Durability and Compressive Strength of High Cement Replacement Ratio Self-Consolidating Concrete

Abstract

1. Introduction

2. Experimental Program

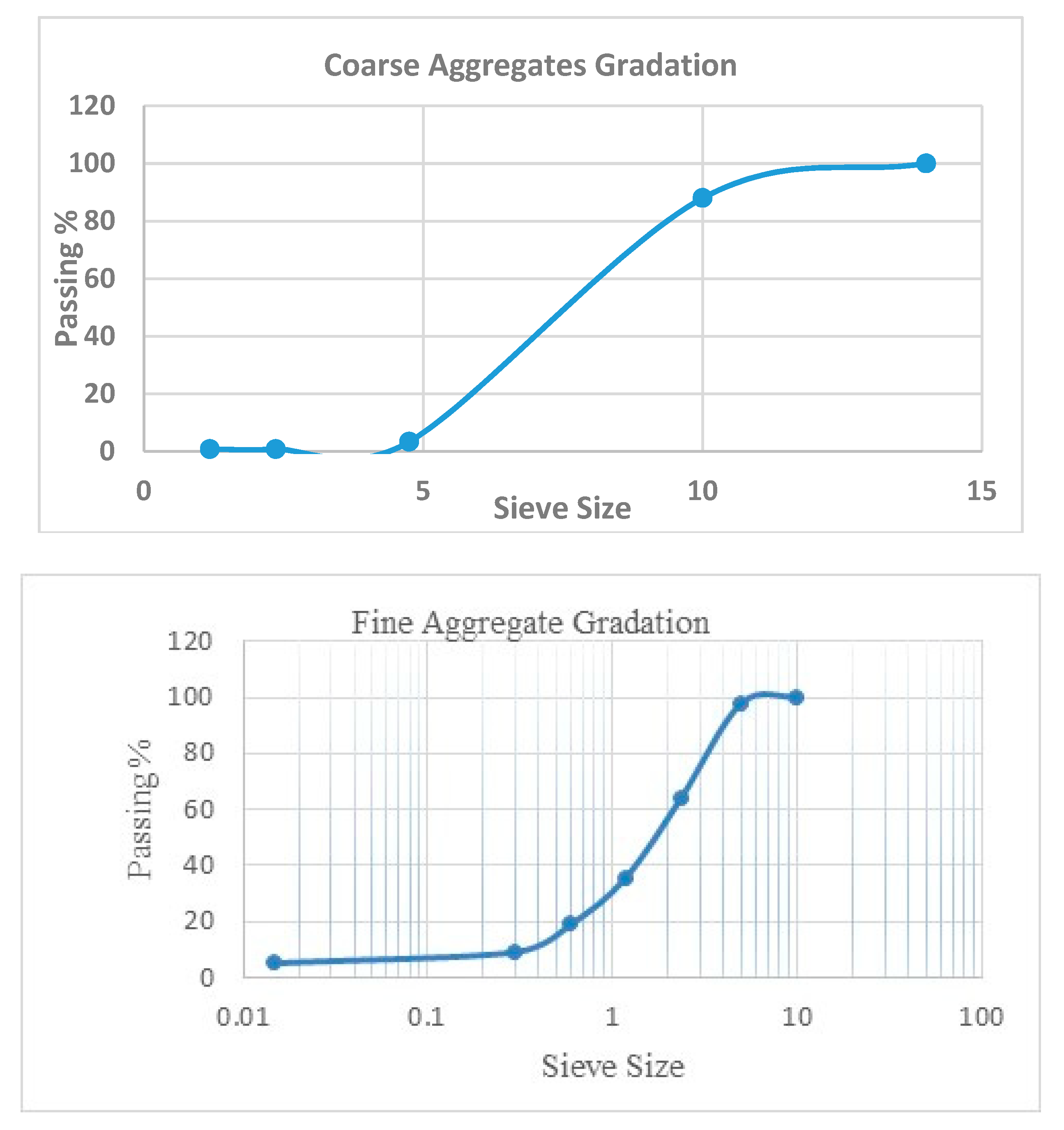

2.1. Material Properties

2.2. SCC Mix Proportions

3. Results and Discussion

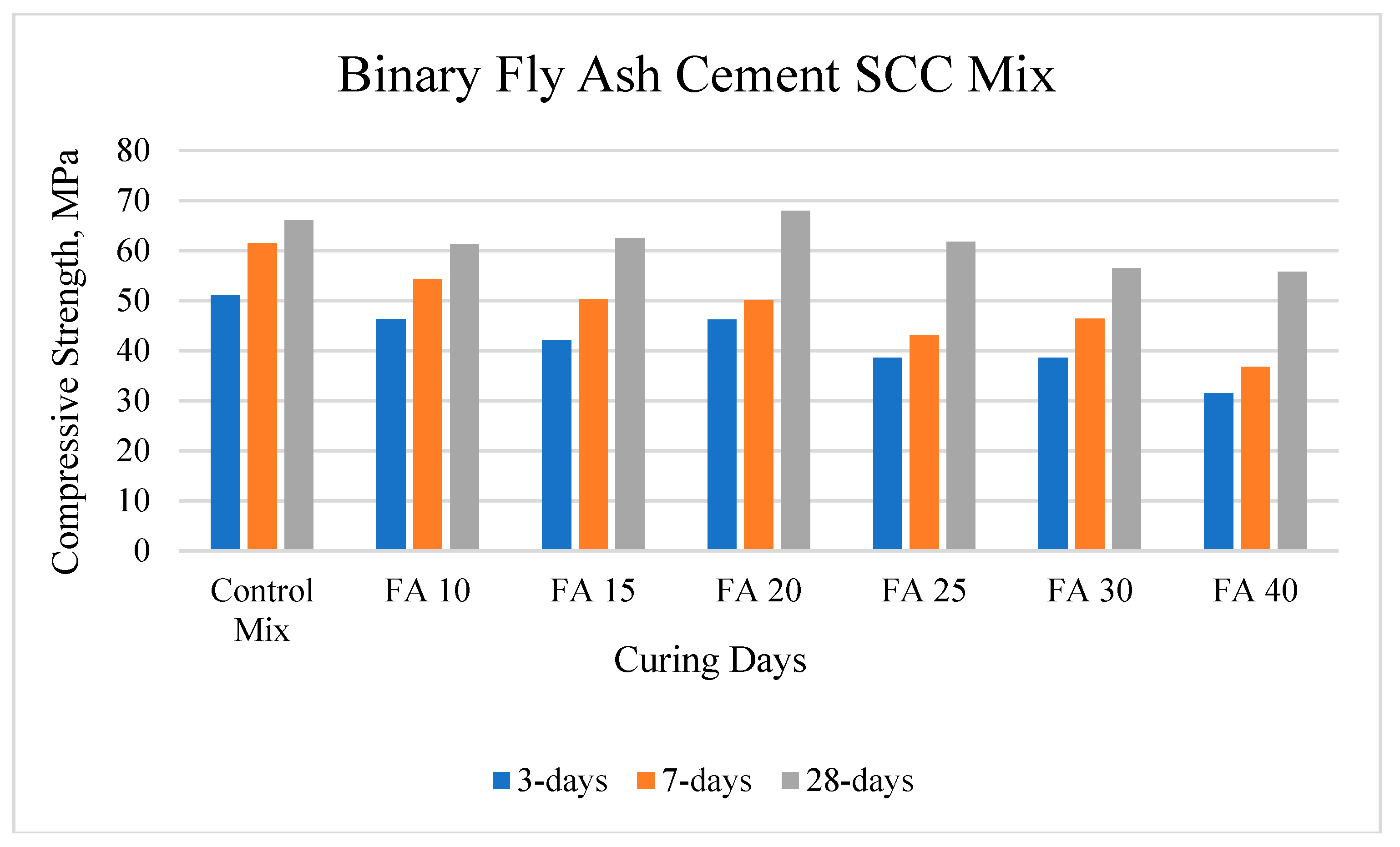

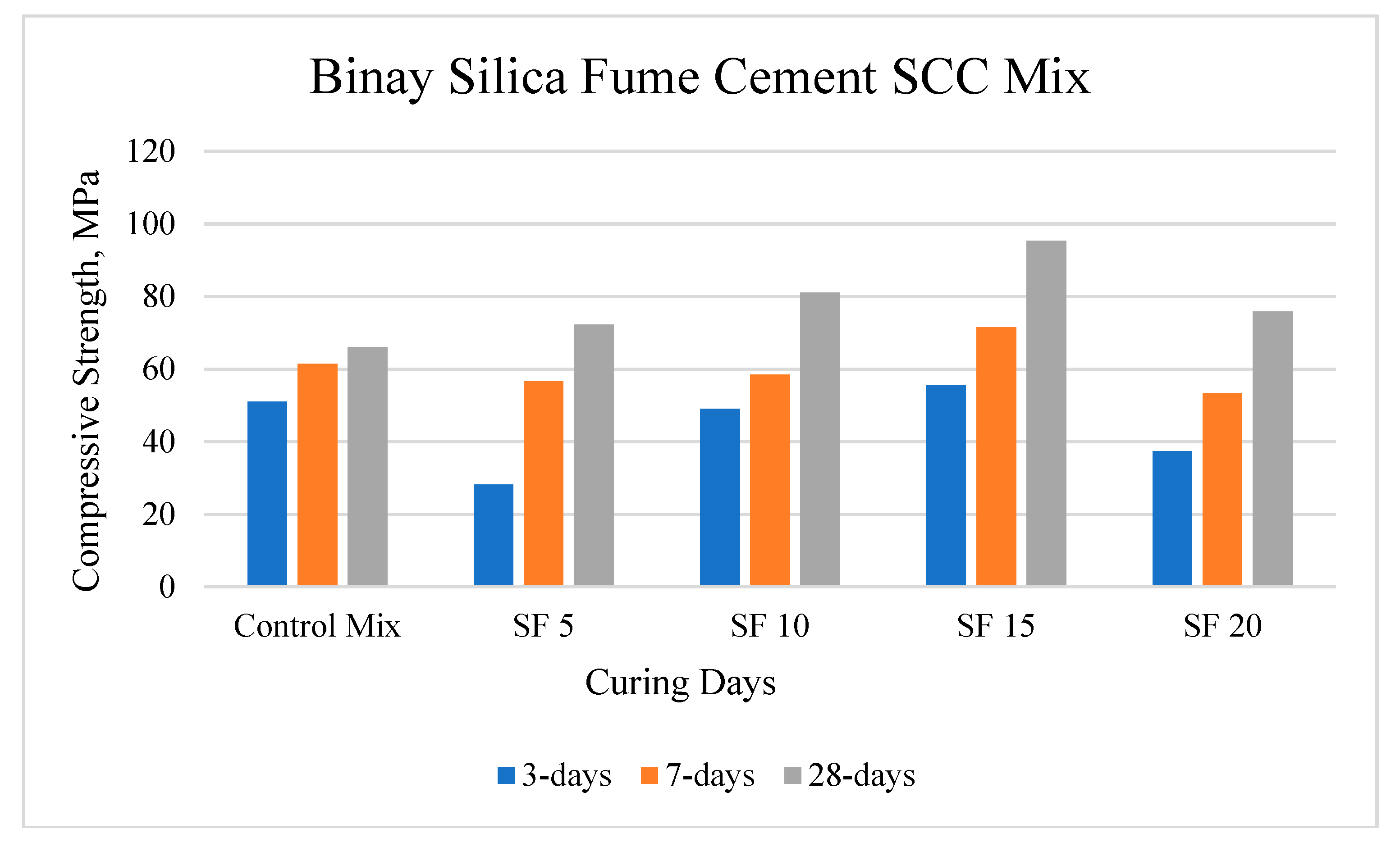

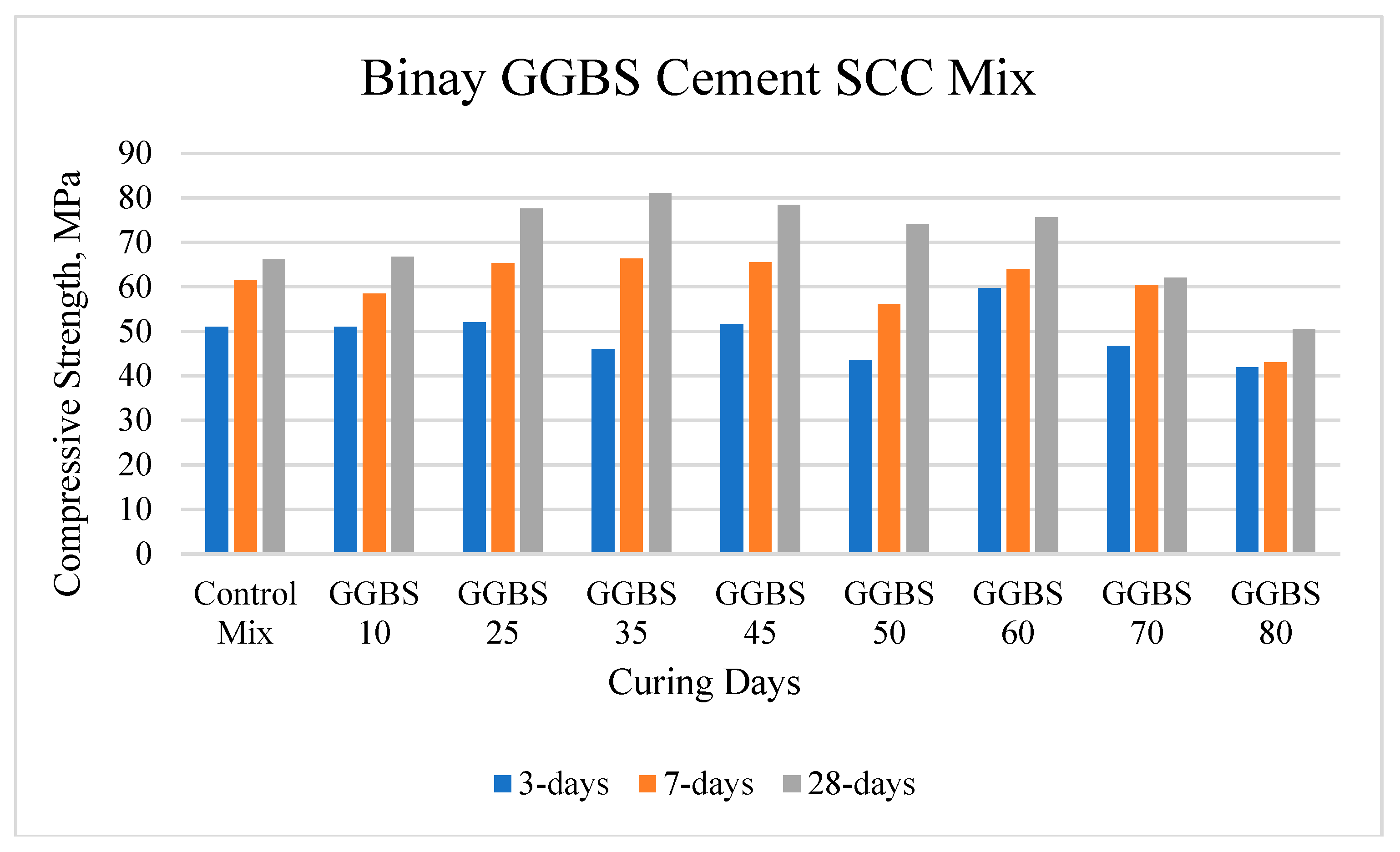

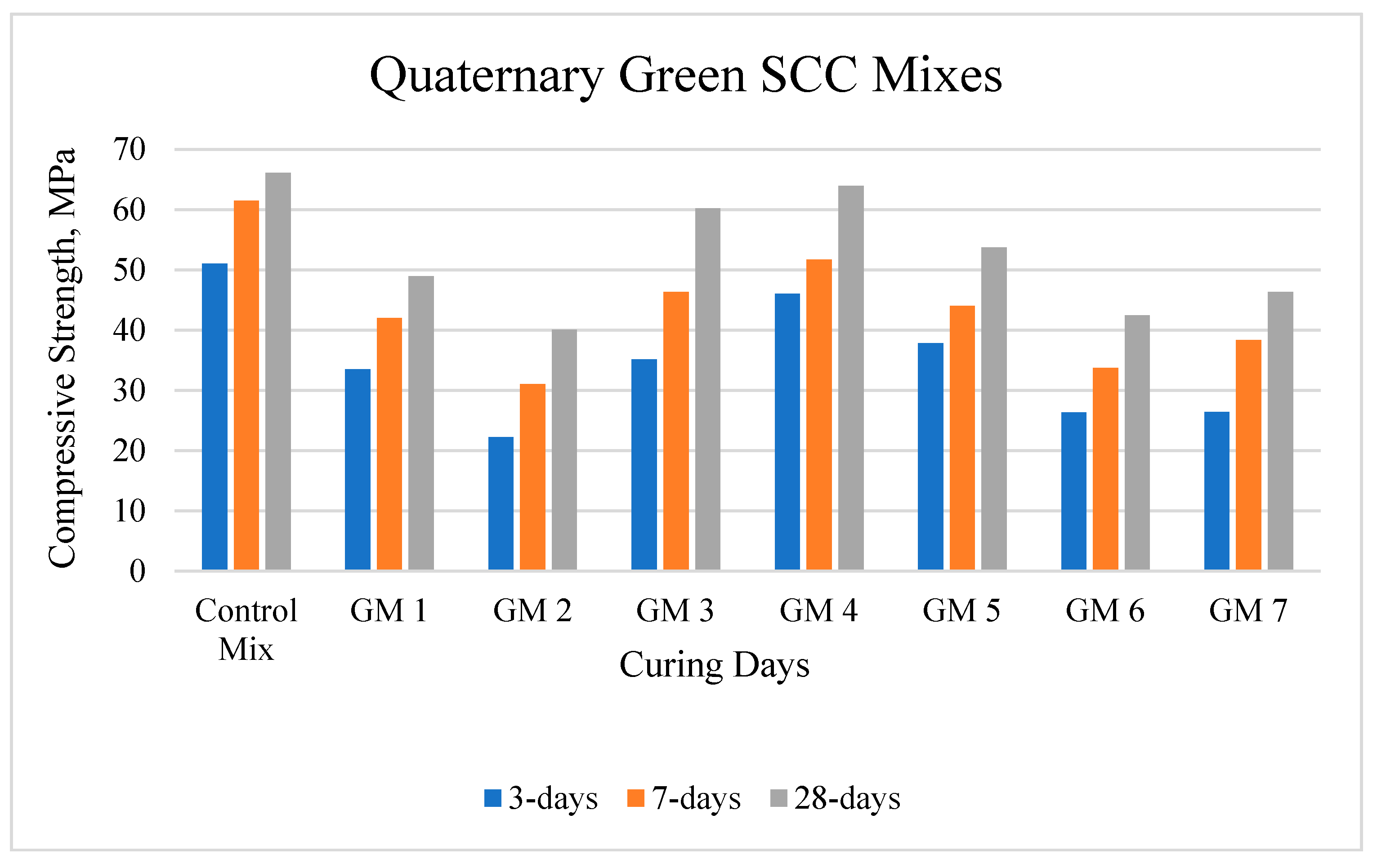

3.1. Development of Compressive Strength in Sustainable SCC Mixes

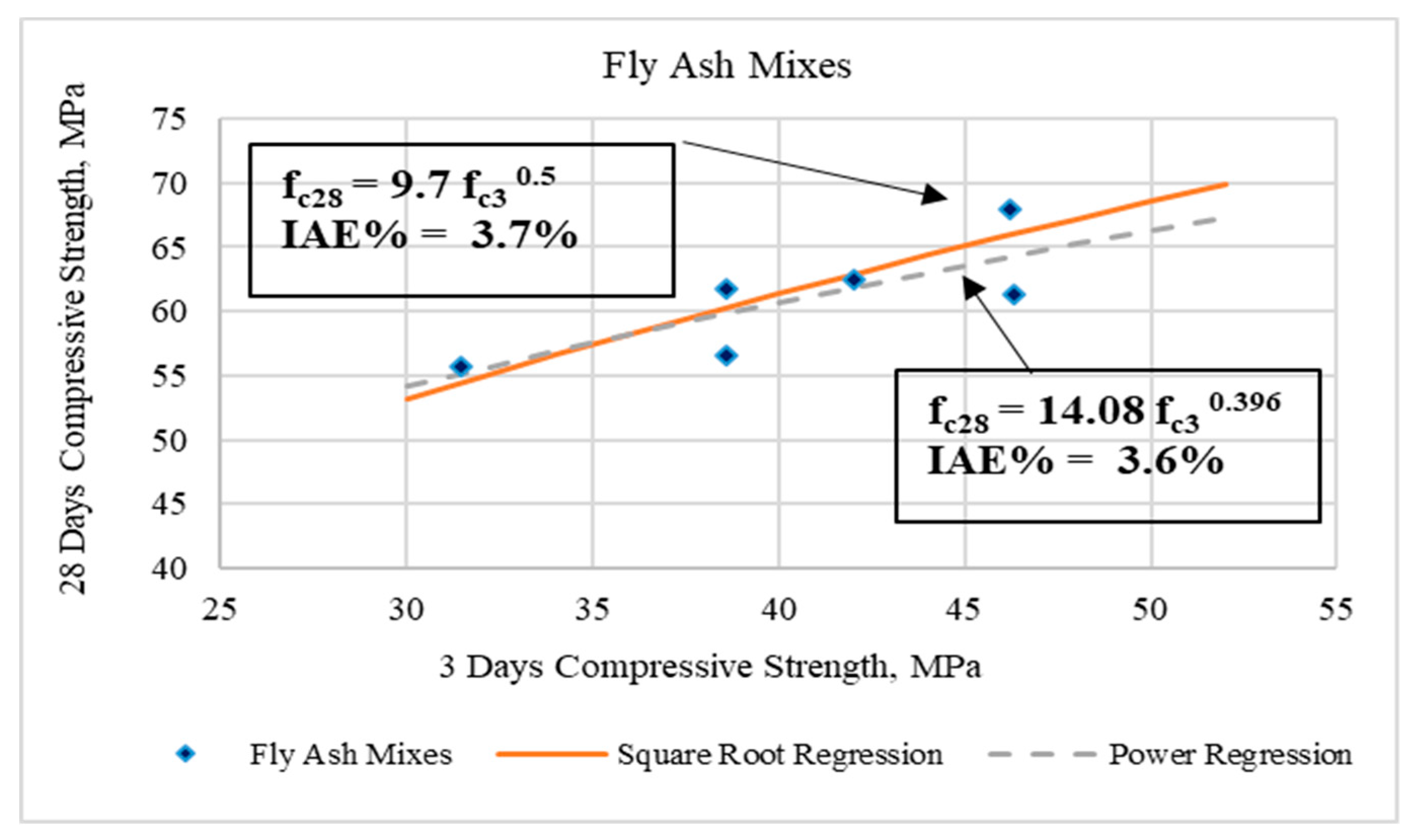

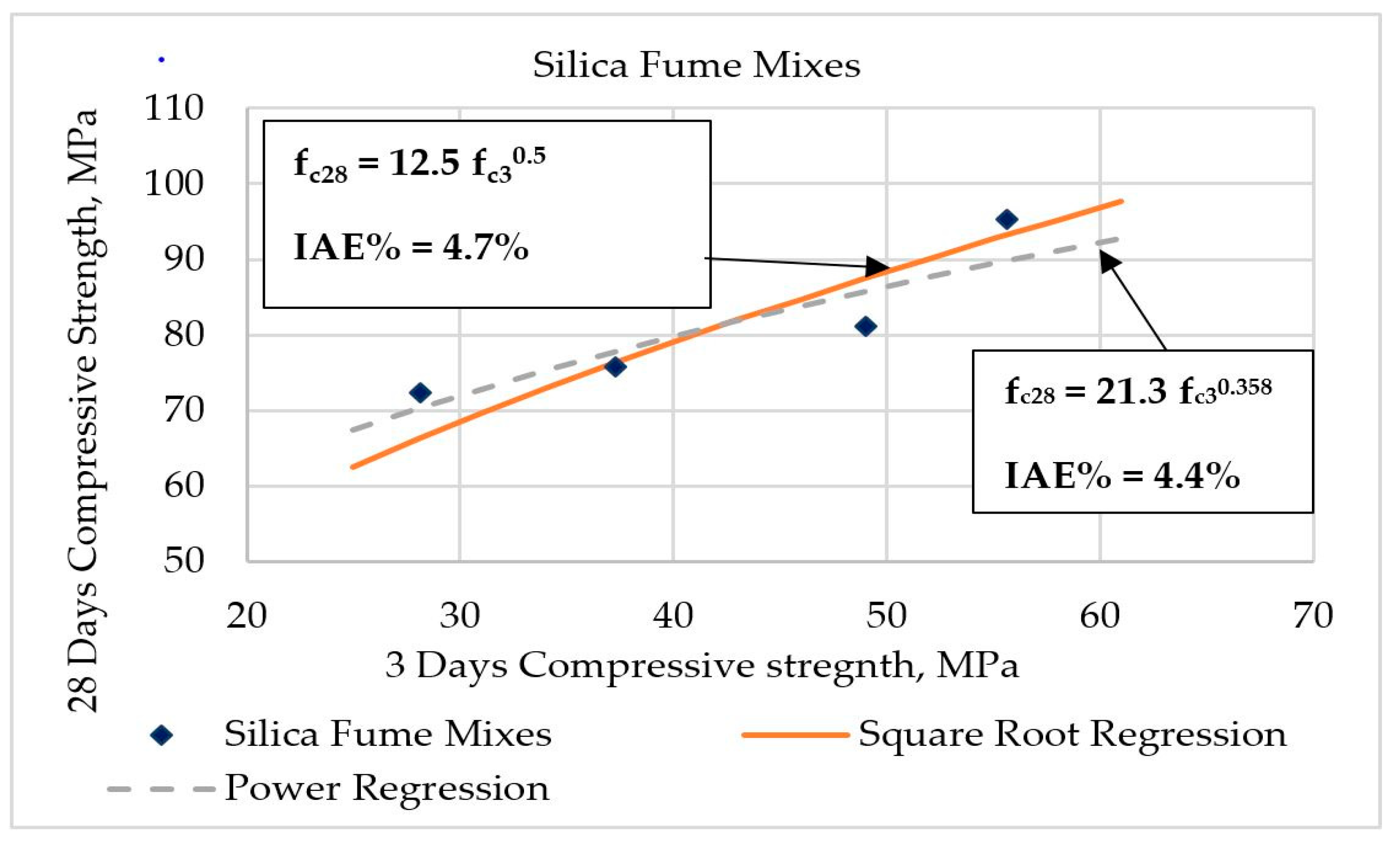

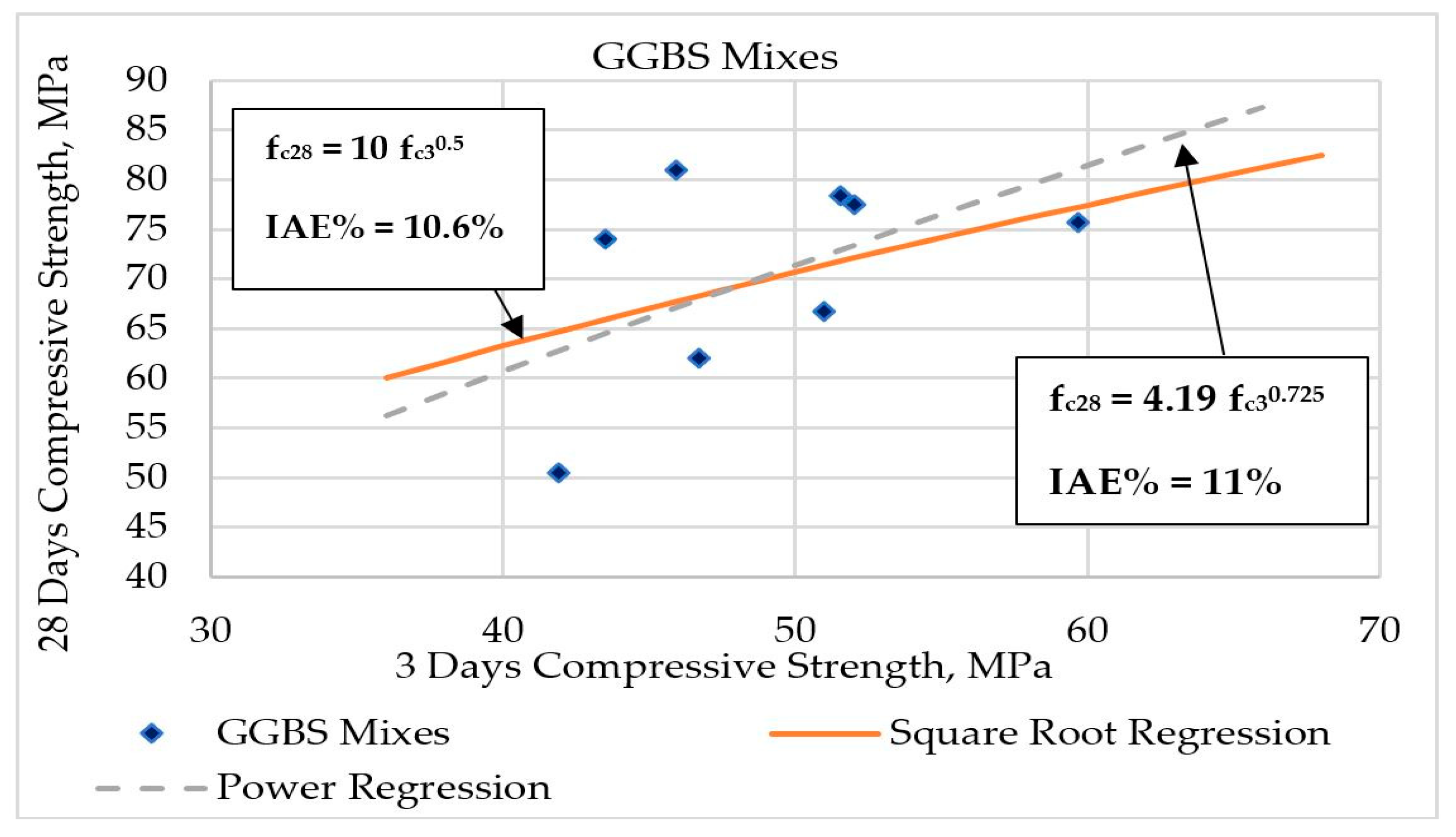

3.2. Compressive Strength Prediction

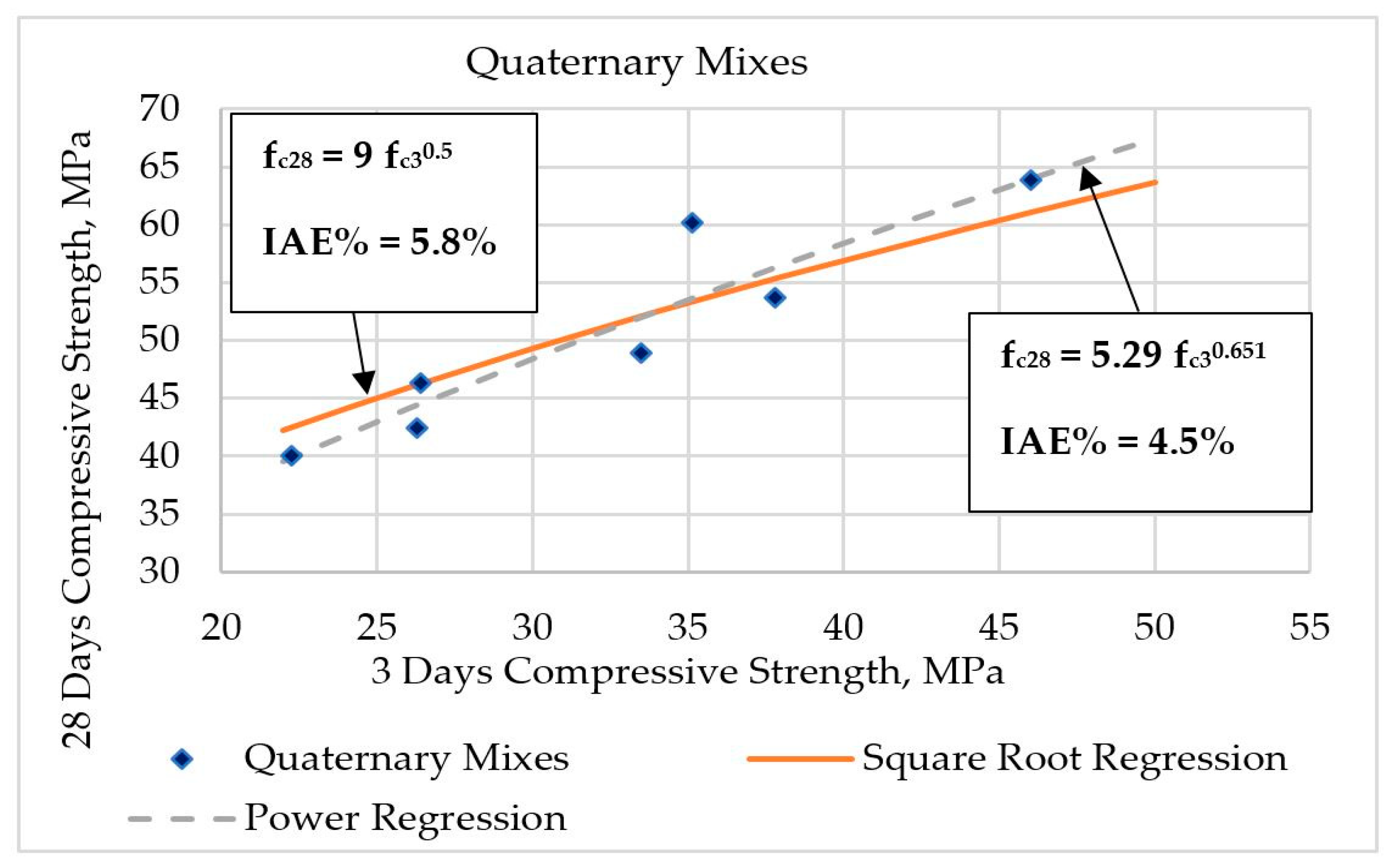

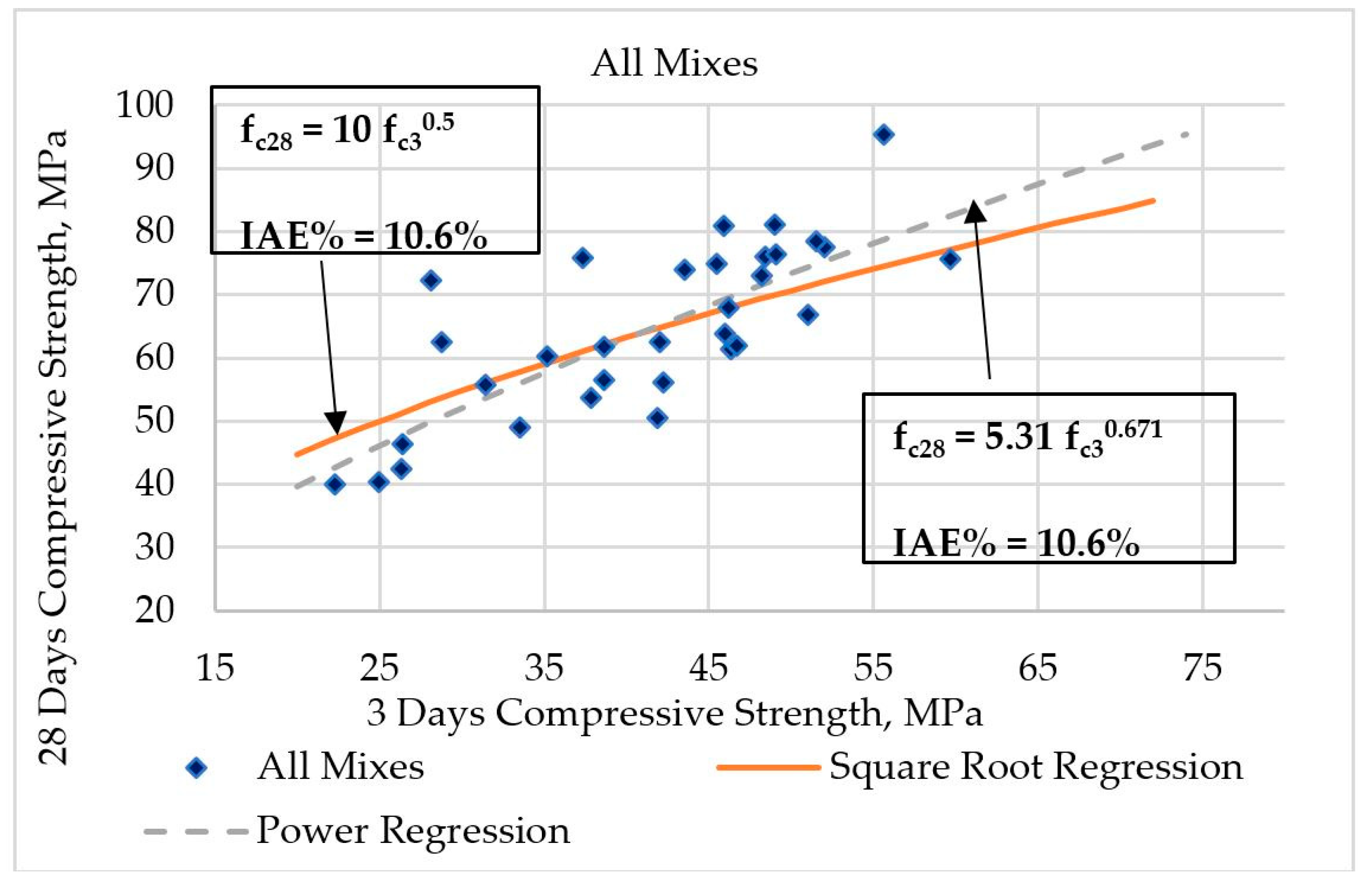

3.2.1. Predicting the 28 Days Compressive Strength from 3 Days Compressive Strength

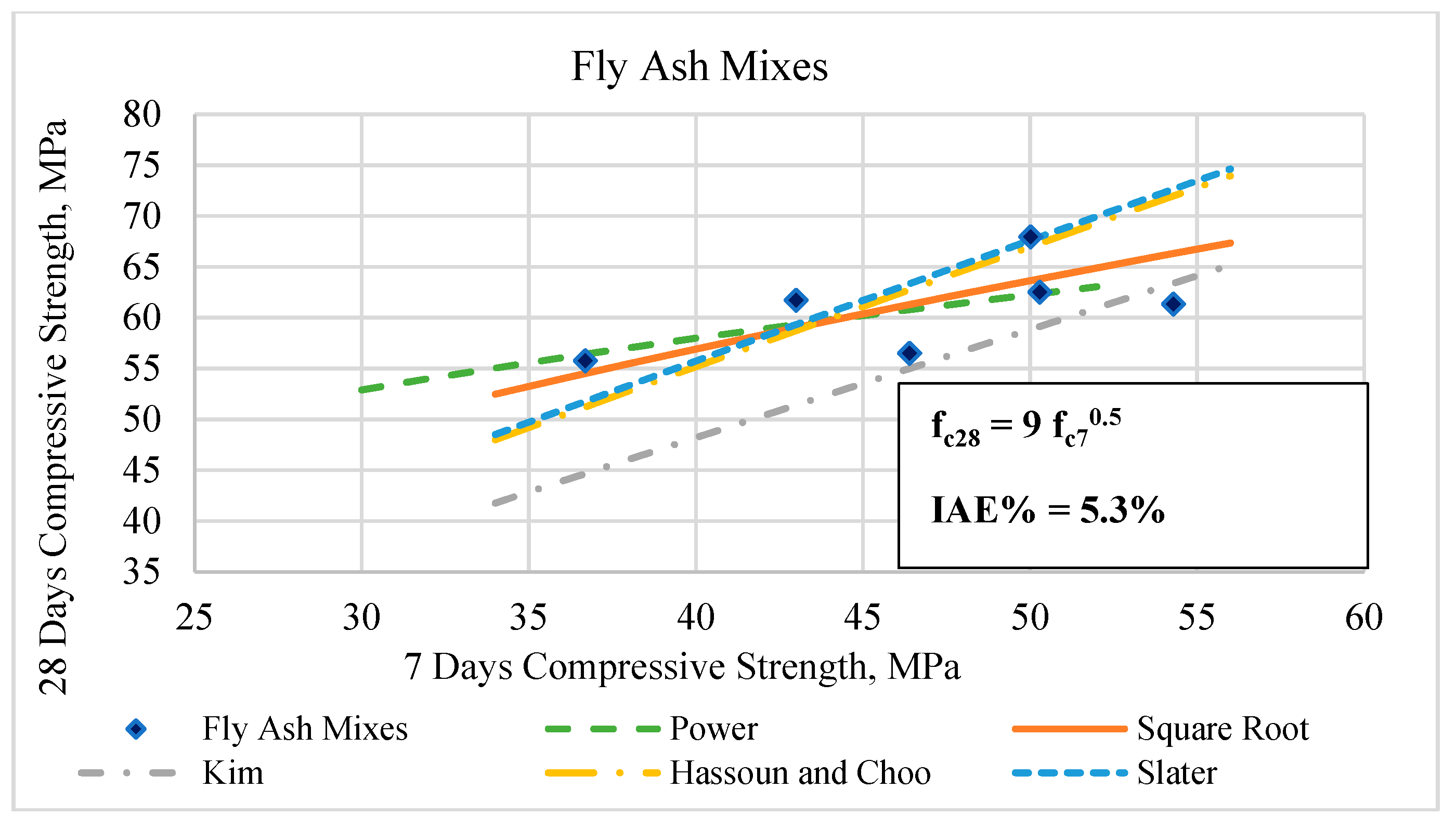

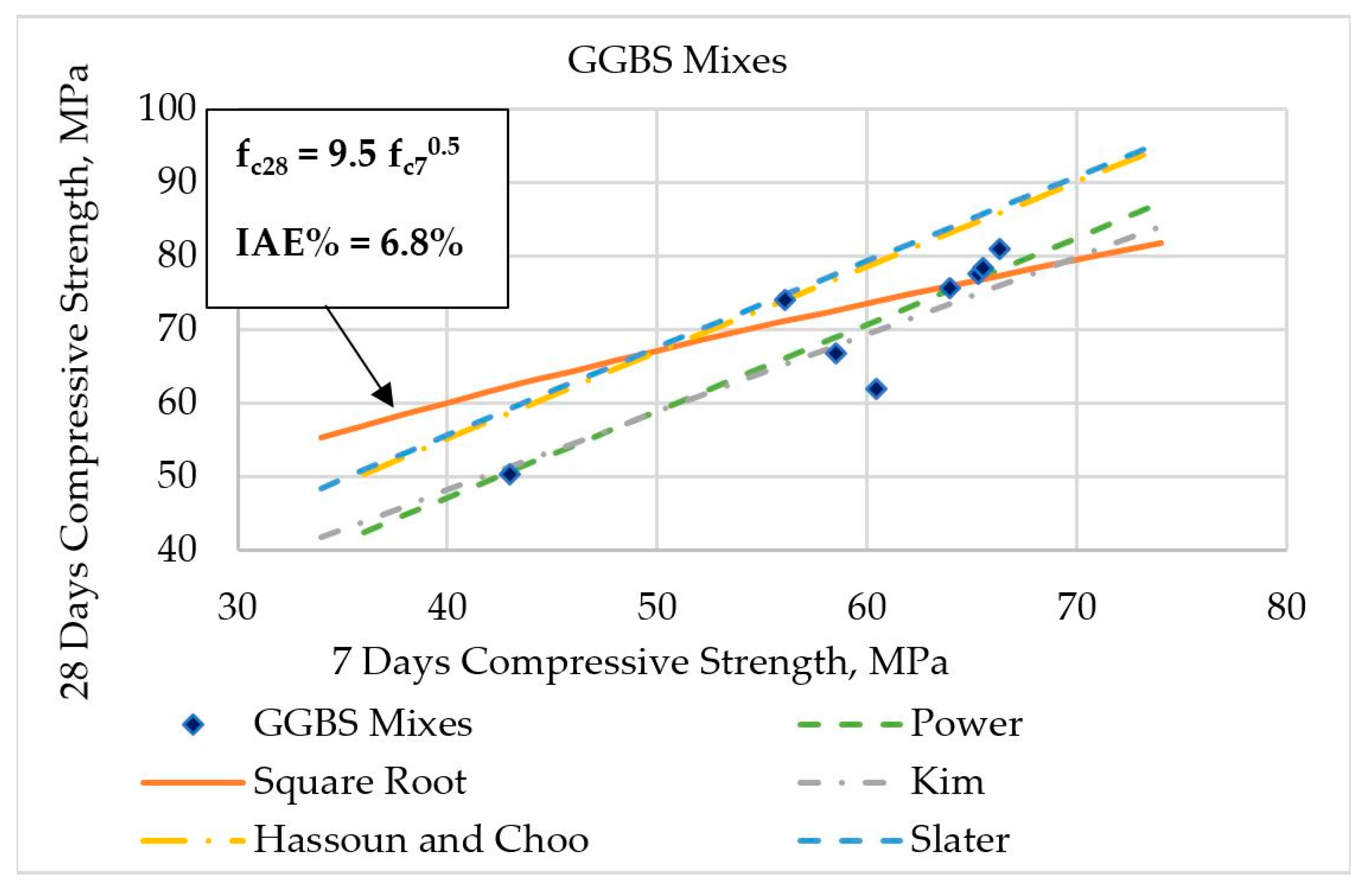

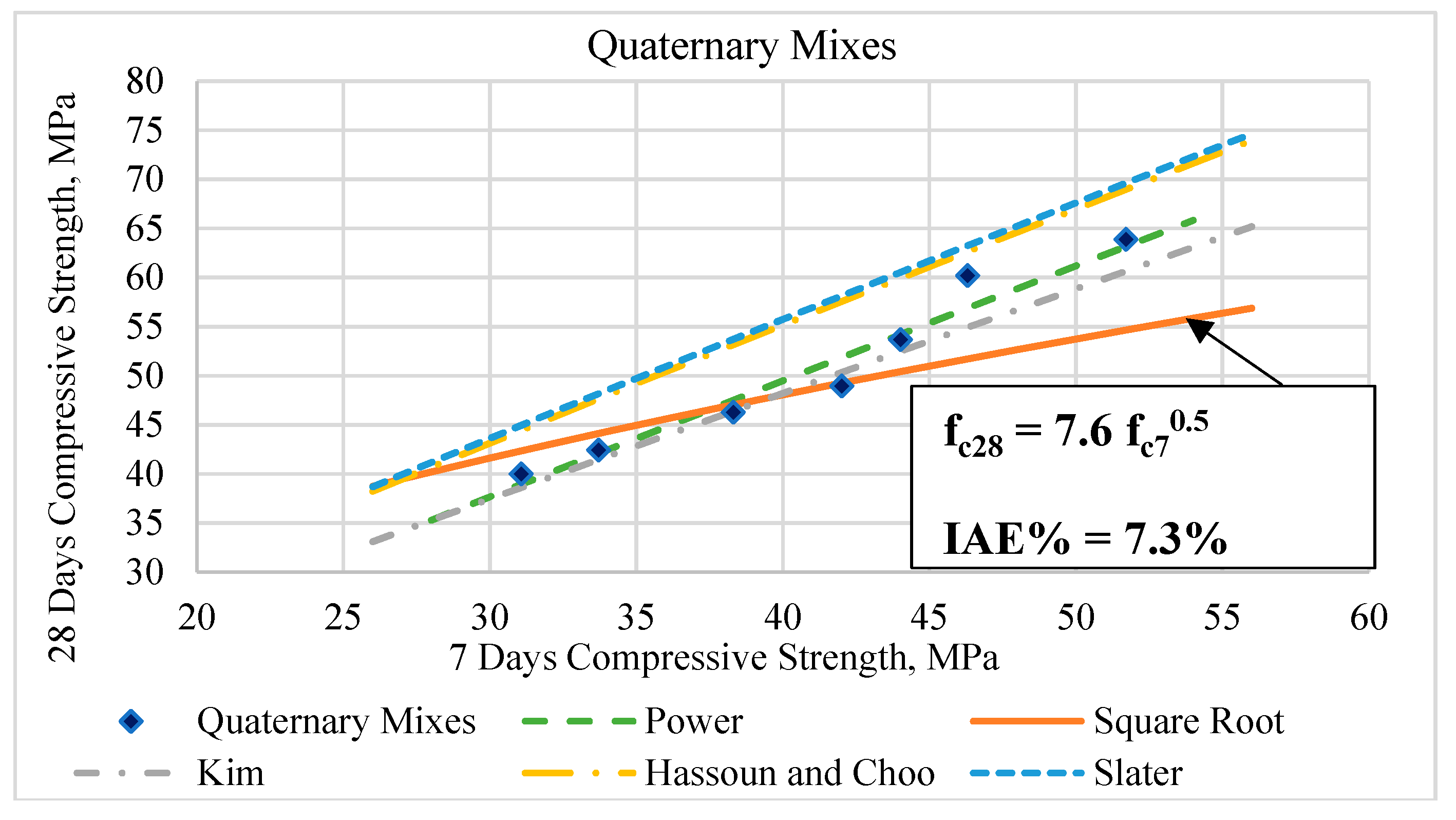

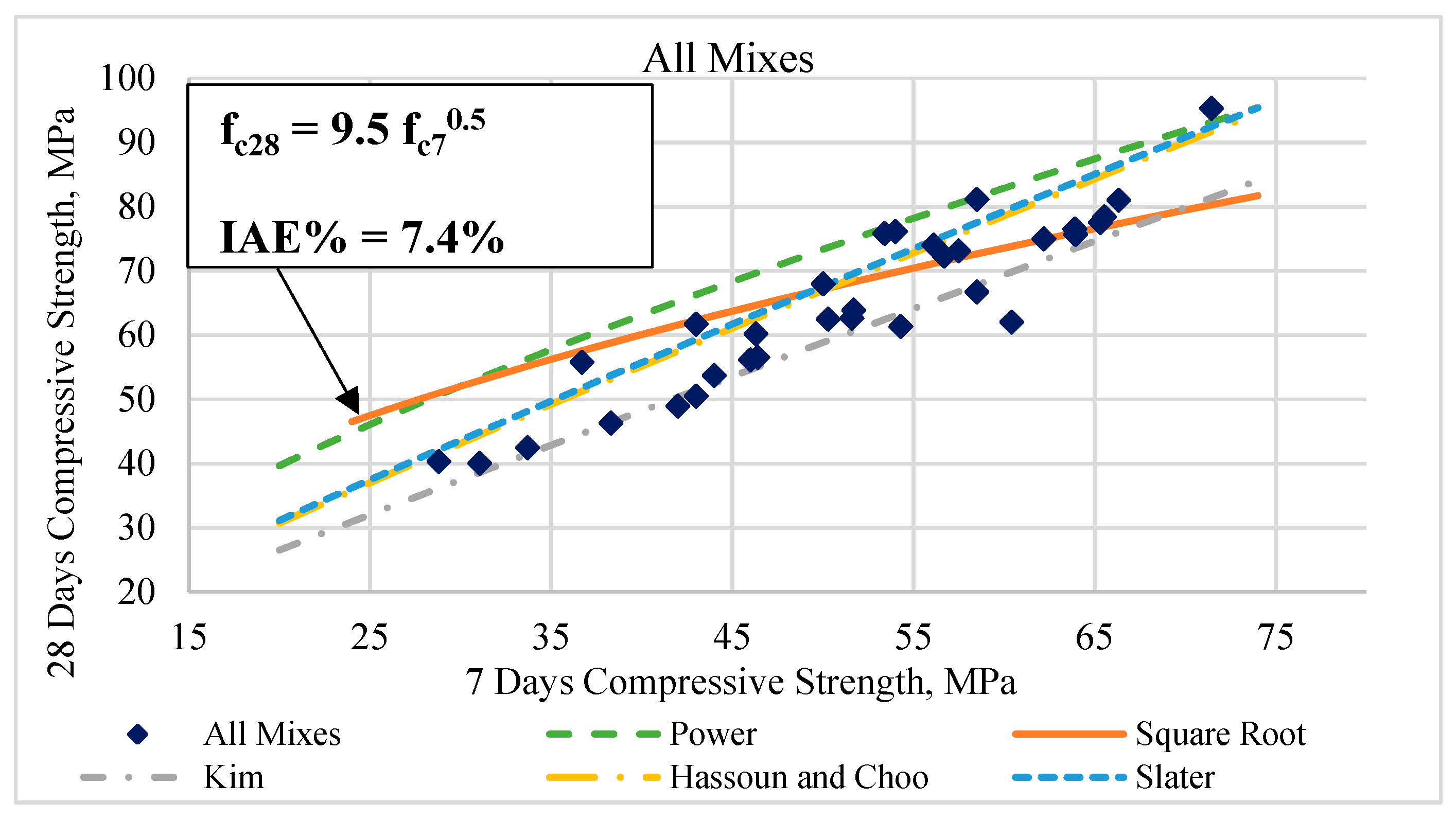

3.2.2. Predicting the 28 Days Compressive Strength from 7 Days Compressive Strength

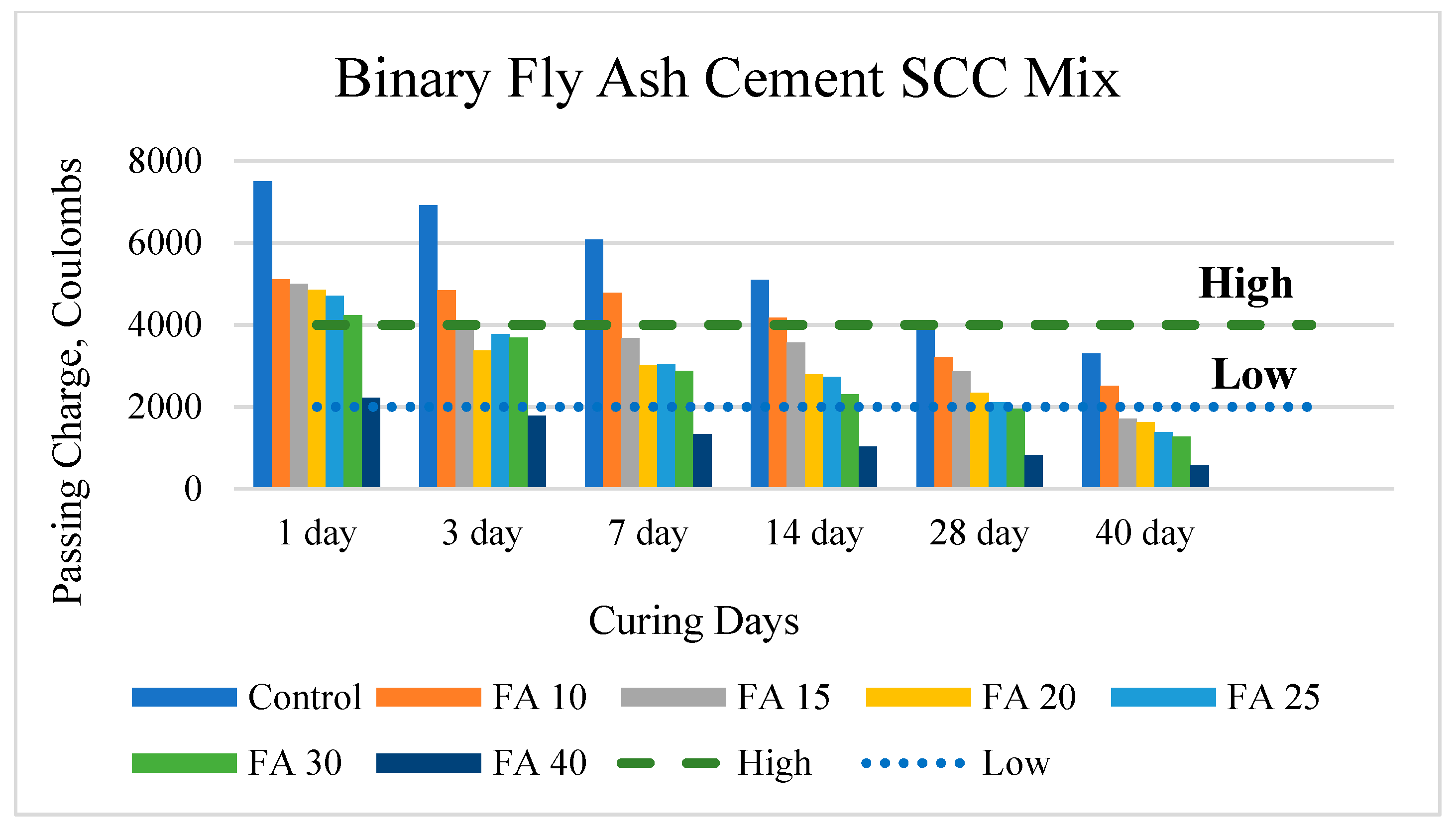

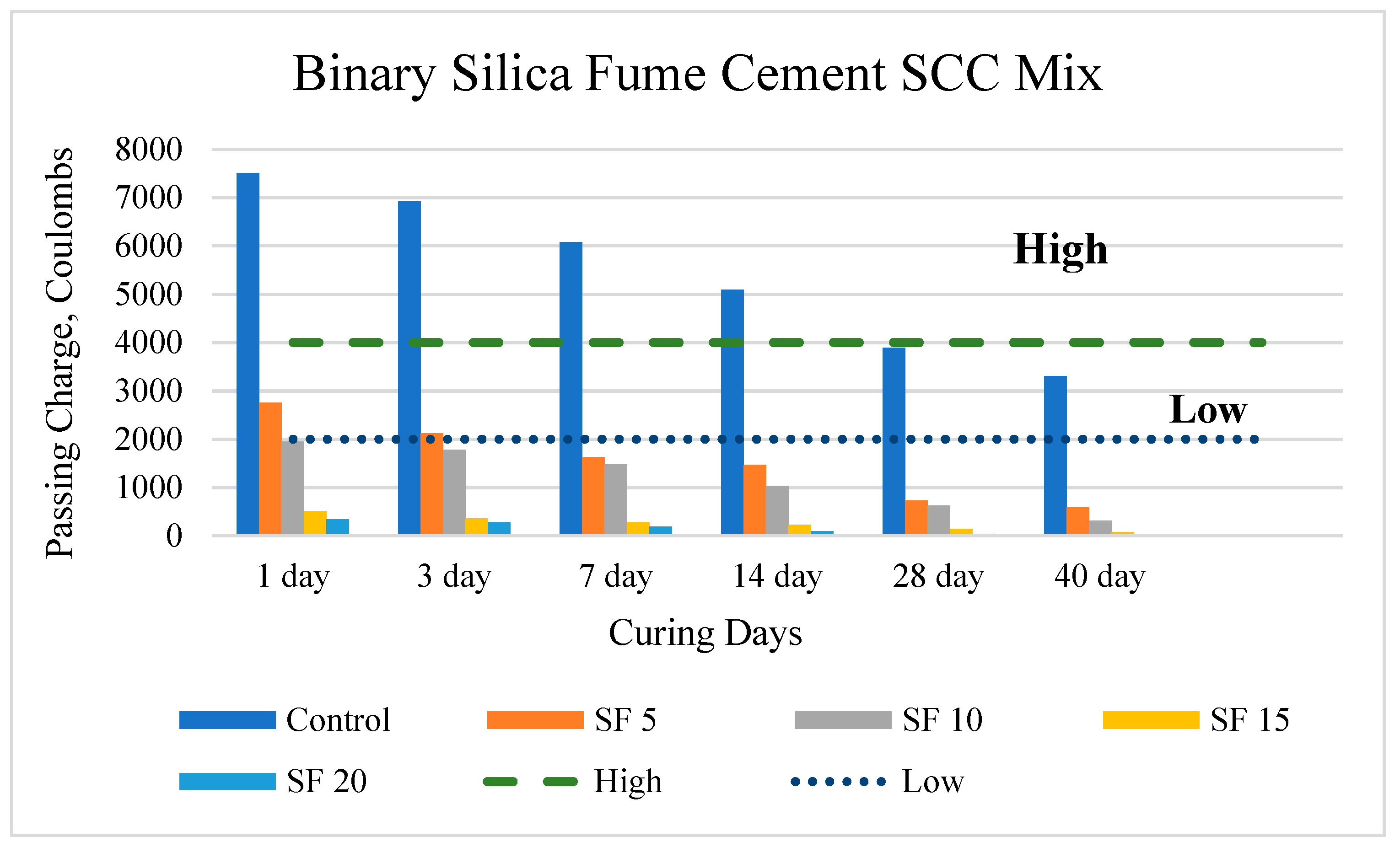

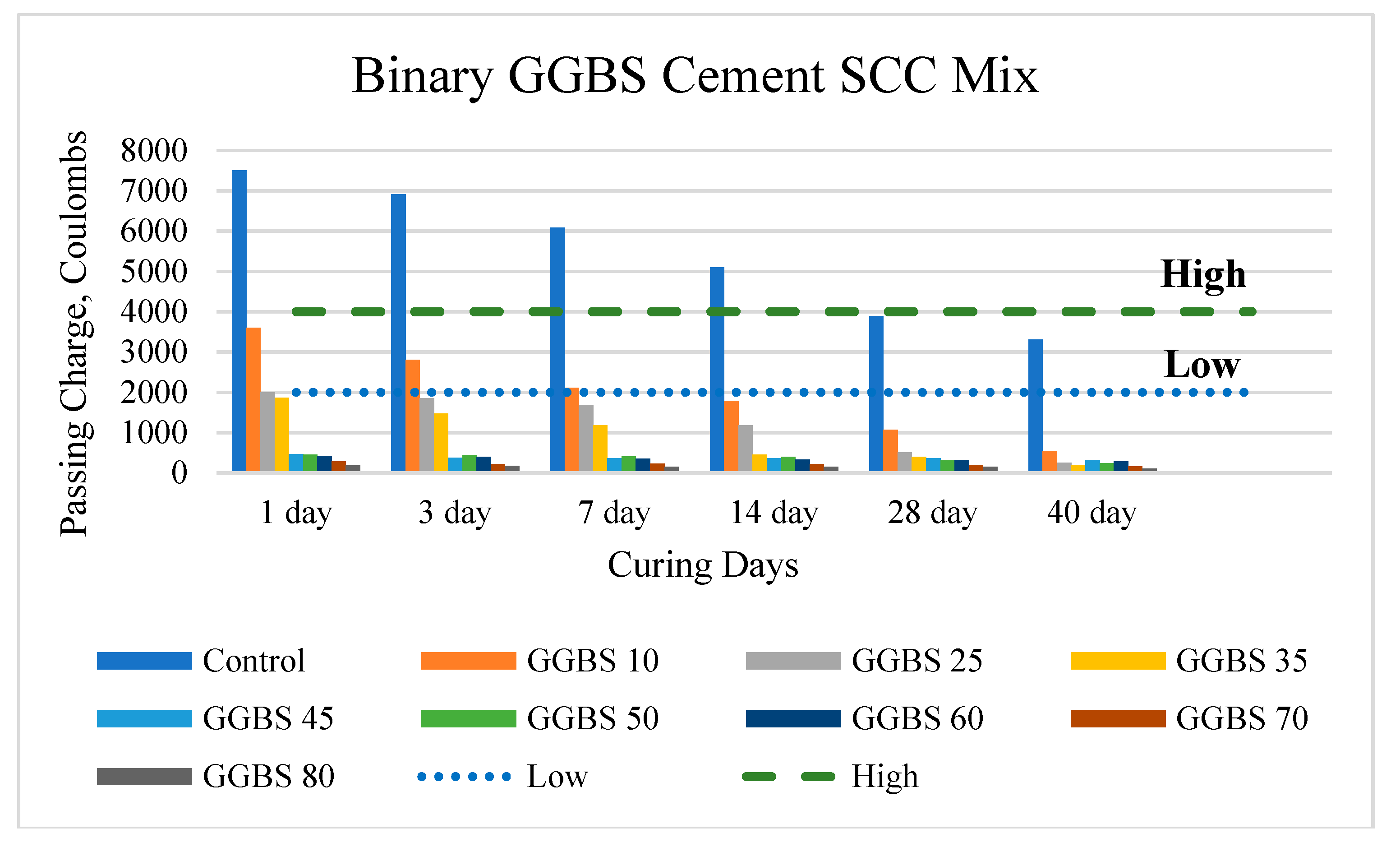

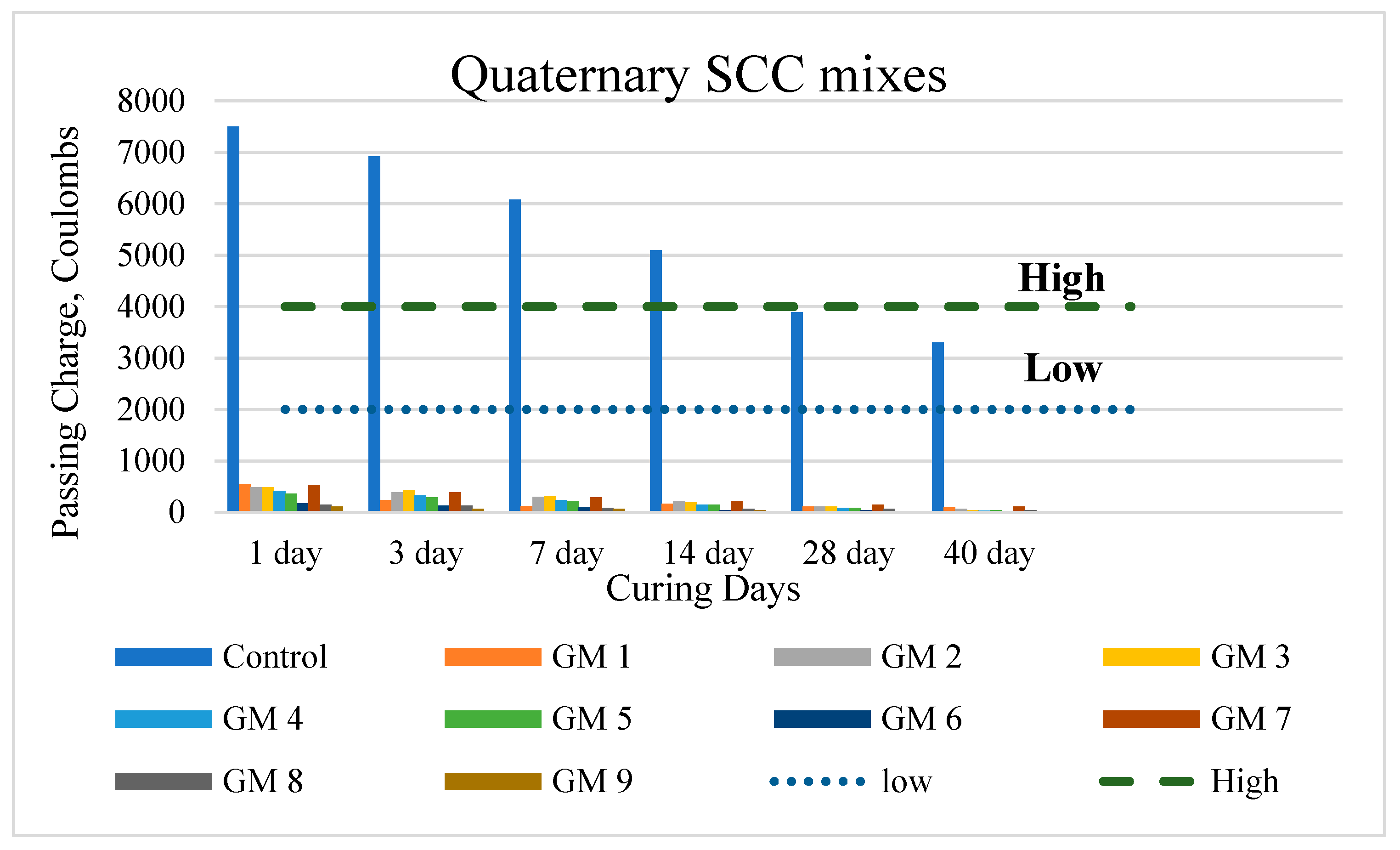

3.3. Chloride Penetration Resistance of SCC Mixes

3.3.1. Binary Mixes

3.3.2. Quaternary Mixes

4. Summary and Conclusions

- Replacing 20% of Portland cement with fly ash produced a 28-day compressive strength of 67.96 MPa, which slightly exceeds the control mix. However, the 20% replacement ratio of cement with fly ash brings a passing charge in RCPT to low after 40-days of curing.

- In binary fly ash + cement SCC mixes, it is necessary to replace up to 40% of the cement with fly ash to bring a decrease for the passing charge to low after one-day of curing and, thereby, enhance resistance to chloride penetration.

- In binary silica fume + cement SCC mixes, replacing cement with 15% silica fume increased the compressive strength and exceeded the control mixes after 3-days, 7-days, and 28-days of curing. The 28-day compressive strength of binary SCC mix with 15% silica fume replacing cement reached 95.8 MPa. Replacing 15% of cement with silica fume also increased to resistance to chloride penetration significantly such that the passing charge in RCTP was very low after 1-day of curing.

- In binary GGBS + cement SCC mixes replacing cement with 35% GGBS produced the highest 28-day compressive strength of its category along with excellent chloride penetration resistance, which is indicated by a very low passing charge after 14-days of curing using RCPT. Replacing 45% of cement with GGBS produced a high 28-day compressive strength of 78.4 MPa along with superior resistance to chloride penetration after 1-day of curing. This superior resistance to chloride penetration after 1-day of curing is the same for all GGBS replacement ratios between 45% and 80%.

- The most sustainable self-consolidating concrete mixes (GM1 to GM9) in which 80% of the cement is replaced with combinations of supplementary cementitious composites exhibited excellent resistance to chloride penetration, which is demonstrated by the Rapid Chloride Penetration Test (RCPT). Green Mix 7 (GM7) exhibited the highest resistance to chloride penetration, which was indicated by the negligible passing charge after one-day of curing. In GM7, 20% of the cement was replaced with silica fume, 50% of the cement was replaced with GGBS, and 10% of the cement was replaced with fly ash. The control mix with 100% Type 1 cement exhibited the lowest resistance to chloride penetration.

- Models meant to predict the 28-day average compressive strength using the seven-day compressive strength were developed by using regression analysis. It was found that, when including all SCC mixes in this study, the average 28-day compressive strength is 9.5 times the square root of 7-day strength, which is the same relationship for binary GGBS + cement SCC mixes. For binary fly + cement, the average 28-day compressive strength is 9 times the square root of the seven-day compressive strength. Similarly, in silica fume + cement binary mixes, the average 28-day compressive strength equals to 10.5 times the square root of the seven-day compressive strength. This higher factor of 10.5 is due to the higher strength development at 28-days for mixes containing silica fume. For green mixes (GM1 to GM7), however, the 28-day strength equals 7.6 times the square root of the seven-day compressive strength. The lower coefficient of 7.6 is due to replacing 80% of the cement by supplementary cementitious composites, which leads to slower strength development after 28 days.

- Models that predict the 28-day average compressive strength using the three-day compressive strength were developed by using regression analysis. It was found that, when including all SCC mixes in the analysis, the average 28-day compressive strength is 10 times the square root of the three-day compressive strength, which is the same relationship for binary GGBS + cement SCC mixes and approximately the same relationship for binary fly ash + cement SCC mixes. For binary silica fume + cement, the average 28-day compressive strength is 12.5 times the square of the three-day compressive strength.

Funding

Acknowledgments

Conflicts of Interest

References

- American Concrete Institute (ACI). Building Code Requirements for Structural Concrete (ACI 318-14) and Commentary (ACI 318R-14); ACI Committee 318; American Concrete Institute: Farmington Hills, MI, USA, 2014. [Google Scholar]

- Kathirve, P.; Saraswathy, V.; Karthik, S.P.; Sekar, A.S.S. Strength and Durability Properties of Quaternary Cement Concrete Made with Fly Ash, Rice Husk Ash and Limestone Powder. Arab. J. Sci. Eng. 2013, 38, 589–598. [Google Scholar] [CrossRef]

- Mohamed, O.A.; Al-Hawat, W. Influence of Fly Ash and Basalt Fibers on Strength and Chloride Penetration Resistance of Self-Consolidating Concrete. Mater. Sci. Forum 2016, 866, 3–8. [Google Scholar] [CrossRef]

- Yazıcı, H. The effect of silica fume and high-volume Class C fly ash on mechanical properties, chloride penetration and freeze–thaw resistance of self-compacting concrete. Constr. Build. Mater. 2008, 22, 456–462. [Google Scholar] [CrossRef]

- Quercia, G.; Spiesz, P.; Hüsken, G.; Brouwers, H.J.H. SCC modification by use of amorphous Nano-silica. Cem. Concr. Compos. 2014, 45, 69–81. [Google Scholar] [CrossRef]

- Mohamed, O.A.; Najim, O.F. Compressive Strength and Stability of Sustainable Self-Consolidating Concrete Containing Fly Ash, Silica Fume, and GGBS. Front. Struct. Civ. Eng. 2017, 11, 406–411. [Google Scholar] [CrossRef]

- Adekunle, S.; Ahmad, S.; Maslehuddin, M.; Al-Gahtani, H.J. Properties of SCC prepared using natural pozzolana and industrial wastes as mineral fillers. Cem. Concr. Compos. 2015, 62, 125–133. [Google Scholar] [CrossRef]

- Ryan, C.P.; O’Connor, A. Comparing the durability of self-compacting concretes and conventionally vibrated concretes in chloride rich environments. Constr. Build. Mater. 2016, 120, 504–513. [Google Scholar] [CrossRef]

- El-Chabib, H.; Syed, A. Properties of Self-Consolidating Concrete Made with High Volumes of Supplementary Cementitious Materials. J. Mater. Civ. Eng. ASCE 2013. [Google Scholar] [CrossRef]

- Mohamed, O.A.; Rens, K.L. Time Effect of Alkali-Aggregate Reaction on Performance of Concrete. J. Mater. Civ. Eng. ASCE 2001, 13, 14–151. [Google Scholar] [CrossRef]

- Mohamed, O.A.; Najim, O. Splitting Tensile Strength of Self-Consolidating Concrete Containing Slag. In Proceedings of the 29th AES-ATEMA International Conference Advances and Trends in Engineering Materials and their Applications, Toronto, ON, Canada, 4–8 July 2016; pp. 4–8. [Google Scholar]

- Mohamed, O.A.; Imam, Z.S.; Najim, O. Splitting tensile strength of sustainable self-consolidating concrete. Procedia Eng. 2016, 145, 1218–1225. [Google Scholar] [CrossRef]

- Miura, T.; Iwaki, I. Strength Development of Concrete Incorporating High Levels of Ground Granulated Blast-Furance Slag at Low Temperature. ACI Mater. J. 2000, 97, 66–71. [Google Scholar]

- ASTM International. ASTM C150/C150M. Standard Specification for Portlan7 Cement; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- British Standards Institution. BSI EN 197-1:2011. Cement, Composition, Specifications and Conformity Criteria for Common Cements; British Standards Institution: London, UK, 2011. [Google Scholar]

- British Standards Institution. BS EN 450-1:2012. Fly Ash for Concrete. Definition, Specifications and Conformity Criteria; British Standards Institution: London, UK, 2012. [Google Scholar]

- British Standards Institution. BSI 3892-1:1997. Pulverized-Fuel Ash. Specification for Pulverized-Fuel Ash for Use with Portland Cement; British Standards Institution: London, UK, 1997. [Google Scholar]

- British Standards Institution. BSI 6699:1992. Specification for Ground Granulated Blast-Furnace Slag for Use with Portland Cement; British Standards Institution: London, UK, 1992. [Google Scholar]

- Meddah, M.S.; Ismail, M.A.; El-Gamal, S.; Fitriani, H. Performance evaluation of binary concrete designed with silica fume and metakaolin. Constr. Build. Mater. 2018, 166, 400–412. [Google Scholar] [CrossRef]

- British Standards Institution. BS EN 12390-3:2009. Testing Hardened Concrete Part 3. Compressive Strength of Test Specimens; British Standards Institution: London, UK, 2009. [Google Scholar]

- Celik, K.; Meral, C.; Gursel, A.P.; Mehta, P.K.; Horvath, A.; Monteiro, P.J. Mechanical properties, durability, and life-cycle assessment of self-consolidating concrete mixtures made with blended Portland cements containing fly ash and limestone powder. Cem. Concr. Compos. 2015, 56, 59–72. [Google Scholar] [CrossRef]

- Moffatt, E.G.; Thomas, M.; Fahim, A. Performance of high-volume fly ash concrete in marine environment. Cem. Concr. Res. 2017, 102, 127–135. [Google Scholar] [CrossRef]

- Ahari, R.S.; Erdem, T.K.; Ramyar, K. Permeability properties of self-consolidating concrete containing various supplementary cementitious materials. Constr. Build. Mater. 2015, 79, 326–336. [Google Scholar] [CrossRef]

- Ramakrishnan, K.; Pugazhmani, G.; Sripragadeesh, R.; Muthu, C.; Venkatasubramanian, D. Experimental study on the mechanical and durability properties of concrete with waste glass powder and ground granulated blast furnace slag as supplementary cementitious materials. Constr. Build. Mater. 2017, 156, 739–749. [Google Scholar] [CrossRef]

- Kuder, K.; Lehman, D.; Berman, J.; Hannesson, G.; Shogren, R. Mechanical properties of self-consolidating concrete blended with high volumes of fly ash and slag. Constr. Build. Mater. 2012, 34, 285–295. [Google Scholar] [CrossRef]

- Kim, S.W.; Park, W.S.; Jang, Y.I.; Yun, S.H.; Yun, H.D.; Kim, D.G. The effect of mineral admixture on the compressive strength development of concrete. Contemp. Eng. Sci. 2015, 8, 541–547. [Google Scholar] [CrossRef]

- Hassoun, J.; Choo, B.S. Concrete properties. Adv. Concr. Technol. 2003, 4, 6–22. [Google Scholar]

- Slater, W.A. Relation of 7-day to 28-day compressive strength of mortar and concrete. J. Proc. 1926, 22, 437–449. [Google Scholar]

- ASTM International. ASTM C1202-17. Standard Test Method for Electrical Indication of Concrete & Aposs Ability to Resist Chloride Ion Penetration; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Yehia, S.; Douba, A.; Abdullahi, O.; Farrag, S. Mechanical and durability evaluation of fiber-reinforced self-compacting concrete. Constr. Build. Mater. 2016, 121, 120–133. [Google Scholar] [CrossRef]

| Chemical Properties | Cement (%) | GGBS (%) | Fly Ash (%) | Silica Fume (%) |

|---|---|---|---|---|

| Silicon dioxide, SiO2 | 20.62 | 34.24 | 37 | 93.17 |

| Alumina, Al2O3 | 4.87 | 13.75 | 9.89 | 0.14 |

| Iron Oxide, Fe2O3 | 3.35 | 1.10 | 4.45 | 0.04 |

| Calcium oxide, CaO | 63.87 | 42.26 | 21 | 0.89 |

| Magnesium oxide, MgO | 1.54 | 5.88 | 3.5 | 0.51 |

| Sulphur trioxide, SO3 | 2.5 | 0.24 | 1.91 | 0.004 |

| Sodium oxide, Na2O | -- | 0.28 | 0.56 | 0.58 |

| Potassium oxide, K2O | -- | 0.32 | -- | 2.01 |

| Loss on ignition (LOI) | 1.5 | 0.72 | 3.12 | 2.43 |

| Binary Mix | Mixture Type | Cement kg/m3 | FA kg/m3 | SF kg/m3 | GGBS kg/m3 |

|---|---|---|---|---|---|

| Control Mix | 480 | 0 | 0 | 0 | |

| Cement + fly ash | FA10 | 432 | 48 | 0 | 0 |

| FA15 | 408 | 72 | 0 | 0 | |

| FA20 | 384 | 96 | 0 | 0 | |

| FA25 | 360 | 120 | 0 | 0 | |

| FA30 | 336 | 144 | 0 | 0 | |

| FA40 | 288 | 192 | 0 | 0 | |

| Cement + silica fume | SF5 | 456 | 0 | 24 | 0 |

| SF10 | 432 | 0 | 48 | 0 | |

| SF15 | 408 | 0 | 72 | 0 | |

| SF20 | 384 | 0 | 96 | 0 | |

| Cement + GGBS | GGBS10 | 432 | 0 | 0 | 48 |

| GGBS25 | 360 | 0 | 0 | 120 | |

| GGBS35 | 312 | 0 | 0 | 168 | |

| GGBS45 | 264 | 0 | 0 | 216 | |

| GGBS50 | 240 | 0 | 0 | 240 | |

| GGBS60 | 192 | 0 | 0 | 288 | |

| GGBS70 | 144 | 0 | 0 | 336 | |

| GGBS80 | 96 | 0 | 0 | 384 |

| Mixture Type | Cement Kg/m3 | FA kg/m3 | SF kg/m3 | GGBS kg/m3 |

|---|---|---|---|---|

| GM 1 | 96 | 96 | 48 | 240 |

| GM 2 | 96 | 120 | 72 | 192 |

| GM 3 | 96 | 72 | 24 | 288 |

| GM 4 | 96 | 72 | 72 | 240 |

| GM 5 | 96 | 48 | 72 | 264 |

| GM 6 | 96 | 72 | 96 | 216 |

| GM 7 | 96 | 48 | 96 | 240 |

| Compressive Strength (MPa) | |||

|---|---|---|---|

| Curing A | |||

| Mixture Type | 3-days | 7-days | 28-days |

| Control Mix | 51 | 61.48 | 66.08 |

| FA 10 | 46.3 | 54.3 | 61.325 |

| FA 15 | 42 | 50.3 | 62.5 |

| FA 20 | 46.225 | 50.025 | 67.96 |

| FA 25 | 38.6 | 43 | 61.7 |

| FA 30 | 38.6 | 46.4 | 56.5 |

| FA 40 | 31.43 | 36.7 | 55.75 |

| SF 5 | 28.11 | 56.7 | 72.3 |

| SF 10 | 49 | 58.5 | 81.11 |

| SF 15 | 55.65 | 71.45 | 95.3 |

| SF 20 | 37.3 | 53.41 | 75.83 |

| GGBS 10 | 51 | 58.5 | 66.75 |

| GGBS 25 | 52.02 | 65.3 | 77.53 |

| GGBS 35 | 45.93 | 66.33 | 81 |

| GGBS 45 | 51.55 | 65.54 | 78.4 |

| GGBS 50 | 43.5 | 56.11 | 74 |

| GGBS 60 | 59.66 | 63.95 | 75.655 |

| GGBS 70 | 46.7 | 60.42 | 62 |

| GGBS 80 | 41.9 | 43 | 50.45 |

| Compressive Strength (MPa) | ||||||

|---|---|---|---|---|---|---|

| Curing Age (Days) | ||||||

| Mixture Type | FA kg/m3 | SF kg/m3 | GGBS kg/m3 | 3 | 7 | 28 |

| GM 1 | 96 | 48 | 240 | 33.49 | 42 | 48.95 |

| GM 2 | 120 | 72 | 192 | 22.26 | 31.055 | 40.02 |

| GM 3 | 72 | 24 | 288 | 35.15 | 46.3 | 60.2 |

| GM 4 | 72 | 72 | 240 | 46 | 51.7 | 63.9 |

| GM 5 | 48 | 72 | 264 | 37.8 | 44 | 53.69 |

| GM 6 | 72 | 96 | 216 | 26.3 | 33.7 | 42.455 |

| GM 7 | 48 | 96 | 240 | 26.4 | 38.3 | 46.3 |

| Mix Type | Study | Equation | IAE% |

|---|---|---|---|

| Fly Ash Mixes | Current Study (Power) | 4.3% | |

| Current Study (Square Root) | 5.3% | ||

| Kim [26] | 10.2% | ||

| Hassoun and Choo [27] | 8.2% | ||

| Slater [28] | 8.3% | ||

| Silica Fume Mixes | Current Study (Power) | 3.2% | |

| Current Study (Square Root) | 4.6% | ||

| Kim [26] | 14.4% | ||

| Hassoun and Choo [27] | 4.7% | ||

| Slater [28] | 4.2% | ||

| GGBS Mixes | Current Study (Power) | 4.3% | |

| Current Study (Square Root) | 6.8% | ||

| Kim [26] | 5.5% | ||

| Hassoun and Choo [27] | 10.9% | ||

| Slater [28] | 11.9% | ||

| Quaternary Mixes | Current Study (Power) | 4.5% | |

| Current Study (Square Root) | 7.3% | ||

| Kim [26] | 3.8% | ||

| Hassoun and Choo [27] | 10.9% | ||

| Slater [28] | 12.0% | ||

| All Mixes | Current Study (Power) | 6.2% | |

| Current Study (Square Root) | 9.4% | ||

| Kim [26] | 11.5% | ||

| Hassoun and Choo [27] | 14.1% | ||

| Slater [28] | 15.1% |

| Charge Passed (Coulombs) | Chloride Ion Penetrability |

|---|---|

| >4000 | High |

| 2000–4000 | Moderate |

| 1000–2000 | Low |

| 100–1000 | Very Low |

| <100 | Negligible |

© 2018 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohamed, O. Durability and Compressive Strength of High Cement Replacement Ratio Self-Consolidating Concrete. Buildings 2018, 8, 153. https://doi.org/10.3390/buildings8110153

Mohamed O. Durability and Compressive Strength of High Cement Replacement Ratio Self-Consolidating Concrete. Buildings. 2018; 8(11):153. https://doi.org/10.3390/buildings8110153

Chicago/Turabian StyleMohamed, Osama. 2018. "Durability and Compressive Strength of High Cement Replacement Ratio Self-Consolidating Concrete" Buildings 8, no. 11: 153. https://doi.org/10.3390/buildings8110153

APA StyleMohamed, O. (2018). Durability and Compressive Strength of High Cement Replacement Ratio Self-Consolidating Concrete. Buildings, 8(11), 153. https://doi.org/10.3390/buildings8110153