLZT Ceramics

2.3.1. Sintering Aids

2.3.2. Composites

| PLZT Composition (Matrix) | Reinforcement (Amount) | Remarks * | Ref. |

|---|---|---|---|

| Magnetoelectric 10/65/35 7/60/40 7/60/40 0-3/65/35 2/90/10 | |||

| BiFeO3 (10–100 mol%) | Ms = 0.5 emu/g | [44] | |

| NiFe2O4 (15–100 mol%) Ni0.8Zn0.2Fe2O4 (15–100 mol%) Ni0.8Zn0.2Fe2O4 (10 mol%) Ni0.64Zn0.36Fe2O4 (10 mol%) | Ps = 40.879 μC/cm2, Pr = 31.157 μC/cm2 Ms = 35.00 emu/g, Mr = 16.392 emu/g Ps = 39.871 μC/cm2, Pr = 31.708 μC/cm2 Ms = 38.36 emu/g, Mr = 19.096 emu/g Ps = 5.4 μC/cm2, Pr = 1.8 μC/cm2 d33 = 89 pC/N Pr = 18.15 μC/cm2 εr = 8633 | [45] [46] [47] [48] | |

| Structural 5/53/47 5/95/5 9/70/30 9/65/35 9/60/40 | |||

| Al2O3 (0–8 vol%) SiO2 (1–4 wt%) ZrO2 (8.6–27.5 mol%) | fr, fa ↓ Wre = 2.29 J/cm3 Smax = 0.076% εr = 10,539 Ps = 40.81 μC/cm2, Pr = 29.05 μC/cm2 | [49] [50] [52] | |

| Electrical 4/70/30 3/54/46 8/40/60 9/65/35 8/20/80 | |||

| SrBi2Ta2O9 (2.5–10 vol%) PZN (30 mol%) PZN (5–25 mol%) BT (5–25 mol%) BT (50 mol%) | electrical fatigue ↑ εr = 17,000, n = 2.569 εr = 14,290 εr = 10,463 εr ~ 4000 | [53] [54] [55] [56] |

2.3.3. Doping

| PLZT Composition | Dopant(s) | Remarks * | Ref. |

|---|---|---|---|

| Single A-site soft doping 8/69/31 10/53/47 8/60/40 10/55/45 8/65/35 8/65/35 10/65/35 8/60/40 8/65/35 8/65/35 7/82/18 9/65/35 8/65/35 6/57/43 6/57/43 7/65/35 8/60/40 8/60/40 10/65/35 8/65/35 Single A-site hard doping 12/70/30 | |||

| Bi (0.14, 0.28, 0.42 at%) Bi (1.0–7.0 at%) | Ps = 34.69 μC/cm2, Pr = 4.99 μC/cm2 εr = 8633, γ = 1.5 | [58] [59] | |

| Bi (2.4–8.0 at%) Bi (3.0–7.0 at%) Fe (0.01, 0.1, 1.0 wt%) Fe (2–10 at%) Fe (3.0–7.0 at%) Fe (7.2 at%) Mn (0.01, 0.1, 1.0 wt%) Mn (0.1–3.0 wt%) Mn (0.1–0.5 at%) Mn (0.5–3.0 wt%) Mn (4–20 at%) Cr (0.05, 0.11, 0.16 at%) Cr (0.05–1.08 at%) Cr (0.1–1.0 wt%) Al (2.4–8.0 at%) Ga (2.4–8.0 at%) Dy (0.02–0.06 at%) Nd (0.5–1.0 at%) Ag (1.0–3.0 at%) | εr = 17,044, γ = 1.68 εr = 19,340, γ = 1.90 εr ~ 13,000 εr ~ 2200, Pr, Ec ↓ εr = 5346, γ = 1.85 εr = 12,500 εr ~ 5000 εr = 8300 εr = 2128 εr = 1250, d33 = 190 pC/N Ps = 15.3 μC/cm2, Pr = 7.5 μC/cm2 εr = 37,780 εr = 2680 εr = 1608 εr = 13,760 fr, fa ↑ εr = 4850, γ = 1.77 εr ~ 6000 Ps = 30 μC/cm2, Pr = 0.2 μC/cm2 εr = 11,260 εr ↓ | [60] [61] [62] [63] [64] [66] [62] [67] [68] [69] [70] [71] [72] [73] [74] [75] [76] [77] [78] | |

| Single B-site soft doping x/52/48 (x = 2–16) 8/60/40 10/55/45 3/52/48 3/52/48 10/65/35 3/52/48 9/65/35 Single B-site hard doping 8/65/35 | |||

| Sb (1.5 wt%) Sb (2.4–8.0 at%) Sb (3.0–7.0 at%) W (0.2–1.0 at%) W (0.5 at%) W (0.5–2.0 at%) Ta (0.5–1.75 at%) Nb (0.5–1.5 at%) Cu (0.001–0.01 at%) | εr ~ 3600 εr = 4444, γ = 1.88 εr = 17,589, γ = 1.91 εr ~ 12,000, Pmax = 4.5 μW/cm2 εr = 12,700, d33 = 315 pm/V Transmittance ↓ εr ~ 13,900, Pmax = 6.0 μW/cm2 εr = 6078, γ = 1.93 εr ~ 12,600 Ps = 29.67 μC/cm2, Pr = 22.58 μC/cm2 | [79] [80] [81] [82] [5] [83] [82] [84] [85] | |

| Single A-site isovalent 9/65/35 1.2/55/45 Single B-site isovalent 9/65/35 2/94.5/5.5 x/85/15 (x = 2–8) 12/86/14 | |||

| Ba (1.0–4.0 at%) Ba (1.0–6.0 at%) Sn (0.2–0.6 wt%) Sn (9.5–29.5 at%) Sn (20 at%) Sn (8.6–52.8 at%)+ 8.0 wt% PbO + 2.5 wt% ZnO | εr = 8034, γ = 1.75 εr = 32,000 Ps = 33.4 μC/cm2, Pr = 2.25 μC/cm2 εr ~ 3500 εr ~ 12,500, Ps = 40.5 μC/cm2 εr ~ 700, Wre = 3.5 J/cm3 | [86] [19] [87] [88] [89] [90] | |

| Co-doping isovalent 4/85/15 2/65/35 Co-doping aliovalent 8/65/35 9/65/35 9/65/35 8/60/40 8/55/45 8/50/50 2/52/48 1/53/47 7/82/18 | |||

| Ba (4 at%) + Sn (34 at%) Ba (8 at%) + Sr (2 at%) + Sn (27 at%) Na/B, Na/Bi, Li/Bi (0.5 wt%) Li/Bi (0.15–0.75 at%) Bi/Cu (0.25–1.0 wt%) Mn (10 at%) + Fe (10 at%) Nb/Fe (2–8 at%) Sr (0.2–1.0 at%) + Mn (0.5 at%) Gd (1–2 at%) + Sn (4–8 at%) | Ps = 25.65 μC/cm2, Wre = 0.47 J/cm3 εr ~ 2800 εr ~ 2000, 2700, 2200 εr = 7819, γ = 1.70 εr = 11,290, γ = 1.89 εr ~ 6000, γ = 1.51 εr ~ 26,000 εr = 10,974, d33 = 534 pC/N εr = 2994, γ = 1.65 | [91] [92] [93] [94] [95] [96] [97] [98] [99] |

3. Strain Measurement of PLZT-Based Ceramics

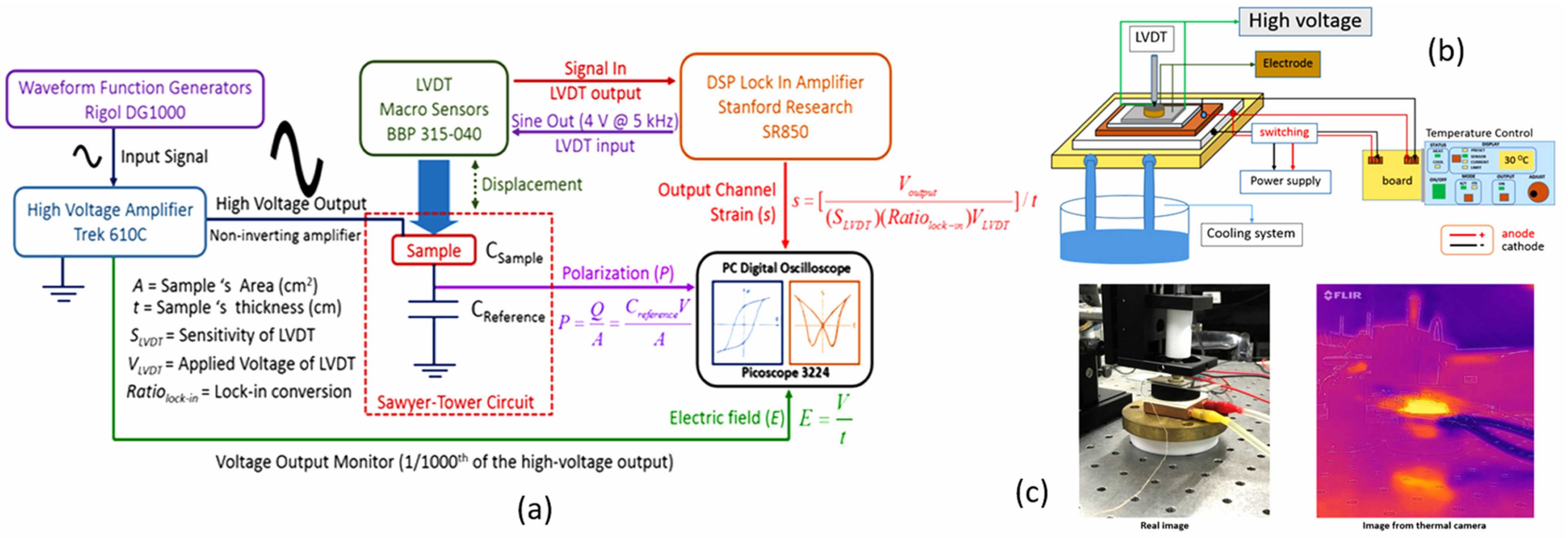

3.1. Strain Measurement Techniques

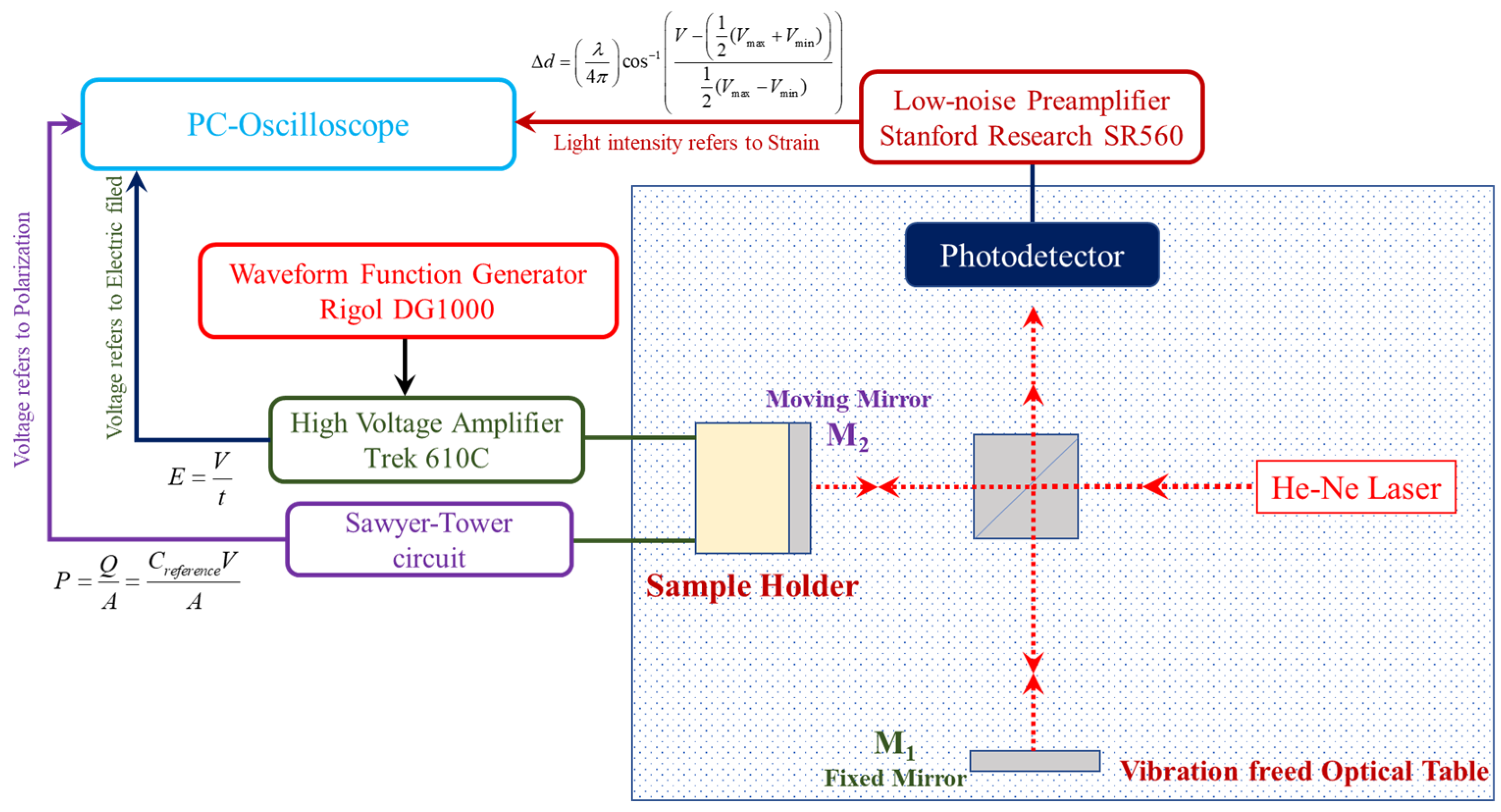

3.1.1. Michelson Interferometer

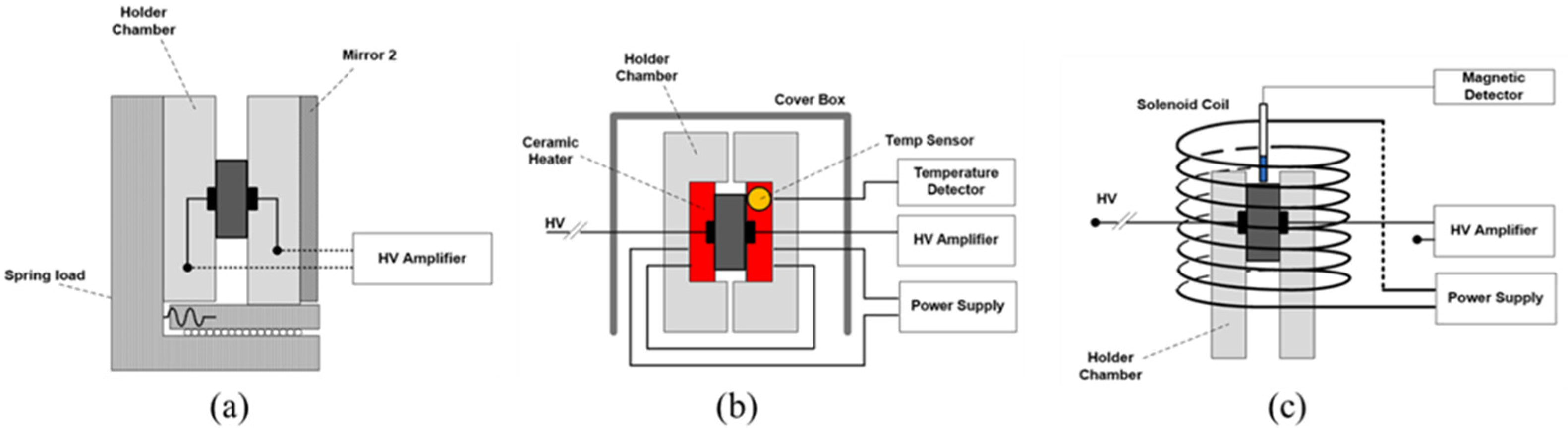

3.1.2. Sample Holders

3.2. Case Studies in PLZT-Based Ceramics

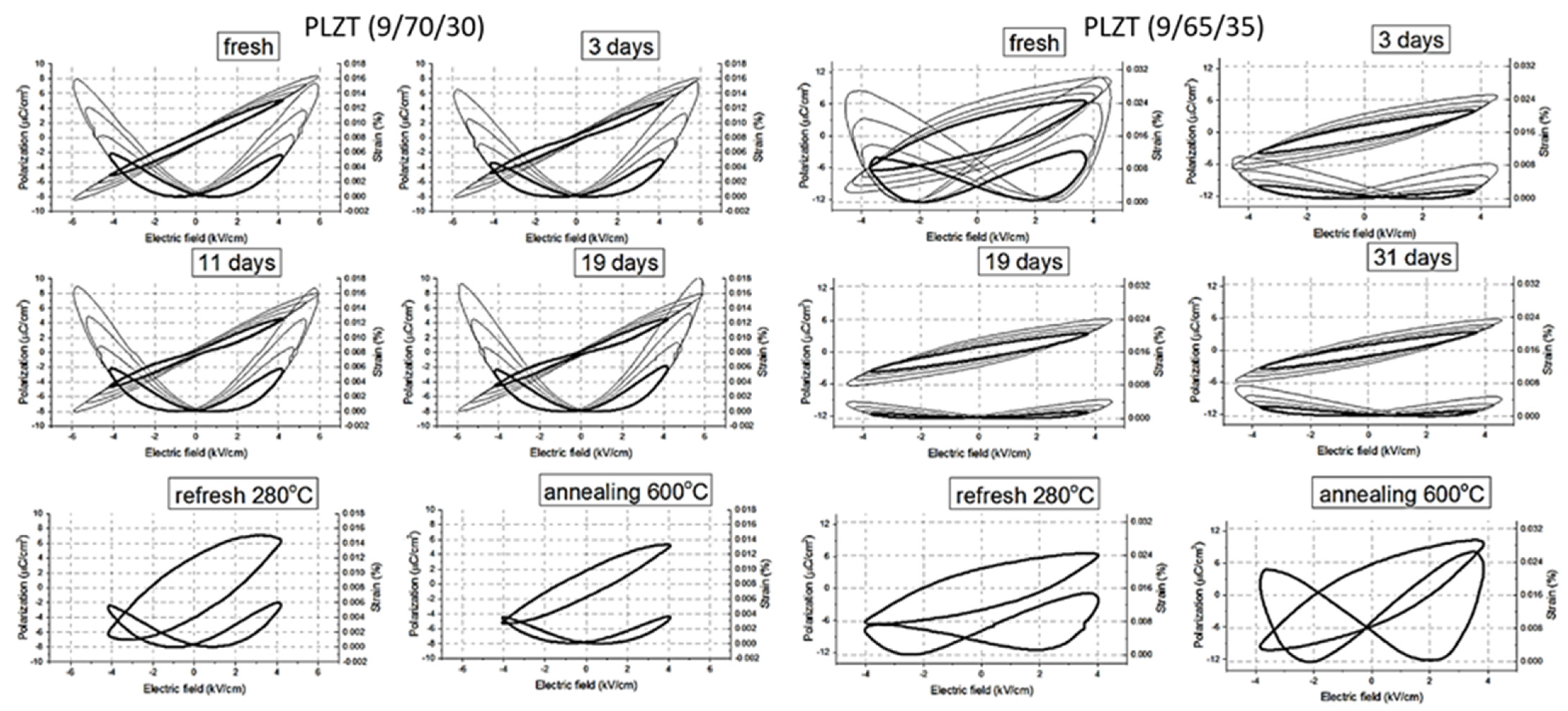

3.2.1. Aging Effect

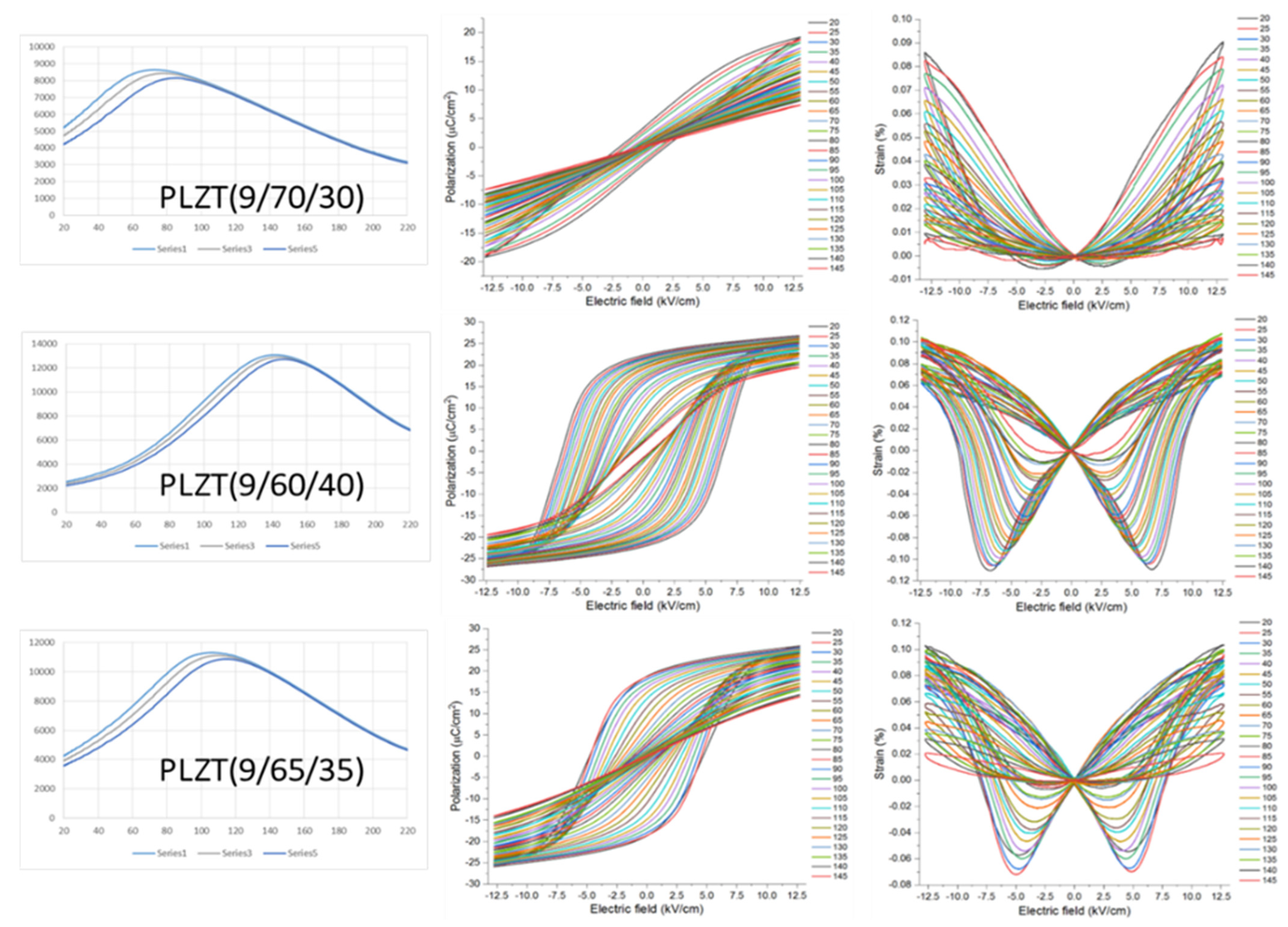

3.2.2. Temperature Dependence

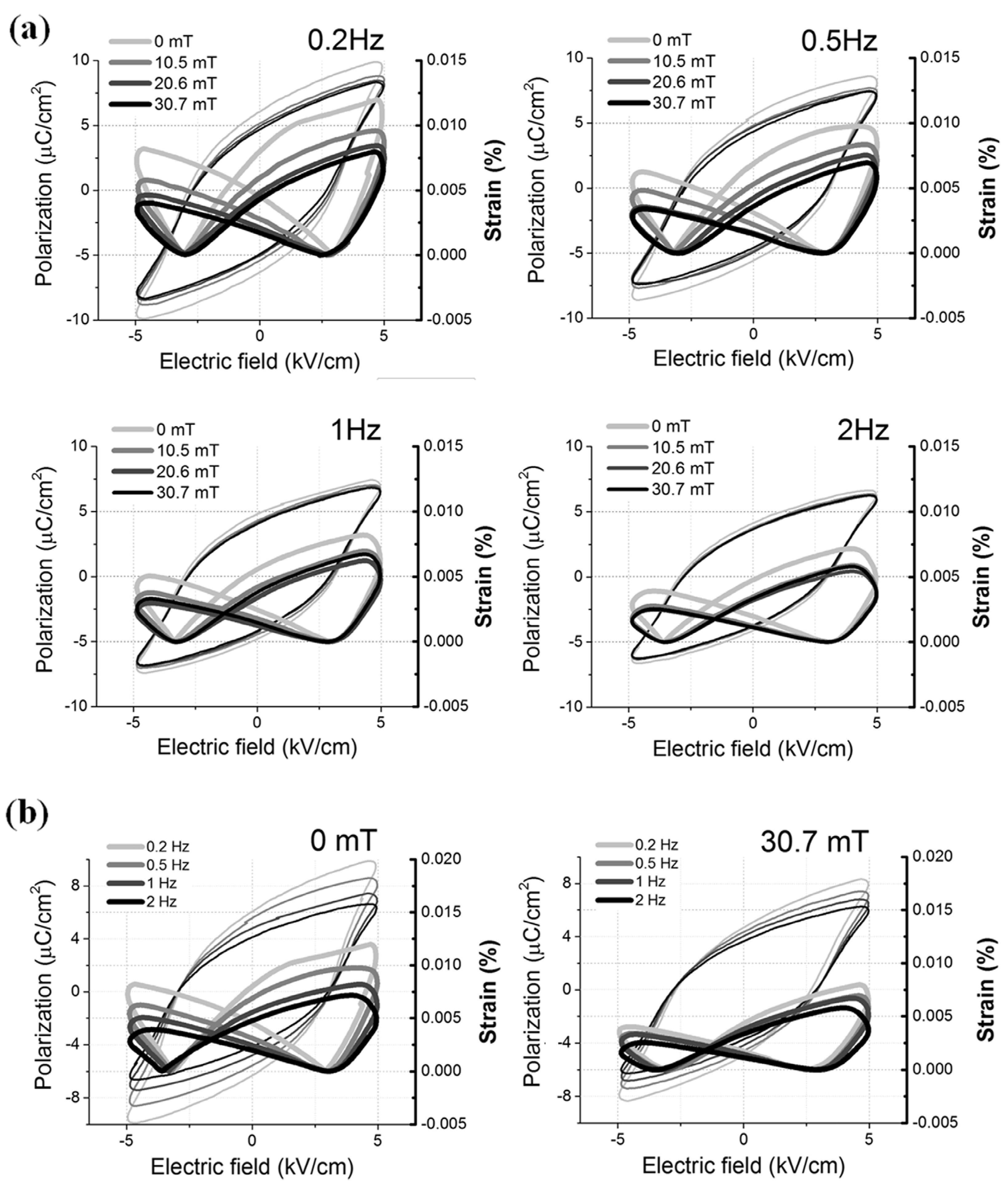

3.2.3. External Magnetic Field Effect

4. Concluding Remarks

- Bulk properties are generally investigated in ceramic samples. However, grain boundaries should be taken into account to better understand dielectric, ferroelectric, and piezoelectric properties. Migration of defects towards grain boundaries causes the change of electrical properties, and segregation at grain boundaries results in the change of grain boundary composition.

- Production of PLZT ceramics using sintering aids to create a glassy phase is still ongoing. The main advantage is a significant decrease in sintering temperature and a dense microstructure with a glassy phase at the grain boundaries. In terms of composites, multiferroic ceramics can be developed by a suitable selection of matrix and reinforcement. Doping is, in addition, still quite promising to enhance dielectric, ferroelectric, and piezoelectric properties as one of the most common methods. Co-doping offers the possibility to obtain a significant improvement of electrical properties in PLZT-based ceramics.

- Michelson interferometry is a useful method for strain measurement because a small change of sample length can be detected. Sample holders can be equipped with additional instruments to measure strain in different conditions. Further study of aging and temperature dependence is required to develop actuators that can function in the extreme conditions of high cycle services or high temperatures. The effect of an external magnetic field can be further investigated to apply the knowledge for devices utilizing magnetoelectric properties.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Moulson, A.J.; Herbert, J.M. Electroceramics: Materials, Properties, Applications, 2nd ed.; John Wiley & Sons: Chichester, UK, 2003; pp. 433–468. [Google Scholar]

- Sabat, R.G. Characterization of PLZT Ceramics for Optical Sensor and Actuator Devices. In Ceramic Materials—Progress in Modern Ceramics; Shi, F., Ed.; InTech Open: London, UK, 2012; pp. 1–24. [Google Scholar] [CrossRef]

- Knopf, G.K.; Uchino, K. Light Driven Micromechanics, 1st ed.; CRC Press: Boca Raton, FL, USA, 2018; pp. 171–196. [Google Scholar] [CrossRef]

- Poosanaas, P.; Uchino, K. Photostrictive effect in lanthanum-modified lead zirconate titanate ceramics near the morphotropic phase boundary. Mater. Chem. Phys. 1999, 61, 36–41. [Google Scholar] [CrossRef]

- Poosanaas-Burke, P.; Abothu, I.R.; Uchino, K. Fabrication and Device Design of Bulk and Thin Films Photostrictive Materials. In Proceedings of the IEEE Instrumentation and Measurement Technology Conference, Budapest, Hungary, 21–23 May 2001. [Google Scholar]

- Chen, C.; Li, X.; Lu, T.; Liu, Y.; Yi, Z. Reinvestigation of the photostrictive effect in lanthanum-modified lead zirconate titanate ferroelectrics. J. Am. Ceram. Soc. 2020, 103, 4074–4082. [Google Scholar] [CrossRef]

- Li, B.; Liu, Q.; Tang, X.; Zhang, T.; Jiang, Y.; Li, W.; Luo, J. High energy storage density and impedance response of PLZT 2/95/5 antiferroelectric ceramics. Materials 2017, 10, 143. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Wang, X.; Wang, J.; Chen, H. The light-controlled actuator driven by the novel opto-electronic hybrid driving method based on PLZT ceramics. Int. J. Appl. Electromagn. Mech. 2020, 62, 283–294. [Google Scholar] [CrossRef]

- Lv, Z.; Uzair, M.; Wang, X.; Liu, Y. A closed-loop control mathematical model for photovoltaic-electrostatic hybrid actuator with a slant lower electrode based on PLZT ceramics. Actuators 2021, 10, 285. [Google Scholar] [CrossRef]

- Huang, J.; Jiang, C.; Li, G.; Lu, Q.; Chen, H. Design and analysis of a light-operated microgripper using an opto-electrostatic repulsive combined actuator. Micromechanics 2021, 12, 1026. [Google Scholar] [CrossRef]

- Haertling, G.H. Ferroelectric ceramics: History and technology. J. Am. Ceram. Soc. 1999, 82, 797–818. [Google Scholar] [CrossRef]

- Feng, Y.; Wu, J.; Chi, Q.; Li, W.; Yu, Y.; Fei, W. Defects and aliovalent doping engineering in electroceramics. Chem. Rev. 2020, 120, 1710–1787. [Google Scholar] [CrossRef]

- Huang, Z.; Leighton, G. Interferometry for Piezoelectric Materials and Thin Films. In Characterization of Ferroelectric Bulk Materials and Thin Films, Springer Series in Measurement Science and Technology 2; Cain, M.G., Ed.; Springer Verlag: New York, NY, USA, 2014; pp. 87–113. [Google Scholar] [CrossRef]

- Rödel, J.; Li, J.-F. Lead-free piezoceramics: Status and perspectives. MRS Bull. 2018, 43, 576–580. [Google Scholar] [CrossRef]

- Acosta, M. Theoretical Background. In Strain Mechanisms in Lead-Free Ferroelectrics for Actuators; Springer International Publishing: Cham, Switzerland, 2016; pp. 27–37. [Google Scholar] [CrossRef]

- Baker, A.; Gou, H.; Guo, J.; Randall, C. Utilizing the cold sintering process for flexible-printable electroceramic device fabrication. J. Am. Ceram. Soc. 2016, 99, 3202–3204. [Google Scholar] [CrossRef]

- Chumprasert, L.; Limpichaipanit, A.; Chokethawai, K.; Ananta, S.; Ngamjarurojana, A. Effect of soaking time on phase formation and electrical properties of PLZT based ceramics. Ferroelectrics 2013, 457, 16–22. [Google Scholar] [CrossRef]

- Hao, J.; Li, W.; Zhai, J.; Chen, H. Progress in high-strain perovskite piezoelectric ceramics. Mater. Sci. Eng. R 2019, 135, 1–57. [Google Scholar] [CrossRef]

- Ramam, K.; Miguel, V. Microstructure, dielectric and ferroelectric characterization of Ba doped PLZT ceramics. Eur. Phys. J. Appl. Phys. 2006, 35, 43–47. [Google Scholar] [CrossRef]

- Hinterstein, M.; Rouquette, J.; Haines, J.; Papet, P.; Knapp, M.; Glaum, J.; Fuess, H. Structural description of the macroscopic piezo- and ferroelectric properties of lead zirconate titanate. Phys. Rev. Lett. 2011, 107, 077602. [Google Scholar] [CrossRef]

- Kumar, A.; Kalyani, A.K.; Ranjan, R.; Raju, K.C.J.; Ryu, J.; Park, N.; James, A.R. Evidence of monoclinic phase and its variation with a temperature at morphotropic phase boundary of PLZT ceramics. J. Alloys Compd. 2020, 816, 152613. [Google Scholar] [CrossRef]

- Hinterstein, M.; Hoelzel, M.; Rouquette, J.; Haines, J.; Glaum, J.; Kungl, H.; Hoffman, M. Interplay of strain mechanisms in morphotropic piezoceramics. Acta Mater. 2015, 94, 319–327. [Google Scholar] [CrossRef]

- Somwan, S.; Funsueb, N.; Limpichaipanit, A.; Ngamjarurojana, A. Temperature and induced electric field dependence on the phase transition of 9/70/30, 9/65/35 and 9/60/40 PLZT ceramics. Phase Transit. 2018, 91, 461–468. [Google Scholar] [CrossRef]

- Tilley, R.J.D. Perovskites: Structure-Property Relationships, 1st ed.; John Wiley & Sons: Chichester, UK, 2016; pp. 208–212. [Google Scholar]

- Samara, G.A. The relaxational properties of compositionally disordered ABO3 perovskites. J. Phys. Condens. Matter 2003, 15, R367–R411. [Google Scholar] [CrossRef]

- James, A.R.; Kumar, A. Development of PLZT Electroceramics with Ultrahigh Piezoelectric Properties by A Novel Material Engineering Approach. In Handbook of Advanced Ceramics and Composites; Mahajan, Y., Johnson, R., Eds.; Springer Nature Switzerland AG: Cham, Switzerland, 2020; pp. 1–36. [Google Scholar] [CrossRef]

- Funsueb, N.; Limpichaipanit, A.; Ngamjarurojana, A. Temperature dependence on ferroelectric properties and strain performance of PLZT ceramics containing 9 mol% La. Phase Transit. 2020, 93, 678–689. [Google Scholar] [CrossRef]

- Maier, J. Transport in electroceramics: Micro- and nano- structural aspects. J. Eur. Ceram. Soc. 2004, 24, 1251–1257. [Google Scholar] [CrossRef]

- Waser, R.; Hagenbeck, R. Grain boundaries in dielectric and mixed-conducting ceramics. Acta Mater. 2000, 48, 797–825. [Google Scholar] [CrossRef]

- Cantwell, P.R.; Tang, M.; Dillon, S.J.; Luo, J.; Rohrer, G.S.; Harmer, M.P. Grain boundary complexions. Acta Mater. 2014, 62, 1–48. [Google Scholar] [CrossRef]

- Bowman, W.J.; Kelly, M.N.; Rohrer, G.S.; Hernandez, C.A.; Crozier, P.A. Enhanced ionic conductivity in electroceramics by nanoscale enrichment on grain boundaries with high solute concentration. Nanoscale 2017, 9, 17293–17302. [Google Scholar] [CrossRef] [PubMed]

- Okazaki, K.; Nagata, K. Effects of grain size and porosity on electrical and optical properties of PLZT ceramics. J. Am. Ceram. Soc. 1973, 56, 82–86. [Google Scholar] [CrossRef]

- Jiang, Q.Y.; Cross, L.E. Effects of porosity on electrical fatigue behavior in PLZT and PZT ferroelectric ceramics. J. Mater. Sci. 1993, 28, 4536–4543. [Google Scholar] [CrossRef]

- Curecheriu, L.; Lukacs, V.A.; Padurariu, C.; Stoian, G.; Ciomaga, C.E. Effect of porosity on functional properties of lead-free piezoelectric BaZr0.15Ti0.85O3 Porous Ceramics. Materials 2020, 13, 3224. [Google Scholar] [CrossRef]

- Zhou, X.; Zhou, K.; Zhang, D.; Bowen, C.; Wang, Q.; Zhong, J.; Zhang, Y. Perspective on porous piezoelectric ceramics to control unternal stress. Nanoenerg. Adv. 2022, 2, 269–290. [Google Scholar] [CrossRef]

- Zhang, Y.; Roscow, J.; Lewis, R.; Khanbareh, H.; Topolov, V.Y.; Xie, M.; Bowen, C.R. Understanding the effect of porosity on the polarisation-field response of ferroelectric materials. Acta Mater. 2018, 154, 100–112. [Google Scholar] [CrossRef]

- Liang, R.; Zhang, W.; Gao, M.; Wang, L.; Dong, X. Excellent electrostrictive properties of low temperature sintered PZT ceramics with high concentration LiBiO2 sintering aid. Ceram. Int. 2013, 39, 563–569. [Google Scholar] [CrossRef]

- Liu, Z.; Shi, D.; Zhiu, H.; Deng, L.; Li, K. Fabrication and evaluation of Pb(W0.5Cu0.5)O3 modified PLZT piezoelectric ceramics. Ceram. Int. 2015, 41, 941–946. [Google Scholar] [CrossRef]

- Limpichaipanit, A.; Ngamjarurojana, A. Effect of PbO/CuO addition to microstructure and electrical properties of PLZT 9/65/35. Ferroelectrics 2015, 486, 57–65. [Google Scholar] [CrossRef]

- Yadav, A.K.; Gautam, C.R. A review on crystallization behaviour of perovskite glass ceramics. Adv. Appl. Ceram. 2014, 113, 193–207. [Google Scholar] [CrossRef]

- Hu, Q.; Wang, T.; Zhao, L.; Jin, L.; Xu, Z.; Wei, X. Dielectric and energy storage properties of BaTiO3-Bi(Mg1/2Ti1/2)O3 ceramic: Influence of glass addition and biasing electric field. Ceram. Int. 2017, 43, 35–39. [Google Scholar] [CrossRef]

- Khalf, A.Z.; Hall, D.A. Influence of barium borosilicate glass on microstructure and dielectric properties of (Ba,Ca)(Zr,Ti)O3 ceramics. J. Eur. Ceram. Soc. 2018, 38, 4422–4432. [Google Scholar] [CrossRef]

- Li, T.; Segawa, H.; Ohashi, N. Exploration of BaO-B2O3-Bi2O3 glasses as sintering aids for BaTiO3 ceramics. Ceram. Int. 2020, 46, 10233–10241. [Google Scholar] [CrossRef]

- Kanai, T.; Ohkoshi, S.; Nakajima, A.; Watanabe, T.; Hashimoto, K. A ferroelectric ferromagnet composed of (PLZT)x(BiFeO3)1−x solid solution. Adv. Mater. 2001, 13, 487–490. [Google Scholar] [CrossRef]

- Fawzi, A.S.; Sheikh, A.D.; Mathe, V.L. Multiferroic properties of Ni ferrite-PLZT composites. Phys. B 2010, 405, 340–344. [Google Scholar] [CrossRef]

- Fawzi, A.S.; Sheikh, A.D.; Mathe, V.L. Dielectric, electrical and magnetoelectric characterization of (x)Ni0.8Zn0.2Fe2O4 + (1 − x)Pb0.93La0.07(Zr0.60Ti0.40)O3 composites. Mater. Res. Bull. 2010, 45, 1000–1007. [Google Scholar] [CrossRef]

- Rani, R.; Juneya, J.K.; Singh, S.; Raina, K.K.; Prakash, C. Study of 0.1Ni0.8Zn0.2Fe2O4-0.9Pb1−3x/2LaxZr0.65Ti0.35O3 magnetoelectric composites. J. Mag. Mag. Mater. 2013, 325, 47–51. [Google Scholar] [CrossRef]

- Bochenek, D.; Miemiec, P.; Korzekwa, J.; Durtka, B.; Stokłosa, Z. Microstructure and properties of the ferroelectric-ferromagnetic PLZT-ferrite composites. Symmetry 2018, 10, 59. [Google Scholar] [CrossRef]

- Thommerel, E.; Madigou, V.; Villian, S.; Musso, J.; Valmalette, J.-C.; Gavarn, J.-R. Microstructure modifications and modulated piezoelectric responses in PLZT/Al2O3 composites. Mater. Sci. Eng. B 2003, 97, 74–82. [Google Scholar] [CrossRef]

- Qin, X.; Wu, H.; Chen, C.; Ao, H.; Li, W.; Gao, R.; Cai, W.; Chen, G.; Deng, X.; Wang, Z.; et al. Enhanced energy-storage performance of Pb0.925La0.05Zr0.95Ti0.05 @ x wt% SiO2 composite ceramics. J. Alloys Compd. 2021, 890, 161869. [Google Scholar] [CrossRef]

- Zhang, H.; Wei, T.; Zhang, Q.; Ma, W.; Fan, P.; Salamon, D.; Zhang, S.-T.; Nan, B.; Tau, H.; Ye, Z.-G. Review on the development of lead-free ferroelectric energy storage ceramics and multilayer capacitors. J. Mater. Chem. C 2020, 8, 16648–16667. [Google Scholar] [CrossRef]

- Funsueb, N.; Ngamjarurojana, A.; Tunkasiri, T.; Limpichaipanit, A. Effect of composition and grain size on dielectric, ferroelectric and induced strain behavior of PLZT/ZrO2 composites. Ceram. Int. 2018, 44, 6343–6353. [Google Scholar] [CrossRef]

- Zhang, N.X.; Li, L.T.; Li, B.R.; Guo, D.; Gui, Z.L. Improvement of electric fatigue properties in PLZT ferroelectric ceramics due to SrBi2Ta2O9 incorporation. Mater. Sci. Eng. B 2002, 90, 185–190. [Google Scholar] [CrossRef]

- Yin, Q.R.; Ding, A.L.; Zheng, X.S.; Qin, P.S. Preparation and characterization of transparent PZN-PLZT ceramics. J. Mater. Res. 2004, 19, 729–732. [Google Scholar] [CrossRef]

- Funsueb, N.; Limpichaipanit, A.; Ngamjarurojana, A. Effect of sintering temperature on phase formation and dielectric property of modified PLZT ceramics with addition of BT and PZN. Phase Transit. 2022, 95, 363–371. [Google Scholar] [CrossRef]

- Curecheriu, L.-P.; Buscaglia, M.T.; Maglia, F.; Padurariu, C.; Ciobanu, G.; Anselmi-Tamburini, U.; Buscaglia, V.; Mitoseriu, L. Tailoring the functional properties of PLZT-BaTiO3 composite ceramics by core-shell approach. J. Appl. Phys. 2017, 121, 144101. [Google Scholar] [CrossRef]

- Tilley, R.J.D. Understanding Solids: The Science of Materials, 2nd ed.; John Wiley & Sons: Chichester, UK, 2013; pp. 19–24. [Google Scholar]

- Zhu, B.; Zeng, X.; Qiu, P.; Ling, L.; Sun, D.; Zhao, S.; He, X. Effects of Bi3+ doping on the optical and electric-induced light scattering performance of PLZT (8.0/69/31) transparent ceramics. Materials 2019, 12, 1437. [Google Scholar] [CrossRef]

- Choudary, R.N.P.; Mal, J. Phase transition in Bi-modified PLZT ferroelectrics. Mater. Lett. 2002, 54, 175–180. [Google Scholar] [CrossRef]

- Dutta, S.; Choudhary, R.N.P.; Sinha, K. Ferroelectric phase transition in Bi-doped PLZT ceramics. Mat. Sci. Eng. B 2003, 98, 74–80. [Google Scholar] [CrossRef]

- Rai, R.; Sharma, S. Structural and dielectric properties of (La,Bi) modified PZT ceramics. Solid State Commu. 2004, 129, 305–309. [Google Scholar] [CrossRef]

- Kundzina, L.; Kundzins, M.; Kundzins, K.; Plaude, A.; Livinsh, M.; Antonova, M.; Dimza, V. The effects of 3d admixtures on properties of relaxor PLZT 8/65/35 ceramics. Ferroelectrics 2012, 436, 38–48. [Google Scholar] [CrossRef]

- Ahamad Mohiddon, M.; Yadav, K.L. Effect of Fe doping on dielectric, ferroelectric and pyroelectric properties of PLZT (8/65/35). J. Phys. D Appl. Phys. 2007, 40, 7540–7547. [Google Scholar] [CrossRef]

- Rai, R.; Sharma, S.; Chouhary, R.N.P. Dielectric and piezoelectric studies of Fe doped PLZT ceramics. Mater. Lett. 2005, 59, 3921–3925. [Google Scholar] [CrossRef]

- Limpichaipanit, A.; Somwan, S.; Ngamjarurojana, A. Dielectric properties of PFN–PZT composites: From relaxor to ferroelectric behavior. Ceram. Int. 2018, 44, 14797–14802. [Google Scholar] [CrossRef]

- Dutta, S.; Choudhary, R.N.P.; Sinha, P.K. Impedance spectroscopy studies on Fe3+ ion modified PLZT ceramics. Ceram. Int. 2007, 33, 13–20. [Google Scholar] [CrossRef]

- Dimza, V.; Popov, A.I.; Lāce, L.; Kundzins, M.; Kundzins, K.; Antonava, M.; Livins, M. Effects of Mn doping on dielectric properties of ferroelectric relaxor PLZT ceramics. Curr. Appl. Phys. 2017, 17, 169–173. [Google Scholar] [CrossRef]

- Kumar, A.; Yoon, J.Y.; Thakre, A.; Peddigari, M.; Jeong, D.-Y.; Kong, Y.-M.; Ryu, J. Dielectric, ferroelectric, energy storage, and pyroelectric properties of Mn doped (Pb0.93La0.07)(Zr0.82Ti0.18)O3 anti-ferroelectric ceramics. J. Korean Ceram. Soc. 2019, 56, 412–420. [Google Scholar] [CrossRef]

- Perez-Delfin, E.; García, J.E.; Ochoa, D.A.; Pérez, R.; Guerrero, F.; Eiras, J.A. Effect of Mn-acceptor dopant on dielectric and piezoelectric responses of lead lanthanum zirconate titanate piezoceramics. J. Appl. Phys. 2011, 110, 034106. [Google Scholar] [CrossRef]

- Ahamad Mohiddon, M.; Yadav, K.L. Dielectric dispersion study of Mn-doped PLZT (8/65/35). Phys. Status Solidi A 2009, 206, 1606–1615. [Google Scholar] [CrossRef]

- Bajpai, K.K.; Sreenivas, K.; Gupta, A.K.; Shukla, A.K. Cr-doped lead lanthanum zirconate titanate (PLZT) ceramics for pyroelectric and energy harvesting device applications. Ceram. Int. 2019, 45, 14111–14120. [Google Scholar] [CrossRef]

- Shukla, A.K.; Argawal, V.K.; Das, I.M.L.; Singh, J.; Singh, D.P.; Sood, K.N. Structural, dielectric and electrochemical properties of Cr-doped PLZT close to the morphotropic phase boundary region. Phase Transit. 2006, 79, 875–887. [Google Scholar] [CrossRef]

- Selvamani, R.; Singh, G.; Tiwari, V.S.; Karnal, A.K. Dielectric and piezoelectric properties of Cr2O3-doped PLZT (7/65/35) hot pressed ceramics. Mater. Today Commun. 2018, 15, 100–104. [Google Scholar] [CrossRef]

- Dutta, S.; Choudhary, R.N.P.; Sinha, P.K. Structural, dielectric and piezoelectric properties of aluminium doped PLZT ceramics prepared by sol–gel route. J. Alloys Compd. 2007, 430, 344–349. [Google Scholar] [CrossRef]

- Dutta, S.; Choudhary, R.N.P.; Sinha, P.K. Effect of Ga+3-ion Substitution on structural, dielectric and electrical properties of PLZT ceramics. Ferroelectrics 2006, 330, 75–84. [Google Scholar] [CrossRef]

- Zeng, X.; He, X.; Cheng, W.; Qiu, P.; Xia, B. Effect of Dy substitution on ferroelectric, optical and electro-optic properties of transparent Pb0.90La0.10(Zr0.65Ti0.35)O3 ceramics. Ceram. Int. 2014, 40, 6197–6202. [Google Scholar] [CrossRef]

- Płońska, M.; Adamczyk, M. Dielectric properties of neodymium-modified PLZT ceramics. Phase Transit. 2015, 88, 786–798. [Google Scholar] [CrossRef]

- Maher, G.H. Effect of silver doping on the physical and electrical properties of PLZT ceramics. J. Am. Ceram. Soc. 1983, 66, 408–413. [Google Scholar] [CrossRef]

- Tong, S.; Ling, Z. Ferroelectric-to-relaxor crossover in Sb doped PLZT x/52/48 (2 ≤ x ≤ 16) piezoelectric ceramics. J. Asian Ceram. Soc. 2014, 2, 1–4. [Google Scholar] [CrossRef]

- Dutta, S.; Choudhary, R.N.P.; Sinha, P.K. Electrical properties of antimony doped PLZT ceramics prepared by mixed–oxide route. J. Alloys Compd. 2006, 426, 345–351. [Google Scholar] [CrossRef]

- Rai, R.; Sharma, S. Structural and dielectric properties of Sb-doped PLZT ceramics. Ceram. Int. 2004, 30, 1295–1299. [Google Scholar] [CrossRef]

- Chu, S.-Y.; Uchino, K. Photostrictive effect in PLZT-based ceramics and its applications. Ferroelectrics 1995, 174, 185–196. [Google Scholar] [CrossRef]

- Favaretto, R.; Garcia, D.; Eiras, J.A. Effects of WO3 on the microstructure and optical transmittance of PLZT ferroelectric ceramics. J. Eur. Ceram. Soc. 2007, 27, 4037–4040. [Google Scholar] [CrossRef]

- Xu, Z.; Zeng, X.; Cao, Z.; Ling, L.; Qiu, P.; He, X. The electrical and optical properties of Nb-doping PLZT (9/65/35) transparent ceramics. J. Electroceramics 2020, 44, 215–222. [Google Scholar] [CrossRef]

- Divya, A.S.; Kumar, V. A novel mechanism for relaxor–ferroelectric transition in PLZT (8/65/35). J. Am. Ceram. Soc. 2009, 92, 2029–2032. [Google Scholar] [CrossRef]

- Xu, Z.; Zeng, X.; Cao, Z.; Ling, L.; Qiu, P.; He, X. Effects of barium substitution on the optical and electrical properties of PLZT transparent electro-optical ceramics. Ceram. Int. 2019, 45, 17890–17897. [Google Scholar] [CrossRef]

- Chen, Y.; Sun, D.; Zhu, Y.; Zeng, X.; Ling, L.; Qiu, P.; He, X. The effect of Sn4+ doping on the electrostrictive property of PLZT (9/65/35) transparent ceramics. Ceram. Int. 2020, 46, 6738–6744. [Google Scholar] [CrossRef]

- Zhang, Q.; Dan, Y.; Chen, J.; Lu, Y.; Yang, T.; Yao, X.; He, Y. Effects of composition and temperature on energy storage properties of (Pb,La)(Zr,Sn,Ti)O3 antiferroelectric ceramics. Ceram. Int. 2017, 43, 11428–11432. [Google Scholar] [CrossRef]

- Xu, R.; Tian, J.; Zhu, Q.; Zhao, T.; Feng, Y.; Wei, X.; Xu, Z. Effects of La-induced phase transition on energy storage and discharge properties of PLZST ferroelectric/antiferroelectric ceramics. Ceram. Int. 2017, 43, 13918–13923. [Google Scholar] [CrossRef]

- Choi, J.-S.; Kim, D.-C.; Shin, H.-S.; Yeo, D.-H.; Lee, J.-H. Effects of the Sn4+ substitution and the sintering additives on the sintering behavior and electrical properties of PLZT. Appl. Sci. 2022, 12, 2591. [Google Scholar] [CrossRef]

- Xu, R.; Xu, Z.; Feng, Y.; He, H.; Tian, J.; Yu, K. Fatigue resistance of Pb0.90La0.04Ba0.04[(Zr0.6Sn0.4)0.85Ti0.15]O3 antiferroelectric ceramics under fast charge-discharge cycling. Ceram. Int. 2016, 42, 9094–9099. [Google Scholar] [CrossRef]

- Wang, X.; Yang, T.; Shen, J. Unique dielectric behavior of (Pb0.87Ba0.08Sr0.02La0.02)(Zr0.65Sn0.27Ti0.08)O3 antiferroelectric ceramics. Mater. Lett. 2016, 181, 220–222. [Google Scholar] [CrossRef]

- Fu, S.-L.; Cheng, S.-Y.; Wei, C.-C. Effects on doping pairs on the preparation and dielectricity of PLZT ceramics. Ferroelectrics 1986, 67, 93–102. [Google Scholar] [CrossRef]

- Limpichaipanit, A.; Ngamjarurojana, A. Effect of Li and Bi co-doping and sintering temperature on dielectric properties of PLZT 9/65/35 ceramics. Ceram. Int. 2017, 43, 4450–4455. [Google Scholar] [CrossRef]

- Somwan, S.; Ngamjarurojana, A.; Limpichaipanit, A. Dielectric, ferroelectric and induced strain behavior of modified PLZT 9/65/35 by Bi2O3 and CuO co-doping. Ceram. Int. 2016, 42, 10690–10696. [Google Scholar] [CrossRef]

- Rai, R.; Mishra, S.; Singh, N.K. Effect of Fe and Mn doping at B-site of PLZT ceramics on dielectric properties. J. Alloys Compd. 2009, 487, 494–498. [Google Scholar] [CrossRef]

- Samanta, S.; Sankaranarayanan, V.; Senthupathi, K. Effect of Nb and Fe co-doping on microstructure, dielectric response, ferroelectricity and energy storage density of PLZT. J. Mater. Sci. Mater. Electron. 2018, 29, 20383–20394. [Google Scholar] [CrossRef]

- Ramam, K.; Chandramondi, K. Dielectric and piezoelectric properties of combinatory effect of A-site isovalent and B-site acceptor doped PLZT ceramics. Ceram.—Silik. 2009, 53, 189–194. [Google Scholar]

- Lu, B.; Yao, Y.; Jian, X.; Tao, T.; Liang, B.; Zhang, Q.M.; Lu, S.-G. Enhancement of the electrocaloric effect pver a wide temperature range in PLZT ceramics by doping with Gd3+ and Sn4+ ions. J. Eur. Ceram. Soc. 2019, 39, 1093–1102. [Google Scholar] [CrossRef]

- Limpichaipanit, A.; Funsueb, N.; Somwan, S.; Ngamjarurojana, A.; Tunkasiri, T. Electrocaloric properties of Bi and Cu doped PLZT 9/65/35 ceramics at low electric field. Ceram. Int. 2020, 46, 5252–5261. [Google Scholar] [CrossRef]

- Li, J.F. Lead-Free Piezoelectric Materials, 1st ed.; Wiley-VCH GmbH: Weinheim, Germany, 2021; pp. 1–18. [Google Scholar]

- Uchino, K. Ferroelectric Devices, 2nd ed.; Marcel Dekker Inc.: New York, NY, USA, 2009; pp. 1–22. [Google Scholar]

- Uchino, K. Ferroelectric Devices & Piezoelectric Actuators, 1st ed.; DEStech Publications: Lancaster, PA, USA, 2017; pp. 1–41. [Google Scholar]

- Li, F.; Jin, L.; Xu, Z.; Zhang, S. Electrostrictive effect in ferroelectrics: An alternative approach to improve piezoelectricity. Appl. Phys. Rev. 2014, 1, 011103. [Google Scholar] [CrossRef]

- Uchino, K.; Giniewicz, R. Micromechatronics, 1st ed.; Marcel Dekker Inc.: New York, NY, USA, 2003; pp. 1–36. [Google Scholar]

- Fan, P.; Liu, K.; Ma, W.; Tan, H.; Zhang, Q.; Zhang, L.; Zhou, C.; Salamon, D.; Zhang, S.-T.; Zhang, Y.; et al. Progress and perspective of high strain NBT-based lead-free piezoceramics and multilayer actuators. J. Mater. 2021, 7, 508–544. [Google Scholar] [CrossRef]

- Trolier-McKinstry, S. Piezoelectric Characterization. In Polar Oxides: Properties, Characterization, and Imaging; Waser, R., Böttger, U., Tiedke, S., Eds.; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2005; pp. 39–52. [Google Scholar]

- Nesser, H.; Lubineau, G. Strain sensing by electrical capacitive variation: From stretchable materials to electronic interfaces. Adv. Electron. Mater. 2021, 7, 2100190. [Google Scholar] [CrossRef]

- Stewart, M.; Cain, M.G. Direct Piezoelectric Measurement: The Berlincourt Method. In Characterization of Ferroelectric Bulk Materials and Thin Films, Springer Series in Measurement Science and Technology 2; Cain, M.G., Ed.; Springer Verlag: New York, NY, USA, 2014; pp. 37–64. [Google Scholar] [CrossRef]

- Reichmann, K.; Feteira, A.; Li, M. Bismuth sodium titanate based materials for piezoelectric actuators. Materials 2015, 8, 8467–8495. [Google Scholar] [CrossRef]

- Damjanovic, D. Hysteresis in Piezoelectric and Ferroelectric Materials. In The Science of Hysteresis; Mayergoyz, I., Bertotti, G., Eds.; Academic Press: Oxford, UK, 2006; Volume 3, pp. 337–465. [Google Scholar]

- Koval, V.; Viola, G.; Tan, Y. Biasing Effects in Ferroic Materials. In Ferroelectric Materials-Synthesis and Characterization; Peláiz-Barranco, A., Ed.; InTech Open: London, UK, 2015; pp. 205–245. [Google Scholar] [CrossRef]

- Genenko, Y.A. Space-charge mechanism of aging in ferroelectrics: An analytically solvable two-dimensional model. Phys. Rev. B 2008, 78, 214103. [Google Scholar] [CrossRef]

- Genenko, Y.A.; Glaum, J.; Hoffmann, M.J.; Albe, K. Mechanisms of aging and fatigue in ferroelectrics. Mater. Sci. Eng. B 2015, 192, 52–82. [Google Scholar] [CrossRef]

- Ketsuwan, P.; Prasatkhetragarn, A.; Ngamjarurojana, A.; Ananta, S.; Yimnirum, R. Dielectric aging of Cr-doped PZT ceramics. Ferroelectrics 2013, 149, 67–74. [Google Scholar] [CrossRef]

- Burkhanov, A.; Shilnikov, A.; Sternberg, A. Aging and after-effects in PLZT X/65/35 ferroelectric ceramics. Ferroelectrics 1989, 90, 39–43. [Google Scholar] [CrossRef]

- Somwan, S.; Ngamjarurojana, A. Study of aging behavior of 9/70/30 and 9/65/35 PLZT by optical interferometric technique. Ceram. Int. 2015, 41, 7536–7542. [Google Scholar] [CrossRef]

- Somwan, S. Development of Michelson Interferometer for Induced-Strain Measurement in Ferroic Materials. Ph.D. Thesis, Chiang Mai University, Chiang Mai, Thailand, 2015. [Google Scholar]

- Damjanovic, D. Ferroelectric, dielectric and piezoelectric properties of ferroelectric thin films and ceramics. Rep. Prog. Phys. 1998, 61, 1267–1324. [Google Scholar] [CrossRef]

- Damjanovic, D. A morphotropic phase boundary system based on polarization rotation and polarization extension. Appl. Phys. Lett. 2010, 97, 062906. [Google Scholar] [CrossRef]

- Damjanovic, D. Contributions to piezoelectric effect in ferroelectric single crystals and ceramics. J. Am. Ceram. Soc. 2005, 88, 2663–2676. [Google Scholar] [CrossRef]

- Funsueb, N. Investigation on Strain Characteristics of Ferroelectric Ceramics for Micromechatronic Actuator. Ph.D. Thesis, Chiang Mai University, Chiang Mai, Thailand, 2020. [Google Scholar]

- Kungl, H.; Hoffmann, M.J. Temperature dependence of poling strain and strain under high electric fields in LaSr-doped morphotropic PZT and its relation to changes in structural characteristics. Acta Mater. 2007, 55, 5780–5791. [Google Scholar] [CrossRef]

- Rauls, M.B.; Dong, W.; Huber, J.E.; Lynch, C.S. The effect of temperature on the large field electromechanical response of relaxor ferroelectric 8/65/35 PLZT. Acta Mater. 2011, 59, 2713–2722. [Google Scholar] [CrossRef]

- Somwan, S.; Limpichaipanit, A.; Ngamjarurojana, A. Effect of temperature on loss mechanism of 0.7PMN-0.3PZT ceramics. Sens. Actuator A Phys. 2015, 236, 19–24. [Google Scholar] [CrossRef]

- Gözüaçık, N.K.; Mensur-Alkoy, E.; Alkoy, S. Effects of lanthanum doping on electrical and electromechanical properties of (Pb1−xLax)(Zr0.70Ti0.30)O3 ceramics. J. Mater. Sci. Mater. Electron. 2019, 30, 14045–14052. [Google Scholar] [CrossRef]

- Bobnar, V.; Kutnjak, Z.; Levstik, A. Temperature dependence of material constants of PLZT ceramics. J. Eur. Ceram. Soc. 1999, 19, 1281–1284. [Google Scholar] [CrossRef]

- Otonicar, M.; Reichmann, A.; Reichmann, K. Electric field-induced changes of domain structure and properties in La-doped PZT—From ferroelectrics towards relaxors. J. Eur. Ceram. Soc. 2016, 36, 2495–2504. [Google Scholar] [CrossRef]

- Hu, Z.; Wang, X.; Nan, T.; Zhou, Z.; Ma, B.; Chen, X.; Jones, J.G.; Howe, B.M.; Brown, G.J.; Cao, Y.; et al. Non-volatile ferroelectric switching of ferromagnetic resonance in NiFe/PLZT multiferroic thin film heterostructures. Sci. Rep. 2016, 6, 32408. [Google Scholar] [CrossRef]

- Kumar, A.; Goswami, A.; Singh, K.; McGee, R.; Thundat, T.; Kaur, D. Magnetoelectric coupling in Ni−Mn−In/PLZT artificial multiferroic heterostructure and its application in mid-IR photothermal modulation by external magnetic field. ACS Appl. Electron. Mater. 2019, 1, 2226–2235. [Google Scholar] [CrossRef]

- Song, H.; Listyawan, M.A.; Ryu, J. Core-shell magnetoelectric nanoparticles: Materials, synthesis, magnetoelectricity, and applications. Actuators 2022, 11, 380. [Google Scholar] [CrossRef]

- Somwan, S.; Funsueb, N.; Limpichaipanit, A.; Ngamjarurojana, A. Influence of low external magnetic field on electric field induced strain behavior of 9/70/30, 9/65/35 and 9/60/40 PLZT ceramics. Ceram. Int. 2016, 42, 13223–13231. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Limpichaipanit, A.; Ngamjarurojana, A. Strain Characteristics of PLZT-Based Ceramics for Actuator Applications. Actuators 2023, 12, 74. https://doi.org/10.3390/act12020074

Limpichaipanit A, Ngamjarurojana A. Strain Characteristics of PLZT-Based Ceramics for Actuator Applications. Actuators. 2023; 12(2):74. https://doi.org/10.3390/act12020074

Chicago/Turabian StyleLimpichaipanit, Apichart, and Athipong Ngamjarurojana. 2023. "Strain Characteristics of PLZT-Based Ceramics for Actuator Applications" Actuators 12, no. 2: 74. https://doi.org/10.3390/act12020074

APA StyleLimpichaipanit, A., & Ngamjarurojana, A. (2023). Strain Characteristics of PLZT-Based Ceramics for Actuator Applications. Actuators, 12(2), 74. https://doi.org/10.3390/act12020074