Capillary Water Absorption Characteristics of Steel Fiber-Reinforced Concrete

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Mix Proportions

2.3. Compressive Strength

2.4. Capillary Water Absorption

2.5. Calculation of Capillary Water Absorption Rate

2.6. Determination of Microstructural Characteristics by Scanning Electron Microscopy

2.7. Determination of Pore Structure by Mercury Intrusion Porosimetry

2.8. Determination of Internal Water Migration Using 1H Low-Field Nuclear Magnetic Resonance

3. Results

3.1. Cumulative Capillary Water Absorption

3.2. Capillary Water Absorption Rate in Concrete

3.2.1. The Initial Capillary Water Absorption Rate

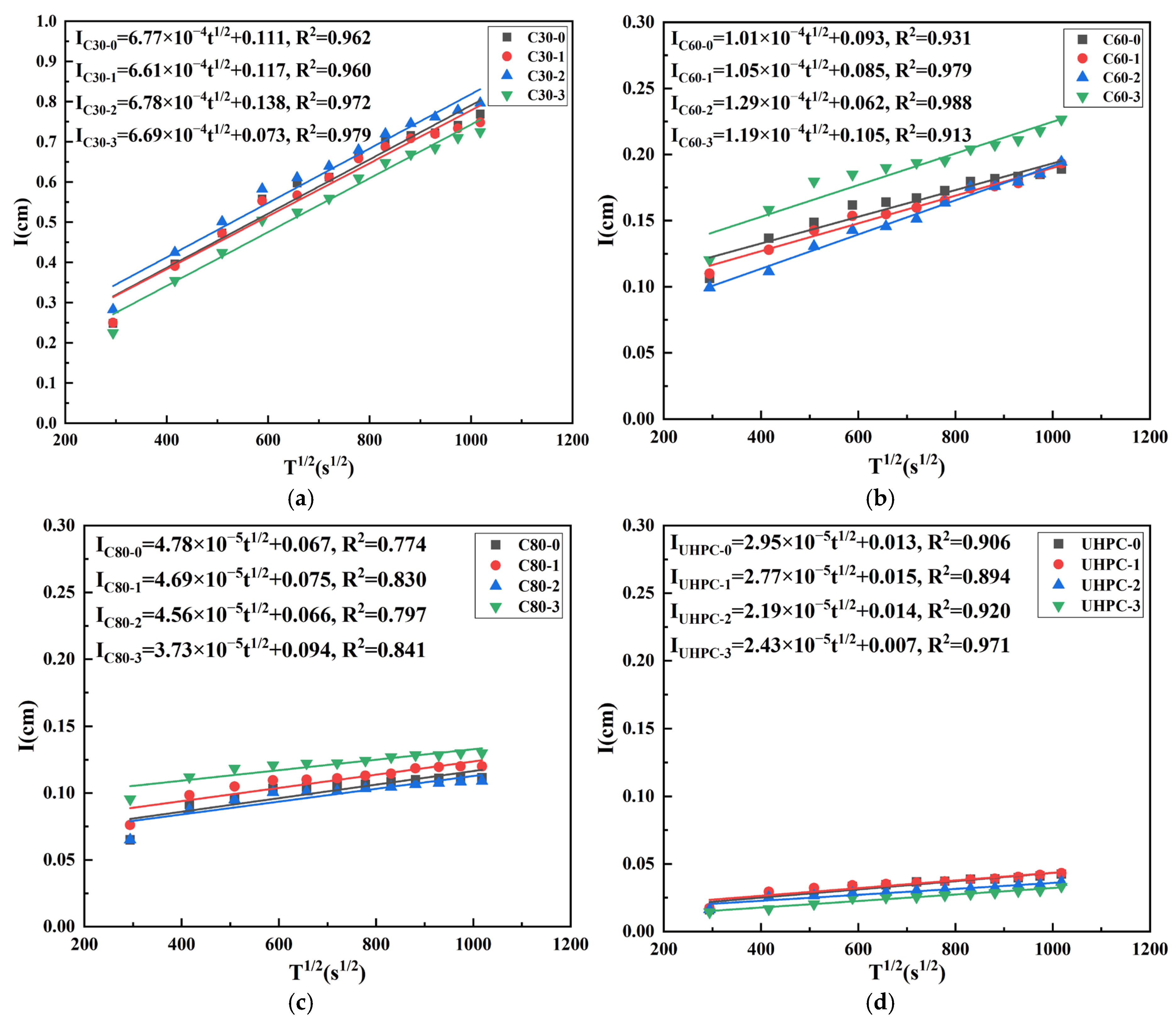

3.2.2. The Secondary Capillary Water Absorption Rate

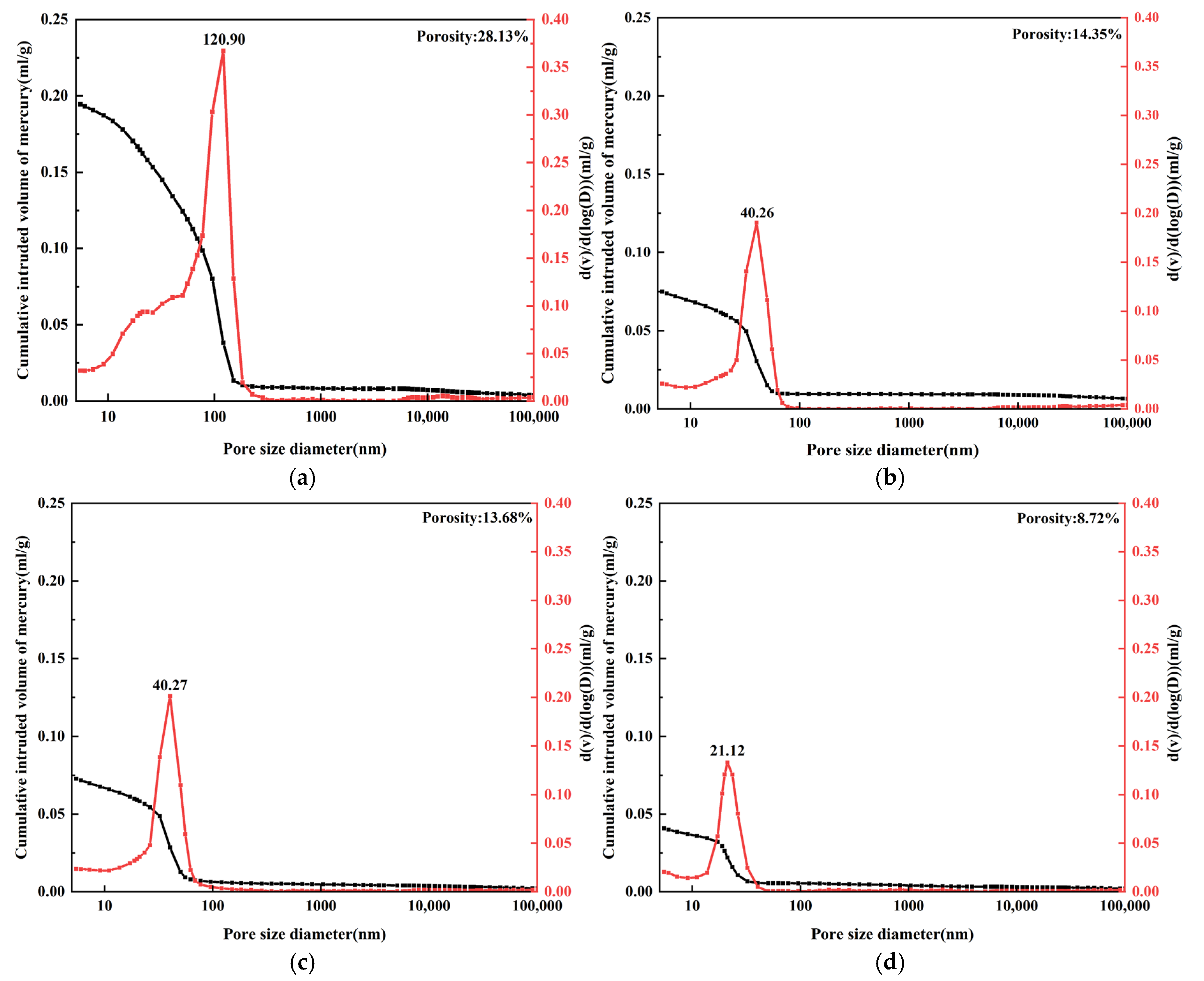

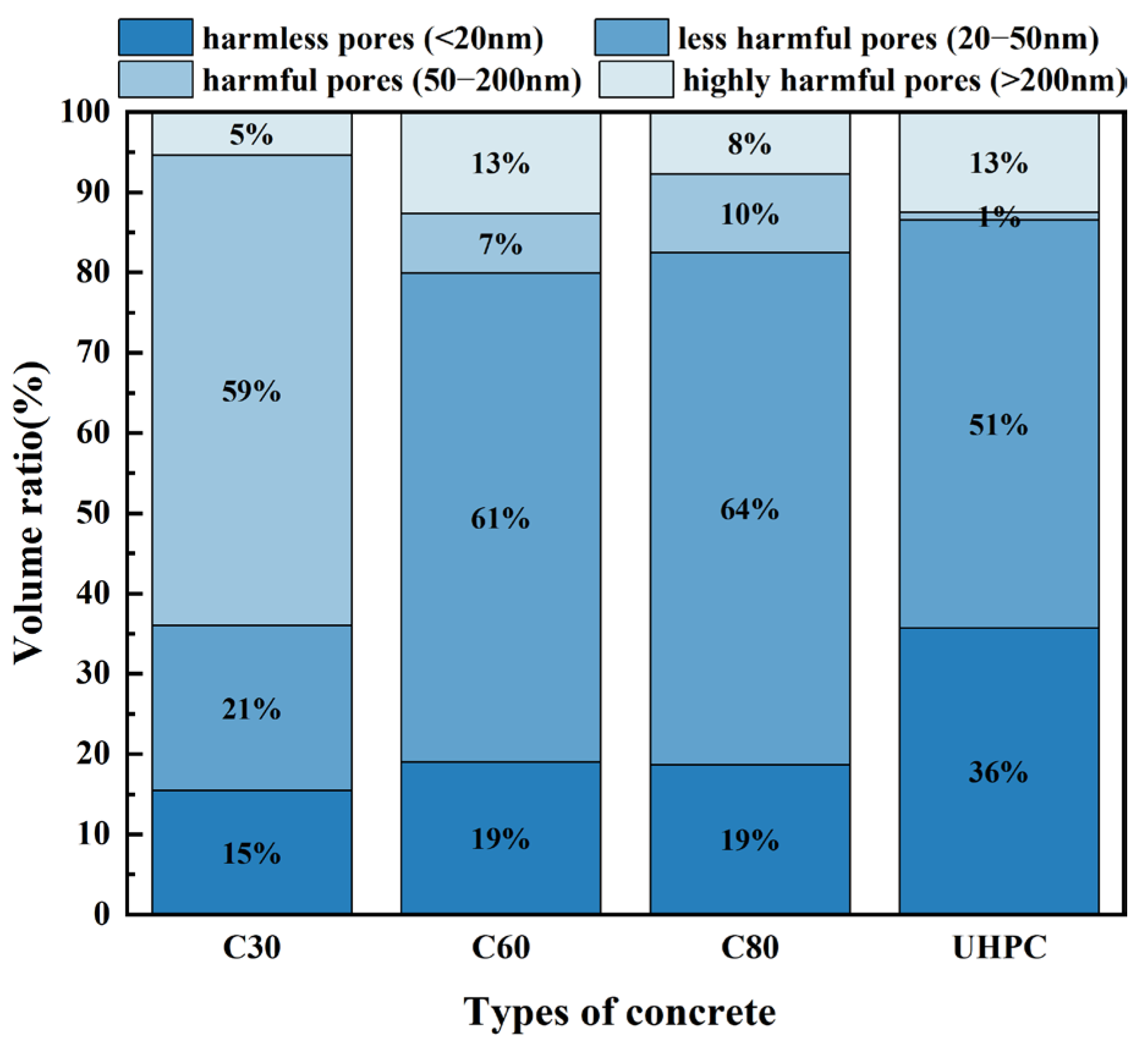

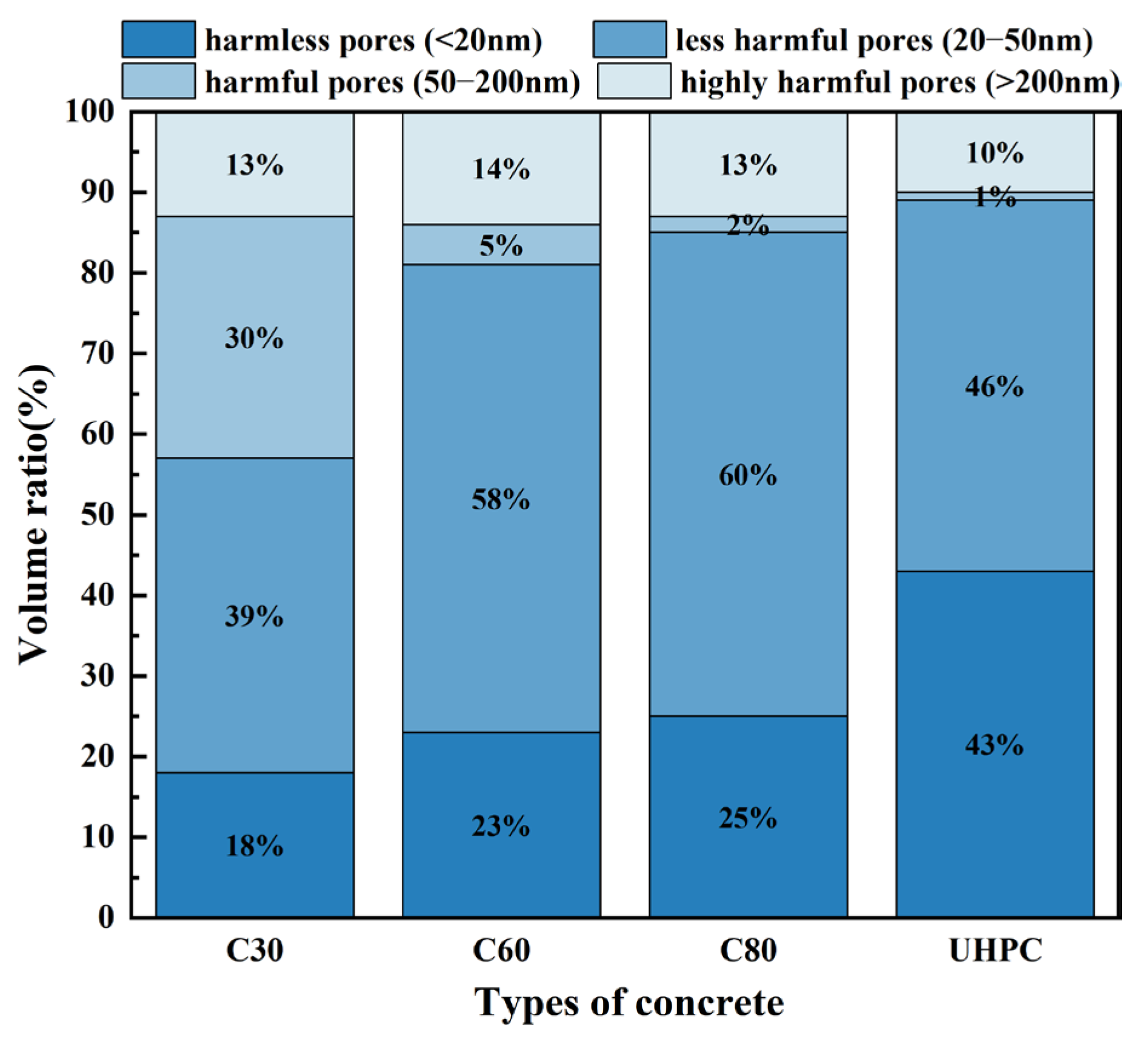

3.3. Pore Structure Characteristics

4. Discussions

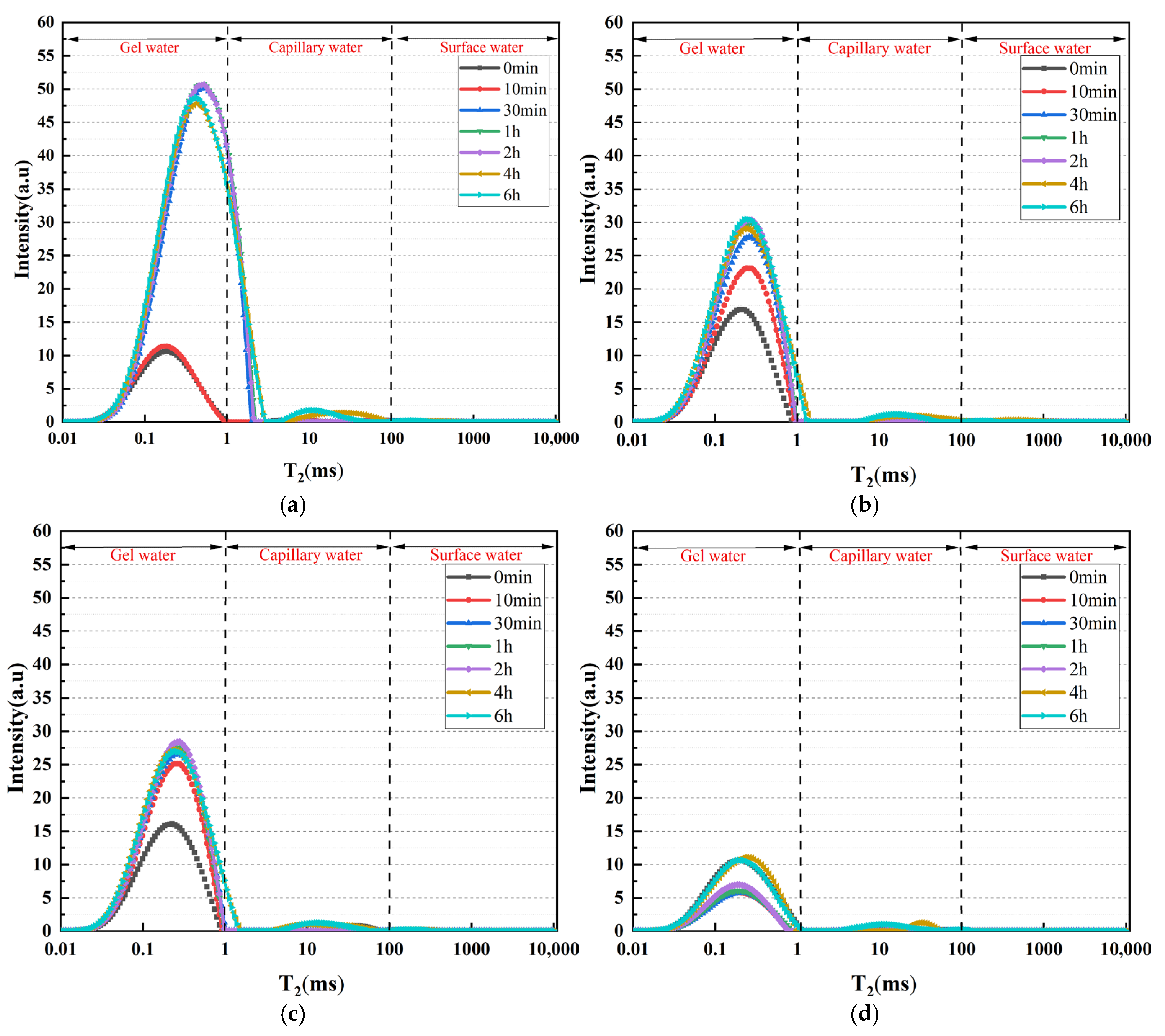

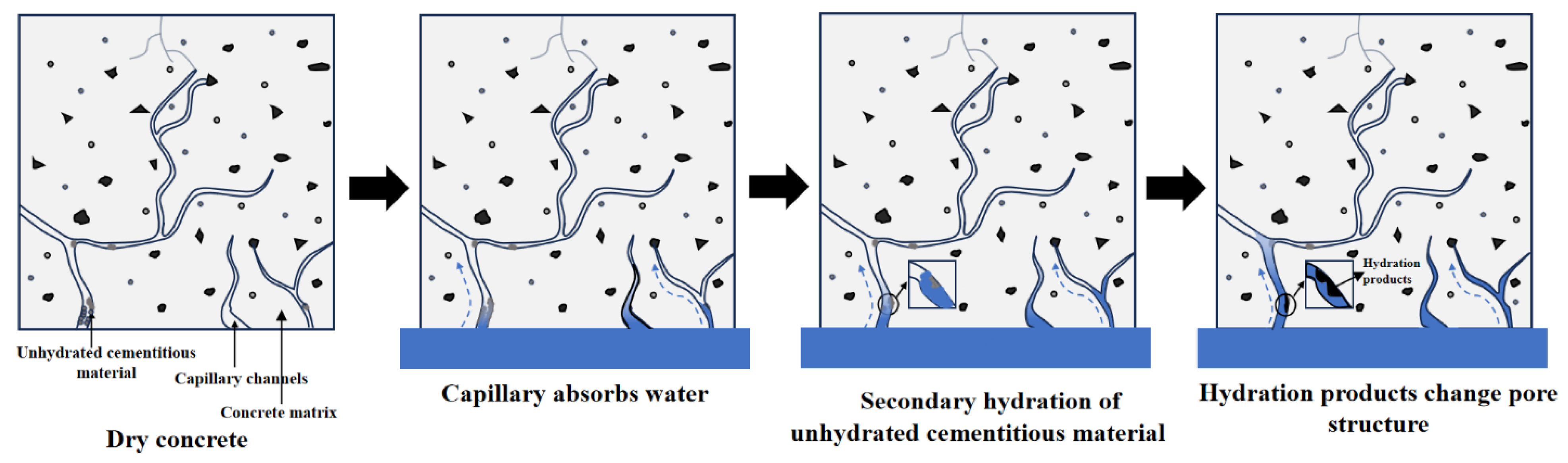

4.1. Water Transport Process and Mechanism

4.2. Explanation of the Abnormal Water Absorption Phenomenon

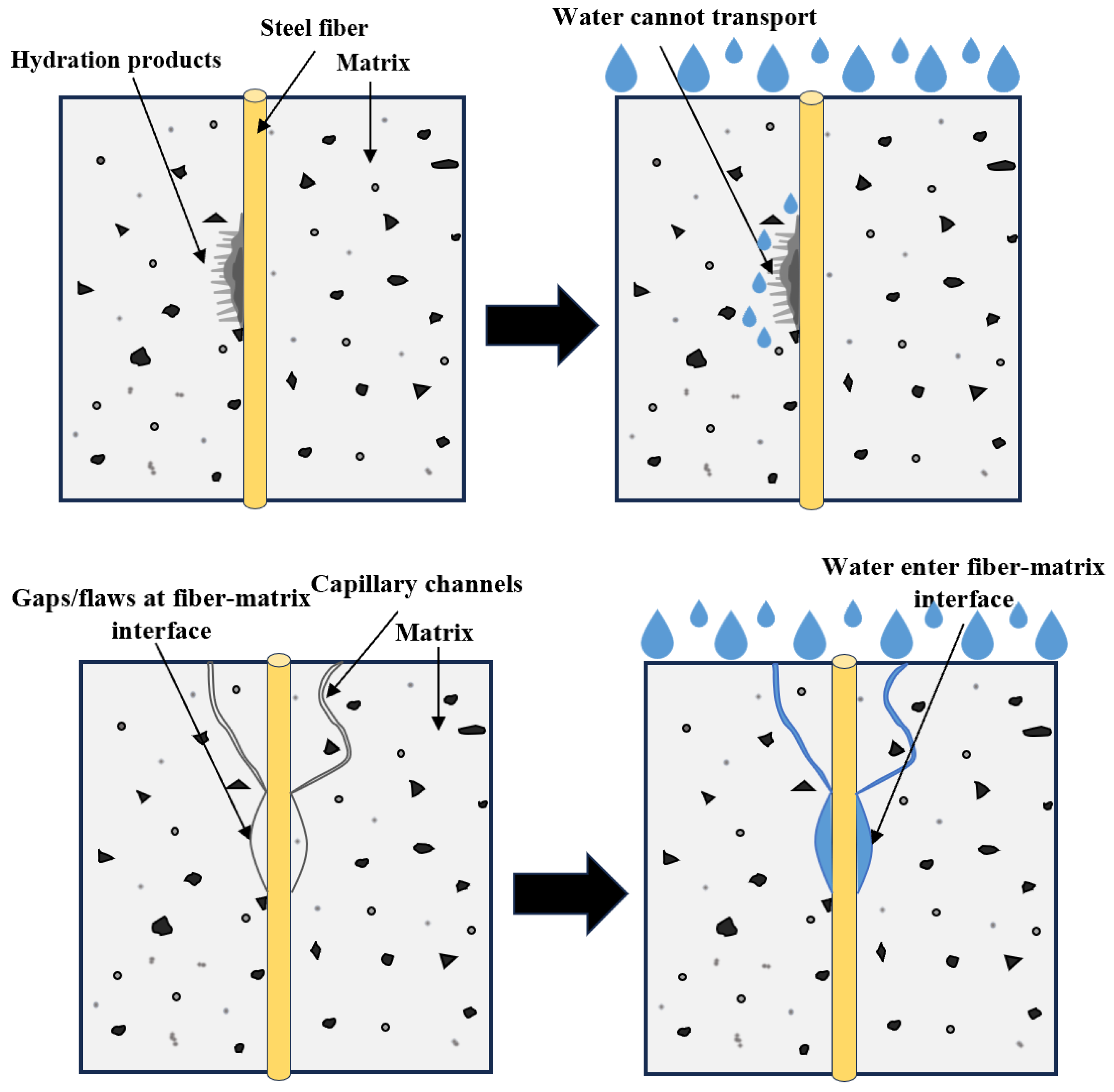

4.3. Influence of Steel Fibers on the Capillary Water Absorption

5. Conclusions

- The capillary water absorption process in concrete occurs in two distinct stages. The initial stage (0 min to 6 h) is characterized by rapid water absorption, while the secondary stage (1 day to 12 days) involves a slower rate of water absorption. Over time, the cumulative capillary water absorption rate decreases and eventually stabilizes.

- Significant differences in capillary water absorption rates are observed among the various types of concrete, primarily due to differences in their compactness. Lower strength grades, like C30, exhibit higher porosity, including a greater proportion of harmful pores, which enhances water transmission pathways and pore connectivity. By reducing the water–binder ratio and optimizing the composition of cementitious materials, the compactness of concrete improves, leading to reduced porosity and a lower proportion of harmful pores, thereby decreasing capillary water absorption.

- 1H low-field NMR analysis reveals that external water initially enters larger capillary pores through capillary absorption, filling gel pores near these capillary pores. Over time, as larger capillary pores reach partial saturation, water begins to migrate into smaller capillary pores. Larger capillary pores continue to absorb water at a diminished rate until a dynamic equilibrium is achieved. For pores smaller than gel pores, water migrates predominantly in the form of water vapor.

- Over extended periods, the capillary water absorption rate deviates from a linear relationship. This phenomenon is mainly attributed to water entering the concrete and reacting with unhydrated cement particles, producing additional C-S-H. The formation of C-S-H fills smaller pores, altering the internal pore structure, reducing pore connectivity, and increasing pore tortuosity. This phenomenon, termed the “C-S-H blocking effect”, plays a key role in reducing water absorption rates.

- Steel fibers influence water migration in concrete primarily through the following two mechanisms: the interfacial effect between steel fibers and the matrix and the blocking effect of steel fibers. These effects collectively determine the extent to which steel fibers affect the capillary water absorption rate of concrete.

- This study systematically investigates the effects and mechanisms of varying steel fiber contents on the capillary water absorption behavior of concrete. However, the dynamic transport process of water within the material’s microstructure was not directly monitored in real time. Future research should aim to integrate advanced, non-destructive evaluation methods capable of providing sufficient spatio-temporal resolution to track water movement dynamically. Coupling such experimental approaches with refined theoretical modeling will be crucial for fully elucidating the kinetic mechanisms underlying the water absorption process.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Monteiro, P.; Miller, S.A.; Horvath, A. Towards sustainable concrete. Natu. Mater. 2017, 16, 698–699. [Google Scholar] [CrossRef] [PubMed]

- Tian, Y.; Zhang, G.; Ye, H.; Zeng, Q.; Zhang, Z.; Tian, Z.; Jin, X.; Jin, N.; Chen, Z.; Wang, J. Corrosion of steel rebar in concrete induced by chloride ions under natural environments. Constr. Build. Mater. 2023, 369, 130504. [Google Scholar] [CrossRef]

- Gan, L.; Zou, Z.; Zhang, Z.; Zhang, H.; Gu, H. Investigation on the evolution of concrete pore structure under freeze-thaw and fatigue loads. J. Build. Eng. 2024, 97, 110914. [Google Scholar] [CrossRef]

- Qiu, H.; Liang, C.; Tu, B.; Liu, L.; Zhang, F. Study on mechanical properties of cemented backfill with different mineral admixtures. Constr. Build. Mater. 2023, 367, 130251. [Google Scholar] [CrossRef]

- Liu, Z.; Gan, L.; Rong, H. Durability of concrete exposed to laboratory-simulated marine microbe-induced corrosion. Constr. Build. Mater. 2023, 400, 132563. [Google Scholar] [CrossRef]

- Castro, J. Moisture Transport in Cement Based Materials: Application to Transport Tests and Internal Curing. Ph.D. Thesis, Purdue University, West Lafayette, IN, USA, 2011. [Google Scholar]

- Singla, A.; Šavija, B.; Sluys, L.J.; Rodríguez, R.C. Modelling of capillary water absorption in sound and cracked concrete using a dual-lattice approach: Computational aspects. Constr. Build. Mater. 2022, 320, 125826. [Google Scholar] [CrossRef]

- Wang, X.; Sun, M.; Guo, S. Water absorption characteristics of cement-based materials based on the chemical reaction. Constr. Build. Mater. 2019, 220, 607–614. [Google Scholar] [CrossRef]

- Liu, B.; Luo, G.; Xie, Y. Effect of curing conditions on the permeability of concrete with high volume mineral admixtures. Constr. Build. Mater. 2018, 167, 359–371. [Google Scholar] [CrossRef]

- Fang, J.; Jiang, C.; Gu, X. Moisture transports in high-cycle compressive fatigue-damaged concrete. Constr. Build. Mater. 2023, 409, 133994. [Google Scholar] [CrossRef]

- Bahmani, H.; Mostafaei, H.; Santos, P.; Chamasemani, N. Enhancing the Mechanical Properties of Ultra-High-Performance Concrete (UHPC) Through Silica Sand Replacement with Steel Slag. Buildings 2024, 14, 3520. [Google Scholar] [CrossRef]

- Wang, L.; Yin, H.; Zou, K. Mesoscopic method for simulating the two-dimensional capillary water absorption process of concrete. Chin. J. Comput. Mech. 2024, 7, 1–8. (In Chinese) [Google Scholar]

- Zhang, H.; Chen, W.; He, B.; Zhu, X.; Jiang, Z. Compressive behaviour and microstructure of geopolymer mortar subjected to cryogenic freeze-thaw cycle: Effects of cycles and polypropylene fiber. Cem. Concr. Compos. 2024, 149, 105505. [Google Scholar] [CrossRef]

- Multon, S.; Verdier, J.; Cagnon, H.; Nehme, A.; Sogbossi, H. Numerical analysis of concrete permeability measurements in laboratory and in field. Cem. Concr. Res. 2024, 178, 107455. [Google Scholar] [CrossRef]

- Du, W.; Yu, F.; Qiu, L.; Guo, Y.; Wang, J. Effect of Steel Fibers on Tensile Properties of Ultra-High-Performance Concrete: A Review. Material. 2024, 17, 1108. [Google Scholar] [CrossRef]

- Mu, R.; Chen, J.; Chen, X.; Diao, C.; Wang, X. Effect of the orientation of steel fiber on the strength of ultra-high-performance concrete (UHPC). Constr. Build. Mater. 2023, 406, 133431. [Google Scholar] [CrossRef]

- He, B.; Zhu, X.; Zhang, H.; Sun, D.; Banthia, N.; Jiang, Z. Nano-engineering steel fiber for UHPC: Implication for varying cryogenic and elevated exposure. Cem. Concr. Compos. 2025, 156, 105851. [Google Scholar] [CrossRef]

- Yu, L.; Liu, Y.; Liu, Y. Advanced monitoring of damage behavior and 3D visualization of fiber distribution in assessing crack resistance mechanisms in steel fiber-reinforced concrete. J. Build. Eng. 2024, 97, 110980. [Google Scholar] [CrossRef]

- Filazi, A.; Tortuk, S.; Pul, M. Determination of optimum blast furnace slag ash and hemp fiber ratio in cement mortars. Structures 2023, 57, 105024. [Google Scholar] [CrossRef]

- GB/T 50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2019.

- ASTM International. 1585; Standard Test Method for Measurement of Rate of Absorption of Water by Hydraulic-Cement Concretes. ASTM International: West Conshohocken, PA, USA, 2004.

- Stephen, W. Flow in porous media I: A theoretical derivation of Darcy’s law. Trans. Por. Med. 1986, 1, 3–25. [Google Scholar]

- GB/T 21650.1-2008; Pore Size Distribution and Porosity of Solid Materials by Mercury Porosimetry and Gas Adsorption. Part 1: Mercury Porosimetry. Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2008.

- Hu, Z.; Wyrzykowski, M.; Scrivener, K.; Lura, P. A novel method to predict internal relative humidity in cementitious materials by 1H NMR. Cem. Concr. Res. 2018, 104, 80–93. [Google Scholar] [CrossRef]

- De, K.S.; Mukherjee, A. A multiscale model including the effect of pores, aggregates and their interfaces for moisture diffusion in concrete. Cem. Concr. Compos. 2020, 111, 103595. [Google Scholar] [CrossRef]

- Hwang, W.; Ann, K.Y. Determination of rust formation to cracking at the steel-concrete interface by corrosion of steel in concrete. Constr. Build. Mater. 2023, 367, 130215. [Google Scholar] [CrossRef]

- Liu, H.; Sun, Z.; Yang, J.; Ji, Y. A novel method for semi-quantitative analysis of hydration degree of cement by 1H low-field NMR. Cem. Concr. Res. 2021, 141, 106329. [Google Scholar] [CrossRef]

- Villagrán-Zaccardi, Y.A.; Alderete, N.M.; Benítez, A.; Carrasco, M.F.; Corallo, P.; López, R.; Rios, C. Relationship between sorptivity coefficients of concrete as calculated from the evolution of water uptake versus t0.5 or t0.25. Constr. Build. Mater. 2022, 342, 128084. [Google Scholar] [CrossRef]

- Srimook, P.; Ogawa, K.; Maruyama, I. Meso-scale Modeling of Anomalous Moisture Transport in Concrete Considering Microstructural Change of Cement-based Material. J. Adv. Concr. Technol. 2024, 22, 344–371. [Google Scholar] [CrossRef]

- Pradhan, B.; Nagesh, M.; Bhattacharjee, B. Prediction of the hydraulic diffusivity from pore size distribution of concrete. Cem. Concr. Res. 2004, 35, 1724–1733. [Google Scholar] [CrossRef]

- Rucker-Gramm, P.; Beddoe, E. Effect of moisture content of concrete on water uptake. Cem. Concr. Res. 2009, 40, 102–108. [Google Scholar] [CrossRef]

- Fischer, N.; Haerdtl, R.; McDonald, J.P. Observation of the redistribution of nanoscale water filled porosity in cement based materials during wetting. Cem. Concr. Res. 2015, 68, 148–155. [Google Scholar] [CrossRef]

- Jennings, H.; Kropp, J.; Scrivener, K. The Modelling of Microstructure and its Potential for Studying Transport Properties and Durability; Springer: Dordrecht, The Netherlands, 1996; pp. 54–78. [Google Scholar]

- Prayuda, H.; Monika, F.; Cahyati, M.; Saleh, F. Self Fiber Compacting Concrete (SFCC) Properties Incorporated with Silica Fume and Fiber. Civ. Eng. J. 2020, 29, 52–60. [Google Scholar]

| Raw Material | SiO2 | CaO | Al2O3 | Fe2O3 | SO3 | MgO | K2O | TiO2 | Na2O |

|---|---|---|---|---|---|---|---|---|---|

| Cement | 17.00 | 65.05 | 4.95 | 3.72 | 2.93 | 0.96 | 0.69 | 0.28 | 0.11 |

| Fly ash | 45.69 | 2.94 | 42.20 | 2.72 | 0.52 | 0.31 | 0.53 | 2.04 | 0.13 |

| GGBFS | 29.98 | 44.40 | 14.50 | 0.50 | 2.18 | 6.20 | 0.25 | 0.80 | 0.34 |

| Silica fume | 84.92 | 1.04 | 0.63 | 3.44 | 0.89 | 1.18 | 2.58 | 0 | 0.97 |

| Mixtures | Cement | Fly Ash | GGBFS | Silica Fume | Fine Aggregate | Coarse Aggregate | PCE | Steel Fiber | Water |

|---|---|---|---|---|---|---|---|---|---|

| C30-0 | 350 | / | / | / | 800 | 1045 | 0.017 | 0 | 190 |

| C30-1 | 350 | / | / | / | 800 | 1045 | 0.017 | 20 | 190 |

| C30-2 | 350 | / | / | / | 800 | 1045 | 0.017 | 40 | 190 |

| C30-3 | 350 | / | / | / | 800 | 1045 | 0.017 | 60 | 190 |

| C60-0 | 350 | 60 | 100 | / | 730 | 1000 | 0.020 | 0 | 160 |

| C60-1 | 350 | 60 | 100 | / | 730 | 1000 | 0.020 | 20 | 160 |

| C60-2 | 350 | 60 | 100 | / | 730 | 1000 | 0.020 | 40 | 160 |

| C60-3 | 350 | 60 | 100 | / | 730 | 1000 | 0.020 | 60 | 160 |

| C80-0 | 380 | 70 | 120 | / | 720 | 992 | 0.022 | 0 | 148 |

| C80-1 | 380 | 70 | 120 | / | 720 | 992 | 0.022 | 20 | 148 |

| C80-2 | 380 | 70 | 120 | / | 720 | 992 | 0.022 | 40 | 148 |

| C80-3 | 380 | 70 | 120 | / | 720 | 992 | 0.022 | 60 | 148 |

| UHPC-0 | 700 | 100 | 100 | 100 | 1000 | / | 0.060 | 0 | 170 |

| UHPC-1 | 700 | 100 | 100 | 100 | 1000 | / | 0.060 | 80 | 170 |

| UHPC-2 | 700 | 100 | 100 | 100 | 1000 | / | 0.060 | 160 | 170 |

| UHPC-3 | 700 | 100 | 100 | 100 | 1000 | / | 0.060 | 240 | 170 |

| Concrete Strength Grade | Compressive Strength (MPa) | |||

|---|---|---|---|---|

| Concrete-0 | Concrete-1 | Concrete-2 | Concrete-3 | |

| C30 | 32.5 | 35.3 | 39.1 | 40.8 |

| C60 | 62.0 | 64.5 | 66.3 | 68.4 |

| C80 | 84.1 | 86.3 | 88.6 | 92.2 |

| UHPC | 108.7 | 115.5 | 122.7 | 128.3 |

| Concrete Strength Grade | Specimen Number | The Initial Water Absorption (cm/s1/2) | The Secondary Water Absorption (cm/s1/2) |

|---|---|---|---|

| C30 | C30-0 | 9.82 × 10−4 | 6.77 × 10−4 |

| C30-1 | 9.98 × 10−4 | 6.61 × 10−4 | |

| C30-2 | 1.16 × 10−3 | 6.78 × 10−4 | |

| C30-3 | 8.82 × 10−4 | 6.69 × 10−4 | |

| C60 | C60-0 | 4.19 × 10−4 | 1.01 × 10−4 |

| C60-1 | 4.12 × 10−4 | 1.05 × 10−4 | |

| C60-2 | 4.08 × 10−4 | 1.29 × 10−4 | |

| C60-3 | 4.59 × 10−4 | 1.19 × 10−4 | |

| C80 | C80-0 | 2.36 × 10−4 | 4.78 × 10−5 |

| C80-1 | 2.88 × 10−4 | 4.69 × 10−5 | |

| C80-2 | 2.25 × 10−4 | 4.56 × 10−5 | |

| C80-3 | 3.23 × 10−4 | 3.73 × 10−5 | |

| UHPC | UHPC-0 | 7.17 × 10−5 | 2.95 × 10−5 |

| UHPC-1 | 3.65 × 10−5 | 2.77 × 10−5 | |

| UHPC-2 | 4.74 × 10−5 | 2.19 × 10−5 | |

| UHPC-3 | 5.69 × 10−5 | 2.43 × 10−5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nan, F.; Shen, Q.; Zou, S.; Yang, H.; Sun, Z.; Yang, J. Capillary Water Absorption Characteristics of Steel Fiber-Reinforced Concrete. Buildings 2025, 15, 1542. https://doi.org/10.3390/buildings15091542

Nan F, Shen Q, Zou S, Yang H, Sun Z, Yang J. Capillary Water Absorption Characteristics of Steel Fiber-Reinforced Concrete. Buildings. 2025; 15(9):1542. https://doi.org/10.3390/buildings15091542

Chicago/Turabian StyleNan, Fang, Qing Shen, Shuang Zou, Haijing Yang, Zhenping Sun, and Jingbin Yang. 2025. "Capillary Water Absorption Characteristics of Steel Fiber-Reinforced Concrete" Buildings 15, no. 9: 1542. https://doi.org/10.3390/buildings15091542

APA StyleNan, F., Shen, Q., Zou, S., Yang, H., Sun, Z., & Yang, J. (2025). Capillary Water Absorption Characteristics of Steel Fiber-Reinforced Concrete. Buildings, 15(9), 1542. https://doi.org/10.3390/buildings15091542