Development and Experimental Study of a Novel Diaphragm Wall Joint with Retractable Shear Studs

Abstract

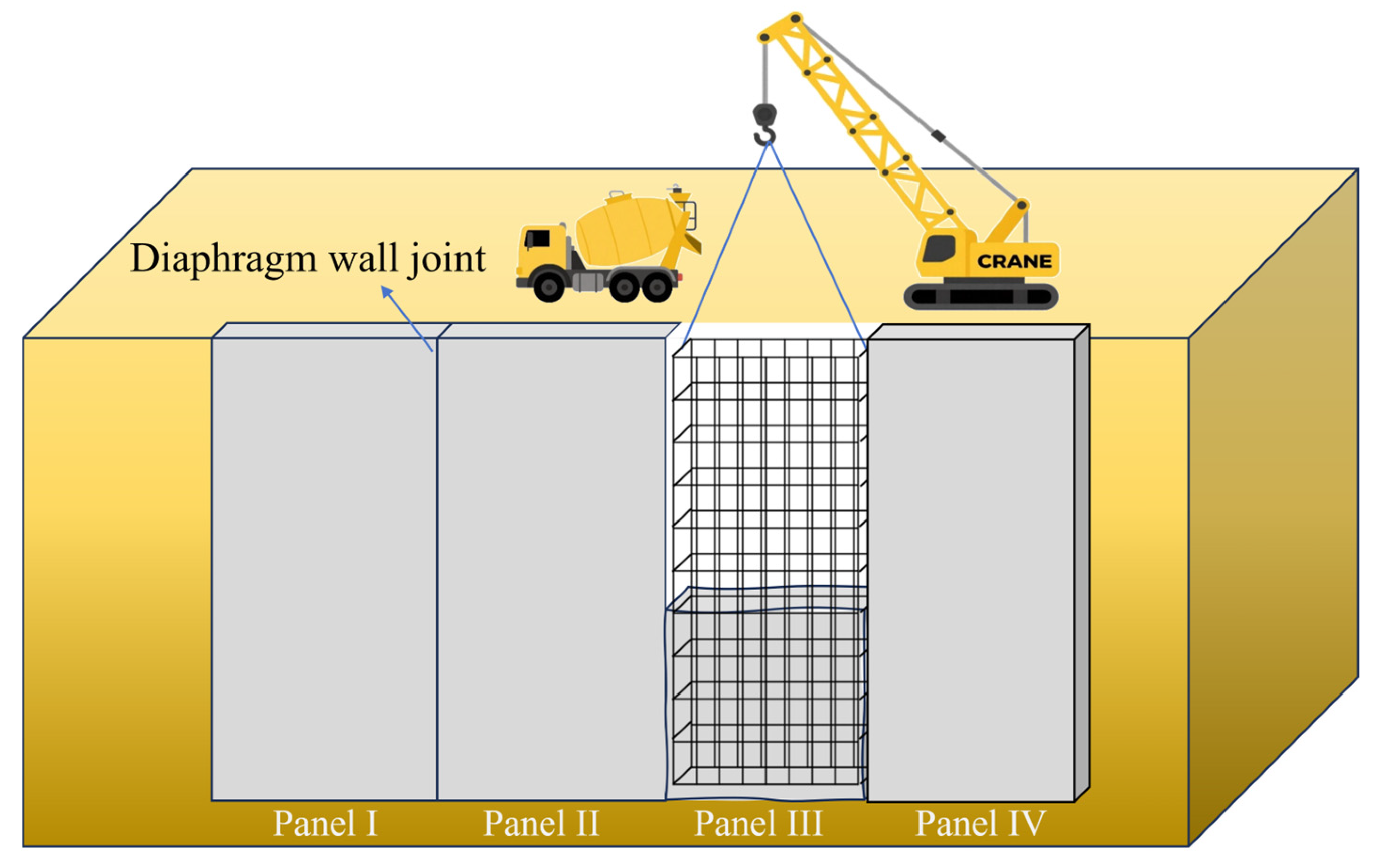

1. Introduction

2. Development of the Novel Diaphragm Wall Joint with Retractable Shear Studs

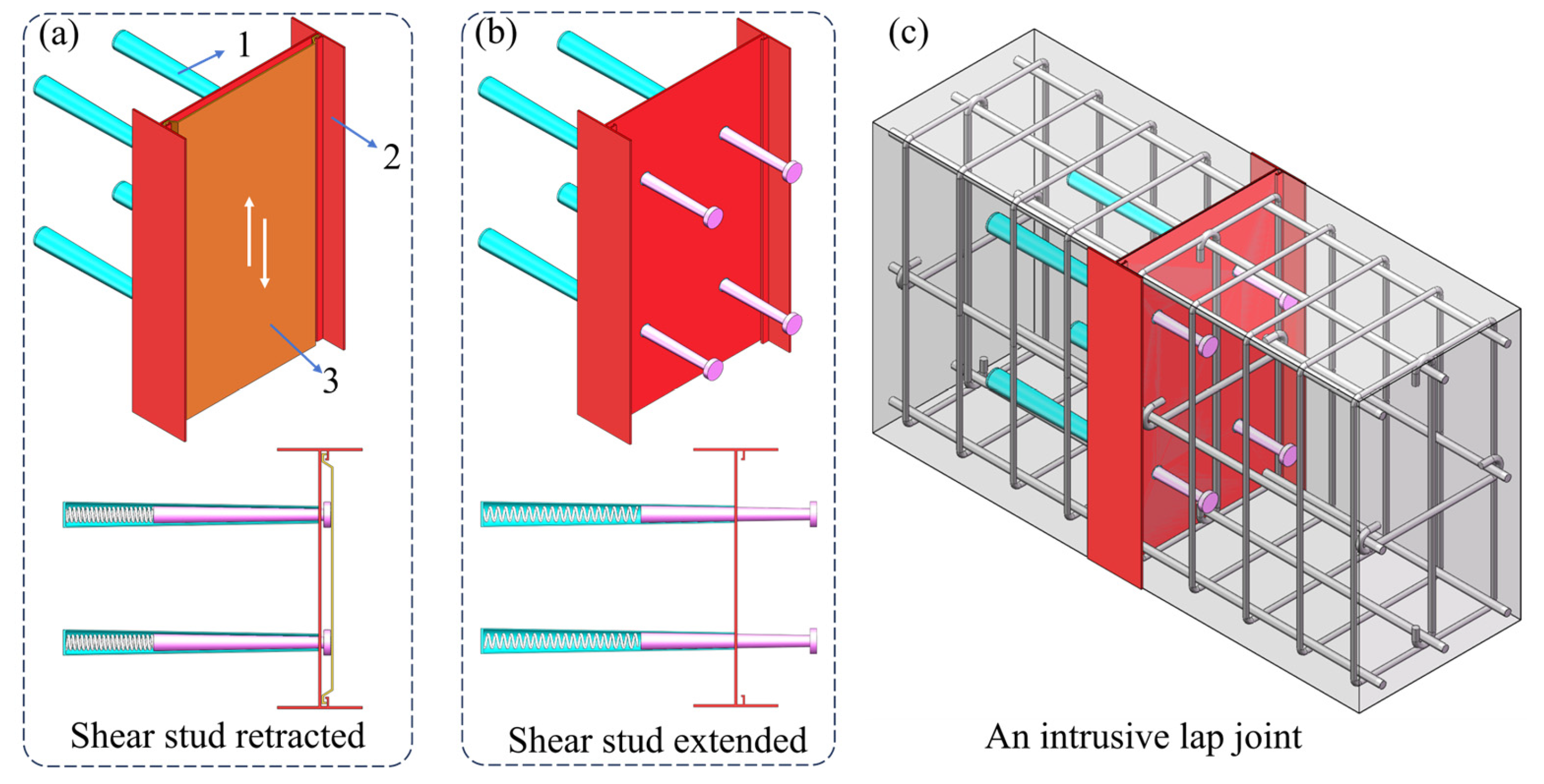

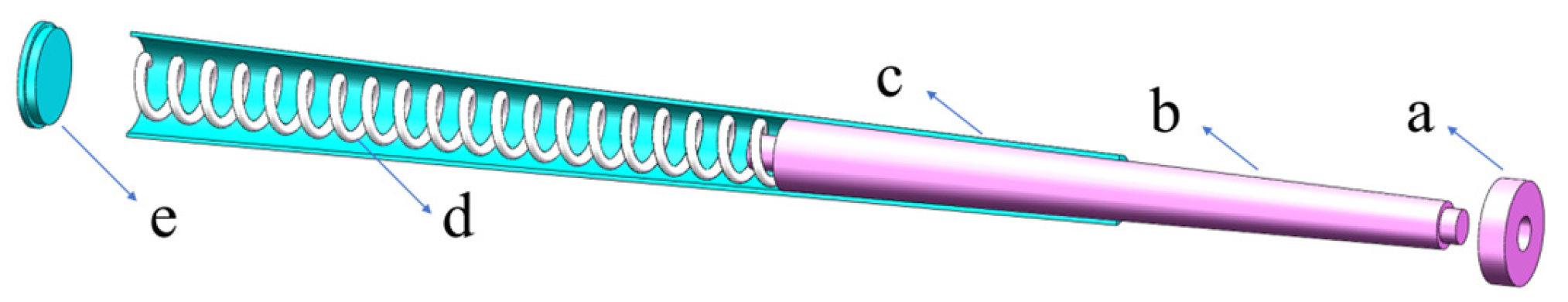

2.1. Design of the New Diaphragm Wall Joint

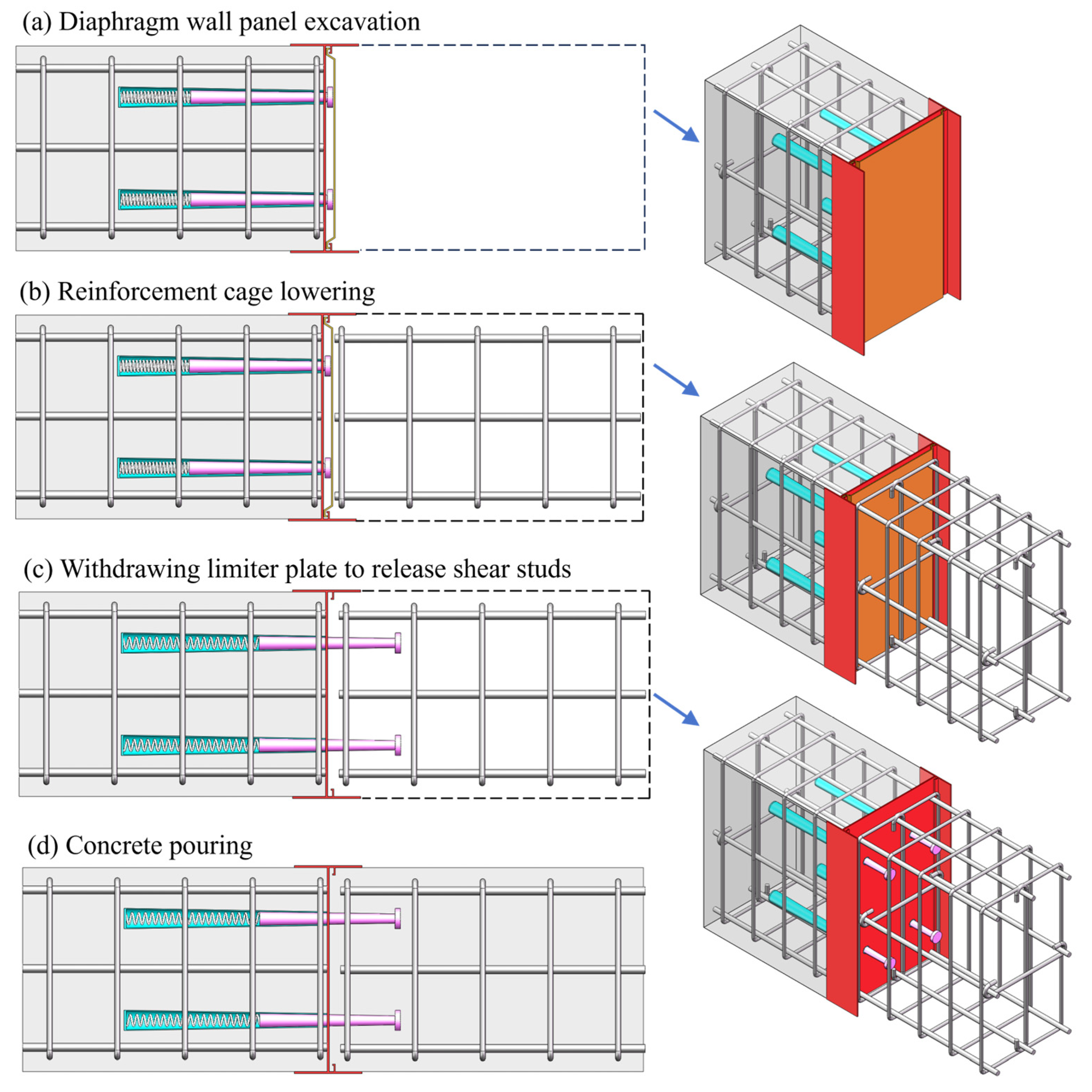

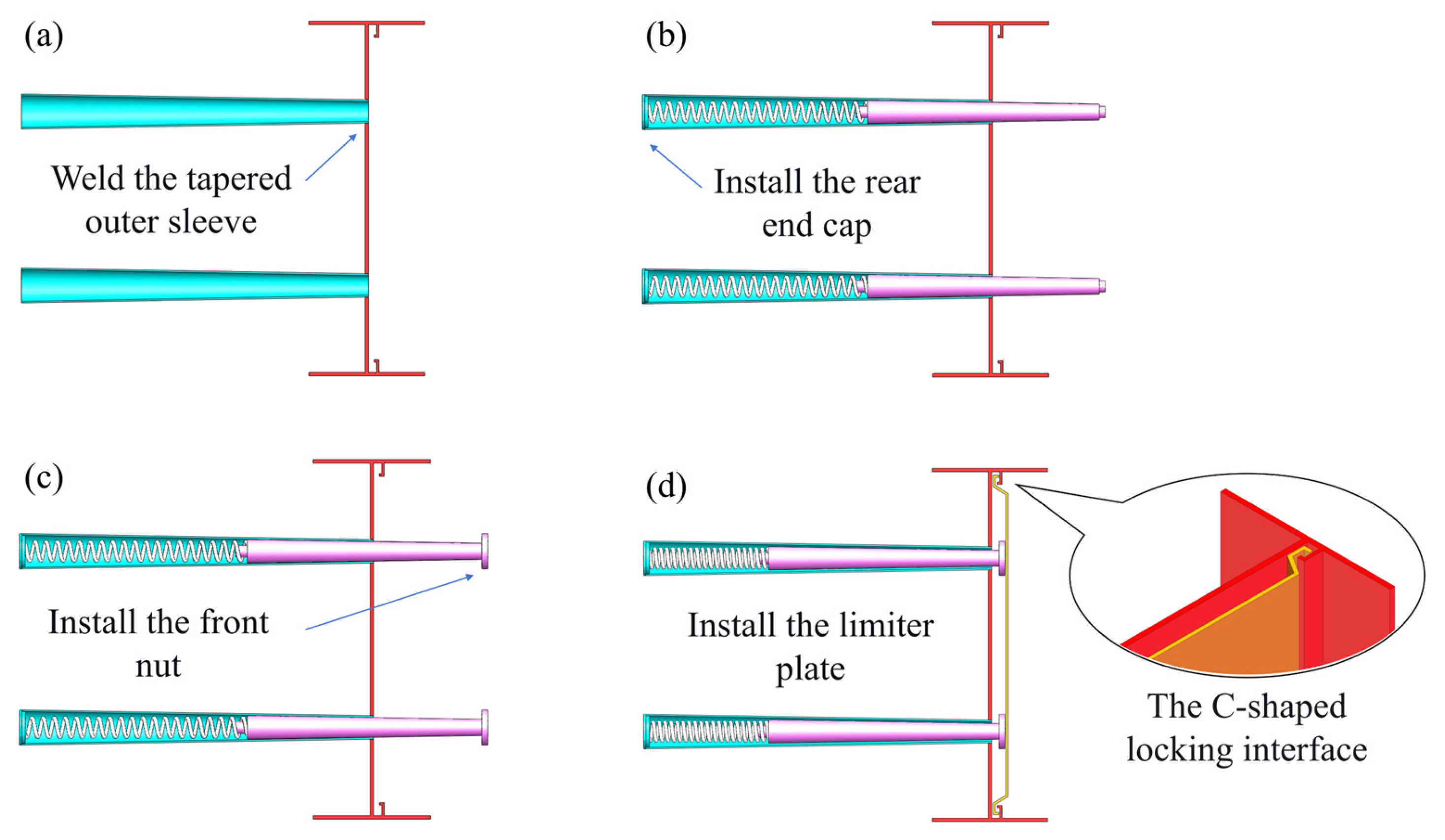

2.2. Construction Process of the New Diaphragm Wall Joint

- Weld the new joint onto the reinforcement cage of the preceding diaphragm wall panel. After inserting the shear stud limit plates, the shear studs at the joint are in a retracted state, concealed within the leading panel.

- After casting the concrete for the preceding panel, excavate the trench segment for the subsequent panel. Lower the reinforcement cage of the adjacent panel vertically.

- After the reinforcement cage is positioned, pull the shear stud limit plates upward. The shear studs then extend from the preceding panel and penetrate into the reinforcement cage of the subsequent panel, forming an intrusive lap.

- Cast concrete into the trench segment. After the concrete hardens, a rigid joint is formed between the two panels, integrating them.

- Repeat steps (1) to (4) until the entire diaphragm wall structure construction is completed.

2.3. Advantages of the New Diaphragm Wall Joint

- Straightforward and reliable structure; convenient construction: Simply withdrawing the limit plates allows the shear studs to automatically extend and penetrate the adjacent reinforcement cage, forming an intrusive lap joint. Moreover, each shear stud operates independently; even if individual studs fail to engage effectively, the impact on the overall joint capacity is minimal.

- Good compatibility with existing methods; ease of promotion: The construction process for this new joint is highly compatible with that of common H-section steel joints, differing mainly by the added step of withdrawing the limit plates. Therefore, it is easy to promote and implement.

- Favorable overall economy: This joint only adds a certain number of retractable shear studs to a conventional H-section steel joint. The retractable shear stud structure is simple and low-cost, yet it significantly enhances the joint’s load-bearing capacity. This improvement can effectively optimize the overall diaphragm wall design, leading to potential savings in total project cost.

3. Shear and Tensile Mechanical Tests of the Novel Diaphragm Wall Joint

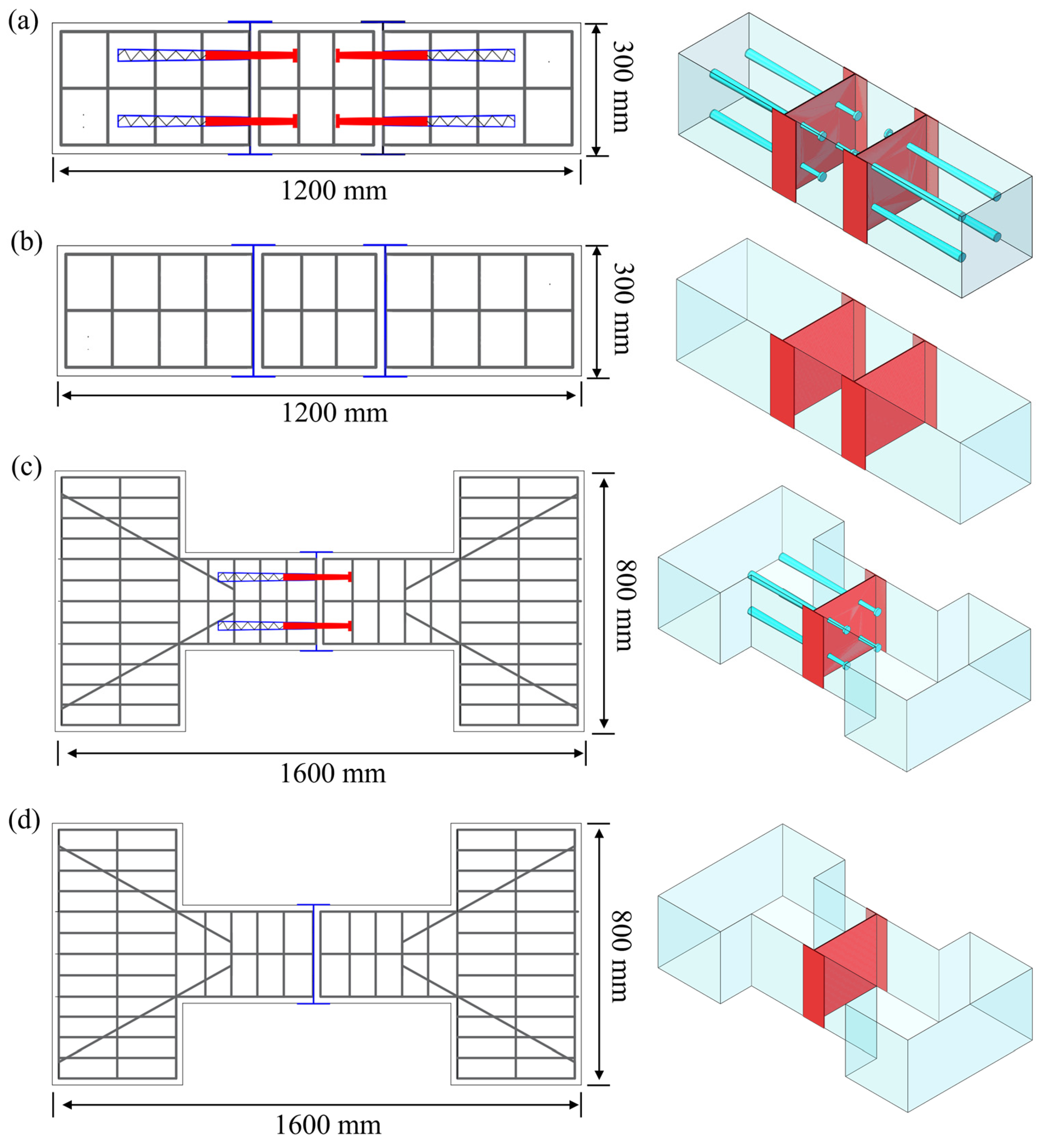

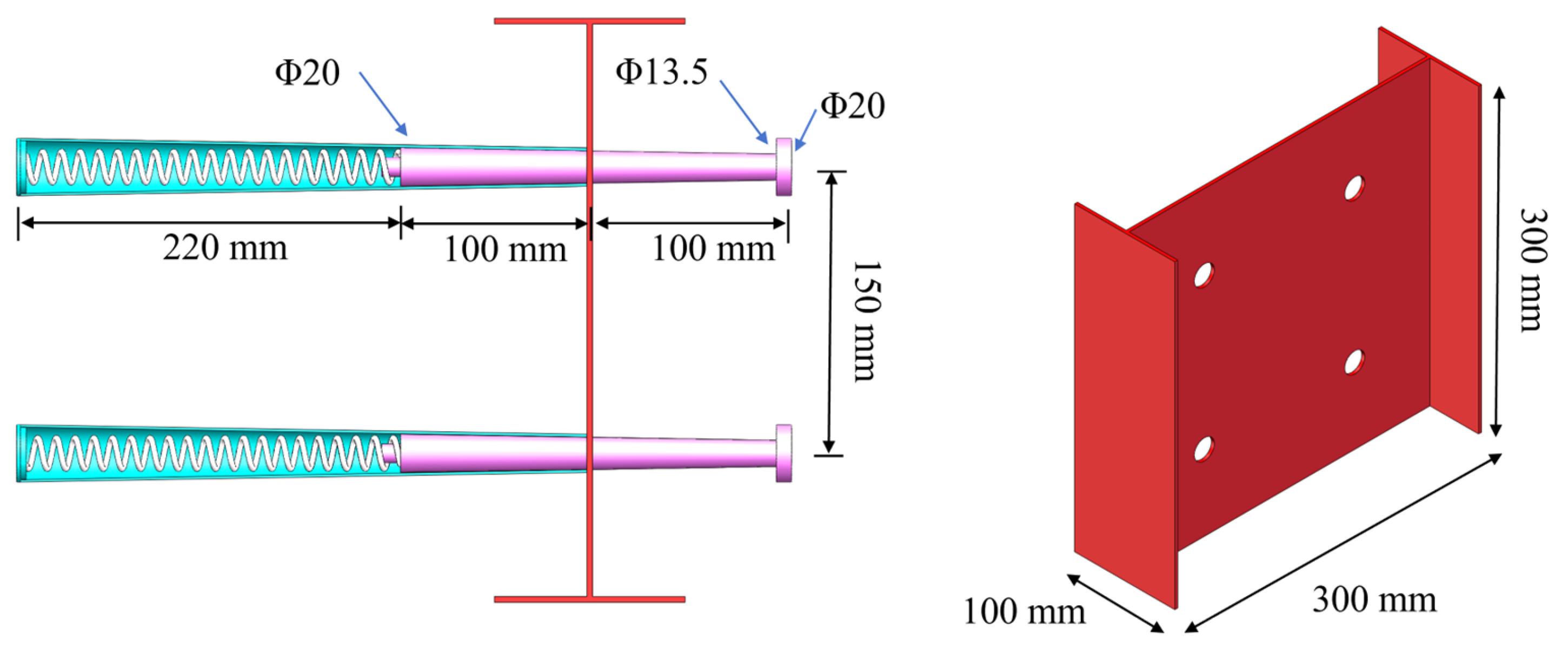

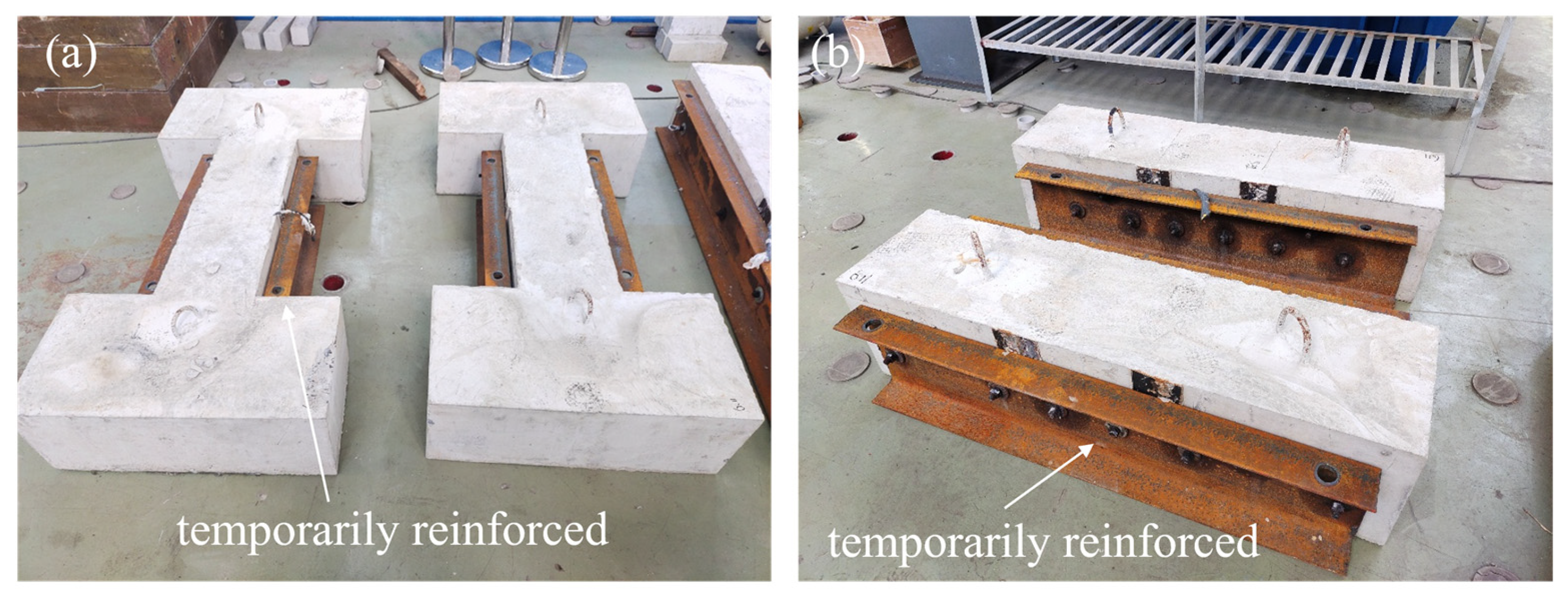

3.1. Joint Specimen Fabrication

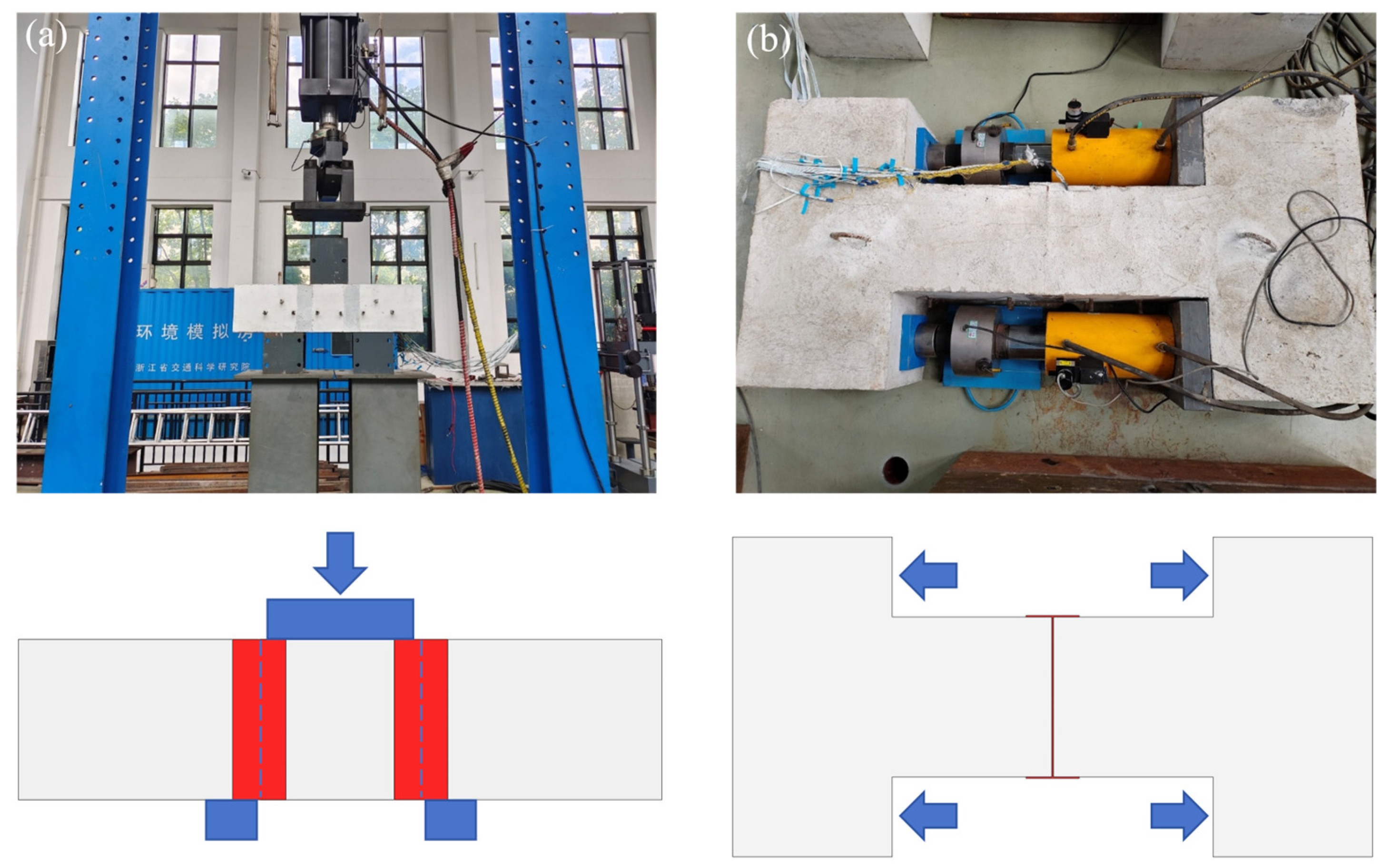

3.2. Test Setup and Procedure

4. Analysis of Joint Mechanical Test Results

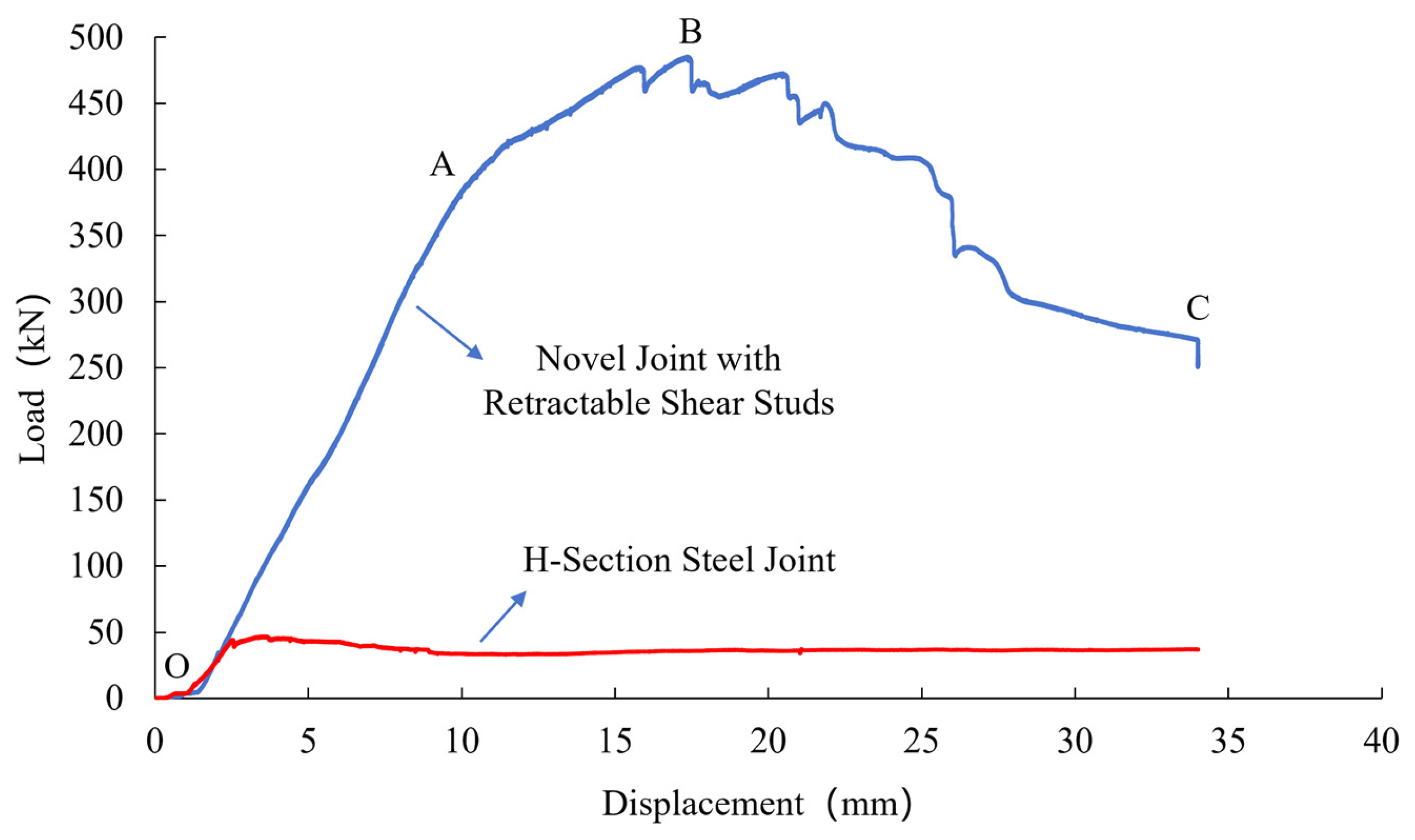

4.1. Shear Test Results

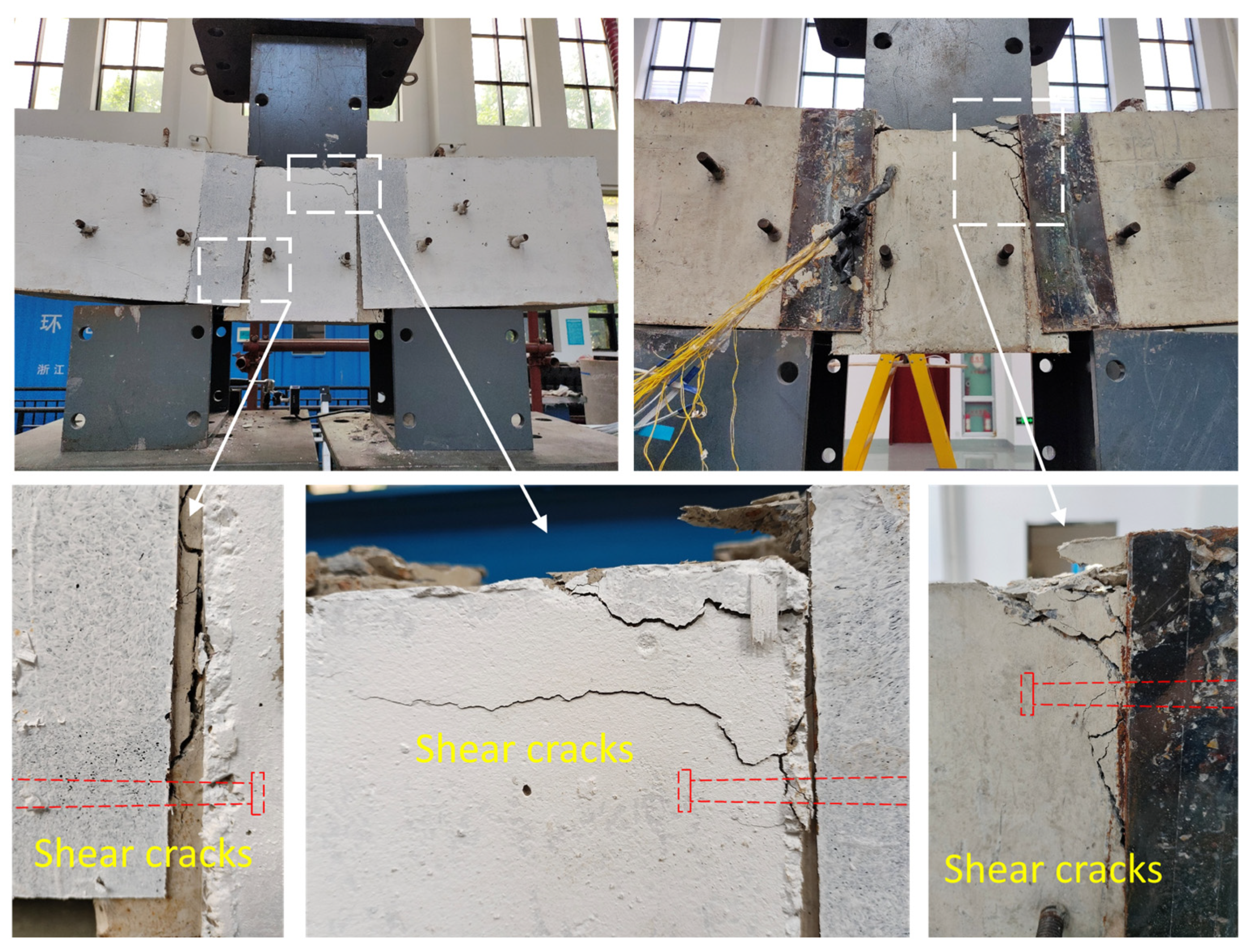

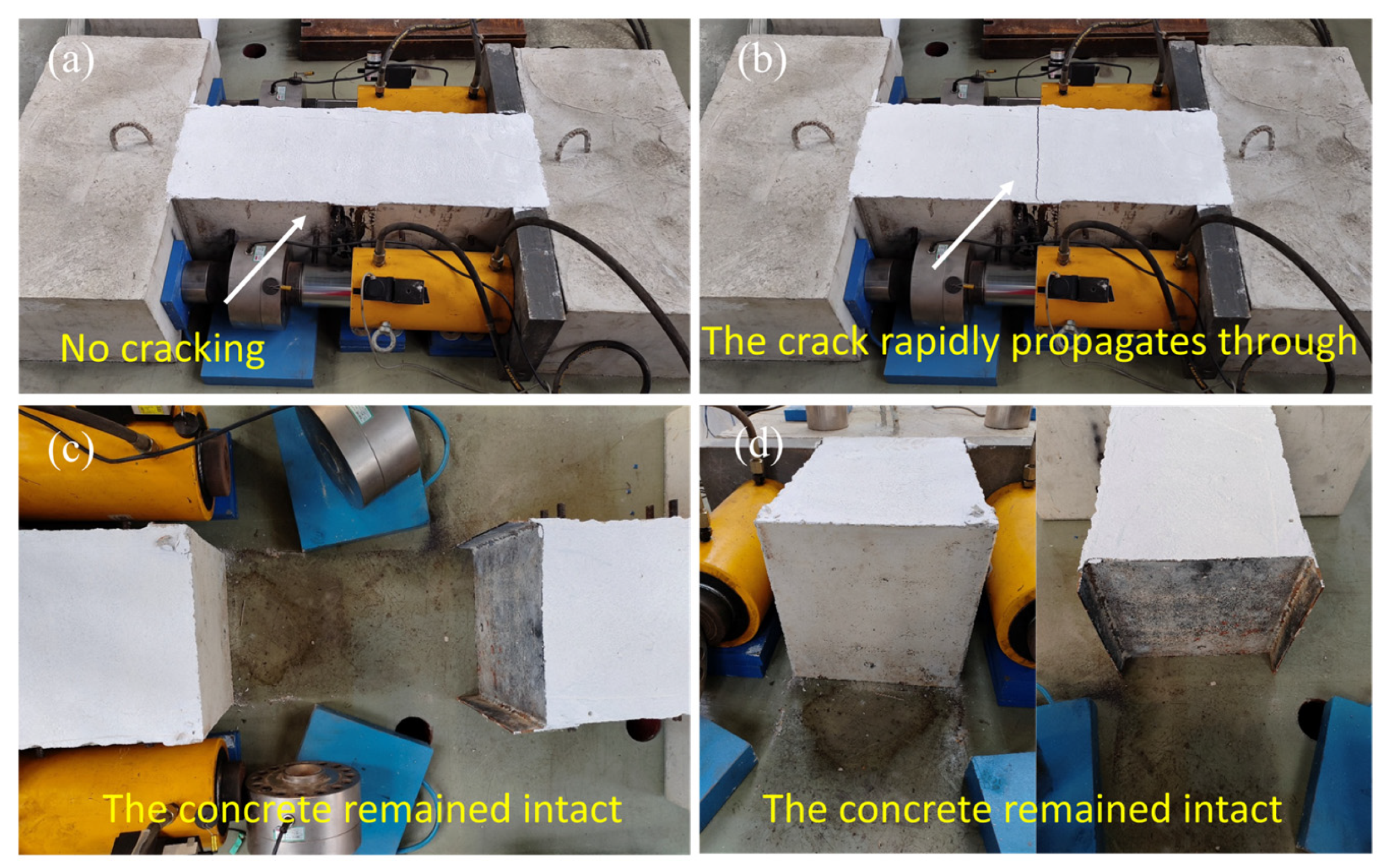

4.1.1. Joint Shear Mechanical Performance and Failure Characteristics

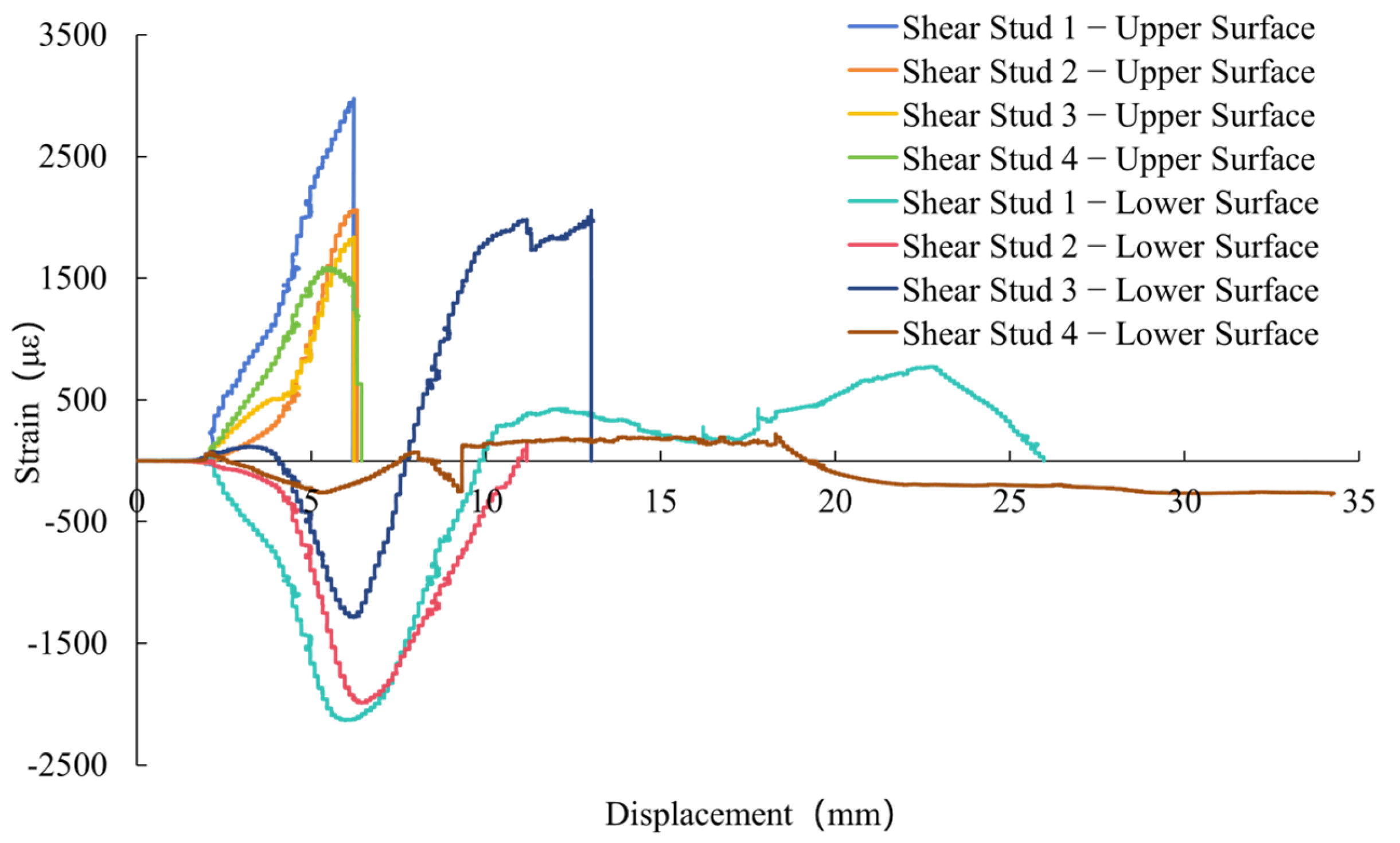

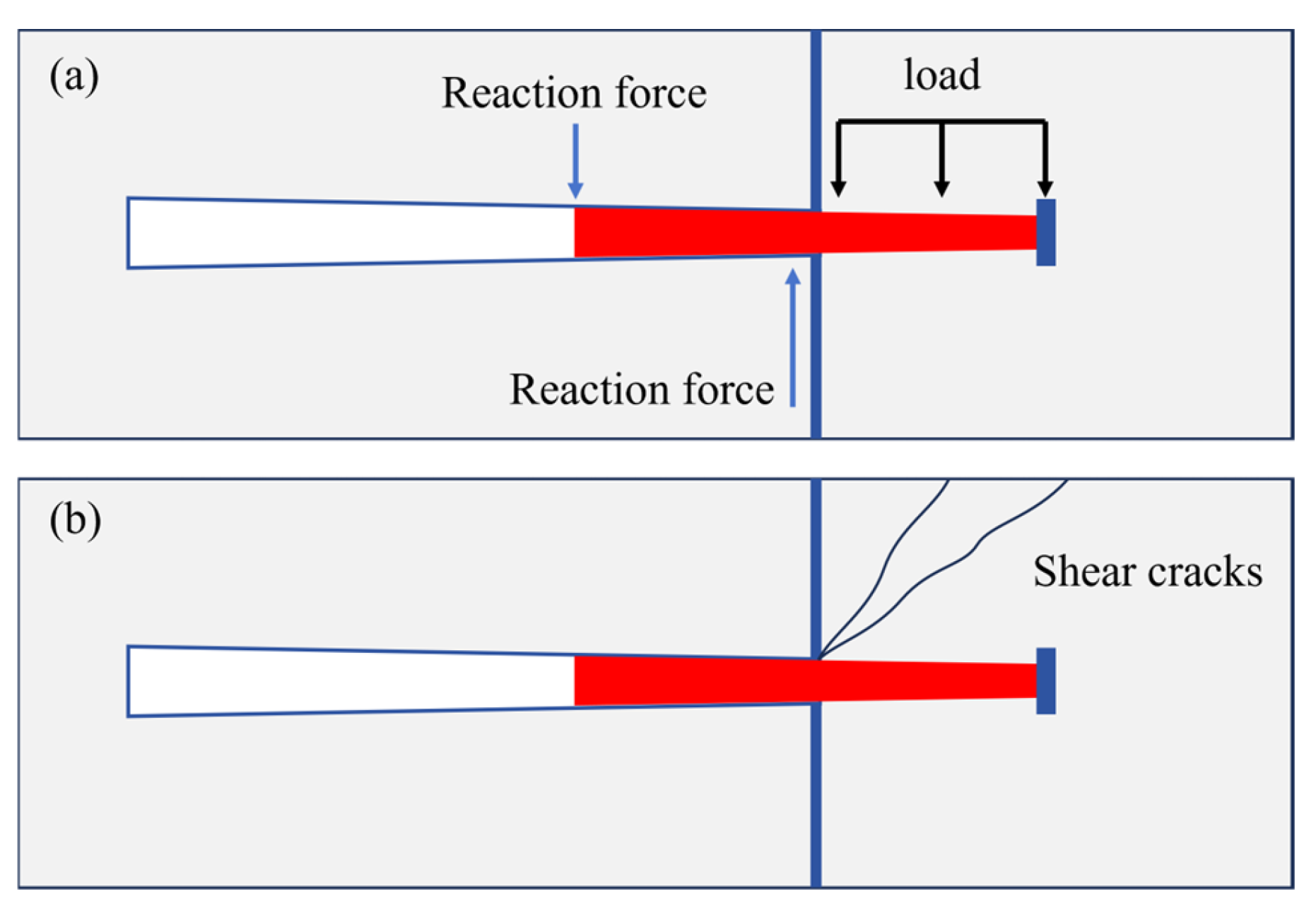

4.1.2. Analysis of Joint Shear Bearing Mechanism

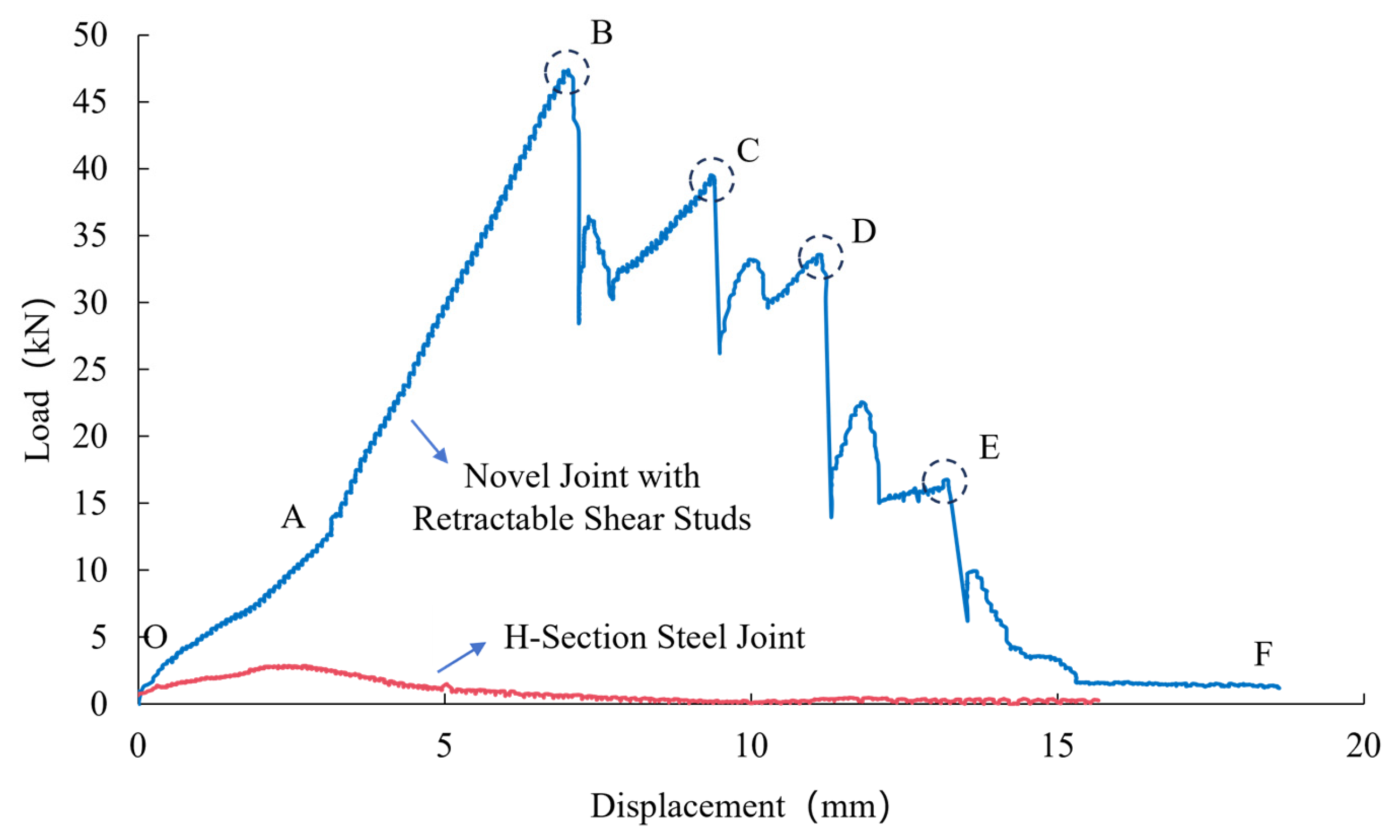

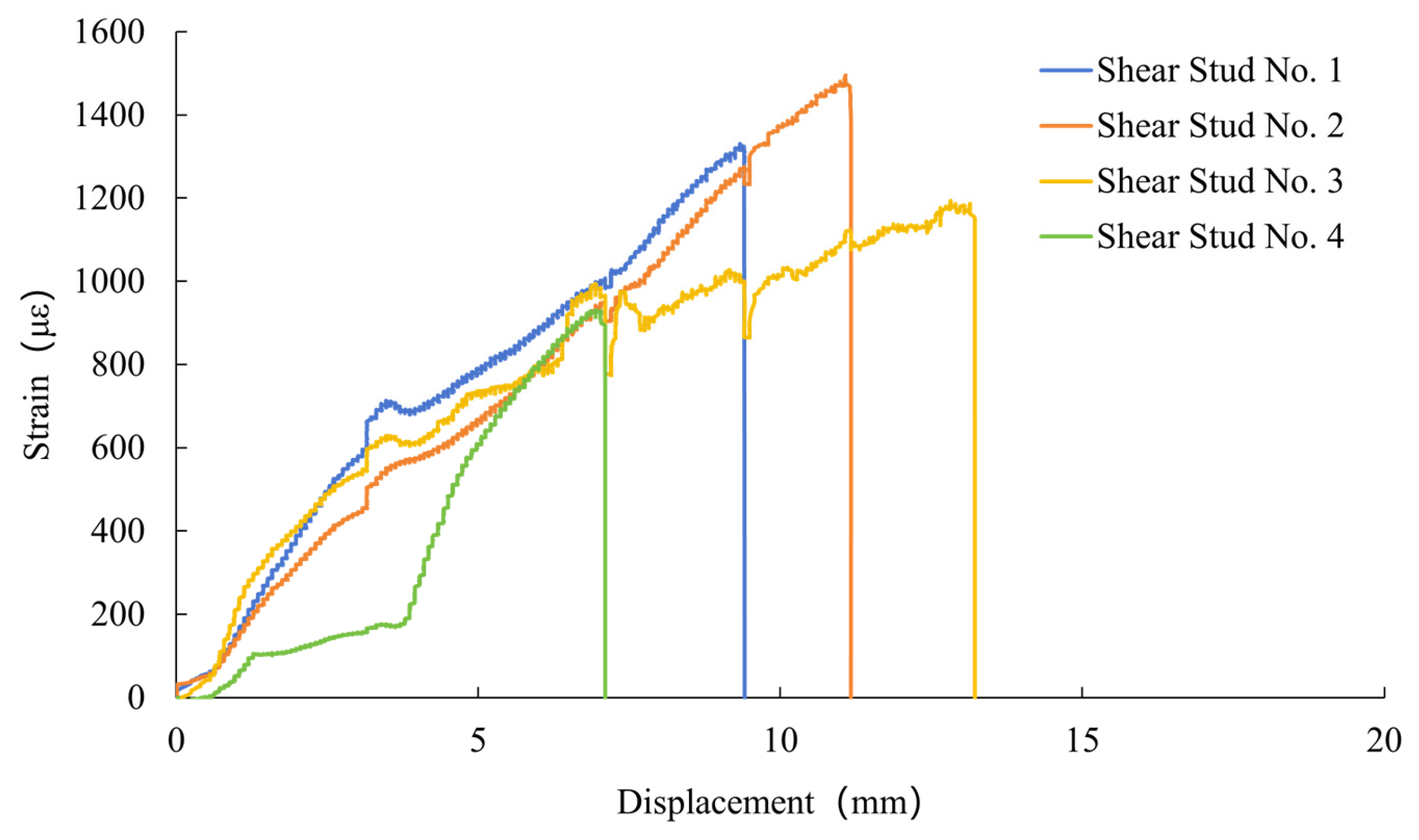

4.2. Tensile Test Results

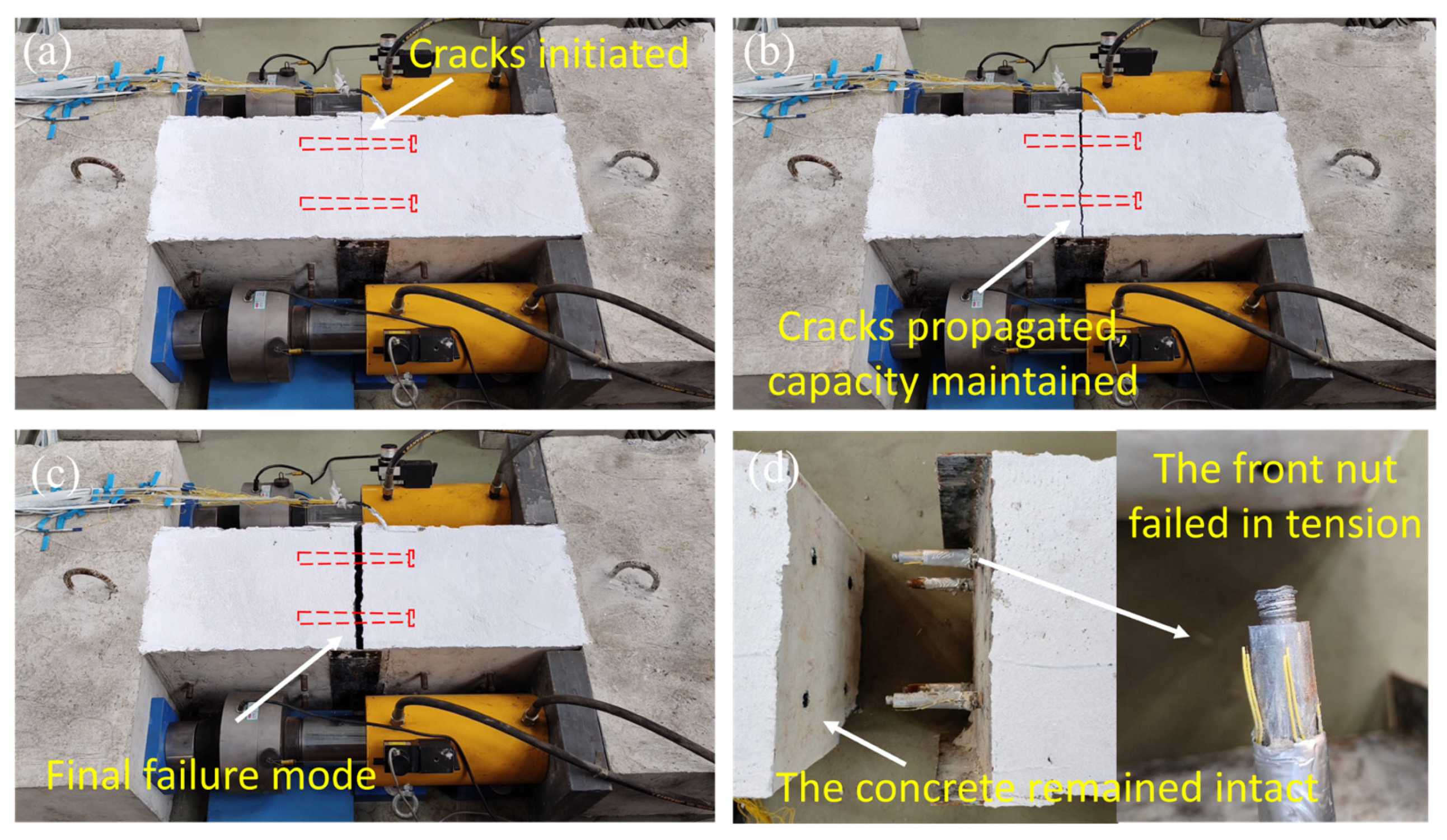

4.2.1. Joint Tensile Mechanical Performance and Failure Characteristics

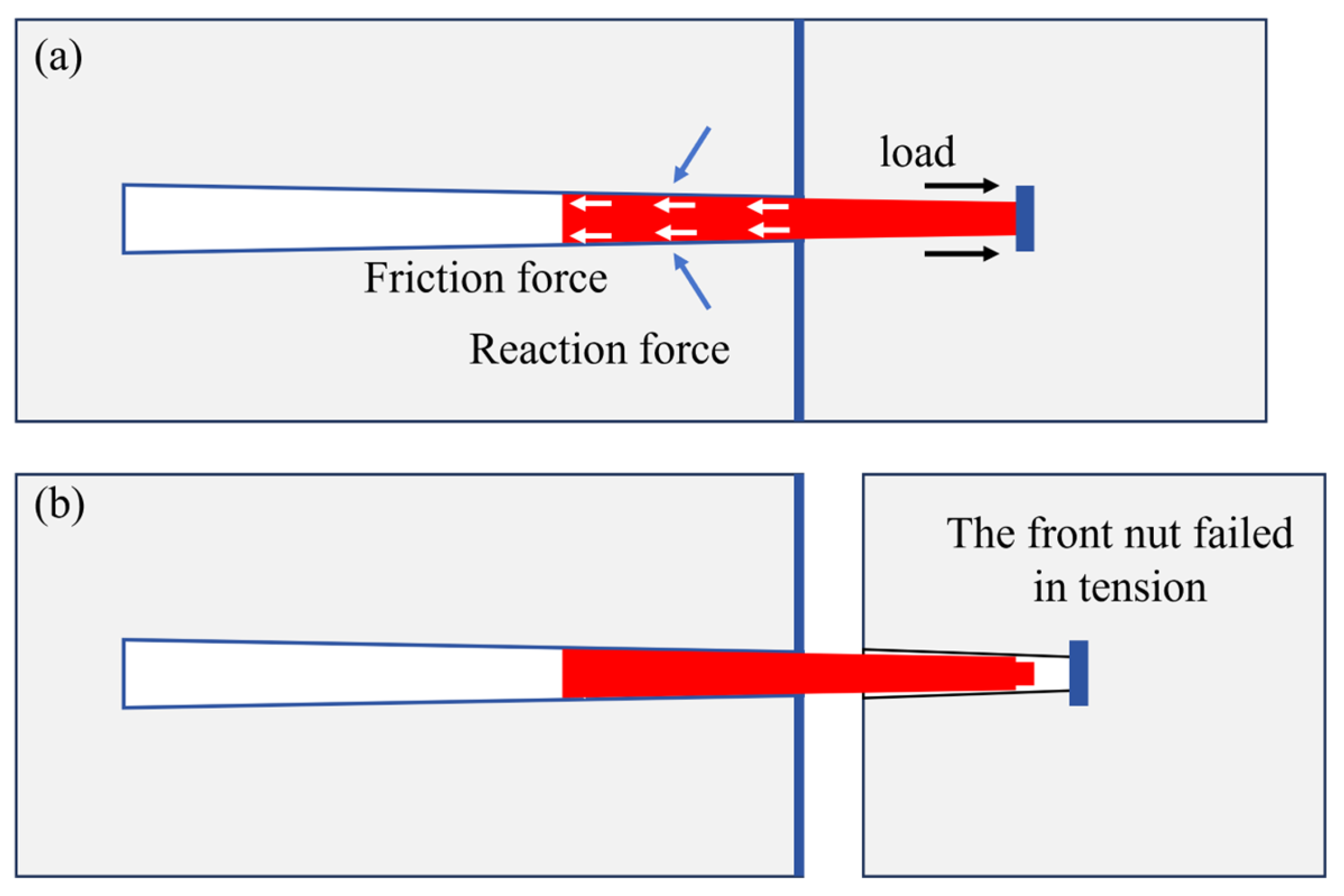

4.2.2. Analysis of Joint Tensile Bearing Mechanism

5. Discussion and Conclusions

- The novel diaphragm wall joint based on retractable shear studs provides a rapid and effective solution for establishing an intrusive lap between reinforcement cages of adjacent panels. The joint features a straightforward structure, convenient construction, and is highly compatible with conventional H-section steel joint practices, making it readily suitable for widespread promotion and application.

- The new joint exhibits significantly superior load-bearing capacity compared to the conventional H-section steel joint, with its shear and tensile strengths increased by a factor of approximately 10 and 16, respectively. Consequently, its application will substantially enhance the overall safety redundancy and risk resistance of the diaphragm wall as an integrated structure, while also effectively broadening its range of application, such as ultra-deep foundation pits and anchorage foundations for ultra-long-span suspension bridges.

- The failure modes and underlying load-transfer mechanisms have been preliminarily elucidated. Under shear, load is transferred via a fixed-end cantilever action of the studs, leading to progressive concrete shear failure. Under tension, the load is carried primarily by the studs through a wedging action, with failure occurring via sequential fracture at the front-end nut connections. These insights establish a solid foundation for further optimization of the joint design.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ou, C.-Y.; Liao, J.-T.; Lin, H.-D. Performance of diaphragm wall constructed using top-down method. J. Geotech. Geoenviron. Eng. 1998, 124, 798–808. [Google Scholar] [CrossRef]

- James, A.; Kurian, B. Design specifications for diaphragm wall: State of the art. Indian Geotech. J. 2020, 50, 838–847. [Google Scholar] [CrossRef]

- Chiu, H.-W.; Hsu, C.-F.; Tsai, F.-H.; Chen, S.-L. Influence of Different Construction Methods on Lateral Displacement of Diaphragm Walls in Large-Scale Unsupported Deep Excavation. Buildings 2024, 14, 23. [Google Scholar] [CrossRef]

- Tan, Y.; Wang, D. Structural behaviors of large underground earth-retaining systems in Shanghai. I: Unpropped circular diaphragm wall. J. Perform. Constr. Facil. 2015, 29, 04014058. [Google Scholar] [CrossRef]

- Tan, Y.; Wang, D. Structural behaviors of large underground earth-retaining systems in Shanghai. II: Multipropped rectangular diaphragm wall. J. Perform. Constr. Facil. 2015, 29, 04014059. [Google Scholar] [CrossRef]

- Xu, Q.; Xie, J.; Sun, Z.; Lu, L.; Yu, H. Stability Analysis of Trench Wall for Diaphragm Wall in Ultra-Deep Circular Foundation Pit: A Comprehensive Investigation. Appl. Sci. 2023, 13, 12037. [Google Scholar] [CrossRef]

- Teparaksa, J. Behavior and performance of a diaphragm wall for an underground automatic car park in Bangkok. Geomate J. 2024, 27, 85–94. [Google Scholar] [CrossRef]

- Xie, W.; Li, Y.; Wang, H.; Cao, W. A novel stability analysis method of diaphragm wall trench and its application. Geotech. Geol. Eng. 2023, 41, 1603–1613. [Google Scholar] [CrossRef]

- Xu, Q.; Xie, J.; Zhu, H.; Lu, L. Supporting behavior evolution of ultra-deep circular diaphragm walls during excavation: Monitoring and assessment methods comparison. Tunn. Undergr. Space Technol. 2024, 143, 105495. [Google Scholar] [CrossRef]

- Jasmine Nisha, J.; Muttharam, M. Deep excavation supported by diaphragm wall: A case study. Indian Geotech. J. 2017, 47, 373–383. [Google Scholar] [CrossRef]

- Cheng, Q.; Wu, J.; Song, Z.; Wen, H. The behavior of a rectangular closed diaphragm wall when used as a bridge foundation. Front. Struct. Civ. Eng. 2012, 6, 398–420. [Google Scholar] [CrossRef]

- Li, W.; Tao, Q.; Li, C.; Wang, X.; Gong, W.; Dai, G. In-situ experimental study of closed-diaphragm wall foundations for cross-sea suspension bridges. J. Mar. Sci. Eng. 2024, 12, 2304. [Google Scholar] [CrossRef]

- Wen, H.; Cheng, Q.; Meng, F.; Chen, X. Diaphragm wall-soil-cap interaction in rectangular-closed-diaphragm-wall bridge foundations. Front. Archit. Civ. Eng. China 2009, 3, 93–100. [Google Scholar] [CrossRef]

- Wu, J.-J.; Wang, L.-J.; Cheng, Q.-G. Soil arching effect of Lattice-Shaped Diaphragm Wall as bridge foundation. Front. Struct. Civ. Eng. 2017, 11, 446–454. [Google Scholar] [CrossRef]

- Li, C.; Ge, H.; Zhou, X. The Dongting lake bridge for an expressway in China: Design, construction and analysis. Struct. Eng. Int. 2022, 32, 291–297. [Google Scholar] [CrossRef]

- You, X.; Hu, W.; Peng, C.; Ma, C. Construction technology innovation of 2300-meter suspension bridge: New diaphragm wall and composite tower. In IABSE Symposium Istanbul 2023, Proceedings of the IABSE Symposium: Long Span Bridges, Istanbul, Turkey, 26–28 April 2023; International Association for Bridge and Structural Engineering (IABSE): Zurich, Switzerland, 2023. [Google Scholar] [CrossRef]

- Wu, J.; Hu, H.; Zhang, Y.; Pu, L.; Yin, J. Experimental investigation on the behavior of cyclic-laterally loaded lattice-shaped diaphragm wall in soft soil. Ocean Eng. 2024, 303, 117805. [Google Scholar] [CrossRef]

- Wu, J.; Pu, L. Py curve models for laterally loaded lattice-shaped diaphragm wall as sea-crossing bridge foundations. Appl. Ocean Res. 2025, 159, 104610. [Google Scholar] [CrossRef]

- Wu, J.; Xiao, L.; Yang, T.; Hu, H.; Pan, S. Cyclic Response and Bending Behavior of Lattice-Shaped Diaphragm Wall Foundations for Cross-Sea Bridges: A Follow-Up Laboratory Study. Geotech. Geol. Eng. 2025, 43, 257. [Google Scholar] [CrossRef]

- Du, G.; Xi, S.; Ling, C.; Shi, W.; Li, X.; Zhu, M.; Li, S. Experimental Study on the Horizontal Bearing Characteristic of a Strip-Walled Underground Diaphragm Wall. Buildings 2024, 14, 1637. [Google Scholar] [CrossRef]

- Lu, J.; Ren, L. Stability analysis and safety monitoring on anchorage foundation with building envelope of diaphragm wall. In Proceedings of the 2011 International Conference on Electric Technology and Civil Engineering (ICETCE), Lushan, China, 22–24 April 2011; IEEE: Piscataway, NJ, USA. [CrossRef]

- Wang, J.; Xiong, W.; Cai, C.S. Flexural performance of rigid joints for diaphragm walls: Experimental investigation and numerical analysis. Case Stud. Constr. Mater. 2024, 20, e02936. [Google Scholar] [CrossRef]

- Chen, J.-J.; Wang, J.-H.; Qiao, P.; Hou, Y.-M.; Gu, Q.-Y. Shear bearing of cross-plate joints between diaphragm wall panels–I: Model tests and shear behaviour. Mag. Concr. Res. 2016, 68, 902–915. [Google Scholar] [CrossRef]

- Teparaksa, W.; Teparaksa, J. Comparison of diaphragm wall movement prediction and field performance for different construction techniques. Undergr. Space 2019, 4, 225–234. [Google Scholar] [CrossRef]

- Yang, M.; Wu, R.; Tong, C.; Chen, J.; Tang, B. Displacement Analyses of Diaphragm Wall in Small-Scale Deep Excavation Considering Joints between Panels. Buildings 2024, 14, 1449. [Google Scholar] [CrossRef]

- Yang, M.; Tong, C.; Wu, R.; Wang, G.; Tong, S. A Simplified Multi-Linear Spring Model for Cross-Plate Joint in Diaphragm Walls Based on Model Tests. Buildings 2025, 15, 2890. [Google Scholar] [CrossRef]

- Li, K.; Yang, R.; Tu, W.; Hu, Q.; Kong, Q. Lateral bending behavior and calculation of perforated cross-plate joints in lattice-shaped diaphragm walls. Front. Earth Sci. 2025, 13, 1674671. [Google Scholar] [CrossRef]

- Lam, D.; El-Lobody, E. Behavior of headed stud shear connectors in composite beam. J. Struct. Eng. 2005, 131, 96–107. [Google Scholar] [CrossRef]

- Wang, Y.-H.; Yu, J.; Liu, J.-P.; Chen, Y.F. Shear behavior of shear stud groups in precast concrete decks. Eng. Struct. 2019, 187, 73–84. [Google Scholar] [CrossRef]

- Kruszewski, D.; Wille, K.; Zaghi, A.E. Push-out behavior of headed shear studs welded on thin plates and embedded in UHPC. Eng. Struct. 2018, 173, 429–441. [Google Scholar] [CrossRef]

| Joint Type | Shear Peak Load (kN) | Shear Peak Disp. (mm) | Initial Stiffness (KN/m) |

|---|---|---|---|

| New Joint | 485.3 | 17.37 | 44,614 |

| H-section Steel Joint | 46.8 | 3.52 | 22,571 |

| Joint Type | Tensile Peak Load (kN) | Tensile Peak Disp. (mm) | Initial Stiffness (KN/m) |

|---|---|---|---|

| New Joint | 47.41 | 7.02 | 8960 |

| H-section Steel Joint | 2.86 | 2.29 | 1249 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Zhang, Y.; Wang, C.; Hu, X. Development and Experimental Study of a Novel Diaphragm Wall Joint with Retractable Shear Studs. Buildings 2026, 16, 681. https://doi.org/10.3390/buildings16030681

Zhang Y, Wang C, Hu X. Development and Experimental Study of a Novel Diaphragm Wall Joint with Retractable Shear Studs. Buildings. 2026; 16(3):681. https://doi.org/10.3390/buildings16030681

Chicago/Turabian StyleZhang, Yue, Changjiang Wang, and Xiewen Hu. 2026. "Development and Experimental Study of a Novel Diaphragm Wall Joint with Retractable Shear Studs" Buildings 16, no. 3: 681. https://doi.org/10.3390/buildings16030681

APA StyleZhang, Y., Wang, C., & Hu, X. (2026). Development and Experimental Study of a Novel Diaphragm Wall Joint with Retractable Shear Studs. Buildings, 16(3), 681. https://doi.org/10.3390/buildings16030681