Performance Review of Prefabricated Building Systems and Future Research in Australia

Abstract

:1. Introduction

2. Previous Research Studies on the Benefits

2.1. Cost and Time

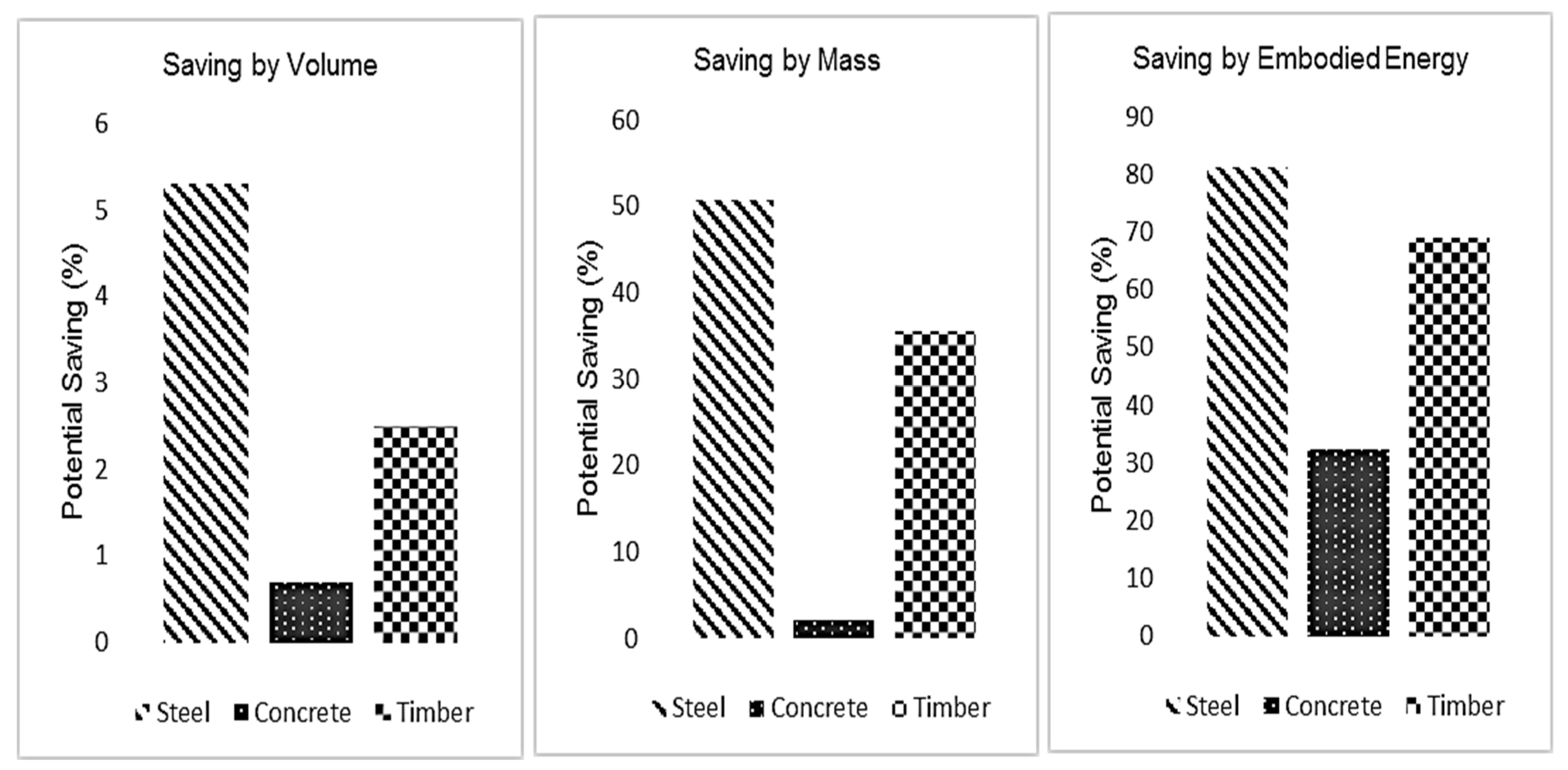

2.2. Other Benefits

3. Structural Performance of Prefabricated Building Systems

3.1. Fire Resistance and Acoustic Performance

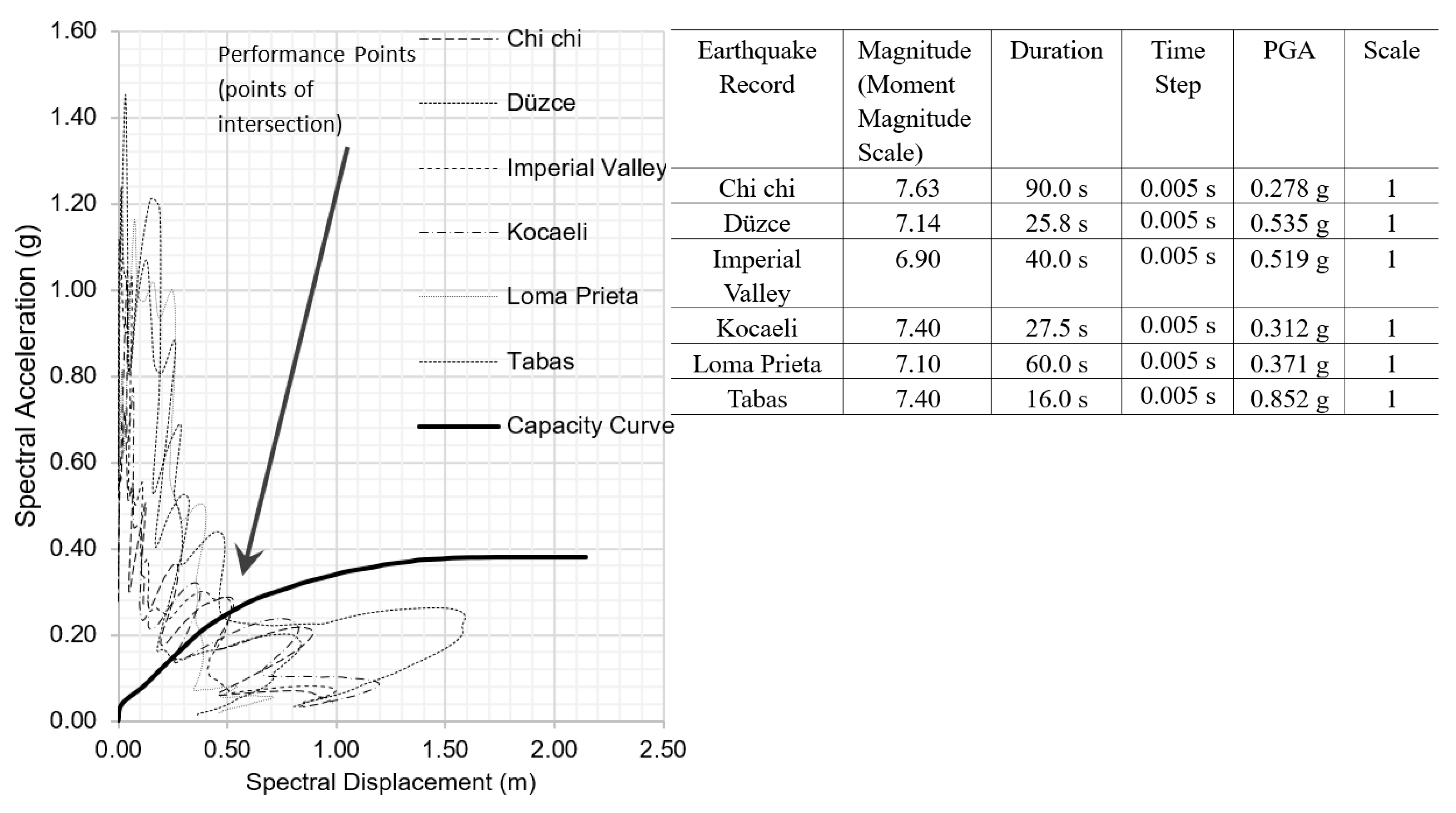

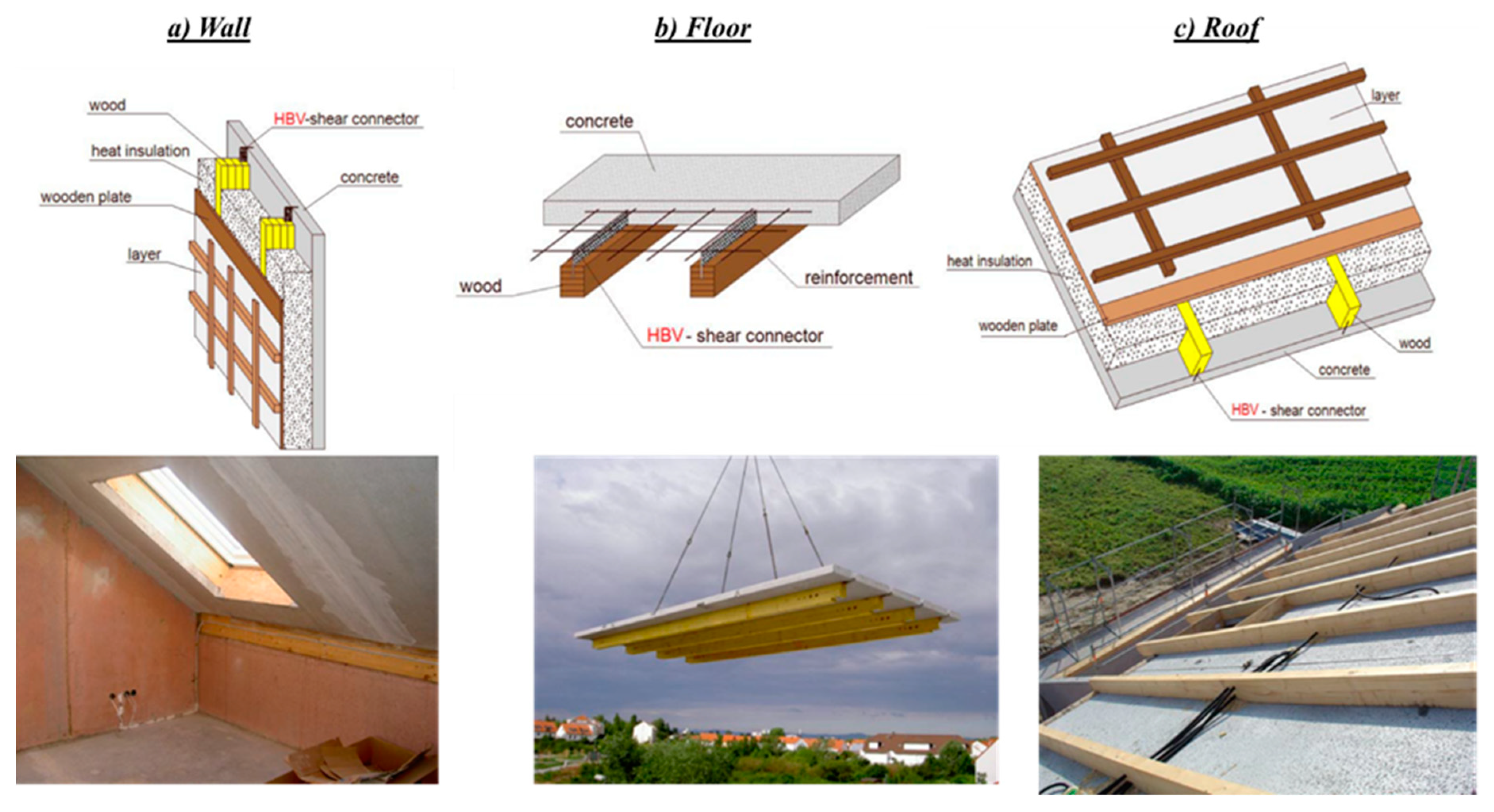

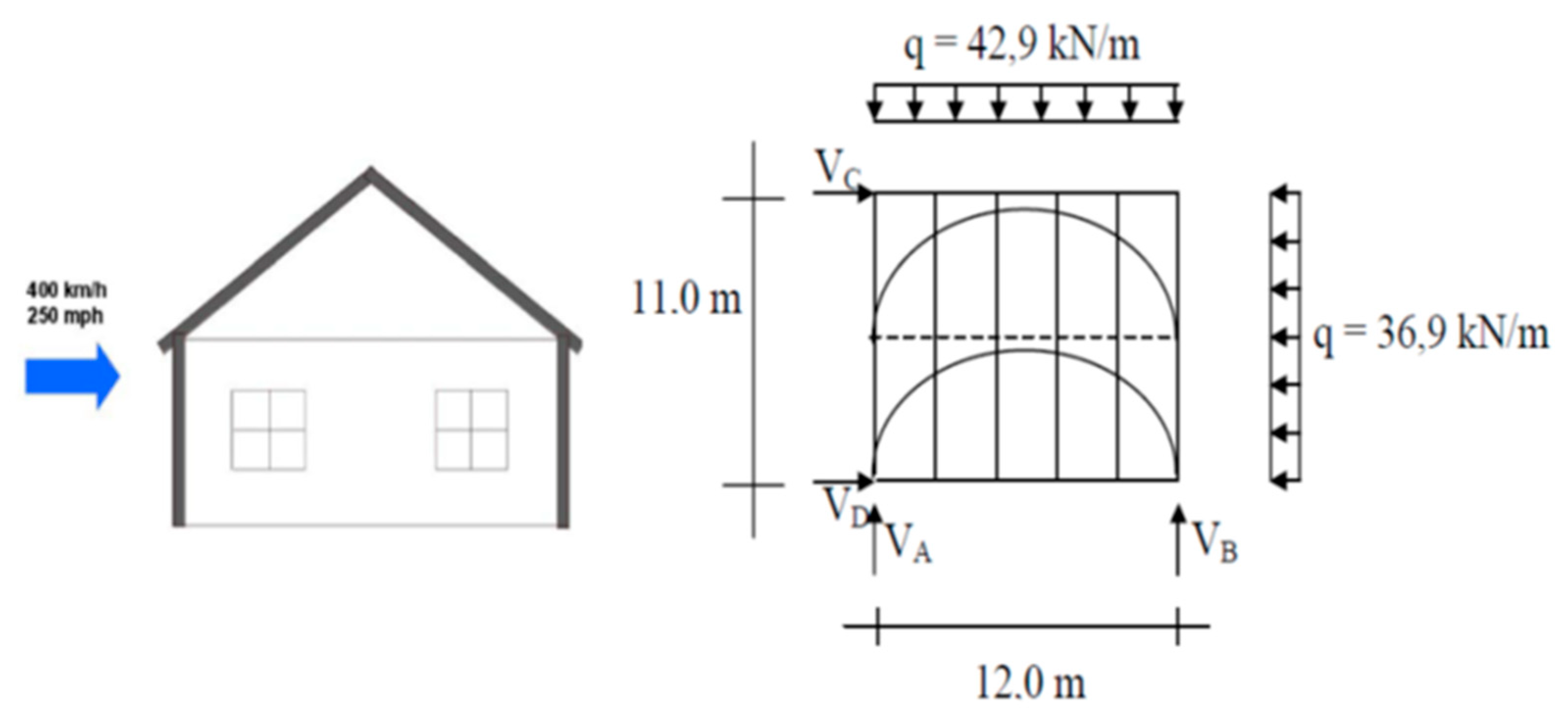

3.2. Performance of the Structure under Earth Quake and Wind Load

4. Constraints, Challenges and Future Research

5. Conclusions

- The limitations of transportation, regulations, and special traffic control in the construction area are the main factors to be considered in transportation planning. Therefore, more case studies are needed to evaluate project planning, scheduling, and the cost of small- and large-scale projects.

- More research and case studies are needed to develop and include the design specifications and recommendation for prefabricated structures according to Australian design standards.

- Previous study has highlighted that most often, structural performance of prefabricated building systems is assessed by individual component testing and numerical models. There could be an inherent redundancy in the structural behaviour when the structural response between individual components and the whole structure are compared. Therefore, numerical modelling, hybrid simulations and full-scale tests need to be conducted on prefabricated whole buildings to evaluate the structural responses and performance under fire, wind and earthquake loads.

- A lack of awareness on the performance, benefits, and affordability design and techniques provided by the prefabricated systems is a major challenge for the marketing of prefabricated building construction in Australia. This could have been achieved through social and economic research. This research should focus on the following activities, such as questionnaires, workshops, conferences and media interviews.

- Although a great deal of previous academic research has proven the sustainability aspects of prefabricated construction, this knowledge needs to be more effectively communicated to the general public. This needs to be accompanied by real case studies on public infrastructure projects where the general public benefits from the performance of prefabricated structures.

- The skills and knowledge required for prefabrication design and construction practices in Australia need to be developed and strengthened through relevant educational courses, workshops, conferences and vocational training. Also, universities, TAFE and vocational education institutes should consider including prefabrication design and construction in their courses. This will increase the professional skills and knowledge required for the design and construction practices, as well as increasing their productivity.

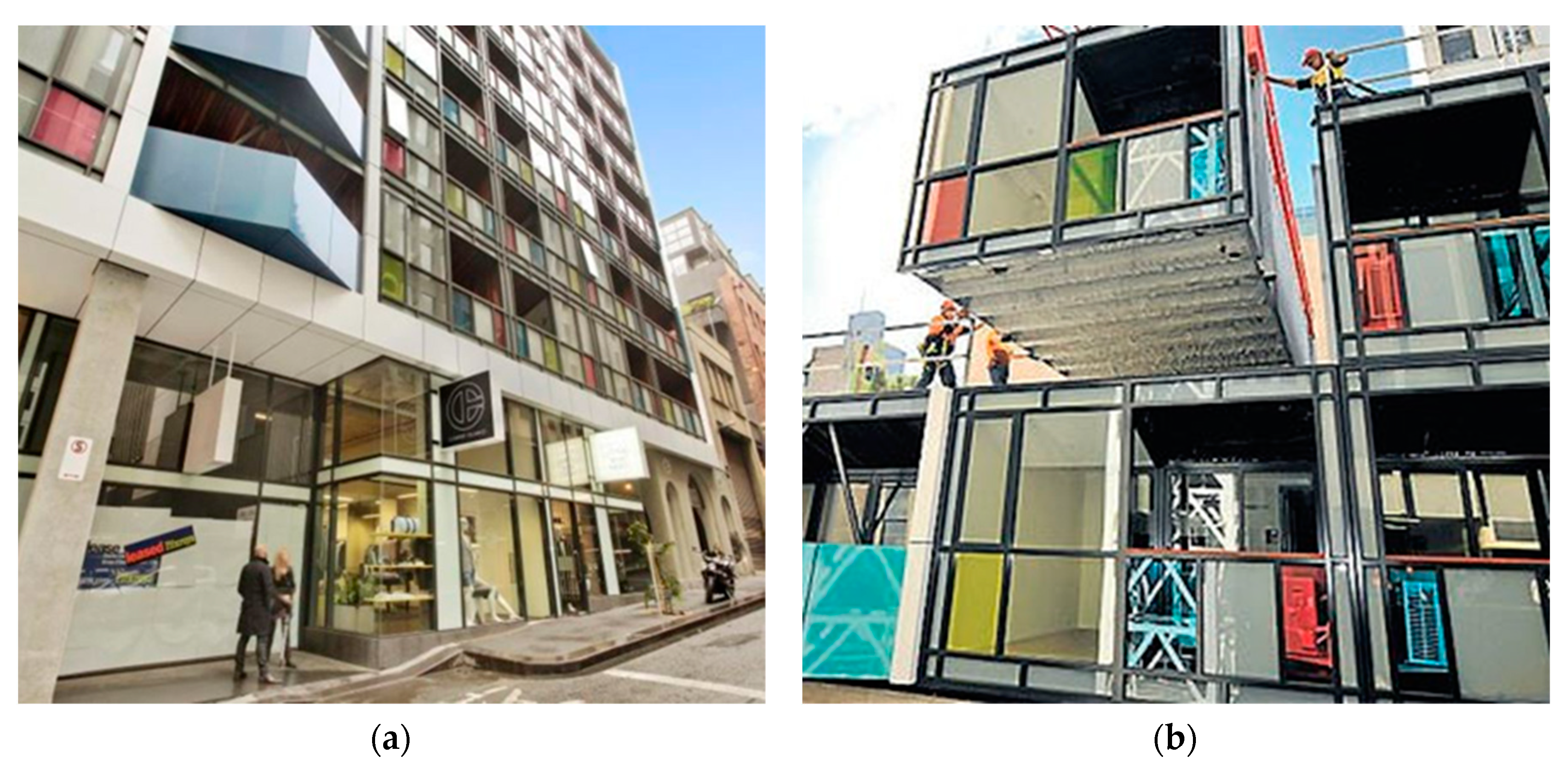

- The government and building industry need to encourage the building of some trademark structures similar to the ‘Little Hero’ low-rise apartment building in Melbourne. This will increase the market demand and development of prefabricated building systems in Australia.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hampson, K.D.; Brandon, P. Construction 2020—A Vision for Australia’s Property and Construction Industry; CRC Construction Innovation: Brisbane, Australia, 2004. [Google Scholar]

- Lawson, R.M.; Ogden, R.G.; Bergin, R. Application of modular construction in high-rise buildings. J. Archit. Eng. 2012, 18, 148–154. [Google Scholar] [CrossRef]

- Gunawardena, T.; Ngo, T.D.; Mendis, P.; Alfano, J. Innovative flexible structural system using prefabricated modules. J. Arch. Eng. 2016, 22, 05016003. [Google Scholar] [CrossRef]

- Kamali, M.; Hewage, K. Life cycle performance of modular buildings: A critical review. Renew. Sustain. Energy Rev. 2016, 62, 1171–1183. [Google Scholar] [CrossRef]

- Paya-Marin, M.A.; Lim, J.; Sengupta, B. Life cycle energy analysis of a modular/ off-site building school. Am. J. Civ. Eng. Archit. 2013, 1, 59–63. [Google Scholar] [CrossRef]

- Blismas, N.; Wakefield, R. Drivers, constraints and the future of offsite manufacture in Australia. Construct. Innov. Inf. Process Manag. 2009, 9, 72–83. [Google Scholar] [CrossRef]

- Bildsten, L. Exploring the opportunities and barriers of using prefabricated house components. In Proceedings of the 19th Conference of the International Group of Lean Construction (IGLC), Lima, Peru, 13–15 July 2011. [Google Scholar]

- Nadim, W.; Goulding, J.S. Offsite production: A model for building down barriers: A European construction industry perspective. Eng. Construct. Archit. Manag. 2011, 18, 82–101. [Google Scholar] [CrossRef]

- Pan, W.; Gibb, A.G.F.; Dainty, A.R.J. Perspectives of UK housebuilders on the use of offsite modern methods of construction. Construct. Manag. Econ. 2007, 25, 183–194. [Google Scholar] [CrossRef]

- Cameron, P.J.; Di Carlo, N.G. Piecing Together Modular: Understanding the Benefits and Limitations of Modular Construction Methods for Multifamily Development. Master’s Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2007. [Google Scholar]

- Steinhardt, D.A.; Manley, K. Exploring the belief of Australian prefabricated house builders. Construct. Econ. Build. 2016, 16, 27–41. [Google Scholar] [CrossRef]

- Gunawardena, T.; Karunaratne, R.; Mendis, P.; Ngo, T. Prefabricated Construction Technologies for the Future of Sri Lanka’s Construction Industry. In Proceedings of the 7th International Conference on Sustainable Built Environment (ICSBE), Earl’s Regency Hotel, Kandy, Sri Lanka, 16–18 December 2016. [Google Scholar]

- Blismas, N. Off-Site Manufacture in Australia: Current State and Future Directions; Cooperative Research Centre for Construction Innovation: Brisbane, QLD, Australia, 2007. [Google Scholar]

- Victorian School Building Authority [VSBA]; © State of Victoria (Department of Education and Training). Permanent Modular School Buildings Program. 2018. Available online: https://www.schoolbuildings.vic.gov.au/Pages/Permanent-Modular-School-Buildings-Program.aspx (accessed on 11 October 2018).

- Prebuilt Pty. Ltd. Ballarat Health Cancer Unit. 2018. Available online: https://commercial.prebuilt.com.au/our-projects/health/ballarat-health-cancer-care-unit/ (accessed on 11 October 2018).

- Kozlovská, M.; Kaleja, P.; Struková, Z. Sustainable construction technology based on building modules. Adv. Mater. Res. 2014, 1041, 231–234. [Google Scholar] [CrossRef]

- Haas, C.T.; O’Connor, J.T.; Tucker, R.L.; Eickmann, J.A.; Fagerlund, W.R. Prefabrication and Pre-Assembly Trends and Effects on the Construction Workforce; Report; Center for Construction Industry Studies, University of Texas: Austin, TX, USA, 2000. [Google Scholar]

- Pasquire, C.L.; Gibb, A.G.F. Considerations for assessing the benefits of standardization and pre-assembly in construction. J. Financ. Manag. Prop. Constr. 2002, 7, 151–161. [Google Scholar]

- Aye, L.; Ngo, T.; Crawford, R.H.; Gammampila, R.; Mendis, P. Life cycle greenhouse gas emissions and energy analysis of prefabricated reusable building modules. Energy Build. 2012, 47, 159–168. [Google Scholar] [CrossRef]

- Kawecki, L.R. Environmental Performance of Modular Fabrication: Calculating the Carbon Footprint of Energy Used in the Construction of a Modular Home. Ph.D. Thesis, Arizona State University, Tempe, AZ, USA, 2010. [Google Scholar]

- Mah, D.E. Framework for Rating the Sustainability of The Residential Construction Practice. Ph.D. Thesis, University of Alberta, Edmonton, AB, Canada, 2011. [Google Scholar]

- Lawson, R.M.; Ogden, R.G. Sustainability and process benefits of modular construction. In Proceedings of the 18th CIB World Building Congress, Salford, UK, 10–13 May 2010; pp. 38–51. [Google Scholar]

- Zenga, M.; Javor, A. Modular Homes: The Future Has Arrived; Fideli Publishing: Paragon, Indiana, 2008. [Google Scholar]

- Schoenborn, J.M. A Case Study Approach to Identifying the Constraints and Barriers to Design Innovation for Modular Construction. Master’s Thesis, Virginia Polytechnic Institute and State University, Blacksburg, VS, USA, 2012. [Google Scholar]

- Haas, C.T.; Fagerlund, W.R. Preliminary Research on Prefabrication, Pre-Assembly, Modularization and Off-Site Fabrication in Construction; Report; The Construction Industry Institute, The University of Texas at Austin: Austin, TX, USA, 2002. [Google Scholar]

- Na, L. Investigation of the Designers’ and General Contractors’ Perceptions of Offsite Construction Techniques in the United States Construction Industry. Ph.D. Thesis, Clemson University, Clemson, SC, USA, 2007. [Google Scholar]

- Quale, J.; Eckelman, M.J.; Williams, K.W.; Sloditskie, G.; Zimmerman, J.B. Construction matters: Comparing environmental impacts of building modular and conventional homes in the United States. J. Ind. Ecol. 2012, 16, 243–253. [Google Scholar] [CrossRef]

- Chiu, S.T.L. An Analysis on the Potential of Prefabricated Construction Industry. Ph.D. Thesis, The University of British Columbia, Vancouver, BC, Canada, 2012. [Google Scholar]

- Chiang, Y.H.; Chan, E.H.W.; Lok, L.K.L. Prefabrication and barriers to entry—A case study of public housing and institutional buildings in Hong Kong. Habitat. Int. 2006, 30, 482–499. [Google Scholar] [CrossRef]

- Lawson, R.M.; Ogden, R.G. “Hybrid” light steel panel and modular systems. Thin Wall Struct. 2008, 46, 720–730. [Google Scholar] [CrossRef]

- Pan, Y.; Wong, F.K.W.; Hui, E.C.M. Application of industrialized housing system in China: A Chongqing study. In Modeling Risk Management in Sustainable Construction, Computational Risk Management; Springer: Berlin, Germany, 2011; pp. 161–168. [Google Scholar]

- Cartz, J.P.; Crosby, M.; Symonds, D.C. Building high rise modular homes. Struct. Eng. 2007, 85, 20–21. [Google Scholar]

- Rogan, A.L.; Lawson, R.M.; Bates-Brkljac, N. Value and Benefits Assessment of Modular Construction; Report; Steel Construction Institute: Berkshire, UK, 2000. [Google Scholar]

- Gibb, A.; Isack, F. Re-engineering through pre-assembly: Client expectations and drivers. Build. Res. Inf. 2003, 31, 146–160. [Google Scholar] [CrossRef]

- Matic, D.; Calzada, J.R.; Todorovic, M.S.; Erić, M.; Babin, M. Cost-Effective Energy Refurbishment of Prefabricated Buildings in Serbia. In Cost-Effective Energy Efficient Building Retrofitting; Elsevier: Cambridge, UK, 2017; pp. 455–487. [Google Scholar]

- Salavatian, S.; D’Orazio, M.; Di Perna, C.; Di Giuseppe, E. Assessment of Cardboard as an Environment-Friendly Wall Thermal Insulation for Low-Energy Prefabricated Buildings. In Sustainable Building for a Cleaner Environment; Springer: Cham, Switzerland, 2019; pp. 463–470. [Google Scholar]

- Minunno, R.; O’Grady, T.; Morrison, G.; Gruner, R.; Colling, M. Strategies for Applying the Circular Economy to Prefabricated Buildings. Buildings 2018, 8, 125. [Google Scholar] [CrossRef]

- Chang, Y.; Li, X.; Masanet, E.; Zhang, L.; Huang, Z.; Ries, R. Unlocking the green opportunity for prefabricated buildings and construction in China. Resour. Conserv. Recycl. 2018, 139, 259–261. [Google Scholar] [CrossRef]

- Hong, J.; Shen, G.Q.; Li, Z.; Zhang, B.; Zhang, W. Barriers to promoting prefabricated construction in China: A cost–benefit analysis. J. Clean. Prod. 2018, 172, 649–660. [Google Scholar] [CrossRef]

- Pons, O. Assessing the sustainability of prefabricated buildings. In Eco-Efficient Construction and Building Materials: Life Cycle Assessment (LCA), Eco-Labelling and Case Studies; Elsevier: Cambridge, UK, 2014; pp. 434–456. [Google Scholar]

- Waskett, P. Current Practice and Potential Uses of Prefabrication; DTI Construction Industry Directorate: Watford, UK, 2001. [Google Scholar]

- Gunawardena, T.; Ngo, T.D.; Mendis, P. Behaviour of multi-storey prefabricated modular buildings under seismic loads. Earthq. Struct. 2016, 11, 1061–1076. [Google Scholar] [CrossRef]

- Lacey, A.W.; Chen, W.; Hao, H.; Bi, K. Structural response of modular buildings—An overview. J. Build. Eng. 2018, 16, 45–56. [Google Scholar] [CrossRef]

- Boughton, G.N.; Parackal, K.; Satheeskumar, N.; Henderson, D.J. Development of a Full-Scale Structural Testing Program to Evaluate the Resistance of Australian Houses to Wind Loads. Front. Built Environ. 2017, 3, 21. [Google Scholar] [CrossRef]

- Standards Australia. Structural Design Actions. Part 2: Wind Actions; AS 1170.2; Standards Australia: New South Wales, Australia, 2011. [Google Scholar]

- Standards Australia. Structural Design Actions. Part 4: Earthquake Actions in Australia; AS 1170.4; Standards Australia: New South Wales, Australia, 2007. [Google Scholar]

- Standards Australia. AS 1530.4-2005 Part 4: Fire Resistance Test of Elements of Construction. In Methods for Fire Tests on Building Materials, Components and Structures; Standards Australia: Sydney, Australia, 2005. [Google Scholar]

- Standards Australia. Fire Propagation Testing and Classification of External Walls of Buildings; AS 5113; Standards Australia: Sydney, Australia, 2016. [Google Scholar]

- Building Code of Australia. National Construction Code; NCC 2016, Building Code of Australia: Canberra, ACT, Australia, 2016.

- Williams, L.T. The Worst Bushfires in Australia’s History. Available online: https://www.australiangeographic.com.au/topics/science-environment/2011/11/the-worst-bushfires-in-australias-history/ (accessed on 11 October 2018).

- Wang, Y.C. An analysis of the global structural behaviour of the Cardington steel-framed building during the two BRE fire tests. Eng. Struct. 2000, 22, 401–412. [Google Scholar] [CrossRef]

- Nguyen, Q.T.; Ngo, T.D.; Tran, P.; Mendis, P.; Bhattacharyya, D. Influences of clay and manufacturing on fire resistance of organoclay/thermoset nanocomposites. Compos. Part A 2015, 74, 26–37. [Google Scholar] [CrossRef]

- Nguyen, Q.T.; Ngo, T.; Tran, P.; Mendis, P.; Zobec, M.; Aye, L. Fire performance of prefabricated modular units using organoclay/glass fibre reinforced polymer composite. Constr. Build. Mater. 2016, 129, 204–215. [Google Scholar] [CrossRef]

- Nguyen, Q.T.; Ngo, T.; Tran, P.; Mendis, P.; Aye, L.; Baduge, S.K. Fire resistance of a prefabricated bushfire bunker using aerated concrete panels. Constr. Build. Mater. 2018, 174, 410–420. [Google Scholar] [CrossRef]

- Lineham, S.A.; Thomson, D.; Bartlett, A.I.; Bisby, L.A.; Hadden, R.M. Structural response of fire-exposed cross-laminated timber beams under sustained loads. Fire Safety J. 2016, 85, 23–34. [Google Scholar] [CrossRef]

- Barber, D. Determination of fire resistance rating for glulam connectors within US high rise timber buildings. Fire Safety J. 2017, 2017, 91. [Google Scholar] [CrossRef]

- Annan, C.D.; Youssef, M.A.; El-Naggar, M.H. Seismic performance of modular steel braced frames. In Proceedings of the Ninth Canadian Conference on Earthquake Engineering, Ottawa, ON, Canada, 26–29 June 2007. [Google Scholar]

- Annan, C.D.; Youssef, M.A.; El Naggar, M.H. Seismic Vulnerability Assessment of Modular Steel Buildings. J. Earthq. Eng. 2009, 13, 1065–1088. [Google Scholar] [CrossRef]

- Annan, C.D.; Youssef, M.A.; El Naggar, M.H. Seismic Overstrength in Braced Frames of Modular Steel Buildings. J. Earthq. Eng. 2008, 13, 1–21. [Google Scholar] [CrossRef]

- Federal Emergency Federal Agency. FEMA-356, Pre-standard and Commentary for Seismic Rehabilitation of Buildings; Federal Emergency Federal Agency: Washington, DC, USA, 2000. [Google Scholar]

- Lawson, R.M.; Ogden, R.G.; Pedreschi, R.; Popo-Ola, S.O. Development in prefabricated systems in light steel and modular construction. Struct. Eng. 2005, 83, 28–35. [Google Scholar]

- Ramaji, I.J.; Memari, A.M. Identification of structural issues in design and construction of multistory modular buildings. In Proceedings of the 1st Residential Building Design & Construction Conference, Pennsylvania Housing Research Center (PHRC), Bethlehem, PA, USA, 19–20 February 2013; pp. 294–303. [Google Scholar]

- Bathon, L.; Bletz, O.; Schmidt, J. Hurricane proof buildings—An innovative solution using prefabricated modular wood concrete-composite elements. In Proceedings of the 9th World Conference on Timber Engineering, Portland, OR, USA, 6–10 August 2006. [Google Scholar]

- Reardon, G.F. Simulated Cyclone Wind Loading of a Nu-Steel House Technical Report No. 36; Cyclone Testing Station, James Cook University: Townsville, Australia, 1990. [Google Scholar]

- O’Connor, J.T.; O’Brien, W.J.; Choi, J.O. Industrial project execution planning: Modularization versus stick-built. Pract. Period Struct. Des. Constr. 2016, 21, 4015014. [Google Scholar] [CrossRef]

- Ramaji, I.; Memari, A. Information exchange standardization for BIM application to multistory modular residential buildings. In Proceedings of the 6th Biennial Professional Conference (AEI 2015), Milwaukee, WI, USA, 24–27 March 2015; pp. 13–24. [Google Scholar]

- Satheeskumar, N.; Henderson, D.J.; Ginger, J.D.; Humphreys, M.T.; Wang, C.H. Load sharing and structural response of roof-wall system in a timber-framed house. Eng. Struct. 2016, 122, 310–322. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Navaratnam, S.; Ngo, T.; Gunawardena, T.; Henderson, D. Performance Review of Prefabricated Building Systems and Future Research in Australia. Buildings 2019, 9, 38. https://doi.org/10.3390/buildings9020038

Navaratnam S, Ngo T, Gunawardena T, Henderson D. Performance Review of Prefabricated Building Systems and Future Research in Australia. Buildings. 2019; 9(2):38. https://doi.org/10.3390/buildings9020038

Chicago/Turabian StyleNavaratnam, Satheeskumar, Tuan Ngo, Tharaka Gunawardena, and David Henderson. 2019. "Performance Review of Prefabricated Building Systems and Future Research in Australia" Buildings 9, no. 2: 38. https://doi.org/10.3390/buildings9020038

APA StyleNavaratnam, S., Ngo, T., Gunawardena, T., & Henderson, D. (2019). Performance Review of Prefabricated Building Systems and Future Research in Australia. Buildings, 9(2), 38. https://doi.org/10.3390/buildings9020038