1. Introduction

Due to its excellent compressive strength, remarkable durability, and economic efficiency, cement concrete has gradually emerged as one of the most commonly utilized materials in the construction of highways, bridges, and various infrastructure projects. Its performance is directly linked to the safety, durability, and economic benefits of buildings. Nevertheless, in real-world engineering conditions, especially in the northeastern regions of China, cement concrete faces the dual challenges of temperature differential cycling and freeze–thaw cycling. It is widely recognized that freeze–thaw cycles are among the primary factors compromising the durability of cement concrete structures in cold climates. This process, by altering the state of water in the concrete’s pores and causing changes in the volume of pore water, generates internal stresses, subsequently deteriorating the concrete’s performance. Additionally, due to the various components within concrete and their differing thermal properties, uneven deformation under temperature cycles leads to the generation of thermal stresses and the formation and development of internal microcracks, adversely affecting the concrete’s performance. Such effects are particularly pronounced in regions with large diurnal temperature fluctuations, where the impact on the long-term durability of concrete structures becomes even more critical. Although numerous studies have investigated the effects of either freeze–thaw cycling or temperature differential cycling on concrete performance, systematic research on their combined action remains limited. In practice, these two environmental factors often occur simultaneously, and their coupling may lead to more complex and severe damage mechanisms. Therefore, understanding the performance evolution of concrete under the combined effects of temperature differential and freeze–thaw cycles is of critical importance for improving the durability of structures operating in extreme climatic conditions.

Extensive research, both domestically and internationally, has been conducted on the durability of concrete under freeze–thaw cycles. Beginning in the 1940s, numerous hypotheses, such as hydrostatic pressure theory and osmotic pressure theory, have been proposed to elucidate the underlying mechanisms responsible for freeze–thaw-induced deterioration [

1,

2,

3,

4,

5,

6,

7]. Shi [

8] examined how freeze–thaw cycles influence the mechanical properties of concrete, concluding that compressive strength, tensile strength, shear strength, and elastic modulus all degrade to varying degrees with increased freeze–thaw cycling. Additionally, Shang et al. [

9,

10], through experimental investigations, observed significant reductions in concrete’s uniaxial compressive and tensile strengths post freeze–thaw cycling, accompanied by increases in peak strain on the stress–strain curves and notable declines in deformation modulus. Cho [

11] studied the relationships among key parameters of cement concrete (such as water–cement ratio, air content, and number of freeze–thaw cycles) and proposed a new prediction method—the Response Surface Method (RSM)—to predict the cumulative damage of cement concrete under the freeze–thaw cycle, which was validated through experiments. Vesikarr et al. [

12] investigated the relationship between freeze–thaw damage in concrete and the frequency of rapid freeze–thaw cycles, subsequently developing a predictive equation for estimating the service life of concrete structures subjected to a predetermined number of freeze–thaw cycles. Guan et al. [

13,

14] proposed a universal multivariate model for predicting the fatigue life of cement concrete under different boundary conditions and single- or multiple-factor compound actions, which was validated through rapid freeze–thaw tests and combined action tests of ammonium sulfate and freeze–thaw cycles. Ou et al. [

15] conducted research on the fatigue life and associated characteristics of concrete beams under varying degrees of freeze–thaw deterioration. Their findings demonstrated that the flexural fatigue life can be accurately characterized by a Weibull distribution, with reliability decreasing significantly as the freeze–thaw cycles accumulate. Boyd et al. [

16] investigated the fatigue life of concrete with varying degrees of freeze–thaw damage. Their findings revealed that freeze–thaw damage led to a certain level of degradation in the fatigue performance of concrete. However, during the early stages of damage, the freeze–thaw cycles had little impact on the ultimate tensile load capacity of the concrete. H. Kuosa et al. [

17] studied the degradation mechanisms of concrete under the combined effects of freeze–thaw cycling, carbonation, and chloride ion penetration. The results indicated that freeze–thaw damage can increase the carbonation depth and exacerbate chloride ion migration in concretes with higher water–cement ratios, thereby reducing the overall service life of the material. In summary, existing research shows that freeze–thaw cycles have a significant deteriorating effect on the mechanical properties of concrete; hence, the study of concrete’s frost resistance is of utmost importance.

In recent years, increasing research interest has focused on the impact of temperature differential cycling on concrete performance. Al-Tayyib et al. [

18] examined the durability of cement concrete exposed to repeated temperature differentials ranging from ambient temperature to 80 °C over a total of 90 cycles. Their results demonstrated that, after completing 90 cycles, compressive and flexural strengths were reduced by nearly 30%, with the greatest rate of strength loss occurring around cycle 30. Kanellopoulos et al. [

19] observed that the mechanical properties of cement concrete improved significantly after 30 temperature cycles (20 °C to 90 °C) but declined after 90 cycles. Research by Shokrieh et al. [

20] showed that optimized polymer cement concrete experienced a reduction of 4.9% in compressive strength and 17.4% in flexural strength after undergoing Temperature Differential Cycling II (25 °C to 70 °C), while Temperature Differential Cycling I (25 °C to −30 °C) and Temperature Differential Cycling III (−30 °C to 70 °C) had no significant impact on strength. Heidari-Rarani et al. [

21] examined the influence of different temperature differential cycles (25–30 °C, 25–70 °C, and 30–70 °C) on the mechanical characteristics of resin cement concrete. Their results indicated substantial reductions in both tensile strength and fracture toughness under temperature differential cycling, with further deterioration occurring as the average cycling temperature increased. Huang et al. [

22] investigated how alterations in the microstructure of the cement matrix and interfacial transition zone caused by thermal cycling relate to the mechanical behavior of concrete, and developed a micromechanical model incorporating porosity and microcrack parameters. Xiao et al. [

23] studied the changes in mechanical properties and microstructural damage of different concretes (C25, C40) after thermal fatigue, finding that the degree of deterioration of concrete under thermal fatigue was significant, and the extent of strength degradation increased with the temperature difference (20 °C, 30 °C, 40 °C) and number of temperature differential cycles. These studies demonstrate that temperature differential cycling significantly deteriorates the performance of concrete; hence, considering the impact of temperature differential cycling is crucial in enhancing the design precision and durability of concrete structures in regions with large diurnal temperature differences, such as Northeast and Northwest China.

Furthermore, fatigue behavior has consistently been a central research focus within concrete durability studies. Byung [

24] carried out statistical analyses on the fatigue life of concrete beams under variable amplitude loading, concluding that the fatigue life distribution closely fits a two-parameter Weibull model. Zhou et al. [

25] studied the axial compression fatigue strength of concrete after high-temperature treatment, finding that after being subjected to 200 °C, the axial compression fatigue strength of concrete decreased by about 28% compared to its normal temperature state, and the axial compression fatigue strength of the high-temperature-treated concrete was more significantly affected by the number of fatigue load cycles. Zhao et al. [

26] investigated the effects of different high-temperature regimes (varying temperatures, varying constant temperature durations) on the performance of high-strength concrete. They found that with the increase in heating temperature and constant temperature duration, the compressive strength, modulus elasticity, and mass of high-strength concrete generally showed a downward trend, with the heating temperature having a more significant impact on the deterioration of the mechanical properties of high-strength concrete. Xue et al. [

27] performed a reliability assessment on the compressive fatigue life of slag powder concrete exposed to freeze–thaw cycles. They proposed a compressive fatigue life prediction model utilizing equivalent damage theory. Zhu et al. [

28] investigated the flexural fatigue life distribution characteristics of self-compacting concrete after freeze–thaw cycles. Their findings demonstrated that fatigue life data align closely with a two-parameter Weibull distribution, with increased dispersion observed as the number of freeze–thaw cycles rose, but a decreasing trend was noted with higher stress levels. These studies indicate that in the research on concrete fatigue performance, scholars primarily focus on the impact of fixed factors such as constant mechanical loads, seismic action [

29], or temperatures. Consideration of variable factors is less common, with the majority of research concentrating on exploring the effects of freeze–thaw cycles. However, as a form of temperature variation, temperature cycles and their impact on the fatigue performance of concrete also warrant in-depth investigation.

In summary, current research on the durability of concrete has primarily focused on exploring the effects of freeze–thaw cycles, fixed temperatures, or temperature histories, with less emphasis on the combined effects of temperature differential cycling and freeze–thaw cycles. In reality, within engineering environments, daily diurnal temperature variations leading to temperature differential cycling and seasonal freeze–thaw cycling often coexist. Neglecting such coupled environmental actions may lead to premature damage within the designed service life of structures, or result in significant economic losses and safety risks due to insufficient preventive measures [

30]. Therefore, investigating the combined influence of temperature differential and freeze–thaw cycling on concrete durability is of great significance—not only from a theoretical standpoint, but also for the practical optimization of cement concrete materials and durability design in engineering applications. Therefore, studying the combined effects of temperature differential cycling and freeze–thaw cycling on the durability of concrete is not only of significant theoretical relevance, but also provides practical guidance for the optimization of performance and durability design of cement concrete materials in actual engineering applications.

This study specifically evaluates the combined effects of temperature differential cycling and freeze–thaw conditions on the mechanical properties of C40-grade cement concrete. Its objective is to deepen the current understanding and enhance concrete performance under severe environmental conditions. Through comprehensive experimental design, this research investigates cement concrete subjected to various temperature differential cycling (60 to 300 cycles, with tests conducted after every 60 cycles) and subsequent freeze–thaw cycling (75 to 200 cycles, with tests conducted after every 75 cycles). The research encompasses statistical and analytical assessments of mass, dynamic elastic modulus, compressive strength, and compressive fatigue life. This research aims to summarize the patterns of impact caused by the combined effects of temperature cycles and freeze–thaw cycles on cement concrete performance, revealing the mechanism of their interaction. The results obtained are expected to provide critical insights into improving concrete frost resistance within complex environmental contexts, as well as offer theoretical guidance for optimizing material performance in engineering practice.

4. Conclusions and Outlook

This study investigated the combined effects of temperature differential cycling and freeze–thaw cycles on the performance of concrete through comprehensive experiments and statistical analysis. It particularly focused on the analysis and discussion of concrete quality, dynamic modulus, compressive strength, and compressive fatigue life. The main conclusions are as follows:

- (1)

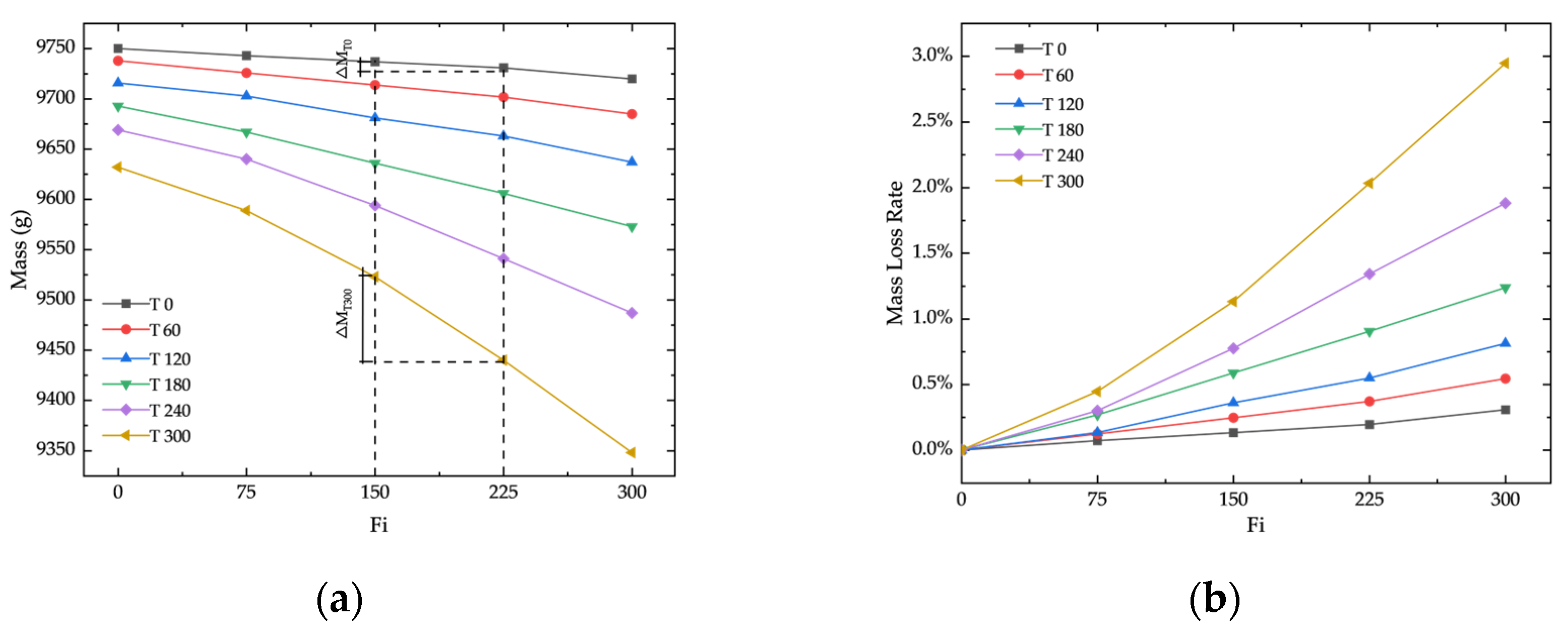

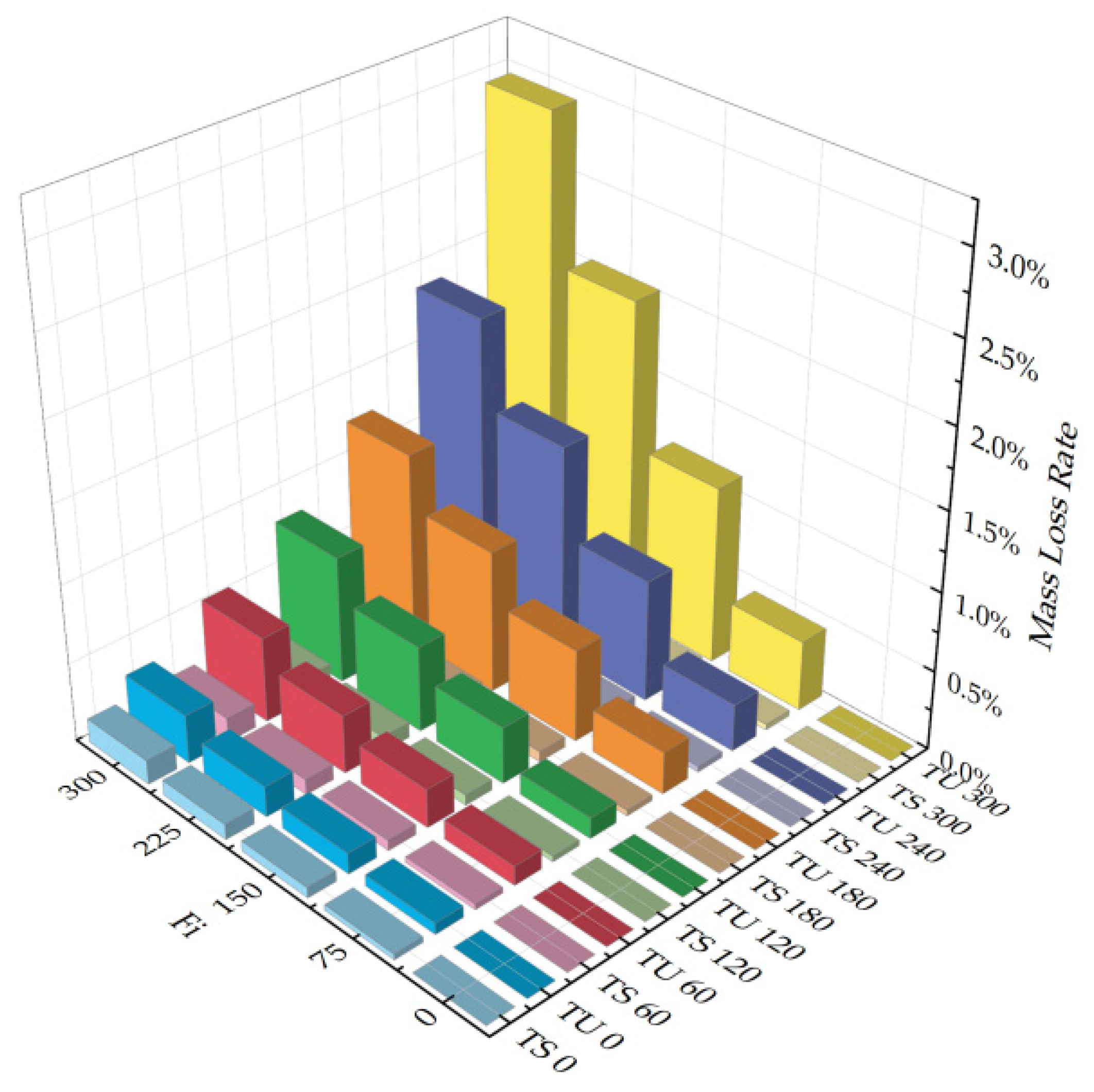

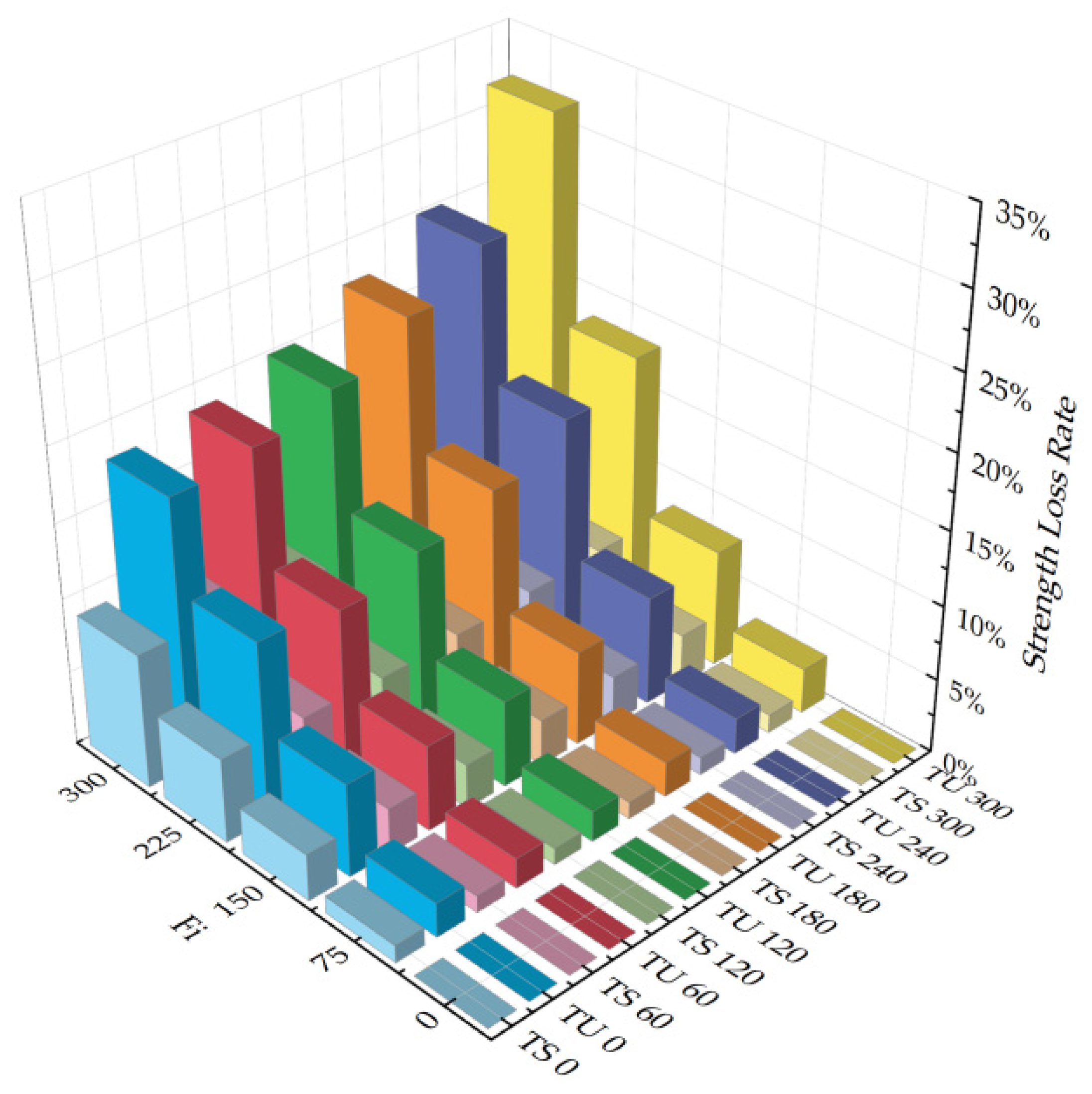

Concrete exhibits significant quality deterioration under combined temperature differential and freeze–thaw cycles. Mass loss increases progressively with both temperature differential and freeze–thaw cycle counts, reaching approximately 3% after 300 temperature differential cycles combined with 300 freeze–thaw cycles. Moreover, the combined cycling effects result in notably greater mass deterioration compared to individual temperature differential or freeze–thaw cycles alone.

- (2)

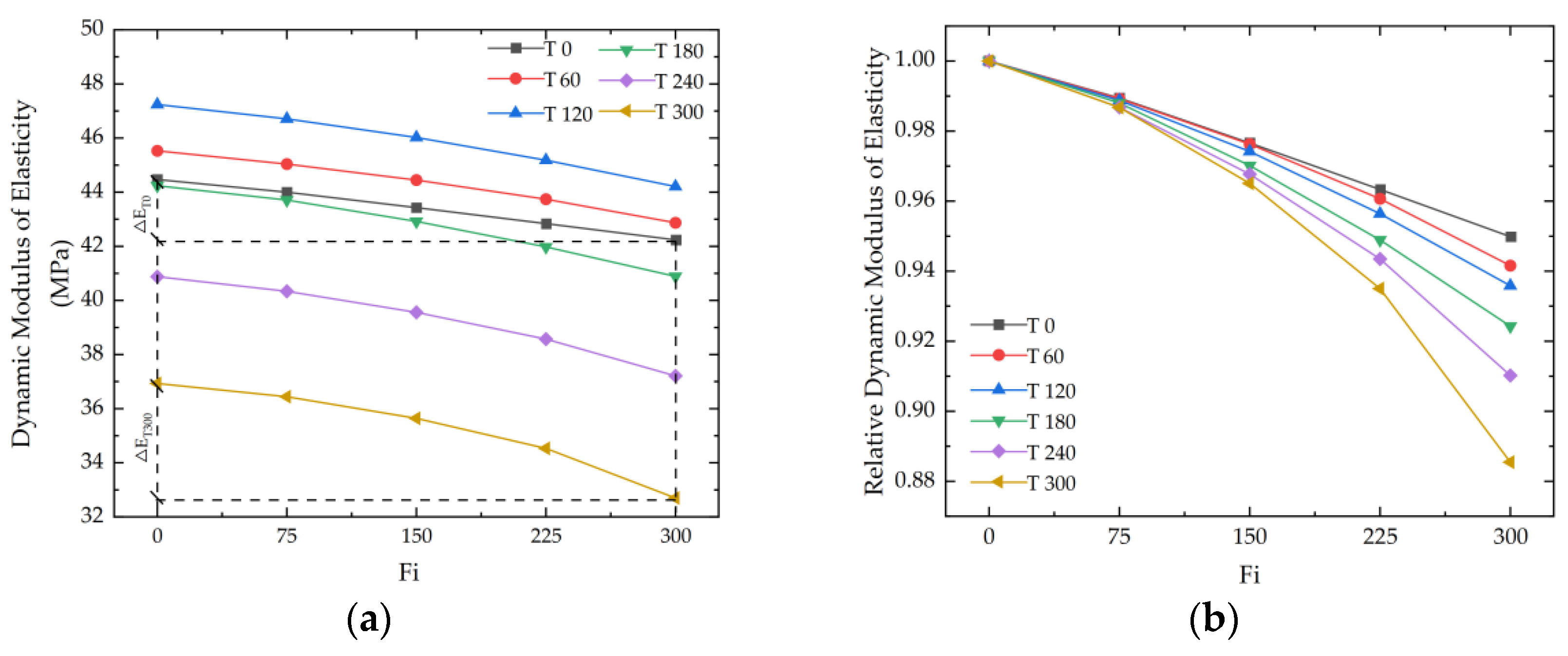

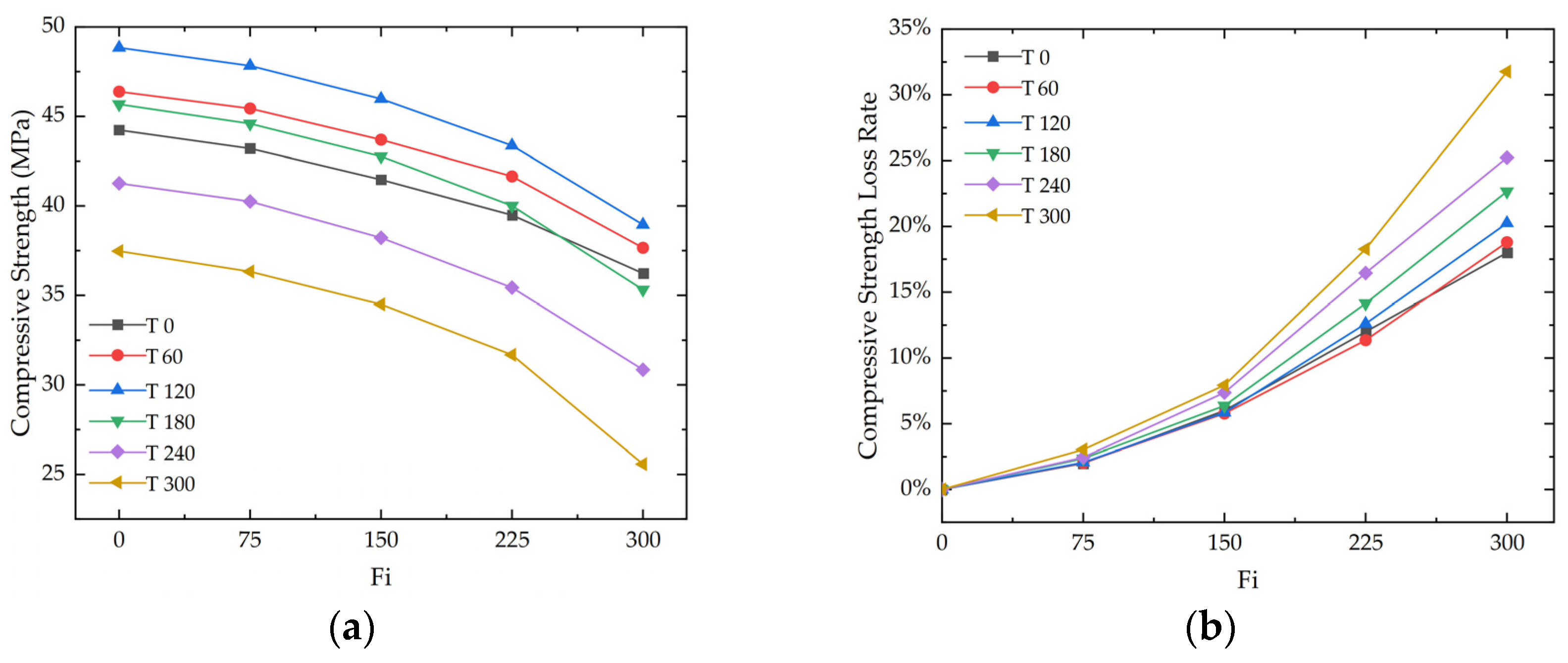

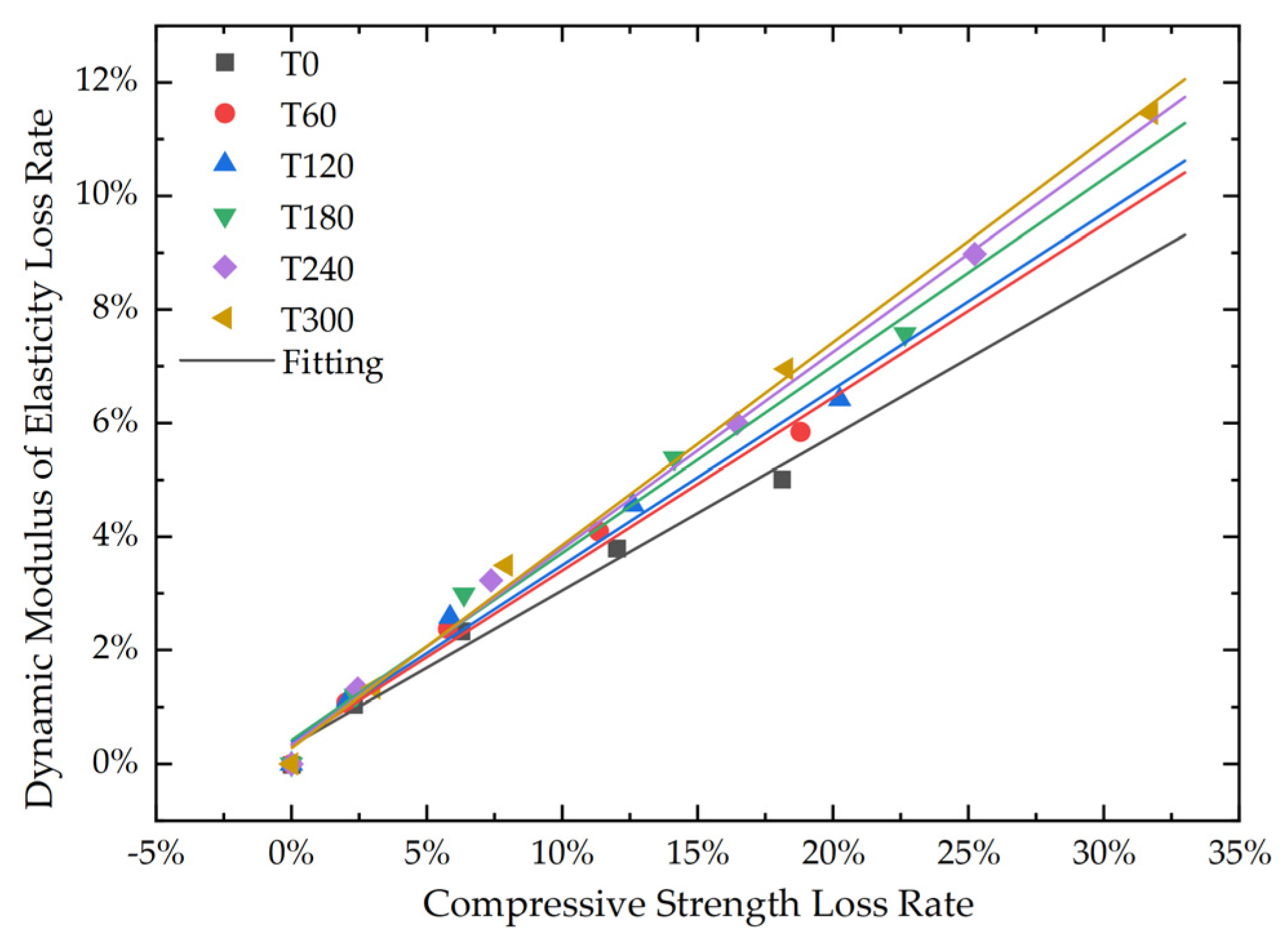

The dynamic modulus and compressive strength of concrete are significantly influenced by temperature differential and freeze–thaw cycling. As the number of temperature fluctuation cycles increases, both the dynamic modulus and strength exhibit a “rise, then fall” trend. Furthermore, an increase in the number of temperature differential cycles leads to a continuous decline in both dynamic modulus and strength. Additionally, under the combined influence of temperature differential and freeze–thaw cycles, a strong linear relationship is observed between compressive strength loss and dynamic modulus loss, indicating that changes in dynamic modulus can quantitatively characterize variations in concrete strength.

- (3)

Compared to the superimposed effects of temperature differential cycling and freeze–thaw cycling when acting independently, the combined action of temperature differential and freeze–thaw cycles exhibited significantly greater impacts on the mass, dynamic elastic modulus, and axial compressive strength of cement concrete. Under the condition of 300 temperature differential cycles combined with 300 freeze–thaw cycles, the combined effect was found to be 18 times greater in terms of mass loss rate, 3.7 times greater in terms of dynamic modulus reduction rate, and 1.8 times greater in terms of axial compressive strength loss rate, relative to the sum of the individual effects. These findings indicate that the coupled temperature differential–freeze–thaw action further intensifies the degradation of cement concrete.

- (4)

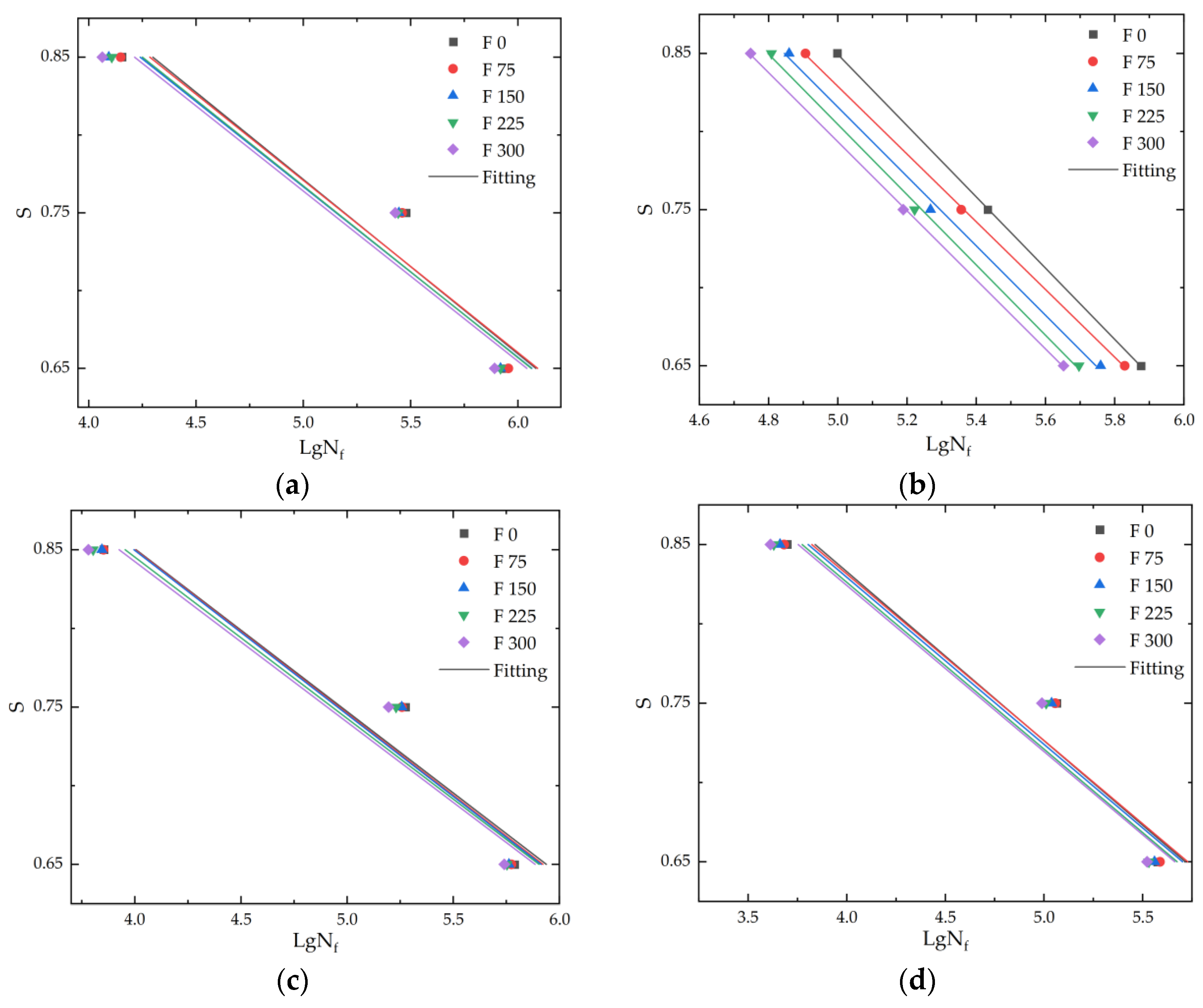

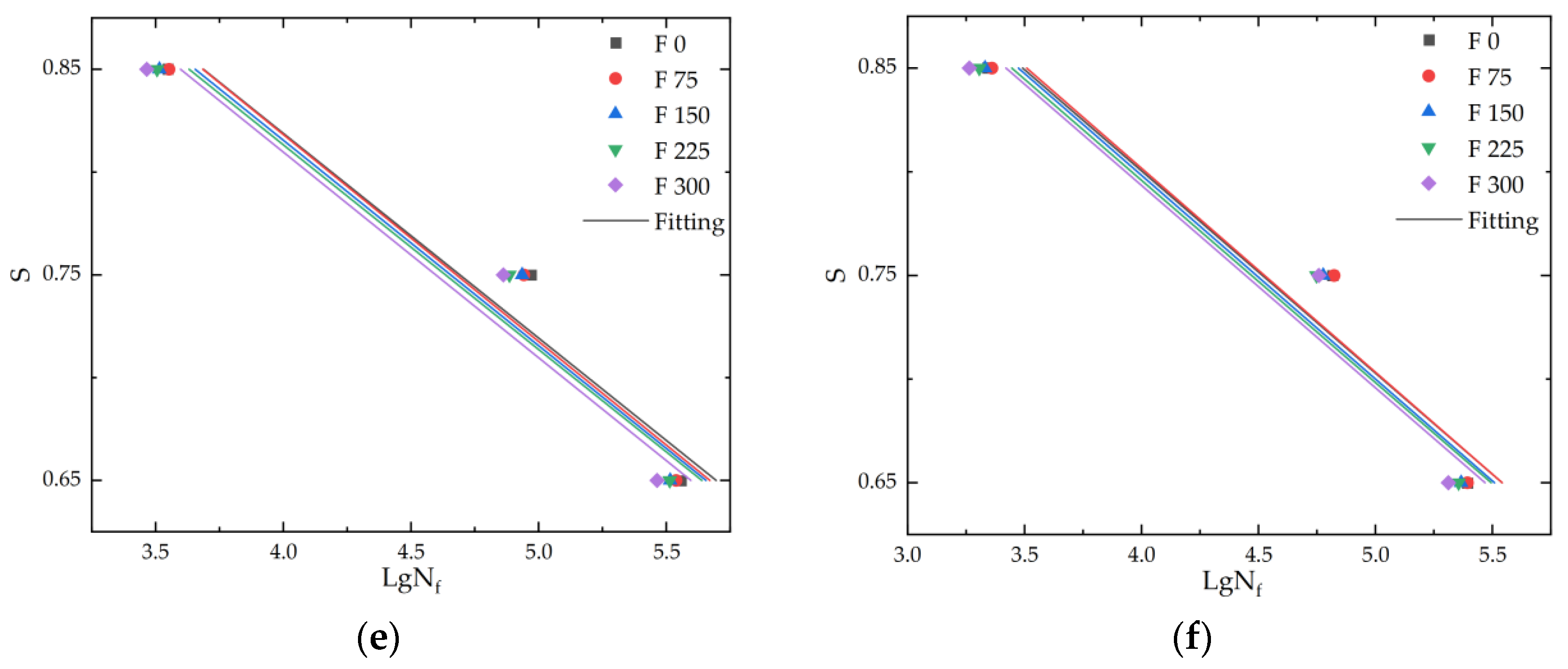

The parameters of the two-parameter Weibull distribution describing cement concrete fatigue life were estimated using the method of moments. Kolmogorov–Smirnov (K-S) tests confirmed a high degree of conformity between the experimental fatigue life data and the two-parameter Weibull distribution, verifying its suitability in accurately characterizing fatigue life under the combined environmental effects of temperature differential and freeze–thaw cycles.

- (5)

The S-Nf curves of cement concrete after temperature differential freeze–thaw cycle were fitted using an exponential function. It was found that the reduction in fatigue life after 300 freeze–thaw cycles without temperature differential cycling was 1.22%. However, under the combined influence of temperature differential and freeze–thaw cycling, this reduction can be as high as 4.40%. This demonstrates that the combined effect of temperature differential and freeze–thaw cycling accelerates the deterioration of the durability of cement concrete.

In summary, this study systematically revealed the significant impact of the combined action of temperature differential cycling and freeze–thaw cycling on the performance of cement concrete. Statistical analyses of mass loss, dynamic elastic modulus, axial compressive strength, and fatigue life consistently demonstrated that, under coupled environmental loading, the degradation process of concrete is markedly accelerated, exhibiting a level of damage intensity and rate far beyond the superposition of individual effects. This nonlinear synergistic effect indicates that the material property parameters obtained under conventional test conditions may not fully reflect the complex deterioration mechanisms experienced in real-world service environments. Particularly in terms of fatigue life, although current standards generally adopt 2 million cycles as the design target for the axial compressive fatigue life of cement concrete, extensive engineering practice has shown that many structures experience fatigue failure at much lower cycle counts, thereby posing serious concerns for structural safety and durability. A primary reason lies in the current design frameworks, which often fail to incorporate environmental factors such as temperature differential cycling and freeze–thaw cycling into the fatigue life evaluation systems. Based on the findings of this study, it is suggested that the coupled effects of temperature differential and freeze–thaw cycling should be explicitly considered in the durability design and service life assessment of concrete structures. Such consideration is essential for achieving a more scientific, rational, and environmentally adaptive design approach. Moreover, this work provides both theoretical support and experimental data that can guide future performance-oriented optimization of concrete materials for use in cold and complex climatic regions.

Future studies may consider integrating end-to-end vision models into concrete performance analysis to establish a deeper correlation between microcrack evolution and macroscopic mechanical degradation. In subsequent work, high-resolution cameras or microscopes can be employed to acquire multi-view images of specimen surfaces. These images can then be processed using advanced deep learning frameworks—such as the DeepLab model [

40], which leverages Atrous Spatial Pyramid Pooling (ASPP) and depthwise separable convolutions—for the pixel-level semantic segmentation of microcracks, enabling the extraction of morphological indicators such as total crack length, width distribution, connectivity, and crack density. Additionally, lightweight networks based on EfficientNet [

41] can utilize compound scaling strategies to efficiently encode the texture features surrounding cracks. When combined with feature alignment and temporal tracking algorithms, these methods can support the quantitative analysis of crack propagation rates and the emergence of new cracks. By integrating these microstructural crack parameters with dynamic modulus, compressive strength, and fatigue life data through multimodal regression or joint predictive modeling, we aim not only to establish a quantitative relationship between crack evolution and mechanical deterioration, but also to significantly enhance the accuracy of concrete life prediction under temperature differential and freeze–thaw cycling conditions.