Abstract

Academics, executives and top managers have solid, but also diverse, views on the Industry 4.0 issue, as do the employment policymakers. Without urgent and targeted measures to manage the short-term transition and shape the labor force with the skills needed for the future, governments will have to face increasing unemployment and social impacts, while companies will have to deal with a sluggish consumer base. The main goal of this paper is to find out how managers are perceived and informed about the Industry 4.0 concept and how quickly these views are changing. To accomplish this goal, methods such as analysis, synthesis, statistical methods and logical deduction are to used along with the conducted survey being executed by a questioner method. The conducted survey presented by the authors in this paper aims to support the discussion and open up opportunities for further action by providing views to HR managers in strategic employers who are among the leading representatives of new trends and are the key actors in the implementation of future labor development strategies in the Slovak Republic.

1. Introduction

The ongoing discussions on the impact of (unfavorable) changes in employment often lead to fundamentally divergent views among those who expect unlimited opportunities in emerging types of jobs along with the prospects for increasing workers’ productivity and relieving workers from physical and routine work, as well as those who expect massive compensation for the work of human beings and the transfer of jobs to other countries. A lot of data shows that while the prognoses differ across sectors and regions, significant changes are occurring. The issue is whether this change will result in a massive outflow of workers or the emergence of new jobs.

The presented study analyzes the impact of Industry 4.0 on Slovak enterprises and the current state of automation and robotics implementation in these enterprises. The real-status detection provides us with the information necessary for further analysis of rate development and, in particular, analysis of potential impacts on the labor market. Slovak entrepreneurs are relatively conservative in terms of implementing any changes and often do not know how to catch up with the trends in advanced economies because the Slovak economy still uses its comparative advantage of cheap labor.

2. Theoretical Background and Literature Overview

At Hanover Exhibition in 2011, scientists, government representatives and key industry representatives jointly presented a project called Industry 4.0. At that time, it was not still clear yet that it would become such a widely used concept (Balaz and Hamara 2016; Balaz 2015). According to Malec and Abrham (2016), this approach is about a digital transformation of production when using platforms such as: Big Data and its analysis (especially data value), the Internet of Things, the Industrial Internet of Things, and Cloud Services. This change will require the transformation of information technologies, operating technologies, internet devices; sensors and controllers, robotic systems, artificial intelligence and manufacturing processes to conduct interconnected factories and smart decentralized production (Danaj et al. 2018). According to Cihelkova (2016), all of this is executed within informational cyber-mass systems in the environment of the Fourth Industrial Revolution. It is about a whole new stage in organizing and controlling the value chain throughout the life of the product.

As stated by Daňo and Lesáková (2018), within the Industry 4.0 concept the basic element is the customer’s demand, and product personalization is the driving force behind this transformation process. Various technologies that supported the emergence of the fourth industrial revolution are in constant evolution (Zemanová et al. 2015). These include virtual reality, the Internet of Things, Artificial Intelligence, autonomous vehicles, virtual assistants, investment software, massive data analysis, 3D printing, nanotechnology, biotechnology and quantum computers. We often think that these technologies are still at an early stage in terms of their general use, however they have already become an integral part of the industry (Taušer et al. 2015). For example, virtual reality allows us to change the environment in which product testing is being performed (Taušer and Čajka 2014).

Fabus (2018) argues that the Internet of Things connects machines and people to increase work efficiency, while using Big Data allows machines to predict future mistakes and automate maintenance steps to prevent them from doing so. According to Bejtkovský et al. (2018) if everything in production system and its surroundings is connected to sensors, software, internet technology, knowledge systems, and customers, the quality of products being produced can be improved. Automation here definitely plays a big role along with typical components of cyber-physical systems and the Internet of Things. As a result, quality aspects can be tracked in real time, and robots will reduce the error rate (Miklosik et al. 2018). On the other hand, one of the challenges for the solution is that the more automation is implemented into production, the more people will lose work. The same applies to other mentioned benefits such as reducing the error rate (the less malfunctions, the fewer technicians needed for service support). Experts know that not all human work will soon be performed by robots. According to Bilan et al. (2017), many companies that have already increased the number of robots implemented into production are looking for more and more workers. The reason for this, when it comes to the quality of production, is that collaborative robots and advanced robots working with humans are being implemented into production processes.

Industrial businesses in Slovakia, represented by their management, have not taken Industry 4.0’s challenges into account for a long time. They saw it as a Western fashion trend, and the implementation of platforms such as the Internet, Big Data, cloud computing operations, virtual reality and 3D printing have not been implemented in almost any domestic industry (Lipkova et al. 2017). Regarding foreign investors, a different situation occurred, especially in automotive industry companies and their subcontracting suppliers’ networks.

In the last two years, however, the situation has changed radically, as businesses have become more interested in the Industry 4.0 platform. The problem remains the uncertainty in which way the Industry 4.0 should be implemented into practice more effectively with all of its components. According to Abrhám and Lžičař (2018) a fifth of automotive suppliers have already invested in Industry 4.0 and a third of investments are about to do so within the next two years. As argued by Abrham et al. (2015), a quarter of suppliers will invest less than 1% and 30% of them more than 1% of their revenues. At the end of 2016, the Slovak government also began to be respond to Industry’s 4.0 challenges, and its resolution entitled “Intelligent Industry Concept Slovakia” describes the current situation and requires the relevant ministries to set up the Intelligent Industry Platform and develop an Intelligent Industry Action Plan for the Slovak Republic (Vojtovic et al. 2018). As argued by Abrhám (2017), the area where governmental support is expected is the continuing low added value for the automotive industry in particular.

According to Hanulakova and Dano (2018) the implementation of research and development in the Slovak Republic is low and has been underfunded. Innovations arise away from our country, and foreign investors only engage with Slovakia to manufacture parts. The Intelligent Industry Action Plan in Slovakia deals with a strong support for R & D activities and in particular investments enhancement in this area of foreign investors. Greater support for domestic innovation projects is to be expected (Burda et al. 2017). According to Hamid et al. (2018) the basis for this kind of shift towards intelligent industry must be the change within the education industry, not for the needs of the present, but for the needs of future industry. The speed at which this industry transformation occurs puts into the spotlight another challenge on which the government must actively take a stand—it is a lifelong learning issue (Zadrazilova 2016; Zak 2012). New technologies will increasingly remove low-skilled labor and physical work, and emerging job challenges will increasingly raise demands on human intellect (Sejkora 2014).

3. The Main Goal and Methodology

The concept of intelligent industry is a great challenge for entrepreneurship in different areas of its business. It is a huge challenge to determine how to remain competitive in the market. Success nowadays depends on the speed of putting new knowledge and technology into action. The aim of the study is to find out how managers perceive and are informed about the Industry 4.0 concept and how fast these views are subject to change. To meet this goal, a survey was conducted in 2017 and 2018 in which 80 companies participated. The companies were approached by random selection, based on the addresses being searched in the Commercial and Trade Registers of the Slovak Republic. The survey was attended by 80 companies operating in the mechanical engineering sector, which were small and medium-sized enterprises that have up to 250 employees. In our opinion, however, the size of the firm does not have to be a crucial factor unlike the amount of output, turnover and profit. For the selection of subjects to be observed, the assumption was that the subjects were active in the manufacturing industry and within the engineering industry. Thus, the initial selection consisted of compiling entities that met three basic conditions: the subject must be registered in Slovak Trade/Commercial registers, be currently active on Slovak market and belong to the category of small or medium-sized enterprises. In the selection of subjects which matched the first set of criteria, effort was made to take into account the region where the subject is located and operates to avoid concentration of entities within a single region. This criterion was difficult to meet due to the concentration of entities operating in the engineering industry in western Slovakia, most of which are subcontractors for the automotive industry that is concentrated in one particular part of the country. Another criterion regarding the size of the enterprise was chosen intentionally, as it is clear that automation is in progress in large enterprises. We wanted to know the situation in small and medium-sized enterprises where this trend could be different and we wanted to explore their efforts to adapt to innovation and trends in production processes. The criterion of focusing on the engineering industry was chosen because Industry 4.0 is a trend in this sector and the Slovak Republic is among the leaders in this area in terms of the number of produced cars per capita. The engineering industry accounts for 70% of all Slovak production. The survey was also conducted as a basis for further research to be carried out in upcoming years. The results obtained by the questionnaire survey were processed by means of statistical methods. Next the methods of analysis and deduction were used. Selected questions and their responses are presented in the following study.

4. Results

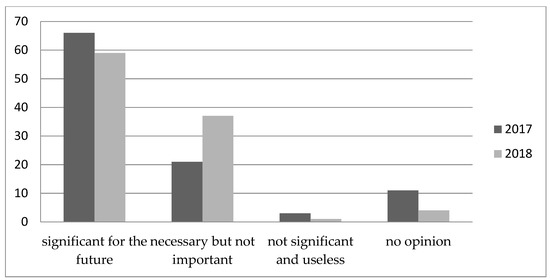

In our survey, the addressed businesses expressed their approach to Industry 4.0 applications. In 2017, as shown in Figure 1, 2% of companies stated it was an insignificant or unnecessary issue for them, but a year later any questioned company did not think like that. However, it is interesting that while 66% of respondents stated that Industry 4.0 was very important for the future in 2017, in 2018 a slight decline occurred and only 59% of respondents maintained this opinion. On the other hand, the need to deal with the implementation of intelligent industry elements has increased by 16%, following increased awareness of the issue as well as new technology developments that are becoming more accessible.

Figure 1.

The significance of Industry 4.0 application, Industry 4.0 application in your company in %. Source: own processing based on survey results.

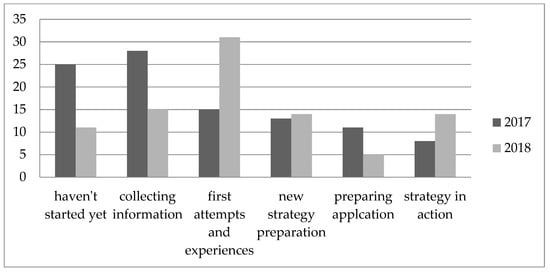

We also looked at where businesses are located in implementing the Industry 4.0 concept. As shown in Figure 2, compared to 2017, the number of businesses that are beginning to apply the concept has double. The number of businesses that have not started yet to deal with the Industry 4.0 issue has dropped rapidly from 25% to 11% compared to 2017. This means that the real deployment of intelligent industry elements will gain momentum in future years. Leaders, business managers and high-level executives must realize that they need to understand this changing environment. They have to re-evaluate everything they are used to and continue to work on improvements and innovations if they want to be competitive. Drulák and Drulákova (2014) highlight that so far, all previous industrial revolutions have caused changes at the workplace over the course of several decades. Now, however, the potential of the fourth industrial revolution is expected to be occurred at an unprecedented rate, with the risk that businesses and society will not be sufficiently prepared to anticipate these challenges, effectively generating enormous financial costs (Gärtner et al. 2017).

Figure 2.

Your status with Industry 4.0 applications in %. Source: own processing based on survey results.

By De Castro et al. (2017) the World Economic Forum concluded that the Fourth Industrial Revolution is still at its early stage of development and suggests several causes of the following apparent conditions:

- -

- lack of knowledge about future changes,

- -

- budget constraints,

- -

- short-term pressure on profitability growth,

- -

- lack of engagement of executive power within the processes.

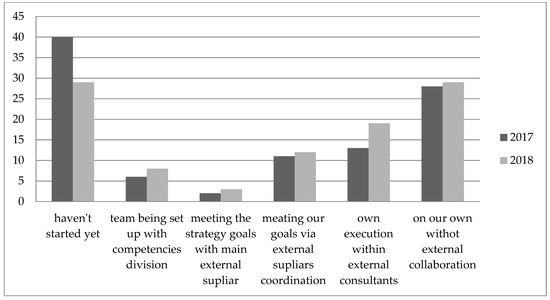

For this reason, we observed the companies´ approach to Industry 4.0. The companies generally try to be involved in Industry 4.0 without external cooperation; compared to 2017, the number of businesses that have not yet started to outsource dropped significantly by 11%. As shown in Figure 3, firms have slightly increased the use of external consultants to implement intelligent industry elements. Regarding the way to put the Industry 4.0 into action, a positive shift has been observed. The number of entrepreneurs who did not start implementing Industry 4.0. into practice dropped by 12% (from 40% to 28%). There were no major changes regarding other questions. Our findings, however, point out to the fact that almost one third of companies do not pay enough attention to upcoming changes and state that they have not yet begun to deal with this particular issue, which could have fatal consequences for them in the future in terms of market competitiveness as well as the personalization of produced products.

Figure 3.

The way how to put Industry 4.0 into action in %. Source: own processing based on survey results.

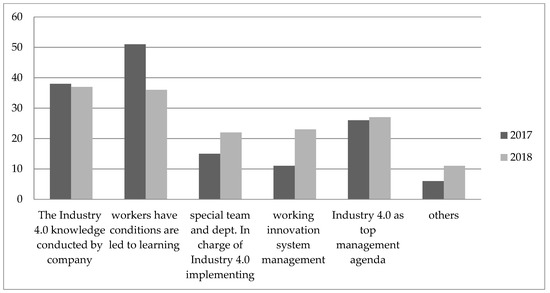

In our survey, we observed how companies are letting their employees know new information; the results are shown in the following chart in Figure 4. From our point of view, these activities seem to be inadequate, due to the predicted dynamics of new technologies development not only within internal but also external environment of companies in which they operate. It can be observed from the Figure 4 that the number of entities having the conditions for workers in order to be led to learning dropped in 2018 by 14%, in contrast to the increase in implementing the working innovation system by management. This can significantly affect companies’ readiness for change in the future, and in case of slow activity, this can lead to a negative result, even though training and preparation of employees may seem to be financially demanding and not currently economical for the enterprise.

Figure 4.

The motivation to apply Industry 4.0 witnin the internal corporate culture in %. Source: own processing based on survey results.

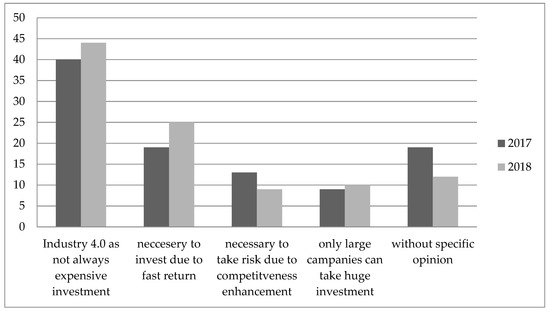

By asking our respondents, we were observing their opinion on the Industry 4.0’s investment demand issue. Basically we did not notice a significant shift in opinion over the years, and 44% of respondents believe that this is not a demanding investment, but only a few companies have started implementation of aspects of Industry 4.0. The answers are presented in the following chart in Figure 5 where several issues could be highlighted. Firstly, the opinions that Industry 4.0 is always not an expensive investment and the need to invest because of fast returns gained higher support in 2018 than in 2017; secondly, the number of entities not having this specific opinion dropped in 2018.

Figure 5.

Your point of view on Industry 4.0 as investment demand in %. Source: own processing based on survey results.

In developed countries, the number of jobs in industry sectors has fallen sharply. The reason is not just the automation of processes but, in particular, the relocation of production capacities to less advanced economies and developing countries. According to Lipkova and Hovorkova (2018) the relocation of production capacities outside the country does not always concern just the production expansion, but also concerns labor costs. Of course, countries such as Germany, the US, France, are looking for countries where they will also place their manufacturing businesses under other criteria, such as:

- -

- industrial landscape development,

- -

- the level and type of population education,

- -

- political stability,

- -

- various government benefits and support,

- -

- pricing levels in the country,

- -

- membership in international regional and integration blocs.

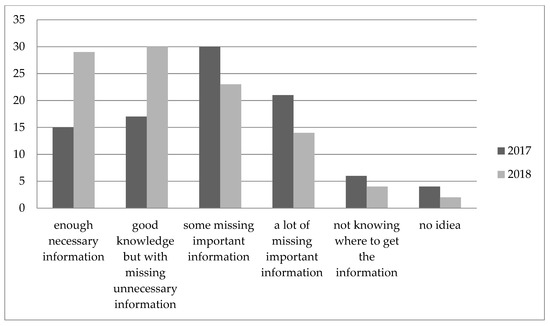

As stated above, we were interested in the respondents’ opinions regarding the availability of Industry 4.0 information. We can see their views in the following chart in Figure 6. The results show that there is not a good awareness of the current state of this issue.

Figure 6.

Availability of information in %. Source: own processing based on survey results.

As follows from Figure 6, the situation development regarding the availability of information on Industry 4.0 has changed positively in 2018. Slovak entrepreneurs had much more information on Industry 4.0 available, as well as better knowledge than in the previous year. The amount of missing important information along with the knowledge where to get it dropped in 2018. This means they are supposed to know what the Industry 4.0. is all about, they have proper information and they should be ready to implement the Industry 4.0 into action.

5. Discussion

As argued by Krajnakova et al. (2015) the Fourth Industrial Revolution is subject to severe technological, demographic and socio-economic changes affecting almost every area of business, and, in the case of human resources, it is expected that these changes will cause both labor surplus and the creation of completely new professions. According to Lipkova and Braga (2016) it is estimated that 65% of children currently attending elementary schools will be working in professions that do not exist today. These facts are already a challenge not only for human resources departments in companies but also for the entire education system that will need to be able to prepare a new workforce to flexibly adapt to ever-changing conditions for new knowledge demand.

Discussions on people, human and social dimensions are ubiquitous within Industry 4.0 when it comes to possibilities and benefits. Human, social, employment and environmental factors are key aspects regarding how to meet the goals of Industry 4.0 (Lazányi and Bilan 2017). With regard to the emergence of new technologies, the improvement of temperature, humidity and other measurable and controllable working conditions affecting workplace comfort is to be expected. According to Fojtikova and Stanickova (2017) factors such as security with the help of rapid detection and increased protection in case of accidents, the presence detection of gases, harmful radiation, and fire hazards including their prevention and efficient automated disposal, will also be enhanced. The possibilities for communication and cooperation will change completely, and more and more emphasis will be put on ergonomic, exhalation reduction and environmental protection. According to Fojtikova (2016) and Jovanović (2014), the European Union has the ambition to be a leader in “green” technologies and strongly supports the initiative of clean factories.

Just like the revolutions that occurred before, the Fourth Industrial Revolution has the potential to increase revenue at global scale and improve the quality of life for populations around the world. Those who have gained the most since the start of Industry 4.0 are the customers, having the opportunity to access the digital world (Machkova and Sato 2017). According to Sejkora and Sankot (2017) technologies enabled them to use new products and services to enhance their efficiency and intensify leisure time in their personal lives. For example, ordering a taxi, booking a flight or accommodation, purchasing products, online payments, listening to music, watching movies, or playing games all can now be done at a distance.

In the future, technological innovation will also lead to revolutionary changes within the supply processes, highlighting the long-term benefits in efficiency and productivity. The cost of transport and communications will drop, logistics and global supply networks will become more efficient and the cost of trading will be drastically reduced and all this will open up new markets and lead to economic growth. As Varadzin (2016) pointed out, this revolution can also lead to deepening differences, especially in terms of unfavorable changes on the labor market, through substitution of robots for manual work across the economy. The imbalance of workers to machines could increase the gap between the profits from capital and wages of the working class. On the other hand, it is also possible that the changes within the job opportunities caused by this technology will lead to an increasing number of new jobs.

As stated by Obadi and Korcek (2016) based on these practices of large corporations in the United States alone in the last 30 years, nearly 8 million jobs have been lost in industry, accounting for almost 40% of workers in industry sectors. In order to prevent this phenomenon, developed industrial countries have chosen to implement Industry 4.0 aspects into their manufacturing companies, for which huge investments have been agreed upon. According to Bilan et al. (2018) and Marr (2018) by 2020 industrial companies are planning to invest into innovation within the Industry 4.0 an amount equal to at least 5% of their annual GDP revenues, representing 907 billion USD. This should prevent the next transfer of industrial enterprises parts to other countries and keep the production capacities in the home countries. Not only businesses but also governments have to be prepared for this challenge.

Our relations with our smartphones are a very good example. Permanent connections can deprive us from some of the most important human qualities or values, such as the time we set aside for self-restraint and self-reflection, and time for a conversation that has some meaning. According to Lorincová et al. (2018), one of the biggest individual challenges we face because of new information technologies is privacy. It can be understood why it is so important, but tracking and sharing information about us is the very cornerstone of this new technology, as is being connected always and everywhere. Considerations and debates on fundamental issues, such as the impact on our privacy and losing the control of data about us, will only become more intense in the upcoming years.

Similarly, the revolution in biotechnology and artificial intelligence, which redefines what it means to be a human being, only overshadows the current limitations of long-term, health and mental issues. The ongoing discussions on the (unfavorable) changes impacts on employment often provide fundamentally different views among those who expect unlimited opportunities within the new emerging jobs as well as improved prospects on how to increase workers’ productivity to relieve them from physical and routine work, and those who expect massive replacement of labor and relocation of jobs to other countries.

6. Conclusions and Further Directions

Based on the findings from our research, we have arrived at the conclusion that the fourth industrial revolution will not only change what we are doing, but also who we are in this world. It affects our identity and all the related aspects. Our sense of privacy, our understanding of property, our consumption habits, the time we devote to work and fun, and how we build a career, how we cultivate our abilities, how we meet people and how we maintain relationships. This is already changing our health and leading to a measurable personality change, and before we can imagine it, this could lead to the improvement of mankind. This list is endless because it is bounded by our imagination. On the other hand, it can also make people doubt whether the endless inevitable integration of technologies into our lives cannot reduce pure human abilities, such as the ability to cooperate, comprehend, and so on.

Academicians and executives have their solid, but at the same time, diverse views on this issue, as do employment policymakers. It is clear from the survey results that while the forecasts differ with respect to sectors and regions, significant changes are taking place. Ultimately, it is our next move matters, if this change could result in a massive outflow of labor or the emergence of new jobs. Without current urgent and targeted measures on how to manage the short-term transition and shape the labor force with skills of the future, governments will have to face increasing unemployment and social impacts, as well as companies with a sluggish consumer base. The research outcomes should open up discussion and opportunities for further action by providing a perspective to human resources leaders of strategic employers who are among the leading representatives of these new trends and are key actors in implementing future labor strategies.

We believe that it is very important to conduct surveys and studies dealing with the state and impact of Industry 4.0 directly within individual industries and sectors of the economy and to reveal hidden links. Slovakia has its own specifics and one of them is a conservativism that shows high distrust towards implementing new changes. Another impetus for the low number of emerging new technologies so far appears to be the persisting comparative advantage of the Slovak economy, as that advantage is Slovakia’s cheap labor. When it comes to further directions, the presented study is crucial in terms of the focus of next research that will be executed by authors in the next stages of the project, in which this study will follow the field of investigation associated with the impact of Industry 4.0 on the labor market of the Slovak Republic compared to the labor market situation in the economies of the EU and the USA.

Author Contributions

Conceptualization, M.K.; methodology, A.G.; software, J.S. validation, A.G.; formal analysis, M.K.; investigation, J.S.; resources, A.G. and M.K.; data curation, A.G. and J.S.; writing—original draft preparation, A.G.; writing—review and editing, M.K.; visualization, M.K. and J.S.; supervision, A.G.; project administration, A.G.; funding acquisition, A.G.

Funding

This research was funded by the Slovak Ministry of Education’s Scientific Grant Agency VEGA: “The impact of Industry 4.0 on jobs structure changes”. Project registration number: [Reg. No.: 1/0430/18].

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Abrhám, Josef. 2017. Project management and funding in the euroregions. Polish Journal of Management Studies 16: 7–20. [Google Scholar] [CrossRef]

- Abrhám, Josef, and Petr Lžičař. 2018. Risk management in the sustainable development: Analysis of a selected key industry. Journal of Security and Sustainability Issues 8: 171–80. [Google Scholar] [CrossRef]

- Abrham, Josef, Yuriy Bilan, Alion Krauchenia, and Wadim Strielkowski. 2015. Planning horizon in labour supply of Belarusian small entrepreneurs. Economic Research-Ekonomska Istrazivanja 28: 773. [Google Scholar] [CrossRef]

- Balaz, Peter. 2015. Japan’s economy in the 21st century. Trends and challenges. Ekonomicky Casopis 63: 869–72. [Google Scholar]

- Balaz, Peter, and Andrej Hamara. 2016. Export Dependency of Slovakia on German’s Economy. Politicka Ekonomie 64: 573–90. [Google Scholar] [CrossRef]

- Bejtkovský, Jiří, Zoltán Rózsa, and Hendrati Dwi Mulyaningsih. 2018. A phenomenon of digitalization and E-recruitment in business environment. Polish Journal of Management Studies 18: 58–68. [Google Scholar] [CrossRef]

- Bilan, Yuriy, Halyna Mishchuk, and Tetiana Dzhyhar. 2017. Human capital factors and remuneration: Analysis of relations, modelling of influence. Business: Theory and Practice 18: 208–14. [Google Scholar] [CrossRef]

- Bilan, Yuriy, Stanislaw Gedek, and Grzegorz Mentel. 2018. The Analysis of Oil Price and Ruble Exchange Rate. Transformations in Business & Economics 17: 195–205. [Google Scholar]

- Burda, Petr, Josef Abrham, and Zuzana Horvathova. 2017. Factors influencing online civic participation in mid-sized czech towns. Transformations in Business and Economics 16: 607–18. [Google Scholar]

- Cihelkova, Eva. 2016. Formation of the theoretical framework for the comparative analysis of post-socialist countries. Agricultural Economics (Czech Republic) 62: 407–20. [Google Scholar] [CrossRef]

- Danaj, Adela, Kornélia Lazanyi, and Yuriy Bilan. 2018. Perceptions and Implications of Immigration in France—Economic, Social, Political and Cultural Perspectives. Economics & Sociology 11: 226–47. [Google Scholar] [CrossRef]

- Daňo, Ferdinad, and Dagmar Lesáková. 2018. The role of environmental stimuli in shopping evaluation and responses. Ekonomicky Casopis 66: 465–78. [Google Scholar]

- De Castro, Tereza, Jana Vlčková, and Pavel Hnát. 2017. Trade and investment relations between the Czech Republic and China: The Czech Republic as a gateway to the EU? Society and Economy 39: 481–99. [Google Scholar] [CrossRef]

- Drulák, Petr, and Radka Drulákova. 2014. The richness of the liberal tradition in international relations: Karl Deutsch on political community and the European integration. International Relations 28: 333–49. [Google Scholar] [CrossRef]

- Fabus, Michal. 2018. Business environment analysis based on the Global Competitiveness Index (GCI) and Doing Business (DB): Case study Slovakia. Journal of Security and Sustainability Issues 7: 831–39. [Google Scholar] [CrossRef]

- Fojtikova, Lenka. 2016. Trends in the revealed comparative advantages of the EU member states. Economic Annals-XXI 161: 7–11. [Google Scholar] [CrossRef]

- Fojtikova, Lenka, and Michaela Stanickova. 2017. The EU member states export competitiveness and productivity. Politicka Ekonomie 65: 669–89. [Google Scholar] [CrossRef]

- Gärtner, Michal, Tomáš Sadílek, and Dana Zadražilová. 2017. Cross-cultural adaptability in a sample of international university students in prague—Gender and culture effect. Journal of Applied Economic Sciences 12: 893–906. [Google Scholar]

- Hamid, Nadiah Abd, Fairus Halizam Hamzah, and Md Noor Rohaya. 2018. Determinats of reinvestment allowance (RA) tax incentive utilization in embracing industry 4.0. Polish Journal of Management Studies 18: 94–104. [Google Scholar] [CrossRef]

- Hanulakova, Eav, and Ferdinand Dano. 2018. Circular Economy as a New Managerial Approach. AD ALTA-Journal of Interdisciplinary Research 8: 95–98. [Google Scholar]

- Jovanović, Miroslav. 2014. The Economics of European Integration, 2nd rev. ed. Cheltenham: Edward Elgar Pub. [Google Scholar]

- Krajnakova, Emilia, Aida Navikaite, and Valentinas Navickas. 2015. Paradigm Shift of Small and Medium-Sized Enterprises Competitive Advantage to Management of Customer Satisfaction. Inzinerine Ekonomika-Engineering Economics 26: 327–32. [Google Scholar] [CrossRef]

- Lazányi, Kornélia, and Yuriy Bilan. 2017. Generetion z on the labour market—Do they trust others within their workplace? [Pokolenie z na rynku pracy—Czy w swoim miejscu pracy ufają innym?]. Polish Journal of Management Studies 16: 78–93. [Google Scholar] [CrossRef]

- Lipkova, Ludmila, and Denys Braga. 2016. Measuring Commercialization Success of Innovations in the EU. Marketing and Management of Innovations 4: 15–30. [Google Scholar]

- Lipkova, Ludmila, and Katarína Hovorkova. 2018. Economic situation in Norway after the outbreak of the global financial and oil crises in the context of EU integration trends. Economic Annals-XXI 169: 12–14. [Google Scholar] [CrossRef]

- Lipkova, Ludmila, Michal Gress, and Alena Poncarova. 2017. Tax systems in the Czech Republic and the Slovak Republic: Comparison with an emphasis on income tax. Economic Annals-XXI 165: 47–51. [Google Scholar] [CrossRef]

- Lorincová, Silvia, Miloš Hitka, Peter Štarchoň, and Katarína Stachova. 2018. Strategic Instrument for Sustainability of Human Resource Management in Small and Medium-Sized Enterprises Using Management Data. Sustainability 10: 3687. [Google Scholar] [CrossRef]

- Machkova, Hana, and Alexej Sato. 2017. Analysis of Competitiveness of Belgian Sugar Industry. Listy Cukrovarnicke a Reparske 133: 390–92. [Google Scholar]

- Malec, Lukas, and Josef Abrham. 2016. Determinants of tourism industry in selected European countries: A smooth partial least squares approach. Economic Research-Ekonomska Istrazivanja 29: 66–84. [Google Scholar] [CrossRef]

- Marr, Bernard. 2018. What is Industry 4.0? Here’s a Super Easy Explanation for Anyone. Forbes. Available online: https://www.forbes.com/sites/bernardmarr/2018/09/02/what-is-industry-4-0-heres-a-super-easy-explanation-for-anyone/#7844ca519788 (accessed on 13 February 2019).

- Miklosik, Andrej, Martin Kuchta, and Stefan Zak. 2018. Monetising Content through Delivery of Advertisements: The Case of Ad Blockers. AD ALTA-Journal of Interdisciplinary Research 8: 175–79. [Google Scholar]

- Obadi, Saleh Mothana, and Matej Korcek. 2016. The “Revealed” Comparative Advantage and Competitiveness of the EU’s International Trade visa vis the USA. Ekonomicky Casopis 64: 397–422. [Google Scholar]

- Sejkora, Jiri. 2014. Poor Economics: A Radical Rethinking of the Way to Fight Global Poverty. Ekonomicky Casopis 62: 431–35. [Google Scholar]

- Sejkora, Jiri, and Odrej Sankot. 2017. Comparative advantage, economic structure and growth: The case of Senegal. South African Journal of Economic and Management Sciences 20: a1685. [Google Scholar] [CrossRef]

- Taušer, Josef, and Radek Čajka. 2014. Hedging techniques in commodity risk management. Agricultural Economics (Czech Republic) 60: 174–82. [Google Scholar] [CrossRef]

- Taušer, Josef, Marketa Arltová, and Pavel Žamberský. 2015. Czech exports and german GDP: A closer look. Prague Economic Papers 24: 17–37. [Google Scholar] [CrossRef]

- Varadzin, Frantisek. 2016. Global Public Goods and Integration. Paper presented at 3rd International Conference on European Integration, Ostrava, Czech Republic, May 19–20; pp. 1052–59. [Google Scholar]

- Vojtovic, Sergej, Alina Stundziene, and Rima Kontautiene. 2018. The impact of socio-economic indicators on sustainable consumption of domestic electricity in lithuania. Sustainability 10: 162. [Google Scholar] [CrossRef]

- Zadrazilova, Dana. 2016. Current Trends in German Sugar Industry. Listy Cukrovarnicke a Reparske 132: 390–93. [Google Scholar]

- Zak, Stefan. 2012. International Marketing: Theory, Practices and New Trends. Prague Economic Papers 21: 251–54. [Google Scholar] [CrossRef]

- Zemanová, Štěpánka, Radka Druláková, Jana Peterková, and Pavel Přikryl. 2015. Foreign policy strategies of small states in contemporary international relations [Zahraničněpolitické strategie malých států v současném mezinárodním prostředí]. Mezinarodni Vztahy 50: 5–23. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).