Impacts of Internet of Things on Supply Chains: A Framework for Warehousing

Abstract

:1. Introduction

2. Literature Review

2.1. Industry 4.0 Key Technologies

2.2. Information Sharing in Supply Chains

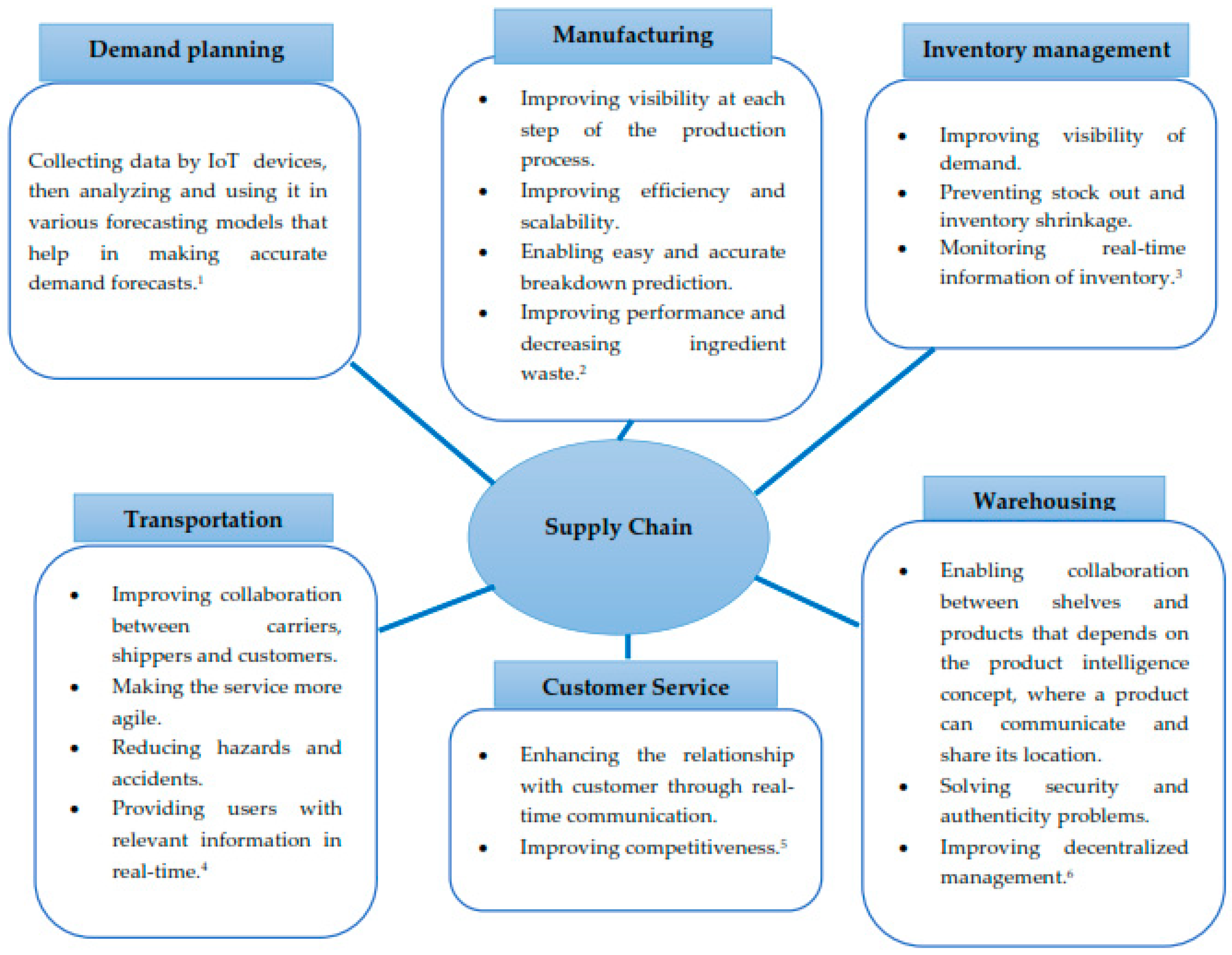

2.3. The Implementation of Industry 4.0 and IoT Technology in Supply Chains

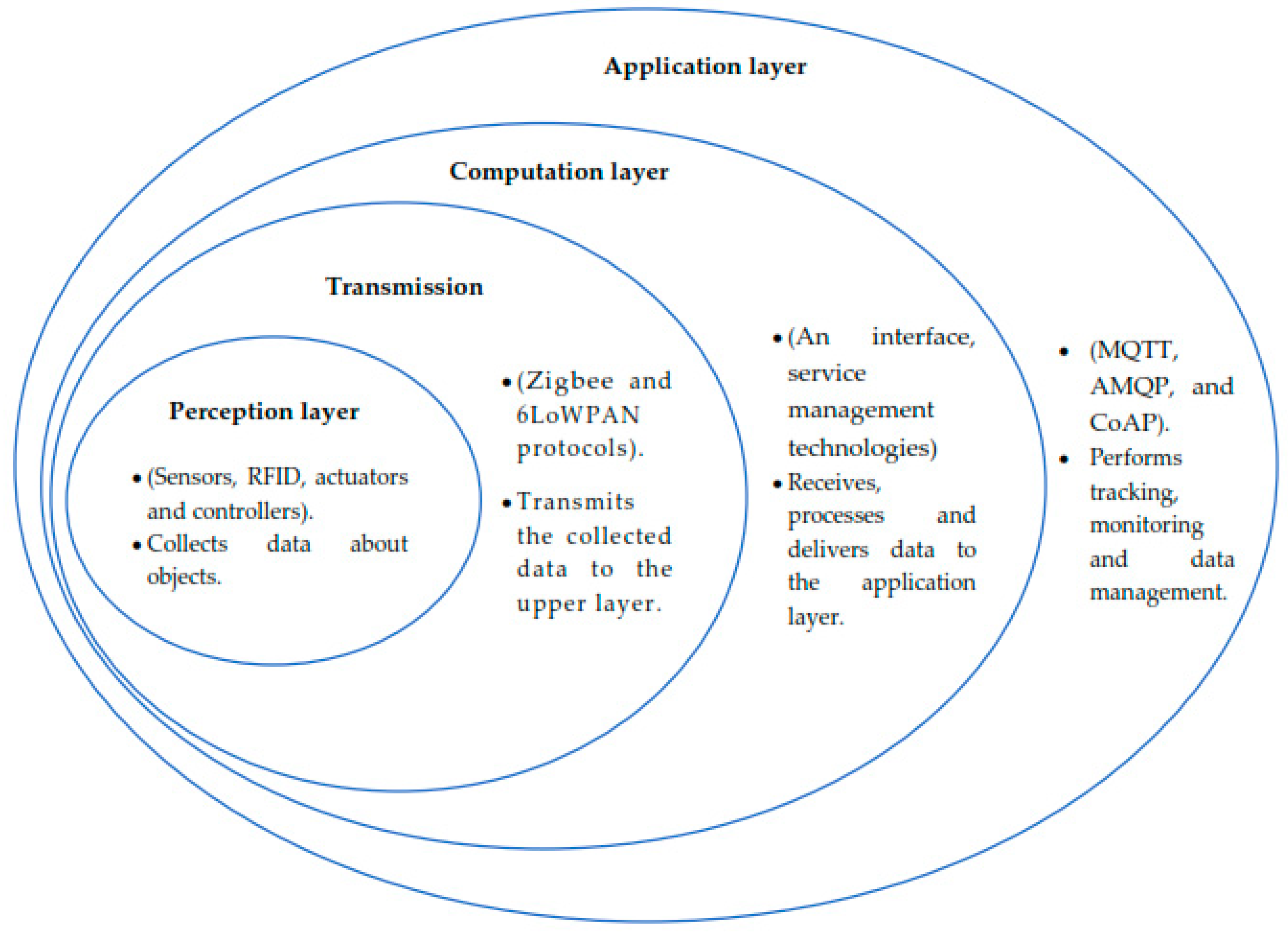

3. Components of IoT Infrastructure

4. Implementation of IoT in Warehousing

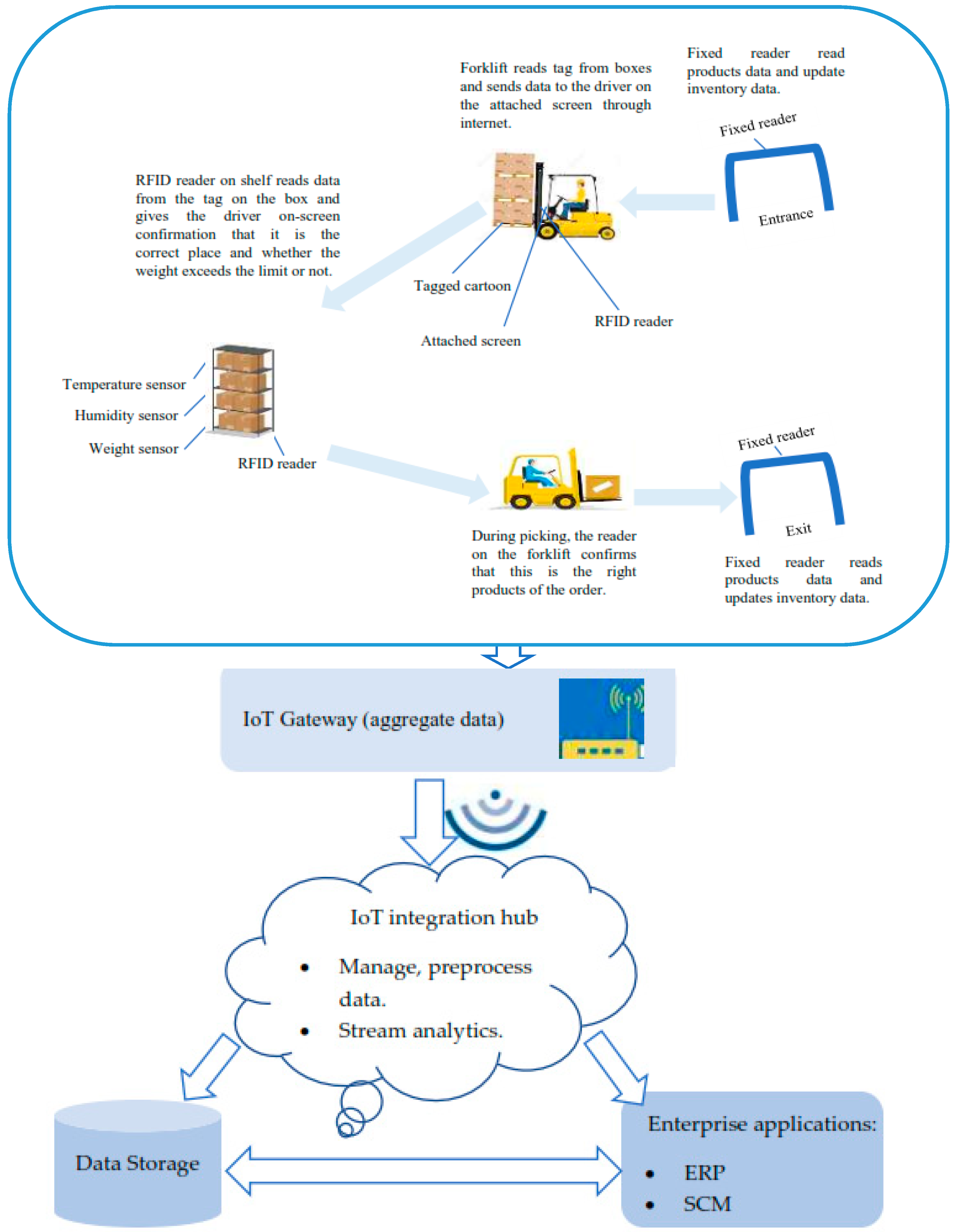

4.1. Conceptual Framework of IoT Implementation in a Warehouse

4.2. Economic and Social Impact of the Proposed Framework

- Increasing efficiency.

- Ensuring safety of labor and goods.

- Reducing operational time.

- Reducing accidents.

- Minimizing the number of workers.

- Increasing reliability and accuracy of packing and picking processes.

- Decreasing counterfeiting, fraud and theft.

- Helping companies improve forecasts due to the availability of accurate data.

- Real-time data helps in accurate decision making.

- Enhancing the overall performance of companies.

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Anita, R., and Bodla Abhinav. 2017. Internet of Things (IoT)—Its Impact on Manufacturing Process. International Journal of Engineering Technology Science and Research IJETSR 4: 889–95. [Google Scholar]

- Azab, Ahmed, Noha Mostafa, and Jaehyun Park. 2016. OnTimeCargo: A Smart Transportation System Development in Logistics Management by a Design Thinking Approach. Paper presented at 20th Pacific Asia Conference on Information Systems (PACIS 2016), Chiayi, Taiwan, June 27–July 1; p. 44. [Google Scholar]

- Baihaqia, Imam, and Amrik S. Sohal. 2013. The impact of information sharing in supply chains on organizational performance: An empirical study. Production Planning & Control: The Management of Operations 24: 743–58. [Google Scholar]

- BCS—The Chartered Institute for IT. 2013. The Societal Impact of the Internet of Things. Available online: https://www.bcs.org/upload/pdf/societal-impact-report-feb13.pdf (accessed on 27 January 2019).

- Chopra, Sunil, and Peter Meindl. 2013. Supply Chain Management: Strategy, Planning, and Operation, 5th ed. London: Pearson Education. [Google Scholar]

- Choy, King Lun, Angappa Gunasekaran, Hoi Yan Lam, Ka Ho Chow, Yick Chi Tsim, Tsz Wing Ng, Ying Kei Tse, and Xiao Ang Lu. 2014. Impact of information technology on the performance of logistics industry: The case of Hong Kong and Pearl Delta region. Journal of the Operational Research Society 65: 904–16. [Google Scholar] [CrossRef]

- Cortés, Beatriz, Andres Boza, David Pérez, and Llsnod Cuenca. 2015. Internet of Things Applications on Supply Chain Management. International Journal of Computer, Electrical, Automation, Control and Information Engineering 9: 2493–98. [Google Scholar]

- Degryse, Christophe. 2016. Digitalisation of the Economy and its Impact on Labour Markets (10 February 2016). ETUI Research Paper—Working Paper 2016.02. Available online: https://ssrn.com/abstract=2730550 (accessed on 27 January 2019).

- Dhumale, R. B., N. D. Thombare, and P. M. Bangare. 2017. Supply Chain Management using Internet of Things. International Research Journal of Engineering and Technology (IRJET) 4: 787–91. [Google Scholar]

- Grabara, Janusz, Michal Kolcun, and Sebastian Kot. 2014. The role of information systems in transport logistics. International Journal of Education and Research 2: 1–8. [Google Scholar]

- Hofmann, Erik, and Marco Rüsch. 2017. Industry 4.0 and the current status as well as future prospects on logistics. Computers in Industry 89: 23–34. [Google Scholar] [CrossRef]

- Ibrahim, Sameh, Hatem A. Elayat, Mahassen M. Khater, and Noha A. Mostafa. 2011. Data analysis for inventory management in a multi-echelon supply chain. International Journal of Economic Resources 2: 138–50. [Google Scholar]

- Imran, Muhammad, Waseem ul Hameed, and Adnan ul Haque. 2018. Influence of Industry 4.0 on the Production and Service Sectors in Pakistan: Evidence from Textile and Logistics Industries. Social Sciences 7: 246. [Google Scholar] [CrossRef]

- Ives, Blake, Biagio Palese, and Joaquin A. Rodriguez. 2016. Enhancing Customer Service through the Internet of Things and Digital Data Streams. MIS Quarterly Executive 15: 279–97. [Google Scholar]

- Jia, Xiaolin, Quanyuan Feng, Taihua Fan, and Quanshui Lei. 2012. RFID Technology and Its Applications in Internet of Things (IOT). Paper presented at 2nd International Conference on Consumer Electronics, Communications and Networks (CECNet), Yichang, China, April 21–23; pp. 1282–85. [Google Scholar]

- Jonsson, Patrik, and Stig-Arne Mattsson. 2013. The value of sharing planning information in supply chains. International Journal of Physical Distribution and Logistics Management 43: 282–99. [Google Scholar] [CrossRef]

- Kovács, György, and Sebastian Kot. 2016. New Logistics and Production Trends as The Effect of Global Economy Changes. Polish Journal of Management Studies 14: 115–26. [Google Scholar] [CrossRef]

- Li, Bo, and Yulong Li. 2017. Internet of things drives supply chain innovation: A research framework. International Journal of Organizational Innovation 9: 71–92. [Google Scholar]

- Lin, Jie, Wei Yu, Nan Zhang, Xinyu Yang, Hanlin Zhang, and Wei Zhao. 2017. A Survey on Internet of Things: Architecture, Enabling Technologies, Security and Privacy, and Applications. IEEE Internet of Things Journal 4: 1125–42. [Google Scholar] [CrossRef]

- Manyika, James, Michael Chui, Peter Bisson, Jonathan Woetzel, Richard Dobbs, Jacques Bughin, and Dan Aharon. 2015. Unlocking the potential of the Internet of Things, McKinsey & Company. Available online: https://www.mckinsey.com/business-functions/digital-mckinsey/our-insights/the-internet-of-things-the-value-of-digitizing-the-physical-world (accessed on 12 January 2019).

- Mostafa, Noha, and Amr Eltawil. 2016. Vertical Supply Chain Integrated Decisions: A Critical Review of Recent Literature and a Future Research Perspective. In Supply Chain Management: Applications for Manufacturing and Service Industries. Edited by Mamun Habib. Management Science—Theory and Applications Series; New York: Nova Science Publishers. [Google Scholar]

- Ng, Irene, Kimberley Scharf, Ganna Pogrebna, and Roger Maull. 2015. Contextual variety, Internet-of-Things and the choice of tailoring over platform: Mass customisation strategy in supply chain management. International Journal of Production Economics 159: 76–87. [Google Scholar] [CrossRef]

- Qin, Wei, Ray Y. Zhong, Hongyon Dai, and Z L. Zhuang. 2017. An assessment model for RFID impacts on prevention and visibility of inventory inaccuracy presence. Advanced Engineering Informatics 34: 70–79. [Google Scholar] [CrossRef]

- Reaidy, Paul J., Angappa Gunasekaran, and Alain Spalanzani. 2015. Bottom-up approach based on Internet of Things for order fulfillment in a collaborative warehousing environment. International Journal of Production Economics 159: 29–40. [Google Scholar] [CrossRef]

- Richards, Gwynne. 2017. Warehouse Management: A Complete Guide to Improving Efficiency and Minimizing Costs in the Modern Warehouse, 3rd ed. London: Kogan Page Publishers. [Google Scholar]

- Rodríguez, José María, and Luigi Stammati. 2018. The Economic Impact of IoT putting numbers on a revolutionary technology. Frontier Economics. Available online: https://www.frontier-economics.com/media/1167/201803_the-economic-impact-of-iot_frontier.pdf (accessed on 25 December 2018).

- Schoen, Quentin, Matthieu Lauras, Sébastien Truptil, Franck Fontanili, and Anne-Ghislaine Anquetil. 2016. Towards a Hyperconnected Transportation Management System: Application to Blood Logistics, International Federation for Information Processing. Cham: Springer International Publishing, pp. 3–12. [Google Scholar]

- Swamy, Sowmya Nagasimha, Dipti Jadhav, and Nikita Kulkarni. 2017. Security Threats in the Application layer in IOT Applications. Paper presented at International Conference on I-SMAC (IoT in Social, Mobile, Analytics and Cloud) (I-SMAC 2017), Palladam, India, February 10–11; pp. 477–80. [Google Scholar]

- Szewczyk, Pawel. 2016. Impact of the Internet of Things on the Economy and Society. Organizacja I Zarządzanie/Politechnika Śląska 3: 461–70. [Google Scholar]

- Tejesh, B. Sai Subrahmanya, and K. Sripath Roy. 2017. A low-cost warehouse inventory management system using internet of things and open source hardware. International Journal of Control Theory and Applications 10: 113–22. [Google Scholar]

- Trappey, Amy J. C., Charles V. Trappey, Chin-Yuan Fan, Abby P. T. Hsu, Xuan Kai Li, and Ian J. Y. Lee. 2017. IoT patent roadmap for smart logistic service provision in the context of Industry 4.0. Journal of the Chinese Institute of Engineers 40: 593–602. [Google Scholar] [CrossRef]

- Vanpoucke, Evelyne, Ann Vereecke, and Steve Muylle. 2017. Leveraging the impact of supply chain integration through information technology. International Journal of Operations & Production Management 37: 510–30. [Google Scholar]

- Wielki, Janusz. 2017. The Impact of The Internet of Things Concept Development on Changes in The Operations of Modern Enterprises. Polish Journal of Management Studies 15: 262–75. [Google Scholar] [CrossRef]

- Wollschlaeger, Martin, Thilo Sauter, and Juergen Jasperneite. 2017. The Future of Industrial Communication: Automation Networks in the Era of the Internet of Things and Industry 4.0. IEEE Industrial Electronics Magazine 11: 17–27. [Google Scholar] [CrossRef]

- Yan, Bo, Chang Yan, Chenxu Ke, and Xingchao Tan. 2016. Information sharing in supply chain of agricultural products based on the Internet of Things. Industrial Management & Data Systems 116: 1397–416. [Google Scholar]

- Yerpude, Samir, and Tarun Kumar Singhal. 2017. Impact of Internet of Things (IoT) Data on Demand Forecasting. Indian Journal of Science and Technology 10: 1–5. [Google Scholar] [CrossRef]

- Zhou, Keliang, Taigang Liu, and Lifeng Zhou. 2015. Industry 4.0: Towards future industrial opportunities and challenges. Paper presented at 2015 12th International Conference on Fuzzy Systems and Knowledge Discovery (FSKD), Zhangjiajie, China, August 15–17. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mostafa, N.; Hamdy, W.; Alawady, H. Impacts of Internet of Things on Supply Chains: A Framework for Warehousing. Soc. Sci. 2019, 8, 84. https://doi.org/10.3390/socsci8030084

Mostafa N, Hamdy W, Alawady H. Impacts of Internet of Things on Supply Chains: A Framework for Warehousing. Social Sciences. 2019; 8(3):84. https://doi.org/10.3390/socsci8030084

Chicago/Turabian StyleMostafa, Noha, Walaa Hamdy, and Hisham Alawady. 2019. "Impacts of Internet of Things on Supply Chains: A Framework for Warehousing" Social Sciences 8, no. 3: 84. https://doi.org/10.3390/socsci8030084

APA StyleMostafa, N., Hamdy, W., & Alawady, H. (2019). Impacts of Internet of Things on Supply Chains: A Framework for Warehousing. Social Sciences, 8(3), 84. https://doi.org/10.3390/socsci8030084