Effects of Loading Conditions and Stirrup Arrangement on Corrosion-Induced Expansion Strain and Cracking in Reinforced Concrete Beams

Abstract

1. Introduction

2. Experiment Design

2.1. Materials and Design

2.2. Corrosion Experiment

2.2.1. Apply Sustained Load

2.2.2. Setting of Corrosive Environment

2.3. Measurement of Reinforcement Corrosion

3. Analysis and Discussion of Experiment Results

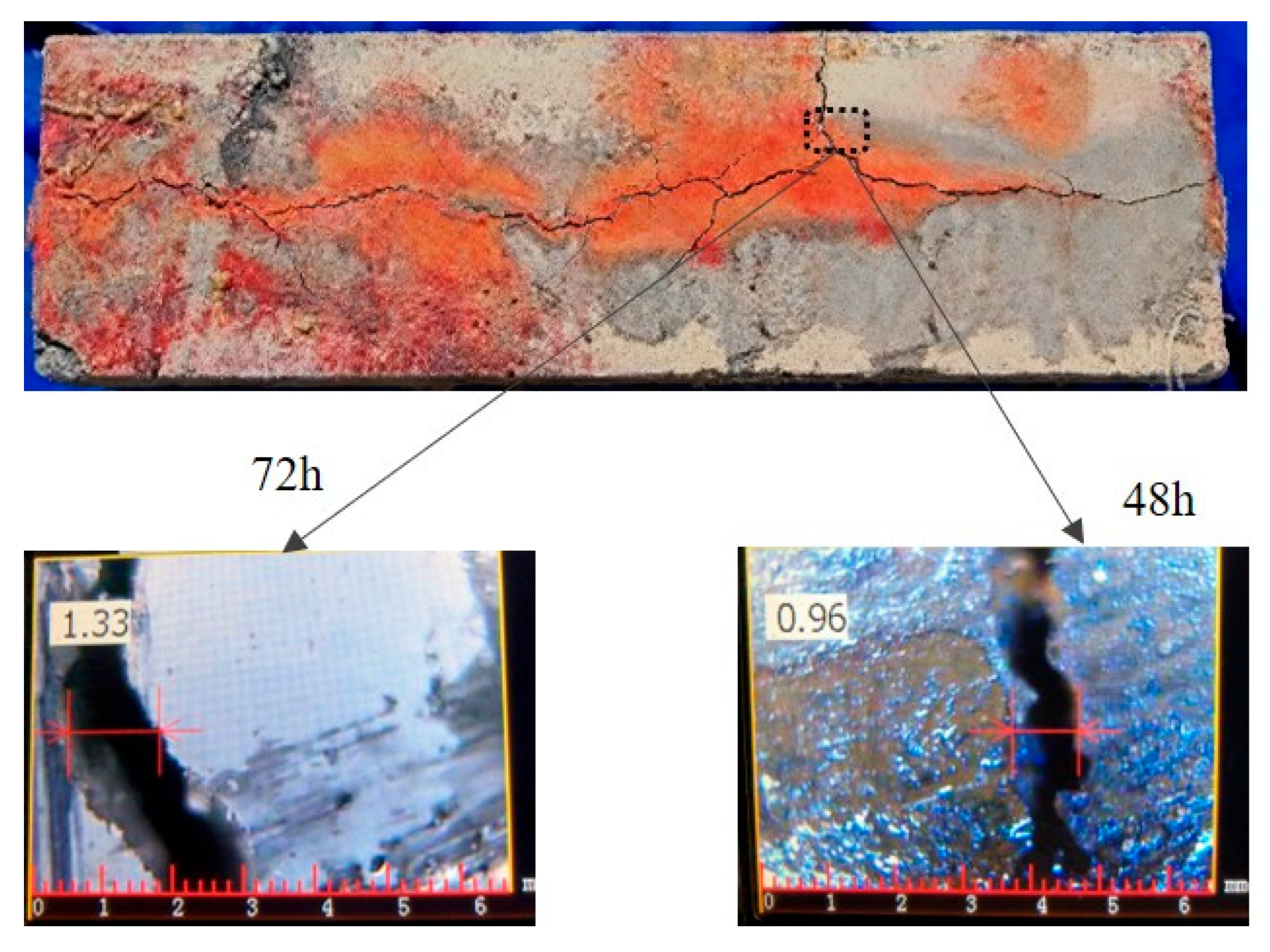

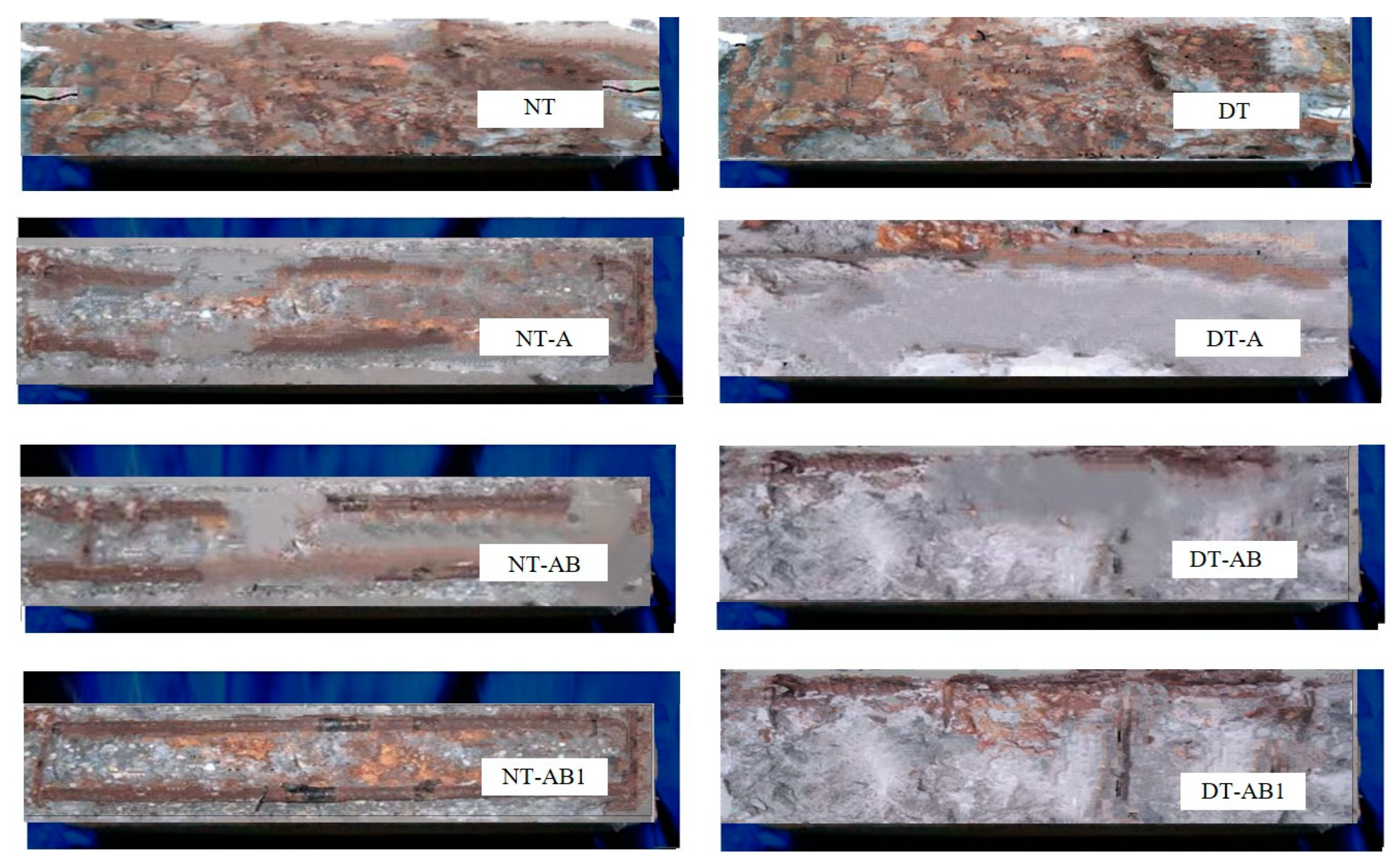

3.1. Distribution of Corrosion Propagation Cracks

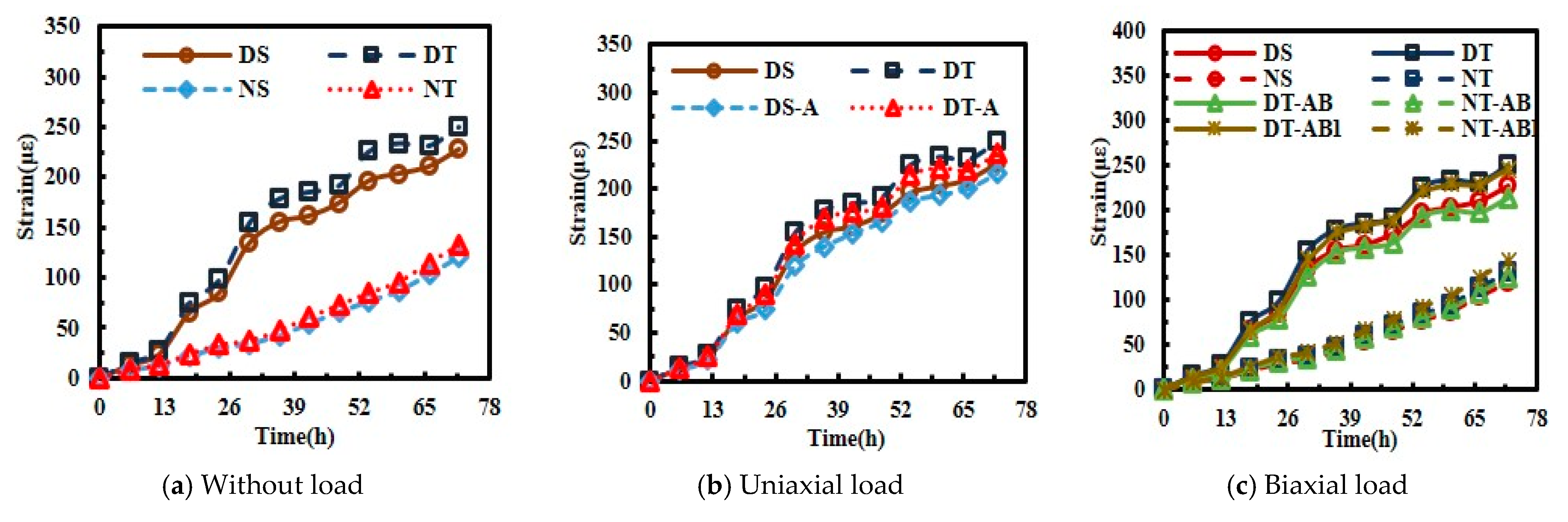

3.2. Concrete Expansion Strain

- (1)

- The cracks on the top surface of each beam were similar, with two longitudinal corrosion cracks of similar length extending beyond the electrode region.

- (2)

- The crack distribution on the sides of the beams was notably different. Longitudinal corrosion cracks appeared only on one side of the beams with normal stirrups, while transverse corrosion cracks were most prominent on the insulated beams and not visible on the beams with normal stirrups.

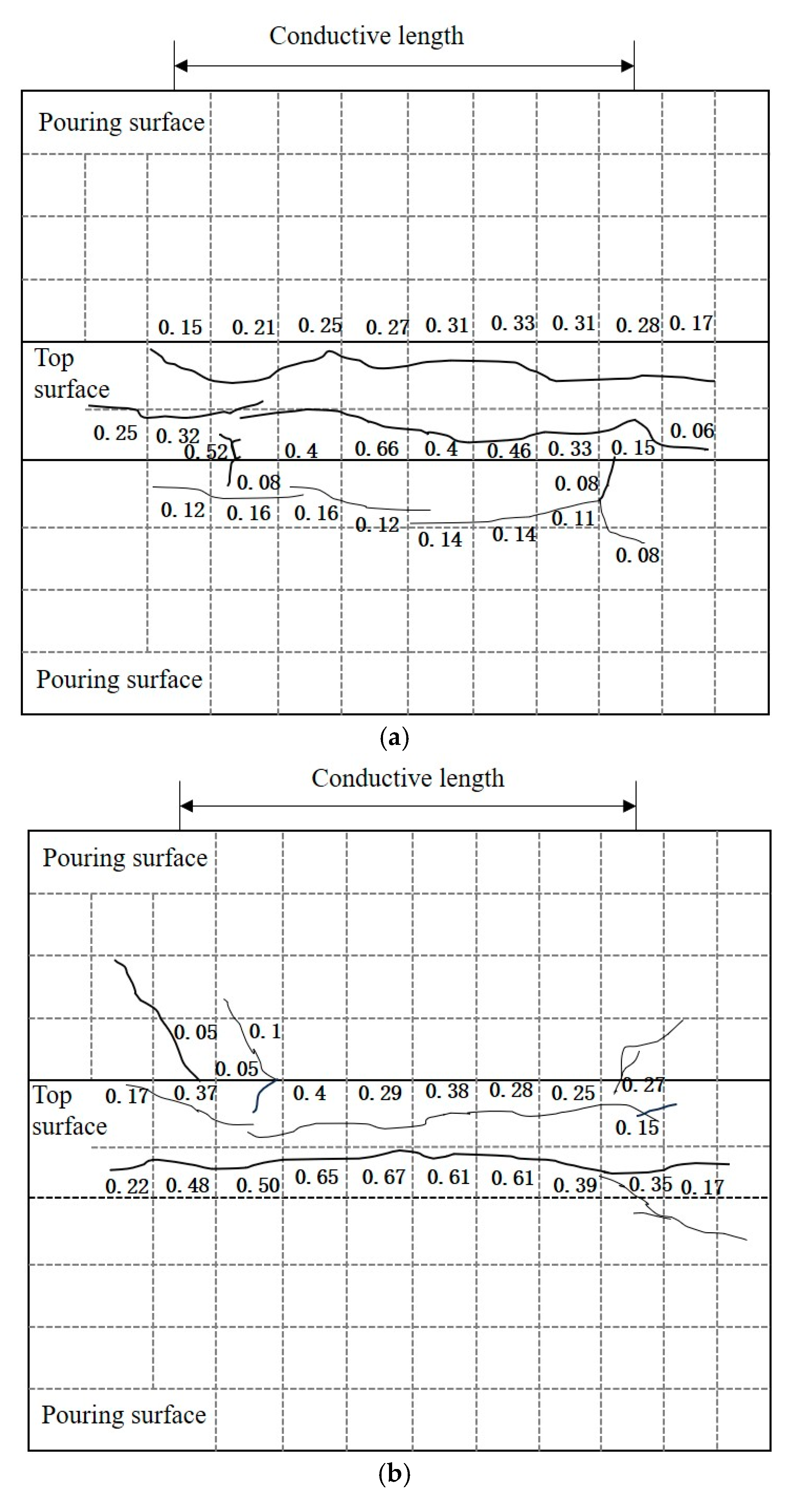

3.3. Delamination Characteristics of the Protective Layer

4. Conclusions

- (1)

- Under the same corrosion conditions, the expansion strain of specimens with normal stirrups was significantly higher than that of specimens without stirrups. Under uniaxial compressive loading, the expansion strain decreased compared to the no-load specimens. Under biaxial compressive loading at 15% of the compressive strength, the expansion strain of the concrete beams was minimal, indicating that the loading compaction effect suppressed crack propagation.

- (2)

- The load level had a significant impact on crack distribution and development. Under biaxial compressive loading, crack propagation was influenced by the Poisson effect, with cracks distributed in a staggered pattern between the compression and tension zones. When the load on one axis exceeded 15% of the compressive strength, the corrosion cracks increased significantly.

- (3)

- Under no load and uniaxial loading conditions, spalling of the protective layer primarily manifested as localized cracks and linear delamination. Under biaxial loading, the Poisson effect intensified tensile deformation in the vertical direction, causing cracks to quickly propagate and the spalling depth and area to increase significantly. In specimens without stirrups, the protective layer spalling was more severe, indicating that stirrups had a significant inhibiting effect on protective layer degradation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Marcotte, T.D.; Hansson, C.M. Corrosion products that form on steel within cement paste. Mater. Struct. 2007, 40, 325–340. [Google Scholar] [CrossRef]

- Peng, J.X.; Cheng, X.K.; Yang, Y.M.; Xiao, J.Y. Chloride transport in concrete subjected to multiple cracks under drying-wetting cycles. Constr. Build. Mater. 2025, 470, 140559. [Google Scholar] [CrossRef]

- Berrocal, C.G.; Fernandez, I.; Rempling, R. The interplay between corrosion and cracks in reinforced concrete beams with non-uniform reinforcement corrosion. Mater. Struct. 2022, 55, 120. [Google Scholar] [CrossRef]

- Zhang, J.; Li, J.; Zhao, Y.; Wang, S.; Guan, Z. Concrete cover cracking and reinforcement corrosion behavior in concrete with new-to-old concrete interfaces. Materials 2023, 16, 5969. [Google Scholar] [CrossRef]

- Agboola, O.; Kupolati, K.W.; Fayomi, O.S.I.; Omoniyi Ayeni, A.O.; Ayodeji, A.; Akinmolayemi, J.J.; Oladokun Olagoke, O.; Sadiku, R.; Oluwasegun, K.M. A review on corrosion in concrete structure: Inhibiting admixtures and their compatibility in concrete. J. Bio-Tribo-Corros. 2022, 8, 25. [Google Scholar] [CrossRef]

- Taheri-Shakib, J.; Al-Mayah, A. Dynamics of localized accelerated corrosion in reinforced concrete: Voids, corrosion products, and crack formation. Ceram. Int. 2024, 50, 48755–48767. [Google Scholar] [CrossRef]

- Cheng, X.K.; Mu, Q.J.; Peng, J.X.; Yang, Y.M. Chloride transport in concrete on the side of anchorage zone under drying-wetting cycles. Constr. Build. Mater. 2025, 498, 143869. [Google Scholar] [CrossRef]

- Ali, M.; Shams, M.A.; Bheel, N.; Almaliki, A.H.; Mahmoud, A.S.; Dodo, Y.A.; Benjeddou, O. A review on chloride induced corrosion in reinforced concrete structures: Lab and in situ investigation. RSC Adv. 2024, 14, 37252–37271. [Google Scholar] [CrossRef]

- Bajić, P.; Leporace-Guimil, B.; Andrade, C.; Tošić, N.; de la Fuente, A. Chloride-induced corrosion effects on the structural performance of concrete with rebar and fibres: A Review. Appl. Sci. 2025, 15, 6457. [Google Scholar] [CrossRef]

- He, S.Q.; Cao, Z.Y.; Liu, W.J.; Zhang, Y.; Shang, F. Experimental study on long-term performance of reinforced concrete beams under a sustained load in a corrosive environment. Constr. Build. Mater. 2020, 234, 117288. [Google Scholar] [CrossRef]

- Zhang, W.L.; François, R.; Wang, R.Y.; Cai, Y.X.; Yu, L.W. Corrosion behavior of stirrups in corroded concrete beams exposed to chloride environment under sustained loading. Constr. Build. Mater. 2021, 274, 121987. [Google Scholar] [CrossRef]

- Imperatore, S.; Rinaldi, Z.; Spagnuolo, S. Experimental investigations on the effects of the steel rebar corrosion at structural level. Struct. Concr. 2019, 20, 2230–2241. [Google Scholar] [CrossRef]

- Hariche, L.; Ballim, Y.; Bouhicha, M.; Kenai, S. Effects of reinforcement configuration and sustained load on the behaviour of reinforced concrete beams affected by reinforcing steel corrosion. Cem. Concr. Compos. 2012, 34, 1202–1209. [Google Scholar] [CrossRef]

- Shen, J.; Gao, X.; Li, B.; Du, K.; Jin, R.Y. Damage evolution of RC beams under simultaneous reinforcement corrosion and sustained load. Materials 2019, 12, 627. [Google Scholar] [CrossRef]

- Tarighat, A.; Zehtab, B. Structural reliability of reinforced concrete beams/columns under simultaneous static loads and steel reinforcement corrosion. Arab. J. Sci. Eng. 2016, 41, 3945–3958. [Google Scholar] [CrossRef]

- Cheng, X.K.; Peng, J.X.; Cai, C.S.; Zhang, J.R. Experimental study on chloride ion diffusion in concrete under uniaxial and biaxial sustained stress. Materials 2020, 13, 5717. [Google Scholar] [CrossRef] [PubMed]

- Korec, E.; Jirásek, M.; Wong, H.S.; Martínez-Pañeda, E. Unravelling the interplay between steel rebar corrosion rate and corrosion-induced cracking of reinforced concrete. Cem. Concr. Res. 2024, 186, 107647. [Google Scholar] [CrossRef]

- Matthews, B.; Palermo, A.; Scott, A. Impact of artificial corrosion technique under variable acceleration on morphological efficacy in reinforced concrete elements. J. Mater. Civ. Eng. 2025, 37, 04024520. [Google Scholar] [CrossRef]

- Alhede, A.; Dijkstra, J.; Tengattini, A.; Lundgren, K. Characterisation of steel corrosion and matrix damage in reinforced mortar combining analytical, electrical and image-based techniques. Cem. Concr. Res. 2025, 190, 107792. [Google Scholar] [CrossRef]

- Ferenc, T.; Wojtczak, E.; Meronk, B.; Rucka, M. Characterization of corrosion in reinforced concrete beams using destructive and non-destructive tests. Case Stud. Constr. Mater. 2024, 20, e03309. [Google Scholar] [CrossRef]

- Hashim, A.A.; Anaee, R.; Nasr, M.S.; Shubbar, A. Mechanical properties, corrosion resistance and microstructural analysis of recycled aggregate concrete made with ceramic wall waste and ultrafine ceria. J. Mater. Res. Technol. 2025, 36, 627–640. [Google Scholar] [CrossRef]

- Zhao, P.; Xu, G.; Wang, Q.; Zhao, J. Influence of stirrup arrangements on the corrosion characteristics of reinforced concrete members. Constr. Build. Mater. 2018, 192, 683–695. [Google Scholar] [CrossRef]

- JTS/T 236-2019; Technical Specification for Concrete Testing of Port and Waterway Engineering. China Architecture & Building Press: Beijing, China, 2019.

- Andisheh, K.; Scott, A.; Palermo, A. Effects of corrosion on stress–Strain behavior of confined concrete. J. Struct. Eng. 2021, 147, 04021087. [Google Scholar] [CrossRef]

- Ying, J.W.; Deng, C.Y.; Qian, S.T.; Chen, B.X. Effect of water-to-binder ratio on chloride ion diffusion in concrete under continuous biaxial compression. Constr. Build. Mater. 2024, 416, 135308. [Google Scholar] [CrossRef]

- Ying, J.W.; Wang, W.B.; Xiao, J.Z. Chloride diffusion in concrete with carbonated recycled coarse aggregates under biaxial compression. Front. Struct. Civ. Eng. 2023, 17, 637–648. [Google Scholar] [CrossRef]

- Askar, M.K.; Al-Kamaki, Y.S.; Ferhadi, R.; Majeed, H.K. Cracks in concrete structures causes and treatments: A review. J. Duhok Univ. 2023, 26, 148–165. [Google Scholar] [CrossRef]

- Zhang, X.H.; Zhang, Y.; Liu, B.; Liu, B.W.; Wu, W.P.; Yang, C.Q. Corrosion-induced spalling of concrete cover and its effects on shear strength of RC beams. Eng. Fail. Anal. 2021, 127, 105538. [Google Scholar] [CrossRef]

- Goharrokhi, A.; Ahmadi, J.; Shayanfar, M.A.; Ghanooni-Bagha, M.; Nasserasadi, K. Effect of transverse reinforcement corrosion on compressive strength reduction of stirrup-confined concrete: An experimental study. Sādhanā 2020, 45, 49. [Google Scholar] [CrossRef]

- Zhang, X.; Zheng, S.S.; Ruan, S.; Yuan, J.W.; Li, C.-L.; Hu, J.-H. State-of-the-art review on the uniaxial compressive properties of corroded stirrup-confined concrete. J. Build. Eng. 2025, 112, 113854. [Google Scholar] [CrossRef]

- Li, Q.; Dong, Z.; He, Q.; Fu, C.Q.; Jin, X.Y. Effects of reinforcement corrosion and sustained load on mechanical behavior of reinforced concrete columns. Materials 2022, 15, 3590. [Google Scholar] [CrossRef]

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | TiO2 | K2O | Loss on Ignition | |

|---|---|---|---|---|---|---|---|---|---|

| Chemical composition (%) | 21.46 | 6.43 | 4.57 | 61.25 | 1.46 | 1.74 | 0.22 | 0.35 | 2.52 |

| Water | Cement | Natural Fine Aggregate | Natural Coarse Aggregate |

|---|---|---|---|

| 180 | 450 | 566.4 | 1203.6 |

| Specimens | Corrosion Time (d) | Load Level in x-Direction | Load Level in y-Direction |

|---|---|---|---|

| DS | 25 | 0 | 0 |

| DT | 25 | 0 | 0 |

| NS | 25 | 0 | 0 |

| NT | 25 | 0 | 0 |

| DS-A | 25 | 15% | 0 |

| DT-A | 25 | 15% | 0 |

| DT-AB | 25 | 15% | 15% |

| NT-AB | 25 | 15% | 15% |

| DT-AB1 | 25 | 15% | 30% |

| NT-AB1 | 25 | 15% | 30% |

| Specimens | Average Corrosion Rate of Longitudinal Reinforcement (%) | Average Corrosion Rate of Stirrups (%) | Total Quality of Corrosion (g) | |||

|---|---|---|---|---|---|---|

| n | s | n | s | n | s | |

| DS | 1.38 | 0.14 | 4.11 | 0.17 | 21.03 | 1.15 |

| DT | 1.47 | 0.18 | 4.21 | 0.21 | 21.45 | 0.82 |

| NS | 2.38 | 0.16 | - | - | 19.43 | 1.34 |

| NT | 2.54 | 0.22 | - | - | 19.62 | 1.22 |

| DS-A | 1.33 | 0.13 | 3.87 | 0.25 | 20.52 | 0.67 |

| DT-A | 1.42 | 0.25 | 3.97 | 0.24 | 21.27 | 1.06 |

| DT-AB | 1.28 | 0.11 | 3.48 | 0.26 | 19.73 | 1.35 |

| NT-AB | 2.39 | 0.17 | - | - | 19.25 | 1.12 |

| DT-AB1 | 1.46 | 0.25 | 4.18 | 0.19 | 20.93 | 0.73 |

| NT-AB1 | 2.51 | 0.18 | - | 19.53 | 1.45 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Ma, W.; Zhou, Y.; Yang, J.; Hu, T.; Li, X. Effects of Loading Conditions and Stirrup Arrangement on Corrosion-Induced Expansion Strain and Cracking in Reinforced Concrete Beams. Buildings 2026, 16, 52. https://doi.org/10.3390/buildings16010052

Ma W, Zhou Y, Yang J, Hu T, Li X. Effects of Loading Conditions and Stirrup Arrangement on Corrosion-Induced Expansion Strain and Cracking in Reinforced Concrete Beams. Buildings. 2026; 16(1):52. https://doi.org/10.3390/buildings16010052

Chicago/Turabian StyleMa, Wenqi, Yingxin Zhou, Jianyu Yang, Tao Hu, and Xiang Li. 2026. "Effects of Loading Conditions and Stirrup Arrangement on Corrosion-Induced Expansion Strain and Cracking in Reinforced Concrete Beams" Buildings 16, no. 1: 52. https://doi.org/10.3390/buildings16010052

APA StyleMa, W., Zhou, Y., Yang, J., Hu, T., & Li, X. (2026). Effects of Loading Conditions and Stirrup Arrangement on Corrosion-Induced Expansion Strain and Cracking in Reinforced Concrete Beams. Buildings, 16(1), 52. https://doi.org/10.3390/buildings16010052