Abstract

This experimental study was focused on the application of a surface-modified hemp- hurds aggregate into composites using an alternative binder of MgO-cement. This paper presents the results of the comparative study of the parameters (chemical and physico-chemical modification, and hardening time) affecting the physical (density, thermal conductivity coefficient and water-absorption behavior) and mechanical properties (compressive strength) of the bio-aggregate-based composite. A test of the parameters of the bio-composite samples showed some differences, which were determined by the chemical and surface properties of the modified filler, and which affected the mechanisms of hardening. The bulk density values of the hemp hurd composites hardened for 28 days place this material in the lightweight category of composites. The values of water absorption and the thermal conductivity coefficient of bio-composites decreased, and the strength parameter increased with an increase in the hardening time. The lower values of compressive strength, water absorption, and thermal conductivity coefficient (except for the ethylenediaminetetraacetic-acid-treated filler) were observed in composites based on fillers chemically treated with NaOH and Ca(OH)2) compared to referential composites (based on original hemp hurds). This is related to changes in the chemical composition of hemp hurds after chemical modification. The composites with ultrasound-treated hemp hurds had the greatest strengths at each hardening time. This is related to pulping the bundles of fibers and forming a larger surface area for bonding in the matrix.

1. Introduction

Innovative building solutions for conserving non-renewable resources are connected to the development of sustainable building materials based on the use of easily renewable natural raw material resources. There is a growing interest in the utilization of natural lignocellulosic materials/fibers (usually derived from plants) as organic fillers and/or their reinforcement into lightweight composites called “green” composites/concretes for sustainable constructions. These provide healthy living solutions, thanks to the natural fibers’ ability to regulate humidity inside buildings by absorbing and/or releasing water molecules, depending on the air conditions [1]. Due to their many advantageous properties—e.g., their eco-friendly and economical characteristics [2]—natural fibers or lignocellulosic materials can adequately replace synthetic fibers or wood particles in composites [3,4]. The increasing trend of using lignocellulosic materials/residues with a rich content of cellulose in the wooden parts of annual plants (hemp, kenaf, jute, sisal, bamboo, hemp) in the preparation of lightweight composite has been recorded in recent years. Although the demand for natural fibers is growing worldwide and its price is increasing, it is still significantly lower than that of synthetic fibers; these plants need further research with respect to the opportunities for their use, and to provide novel products with improved properties. Among a wide variety of lignocellulosic material sources, a great importance is given to technical hemp (Cannabis Sativa) for its application in bio-composites. Industrial hemp is becoming a major focus of the green housing segment because of its energy-efficient cultivation, and because hemp-based composites have no negative effects on human health [5]. The excellent physical and mechanical properties of hemp, including low density, high specific stiffness and strength, biodegradability, sound absorption, low processing costs and the ecological suitability of this fast-growing, carbon-negative and non-toxic plant, predispose it for use in building materials (bio-composites) based on inorganic matrices [6], mainly for their application in the housing construction [7]. Traditional building materials, such as concrete, are increasingly being replaced with advanced composite materials in accordance with the principles of sustainability in civil engineering. One of the options involves a partial replacement of cement with active cementitious substances, such as mineral or industrial solid byproducts and wastes (metakaolin, coal and municipal solid waste fly-ash, agro-technical ash, quarry dust, blast furnace slag and reservoir sediments) [8,9,10,11,12,13]. This practice is favorable to the industry, resulting in a concrete that has lower costs and environmental impact, and greater long-term strength, and durability [14]. Another more innovative way is to develop new hybrid cement systems, incorporating alkaline-activated cement based on supplementary industrial byproducts [15,16]. A further innovative strategy is the reinforcement of cement composites with natural cellulosic fibers to improve their strength, toughness and ductility. A review of the recent research on cellulosic fiber-reinforced cement-based composites is in paper [17]. According to [7], the characteristics of the bond between the cellulosic microfiber reinforcement in cement-based materials remain relatively unexplored. The dependence of the durability of cement composites on the dimensional stability of fiber in the cement matrix has also been found [18].

The adverse effect of cement hydration on the durability of these cement composites and on the deterioration of natural fibers was also found; it can be minimized by modifying the cement matrix by using various supplementary cementitious materials and fiber pre-treatment [19,20]. A new approach to the substitution of conventional binders in fibrous composites is aimed at the use of clinker-free cement. One of these binders is MgO-cement, which mainly produces magnesium hydroxide and magnesium silicate hydrates (M-S-H) as the main compounds during hardening [21].

These approaches are considered to systematically study and develop fiber-reinforced composites with suitable mechanical and durability properties and to meet the requirements of sustainable development.

Currently, waste materials—hemp hurds or shives (woody fibers from the plant core)—derived from bast (non-wood) fibers used in the textile industry [22] appear to be suitable lignocellulosic fibers for the production of building composite. Hemp hurds were first introduced in the early 1990s in France in order to lighten concrete [23]. Composite building materials, combining cementitious binders (limes and cement) with hemp hurds, are generally referred to as hemp concrete or hempcrete [24]. Hemp concrete is largely a non-load-bearing material, commonly used with a load-bearing frame, because of its low compressive strength values. However, its compressive strength is important as it is the most commonly measured property, allowing a comparison between composites with the different binders [25].

A growing interest in using hemp hurds as waste material in lightweight composite preparation has been recorded in recent years [7]. Hemp hurds are one the most widely studied natural fibrous material for sustainable building materials. The use of this renewable resource for the production of composites is attractive and motivating from the environmental and economic point of view. The composites based on natural lignocellulosic fibers/particles are constantly under development and are finding their way to the construction industry. The design of new structures, technologies, and lignocellulosic composite products made from plant waste with a higher added value has been the aim of many studies. Lignocellulosic composites based on inorganic binders (i.e., cement, lime, gypsum) cover a wide range of applications [1,26,27,28,29,30,31,32,33]. The advantages and limitations of the cement-bonded composites made of lignocellulosic wastes have been described in [27].

The properties of lime composites with lignocellulosic raw materials such as hemp shives and flax straw, along with small quantities of Portland cement for the production of wall blocks for use in the energy-efficient construction industry have been investigated in [34,35]. Hemp-based panels produced by bonding hemp fibers and hurds with Portland cement or slaked lime exhibited promising thermo-mechanical properties [36]. The panels based on hemp hurds with novel hybrid organic-inorganic binders characterized by their physical, microstructural, thermal, and mechanical properties have shown parameters comparable to those of commercially available products [5,37].

The objective of many papers is to search for new raw materials of alternative inorganic cementitious materials with a lower carbon footprint compared to Portland cement, and which are suitable for bio-composite preparation [20,38,39,40]. Studies have shown the advantages of using MgO-cement in composites based on hemp hurds in terms of higher compressive strength values compared to composites with hydrated lime and cement matrix [41]. The properties of composites based on hemp hurds depend on the chemical composition and structure of the hemp materials, the matrix properties, and good adhesion at the hemp fiber (hurds)–matrix interface. Key problems for the successful application of hemp hurds in composites are their heterogeneity and hydrophility, resulting in high moisture-sorption sensitivity of biomaterials and the related incompatibility with the matrix. The incompatibility between natural fibers and the matrix leads to low interface strength compared to glass or carbon fiber composites. Many research projects have been devoted to studying the enhancement of the adhesion at the interface of the fiber and inorganic matrix, using various methods for the modification of the surface fibers. The adhesion of the fibers can be optimized by their chemical/physical pre-treatment, which involves removing impurities and amorphous components (pectin, lignin, hemicelluloses) and the separation of bundles of fibers in the fibrils [42,43,44].

In our previous paper [45], the changes in the properties of hemp hurds after their chemical modification were characterized. The durability of the hardened composite based on chemically treated hemp hurds was tested by fully immersing them in water during long-term storage. Based on a comparative study [46], the long-term water-sorption behavior of the composites, which have been reinforced with original and chemically modified hemp hurds, depends on the surface properties of the treated filler in three reagents. Although the composites bonded with magnesia cement are considered to be water-sensitive, they are much less so than cement composites.

The scope of this paper is to assess the influence of different pre-treatment processes of hemp hurds on the physical (density, thermal conductivity coefficient, and water-sorption behavior) and mechanical properties (compressive strength) of bio-composites with MgO-cement.

2. Materials and Methods

2.1. MgO-Cement

MgO-cement consists of magnesium oxide, silica sand (Sastin, Slovakia) and sodium hydrogen carbonate (p.a.). The mean particle diameter (calculated as the first moment of the density of the distribution particle size function) of silica sand particles with the dominant component of SiO2 (95–98 wt. %) was 386 μm. The density of silica sand was 2600 kg·m−3. MgO as a commercial product (CCM 85) made by the calcination of a natural magnesite of the breunerite type with a mean particle diameter of 337 μm was taken from the Slovak Magnesite Factory in Jelsava (Slovakia). An intergrowth of breunerite in fine-grained dolomite is in the mineral texture of magnesite. MgO is used mainly as a refractory material, but its use is increasing in wallboard products. The density of the MgO product was 3490 kg·m−3. The MgO sample was subsequently dry-milled until it was the finest product. A short-term milled product (five minutes) obtained by vibratory milling had a mean particle diameter of 6.85 μm [47]. The MgO chemical composition determined by X-ray fluorescence spectrometry (SPECTRO iQ II, Bruker, Billerica, MA, USA) is given in Table 1.

Table 1.

Chemical composition of MgO.

The results of the chemical analysis of MgO were confirmed by the XRD powder analysis. The main crystalline phase in the MgO product was periclase (low peak intensity corresponding to the röntgen amorphous phase). Calcite, dolomite, and quartz were identified as well.

2.2. Hemp Hurds

Technical hemp hurds (Hempflax, Oude Pekela, The Netherland) were used as a filler material in composites (Figure 1). The particle size distribution of the hemp hurds slices was rather wide (0.063–8 mm), and it also contained fine dust particles originating from the manufacturing disintegration process. This material consisted of a large majority of hemp hurds over hemp bast fibers, and its density was 117.5 kg·m−3. The aggregate lengths prevailed over their diameter; therefore, the particle size was evaluated by their mean length (1.94 mm). The average moisture content of the hemp material determined by weighing the hemp sample before and after drying it for 24 h at 105 °C was found to be 10.78 wt. %. The content of the cellulosic components (cellulose and hemicellulose) in a milled and oven-dried sample was 77.28 wt. %. Non-cellulosic substances such as lignin, waxes and ash, had the amounts of 21.03, 3.04, and 3.57 wt. %, respectively. The important characteristics of the cellulose present in the complex structure of hemp hurds are the polydispersity index (PDI) and the degree of polymerization (DP) calculated from the molecular weight distribution analysis of the cellulose. Their values for the original hemp hurds were 11.33 and 1302, respectively. A more detailed characterization of the properties of hemp hurds has been given in [45].

Figure 1.

View of technical hemp hurd slices.

The dried hemp hurds were modified by chemical and physico-chemical procedures. Three different solutions—sodium hydroxide (NaOH) p.a., calcium hydroxide (Ca(OH)2) ≥ 96%) and ethylenediamintetracetic acid (EDTA)—were used for the chemical modification of organic fillers under the conditions described in the paper [48]. The physico-chemical treatment of hemp material was done by boiling it in water (100 °C) for an hour and by its ultrasonification in an ultrasonic cleaner bath (TESON 10, 220 V, 50 Hz, 650 W) with de-ionized water as a cleaning medium in which the ratio s:l (solid to liquid phase) was 1:10. The designation of the treated hemp hurd samples is given in Table 2.

Table 2.

Nomenclature of the modified hemp hurd samples.

2.3. Preparation of Composites

Six mixes were prepared according to the formula [49]. The representation of individual constituents in the volume of the mixture was 40 vol. % of hemp hurds, 29 vol. % of MgO-cement (the same portion of components) and 31 vol. % of water. To calculate the recipes and express the weights of individual components for the mixing batch, the “absolute volume equation” was applied, taking into account the densities of all the components.

The mixing sequence of the mixture components was established according to our preliminary investigation. Dry homogenization of the components was manually done in a large vessel, and water was gradually added to the mix. The final mixing was done in a 50 L mixer for three 3 min. The mixture was placed into steel molds (100 × 100 × 100 mm) and the samples were manually compacted in three layers by a pestle. The specimens remained in the mold for 48 h. Then, the mold was removed and the cube specimens of the hemp composites were covered with a foil and cured in an indoor climate (temperature: 23 ± 1 °C; relative humidity: 55 ± 3%) for 28, 60, and 90 days.

2.4. Determination of Composite Properties

Since there are no standard procedures for measuring the hemp composite’s properties, the physical and mechanical properties were tested following the standards for concrete. The bulk density of the hardened composites was determined in accordance with the standard [50]. The thermal conductivity coefficient of the samples, as the main parameter of heat transport was measured by the commercial device ISOMET 104 (Applied Precision Ltd., Rača, Slovakia). To determine the credibility of the coefficient of thermal conductivity, the samples dried to a constant weight because of moisture elimination, were measured at selected work points on each side of the cube. The resulting value of this parameter was expressed as the average value of 18 measurements.

Short-term water absorption of the bio-composite samples was determined by the same method as the long-term one that is specified in the standard [51], but after an hour of immersion.

The compressive strength of all the cube specimens after hardening was determined under controlled conditions using a constant loading rate (0.3 MPa/mm2/s = 3.0 kN/mm2/s), as the maximum load per average cross-sectional area by using the instrument ADR ELE 2000 (ELE International Ltd., Bedfordshire, UK) in accordance with the standard [52]. The resulting values are the average of three measurements.

3. Results and Discussion

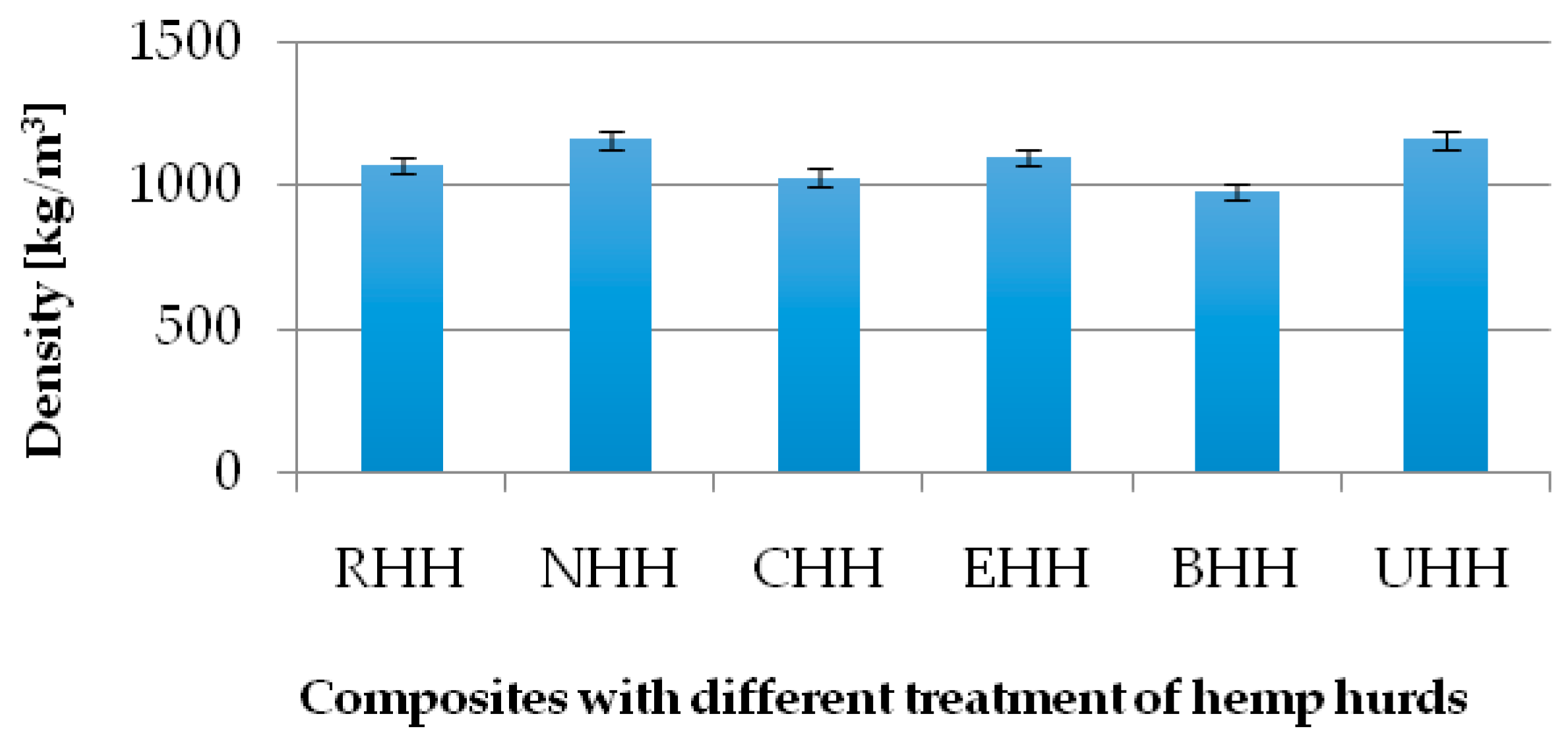

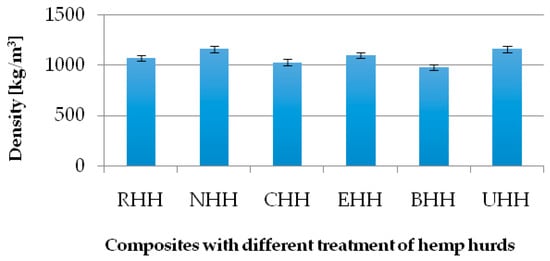

The physico-mechanical properties (bulk density, thermal conductivity, water absorption, compressive strength) of the hardened specimens were measured. The bulk density values of the prepared composite samples after 28 days of hardening, as shown in Figure 2, ranged from 960 to 1160 kg/m3, placing this material in the category of lightweight composites. The measured values of density are comparable with building materials, such as aerated autoclaved concrete (800–1200 kg/m3). When the bulk density value of the reference composite was compared to the composite based on the treated hemp hurds, the difference between these values was about ±90 kg/m3, which was the same as the variance of the measured values of one sample. There was no observed influence of the treatment method of the hemp hurds on density composites.

Figure 2.

Bulk density values of original and treated hemp composites after 28 days of hardening.

The density values of the treated and untreated lightweight composites did not significantly change according to the hardening time dependence. They ranged from 990 to 1220 kg/m3, and these values followed the trend, as seen in Figure 2, such that they were affected by the treatment method of hemp hurds. The variation in the density values of each composite sample with the hardening time was about ±10%.

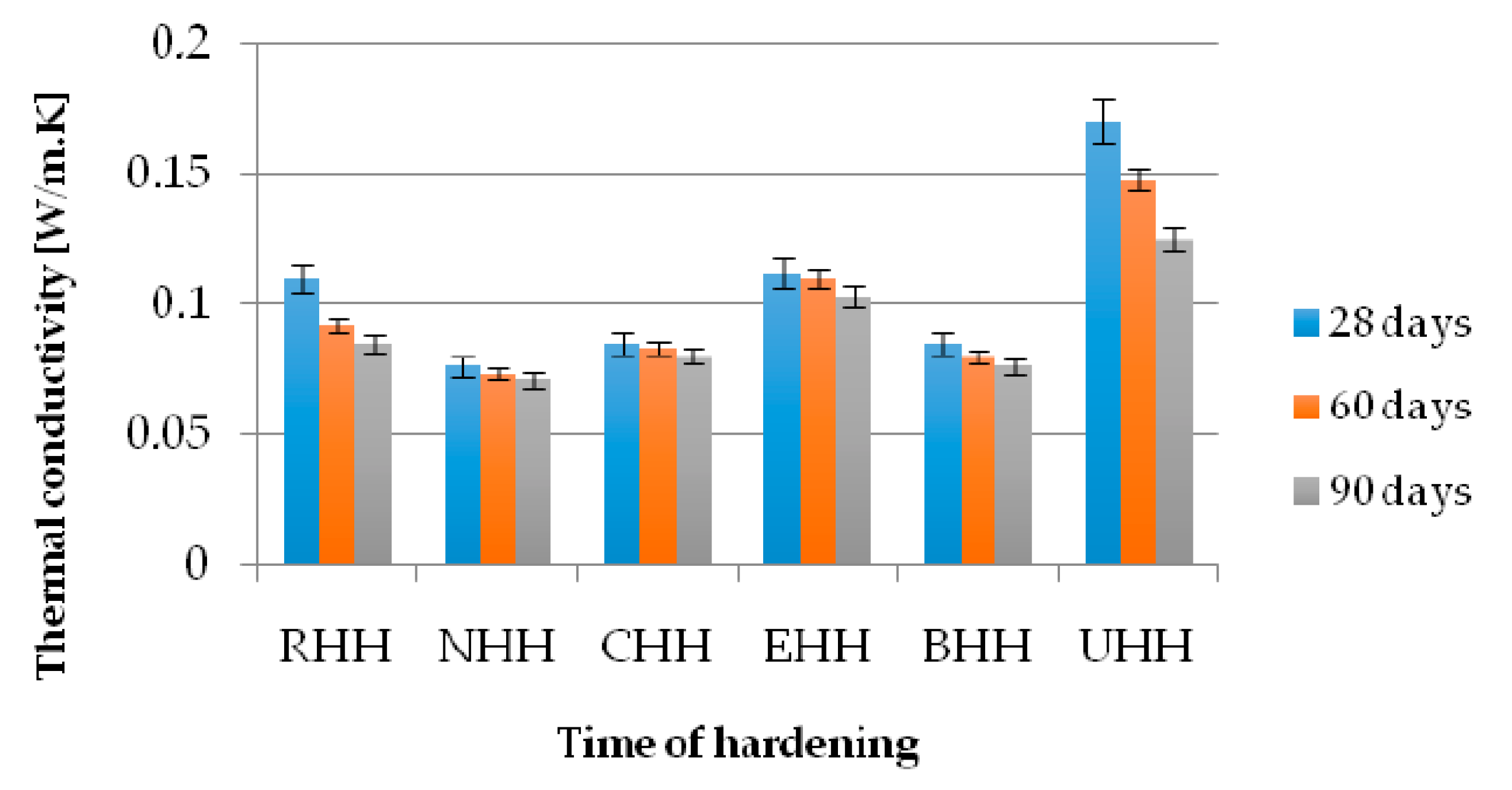

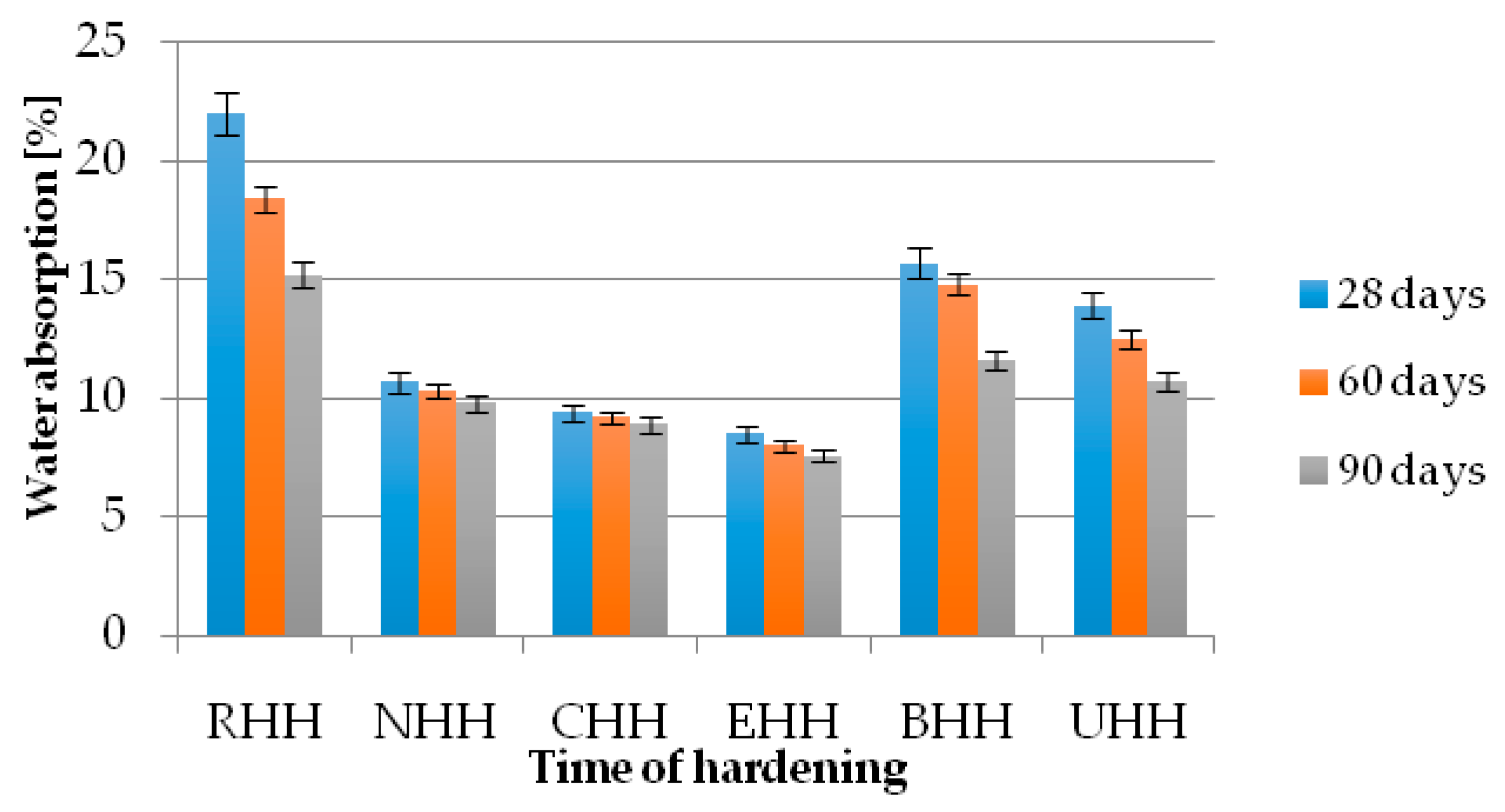

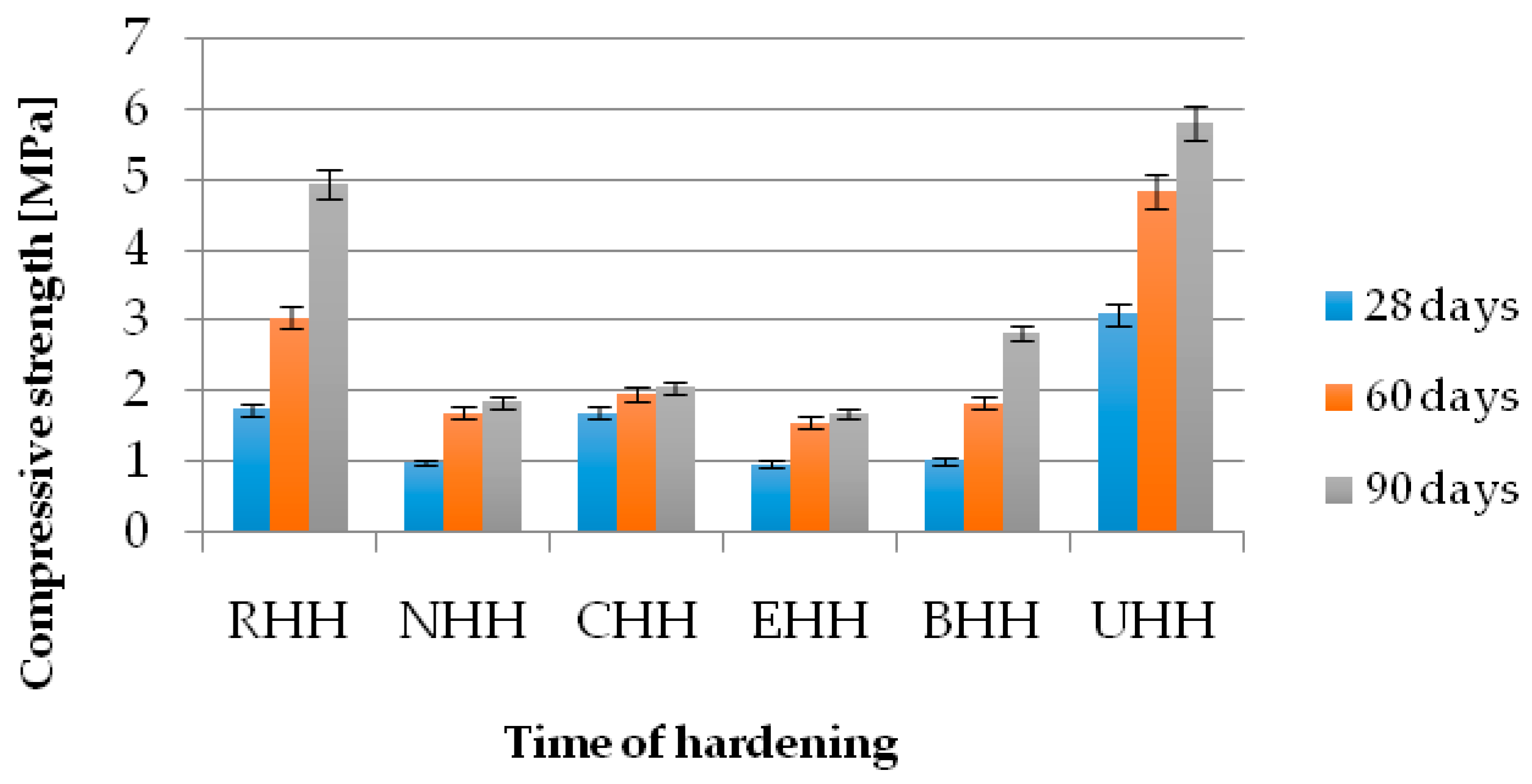

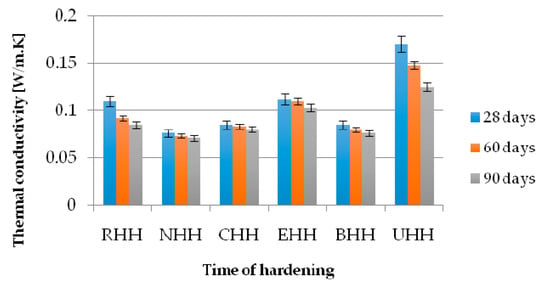

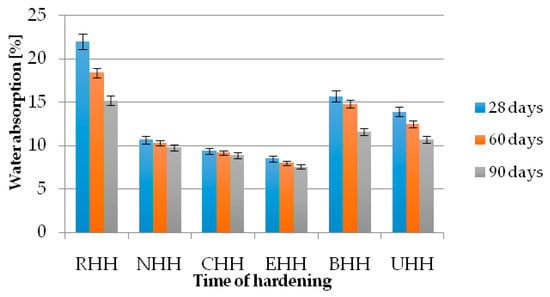

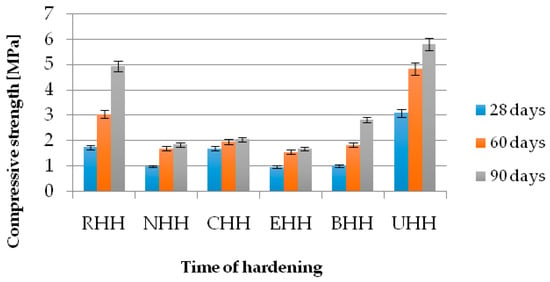

The thermal conductivity coefficient, short-term water absorption, and compressive strength of lightweight composites based on hemp hurds and MgO-cement after hardening times of 28, 60, and 90 days are shown in Figure 3, Figure 4 and Figure 5.

Figure 3.

The thermal conductivity coefficient values of the original and treated hemp composites after 28, 60, and 90 days of hardening.

Figure 4.

Water absorption of the original and treated hemp composites after 28, 60, and 90 days of hardening.

Figure 5.

Compressive strength values of the original and treated hemp composites after 28, 60, and 90 days of hardening.

Lightweight composites are also used as thermal insulation in buildings as well; this is assessed by measuring their coefficient of thermal conductivity. As Figure 3 shows, the values of the thermal conductivity coefficient of all the specimens decrease with an increase in the hardening time. Also, the influence of the treatment method of organic fillers is observed. More favorable values of this parameter compared to referential composites were recorded for the composite samples based on the hemp hurds treated with NaOH, Ca(OH)2, and hot water. On the contrary, the highest values of thermal conductivity were found for the specimens based on the ultrasound-treated sample. Their increase was about 36–40% compared to the reference composite. The observed values of the thermal conductivity coefficient of the specimens prepared with the alternative binder MgO-cement were lower than the conductivity parameter values of hemp composites with a lime binder [53] and also with traditional Portland cement [54]. To compare the achieved results, the characteristic values of the thermal conductivity of some related building materials can be presented: brick (0.4–0.8 W/m·K), lightweight concrete (0.11–1.25 W/m·K), wood (0.18–0.22 W/m·K), and foamed glass (0.04 W/m·K). As for characterization of the thermal insulation ability, the thermal conductivity should be lower than 0.3 W/m·K, while values under 0.1 W/m·K are preferred for highly effective thermal insulation materials [55]. Thus, the measured values of all the prepared bio-composite samples are in range acceptable for the thermal insulation materials.

As Figure 4 shows, short-term water absorption of composites is positively affected by both processes—the hardening of composites and the treatment of hemp hurds. Water absorption decreases with an increase in the hardening time for all the composites. Small differences in the water absorption values (about 2–3%) are observed among samples hardened after 28, 60, and 90 days with chemically treated hemp hurds, compared to the reference composite and specimens based on the physico-chemically-modified hemp hurds. As is evident, the low water absorption of the bio-composites is more affected by the treatment method. The specimens with the treated hemp hurds had observably lower values of water-absorption values compared to the composites based on the original bio-aggregate. The treatment processes of the hemp hurds reduced the hydrophility of the hemp hurds, and the hemp composites showed a better water-absorption behavior. The bio-composite based on alkali-treated hemp hurds had the lowest water-absorption values in each hardening time.

The development of the compressive strength of the bio-composites was also affected by the hardening time, as well as by the treatment procedure of the filler, as was noted above for the studied parameters. The values of the compressive strength of the hardened bio-composites range from 0.90 to 5.75 MPa (Figure 5). The progression in the values of the strength parameter is observed in the dependence of all the composites on hardening time. The bio-composites based on hot-water treatment and the chemically treated hemp hurds have slightly lower values of compressive strength for each hardening time than the original composite sample. However, no significant differences were observed in the determined strength values of the composites hardened for 28, 60, and 90 days based on the chemically treated hemp hurds. The low strength values of these bio-composites varied in the range of 0.8 to 1.9 MPa. The mechanical properties of the hemp hurd composites were significantly affected by the chemical treatment of bio-aggregates. The expected improvement in the mechanical properties of composites based on the chemically treated hemp hurds was not recorded. The cause of this phenomenon could be the alkaline nature of the binder used [56]. The forming magnesium silicate hydrate (M-S-H) gels in the composite were formed via the reaction of MgO with silica in the presence of an alkaline component (in this case, NaHCO3). Magnesium hydroxide (brucite) is a starting point for the development of M-S-H gels. The content of hydration products, such as brucite and magnesium silicate hydrate, in the composite system was indicated to be low by X-ray diffraction and thermal analysis, because of a poor crystalline (disordered) phase [57]. The Mg(OH)2 was converted to M-S-H gel to a low degree due to a high pH value (around 12.6) of MgO-cement due to the NaHCO3 component. The pH of excess brucite in equilibrium with water calculated from the solubility of Mg(OH)2 was around pH 10.5 [58]. The used MgO product contained some CaO (5.3 wt. %), and its presence had the potential to increase the pH up to 12.5 as well. A study of the impact of hemp hurds on cement setting and hardening [59] shows that the high alkalinity of MgO-cement can cause the degradation of lignocellulosic compounds and release byproducts inhibiting the setting and hardening process.

The low reactivity of the starting materials, which are the most common commercially available natural raw materials SiO2 and MgO, is a further reason for the weak formation of the M-S-H phase. M-S-H appears to be restricted by its very slow setting at ambient temperature.

According to a paper [60], the alkaline environment of the cement matrix (pH around 12.5) reduces the durability of vegetable fibers due to their degradation and the destruction of cellulose macromolecular chains during their partial alkaline hydrolysis, leading to a decrease in the degree of polymerization. As was proved using the size exclusion chromatography method in paper [45], structural changes in cellulose occurred during chemical treatment. The average cellulose chain length, measured as the degree of polymerization (DP), decreased in all the chemically treated hemp hurds. However, NaOH treatment caused the biggest change in the degree of cellulose polymerization in hemp hurds (from 1302 ± 40 to 585 ± 7), which is related to the cleavage of glycosidic bonds and shortening cellulose chains. The chemical composition of hemp hurds is another factor that influences the degradation of fibrous composites, as well as the adhesion of the bio-aggregate surface with binder particles. Chemical changes in the surface properties of organic filler lead to poor interaction of binder particles and hemp hurd slices [56]. The treatment of hemp hurd slices in an aqueous sodium hydroxide solution leads to the partial removal of amorphous components (such as hemicelluloses, lignin) from the matrix, in which cellulosic fibrils are inserted, and the impurities are removed (waxes and oils) from the hemp’s surface [45]. Therefore, either the surface roughness increases and/or the cellulose’s cellular structure collapses [61]. On the other hand, the alkali cellulose formed by the reaction of NaOH with the hydroxyl groups present in the cellulose increases the surface alkalinity.

In the works devoted to hemp concrete [28,62,63], several causes of the low strength of the composite are mentioned, such as the ductile nature of hemp particles, their disordered arrangement, the high porosity of the hurds, and the binder’s hydraulicity.

As seen in Figure 5, the composites with ultrasonic-treated hemp hurds behaved quite differently compared to the composites based on chemically modified bio-aggregate; they reached the highest values of compressive strength. These values of the composite at a given hardening time were 1.2 to 1.7 times higher than the corresponding hardened reference bio-composite sample. It seems that this fact is related to the ultrasound process mechanism. A phenomenon known as cavitation, a most striking property of ultrasound, is responsible for the sudden collapse of cavities, creating power shock waves and generating a large amount of mechanical and thermal energy in the liquid [64]. The local high temperature and pressure placed in a volume of water lead to a gradual breakage of the complex structure of the bundles of fibers and the fibrils in hemp hurds’ bio-aggregate, as well as to a cleaning of the surface of bio-aggregates only from impurities like waxes and oil. Pulping subsequently results in the reduction of the degree of cellulose polymerization to 910 ± 21 for the hemp hurd sample (UTHH), and more bonding sites are generated. Better compaction could be achieved by the improved adhesion between the hemp hurd particles and the matrix. No changes in the contents of the main cellulosic and non-cellulosic components in ultrasound-modified hemp hurds were observed [65]. In accordance with [66], lignin and wood extractives protect the fiber from mineralization phenomena.

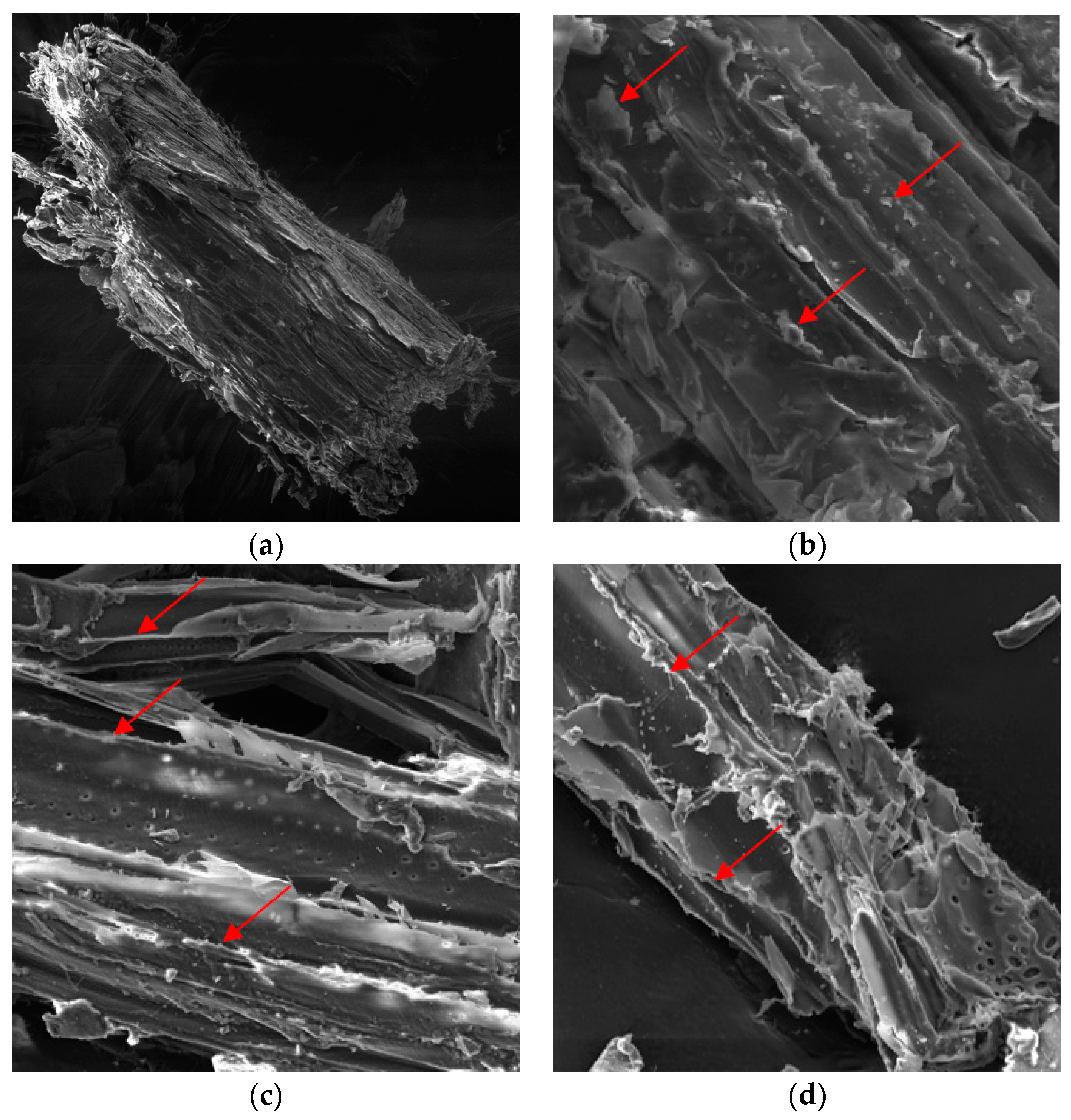

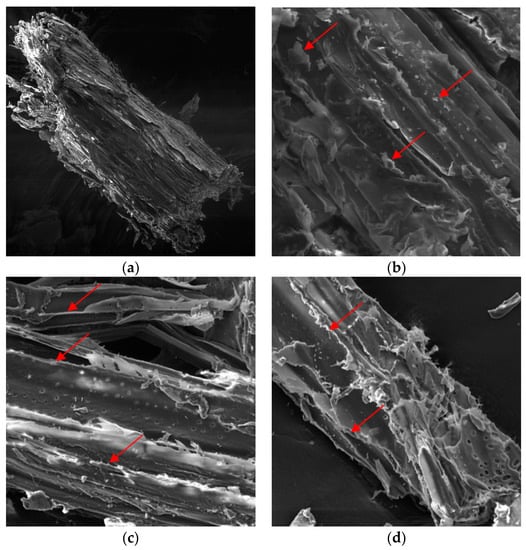

A comparative study of the morphology of treated hemp hurd samples by scanning electron microscopy (TESCAN MIRA 3 FE, Czech Republic) (see Figure 6) confirmed the above-mentioned facts. A check of the fiber quality revealed surface roughness, imperfections and overall geometry. The fiber structure is formed of several bundles of filaments aligned to the plant’s length. When the morphology of the ultrasound-treated sample (Figure 6d) is compared with the original hemp hurd surface topography, the presence of surface impurities is visible in the latter case (Figure 6a,b). The effect of treatments can be seen as a partially cleaned surface and its roughness is formed by the partial pulping of the fibrous structure of the hemp hurd samples (Figure 6c,d).

Figure 6.

SEM micrographs of the hemp hurd samples: (a) original RHH sample (magnified 500 times); (b) RHH—original sample (magnified 4000 times); (c) NHH—chemically treated sample in NaOH (magnified 1500 times); (d) UHH—ultrasound treated sample (magnified 1500 times).

Based on these results, it seems that the morphology of hemp particles plays an important role in the bond strength.

The ultrasound treatment of biomaterials in water is a green chemistry process unlike the chemical procedures because no poluutants are produced. With respect to the obtained compressive strength results of the composite with the ultrasound-treated hemp hurds, future research needs to be directed towards the optimization of the mechanical treatment of bio-aggregates, pulping the bundles for the surface increase, as well as towards ultrasound treatment conditions. Another way could consist of modifying the recipe with the aim of reducing the alkalinity of the MgO binder to increase the reactivity of raw materials, as well as to ensure a good hydration of MgO yielding the enhanced mechanical performance of the hemp hurd composites.

4. Conclusions

Hemp hurds as a bio-aggregate waste material are a very attractive organic filler for bio-composites with inorganic matrices used in the building industry. Bio-aggregate-based composites with alternative binders like MgO-cement present sustainable materials with a low environmental impact. The values of compressive strength, thermal conductivity coefficient and water absorption of the hemp composites depend on the chemical composition of the polymer material, modified by the treatment process and hardening time. Composites based on chemically (aqueous solution of NaOH, Ca(OH)2 and EDTA) and physico-chemically (boiled in hot water and ultrasonification) treated hemp hurds and hardened for 28, 60, and 90 days show a better water-sorption behavior compared to composites with an original organic filler. In terms of thermal conductivity, composites with NaOH-treated hemp hurds achieved the lowest coefficient values, and conversely, the specimens based on ultrasound-treated bio-aggregates had higher values by 40–60% compared to the original hemp hurds. A weaker mechanical performance of hardened composites compared to referential composites was obtained in the case of all the chemically modified hemp hurds due to changes in their chemical composition, which affected the mechanisms of hardening. A significant increase in the compressive strength was reached in the case of ultrasonic-modified hemp hurds due to the changes in the morphological structure brought about by this physical procedure. This performance is positive in terms of future usage of lightweight lignocellulosic composites for low-cost housing constructions with a load-bearing frame.

Acknowledgments

The authors are grateful to the Slovak Grant Agency for financial support of the project VEGA 1/0277/15.

Author Contributions

Nadezda Stevulova conceived and designed the experiments; Julia Cigasova and Ivana Schwarzova performed the experiments of chemical and physico-chemical modification of filler and prepared mixtures and determined physical properties as well as analyzed the data; Alena Sicakova and Jozef Junak contributed by determination of compressive strength; Nadezda Stevulova wrote the paper.

Conflicts of Interest

The authors declare no conflict of interest.

References and Notes

- Elfordy, S.; Lucas, F.; Tancret, F.; Scudeller, Y.; Goudet, L. Mechanical and thermal properties of lime and hemp concrete (“hempcrete”) manufactured by a projection process. Construct. Build. Mater. 2008, 22, 2116–2123. [Google Scholar] [CrossRef]

- Ku, H.; Wang, H.; Pattarachaiyakoop, N.; Trada, M. A review on the tensile properties of natural fibre reinforced polymer composites. Compos. B Eng. 2011, 42, 856–873. [Google Scholar] [CrossRef]

- Gavrilescu, D.; Tofanicä, B.M.; Puitel, A.C.; Pétrea, P. Sustainable use of vegetal fibres in composites. Sources of vegetal fibres. Environ. Eng. Manag. J. 2009, 8, 429–438. [Google Scholar]

- Réh, R. Admixtures of non-wooden lignocellulosic matarials in combination with wood particles in composite materials. PRO LIGNO 2013, 9, 519–524. [Google Scholar]

- Sassoni, E.; Manzi, S.; Motori, A.; Montecchi, M.; Canti, M. Novel sustainable hemp-based composites for application in the building industry: Physical, thermal and mechanical characterization. Energ. Build. 2014, 77, 219–226. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Gassan, J. Composites reinforced with cellulose based fibres. Progress Polym. Sci. 1999, 24, 221–274. [Google Scholar] [CrossRef]

- Santos, S.F.; Tonoli, G.H.D.; Melja, J.E.B.; Florelli, J.; Savastano, H., Jr. Non-conventional cement-based composites reinforced with vegetable fibers: A review of strategies to improve durability. Mater. Constr. 2015, 65, 317. [Google Scholar] [CrossRef]

- Al-Kutii, W.; Nasir, M.; Johari, M.A.M.; Saiful Islam, A.B.M.; Manda, A.A.; Blaisi, N.I. An overview and experimental study on hybrid binders containing date palm ash, fly ash, OPC and activator composites. Constr. Build. Mater. 2018, 159, 567–577. [Google Scholar] [CrossRef]

- Da Silva Magalhaes, M.; Faleschini, F.; Pellegrino, C.; Brunelli, K. Cementing efficiency of electric arc furnace dust in mortars. Constr. Build. Mater. 2017, 157, 141–150. [Google Scholar] [CrossRef]

- Khan, K.; Amin, M.N. Influence of fineness of volcanic ash and its blends with quarry dust in mortars. Constr. Build. Mater. 2017, 154, 514–528. [Google Scholar] [CrossRef]

- Faleschini, F.; Zanini, M.A.; Brunelli, K.; Pellegrino, C. Valorization of co-combustion fly ash in concrete production. Mater. Des. 2015, 85, 687–694. [Google Scholar] [CrossRef]

- Siddique, R. Use of municipal solid waste ash in concrete. Res. Con. Rec. 2010, 55, 83–91. [Google Scholar] [CrossRef]

- Junakova, N.; Junak, J. Sustainable use of reservoir sediment through partial application in building material. Sustainability 2017, 9, 852. [Google Scholar] [CrossRef]

- Juenger, M.C.G.; Siddique, R. Recent advances in understanding the role of supplementary cenetitious materials in concrete. Cem. Concr. Res. 2015, 78, 71–80. [Google Scholar] [CrossRef]

- Fernández-Jiménez, A.; García-Lodeiro, I.; Donatello, S.; Maltseva, O.; Palomo, A. Specific examples of hybrid alkaline cement. MATEC Web Conf. 2014, 11. [Google Scholar] [CrossRef]

- Bocullo, V.; Vaičiukynienė, D.; Kantautas, A.; Borg, R.P.; Briguglio, C. Alkaline activation of hybrid cements binders based on industrial by-products. J. Sustain. Archit. Civ. Eng. 2017, 2, 65–73. [Google Scholar] [CrossRef]

- Ardanuy, M.; Claramunt, J.; Toledo Filho, R.D. Cellulosic fiber reinforced cement based composites: A review of recent research. Constr. Build. Mater. 2015, 79, 115–128. [Google Scholar] [CrossRef]

- Barra, B.; Bergo, P.; Alves, C., Jr.; Savastano, H., Jr.; Ghavami, K. Effects of methane cold plasma in sisal fibers. Key Eng. Mater. 2012, 517, 458–468. [Google Scholar] [CrossRef]

- Wei, J.; Ma, S.; Thomas, D.G. Correlation between hydration of cement and durability of natural fiber-reinforced cement composites. Corros. Sci. 2016, 1–15. [Google Scholar] [CrossRef]

- Toledo Filho, R.D.; de Andrade Silva, F.; Fairbairn, E.M.R.; de Almeida MeloFilho, J. Durability of compression molded sisal fiber reinforced mortar laminates. Constr. Build. Mater. 2009, 23, 2409–2420. [Google Scholar] [CrossRef]

- Savastano, H., Jr.; Fiorelli, J.; Dos Santos, S.F. Sustainable and Nonconventional Construction Materials Using Inorganic Bonded Fiber Composites; Woodhead Publishing: Sawston, UK, 2017; ISBN 9780081020029. [Google Scholar]

- Biagiotti, J.; Puglia, D.; Kenny, J.M. A review on natural fibre based composites—Part I: Structure, processing and properties of vegetable fibres. J. Nat. Fibers 2004, 1, 37–68. [Google Scholar] [CrossRef]

- Evrard, A. Sorption behaviour of Lime-Hemp Concrete and its relation to indoor comfort and energy demand. In Proceedings of the 23rd Conference on Passive and Low Energy Architecture (PLEA 2006), Geneva, Switzerland, 6–8 September 2006. [Google Scholar]

- Allin, S. Building with Hemp, 2nd ed.; Seed Press: Kenmare, Ireland, 2012; p. 146. ISBN 978-0-9551109-1-7. [Google Scholar]

- Walker, R.; Pavia, S.; Mitchell, R. Mechanical properties and durability of hemp lime concretes. Constr. Build. Mater. 2014, 61, 340–348. [Google Scholar] [CrossRef]

- Preikss, I.; Skujans, J.; Adamovics, A.; Iljins, U. Evaluation of hemp (Cannabis Sativa L.) quality parameters for building material from foam gypsum products. Chem. Eng. Trans. 2013, 32, 1639–1643. [Google Scholar] [CrossRef]

- Karade, S.R. Cement-bonded composites from lignocellulosic wastes. Constr. Build. Mater. 2010, 24, 1323–1330. [Google Scholar] [CrossRef]

- De Bruijn, P.B.; Jeppsson, K.H.; Sandin, K.; Nilsson, C.H. Mechanical properties of lime hemp concrete containing shives and fibres. Biosyst. Eng. 2009, 103, 474–479. [Google Scholar] [CrossRef]

- Amziane, S.; Arnaud, L. Bio-Aggregate-Based Building Materials: Applications to Hemp Concrete; ISTE Ltd.: London, UK; John Wiley & Sons, Inc.: Hoboken, NY, USA, 2013; ISBN 978-1-84821-404-0. [Google Scholar]

- Dalmay, P.; Smith, A.; Chotard, T.; Sahay-Turner, P.; Gloaguen, V.; Krausz, P. Properties of cellulosic fibre reinforced plaster: Influence of hemp or flax fibres on the properties of set gypsum. J. Mater. Sci. 2010, 45, 793–803. [Google Scholar] [CrossRef]

- Archila Santos, H.; Pesce, G.; Ansell, M.; Ball, R. Limeboo: Lime as a Replacement for Cement in Wall-Framing Systems with Bamboo-Guadua (Bahareque Encementado). In Proceedings of the 16th International Conference on Non-Conventional Materials and Technologies (NOCMAT 2015), Winnipeg, Canada, 10–13 August 2015. [Google Scholar]

- Hamšík, P.; Král, P. Composite materials from hemp and hydraulic lime for use in building and wood-constructions. Wood Res. 2014, 59, 871–882. [Google Scholar]

- Arizzi, A.; Brümmer, M.; Martin-Sanchéz, I.; Cultrone, G.; Viles, H. The influence of the type of lime on the hygric behavior and bio-receptivity of hemp lime composites used for rendering applications in sustainable new construction and repair works. PLoS ONE 2015, 10, e0125520. [Google Scholar] [CrossRef] [PubMed]

- Brzyski, P.; Barnat-Hunek, D.; Fic, S.; Szelag, M. Hydrophobization of lime composites with lignocellulosic raw materials from flax. J. Nat. Fibers 2017, 14, 609–620. [Google Scholar] [CrossRef]

- Barnat-Hunek, D.; Smarzewski, P.; Brzyski, P. Properties of hemp-flax composites for use in the building industry. J. Nat. Fibers 2017, 14, 410–425. [Google Scholar] [CrossRef]

- Balčiūnas, G.; Vėjelis, S.; Vaitkus, S.; Kairytė, A. Physical properties and structure of composite materials made by using hemp hurds and different binding materials. Procedia Eng. 2013, 57, 159–166. [Google Scholar] [CrossRef]

- Manzi, S.; Sassoni, E.; Motori, A.; Montecchi, M.; Canti, M. New composite with hemp hurds for sustainable buildings. Environ. Eng. Manag. J. 2013, 12, 31–34. [Google Scholar]

- Motori, A.; Manzi, S.; Montecchi, M.; Canti, M. A preliminary study of physical and mechanical properties of sustainable hemp fibers based composite materials for building insulated walls. In Proceedings of the 15th European Conference on Composite Materials (ECCM15), Venice, Italy, 24–28 June 2012. [Google Scholar]

- Fangueiro, R.; Rana, S. Advances in Natural Fibre Composites: Raw Materials, Processing and Analysis; Springer International Publishing: Cham, Switzerland, 2018. [Google Scholar]

- Balčiūnas, G.; Kizinievič, V.; Gargasas, J. Physical properties of building blocks from hemp shives aggregate and cementitious binder, manufactured in the expanded clay (vibro pressing) production line. Mater. Sci. Forum 2017, 908, 118–122. [Google Scholar] [CrossRef]

- Kidalova, L.; Stevulova, N.; Terpakova, E.; Sicakova, A. Utilization of alternative materials in lightweight composites. J. Clean. Prod. 2012, 34, 116–119. [Google Scholar] [CrossRef]

- Kumar, R.; Obrai, S.; Sharma, A. Chemical modifications of natural fiber for composite material. Der Chem. Sin. 2011, 2, 219–228. [Google Scholar]

- Thomsen, A.B.; Thygesen, A.; Bohn, V.; Nielsen, K.V.; Allesen, B.; Jorgensen, M.S. Effects of chemical and physical pre-treatment processes on hemp fibres for reinforcement of composites and for textiles. Ind. Crop. Prod. 2006, 24, 113–118. [Google Scholar] [CrossRef]

- Mwaikambo, L.; Ansell, M. Chemical modification of hemp, sisal, jute and kapok fibres by alkalization. J. Appl. Polym. Sci. 2002, 84, 2222–2234. [Google Scholar] [CrossRef]

- Stevulova, N.; Cigasova, J.; Estokova, A.; Terpakova, E.; Geffert, A.; Kacik, F.; Singovszka, E.; Holub, M. Properties characterization of chemically modified hemp hurds. Materials 2014, 7, 8131–8150. [Google Scholar] [CrossRef] [PubMed]

- Stevulova, N.; Cigasova, J.; Purcz, P.; Schwarzova, I.; Kacik, F.; Geffert, A. Water absorption behavior of hemp hurds composites. Materials 2015, 8, 2243–2257. [Google Scholar] [CrossRef]

- Kidalova, L. Determination of selected characteristics in hemp concrete. In Young Scientist: 3rd PhD. Student Conference of Civil Engineering and Architecture; Faculty of Civil Engineering, Technical university of Kosice: Kosice, Slovakia, 2011; pp. 1–6. ISBN 978-80-553-0639-1. [Google Scholar]

- Terpakova, E.; Kidalova, L.; Estokova, A.; Cigasova, J.; Stevulova, N. Chemical modification of hemp shives and their characterization. Procedia Eng. 2012, 42, 931–941. [Google Scholar] [CrossRef]

- Bydzovsky, J. Utilization of fast renewable raw materials in building products. In Proceedings of the 12th International Scientific Conference; Brno Technical University: Brno, Czech Republic, 2009; pp. 43–46. [Google Scholar]

- STN EN 12390-7: 2011 Testing Hardened Concrete. Part 7: Density of Hardened Concrete.

- STN EN 12087/A1: 2013 Thermal Insulating Products for Building Application. Determination of Long Term Water Absorption by Immersion.

- EN 12390-3: 2010 Testing Hardened Concrete. Part 3: Compressive Strength of Test Specimens.

- Cigasova, J.; Stevulova, N.; Junak, J. Influence of binder nature on properties of lightweight composites based on hemp hurds. Int. J. Mod. Manuf. Technol. 2013, 5, 27–31. [Google Scholar]

- Schwarzova, I.; Cigasova, J. Influence of binder nature on technical parameters of composites based on organic filler. In Young Scientist: 6th PhD. Student Conference of Civil Engineering and Architecture; Faculty of Civil Engineering, Technical University of Kosice: Kosice, Slovakia, 2014; pp. 1–8. ISBN 978-80-553-1668-0. [Google Scholar]

- Rousekova, I. Building Materials (In Slovak); Jaga Group: Bratislava, Slovakia, 2000. [Google Scholar]

- Stevulova, N.; Schwarzova, I. Changes in the properties of composites caused by chemical treatment of hemp hurds. Int. J. Chem. Biomol. Metall. Mater. Sci. Eng. 2014, 8, 363–367. [Google Scholar] [CrossRef]

- Stevulova, N.; Schwarzova, I.; Estokova, A.; Holub, M. MgO-based cement as an inorganic binder for hemp hurds composites. Chem. Technol. 2016, 67, 24–29. [Google Scholar] [CrossRef]

- Zhang, T.; Cheeseman, C.R.; Vandeperre, L.J. Development of low pH cement systems forming magnesium silicate hydrate (M-S-H). Cem. Concr. Res. 2011, 41, 439–442. [Google Scholar] [CrossRef]

- Diquélou, Y.; Gourlay, E.; Arnaud, L.; Kurek, B. Impact of hemp shiv on cement setting and hardening: Influence of the extracted components from the aggregate and study of the interfaces with the inorganic matrix. Cem. Concr. Compos. 2015, 55, 112–121. [Google Scholar] [CrossRef]

- MeloFilho, J.A.; Silva, F.A.; Toledo Filho, R.D. Degradation kinetics and aging mechanisms on sisal fiber cement composites systems. Cem. Concr. Compos. 2013, 40, 30–39. [Google Scholar] [CrossRef]

- Umurigirwa, B.S.; Vroman, I.; Mai, T.H.; Maalouf, C.H. Influence of chemical modification on hemp-starch concrete. Constr. Build. Mater. 2015, 81, 208–215. [Google Scholar] [CrossRef]

- Bouloc, P.; Allegret, S.; Arnaud, L. Le Chanvre Industriel: Production et Utilizations; Agricola: Paris, France, 2006; ISBN 2-85557-130-8. [Google Scholar]

- Murphy, F.; Pavia, S.; Walker, R. An assessment of some physical properties of hemp-lime concrete. In Proceedings of the BCRI Bridge Infrastructure Concrete Research Ireland; University College Cork: Cork, Ireland, 2010; pp. 431–438. [Google Scholar]

- Suslick, K.S. Sonochemistry. Science 1990, 247, 1439–1445. [Google Scholar] [CrossRef] [PubMed]

- Stevulova, N.; Estokova, A.; Cigasova, J.; Schwarzova, I.; Kacik, F.; Geffert, A. Thermal degradation of natural and treated hemp hurds under air and nitrogen atmosphere. J. Therm. Anal. Calorim. 2017, 128, 1649–1660. [Google Scholar] [CrossRef]

- Mohr, B.J.; Biernacki, J.J.; Kurtis, K.E. Microstructural and chemical effects of wet/dry cycling on pulp fiber-cement composites. Cem. Concr. Res. 2006, 36, 1240–1251. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).