Assessment of the Dynamic Range of Magnetorheological Gradient Pinch-Mode Prototype Valves

Abstract

:1. Introduction

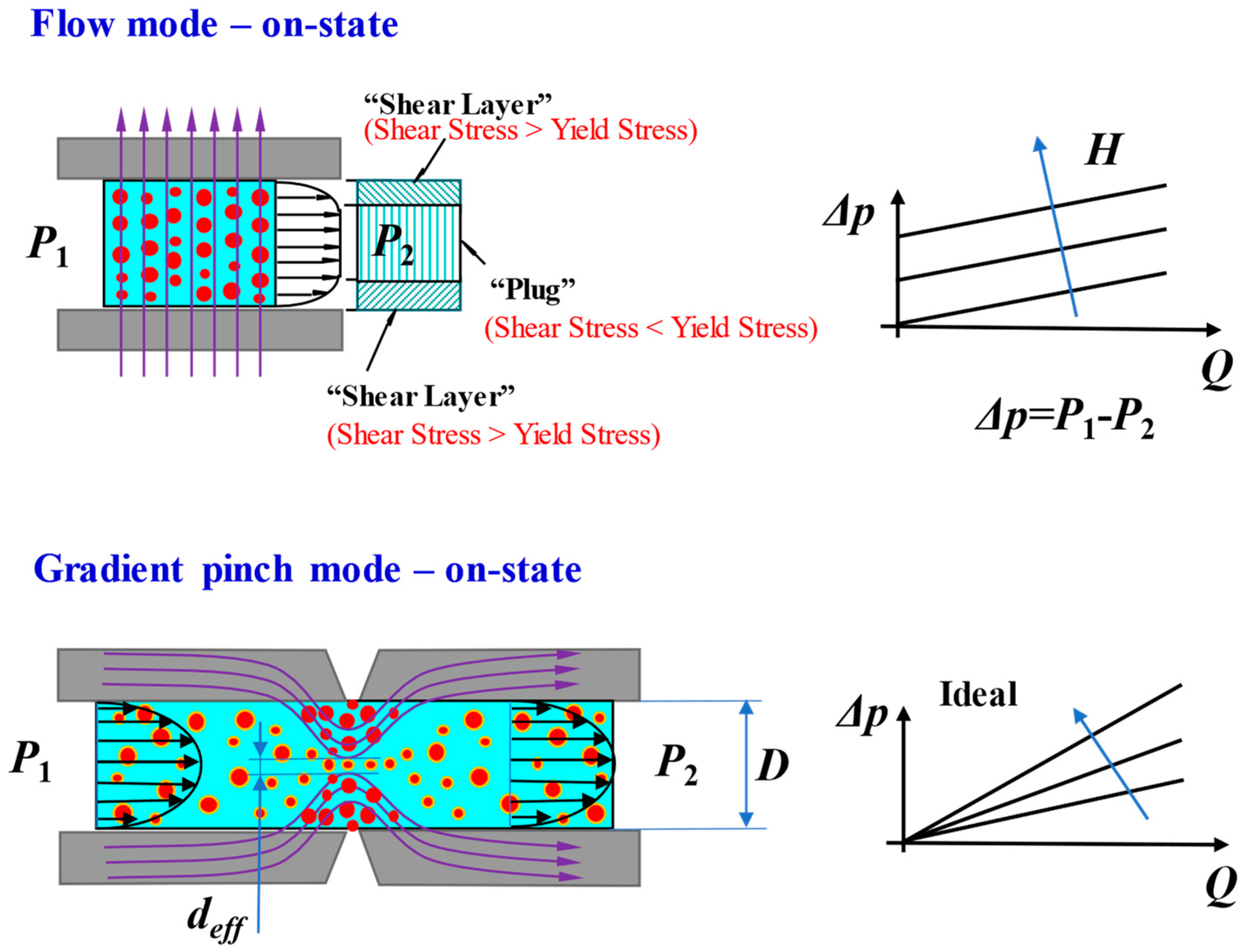

2. Pinch-Mode Fundamentals

3. Experimental Procedure

3.1. Test Rig

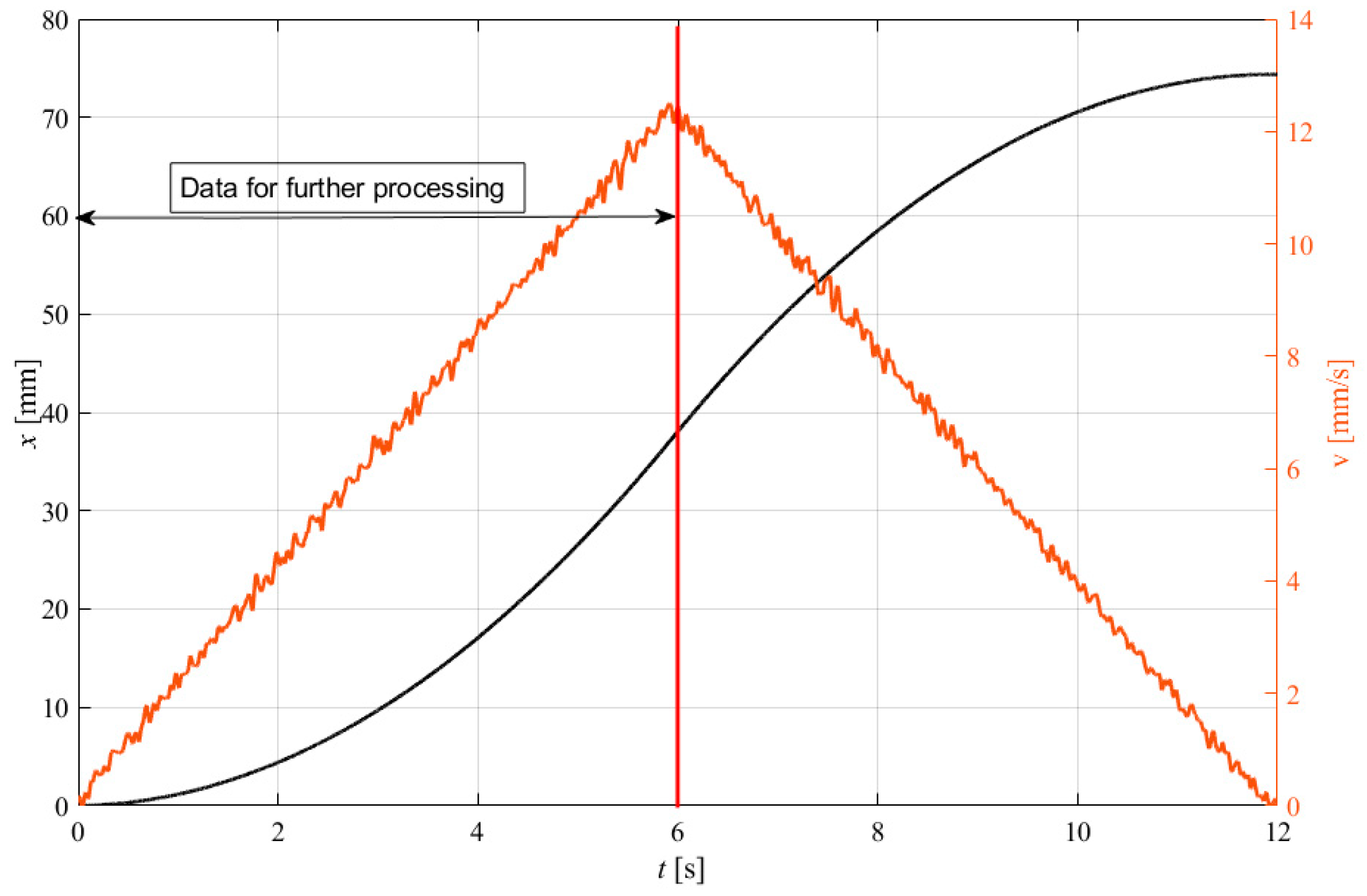

3.2. Test Plan, Material Description, and Data Post-Processing Method

4. MR Pinch-Mode Valves

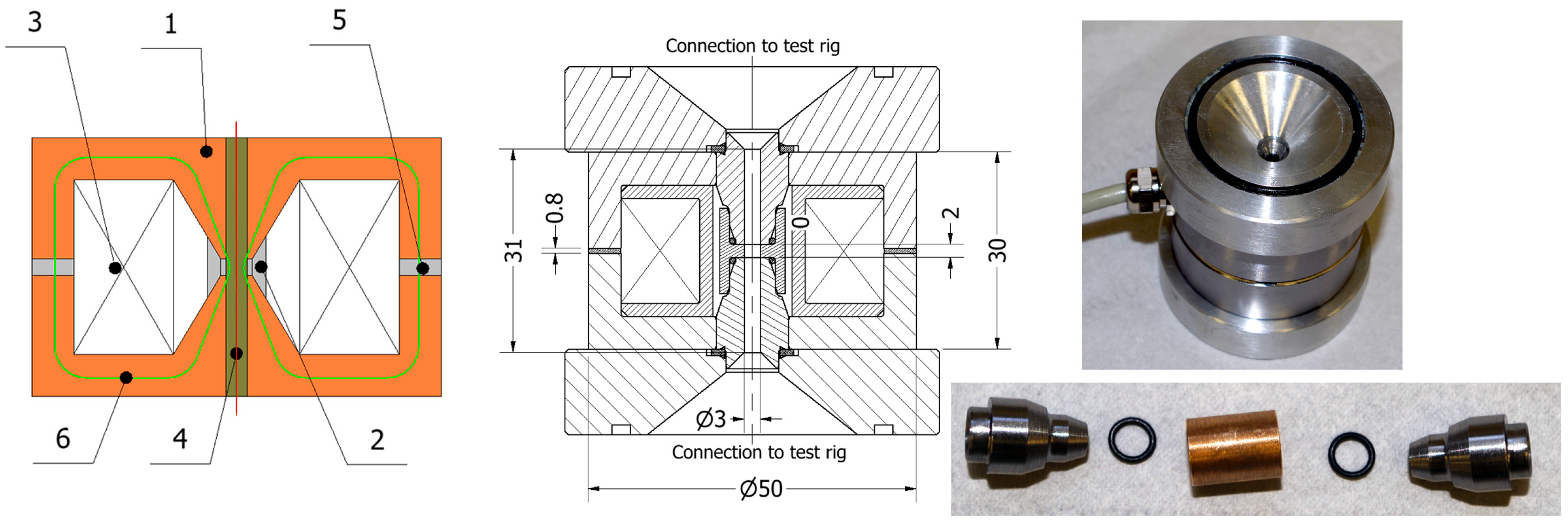

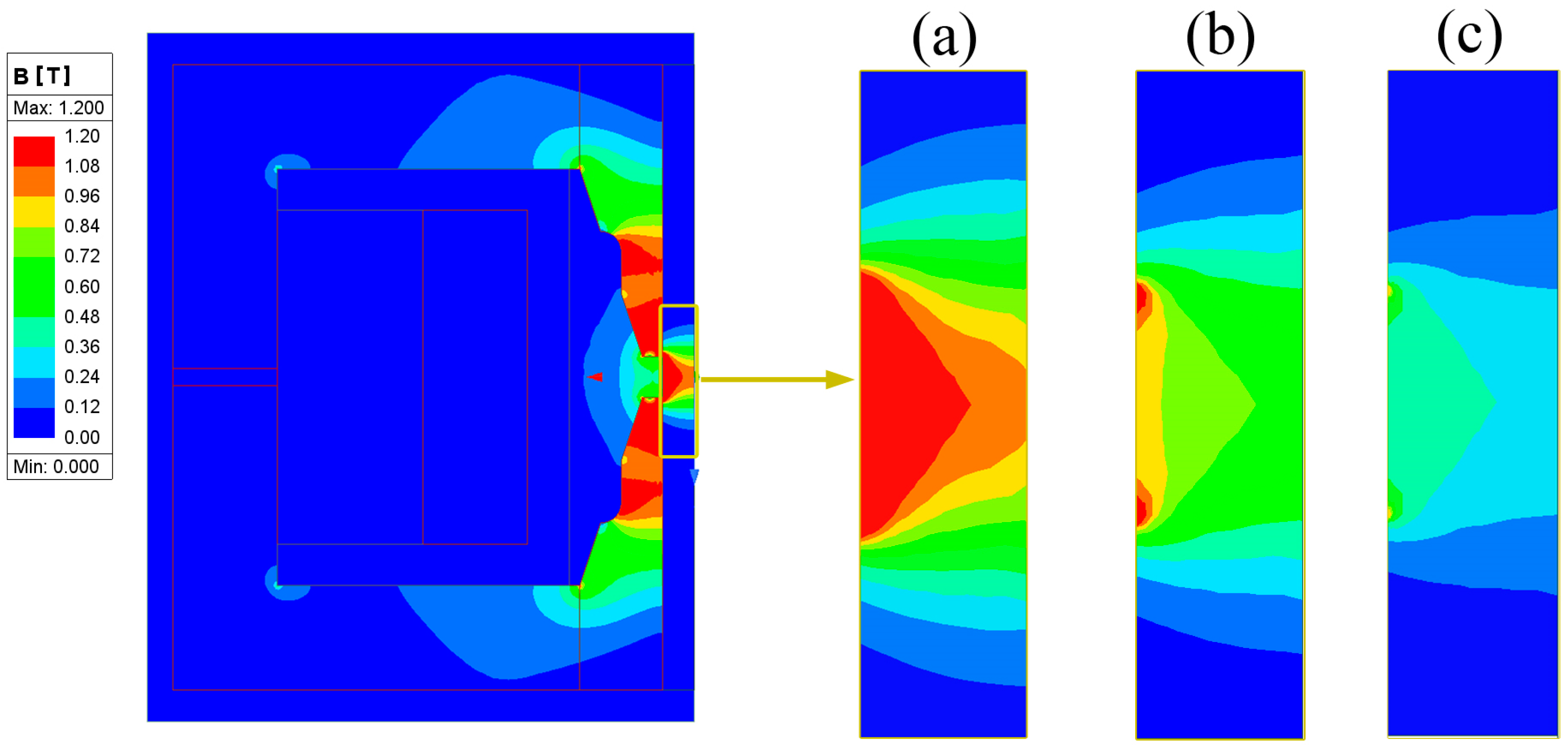

4.1. Single-Stage Prototype

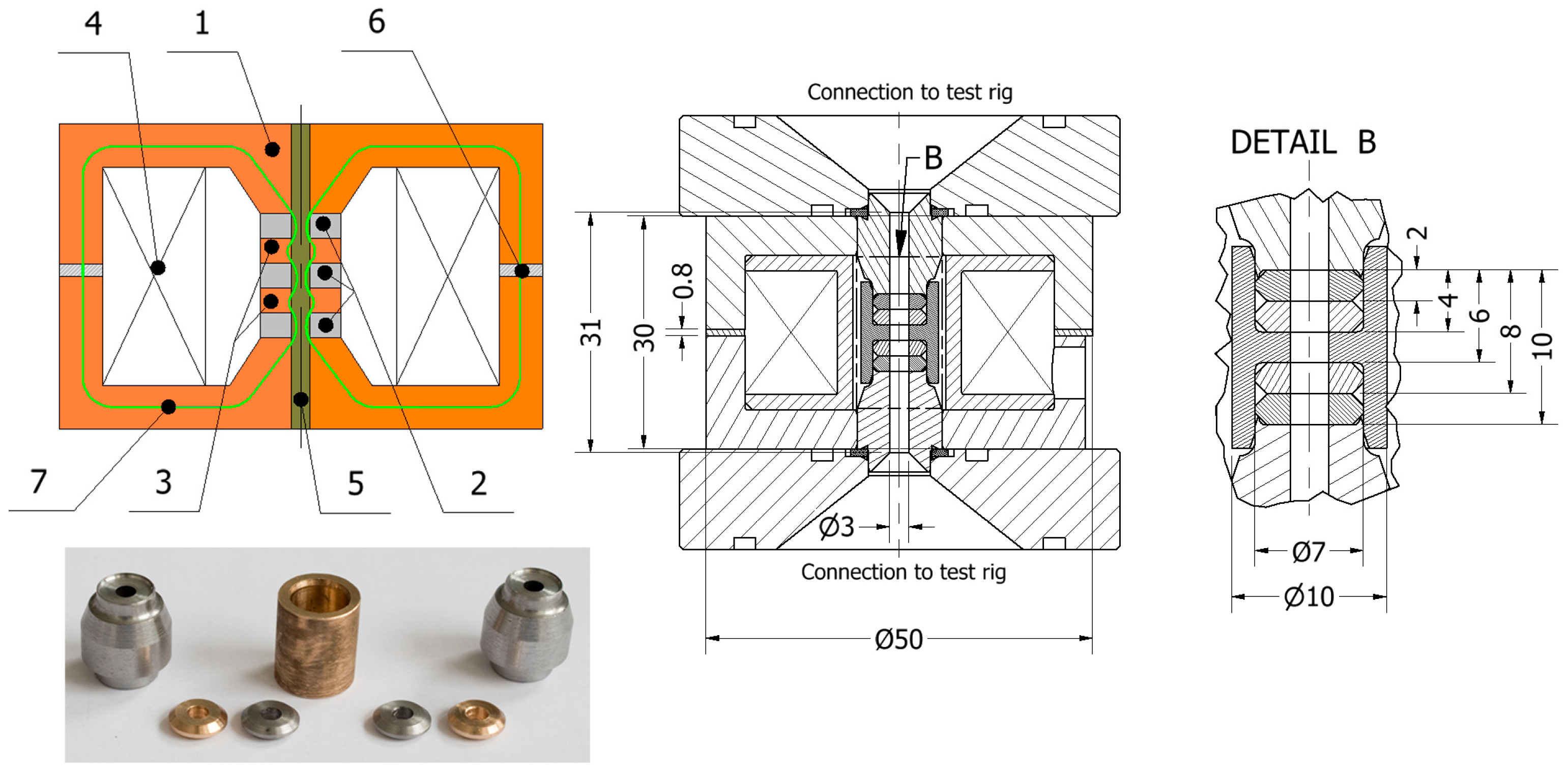

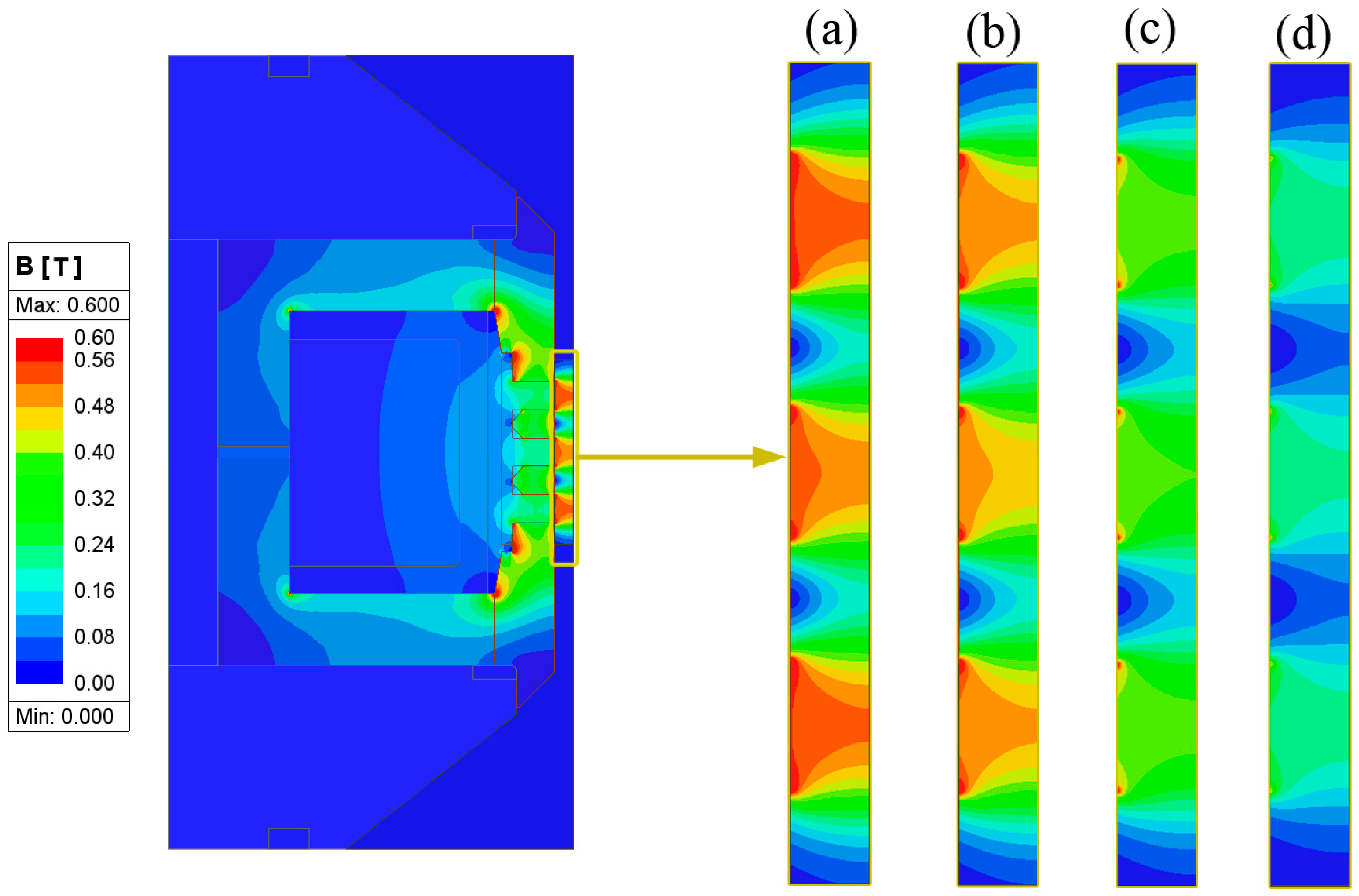

4.2. Three-Stage Prototype

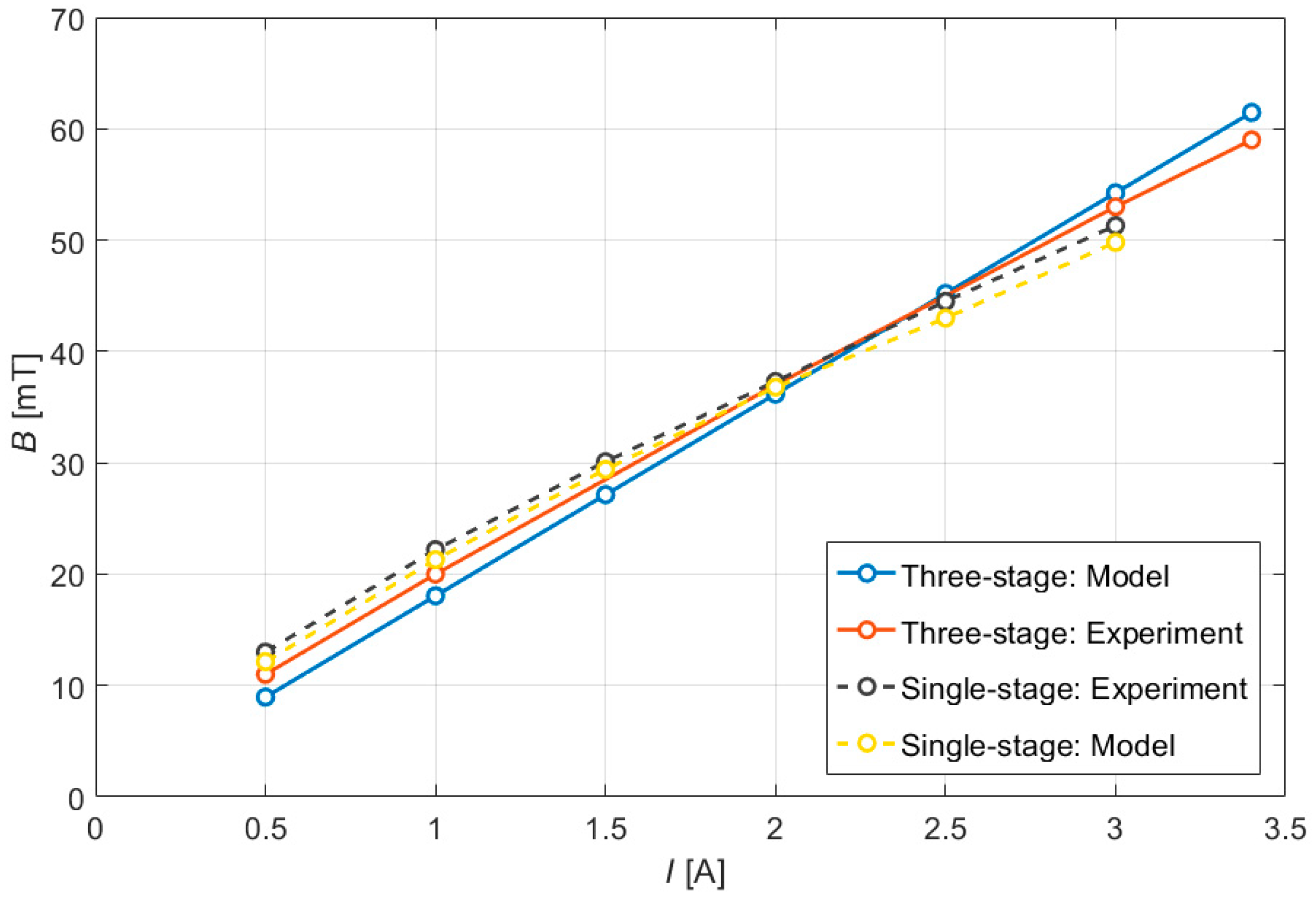

4.3. FE Magnetostatic Analysis and Experimental Validation

5. Magnetostatic Analysis and Laboratory Test Results

5.1. FE Calculations

5.2. Flow Bench Testing

5.2.1. Single-Stage Valve

5.2.2. Three-Stage Valve

5.3. Valve Performance Comparison

6. Conclusions

- The three-stage prototype reveals a superior performance when compared to its single-stage counterpart. The increase in the performance of the three-stage prototype is 55%.

- The three-stage prototype’s performance is somewhat hampered by the sequence of several air gaps in the solenoid for the magnetic flux to pass through. The air gaps are the elements causing the greatest reluctance; therefore, the level of current to generate an equivalent flux density in the flow channel is increased. Thus, the power consumption is higher in the case of the three-stage assembly.

- The three-stage valve is superior in terms of the slope factor variation when compared to the single-stage valve. At low flow rates, the largest slope factor of the three-stage valve is 4.5-times higher than the single-stage valve and augmented by 1.5 times at higher flow rates.

- The three-stage valve exhibits bilinear behavior at the highest current level, which is not observed in the single-stage prototype. This behavior may yield some performance advantages and merits further investigation.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- de Vicente, J.; Klingenberg, D.J.; Hidalgo-Alvarez, R. Magnetorheological fluids: A review. Soft Matter 2011, 7, 3701. [Google Scholar] [CrossRef]

- Kumar, J.S.; Paul, P.S.; Raghunathan, G.; Alex, D.G. A review of challenges and solutions in the preparation and use of magnetorheological fluids. Int. J. Mech. Mater. Eng. 2019, 14, 13. [Google Scholar] [CrossRef]

- Li, P.; Dong, X.; Wang, K.; Ran, J.; Yang, B. Characteristic analysis of magnetorheological fluid porous fabric composite with a novel constitute model. Smart Mater. Struct. 2023, 32, 025002. [Google Scholar] [CrossRef]

- Li, G.; Huang, Q.; Hu, G.; Ding, R.; Zhu, W.; Zeng, L. Semi-active fuzzy cooperative control of vehicle suspension with a magnetorheological damper. J. Intell. Mater. Syst. Struct. 2023, 34, 2106–2123. [Google Scholar] [CrossRef]

- Xia, D.; Fu, J.; Li, W.; Han, G.; Du, X.; Luo, L.; Yu, M. Incremental proportion integration differentiation control of all-terrain vehicle magnetorheological suspension system under low-frequency disturbances. Smart Mater. Struct. 2023, 32, 075019. [Google Scholar] [CrossRef]

- Yang, J.; Sun, S.; Ezani, S.; Gong, N.; Deng, L.; Zhang, S.; Li, W. New magnetorheological engine mount with controllable stiffness characteristics towards improved driving stability and ride comfort. Smart Mater. Struct. 2022, 31, 125009. [Google Scholar] [CrossRef]

- Chen, S.; Li, R.; Du, P.; Zheng, H.; Li, D. Parametric Modeling of a Magnetorheological Engine Mount Based on a Modified Polynomial Bingham Model. Front. Mater. 2019, 6, 68. [Google Scholar] [CrossRef]

- Koutsoloukas, L.; Nikitas, N.; Aristidou, P. Passive, semi-active, active and hybrid mass dampers: A literature review with associated applications on building-like structures. Dev. Built Environ. 2022, 12, 100094. [Google Scholar] [CrossRef]

- Demetriou, D.; Nikitas, N.; Tsavdaridis, K.D. Performance of fixed-parameter control algorithms on high-rise structures equipped with semi-active tuned mass dampers. Struct. Des. Tall Spec. Build. 2016, 25, 340–354. [Google Scholar] [CrossRef]

- Liu, J.; Qu, W.; Nikitas, N.; Ji, Z. Research on extending the fatigue life of railway steel bridges by using intelligent control. Constr. Build. Mater. 2018, 168, 532–546. [Google Scholar] [CrossRef]

- Sapiński, B.; Rosół, M. Autonomous control system for a 3 DOF pitch-plane suspension model with MR shock absorbers. Comput. Struct. 2008, 86, 379–385. [Google Scholar] [CrossRef]

- Strecker, Z.; Jeniš, F.; Kubík, M.; Macháček, O.; Choi, S.-B. Novel Approaches to the Design of an Ultra-Fast Magnetorheological Valve for Semi-Active Control. Materials 2021, 14, 2500. [Google Scholar] [CrossRef]

- Žáček, J.; Šebesta, K.; Mohammad, H.; Jeniš, F.; Strecker, Z.; Kubík, M. Experimental Evaluation of Modified Groundhook Car Suspension with Fast Magnetorheological Damper. Actuators 2022, 11, 354. [Google Scholar] [CrossRef]

- Wereley, N.M.; Cho, J.U.; Choi, Y.T.; Choi, S.B. Magnetorheological dampers in shear mode. Smart Mater. Struct. 2008, 17, 015022. [Google Scholar] [CrossRef]

- Lee, T.-H.; Kang, B.-H.; Choi, S.-B. A quasi-static model for the pinch mode analysis of a magnetorheological fluid flow with an experimental validation. Mech. Syst. Signal Process. 2019, 134, 106308. [Google Scholar] [CrossRef]

- Kubík, M.; Gołdasz, J.; Macháček, O.; Strecker, Z.; Sapiński, B. Magnetorheological fluids subjected to non-uniform magnetic fields: Experimental characterization. Smart Mater. Struct. 2023, 32, 035007. [Google Scholar] [CrossRef]

- Carlson, J.; Goncalves, F.; Catanzarite, D.; Dobbs, D. Controllable Magnetorheological Fluid Valve, Devices, and Methods. U.S. Patent US20080060710A1, 3 March 2008. [Google Scholar]

- Golini, D.; Kordonski, W.I.; Dumas, P.; Hogan, S.J. Magnetorheological Finishing (MRF) in Commercial Precision Optics Manufacturing; Stahl, H.P., Ed.; SPIE: Bellingham, WA, USA, 1999; pp. 80–91. [Google Scholar]

- Kordonsky, W.I.; Prokhorov, I.V.; Gorodkin, G.; Jacobs, S.D.; Puchebner, B.; Pietrowski, D. Magnetorheological Finishing. Opt. Photonics News 1993, 4, 16. [Google Scholar] [CrossRef]

- Jolly, M.R.; Bender, J.W.; Carlson, J.D. Properties and Applications of Commercial Magnetorheological Fluids. J. Intell. Mater. Syst. Struct. 1999, 10, 5–13. [Google Scholar] [CrossRef]

- Gällsjö, A.; Johansson, M. Physical Modelling and Automatic Configuration of CES Valve; Linköping University: Linköping, Sweden, 2012. [Google Scholar]

- Gong, X.; Ruan, X.; Xuan, S.; Yan, Q.; Deng, H. Magnetorheological Damper Working in Squeeze Mode. Adv. Mech. Eng. 2014, 6, 410158. [Google Scholar] [CrossRef]

- Kim, B.-G.; Yoon, D.-S.; Kim, G.-W.; Choi, S.-B.; Tan, A.S.; Sattel, T. Design of a Novel Magnetorheological Damper Adaptable to Low and High Stroke Velocity of Vehicle Suspension System. Appl. Sci. 2020, 10, 5586. [Google Scholar] [CrossRef]

- Kubík, M.; Šebesta, K.; Strecker, Z.; Jeniš, F.; Goldasz, J.; Mazůrek, I. Hydrodynamic response time of magnetorheological fluid in valve mode: Model and experimental verification. Smart Mater. Struct. 2021, 30, 125020. [Google Scholar] [CrossRef]

- Ocalan, M.; McKinley, G.H. Rheology and microstructural evolution in pressure-driven flow of a magnetorheological fluid with strong particle–wall interactions. J. Intell. Mater. Syst. Struct. 2012, 23, 969–978. [Google Scholar] [CrossRef]

- Schümann, M.; Odenbach, S. The microstructure of magnetorheological materials characterized by means of computed X-ray microtomography. Phys. Sci. Rev. 2023, 8, 1487–1511. [Google Scholar] [CrossRef]

- Wang, N.; Liu, X.; Sun, S.; Królczyk, G.; Li, Z.; Li, W. Microscopic characteristics of magnetorheological fluids subjected to magnetic fields. J. Magn. Magn. Mater. 2020, 501, 166443. [Google Scholar] [CrossRef]

- Shen, Y.; Hua, D.; Liu, X.; Li, W.; Krolczyk, G.; Li, Z. Visualizing rheological mechanism of magnetorheological fluids. Smart Mater. Struct. 2022, 31, 025027. [Google Scholar] [CrossRef]

- Zhang, L.; Gu, S.; Guo, S.; Tamiya, T. A Magnetorheological Fluids-Based Robot-Assisted Catheter/Guidewire Surgery System for Endovascular Catheterization. Micromachines 2021, 12, 640. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Žáček, J.; Goldasz, J.; Sapinski, B.; Sedlačík, M.; Strecker, Z.; Kubík, M. Assessment of the Dynamic Range of Magnetorheological Gradient Pinch-Mode Prototype Valves. Actuators 2023, 12, 449. https://doi.org/10.3390/act12120449

Žáček J, Goldasz J, Sapinski B, Sedlačík M, Strecker Z, Kubík M. Assessment of the Dynamic Range of Magnetorheological Gradient Pinch-Mode Prototype Valves. Actuators. 2023; 12(12):449. https://doi.org/10.3390/act12120449

Chicago/Turabian StyleŽáček, Jiří, Janusz Goldasz, Bogdan Sapinski, Michal Sedlačík, Zbyněk Strecker, and Michal Kubík. 2023. "Assessment of the Dynamic Range of Magnetorheological Gradient Pinch-Mode Prototype Valves" Actuators 12, no. 12: 449. https://doi.org/10.3390/act12120449

APA StyleŽáček, J., Goldasz, J., Sapinski, B., Sedlačík, M., Strecker, Z., & Kubík, M. (2023). Assessment of the Dynamic Range of Magnetorheological Gradient Pinch-Mode Prototype Valves. Actuators, 12(12), 449. https://doi.org/10.3390/act12120449