Influence of Flexural Testing Parameters on the Flexural Response of Ultra-High-Performance Concrete

Abstract

1. Introduction

2. Flexural Tensile Test Method for Fiber Reinforced Concrete

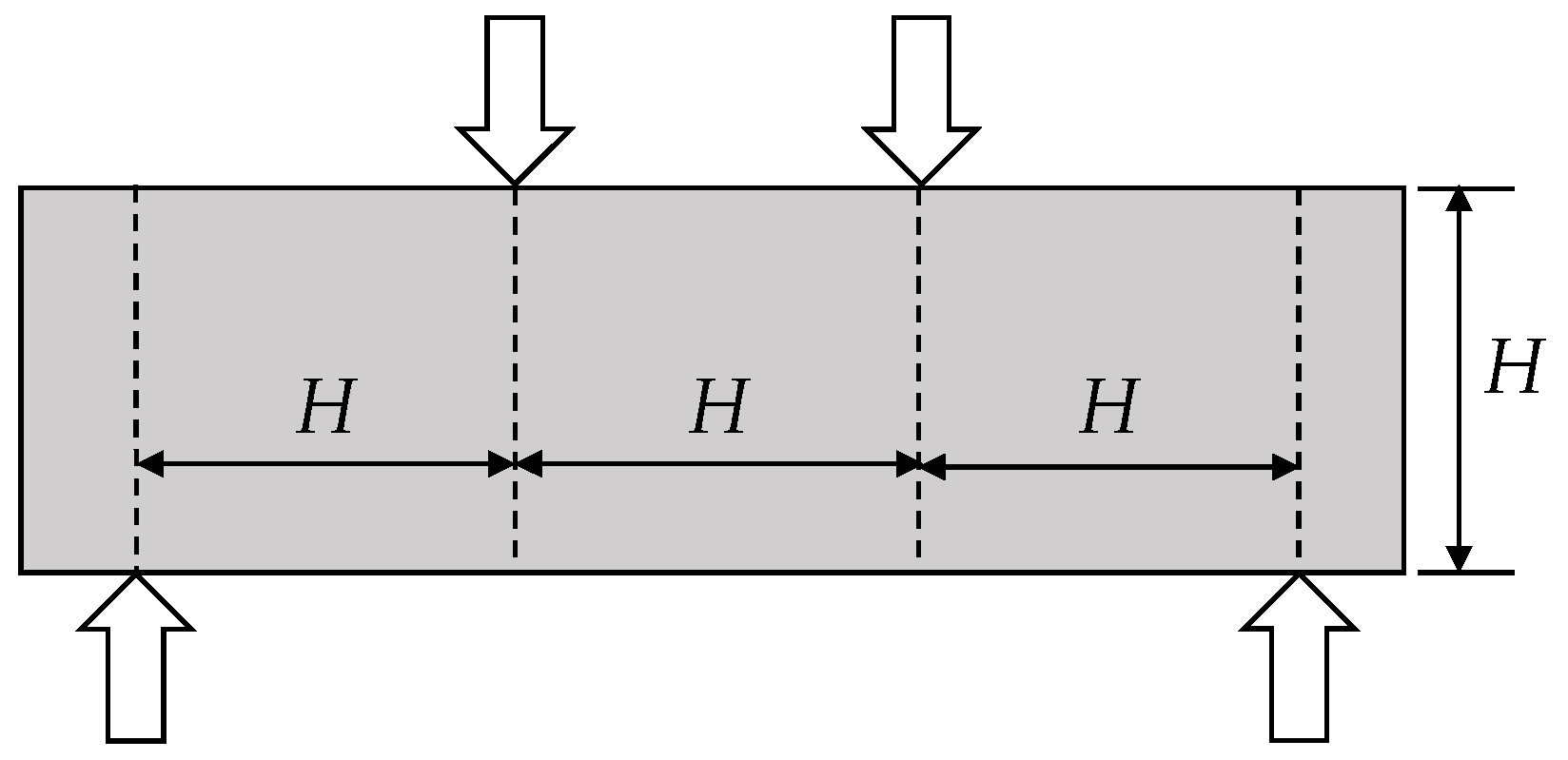

2.1. ASTM C 1609

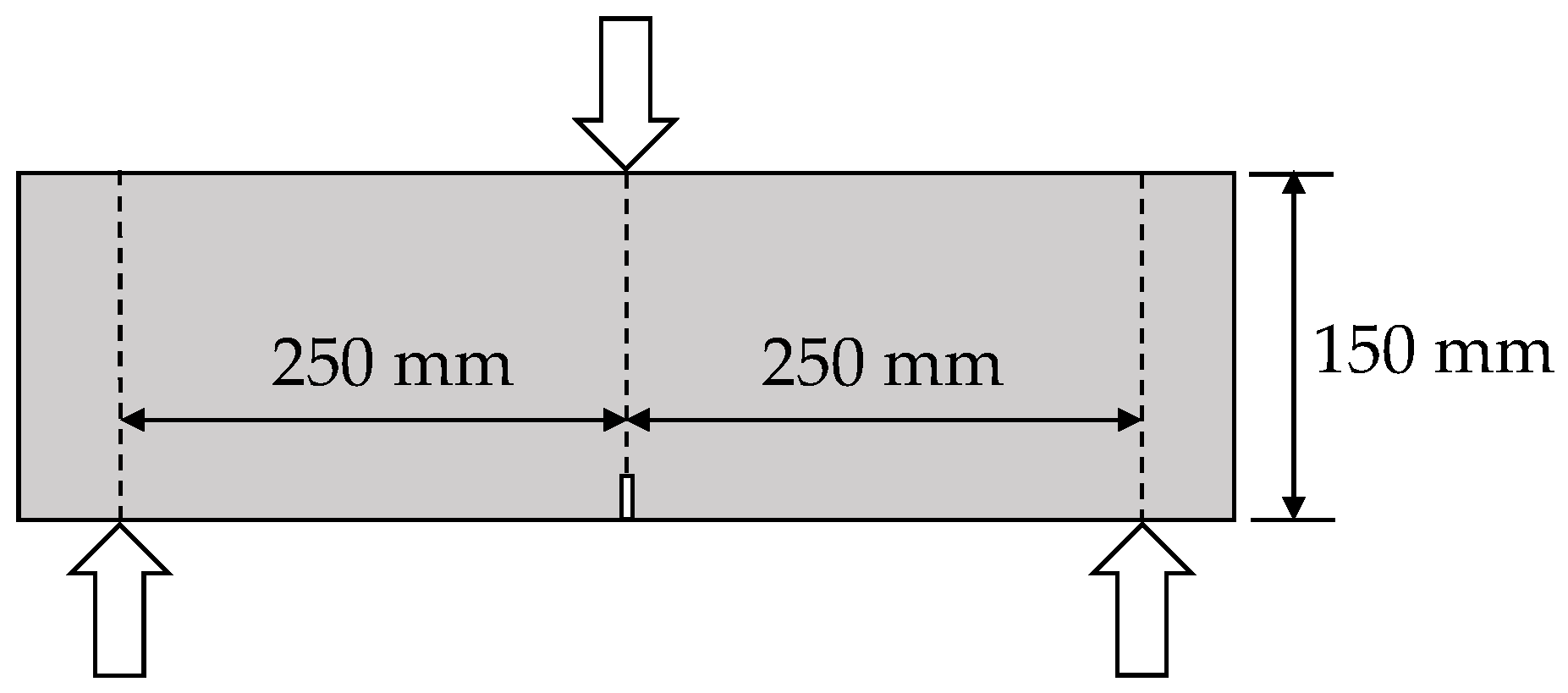

2.2. EN 14651

3. Experiments

3.1. Test Variables

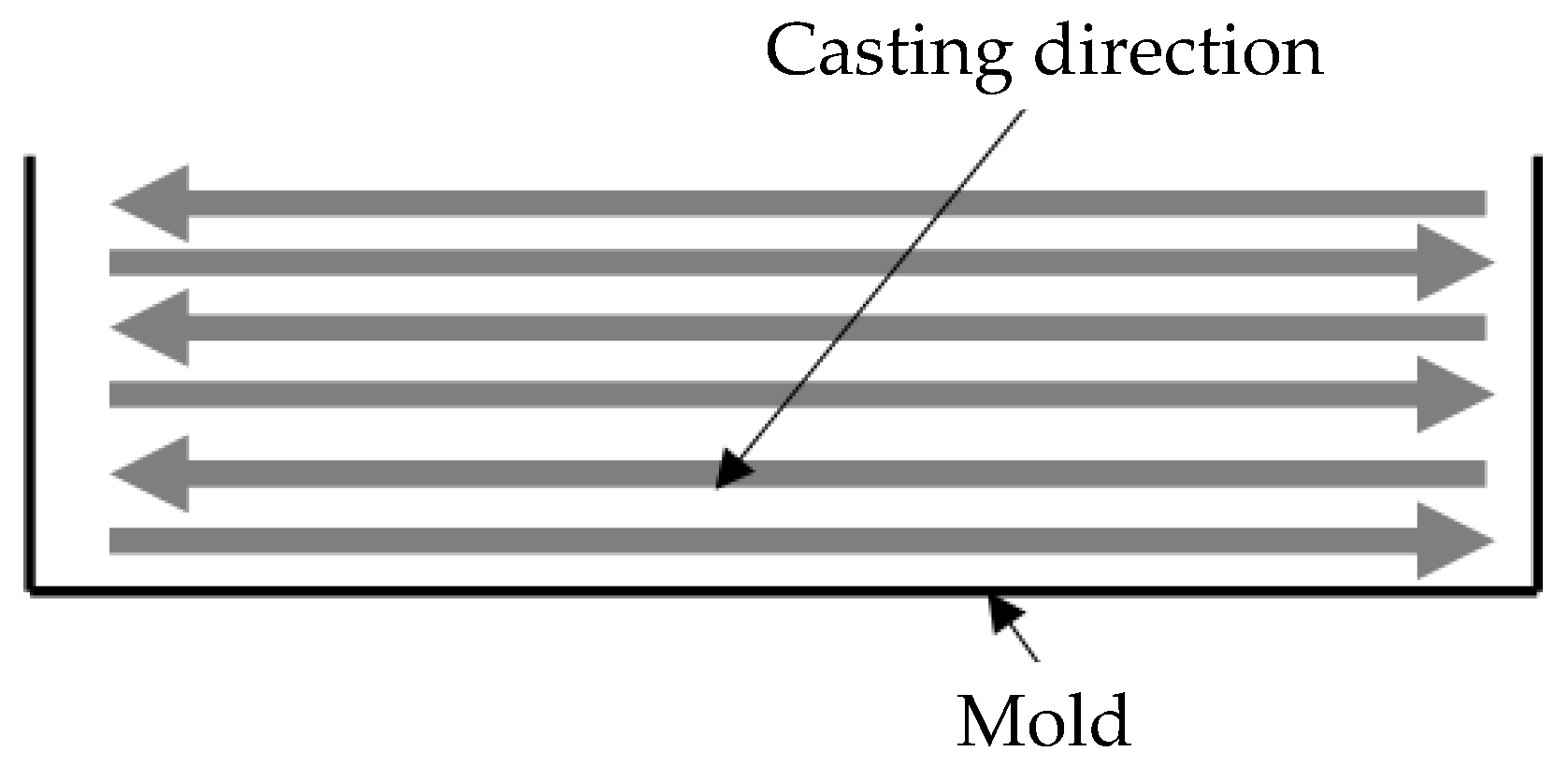

3.2. Materials and Specimen Preparation

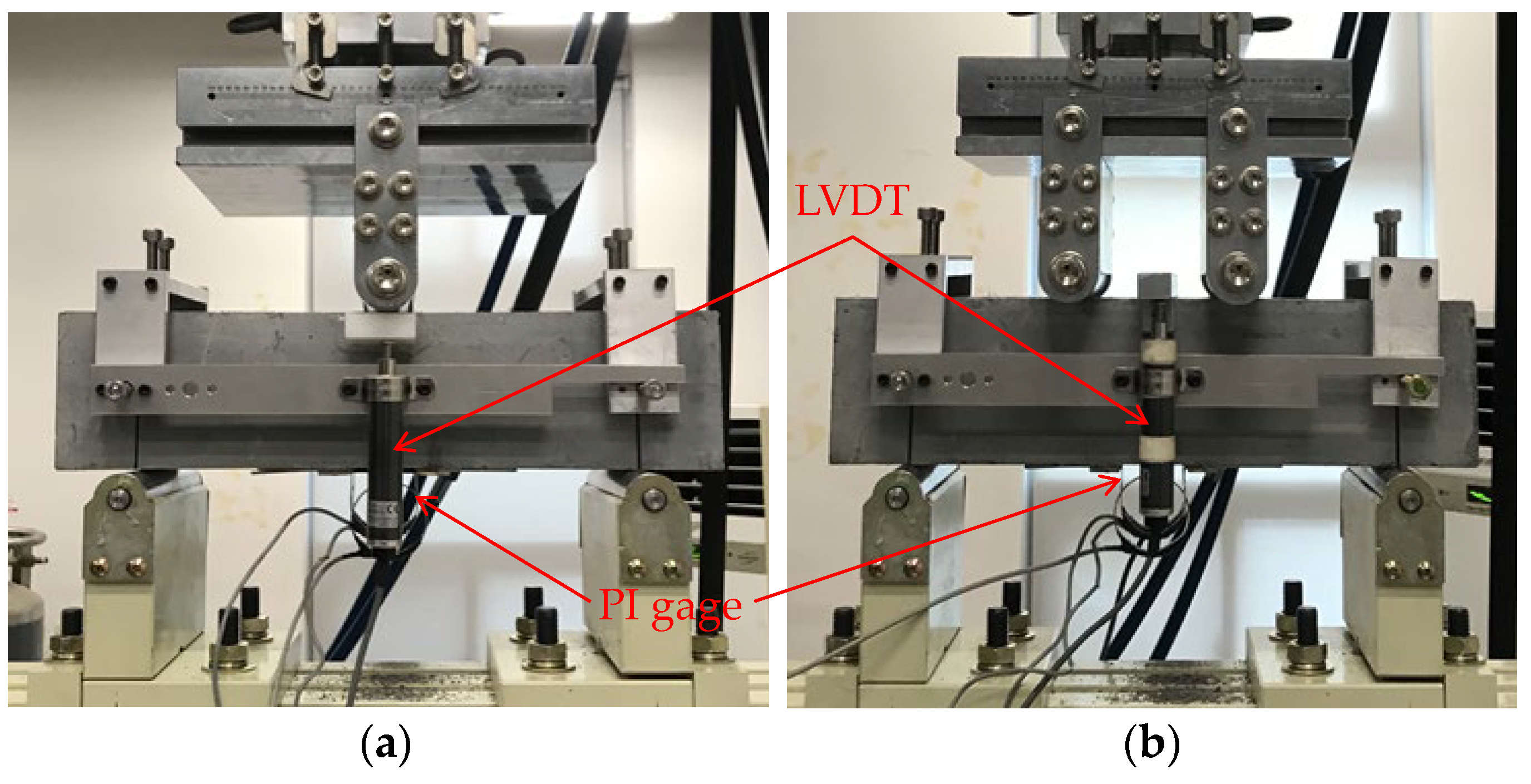

3.3. Testing Instrument and Method

4. Test Result and Discussion

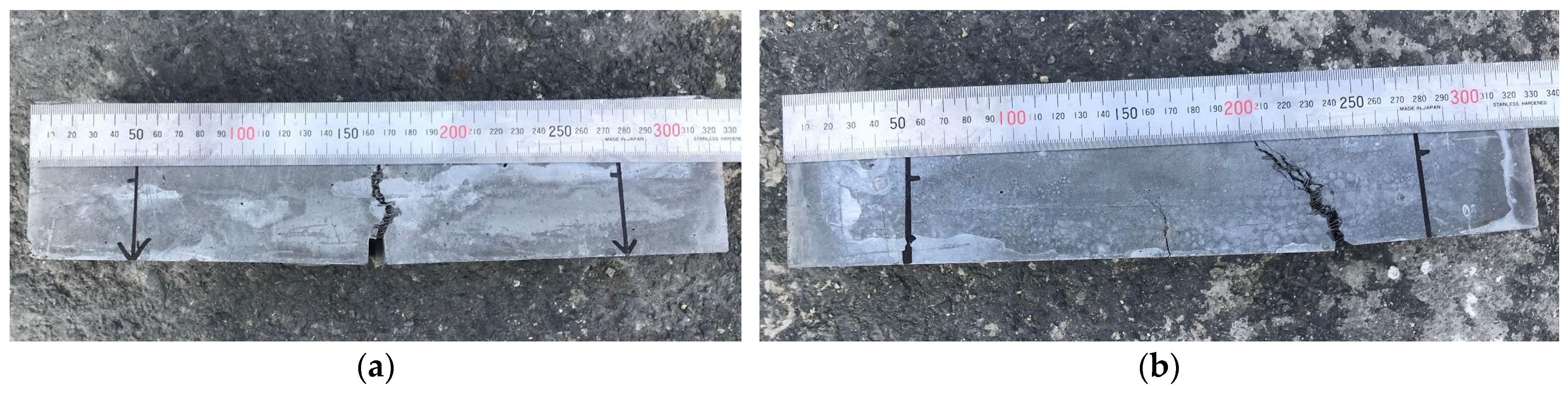

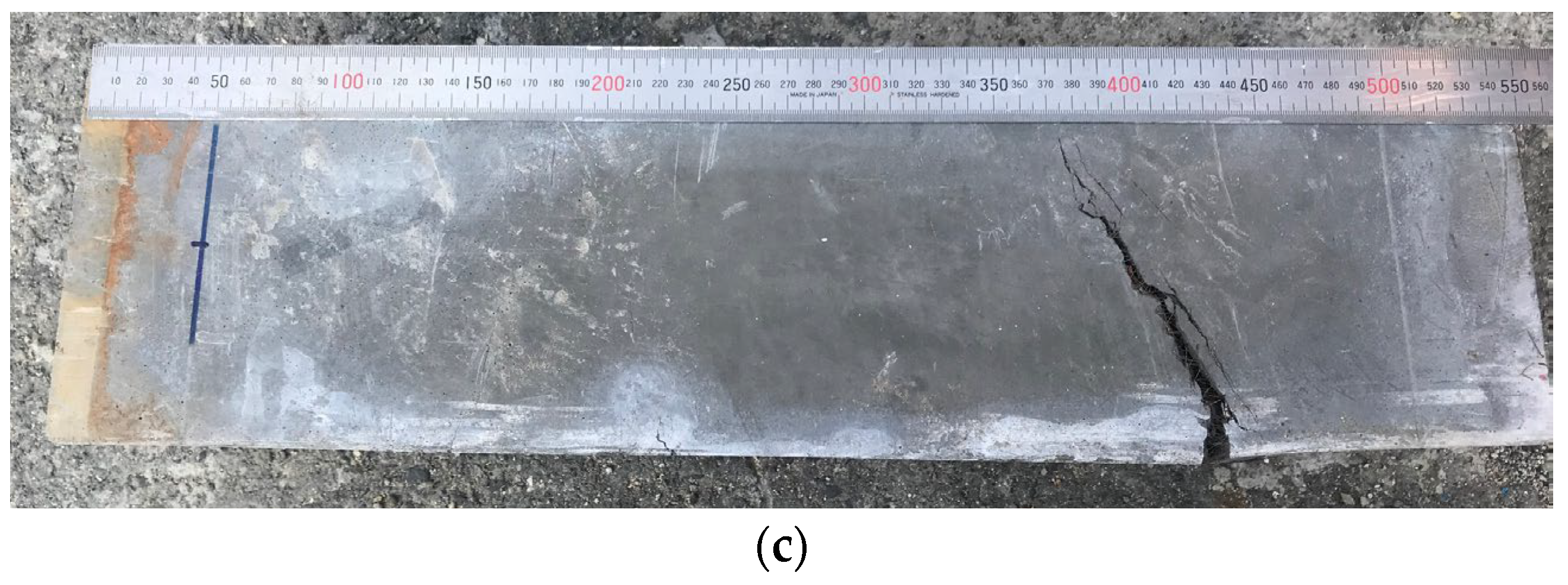

4.1. Effect of Notch Condition

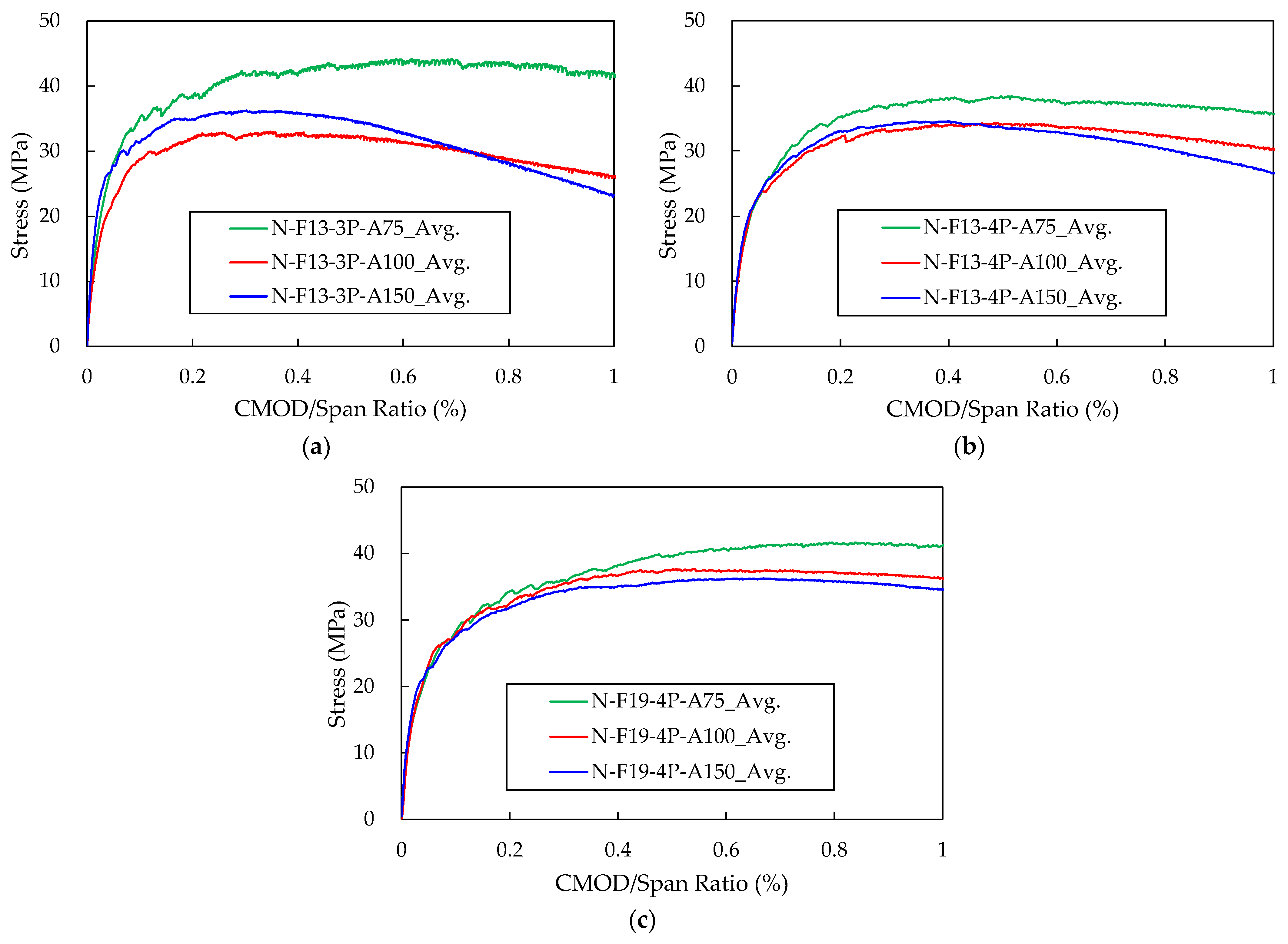

4.2. Effect of Specimen Size

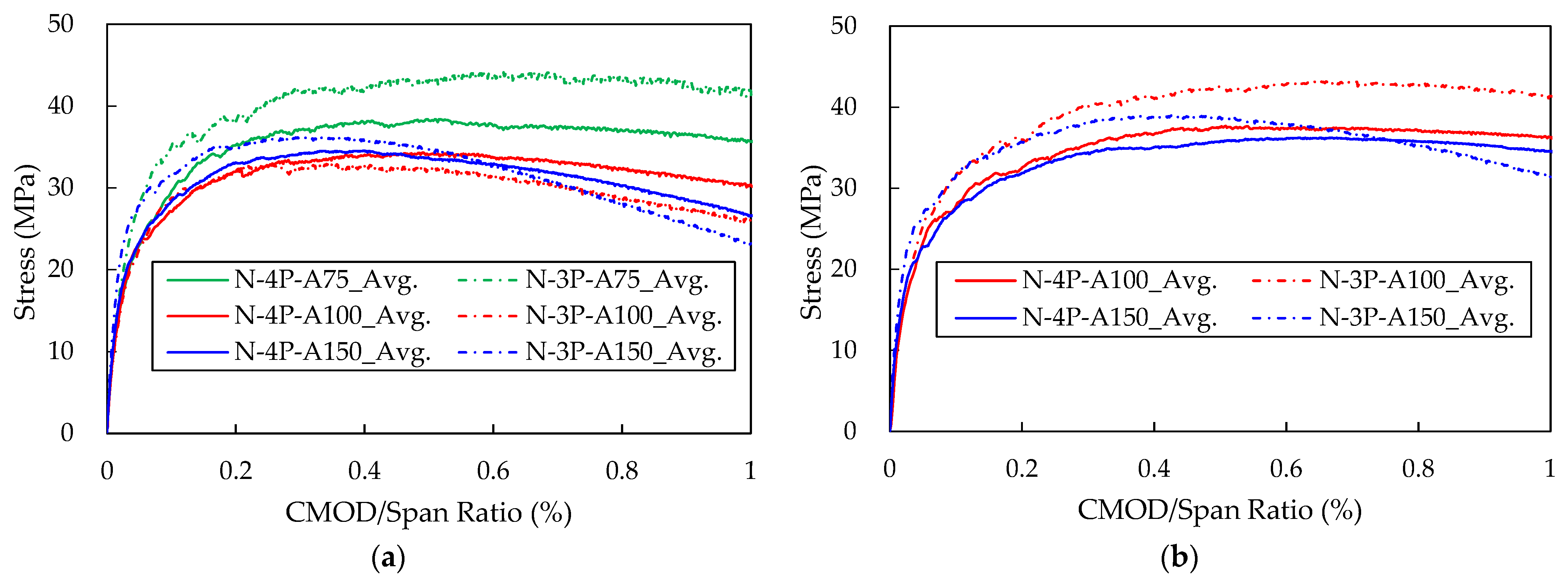

4.3. Effect of Loading Configuration

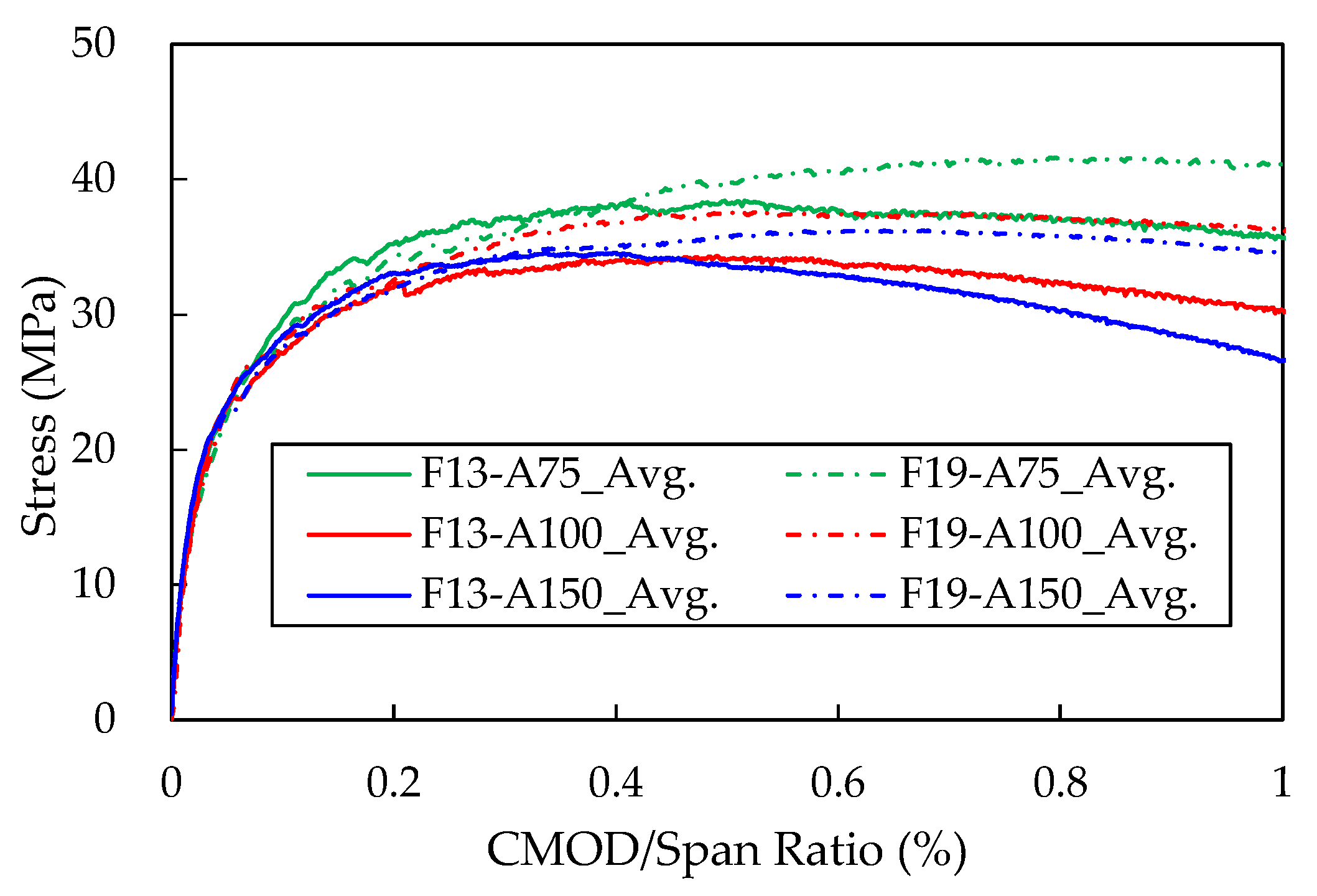

4.4. Effect of Fiber Length

5. Conclusions

- (1)

- The introduction of a notch led to consistent crack initiation and significantly reduced variability among specimens. The standard deviation of peak flexural stress for notched specimens was up to 8.4 times smaller than that of unnotched specimens.

- (2)

- Up to approximately 30% of unnotched specimens exhibited shear failure, with the likelihood increasing for smaller cross-sections (A75). This occurred because the high flexural resistance of UHPC delayed flexural cracking, allowing shear cracking to form first and develop into the governing failure mode. Consequently, the third-point loading test for unnotched beams is not suitable for evaluating the pure flexural performance of UHPC.

- (3)

- The 75 × 75 mm specimens exhibited overestimated flexural performance due to the fiber wall effect. The 100 × 100 mm and 150 × 150 mm specimens showed similar behavior at early cracking, but as CMOD increased, the larger specimens (A150) exhibited lower flexural strength due to a higher probability of internal flaws, confirming the presence of a size effect. The current ASTM C1856 recommendation that allows the use of 75 × 75 mm specimens for UHPC containing 13.0 mm fibers requires further review based on these findings.

- (4)

- Specimens tested under center-point loading (3P) exhibited up to 11.7% higher flexural tensile strength than those tested under third-point loading (4P). This was attributed to the simultaneous concentration of bending moment and shear force at the notch, which activated additional resistance mechanisms such as fiber bridging, friction, and aggregate interlock.

- (5)

- Specimens reinforced with longer fibers (F19) exhibited 5.2–9.7% higher flexural performance than those reinforced with shorter fibers (F13). This improvement is attributed to increased pullout resistance due to longer embedment length, enhanced crack dispersion, and greater energy absorption during fiber pullout.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mindess, S.; Young, J.F.; Darwin, D. Concrete; Prentice-Hall: Hoboken, NJ, USA, 2003. [Google Scholar]

- Zollo, R.F. Fiber-reinforced concrete: An overview after 30 years of research. Cem. Concr. Compos. 1997, 19, 107–122. [Google Scholar] [CrossRef]

- Hassan, H.Z.; Saeed, N.M. Fiber reinforced concrete: A state of the art. Innov. Infrastruct. Solut. 2024, 9, 171. [Google Scholar] [CrossRef]

- Banthia, N. Fiber-reinforced concrete in precast concrete applications: Research leads to innovative products. PCI J. 2012, 57, 33–46. [Google Scholar] [CrossRef]

- Richard, P.; Cheyrezy, M. Composition of reactive powder concretes. Cem. Concr. Res. 1995, 25, 1501–1511. [Google Scholar] [CrossRef]

- Graybeal, B.A. Structural Behavior of Ultra-High Performance Concrete Prestressed I-Girders; FHWA-HRT-06-115; Federal Highway Administration: Washington, DC, USA, 2006.

- Abbas, S.; Soliman, A.M.; Nehdi, M.L. Exploring mechanical and durability properties of ultra-high performance concrete incorporating various steel fiber lengths and dosages. Constr. Build. Mater. 2015, 75, 429–441. [Google Scholar] [CrossRef]

- Matiushin, E.; Sizyakov, I.; Shvetsova, V.; Soloviev, V. The effects of aggregate volume content and particle size on the properties of UHPC and UHPFRC. Buildings 2024, 14, 2891. [Google Scholar] [CrossRef]

- Graybeal, B.A. Material Property Characterization of Ultra-High Performance Concrete; FHWA-HRT-06-103; Federal Highway Administration: Washington, DC, USA, 2006.

- Wille, K.; Kim, D.J.; Naaman, A.E. Strain-hardening UHPFRC with low fiber contents. Mater. Struct. 2011, 44, 583–598. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Banthia, N. Mechanical properties of ultra-high-performance fiber-reinforced concrete: A review. Cem. Concr. Compos. 2016, 73, 267–280. [Google Scholar] [CrossRef]

- Charron, J.P.; Denarié, E.; Brühwiler, E. Permeability of ultra-high performance fiber reinforced concretes. Mater. Struct. 2007, 40, 469–476. [Google Scholar] [CrossRef]

- Kang, S.T.; Lee, Y.; Park, Y.D.; Kim, J.K. Tensile fracture properties of an Ultra High Performance Fiber Reinforced Concrete (UHPFRC) with steel fiber. Compos. Struct. 2010, 92, 61–71. [Google Scholar] [CrossRef]

- Sadaghian, H.; Pourbaba, M.; Andabili, S.Z..; Mirmiran, A. Experimental and numerical study of flexural properties in UHPFRC beams with and without an initial notch. Constr. Build. Mater. 2021, 268, 121196. [Google Scholar] [CrossRef]

- ASTM C 1856/C 1856M-17; Standard Practice for Fabricating and Testing Specimens of Ultra-High Performance Concrete. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM C 1609/C 1609M-19; Standard Test Method for Flexural Performance of Fiber-Reinforced Concrete (Using Beam with Third-Point Loading). ASTM International: West Conshohocken, PA, USA, 2019.

- BS EN 14651:2007; Test method for metallic Fibre Concrete—Measuring the Flexural Tensile Strength (Limit of Proportionality (LOP), Residual). British Standards Institution (BSI): London, UK, 2007.

- Wille, K.; Parra-Montesinos, G.J. Effect of beam size, casting method, and support conditions on flexural behavior of ultra high-performance fiber-reinforced concrete. ACI Mater. J. 2012, 109, 379–388. [Google Scholar] [CrossRef]

- KS F 2566; Standard Test Method for Flexural Performance of Fiber Reinforced Concrete. Korean Agency for Technology and Standards (KATS): Seoul, Republic of Korea, 2014.

- RILEM TC 162-TDF. Test and design methods for steel fibre reinforced concrete—Final recommendation. Mater. Struct. 2002, 35, 579–582. [Google Scholar]

- Teng, L.; Huang, H.; Du, J.; Khayat, K.H. Prediction of fiber orientation and flexural performance of UHPC based on suspending mortar rheology and casting method. Cem. Concr. Compos. 2021, 122, 104142. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Banthia, N.; Kang, S.T.; Yoon, Y.S. Effect of fiber orientation on the rate-dependent flexural behavior of ultra-high-performance fiber-reinforced concrete. Compos. Struct. 2016, 157, 62–70. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Kang, S.T.; Yoon, Y.S. Effect of fiber length and placement method on flexural behavior, tension-softening curve, and fiber distribution characteristics of UHPFRC. Constr. Build. Mater. 2014, 64, 67–81. [Google Scholar] [CrossRef]

- Kang, S.T. Comparison of flexural tensile strength according to the presence of notch and fiber content in ultra-high-performance cementitious composites. J. Korea Concr. Inst. 2012, 24, 525–533. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Banthia, N.; Kang, S.T.; Yoon, Y.S. Size effect in ultra-high-performance concrete beams. Eng. Fract. Mech. 2016, 157, 86–106. [Google Scholar] [CrossRef]

- Fládr, J.; Bílý, P. Specimen size effect on compressive and flexural strength of high-strength fibre-reinforced concrete containing coarse aggregate. Compos. Part B Eng. 2018, 138, 77–86. [Google Scholar] [CrossRef]

- Park, H.M.; Ryu, S.R.; Kwon, O.K.; Yang, J.M. Compressive creep test on fiber-reinforced ultra-high-performance concrete: Effects of strain measuring method, specimen size, sustained load intensity, and fiber length. Buildings 2024, 14, 2136. [Google Scholar] [CrossRef]

- Kang, S.T.; Ryu, G.S.; Koh, K.T.; Kim, S. Comparison of flexural tensile behaviors with different filling directions in producing UHPCC flexural members. KSCE J. Civ. Environ. Eng. Res. 2014, 34, 447–455. [Google Scholar] [CrossRef]

- Chen, H.J.; Chao, S.J.; Graybeal, B.A.; Zheng, W.; Yao, Y. Flexural behavior of ultra-high-performance fiber-reinforced concrete beams after exposure to high temperatures. Materials 2021, 14, 5400. [Google Scholar] [CrossRef] [PubMed]

- Grünewald, S. Performance-Based Design of Self-Compacting Fibre Reinforced Concrete. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2004; p. 233. [Google Scholar]

- Markovic, I. High-Performance Hybrid-Fibre Concrete—Development and Utilisation. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2006; p. 228. [Google Scholar]

- Lochan, P.P.; Polak, M.A. Evaluation of 3-point and 4-point bending tests for tensile strength assessment of GFRP bars. Materials 2024, 17, 5261. [Google Scholar] [CrossRef] [PubMed]

- Yoo, D.Y.; Yoon, Y.S. Structural performance of ultra-high-performance concrete beams with different steel fibers. Eng. Struct. 2015, 102, 409–423. [Google Scholar] [CrossRef]

- Wille, K.; Naaman, A.E.; Parra-Montesinos, G.J. Ultra-high performance concrete with compressive strength exceeding 150 MPa (22 ksi): A simpler way. ACI Mater. J. 2011, 108, 46–54. [Google Scholar] [CrossRef]

| Beam Size (mm) | Span Length, L (mm) | L/900 (mm) | Rate of Increase in Net Deflection (mm/min) | |

|---|---|---|---|---|

| Up to Net Deflection of L/900 | Beyond Net Deflection of L/900 | |||

| 100 × 100 × 350 | 300 | 0.33 | 0.025~0.075 | 0.05~0.20 |

| 150 × 150 × 500 | 450 | 0.50 | 0.035~0.100 | 0.05~0.30 |

| Beam Size (mm) | Span Length, L (mm) | Rate of Increase in CMOD (mm/min) | |

|---|---|---|---|

| Up to CMOD of 0.1 mm | Beyond CMOD of 0.1 mm | ||

| 150 × 150 × 550 | 500 | 0.05 | 0.20 |

| Variable | Description |

|---|---|

| Fiber length | 13.0 mm (F13)/19.5 mm (F19) |

| Loading method | Third-point loading (4P)/three-point loading (3P) |

| Notch condition | Notched (N)/Unnotched (UN) |

| Specimen cross-section geometry | 75 × 75 mm (A75)/100 × 100 mm (A100)/ 150 × 150 mm (A150) |

| Maximum Fiber Length (mm) | Specimen Cross Section |

|---|---|

| < 15 | 75 × 75 mm |

| 15 < < 20 | 100 × 100 mm |

| 20 < < 25 | 150 × 150 mm |

| 25 ≤ | 200 × 200 mm |

| Specimen Cross Section (mm) | Width of Notch (mm) | Depth of Notch (mm) |

|---|---|---|

| 75 × 75 mm | 5 | 12.5 |

| 100 × 100 mm | 5 | 16.7 |

| 150 × 150 mm | 5 | 25.0 |

| Diameter, df (mm) | Length, lf (mm) | Aspect Ratio (lf/df) | Tensile Strength (MPa) |

|---|---|---|---|

| 0.2 ± 0.01 | 13.0 | 65.0 | 2650 |

| 19.5 | 97.5 |

| W/B (%) | Unit Weight (kg/m3) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Water | Cement | Silica Fume | Sand | Filler | SF | HWRA | AFA | ASR | |

| 16.7 | 163.6 | 782.4 | 195.6 | 860.7 | 234.7 | 156.0 | 46.9 | 2.3 | 7.8 |

| Specimen Cross Section | Deflection Criterion for Changing the Loading Rate (mm) | Loading Rate (mm/min) | |

|---|---|---|---|

| Up to the Deflection Criterion | Beyond the Deflection Criterion | ||

| 75 × 75 mm | 0.333 | 0.06 | 0.12 |

| 100 × 100 mm | 0.500 | 0.07 | 0.14 |

| 150 × 150 mm | 0.600 | 0.08 | 0.21 |

| Specimen | F13-4P | F19-4P | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A75 | A100 | A150 | A75 | A100 | A150 | ||||||||

| UN | N | UN | N | UN | N | UN | N | UN | N | UN | N | ||

| Strength (MPa) | @ deflection of L/600 | 33.55 (4.74) | 35.56 (0.69) | 29.70 (4.65) | 32.05 (1.08) | 31.80 (0.74) | 33.10 (1.04) | 32.94 (2.80) | 33.87 (1.27) | 28.50 (0.30) | 33.74 (1.43) | 29.74 (0.60) | 33.06 (1.97) |

| @ deflection of L/150 | 35.90 (7.57) | 34.97 (0.90) | 26.48 (9.58) | 29.28 (2.38) | 22.53 (2.24) | 26.59 (2.58) | 48.34 (2.01) | 40.74 (1.83) | 35.92 (3.40) | 35.51 (2.17) | 39.43 (2.87) | 33.96 (2.35) | |

| Max. | 41.23 (4.74) | 38.82 (0.79) | 33.95 (10.58) | 34.50 (2.69) | 35.61 (2.49) | 34.64 (1.71) | 49.50 (1.61) | 41.91 (2.15) | 36.99 (3.02) | 37.84 (1.84) | 41.19 (2.06) | 36.44 (2.15) | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Woo, S.-J.; Park, I.-B.; Kim, D.-H.; Yang, J.-M. Influence of Flexural Testing Parameters on the Flexural Response of Ultra-High-Performance Concrete. Buildings 2026, 16, 319. https://doi.org/10.3390/buildings16020319

Woo S-J, Park I-B, Kim D-H, Yang J-M. Influence of Flexural Testing Parameters on the Flexural Response of Ultra-High-Performance Concrete. Buildings. 2026; 16(2):319. https://doi.org/10.3390/buildings16020319

Chicago/Turabian StyleWoo, Seong-Jin, In-Beom Park, Dong-Hyun Kim, and Jun-Mo Yang. 2026. "Influence of Flexural Testing Parameters on the Flexural Response of Ultra-High-Performance Concrete" Buildings 16, no. 2: 319. https://doi.org/10.3390/buildings16020319

APA StyleWoo, S.-J., Park, I.-B., Kim, D.-H., & Yang, J.-M. (2026). Influence of Flexural Testing Parameters on the Flexural Response of Ultra-High-Performance Concrete. Buildings, 16(2), 319. https://doi.org/10.3390/buildings16020319