Effect of Straw Characterization on the Mechanical Behavior of Compacted Straw-Reinforced Soils

Abstract

1. Introduction

2. Test Content

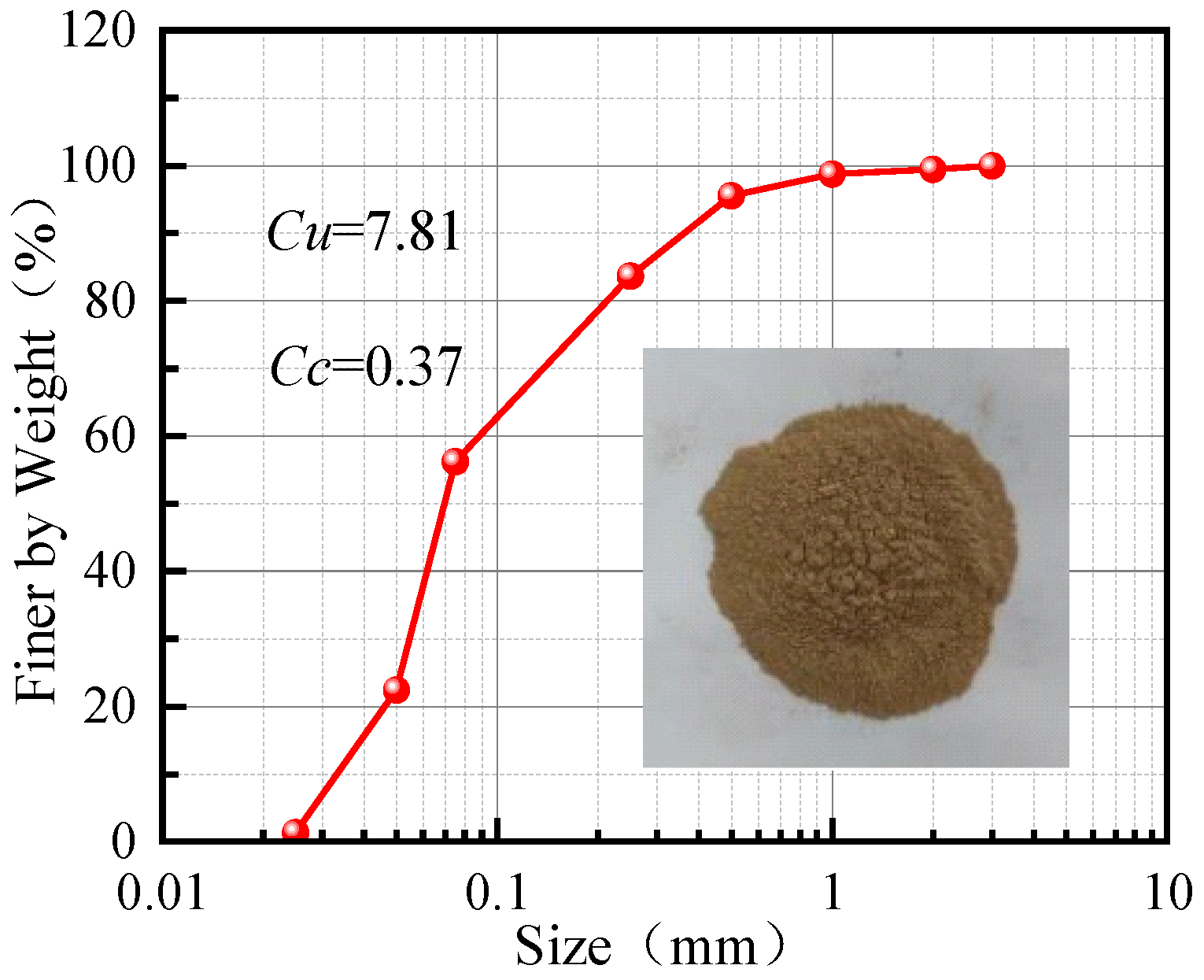

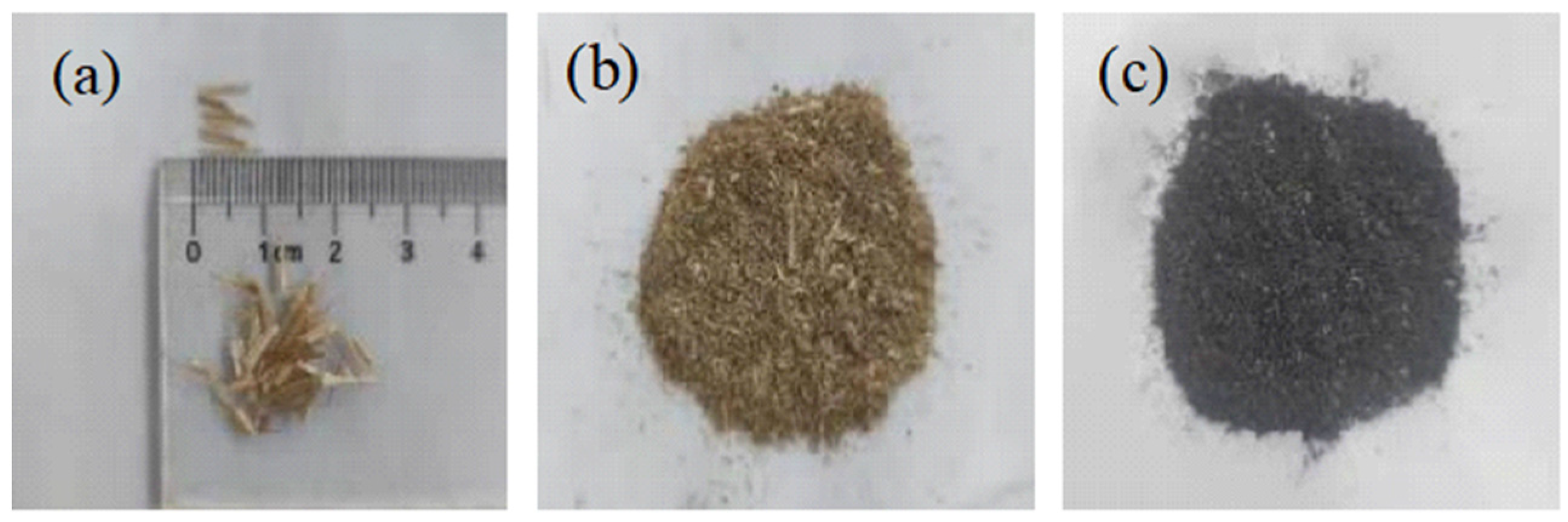

2.1. Test Materials

2.2. Test Program

3. Test Results and Analysis

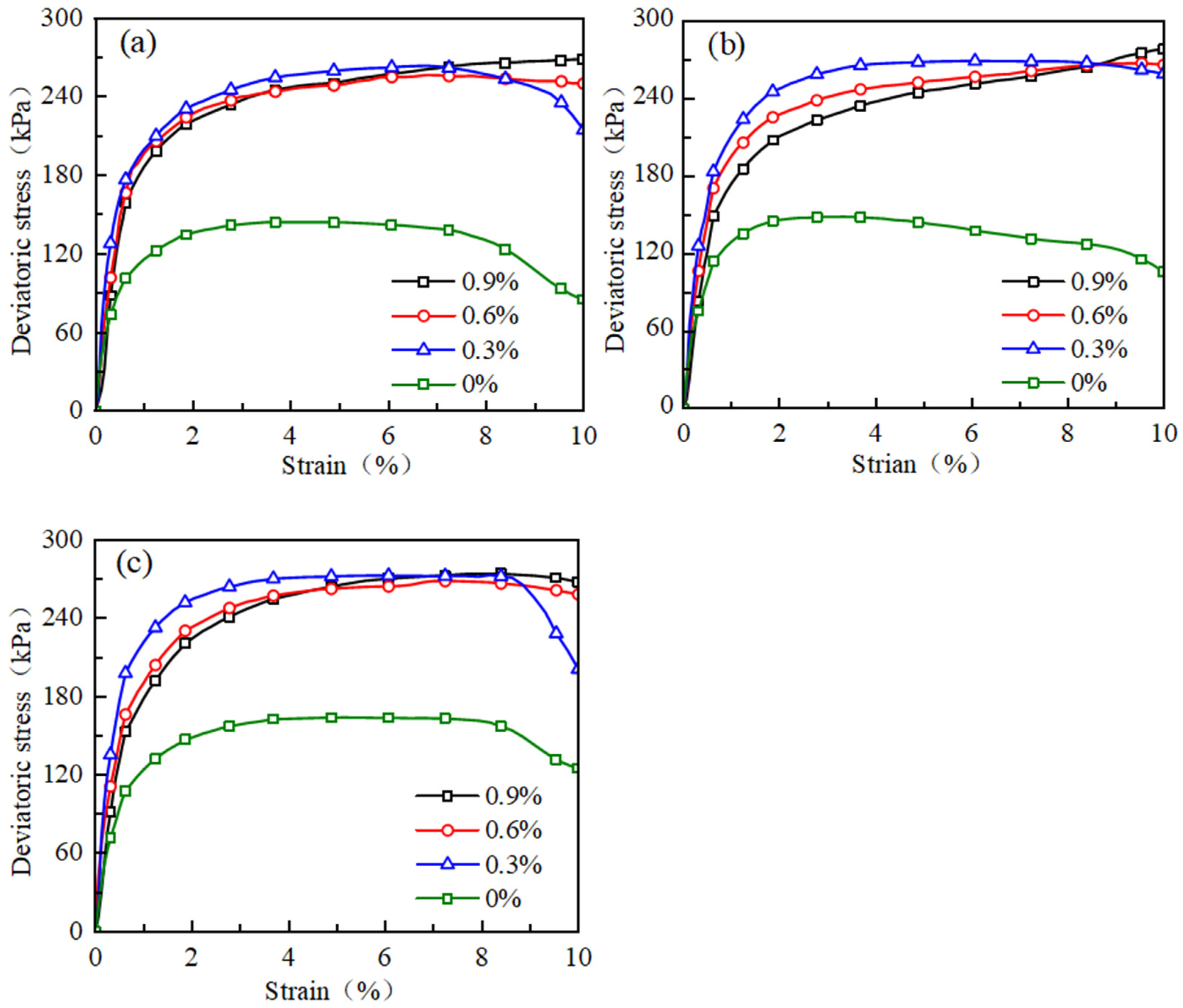

3.1. Effects of Different Confining Pressures and Straw Segment Content on Soil Properties

3.2. Influence of Different Straw States on the Properties of Straw-Reinforced Soil

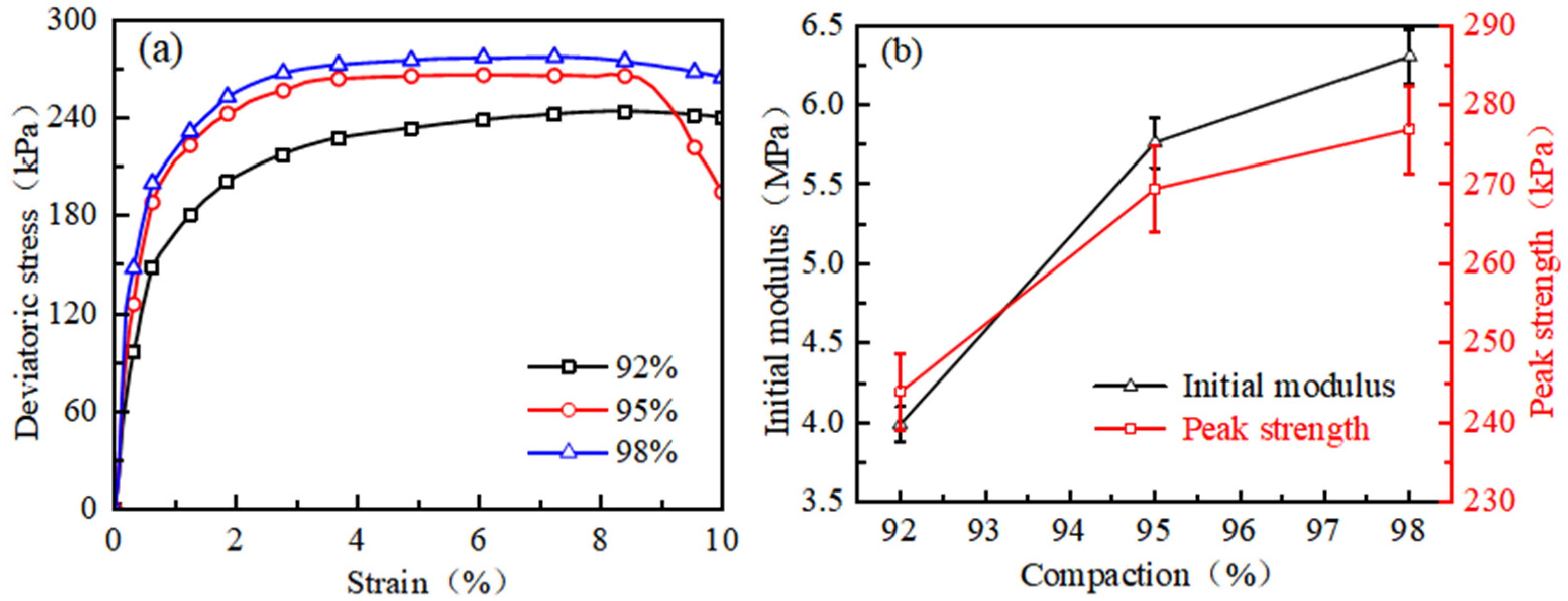

3.3. Effects of Different Compaction Levels on the Properties of Straw-Reinforced Soil

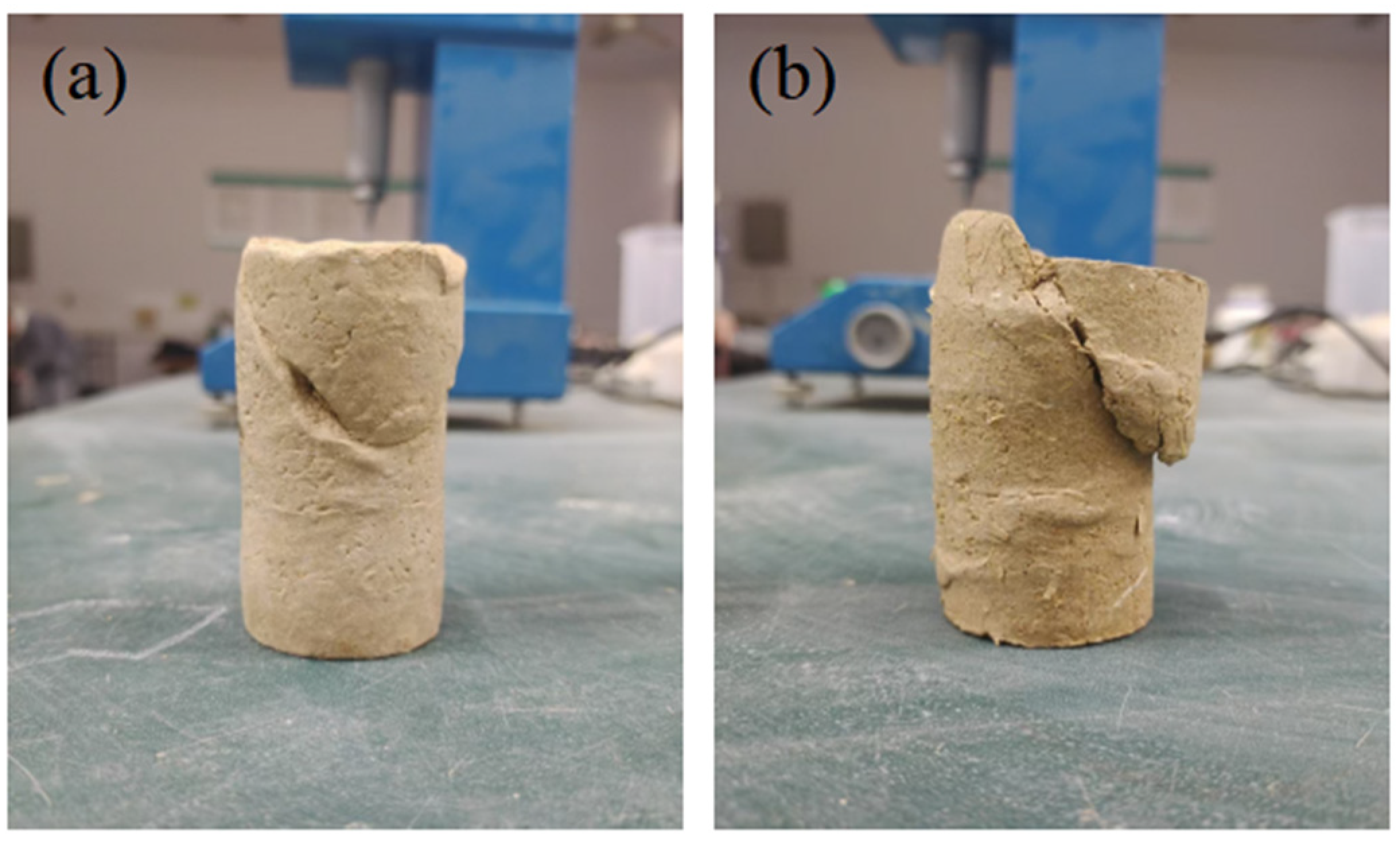

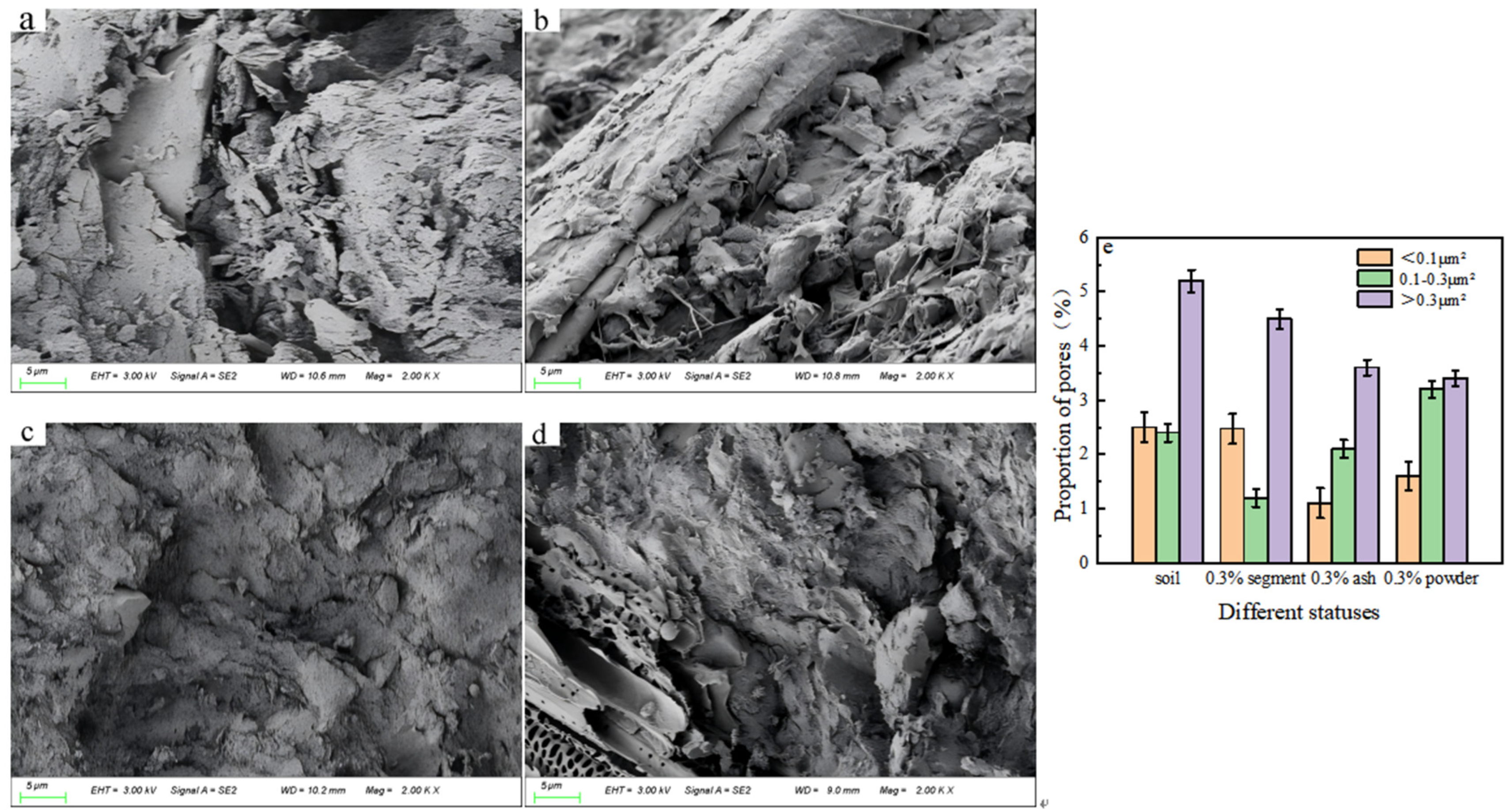

3.4. Microanalysis of Reinforcement/Soil Interface Interactions in Straw-Reinforced Soils

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- National Development and Reform Commission of the People’s Republic of China. Development Plan for Circular Economy in the “14th Five-Year” Plan. Available online: https://www.gov.cn/zhengce/zhengceku/2021-07/07/5623077/files/34f0a690e98643119774252f4f671720.pdf (accessed on 7 July 2021).

- Huang, L.; Zhu, Y.; Wang, Q.; Zhu, A.; Liu, Z.; Wang, Y.; Allen, D.T.; Li, L. Assessment of the effects of straw burning bans in China: Emissions, air quality, and health impacts. Sci. Total Environ. 2021, 789, 147935. [Google Scholar] [CrossRef]

- Shan, A.; Pan, J.; Kang, K.J.; Pan, M.; Wang, G.; Wang, M.; He, Z.; Yang, X. Effects of straw return with N fertilizer reduction on crop yield, plant diseases and pests and potential heavy metal risk in a Chinese rice paddy: A field study of 2 consecutive wheat-rice cycles. Environ. Pollut. 2021, 288, 117741. [Google Scholar] [CrossRef]

- Seglah, P.A.; Wang, Y.; Wang, H.; Bi, Y. Estimation and Efficient Utilization of Straw Resources in Ghana. Sustainability 2019, 11, 4172. [Google Scholar] [CrossRef]

- Vidal, H. The principle of reinforced earth. Highw. Res. Rec. 1969, 282, 1–6. [Google Scholar]

- Shukla, S.K. Discussion: Applications of geosynthetics for soil reinforcement. Proc. Inst. Civ. Eng. 2004, 8, 179–182. [Google Scholar] [CrossRef]

- Chen, L.; Ghorbani, J.; Dutta, T.; Zhou, A.; McCartney, J.; Kodikara, J. A new multi-surface plasticity model for cyclic hardening of unsaturated granular soils. Comput. Geotech. 2024, 173, 106500. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, X.; Zhang, J.; Wang, X. Microscopic investigation of the packing features of soft-rigid particle mixtures using the discrete element method. Adv. Powd. Technol. 2020, 31, 2951–2963. [Google Scholar] [CrossRef]

- Wu, H.; Yao, C.; Li, C.; Miao, M.; Zhong, Y.; Lu, Y.; Liu, T. Review of Application and Innovation of Geotextiles in Geotechnical Engineering. Materials 2020, 13, 1774. [Google Scholar] [CrossRef]

- Tang, C.S.; Shi, B.; Zhao, L.Z. Interfacial shear strength of fiber reinforced soil. Geotext. Geomembr. 2010, 28, 54–62. [Google Scholar] [CrossRef]

- Liu, S.; Wang, Y.; Tian, H.; Sun, S.; Zhang, L.; Zhou, R.; Han, C. Mechanical properties and toughening effect of rice straw fiber-reinforced soil. Case Stud. Constr. Mater. 2024, 21, e03511. [Google Scholar] [CrossRef]

- Lin, Y.; Ma, J.; Lai, Z.; Huang, L.; Lei, M. A FDEM approach to study mechanical and fracturing responses of geo-materials with high inclusion contents using a novel reconstruction strategy. Eng. Fract. Mech. 2023, 282, 109171. [Google Scholar] [CrossRef]

- Jiang, P.; Zhou, L.; Zhang, W.; Wang, W.; Li, N. Unconfined Compressive Strength and Splitting Tensile Strength of Lime Soil Modified by Nano Clay and Polypropylene Fiber. Crystals. 2022, 12, 285. [Google Scholar] [CrossRef]

- Liang, W.; Chen, X.; Huang, S.; Xiong, G.; Yan, K.; Zhou, X. Federal learning edge network based sentiment analysis combating global COVID-19. Comput. Commun. 2023, 204, 33–42. [Google Scholar] [CrossRef] [PubMed]

- Hao, J.; Huang, J.; Yao, J.; Zhang, Z.; Zhang, H. Unconfined compression strength and mesostructure of reinforced soil with wheat straw. Bull. Eng. Geol. Environ. 2021, 80, 9173–9183. [Google Scholar] [CrossRef]

- Meena, S.K.; Sahu, R.; Ayothiraman, R. Utilization of Waste Wheat Straw Fibers for Improving the Strength Characteristics of Clay. J. Nat. Fibers 2021, 18, 1404–1418. [Google Scholar] [CrossRef]

- Xia, C.; Cao, X.; Wen, J.; Li, J.; Dai, L.; Guan, B. Effect of Acrylate Emulsion on the Mechanical and Microscopic Properties of Straw Fiber-Reinforced Cement-Magnesium Slag Stabilized Soil. Polymers 2024, 16, 3462. [Google Scholar] [CrossRef] [PubMed]

- Shen, Y.; Li, Q.; Pei, X.; Wei, R.; Yang, B.; Lei, N.; Zhang, X.; Yin, D.; Wang, S.; Tao, Q. Ecological Restoration of Engineering Slopes in China—A Review. Sustainability 2023, 15, 5354. [Google Scholar] [CrossRef]

- Yao, Y.; Fan, J.; Li, J. A Review of Advanced Soil Moisture Monitoring Techniques for Slope Stability Assessment. Water 2025, 17, 390. [Google Scholar] [CrossRef]

- Paul, S.; Islam, M.S.; Hossain, M.I. Suitability of Vetiver straw fibers in improving the engineering characteristics of compressed earth blocks. Constr. Build. Mater. 2023, 409, 134224. [Google Scholar] [CrossRef]

- Bao, C.; Ding, J. Research and engineering applications of fibrous reinforced soils. Siol Eng. Found. 2012, 26, 80–83. [Google Scholar]

- ASTM D2850; Standard Test Method for Unconsolidated-Undrained Triaxial Compression Test on Cohesive Soils. ASTM International: West Conshohocken, PA, USA, 2015.

- Wang, P.; Yin, Z.; Hicher, P.; Cui, Y. Micro-mechanical analysis of one-dimensional compression of clay with DEM. Int. J. Numer. Anal. Met. 2023, 47, 2706–2724. [Google Scholar] [CrossRef]

- Zhang, Z.; Gao, W. Effect of different test methods on the disintegration behaviour of soft rock and the evolution model of disintegration breakage under cyclic wetting and drying. Eng. Geol. 2020, 279, 105888. [Google Scholar] [CrossRef]

- Chen, L.; Ghorbani, J.; Zhang, C.; Dutta, T.T.; Kodikara, J. A novel unified model for volumetric hardening and water retention in unsaturated soils. Comput. Geotech. 2021, 140, 104446. [Google Scholar] [CrossRef]

- Chen, J.N.; Ren, X.; Xu, H.; Zhang, C.; Xia, L. Effects of Grain Size and Moisture Content on the Strength of Geogrid-Reinforced Sand in Direct Shear Mode. Int. J. Geomech. 2022, 22, 04022006. [Google Scholar] [CrossRef]

- Ensani, A.; Razeghi, H.R.; Mamaghanian, J. Effect of Reinforcement Type and Soil Moisture Content on Marginal Soil-Geosynthetic Interactions. Soil Mech. Found. Eng. 2022, 59, 314–323. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, X.; Yin, Z.Y.; Liang, Z. DEM modeling of large-scale triaxial test of rock clasts considering realistic particle shapes and flexible membrane boundary. Eng. Geol. 2020, 279, 105871. [Google Scholar] [CrossRef]

- Jianbin, H.; Xingmei, W.; Jie, Y.; Zhenbei, Z. Strength Characteristics and Mesostructure of Wheat Straw Reinforced Soil. Tongji Univ. Nat. Sci. 2018, 47, 0764–0768. [Google Scholar]

- Zhang, J.; Wang, X.; Yin, Z. DEM-based study on the mechanical behaviors of sand-rubber mixture in critical state. Constr. Build. Mater. 2023, 370, 130603. [Google Scholar] [CrossRef]

- Hua, W.; Xiao, Y.; Yu, Q.; Wang, M.; Li, W.; Tutumluer, E.; Chen, Y.; Li, Z. Investigating real-time monitoring indices of compaction quality from particle movement characteristics of distinctly-graded unbound aggregate materials subjected to vibratory compaction. Trans. Geotech. 2023, 42, 101084. [Google Scholar] [CrossRef]

- Wang, G.; Singh, J.; Tan, J.; Li, G. Use of predictive model for identification of overall wear state of TBM cutterhead based on tunneling parameters. Expert Syst. Appl. 2024, 268, 126316. [Google Scholar] [CrossRef]

- Almajed, A.; Srirama, D.; Moghal, A.A.B. Response Surface Method Analysis of Chemically Stabilized Fiber-Reinforced Soil. Materials 2021, 14, 1535. [Google Scholar] [CrossRef] [PubMed]

- He, G.; Chen, C.; Fang, C.; Yuan, Z.; Guo, Y. Influence of particle roundness on crushing characteristics and mechanical properties of road crushed stone aggregates. J. Highw. Transp. Res. Dev. 2025, 42, 95–103. [Google Scholar] [CrossRef]

- Xie, K.; Li, T.F.; Zhao, Y.M.; Chen, X.B.; Zhang, Q. Microstructure evolution of coarse-grained soil fillers during subgrade compaction-operation period based on CT technology. Transp. Geotech. 2024, 47, 101279. [Google Scholar] [CrossRef]

- Zhang, J.; Xiao, Y.; Chen, X.; Liu, B.; Yin, Z.Y. Investigating the effects of non-uniformity of mixing on the shear behavior of soft-rigid mixtures with DEM. Comput. Geotech. 2024, 176, 106794. [Google Scholar] [CrossRef]

- Zeng, Y.; Shi, X.; Zhao, J.; Bian, X.; Liu, J. Estimation of compression behavior of granular soils considering initial density effect based on equivalent concept. Acta Geotech. 2025, 20, 1035–1048. [Google Scholar] [CrossRef]

- Akhzeroun, A.; Semcha, A.; Bezazi, A.; Boumediri, H.; Reis, P.N.B.; Scarpa, F. Development and characterization of a new sustainable composite reinforced with date palm stems for rehabilitation and reconstruction of earthen built heritage. Compos. Struct. 2023, 316, 117015. [Google Scholar] [CrossRef]

- Widianti, A.; Diana, W.; Alghifari, M.R. Shear Strength and Elastic Modulus Behavior of Coconut Fiber-Reinforced Expansive Soil. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1144, 012043. [Google Scholar] [CrossRef]

- Wang, X.; Hu, Q.; Liu, Y.; Tao, G. Triaxial Test and Discrete Element Numerical Simulation of Geogrid-Reinforced Clay Soil. Buildings 2024, 14, 1422. [Google Scholar] [CrossRef]

- Li, L.; Zhang, X.; Xiao, H.; Zhang, J.; Chen, N.; Li, W. The Triaxial Test of Polypropylene Fiber Reinforced Fly Ash Soil. Materials 2022, 15, 3807. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, Z.; Wan, W.; Nie, A.; Zhang, Y.; Han, C. Toughening effect and mechanism of rice straw Fiber-reinforced lime soil. Constr. Build. Mater. 2023, 393, 132133. [Google Scholar] [CrossRef]

- Osula, D.O.A. Lime modification of problem laterite. Eng. Geol. 1991, 30, 141–154. [Google Scholar] [CrossRef]

- Li, L.H.; Yu, X.T.; Xiao, H.L.; Ma, Q.; Liu, Y.; Yang, X. Mechanical properties of reinforcement about rice husk ash mixed soil. Rock. Soil Mech. 2020, 41, 2168–2178. [Google Scholar] [CrossRef]

| Status/Content | Plastic Limit (%) | Liquid Limit (%) | Maximum Dry Density (g·cm3) | Optimum Moisture Content (%) |

|---|---|---|---|---|

| 0% | 22.1 ± 0.5 | 45.84 ± 0.6 | 1.94 ± 0.05 | 19.7 ± 0.5 |

| 0.3% segment | 21.26 ± 0.6 | 67.30 ± 0.7 | 1.92 ± 0.06 | 16.2 ± 0.7 |

| 0.6% segment | 20.84 ± 0.8 | 74.72 ± 0.7 | 1.88 ± 0.08 | 15.7 ± 0.7 |

| 0.9% segment | 19.60 ± 0.9 | 78.57 ± 0.9 | 1.85 ± 0.11 | 15.3 ± 0.8 |

| 0.3% powder | 17.19 ± 0.6 | 46.23 ± 0.6 | 1.90 ± 0.06 | 15.6 ± 0.6 |

| 0.3% ash | 16.25 ± 0.6 | 53.75 ± 0.7 | 1.91 ± 0.05 | 15.8 ± 0.5 |

| Status/Content | Confining Pressure/kPa | Compaction/% | Repetition |

|---|---|---|---|

| 0% | 50/100/200 | 95 | 3 |

| 0.3% Straw segment | 50/100/200 | 95 | |

| 0.6% Straw segment | 50/100/200 | 95 | |

| 0.9% Straw segment | 50/100/200 | 95 | |

| 0.3% Segment/ash/powder | 200 | 95 | |

| 0.3% Straw segment | 200 | 92/95/98 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, B.; Zhang, Z.; Huang, X.; Zhang, J.; Cai, Y.; Liu, X.; Tang, F. Effect of Straw Characterization on the Mechanical Behavior of Compacted Straw-Reinforced Soils. Buildings 2025, 15, 1543. https://doi.org/10.3390/buildings15091543

Liu B, Zhang Z, Huang X, Zhang J, Cai Y, Liu X, Tang F. Effect of Straw Characterization on the Mechanical Behavior of Compacted Straw-Reinforced Soils. Buildings. 2025; 15(9):1543. https://doi.org/10.3390/buildings15091543

Chicago/Turabian StyleLiu, Baohua, Zhijian Zhang, Xiaoqiao Huang, Junqi Zhang, Yu Cai, Xiaohu Liu, and Feng Tang. 2025. "Effect of Straw Characterization on the Mechanical Behavior of Compacted Straw-Reinforced Soils" Buildings 15, no. 9: 1543. https://doi.org/10.3390/buildings15091543

APA StyleLiu, B., Zhang, Z., Huang, X., Zhang, J., Cai, Y., Liu, X., & Tang, F. (2025). Effect of Straw Characterization on the Mechanical Behavior of Compacted Straw-Reinforced Soils. Buildings, 15(9), 1543. https://doi.org/10.3390/buildings15091543