Design and First Operation of an Active Lower Limb Exoskeleton with Parallel Elastic Actuation

Abstract

1. Introduction

2. Mechanical Design

2.1. Design Requirements

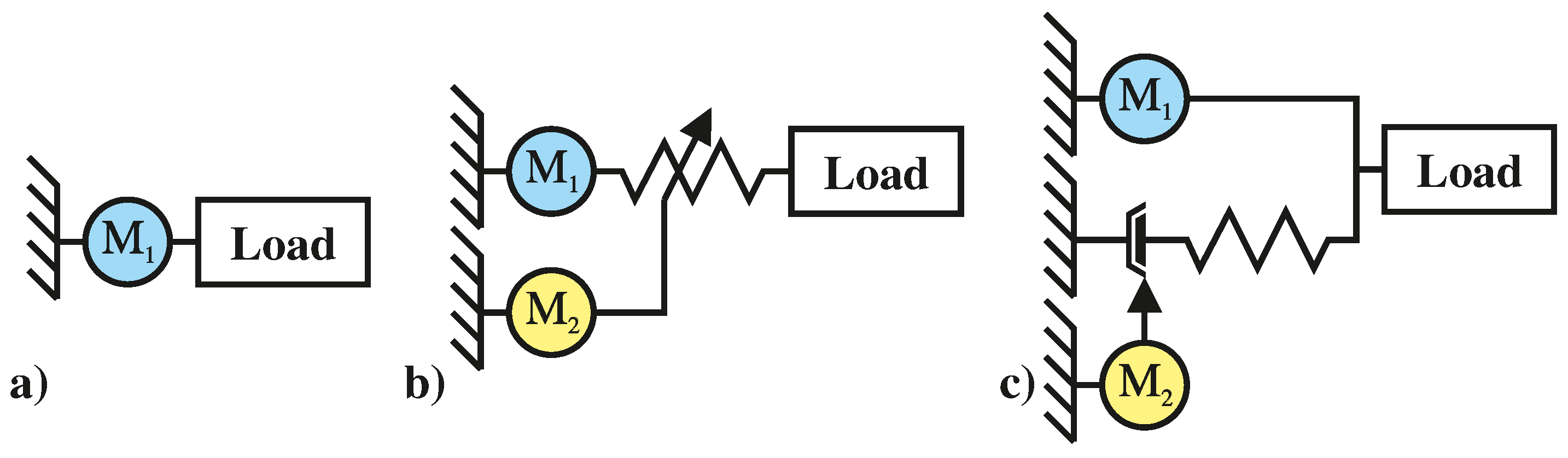

2.2. Actuator Design

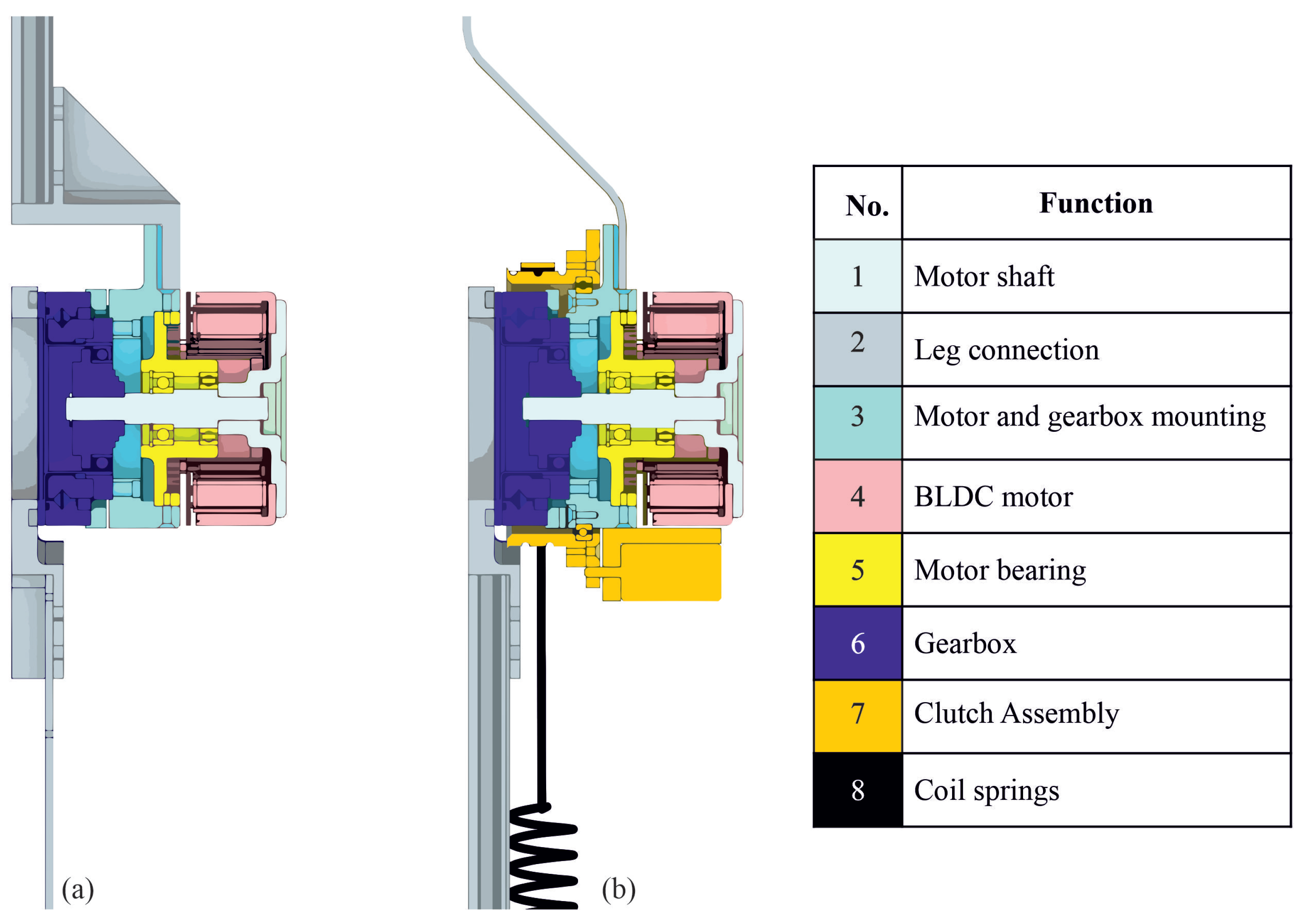

, the motor mounting

, the motor mounting  and an EC90 flat frameless motor

and an EC90 flat frameless motor  (Maxon Motor AG, Sachseln, Switzerland). A Harmonic Drive HFUS-2SO reduction gear (Harmonic Drive AG, Limburg an der Lahn, Germany)

(Maxon Motor AG, Sachseln, Switzerland). A Harmonic Drive HFUS-2SO reduction gear (Harmonic Drive AG, Limburg an der Lahn, Germany)  with a transmission of 50/1 is used in both cases. The integrated cross roller bearing also serves as a joint bearing for the hip and knee. The limitation of the joint angles of the actuators is realized by a two-sided mechanical end stop, which acts between the gearbox output

with a transmission of 50/1 is used in both cases. The integrated cross roller bearing also serves as a joint bearing for the hip and knee. The limitation of the joint angles of the actuators is realized by a two-sided mechanical end stop, which acts between the gearbox output  and the gearbox mounting

and the gearbox mounting  . Thus, the knee movement is limited from 0 to 2.1 rad, and the hip movement from −0.3 to 1.8 rad. The leg connection

. Thus, the knee movement is limited from 0 to 2.1 rad, and the hip movement from −0.3 to 1.8 rad. The leg connection  is designed as a link between the reduction gear or motor attachment

is designed as a link between the reduction gear or motor attachment  and an aluminum profile. In the case of the CPEA, the gearbox mounting

and an aluminum profile. In the case of the CPEA, the gearbox mounting  is encased by a cable drum supported by a four-point bearing and can be locked by a 30 W switching magnet HMB-2218s

is encased by a cable drum supported by a four-point bearing and can be locked by a 30 W switching magnet HMB-2218s  (Tremba GmbH, Hallbergmoos-Goldbach, Germany). Coil springs

(Tremba GmbH, Hallbergmoos-Goldbach, Germany). Coil springs  are mounted on both sides of the cable drum

are mounted on both sides of the cable drum  with a wire rope, thus, realizing a parallel elasticity. Four different coil springs, 1.82, 3.76, 5.49 and 11.96 N/mm, (Gutekunst + Co. KG, Metzingen, Germany) are selected to realize a spring rate of 10.2, 21.1, 30.8 or 67 Nm/rad, respectively, for the PE. The PE provides a maximum torque of ≈ 21 N·m for the spring rate of 30.8 Nm/rad and a maximum deflection of 0.7 rad in both directions. A mass of 3 kg for one actuator was not exceeded for either the CPEA or RA.

with a wire rope, thus, realizing a parallel elasticity. Four different coil springs, 1.82, 3.76, 5.49 and 11.96 N/mm, (Gutekunst + Co. KG, Metzingen, Germany) are selected to realize a spring rate of 10.2, 21.1, 30.8 or 67 Nm/rad, respectively, for the PE. The PE provides a maximum torque of ≈ 21 N·m for the spring rate of 30.8 Nm/rad and a maximum deflection of 0.7 rad in both directions. A mass of 3 kg for one actuator was not exceeded for either the CPEA or RA.2.3. Exoskeleton Design

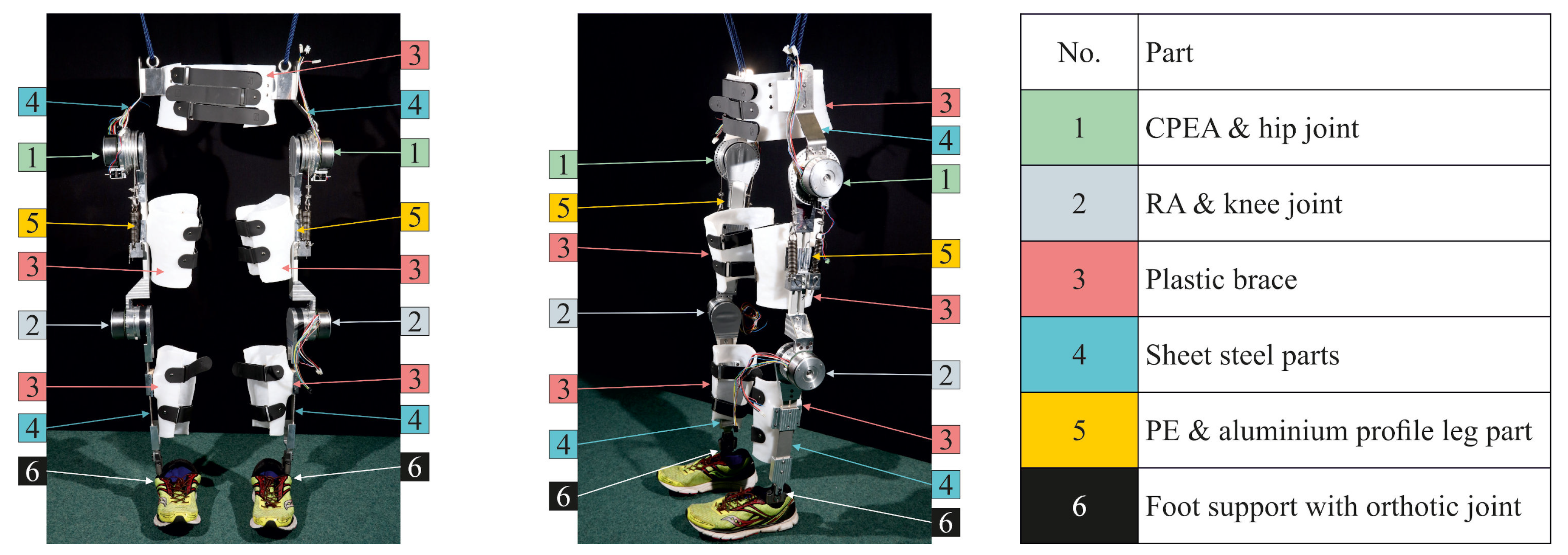

, each as a hip joint, and two RAs

, each as a hip joint, and two RAs  , each as a knee joint. Thus, only the hip joint has a parallel stiffness, which is mounted on the exoskeleton’s thigh part. The thigh Section

, each as a knee joint. Thus, only the hip joint has a parallel stiffness, which is mounted on the exoskeleton’s thigh part. The thigh Section  consists of an aluminum profile (item Industrietechnik GmbH, Mühlhausen, Germany). The linking parts for the lower leg and hip part

consists of an aluminum profile (item Industrietechnik GmbH, Mühlhausen, Germany). The linking parts for the lower leg and hip part  are made of cold formable sheet steel (1.4301). These sheet metal parts can be adapted to the anatomy of a subject in the frontal plane to fit individual knock-knees or bow legs. The thighs, lower legs and hip parts are fitted to a test person size of = 1.81 m. The distance from the ankle to the knee joint and from the knee to the hip joint is = 430 mm each. The length of the lower leg, thigh and hip links can be modified by ±20, ±22 and ±13 mm, respectively. This adjustment would correspond to a height range of = 1.72–1.90 m [23]. Other connecting links can be installed for further adjustments.

are made of cold formable sheet steel (1.4301). These sheet metal parts can be adapted to the anatomy of a subject in the frontal plane to fit individual knock-knees or bow legs. The thighs, lower legs and hip parts are fitted to a test person size of = 1.81 m. The distance from the ankle to the knee joint and from the knee to the hip joint is = 430 mm each. The length of the lower leg, thigh and hip links can be modified by ±20, ±22 and ±13 mm, respectively. This adjustment would correspond to a height range of = 1.72–1.90 m [23]. Other connecting links can be installed for further adjustments. (Streifeneder KG, Emmering, Germany). The shells are fastened with hook-and-loop tape, which is attached to the shells with 4 mm rivets. The foot part

(Streifeneder KG, Emmering, Germany). The shells are fastened with hook-and-loop tape, which is attached to the shells with 4 mm rivets. The foot part  is made of carbon fiber and is equipped with a Nexgear Tango ankle joint (Otto Bock HealthCare Deutschland GmbH, Duderstadt, Germany). The latter is prepared so that it can be spring- or damper-actuated. The material of the foot plates is about 3 mm thick; therefore, they can be worn in the shoes of the test subjects. The complete exoskeleton without an integrated power supply weighs 17.2 kg, of which 11.2 kg is attributed to the actuators.

is made of carbon fiber and is equipped with a Nexgear Tango ankle joint (Otto Bock HealthCare Deutschland GmbH, Duderstadt, Germany). The latter is prepared so that it can be spring- or damper-actuated. The material of the foot plates is about 3 mm thick; therefore, they can be worn in the shoes of the test subjects. The complete exoskeleton without an integrated power supply weighs 17.2 kg, of which 11.2 kg is attributed to the actuators.3. Materials and Methods

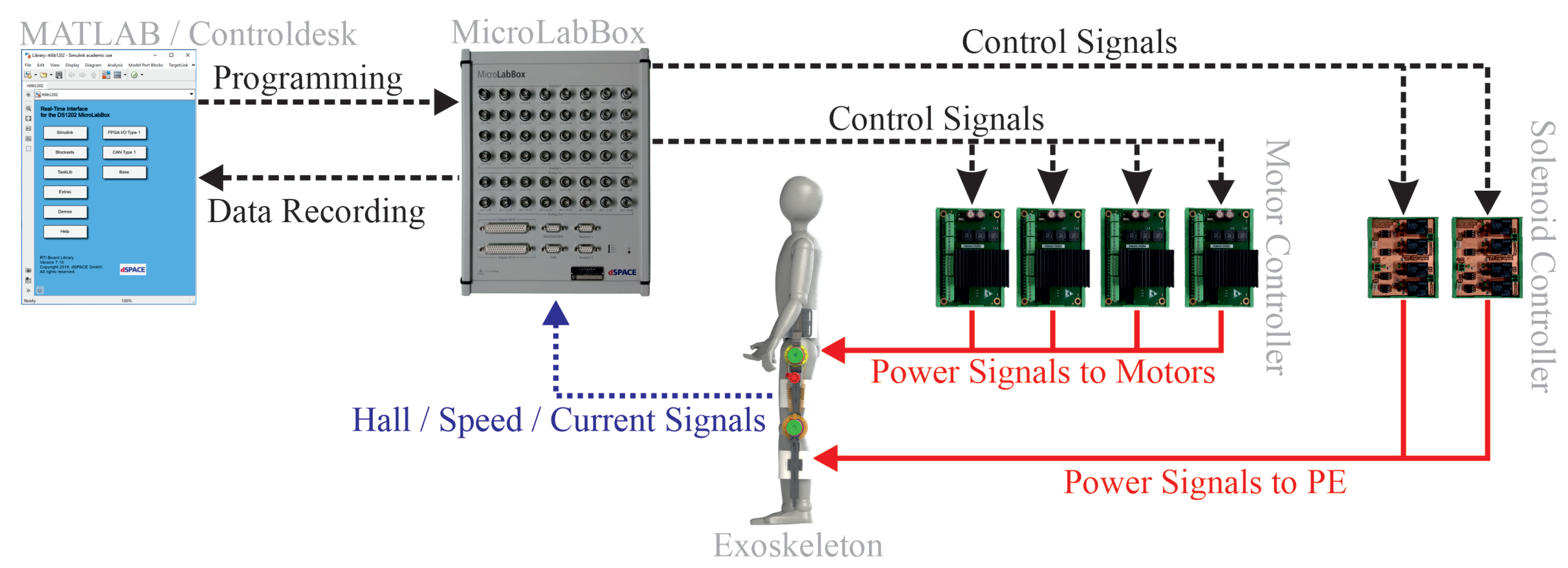

3.1. Experimental Setup

3.2. Actuator Control

3.3. Simulation of Sit-to-Stand

3.4. Gait Experiments

3.5. Ethics Committee (EK190-19)

4. Results

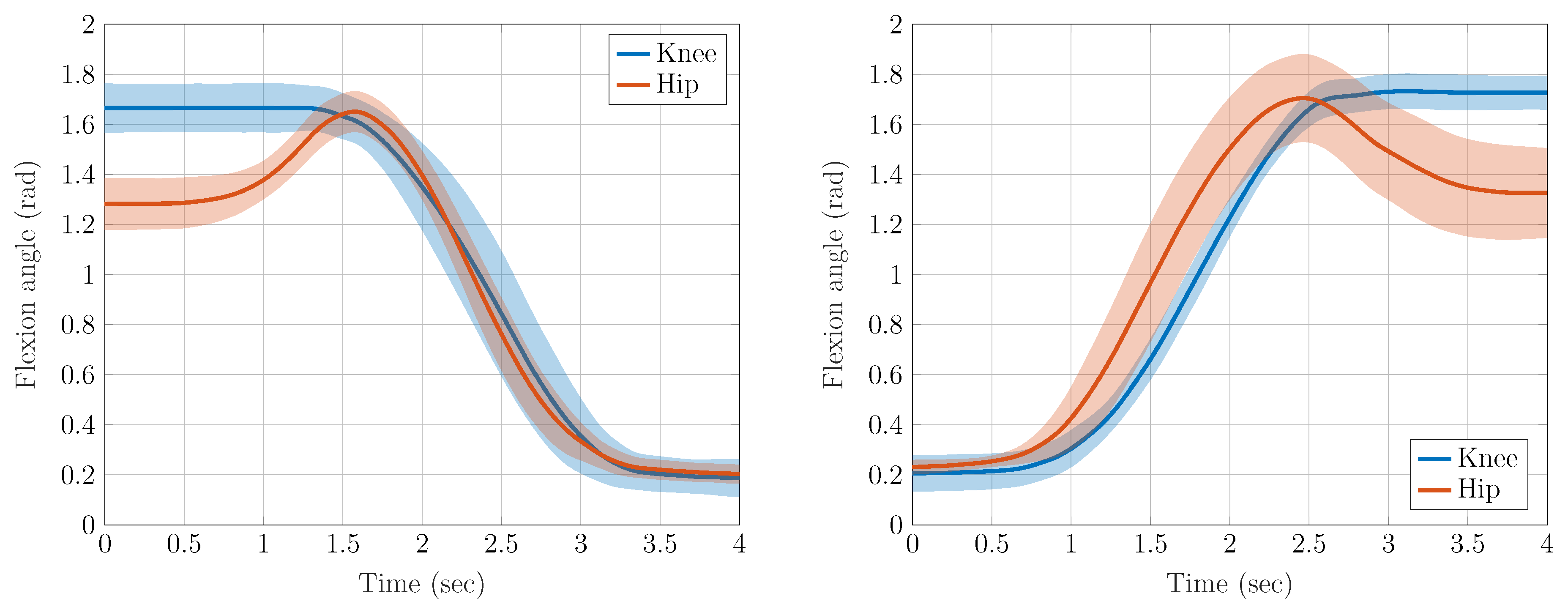

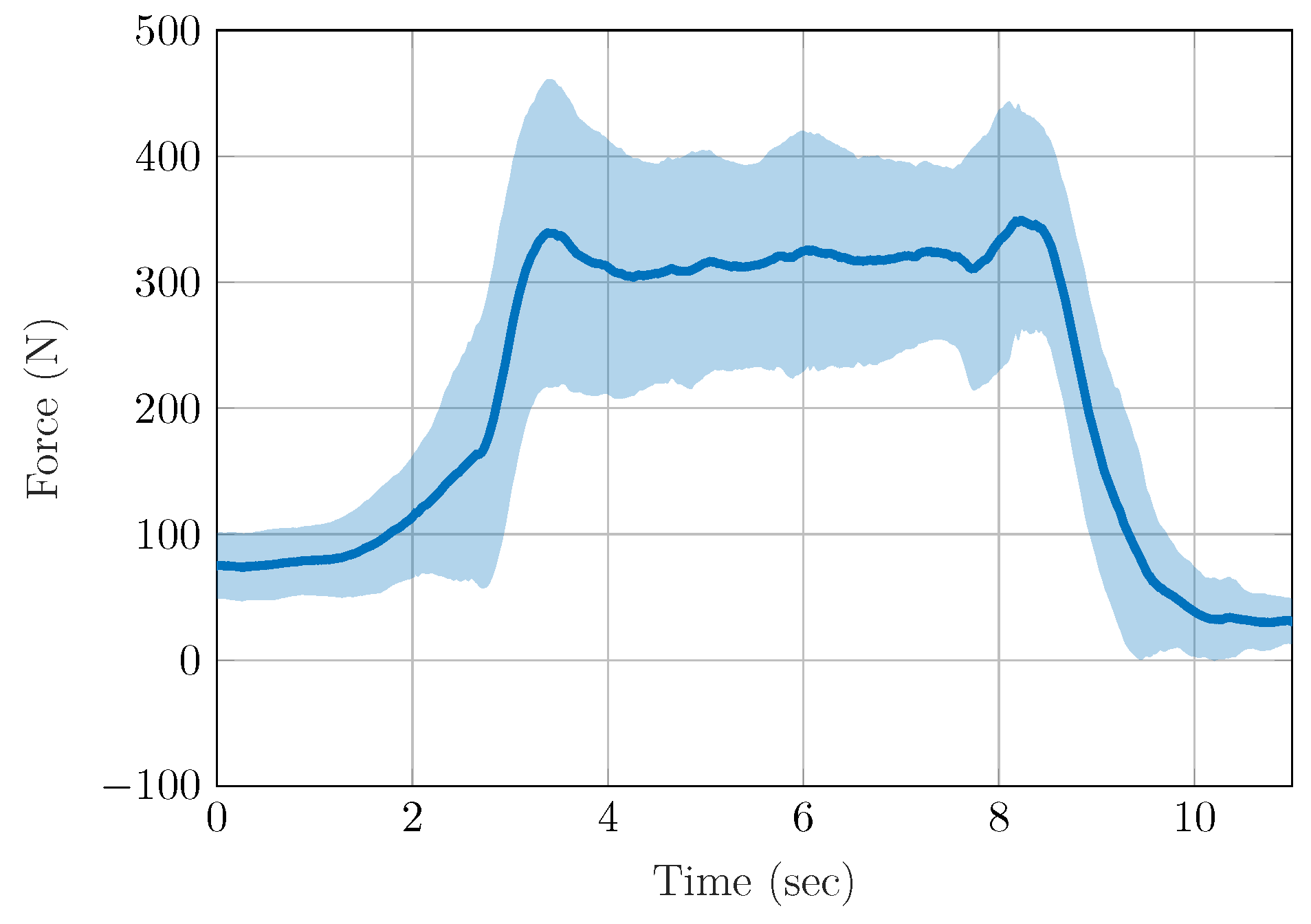

4.1. Results of Sit-to-Stand Experiments

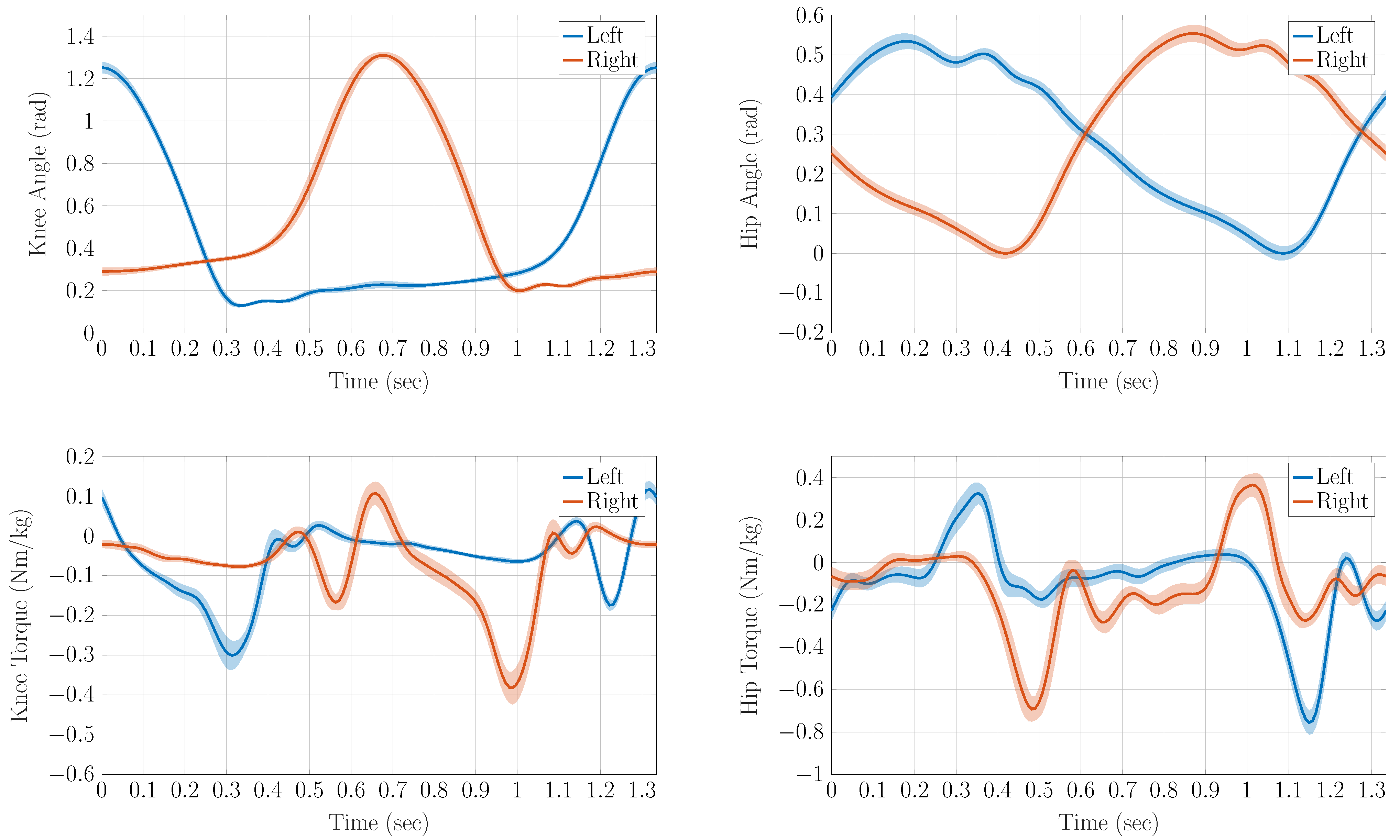

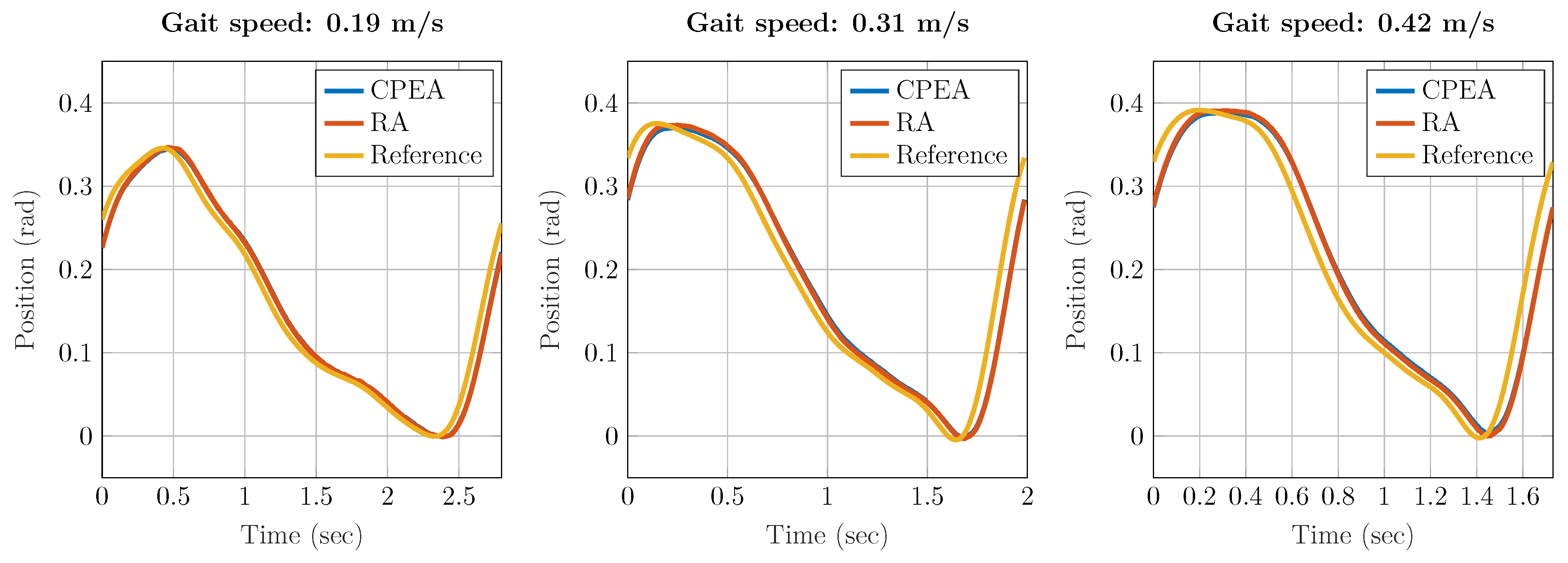

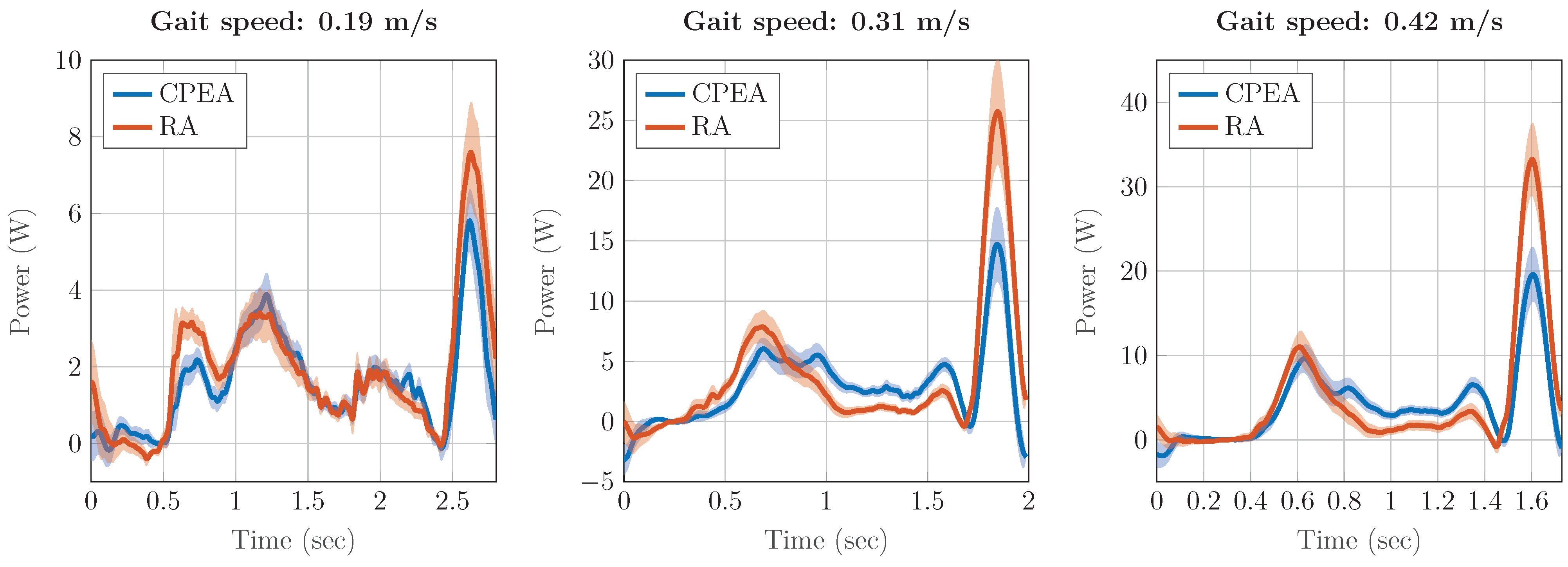

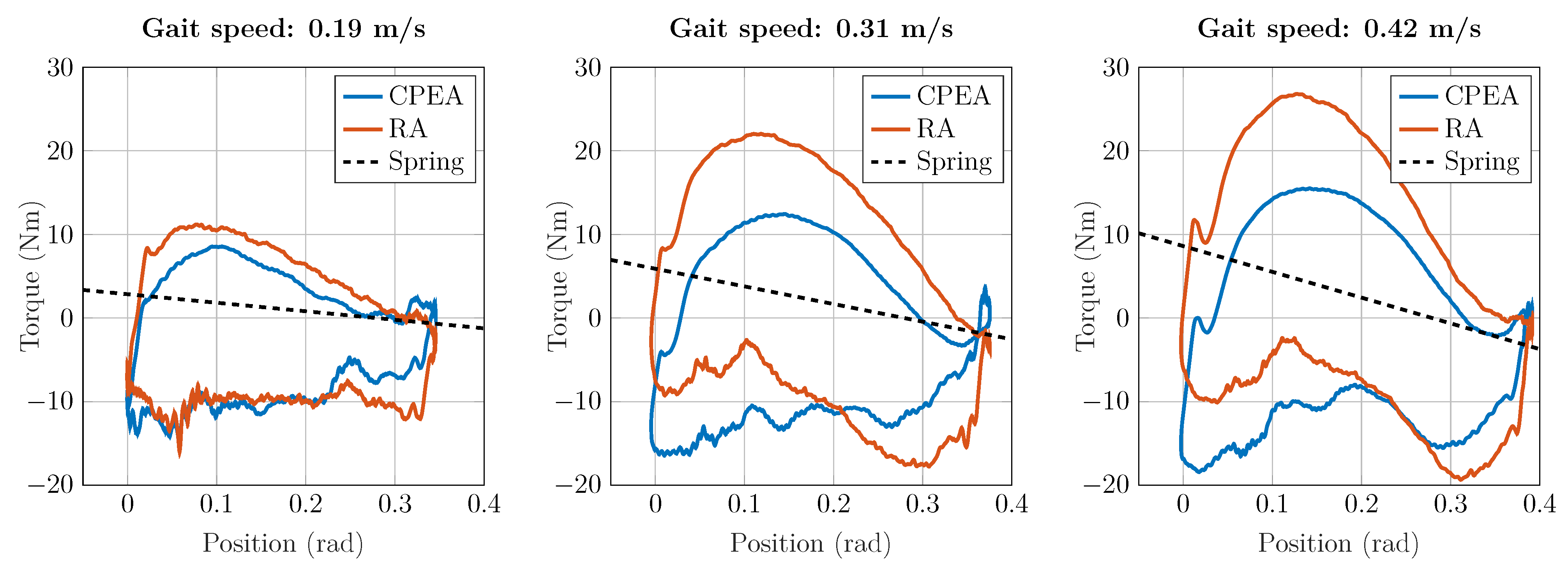

4.2. Results of Gait Experiments

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| BLDC | Brushless Direct Current |

| CPEA | Clutched Parallel Elastic Actuator |

| MLB | MicroLabBox |

| PE | Parallel Elasticity |

| PEA | Parallel Elastic Actuator |

| RA | Rigid Actuator |

| RMS | Root Mean Square |

| SEA | Serial Elastic Actuator |

Appendix A. Lagrange

Appendix A.1. Joint Torques

References

- Schütz, A. Robotic Exoskeleton: For a Better Quality of Life. Maxon Motor 2012. Available online: https://www.maxongroup.com/maxon/view/application/Robotic-exoskeleton-For-a-better-quality-of-life (accessed on 28 March 2021).

- Gorgey, A.S.; Sumrell, R.; Goetz, L.L. Exoskeletal assisted rehabilitation after spinal cord injury. In Atlas of Orthoses and Assistive Devices; Elsevier: Amsterdam, The Netherlands, 2019; pp. 440–447. [Google Scholar]

- Colombo, G.; Joerg, M.; Schreier, R.; Dietz, V. Treadmill training of paraplegic patients using a robotic orthosis. J. Rehabil. Res. Dev. 2000, 37, 693–700. [Google Scholar] [PubMed]

- Tabti, N.; Kardofaki, M.; Alfayad, S.; Chitour, Y.; Ouezdou, F.B.; Dychus, E. A Brief Review of the Electronics, Control System Architecture, and Human Interface for Commercial Lower Limb Medical Exoskeletons Stabilized by Aid of Crutches. In Proceedings of the 2019 28th IEEE International Conference on Robot and Human Interactive Communication (RO-MAN), New Delhi, India, 14–18 October 2019; pp. 1–6. [Google Scholar]

- Zhang, T.; Tran, M.; Huang, H. Design and experimental verification of hip exoskeleton with balance capacities for walking assistance. IEEE/ASME Trans. Mechatron. 2018, 23, 274–285. [Google Scholar] [CrossRef]

- Neuhaus, P.D.; Noorden, J.H.; Craig, T.J.; Torres, T.; Kirschbaum, J.; Pratt, J.E. Design and Evaluation of Mina: A Robotic Orthosis for Paraplegics. In Proceedings of the IEEE International Conference on Rehabilitation Robotics, Zurich, Switzerland, 29 June–1 July 2011; pp. 1–8. [Google Scholar]

- Wang, S.; Wang, L.; Meijneke, C.; Van Asseldonk, E.; Hoellinger, T.; Cheron, G.; Ivanenko, Y.; La Scaleia, V.; Sylos-Labini, F.; Molinari, M.; et al. Design and control of the MINDWALKER exoskeleton. IEEE Trans. Neural Syst. Rehabil. Eng. 2014, 23, 277–286. [Google Scholar] [CrossRef] [PubMed]

- Mummolo, C.; Peng, W.Z.; Agarwal, S.; Griffin, R.; Neuhaus, P.D.; Kim, J.H. Stability of mina v2 for robot-assisted balance and locomotion. Front. Neurorobotics 2018, 12, 62. [Google Scholar] [CrossRef]

- Liu, L.; Hong, Z.; Penzlin, B.; Misgeld, B.; Ngo, C.; Bergmann, L.; Leonhardt, S. Low impedance-guaranteed gain-scheduled GESO for torque-controlled VSA, with application of exoskeleton-assisted sit-to-stand. IEEE/ASME Trans. Mechatron. 2020. [Google Scholar] [CrossRef]

- Masood, J.; Ortiz, J.; Fernández, J.; Mateos, L.A.; Caldwell, D.G. Mechanical Design and Analysis of Light Weight Hip Joint Parallel Elastic Actuator for Industrial Exoskeleton. In Proceedings of the 2016 6th IEEE International Conference on Biomedical Robotics and Biomechatronics (BioRob), Singapore, 26–29 June 2016; pp. 631–636. [Google Scholar] [CrossRef]

- Verstraten, T.; Beckerle, P.; Furnémont, R.; Mathijssen, G.; Vanderborght, B.; Lefeber, D. Series and parallel elastic actuation: Impact of natural dynamics on power and energy consumption. Mech. Mach. Theory 2016, 102, 232–246. [Google Scholar] [CrossRef]

- Plooij, M.; Wisse, M.; Vallery, H. Reducing the energy consumption of robots using the bidirectional clutched parallel elastic actuator. IEEE Trans. Robot. 2016, 32, 1512–1523. [Google Scholar] [CrossRef]

- Aftabi, H.; Nasiri, R.; Ahmadabadi, M.N. A kinematic index for estimation of metabolic rate reduction in running with I-RUN. bioRxiv 2020. [Google Scholar] [CrossRef]

- Wang, S.; Van Dijk, W.; van der Kooij, H. Spring Uses in Exoskeleton Actuation Design. In Proceedings of the IEEE International Conference on Rehabilitation Robotics (ICORR), Zurich, Switzerland, 29 June–1 July 2011. [Google Scholar]

- Penzlin, B.; Enes Fincan, M.; Li, Y.; Ji, L.; Leonhardt, S.; Ngo, C. Design and Analysis of a Clutched Parallel Elastic Actuator. Actuators 2019, 8, 67. [Google Scholar] [CrossRef]

- Li, Y.; Guan, X.; Li, Z.; Tang, Z.; Penzlin, B.; Yang, Z.; Leonhardt, S.; Ji, L. Analysis, design, and preliminary evaluation of a parallel elastic actuator for power-efficient walking assistance. IEEE Access 2020, 8, 88060–88075. [Google Scholar] [CrossRef]

- Li, Y.; Li, Z.; Penzlin, B.; Tang, Z.; Liu, Y.; Guan, X.; Ji, L.; Leonhardt, S. Design of the Clutched Variable Parallel Elastic Actuator (CVPEA) for Lower Limb Exoskeletons. In Proceedings of the 41st Annual International Conference of the IEEE Engineering in Medicine and Biology Society (EMBC), Berlin, Germany, 23–27 July 2019. [Google Scholar]

- Lehmann, A.; Floris, J.; Woitek, U.; Rühli, F.J.; Staub, K. Temporal trends, regional variation and socio-economic differences in height, BMI and body proportions among German conscripts, 1956–2010. Public Health Nutr. 2017, 20, 391–403. [Google Scholar] [CrossRef] [PubMed]

- Wu, A.R.; Simpson, C.S.; van Asseldonk, E.H.; van der Kooij, H.; Ijspeert, A.J. Mechanics of very slow human walking. Sci. Rep. 2019, 9, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Perry, J.; Burnfield, J. Gait Analysis-Normal and Pathological Function, 2nd ed.; Slack Incorporated: Thorofare, NJ, USA, 2010. [Google Scholar]

- Pai, Y.C.; Rogers, M.W. Speed variation and resultant joint torques during sit-to-stand. Arch. Phys. Med. Rehabil. 1991, 72, 881–885. [Google Scholar] [CrossRef]

- Kong, K.; Bae, J.; Tomizuka, M. A Compact Rotary Series Elastic Actuator for Knee Joint Assistive System. In Proceedings of the IEEE International Conference on Robotics and Automation (ICRA), Anchorage, AK, USA, 3–7 May 2010. [Google Scholar]

- De Leva, P. Adjustments to Zatsiorsky-Seluyanovs segment inertia parameters. J. Biomech. 1996, 29, 1223–1230. [Google Scholar] [CrossRef]

- Cappozzo, A.; Catani, F.; Della Croce, U.; Leardini, A. Position and orientation in space of bones during movement: Anatomical frame definition and determination. Clin. Biomech. 1995, 10, 171–178. [Google Scholar] [CrossRef]

- Vukobratović, M.; Borovac, B. Zero-moment point—thirty five years of its life. Int. J. Humanoid Robot. 2004, 1, 157–173. [Google Scholar] [CrossRef]

- Harmonic Drive, A.G. Projektierungsanleitung Units HFUS-2UH / 2SO / 2SH, 2nd ed.; Harmonic Drive AG: Limburg, Germany, 2018; p. 13. [Google Scholar]

- Penzlin, B.; Leipnitz, A.; Bergmann, L.; Li, Y.; Ji, L.; Leonhardt, S.; Ngo, C. Conceptual design, modeling and control of a rigid parallel serial-elastic actuator. at-Automatisierungstechnik 2020, 68, 410–422. [Google Scholar] [CrossRef]

- Yoshioka, S.; Nagano, A.; Hay, D.C.; Fukashiro, S. Peak hip and knee joint moments during a sit-to-stand movement are invariant to the change of seat height within the range of low to normal seat height. Biomed. Eng. Online 2014, 13, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Browning, R.C.; Kram, R. Effects of obesity on the biomechanics of walking at different speeds. Med. Sci. Sport. Exerc. 2007, 39, 1632–1641. [Google Scholar] [CrossRef] [PubMed]

- Lenzi, T.; Carrozza, M.C.; Agrawal, S.K. Powered hip exoskeletons can reduce the user’s hip and ankle muscle activations during walking. IEEE Trans. Neural Syst. Rehabil. Eng. 2013, 21, 938–948. [Google Scholar] [CrossRef]

| Exoskeleton | Gait Velocity | Joint Torque (Hip|Knee) | Joint Power (Hip|Knee) | Mass | Reference |

|---|---|---|---|---|---|

| REX | 0.1 m/s | 150 W|150 W (nominal) | 50 kg | [1] | |

| Mina (V2) | 0.29 m/s | 110 N·m|110 N·m (peak) | 355 W|355 W (nominal) | 34 kg | [6,8] |

| ReWalk | 0.71 m/s | 30 kg | [2] | ||

| Ekso GT | 0.44 m/s | 83 N·m|83 N·m (peak) | 23 kg | [2,4] | |

| Indego | 0.36 m/s | 80 N·m|80 N·m (peak) | 17.7 kg | [2,4] | |

| Zhang et al. | 0.8 m/s | 40 N·m|-(nominal) | 90 W|-(nominal) | 9.2 kg | [5] |

| Lokomat | 0.8 m/s | 50 N·m|30 N·m (nom.) | 150 W|150 W (nominal) | [3] | |

| Mindwalker | 0.8 m/s | 100 N·m|100 N·m (peak) | 960 W|960 W (peak) | 28 kg | [7] |

| Actuator | CPEA | RA |

|---|---|---|

| Nominal torque | 49.4 Nm | 49.4 Nm |

| Nominal speed | 3.7 rad/s | 3.7 rad/s |

| No load speed | 4.4 rad/s | 4.4 rad/s |

| Rated motor power | 260 W | 260 W |

| Mass | 3.0 kg (including 30 Nm/rad springs) | 2.6 kg |

| Axial length | 105 mm | 105 mm |

| Spring rate | 10–67 Nm/rad (Mass: 50–360 g) | – |

| Spring type | Steel tension springs (EN 10270-1) | – |

| Clutch actuator | Bistable solenoid (30 W) | – |

| Joint | Knee | Hip | ||||

|---|---|---|---|---|---|---|

| Gait Velocity | 0.19 m/s | 0.31 m/s | 0.42 m/s | 0.19 m/s | 0.31 m/s | 0.42 m/s |

| (s) | 2.814 | 1.993 | 1.740 | 2.814 | 1.993 | 1.740 |

| (rad) | 0.352 | 0.387 | 0.407 | 0.150 | 0.192 | 0.209 |

| (rad) | 0.221 | 0.309 | 0.339 | 0.138 | 0.176 | 0.187 |

| (rad) | 0.091 | 0.073 | 0.079 | −1.139 | −1.177 | −1.225 |

| (rad) | 0.153 | 0.211 | 0.226 | 0.055 | 0.049 | 0.043 |

| (rad) | 0.075 | −0.010 | −0.038 | −1.142 | −1.070 | −1.010 |

| (rad) | 0.104 | 0.115 | 0.107 | 0.029 | 0.031 | 0.032 |

| (rad) | −0.050 | −0.161 | −0.178 | −0.564 | −0.266 | −0.212 |

| (rad) | 0.063 | 0.044 | 0.030 | 0.014 | 0.015 | 0.012 |

| (rad) | −0.151 | −0.301 | −0.332 | −0.406 | 0.124 | 0.197 |

| (rad) | 0.032 | 0.011 | 0.008 | 0.009 | 0.005 | 0.005 |

| (rad) | −0.070 | 0.255 | 1.334 | 0.187 | 0.671 | 1.754 |

| (rad) | 0.011 | 0.009 | 0.010 | 0.005 | 0.005 | 0.005 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Penzlin, B.; Bergmann, L.; Li, Y.; Ji, L.; Leonhardt, S.; Ngo, C. Design and First Operation of an Active Lower Limb Exoskeleton with Parallel Elastic Actuation. Actuators 2021, 10, 75. https://doi.org/10.3390/act10040075

Penzlin B, Bergmann L, Li Y, Ji L, Leonhardt S, Ngo C. Design and First Operation of an Active Lower Limb Exoskeleton with Parallel Elastic Actuation. Actuators. 2021; 10(4):75. https://doi.org/10.3390/act10040075

Chicago/Turabian StylePenzlin, Bernhard, Lukas Bergmann, Yinbo Li, Linhong Ji, Steffen Leonhardt, and Chuong Ngo. 2021. "Design and First Operation of an Active Lower Limb Exoskeleton with Parallel Elastic Actuation" Actuators 10, no. 4: 75. https://doi.org/10.3390/act10040075

APA StylePenzlin, B., Bergmann, L., Li, Y., Ji, L., Leonhardt, S., & Ngo, C. (2021). Design and First Operation of an Active Lower Limb Exoskeleton with Parallel Elastic Actuation. Actuators, 10(4), 75. https://doi.org/10.3390/act10040075