Systematic Review on the Behaviour of Carbon and Stainless Steel Reinforcing Bars in Buildings Under High Temperatures

Abstract

1. Introduction

2. Materials and Methods

2.1. Introduction to the Research and Resarch Question

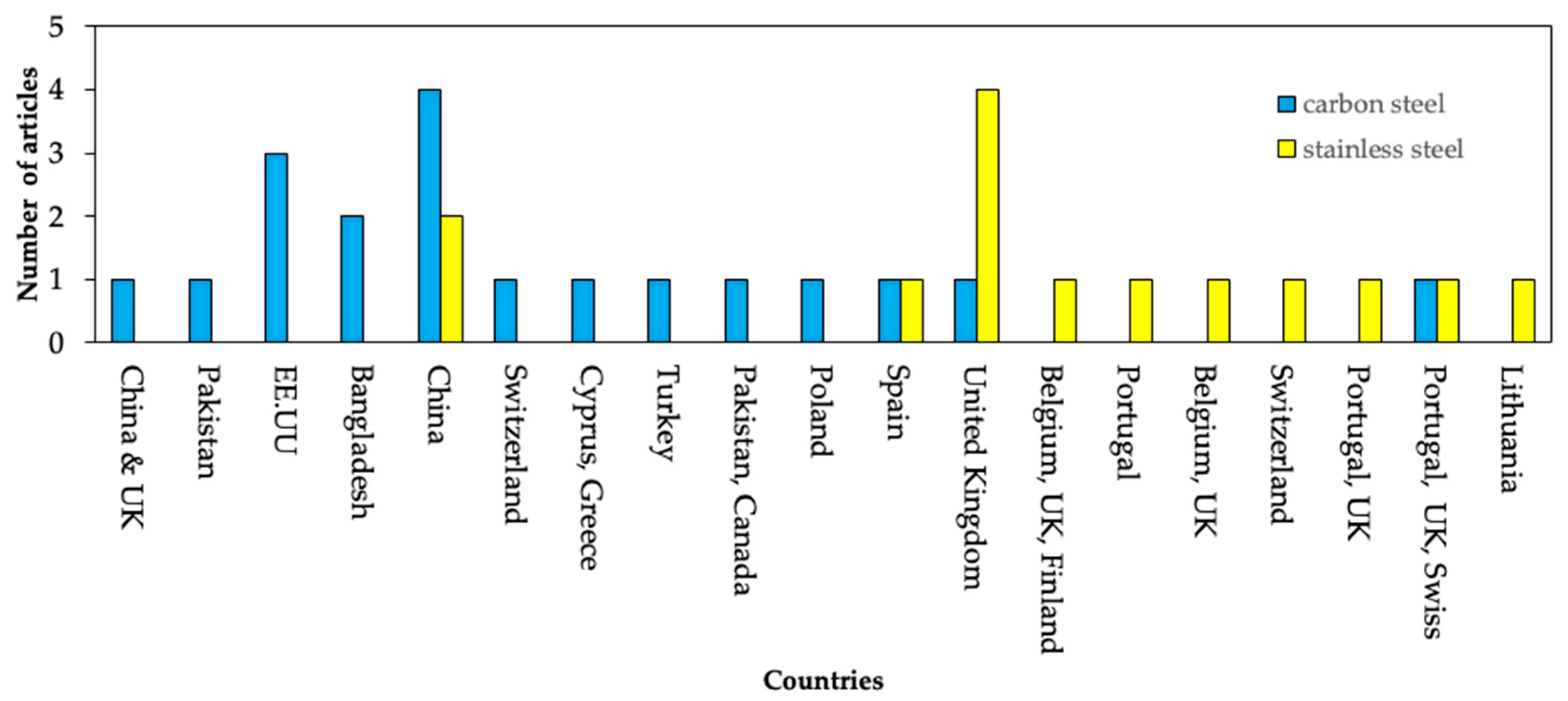

2.2. Search Strategies, Inclusion and Exclusion Criteria, and Article Selection Process

- -

- Peer-reviewed articles.

- -

- Studies published and indexed in journals from the mentioned databases.

- -

- Studies written in English.

- -

- Articles addressing the behaviour of steel under high temperatures and methods to improve structural performance in thermal incidents.

- -

- Articles that specify the steel content or provide the properties of the steel as determined by the authors.

- -

- Articles that specify fire scenarios in buildings or structures, even if chemical composition is not provided.

- -

- Studies that do not specify the type of steel used.

- -

- Studies not related to the behaviour of steel under high temperatures or to improvements in thermal incident resistance.

- -

- Studies published in languages other than English.

- -

- Studies that are not indexed.

- -

- Studies that do not provide the chemical composition or type of steel.

- -

- Studies involving high-carbon steel.

2.3. Data Extraction, Quality Assessment, and Synthesis

2.4. Results, Discussion, and Conclusions

3. Results

3.1. Characteristics of the Steels Analysed

| Author (Year) | Steel Classification | Chemical Composition |

|---|---|---|

| Yang et al. (2021) [60] | EN 10080 [61]; UNE 36068:2011 [62] B500A; ASTM A615 Grade 60 [63] EN 10025-2 [64] S235JR ASTM A36/A36M [65] | C: ≤0.25%, Mn: ≤1.6%, Si: ≤0.80%, P: ≤0.045%, S: ≤0.045%, Cu: ≤0.5% C: ≤0.22%, Mn: ≤1.4%, Si: ≤0.35%, P: ≤0.045%, S: ≤0.045% |

| Rafi et al. (2018) [66] | EN 10080; UNE 36068:2011 B500A ASTM A615 Grade 60 EN 10080 UNE 36065:2011 B500B ASTM A615 Grade 75 | C: 0.188%, Mn: 0.664%, Cr: 0.381%, P: 0.020% C: 0.190%, Mn: 0.697%, Cr: 0.125%, P: 0.035% |

| Quiel et al. (2020) [67] | EN 10080; UNE 36068:2011 B500A ASTM A615 Grade 420/520/690 EN 10080 UNE 36065:2011 B500B/C ASTM A706 Grade 420/500 [68] B500B/B500C | C: 0.19%, Mn: 1.05%, P: 0.015%, S: 0.015%, Si: 0.15%, Cu: 0.45%, Ni: 0.10%, Cr: 0.10%, Mo: 0.03%, Sn: 0.005%, V: 0.02% C: 0.17%, Mn: 1.10%, P: 0.017%, S: 0.015%, Si: 0.18%, Cu: 0.45%, Ni: 0.15%, Cr: 0.18%, Mo: 0.05%, Sn: 0.01%, V: 0.03% C: 0.18%, Mn: 1.30%, P: 0.020%, S: 0.017%, Si: 0.22%, Cu: 0.47%, Ni: 0.20%, Cr: 0.30%, Mo: 0.06%, Sn: 0.015%, V: 0.04%, C: 0.14%, Mn: 1.10%, P: 0.015%, S: 0.015%, Si: 0.25%, Cu: 0.40%, Ni: 0.13%, Cr: 0.25%, Mo: 0.07%, Sn: 0.01%, V: 0.02% C: 0.13%, Mn: 1.45%, P: 0.018%, S: 0.017%, Si: 0.30%, Cu: 0.40%, Ni: 0.17%, Cr: 0.35%, Mo: 0.09%, Sn: 0.015%, V: 0.03% |

| Tariq et al. (2024) [69] | EN 10080; UNE 36065:2011 [70] B500C ASTM A706 Grade 550 | C: 0.25%, S: 0.035%, P: 0.035%, Ceq: 0.40%, N:120 PPM |

| Li et al. (2021) [71] | EN 10080; UNE 36068:2011 B500C ASTM A706 Grade 60 | C: ≤0.30%, Mn: 0.50–1.50%, Si: ≤0.50%, P: ≤0.035%, S: ≤0.045%, Ceq: ≤0.55 |

| Sobhan et al. (2021) [72] | EN 10080; UNE 36068:2011 B400B ASTM A615 Grade 40 | C: 0.23–0.25%, Mn: 0.60–1.30%, Si: 0.40–0.80%, P: ≤0.045%, S: ≤0.045%, Ceq: ~0.50 |

| Ruan et al. (2015) [73] | EN 10080; UNE 36068:2011 B500A ASTM A615 Grade 60 | C: 0.25%, Mn: 1.6%, Si: 0.80, P: ≤0.045, S: ≤0.045%, Ceq: ≤0.52 |

| Cadoni et al. (2021) [74] | EN 10080; UNE 36065:2011 B500A ASTM A615 Grade 75 | C: ≤0.24%, Mn: ≤1.65, P: ≤0.05, S: ≤0.05%, Ceq: ≤0.52 |

| Chousidis et al. (2023) [75] | EN 10080; UNE 36065:2011 B500C ASTM A706 Grade 550 | C: 0.24%, S: 0.055%, P: 0.055%, N: 0.014%, Cu: 0.650%, Ceq: 0.520% |

| Shahriar et al. (2018) [76] | EN 10080; UNE 36065:2011 B500B ASTM A615 Grade 60 ASTM A706 Grade 60 B500B/C | C: 0.24%, Si: 0.21%, Mn: 0.81%, P: 0.026%, S: 0.021%, Cr: 0.011%, Mo: 0.002%, Ni: 0.004%, Al: 0.001% C: 0.21%, Si: 0.18%, Mn: 0.70%, P: 0.011%, S: 0.020%, Cr: 0.077%, Mo: 0.010%, Ni: 0.044%, Al: 0.001% |

| Xu et al. (2023) [77] | EN 10080; UNE 36068:2011 B500B ASTM A615 Grade 65 EN 10025-2S235JR ASTM A36 | C: ≤0.25%, Mn: ≤1.6%, Si: ≤0.80%, P: ≤0.045%, S: ≤0.045%, Cu: 0.8%, Ceq: ≤0.50 C: ≤0.22%, Mn: ≤1.4%, Si: ≤0.35%, P: ≤0.045%, S: ≤0.045% |

| Kültür et al. (2022) [78] | EN 10080; UNE 36065:2011 B500B ASTM A706 Grade 60 UNE-EN 10025-2A S235JR ASTM A36 | C: ≤0.25%, Mn: ≤1.6%, Si: ≤0.80%, P: ≤0.035%, S: ≤0.035%, N: ≤0.012%, Ceq: ≤0.50, C: ≤0.17%, Mn: ≤1.40%, S: ≤0.035%, P: ≤0.035% |

| Abbas et al. (2023) [79] | EN 10080; UNE 36068:2011 B500B/C ASTM A706 Grade 60 ASTM A615 Grade 60 | C: 0.25%, Mn: 1.28%, Si: 0.33%, S: 0.03%, P: 0.042%, Cr: 0.13%, Mo: 0.016%, Ni: 0.11%, Cu: 0.16%, Co: 0.012%, B: 0.005%, Ti: 0.004%, Pb: 0.019%, Bi: 0.0009%, V: 0.011%, Nb: 0.006%, Al: 0.008%, W: 0.002%, Sn: 0.024% C: 0.27%, Mn: 1.25%, Si: 0.30%, S: 0.026%, P: 0.041%, Cr: 0.10%, Mo: 0.018%, Ni: 0.12%, Cu: 0.16%, Co: 0.015%, B: 0.004%, Ti: 0.004%, Pb: 0.031%, Bi: 0.002%, V: 0.025%, Nb: 0.004%, Al: 0.012%, W: 0.042%, Sn: 0.023% C: 0.30%, Mn: 1.26%, Si: 0.29%, S: 0.02%, P: 0.035%, Cr: 0.092%, Mo: 0.007%, Ni: 0.088%, Cu: 0.17%, Co: 0.016%, B: 0.003%, Ti:0.003%, Pb: 0.02%, Bi: 0.003%, V: 0.012%, Nb: 0.003%, Al: 0.009%, W: 0.003%, Sn: 0.08% |

| Hager et al. (2021) [80] | EN 10080; UNE 36065:2011 B500B ASTM A615 Grade 75 | C: 0.21%, Mn: 0.8%, Si: 0.15%, N: 0.009%, S: 0.030%, Ni: 0.12%, Cu: 0.28%, Ceq: 0.39% |

| Albero et al. (2024) [81] | EN 10080:2011 B500B ASTM A615 Gr. 75 | C: ≤0.24%, Mn: ≤1.65, P: ≤0.05, S: ≤0.05%, Ceq: ≤0.52 |

| Hua et al. (2022) [82] | EN 10080:2011; UNE 36068:2011 B500B/C ASTM A615 Gr. 60 | C: 0.25%, Mn: 1.6%, Si: 0.80, P: ≤0.045, S: ≤0.045%, Ceq: ≤0.52 |

| Wu et al. (2023) [83] | EN 10080:2011; UNE 36068:2011 B500B/C ASTM A615 Gr. 60 | C: 0.25%, Mn: 1.6%, Si: 0.80, P: ≤0.045, S: ≤0.045%, Ceq: ≤0.52 |

| Rehman et al. (2022) [84] | EN 10080:2011; UNE 36068:20 B500B; ASTM A706 Gr. 60 | C: ≤0.25%, Mn: ≤1.6%, Si: ≤0.50%, P: ≤0.05%, S: ≤0.05%, Ceq: ≤0.51 |

| Author (Year) | Steel Classification | Chemical Composition |

|---|---|---|

| Albero et al. (2024) [81] | UNE-EN 1992-1-2:2011 [11]; EN 10088-1:2024 [85] EN 1.4362 ASTM A955/A955M [86] | C: ≤0.24%, Mn: ≤1.65, P: ≤0.05, S: ≤0.05%, Ceq: ≤0.52 C: 0.025%, S: 0.003%, P: 0.032%, Si: 0.37%, Mn: 1.2%, Cr: 18.26%, Ni: 8.10%, Mo: 0.34%, Cu: 0.88%, Sn: 0.01%, Al: 0.004, Co: 0.1%, Nb: 0.02%, N: 0.053% |

| Hua et al. (2022) [82] | UNE-EN 1992-1-2:2011; EN 10088-1:2024 EN 1.4301 ASTM A955/A955M | C: 0.25%, Mn: 1.6%, Si: 0.80, P: ≤0.045, S: ≤0.045%, Ceq: ≤0.52 C: 0.025%, S: 0.003%, P: 0.032%, Si: 0.37%, Mn: 1.2%, Cr: 18.26%, Ni: 8.10%, Mo: 0.34%, Cu: 0.88%, Sn: 0.01%, Al: 0.004%, Co: 0.1%, Nb: 0.02%, N: 0.053% |

| Wu et al. (2023) [83] | UNE-EN 1992-1-2:2011; EN 10088-1:2024 EN 1.4301 ASTM A955/A955M | C: 0.25%, Mn: 1.6%, Si: 0.80, P: ≤0.045, S: ≤0.045%, Ceq: ≤0.52 C: 0.025%, S: 0.003%, P: 0.032%, Si: 0.37%, Mn: 1.2%, Cr: 18.26%, Ni: 8.10%, Mo: 0.34%, Cu: 0.88%, Sn: 0.01%, Al: 0.004%, Co: 0.1%, Nb: 0.02%, N: 0.053% |

| Rehman et al. (2022) [84] | UNE-EN 1992-1-2:2011; EN 10088-1:2024 EN 1.4301 EN 1.4401 EN 1.4436 ASTM A955/A955M | C: 0.032%, Mn: 1.72%, Si: 0.46%, S: 0.004%, P: 0.039%, Ni: 8.1%, Cr: 18.4%, Mo: 0.24%, N: 0.183% C: 0.023%, Mn: 1.438%, Si: 0.366%, S: 0.027%, Ni: 10.54%, Cr: 16.685%, Mo: 2.049%, N: 0.046%, Cu: 0.317%, Ti: 0.005% C: 0.028%, Mn: 1.36%, Si: 0.36%, S: 0.007%, P: 0.031%, Ni: 10.54%, Cr: 16.67%, Mo: 2.53%, N:0.061% C: ≤0.25%, Mn: ≤1.6%, Si: ≤0.50%, P: ≤0.05%, S: ≤0.05%, Ceq: ≤0.51 |

| Molkens et al. (2021) [87] | UNE-EN 1992-1-2:2011; EN 10088-1:2024 EN 1.4301 ASTM A955/A955M | C: 0.025%, S: 0.003%, P: 0.032%, Si: 0.37%, Mn: 1.2%, Cr: 18.26%, Ni: 8.10%, Mo: 0.34%, Cu: 0.88%, Sn: 0.01%, Al: 0.004%, Co: 0.1%, Nb: 0.02%, N: 0.053% |

| Arrais et al. (2022) [88] | UNE-EN 1992-1-2:2011; EN 10088-1:2024 EN 1.4301 ASTM A955/A955M | C: 0.025%, S: 0.003%, P: 0.032%, Si: 0.37%, Mn: 1.2%, Cr: 18.26%, Ni: 8.10%, Mo: 0.34%, Cu: 0.88%, Sn: 0.01%, Al: 0.004%, Co: 0.1%, Nb: 0.02%, N: 0.053% |

| Molkens et al. (2024) [89] | UNE-EN 1992-1-2:2011; EN 10088-1:2024; EN 1.4301; ASTM A955/A955M | C: 0.025%, S: 0.003%, P: 0.032%, Si: 0.37%, Mn: 1.2%, Cr: 18.26%, Ni: 8.10%, Mo: 0.34%, Cu: 0.88%, Sn: 0.01%, Al: 0.004%, Co: 0.1%, Nb: 0.02%, N: 0.053% |

| Cadoni and Forni (2019) [90] | UNE-EN 1992-1-2:2011; EN 10088-1:2024 EN 1.4301 ASTM A955/A955M | C: 0.025%, S: 0.003%, P: 0.032%, Si: 0.37%, Mn: 1.2%, Cr: 18.26%, Ni: 8.10%, Mo: 0.34%, Cu: 0.88%, Sn: 0.01%, Al: 0.004%, Co: 0.1%, Nb: 0.02%, N: 0.053% |

| Gao et al. (2018) [91] | UNE-EN 1992-1-2:2011; EN 10088-1:2024 EN 1.4301; EN 1.4401; ASTM A955/A955M | C: 0.023%, Mn: 1.22%, Si: 0.334%, S: 0.006%, P: 0.024%, Cr: 18.08%, Ni: 8.25% C: 0.022%, Mn: 1.12%, Si: 0.409%, S: 0.001%, P: 0.032%, Cr: 16.75%, Ni: 0.01%, Mo: 2.11% |

| Mehwish et al. (2023) [92] | UNE-EN 1992-1-2:2011; EN 10088-1:2024 EN 1.4301; EN 1.4362; ASTM A955/A955M | C: 0.032%, Mn: 1.72%V, Si: 0.46%, S: 0.004%, P: 0.039%, Ni: 8.1%, Cr: 18.4%, Mo: 0.24%, N: 0.183% C: 0.025%, S: 0.003%, P: 0.032%, Si: 0.37%, Mn: 1.2%, Cr: 18.26%, Ni: 8.10%, Mo: 0.34%, Cu: 0.88%, Sn: 0.01%, Al: 0.004%, Co: 0.1%, Nb: 0.02%, N: 0.053% |

| Gardner et al. (2016) [93] | UNE-EN 1992-1-2:2011; EN 10088-1:2024 EN 1.4307 EN 1.4311 EN 1.4162 EN 1.4362 ASTM A955/955M | C: ≤0.030%, Cr: 17.5–19.5%, Ni: 8.0–10.5%, Mn: ≤2.0%, Si: ≤1.0%, P: ≤0.045%, S: ≤0.015% C: ≤0.030%, Cr: 17.5–18.5%, Ni: 8.5–10.5%, N: 0.10–0.16%, Mn: ≤2.0%, Si: ≤1.0%, P: ≤0.045%, S: ≤0.015% C: ≤0.030%, Cr: 21–22%, Ni: 1.35–1.70%, Mn: 4.0–6.0%, N: 0.20–0.25%, Mo: ≤0.3%, Cu: 0.1–0.8% C: ≤0.030%, Cr: 21.5–24.5%, Ni: 3.0–5.5%, Mo: 0.05–0.6%, N: 0.05–0.20%, Mn: ≤2.5%, Si: ≤1.0%, Cu: ≤0.5% |

| Melo et al. (2022) [94] | UNE-EN 1992-1-2:2011; EN 10088-1:2024 EN 1.4462 ASTM A955/955M | C: 0.017%, Cr: 22.76%, Mn: 1.57%, Ni: 4.64%, Mo: 3.21%, N: 0.171%, Si: 0.34%, Co: 0.17%, Ti: 0.004% |

| Melo et al. (2022) [95] | UNE-EN 1992-1-2:2011; EN 10088-1:2024 EN 1.4301 ASTM A955/A955M | C: 0.04%, Si: 0.49%, Mn: 1.65%, Ni: 7.8%, Cr: 16.8%, Mo: 0.37% |

| Plioplys et al. (2024) [96] | UNE-EN 1992-1-2:2011; EN 10088-1:2024 EN 1.4301 ASTM A955/A955M | C: 0.08%, Cr: 20%, Ni: 10.5%, Mn: 2.0%, Si: 1.0%, P: 0.045%, S: 0.03%, N: 0.10% |

3.2. Analysis of Mechanical Properties and Heating Applied or Fire-Exposed

| Ref. | Heating Applied or Fire-Exposed | Mechanical Properties Analysed |

|---|---|---|

| [60] | - ISO 834 fire curve up to ~1000 °C - Duration up to 180 min - Natural air cooling | - Residual axial capacity - Axial/lateral deformations - Failure modes |

| [66] | - Heating 100–900 °C - 40 min soak - Natural air cooling | - Elastic modulus - Yield strength - Ultimate strength - Ductility - Fracture mode |

| [67] | - Slow heating to 800 °C - 45 min soak - Natural air cooling | - Yield strength - Ultimate strength - Elastic modulus - Strain at peak/failure - Microstructure |

| [69] | - ISO 834 to 650 °C - 60 min exposure - Natural cooling | - Ultimate strength - Axial load capacity - Section loss |

| [71] | - ISO 834 to >850 °C - Duration 30–180 min - Natural air cooling | - Axial/flexural residual strength - Thermal deformations - Buckling - Stress redistribution |

| [72] | - ASTM E119 fire curve - ~850 °C for 30 min - Natural air cooling | - Residual flexural moment - Bond loss - Structural damage (via UPV) |

| [73] | - Heating to 200, 500, 850 °C - 1 h soaking - Cooled in air or water | - Corrosion potential and rate - Mass loss - Microstructure (martensite, pearlite) |

| [74] | - Heating to 600 °C at 3 °C/s - 10 min soaking - No cooling studied | - Yield/ultimate strength - Ductility - Energy absorption - Thermal reduction factors |

| [75] | - Heating at 4–7 °C/min - 60 min soak at 400/800 °C - Natural air cooling | - Compressive/flexural strength - Porosity, sorptivity - Corrosion current and rate - Microstructure (SEM) |

| [76] | - Heated to 500/600/650 °C - 1 h soaking - Natural air cooling | - Microstructure only (martensite, ferrite, pearlite) |

| [77] | - Fire temps up to 1000 °C - 60–180 min ISO curve - Natural air cooling | - Residual load capacity (k-factor) - Displacements - Failure modes |

| [78] | - 25–1000 °C ramp in 100 °C steps - 60 min exposure | - Internal forces, displacements - Rotations, plastic hinge formation - Collapse time/temp |

| [79] | - Final rolling at 640 °C, 680 °C, 720 °C, 760 °C, and 800 °C | - Tensile strength - Yield strength - Elongation - Modulus of elasticity - Toughness modulus - Hardness |

| [80] | - Heating to 200 °C, 400 °C, 600 °C, 700 °C, 800 °C, and 1000 °C, followed by slow or rapid cooling | - Tensile strength - Ductility - Microhardness - Fracture behaviour |

| [81] | - Heating to 600 °C at 10 °C/min - Natural air cooling | - Bond strength - Slip displacement - Concrete compressive and tensile strength |

| [82] | - Heating to 900 °C - Soaking for 20 min - Cooling: Air or water | - Yield and ultimate strength - Strains (εy, εu), elongation (δ) - Ductility - Energy indices (P*, Id, A*, W) |

| [83] | - ISO-834 up to 800 °C - No cooling applied | - Elastic modulus - Yield/ultimate strength - Flexural strength - Connector slip |

| [84] | - Heating at 10 °C/min to 900 °C - 1h exposure - Cooling: Water, air, furnace | - Elastic modulus - Yield/ultimate strength - Ultimate strain (εu, εf) - Stress–strain curves |

| Ref. | Heating Applied or Fire-Exposed | Mechanical Properties Analysed | |

|---|---|---|---|

| [81] | - Heating to 600 °C at 10 °C/min - Natural air cooling | - Bond strength - Slip displacement - Concrete compressive and tensile strength | |

| [82] | - Heating to 900 °C - Soaking for 20 min - Cooling: air or water | - Yield and ultimate strength - Strains (εy, εu), elongation (δ) - Ductility - Energy indices (P*, Id, A*, W) | |

| [83] | - ISO-834 up to 800 °C - No cooling applied | - Elastic modulus - Yield/ultimate strength - Flexural strength - Connector slip | |

| [84] | - Heating at 10 °C/min to 900 °C - 1h exposure - Cooling: Water, air, furnace | - Elastic modulus - Yield/ultimate strength - Ultimate strain (εu, εf) - Stress–strain curves | |

| [87] | - Heating up to 838 °C - Soaking for 20 min - Cooling: Furnace (slow) or water (fast) | - Elastic modulus (E) - Yield strength (f0.2) - Ultimate strength (fu) - Ultimate strain (εu) - Fracture resistance | |

| [88] | - Simulated uniform temps: 350 °C, 600 °C, 700 °C | - Yield strength (0.2%, 2%) - Ultimate strength - Elastic modulus - Axial-bending interaction (N-M) - Collapse modes | |

| [89] | - Heating up to 1200 °C - Various cooling methods: Air, furnace, water | - Yield strength (fy) - Elastic modulus (E) - Ultimate tensile strength (fu) - Ultimate strain (εu) | |

| [90] | - Heating to 1000 °C at 2.78 °C/s - 10 min soaking - No cooling post-test | - Yield and ultimate strength - Strain (εu, εf) - Area reduction (Z) - Hardness, energy, stress–strain | |

| [91] | - Ramp: 20 °C/min then 10 min soak - Exposure: 30/180 min - Cooling: Air or water (200 mL) | - Elastic modulus - Yield strength - Ultimate tensile strength - Fracture stress - Ductility | |

| [92] | - ASTM E119 up to 850 °C - Natural air cooling | - Flexural capacity - Deflection - Failure modes | |

| [93] | - Isothermal and transitory heating up to 1000 °C. No water cooling (natural cooling only) | - Elastic modulus E - Yield/ultimate strength fy (0.2%), fu - Ultimate strain εu, εf - Stress–strain curves | |

| [94] | - Heating to high temperatures not specified | - Tensile strength - Slip behaviour of the joint - Load–displacement response - Energy dissipation | |

| [95] | - Standard fire exposure for 30 and 90 min, followed by natural cooling. Temperatures ranged from 20 to 1000 °C. | - Tensile strength - Energy dissipation capacity - Ductility - Secant stiffness | |

| [96] | - Heating at 400 °C, 600 °C, 800 °C, and 1000 °C, followed by air cooling. | - Cold compression strength (CCS) - Pull-out deformation energy - Tensile strength of steel bars | |

3.3. Main Results and Conclusions on Carbon Steel and Stainless Steel

| Ref. | Main Results | Conclusions |

|---|---|---|

| [60] | - Fire resistance decreases with axial load/slenderness - Larger sections improve performance - Simplified equations proposed | - TRC columns outperform conventional ones under fire - Design formulas proposed |

| [66] | - Stable ≤ 200 °C - Yield strength drops to 15% at 700 °C - CTR bars more ductile when hot | - HRD/TMT degrade progressively - CTR retains ductility - Findings match international standards |

| [67] | - Degradation starts at 400–700 °C - Ultimate strength ~40% at 600 °C - Elastic modulus degrades faster | - ASTM A706 performs best - Eurocode is conservative - Improved model proposed |

| [69] | - A total of 60% loss in strength with 20% corrosion + fire - Epoxy coating reduces damage | - Fire + corrosion severely weaken bars - Epoxy coating is protective - Fire-damaged RC must be reassessed |

| [71] | - Initial high fire resistance - Spalling prevented by PP fibres - Strength loss after 90 min exposure | - High-strength composite columns resist fire well initially - Design method with tables proposed |

| [72] | - Residual strength drops up to 85% in high-strength concrete beams - Internal pressure causes spalling - Crack scoring correlates with mass loss | - Corrosion + fire cause major structural degradation - High-strength concretes are more vulnerable - Codes should consider these combined effects |

| [73] | - Fire exposure increases corrosion risk - Water quenching at 850 °C was most damaging (+60% corrosion rate) | - Thermal exposure lowers corrosion resistance - Water cooling forms martensite, higher corrosion susceptibility |

| [74] | - Strength increases with strain rate - Properties degrade with temp - Strain ageing at 200–300 °C | - B500A shows resistance in extreme conditions - Model Code 2010 conservative under dynamic fire/explosion - Calibrated models proposed |

| [75] | - CNT mortars retained +10% fc and +32% fr at 800 °C - A total of 3–6% lower porosity/sorptivity - A 58% lower corrosion rate | - MWCNTs improve fire and corrosion resistance - Act as crack bridges and reduce porosity - Better steel–mortar interface cohesion |

| [76] | - Martensite transforms to ferrite/pearlite with heat - Fully recrystallised grains at 650 °C | - Lack of martensite stabilisers = loss of thermal strength - TMT bars become structurally weak after fire |

| [77] | - Strength loss grows with fire temp/duration - Concrete strength most influential (up to 32.9%) | - SRC columns retain substantial post-fire capacity - Analytical expression proposed for residual strength |

| [78] | - RC building did not collapse even at 1000 °C - Steel structure failed at 807 °C (31.6 min) | - Concrete cover key to RC fire resistance - Steel frames collapse rapidly if unprotected |

| [79] | - Higher final rolling temperatures increased grain size, decreasing tensile strength, yield strength, and hardness but increased elongation and toughness modulus - Higher carbon content increased hardness, tensile strength, and yield strength but decreased elongation and toughness modulus. - The steel bars met ASTM A615 standards for strength and weight per unit length | - The final rolling temperature and carbon content have a significant impact on the mechanical properties of steel reinforcement bars - The production of reinforcement bars from local scrap can meet ASTM standards if processing variables are properly controlled - Measures should be implemented to better control the chemical composition and final rolling temperatures in the local industry to improve the quality of reinforcement steel |

| [80] | - Steel bars previously exposed to fire conditions showed high sensitivity to cooling intensity. - Specimens heated and quenched in water showed an increase in tensile strength but a significant decrease in material plasticity. | - The ductile-to-brittle transition is influenced by the segregation of nitrogen atoms and localised internal stresses at austenite grain boundaries - The anisotropy of residual stresses affects the localization of elastic deformations and brittle cleavage fracture |

| [81] | - Bond loss proportional to concrete strength loss - Stainless and galvanised bars performed best - Predictive model proposed | - Thermal bond degradation manageable with corrosion-resistant bars - Design model modification proposed |

| [82] | - Strength stable <600 °C, drops above 700 °C - Water cooling reduces ductility more - Models validated | - SCBSBs retain cladding integrity post-fire - Water cooling more damaging - Constitutive models proposed |

| [83] | - Strength drops above 600 °C - Slip crucial in design - Traditional methods underestimate deformation | - Design should include connector slip and SS-specific behaviour - Proposed method improves fire resistance prediction |

| [84] | - Strength retained to 600 °C, drops >700 °C - Water cooling increases ductility - SS more stable than carbon | - EN 1.4301 performs well post-fire - Suitable for reuse - Cooling method mainly affects ductility |

| Ref. | Main Results | Conclusions |

|---|---|---|

| [81] | - Bond loss proportional to concrete strength loss - Stainless and galvanised bars performed best - Predictive model proposed | - Thermal bond degradation manageable with corrosion-resistant bars - Design model modification proposed |

| [82] | - Strength stable <600 °C, drops above 700 °C - Water cooling reduces ductility more - Models validated | - SCBSBs retain cladding integrity post-fire - Water cooling more damaging - Constitutive models proposed |

| [83] | - Strength drops above 600 °C - Slip crucial in design - Traditional methods underestimate deformation | - Design should include connector slip and SS-specific behaviour - Proposed method improves fire resistance prediction |

| [84] | - Strength retained to 600 °C, drops >700 °C - Water cooling increases ductility - SS more stable than carbon | - EN 1.4301 performs well post-fire - Suitable for reuse - Cooling method mainly affects ductility |

| [87] | - Stainless steels retain more strength than carbon - Fast cooling improves strength but reduces ductility - Retention factors proposed per steel type and temperature | - Stainless steels often reusable after fire - Safety factors should depend on fire history - Load history crucial for assessment |

| [88] | - EC3 is conservative for EHS - Kucukler’s method more accurate and economical - Slenderness, material, and moment diagram key parameters | - EC3 unsuitable for EHS stainless columns - New methods needed based on slenderness and steel grade |

| [89] | - Retention factors (Rh) defined per steel and temperature - Austenitic steels retained better properties - Ferritic steels degraded faster - Safety factors proposed based on reliability index β | - Applicable to carbon and stainless steels - Reuse more feasible with stainless - Reliability-based safety factors recommended |

| [90] | - Strength decreases with temp, rises with strain rate - Ductility increases at high temp - Dynamic factors proposed | - 1.4301 shows good ductility under extreme fire + blast - Predictive models suitable for design |

| [91] | - Properties stable to 1000 °C - Yield drops after 700 °C - Cooling method has minor effect | - Residual properties remain usable post-fire - Predictive equations developed for residual strength |

| [92] | - SSRC beams outperformed carbon steel beams - Higher deformation capacity and fire duration | - SSRC beams highly fire-resistant - Fire design should consider SS-specific data |

| [93] | Stainless steels retain higher strength and stiffness than carbon steels above 550 °C. Reduction factors proposed by steel grade. | Suitable for fire-resistant design up to 500 MPa class. Ramberg–Osgood model fits well. Limited by lack of cooling data. |

| [94] | 1. Duplex stainless steel bars EN 1.4462 show better ductility and work hardening compared to carbon steel. 2. Columns reinforced with stainless steel exhibit better load capacity and ductility under cyclic loads. | 1. The use of duplex stainless steel EN 1.4462 improves the cyclic behaviour of reinforced concrete columns compared to the use of carbon steel. 2. Stainless steel bars exhibit greater bond slip and enhance the energy dissipation capacity under cyclic loading conditions. |

| [95] | 1. A 30 min fire exposure resulted in moderate damage, while a 90 min exposure caused extensive cracking and disintegration of the concrete layer. 2. Strengthened columns after fire exposure showed better lateral load capacity and ductility compared to columns not exposed to fire. | 1. Fire exposure significantly affects the stiffness and load-bearing capacity of reinforced concrete columns. 2. Strengthening techniques using CFRP (carbon fibre-reinforced polymer) significantly improve the cyclic behaviour and energy dissipation capacity of fire-damaged columns. |

| [96] | 1. LCC samples treated at 1000 °C showed a significant increase in compression strength. 2. The pull-out deformation energy does not directly correlate with cold compression strength. 3. The mineral composition significantly impacts the joint strength. | 1. The 304 stainless steel bars form a reliable bond with the refractory materials analysed. 2. There is no direct correlation between compressive strength and pull-out deformation energy. 3. Mineral transformations, such as the formation of mullite and corundum, significantly affect the bond strength. |

4. Discussion

- Standardise post-fire thermal characterisation procedures, including parameters such as heating rate, hold time, and testing atmospheres.

- Scale up testing, incorporating full-size specimens and extended thermal cycles to more realistically simulate real-world service conditions in buildings.

- Incorporate advanced technologies, such as 3D volumetric scanning, to detect microstructural changes, mass loss, or surface defects after fire exposure.

- Promote an interdisciplinary approach that brings together metallurgy, material science, structural engineering, and sustainability to develop safer, more durable, and cost-effective steels.

- Improve mathematical modelling by applying statistical tools to identify patterns affecting each test condition, thereby enabling more accurate and reliable formulation of predictive equations.

- Conduct cost analysis studies to explore strategies for reducing the production and application costs of stainless steel, thus enhancing its feasibility and adoption in building construction.

5. Conclusions

- Carbon steel reinforcement shows a significant degradation of its mechanical properties when exposed to temperatures above 500 °C. Their behaviour after cooling is highly dependent on the chemical composition (carbon content, manganese, silicon, etc.) and the type of cooling (fast or slow), in some cases showing brittle microstructures.

- Stainless steels, especially austenitic and duplex steels, have shown higher thermal stability and higher residual strength and ductility after being subjected to high temperatures. Elements such as chromium, nickel, and molybdenum play a decisive role in this behaviour compared to carbon steel. However, exposure to extreme thermal conditions or uncontrolled cooling cycles, either during or after a fire, can favour the formation of brittle intermetallic phases in stainless steels, which compromises their structural stability.

- Considerable methodological heterogeneity is observed among the studies analysed, both in thermal exposures and in test scales and cooling conditions. This lack of homogeneity makes it difficult to extrapolate the results directly to professional practice and underlines the need to standardise mechanical testing procedures after a fire or at high temperatures.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ACI | American Concrete Institute |

| PRISMA | Preferred Reporting Items for Systematic Reviews and Meta-Analyses |

References

- Abdallah, S.; Fan, M.; Rees, D.W.A. Effect of elevated temperature on pull-out behaviour of 4DH/5DH hooked end steel fibres. Compos. Struct. 2017, 165, 180–191. [Google Scholar] [CrossRef]

- Sim, S.-R.; Ryu, D.-W. A method for instant estimation of the temperature experienced by fire-damaged reinforced concrete structures using titanium. Materials 2020, 13, 1993. [Google Scholar] [CrossRef] [PubMed]

- Sharafi, S.Q.; Saito, T. Seismic damage probability assessment of existing Reinforced Concrete School buildings in Afghanistan. Buildings 2024, 14, 1054. [Google Scholar] [CrossRef]

- Das, A.; Bošnjak, J.; Sharma, A. Investigations on the effects of rebar diameter on the post-fire bond capacity of RC flexural members and development of a novel post-fire bond model. Dev. Built Environ. 2024, 20, 100536. [Google Scholar] [CrossRef]

- Gardner, L.; Insausti, A.; Ng, K.; Ashraf, M. Elevated temperature material properties of stainless steel alloys. J. Constr. Steel Res. 2010, 66, 634–647. [Google Scholar] [CrossRef]

- Lauwens, K.; Fortan, M.; Arrayago, I.; Arrizabalaga, E.; Rossi, B. On the shear resistance of ferritic stainless steel composite slabs. Constr. Build. Mater. 2018, 189, 728–735. [Google Scholar] [CrossRef]

- Lu, Y.; Narayanan, D.; Brooks, R.; Castaneda, H. Electrochemical evolution of carbon steel and Fe-9% Cr steel rebar in simulated concrete pore solution (SCPS) in the presence of 3.5 wt% NaCl. Corros. Mater. Degrad. 2022, 3, 454–469. [Google Scholar] [CrossRef]

- Hortigón, B.; Gallardo, J.M.; Nieto-García, E.J.; López, J.A. Strain hardening exponent and strain at maximum stress: Steel rebar case. Constr. Build. Mater. 2019, 196, 175–184. [Google Scholar] [CrossRef]

- Liu, Y.J.; Li, C.; Zhou, W.J. Numerical analysis on tensile properties of grout-filled splice sleeve rebars under ISO 834 standard fire. E3S Web Conf. 2018, 38, 03036. [Google Scholar] [CrossRef]

- Estrada, I.; Real, E.; Arrizabalaga, E.M. General behaviour and effect of rigid and non-rigid end post in stainless steel plate girders loaded in shear. part i: Experimental study. J. Constr. Steel Res. 2007, 63, 970–984. [Google Scholar] [CrossRef]

- UNE-EN 1992-1-2:2011. (s/f). Une.org. Available online: https://www.une.org/encuentra-tu-norma/busca-tu-norma/norma?c=N0047257 (accessed on 19 April 2025).

- ACI CODE-318-25: Building Code for Structural Concrete-Code Requirements and Commentary (ACI CODE-318-25). (s/f). Concrete.org. Available online: https://www.concrete.org/store/productdetail.aspx?ItemID=31825&Format=PROTECTED_PDF&Language=English&Units=US_Units (accessed on 19 April 2025).

- Sullivan, P.J.E.; Lee, C.-C.; Fang, I.-C.; Yeh, T.-Y.; Wu, M.-Y. Fire resistance of beam-column subassemblage. ACI Struct. J. 2012, 109, 31. [Google Scholar] [CrossRef]

- Presuel-Moreno, F.; Scully, J.R.; Sharp, S.R. Literature review of commercially available alloys that have potential as low-cost, corrosion-resistant concrete reinforcement. Corrosion 2010, 66, 086001–086013. [Google Scholar] [CrossRef]

- Matilla, A.L.; Barrio, M.I.P.; Escamilla, A.C.; Ferrer, J.P.; Prieto, T.G. Analysis of the effectiveness of the application of corrosion inhibitors to steel re-bars embedded in concrete. Appl. Sci. 2024, 14, 3364. [Google Scholar] [CrossRef]

- Gunalan, S.; Mahendran, M. Experimental investigation of post-fire mechanical properties of cold-formed steels. Thin Walled Struct. 2014, 84, 241–254. [Google Scholar] [CrossRef]

- Cruise, R.B.; Gardner, L. Residual stress analysis of structural stainless steel sections. J. Constr. Steel Res. 2008, 64, 352–366. [Google Scholar] [CrossRef]

- Neuenschwander, M.; Scandella, C.; Knobloch, M.; Fontana, M. Modeling elevated-temperature mechanical behavior of high and ultra-high strength steels in structural fire design. Mater. Des. 2017, 136, 81–102. [Google Scholar] [CrossRef]

- Li, X.; Lo, K.H.; Kwok, C.T.; Sun, Y.F.; Lai, K.K. Post-fire mechanical and corrosion properties of duplex stainless steel: Comparison with ordinary reinforcing-bar steel. Constr. Build. Mater. 2018, 174, 150–158. [Google Scholar] [CrossRef]

- Touileb, K.; Djoudjou, R.; Hedhibi, A.; Ouis, A.; Benselama, A.; Ibrahim, A.; Abdo, H.S.; Samad, U. Comparative microstructural, mechanical and corrosion study between dissimilar atig and conventional tig weldments of 316l stainless steel and mild steel. Metals 2022, 12, 635. [Google Scholar] [CrossRef]

- Li, G.-Q.; Han, J.; Lou, G.-B.; Wang, Y.C. Predicting intumescent coating protected steel temperature in fire using constant thermal conductivity. Thin Walled Struct. 2016, 98, 177–184. [Google Scholar] [CrossRef]

- Schaumann, P.; Tabeling, F.; Weisheim, W. Anwendung von reaktiven Brandschutzsystemen im Stahlbau. Bautechnik 2017, 94, 368–374. [Google Scholar] [CrossRef]

- de Silva, D.; Nuzzo, I.; Nigro, E.; Occhiuzzi, A. Intumescent coatings for fire resistance of steel structures: Current approaches for qualification and design. Coatings 2022, 12, 696. [Google Scholar] [CrossRef]

- Vakhitova, L.; Kalafat, K.; Vakhitov, R.; Drizhd, V. Improving the fire-retardant performance of industrial reactive coatings for steel building structures. Heliyon 2024, 10, e34729. [Google Scholar] [CrossRef]

- Yi, L.; Feng, S.; Wang, Z.; Ding, Y.; Chu, T.; Zhuang, Y. A comprehensive model to predict the fire performance of intumescent fire-retardant coating on steel substrate. J. Build. Eng. 2024, 95, 110127. [Google Scholar] [CrossRef]

- Bilotta, A.; Silva, D.D.; Nigro, E. Structural fire safety of existing steel buildings, possible general approach and application to the case of the intumescent coatings. Appl. Struct. Fire Eng. 2016, 15–16. [Google Scholar] [CrossRef]

- Liu, C.; Yang, M.; Wang, P.; Li, K.; Gao, X.; Zeng, Z. Experimental and numerical study on post-fire flexural capacity of corroded reinforced concrete beams under various cooling methods. Structures 2024, 68, 107256. [Google Scholar] [CrossRef]

- Dehcheshmeh, E.M.; Rashed, P.; Broujerdian, V.; Shakouri, A.; Aslani, F. Predicting seismic collapse safety of post-fire steel moment frames. Buildings 2023, 13, 1091. [Google Scholar] [CrossRef]

- Huang, Y.; Young, B. Post-fire behaviour of ferritic stainless steel material. Constr. Build. Mater. 2017, 157, 654–667. [Google Scholar] [CrossRef]

- Ghajari, F.A.; Yousefpour, H. Residual bond-slip behavior in reinforced concrete members exposed to elevated temperatures. Struct. Concr. 2022, 24, 3281–3298. [Google Scholar] [CrossRef]

- Sajid, H.U.; Kiran, R. Influence of stress concentration and cooling methods on post-fire mechanical behavior of ASTM A36 steels. Constr. Build. Mater. 2018, 186, 920–945. [Google Scholar] [CrossRef]

- Ullah, S.; Ahmad, F.; Al-Sehemi, A.G.; Raza, M.R.; Assiri, M.A.; Irfan, A.; Oñate, E.; Yeoh, G.H. Effects of expandable graphite on char morphology and pyrolysis of epoxy based intumescent fire-retardant coating. J. Appl. Polym. Sci. 2021, 138, 51206. [Google Scholar] [CrossRef]

- Arya, S.; Kaji, A.; Boermeester, M. Prisma reporting guidelines for meta-analyses and systematic reviews. Jama Surg. 2021, 156, 789–790. [Google Scholar] [CrossRef] [PubMed]

- Riberholt, C.G.; Olsen, M.H.; Milan, J.B.; Gluud, C. Major mistakes and errors in the use of trial sequential analysis in systematic reviews or meta-analyses–protocol for a systematic review. Syst. Rev. 2022, 11, 114. [Google Scholar] [CrossRef]

- Knight, S.R. The value of systematic reviews and meta-analyses in surgery. Eur. Surg. Res. 2021, 62, 221–228. [Google Scholar] [CrossRef]

- Yuan, J.; Ou, Z. Research progress and engineering applications of stainless steel-reinforced concrete structures. Adv. Civ. Eng. 2021, 2021, 9228493. [Google Scholar] [CrossRef]

- Blanco, D.; Rubio, E.; Marín, M.; De Agustina, B. Propuesta metodológica para revisión sistemática en el ámbito de la ingeniería basada en PRISMA. Congr. Nac. Ing. Mecánica 2020, 2020, 1–12. [Google Scholar]

- de Lahoz, M.E.; Barjola, P.; Peláez, I.; Ferrera, D.; Fernandes-Magalhaes, R.; Mercado, F. Unveiling the role of Contingent Negative Variation (CNV) in migraine: A review of electrophysiological studies in adults and children. Biomedicines 2023, 11, 3030. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. Declaración PRISMA 2020: Una guía actualizada para la publicación de revisiones sistemáticas. Rev. Esp. Cardiol. 2021, 74, 790–799. [Google Scholar] [CrossRef]

- Haddaway, N.R.; Page, M.J.; Pritchard, C.C.; McGuinness, L.A. PRISMA2020: An R package and Shiny app for producing PRISMA 2020-compliant flow diagrams, with interactivity for optimised digital transparency and Open Synthesis. Campbell Syst. Rev. 2022, 18, e1230. [Google Scholar] [CrossRef]

- Kostina, M.; Rigina, L.; Kostina, V.; Kudryashov, A.; Fedortsov, R. Corrosion-resistant steels based on Fe–~13 % cr: Heat treatment, corrosion- and wear resistance. review. Izv. Ferr. Metall. 2023, 66, 8–26. [Google Scholar] [CrossRef]

- Maraveas, C.; Fasoulakis, Z.; Tsavdaridis, K. Mechanical properties of high and very high steel at elevated temperatures and after cooling down. Fire Sci. Rev. 2017, 6, 3. [Google Scholar] [CrossRef]

- Chi, J.; Peng, P. Using the microstructure and mechanical behavior of steel materials to develop a new fire investigation technology. Fire Mater. 2017, 41, 864–870. [Google Scholar] [CrossRef]

- Aziz, E.; Kodur, V. Effect of temperature and cooling regime on mechanical properties of high-strength low-alloy steel. Fire Mater. 2016, 40, 926–939. [Google Scholar] [CrossRef]

- Jeong, J.; Kim, B.; Kwon, S.; Kang, M.; Kim, D.; Heo, Y.; Lee, J.; Yim, C. Effect of interdendritic impurity segregation on hot ductility behavior of low-carbon steels. Steel Res. Int. 2020, 91, 2000046. [Google Scholar] [CrossRef]

- Zhou, X.; Zhao, W.; Dong, L.; Song, N. Effect of quenching and tempering temperatures on microstructure and properties of ultrahigh strength cast steel. Steel Res. Int. 2022, 93, 2200328. [Google Scholar] [CrossRef]

- Huang, D.; Kodur, V.; Wang, W. Temperature-dependent properties of high-strength steel for evaluating the fire resistance of structures. Adv. Struct. Eng. 2023, 26, 2265–2281. [Google Scholar] [CrossRef]

- Chou, C.-W.; Lin, H.-M.; Chen, G.-B.; Wu, F.-H.; Chen, C.-Y. A study on fire retardant and soundproof properties of stainless steel EAF reducing slag applied to fiber reinforced cement boards. Materials 2023, 16, 3841. [Google Scholar] [CrossRef]

- Koo, B. A theoretical approach for estimating the effect of water-jet quenching on low-carbon steel beams. Sci. Rep. 2021, 11, 15401. [Google Scholar] [CrossRef]

- Kamil, G.; Liang, Q.; Hadi, M. Numerical analysis of axially loaded rectangular concrete-filled steel tubular short columns at elevated temperatures. Eng. Struct. 2019, 180, 89–102. [Google Scholar] [CrossRef]

- Ronanki, V.S.; Aaleti, S.; Valentim, D.B. Experimental investigation of bond behavior of mild steel reinforcement in UHPC. Eng. Struct. 2018, 176, 707–718. [Google Scholar] [CrossRef]

- Ismail, M. Seismic retrofit of steel frame structures. Pollack Period. 2020, 15, 106–117. [Google Scholar] [CrossRef]

- Choi, I.; Chung, K. Residual strength of structural steels: sn400, sm520 and sm570. Appl. Struct. Fire Eng. 2016, 313–318. [Google Scholar] [CrossRef]

- Taufik, A.; Suprapto, A.; Sonief, A. Characteristic microstructure of micro hot rolled plate steel variating the radius of bending treatment with quenching and tempering heat treatment. J. Appl. Eng. Sci. 2018, 16, 464–470. [Google Scholar] [CrossRef]

- Tang, Z.; Cao, S.; Zhang, X. Improvement of microstructure and mechanical properties of a low alloy cast steel processed by direct quenching-partitioning-tempering technique. Steel Res. Int. 2015, 86, 429–435. [Google Scholar] [CrossRef]

- Pons, D.; Ferri, A.; Romero, M. Post-fire residual strength and ductility of structural steels from hollow sections. Ce/Papers 2022, 5, 458–466. [Google Scholar] [CrossRef]

- Tseng, T.; Yu, C.; Shiue, R.; Yang, T.; Huang, C. The effect of tempering on low-temperature toughness of the direct quenched high-strength offshore steel. Key Eng. Mater. 2017, 735, 49–53. [Google Scholar] [CrossRef]

- Hussein, A.; Abdu, M.; El-Banna, E.; Soliman, S.; Tash, M. Interrelation of steel composition, hardening route, and tempering response of medium carbon low-alloy steels. J. Mater. Eng. Perform. 2016, 25, 1463–1473. [Google Scholar] [CrossRef]

- Liu, D.; Liu, X.; Fu, F.; Wang, W. Nondestructive post-fire damage assessment of structural steel members using leeb harness method. Fire Technol. 2020, 56, 1777–1799. [Google Scholar] [CrossRef]

- Yang, D.; Liu, F.; Huang, S.-S.; Yang, H. Structural fire safety design of square and rectangular tubed-reinforced-concrete columns. Structures 2021, 29, 1286–1321. [Google Scholar] [CrossRef]

- UNE-EN 10080:2006. (s/f). Une.org. Available online: https://www.une.org/encuentra-tu-norma/busca-tu-norma/norma?c=N0036048 (accessed on 19 April 2025).

- UNE 36068:2011. (s/f). Une.org. Available online: https://www.une.org/encuentra-tu-norma/busca-tu-norma/norma?c=N0046929 (accessed on 19 April 2025).

- Standard Specification for Deformed and Plain Carbon-Steel Bars for Concrete Reinforcement. (s/f). Astm.org. Available online: https://store.astm.org/a0615_a0615m-20.html (accessed on 19 April 2025).

- UNE-EN 10025-2:2020. (s/f). Une.org. Available online: https://www.une.org/encuentra-tu-norma/busca-tu-norma/norma?c=N0064323 (accessed on 19 April 2025).

- Standard Specification for Carbon Structural Steel. (s/f). Astm.org. Available online: https://store.astm.org/a0036_a0036m-14.html (accessed on 19 April 2025).

- Rafi, M.M.; Dahar, A.B.; Aziz, T. High temperature mechanical properties of steel bars available in Pakistan. J. Struct. Fire Eng. 2018, 9, 203–221. [Google Scholar] [CrossRef]

- Quiel, S.E.; Irwin, C.H.; Naito, C.J.; Vermaak, N. Mechanical characterization of normal and high-strength steel bars in reinforced concrete members under fire. J. Struct. Eng. 2020, 146, 04020110. [Google Scholar] [CrossRef]

- Standard Specification for Low-Alloy Steel Deformed and Plain Bars for Concrete Reinforcement. (s/f). Astm.org. Available online: https://store.astm.org/a0706_a0706m-06.html (accessed on 19 April 2025).

- Tariq, F. Combined effects of corrosion and fire on load-carrying response of hot-rolled steel reinforcement. J. Struct. Fire Eng. 2024, 15, 619–644. [Google Scholar] [CrossRef]

- UNE 36065:2011. (s/f). Une.org. Available online: https://www.une.org/encuentra-tu-norma/busca-tu-norma/norma?c=N0046928 (accessed on 19 April 2025).

- Li, S.; Liew, J.Y.R.; Xiong, M.-X. Fire performance of composite columns made of high strength steel and concrete. J. Constr. Steel Res. 2021, 181, 106640. [Google Scholar] [CrossRef]

- Sobhan, K.; Reddy, D.V.; Martinez, F. Fire resistance of corroded high-strength structural concrete. J. Struct. Fire Eng. 2020, 12, 17–34. [Google Scholar] [CrossRef]

- Ruan, T.; Spandley, N.; Johnson, C.; Poursaee, A. The impact of fire and fire extinguishing method on the corrosion behavior of the steel bars in concrete pore solution. Fire Saf. J. 2015, 78, 196–201. [Google Scholar] [CrossRef]

- Cadoni, E.; Forni, D. Mechanical behaviour of B500A rebars: Effect of elevated temperature and high strain-rate. Fire Saf. J. 2021, 122, 103321. [Google Scholar] [CrossRef]

- Chousidis, N.; Constantinides, G. Fire endurance and corrosion resistance of nano-modified cement mortars exposed to elevated temperatures. Ceram. Int. 2023, 49, 19182–19193. [Google Scholar] [CrossRef]

- Shahriar, M.S.; Nawaz, M.R.; Islam, M.A. Microstructural changes under Fire in TMT 500W Structural Steel rebars. IOP conference series. Mater. Sci. Eng. 2018, 438, 012035. [Google Scholar] [CrossRef]

- Xu, T.; Liang, D.; Fan, S.; Li, W. Post-Fire Behavior of Cross-Shaped Steel Reinforced Concrete Columns: Simulation and Analytical Expressions; The Hong Kong Institute of Steel Construction: HongKong, China, 2023. [Google Scholar]

- Kültür, Ö.F.; Al-Masri, A.; Sayin, B. Effect of high temperature exposure on design parameters and collapse behavior of reinforced concrete and steel-framed buildings. Case Stud. Constr. Mater. 2022, 17, e01263. [Google Scholar] [CrossRef]

- Abbas, S.; Hameed, R.; Nehdi, M.; Afzal, M.; Shaukat, S. Investigation of reinforcing steel rebar manufactured from local scrap at various finishing rolling temperature. Case Stud. Constr. Mater. 2023, 19, e02499. [Google Scholar] [CrossRef]

- Hager, I.; Kańka, S.; Maślak, M. Properties of quenched and self-tempered reinforcing steel subjected to high temperature and different cooling conditions. J. Struct. Fire Eng. 2021, 12, 141–152. [Google Scholar] [CrossRef]

- Albero, V.; Hernández-Figueirido, D.; Roig-Flores, M.; Melchor-Eixea, A.; Piquer, A. High-temperature effects on bond behaviour between concrete and corrosion resistant steel reinforcements. Constr. Build. Mater. 2024, 447, 138086. [Google Scholar] [CrossRef]

- UNE-EN 10088-1:2024. (s/f). Une.org. Available online: https://www.une.org/encuentra-tu-norma/busca-tu-norma/norma?c=N0073437 (accessed on 19 April 2025).

- Standard Specification for Deformed and Plain Stainless Steel Bars for Concrete Reinforcement. (s/f). Astm.org. Available online: https://store.astm.org/a0955_a0955m-20c.html (accessed on 19 April 2025).

- Hua, J.; Wang, F.; Xiang, Y.; Yang, Z.; Xue, X.; Huang, L.; Wang, N. Mechanical properties of stainless-clad bimetallic steel bars exposed to elevated temperatures. Fire Saf. J. 2022, 127, 103521. [Google Scholar] [CrossRef]

- Wu, M.; Fan, S.; Han, Y.; Liang, D.; Xu, Q. Fire-resistant design of stainless steel-concrete composite beam considering slip of stud connector. Thin Walled Struct. 2023, 186, 110713. [Google Scholar] [CrossRef]

- Rehman, F.-U.; Cashell, K.A.; Anguilano, L. Experimental study of the post-fire mechanical and material response of cold-worked austenitic stainless steel reinforcing bar. Materials 2022, 15, 1564. [Google Scholar] [CrossRef]

- Molkens, T.; Cashell, K.A.; Malaska, M.; Alanen, M.; Rossi, B. Performance of structural stainless steel following a fire. Eng. Struct. 2021, 235, 112001. [Google Scholar] [CrossRef]

- Alexandre Matias Arrais, F.; Lopes, N.; Vila Real, P. Fire resistance of stainless steel slender elliptical hollow section beam-columns. J. Struct. Fire Eng. 2022, 13, 224–248. [Google Scholar] [CrossRef]

- Molkens, T.; Rossi, B. The post-fire assessment of steel structures, a reliability-based semi-probabilistic approach. Fire Technol. 2024, 60, 3019–3041. [Google Scholar] [CrossRef]

- Cadoni, E.; Forni, D. Austenitic stainless steel under extreme combined conditions of loading and temperature. J. Dyn. Behav. Mater. 2019, 5, 230–240. [Google Scholar] [CrossRef]

- Gao, X.; Zhang, X.; Liu, H.; Chen, Z.; Li, H. Residual mechanical properties of stainless steels S30408 and S31608 after fire exposure. Constr. Build. Mater. 2018, 165, 82–92. [Google Scholar] [CrossRef]

- Mehwish, J.; Cashell, K.A.; Shamass, R. Flexure response of stainless-steel-reinforced concrete (SSRC) beams subjected to fire. Eng. Proc. 2023, 44, 20. [Google Scholar] [CrossRef]

- Gardner, L.; Bu, Y.; Francis, P.; Baddoo, N.R.; Cashell, K.A.; McCann, F. Elevated temperature material properties of stainless steel reinforcing bar. Constr. Build. Mater. 2016, 114, 977–997. [Google Scholar] [CrossRef]

- Melo, J.; Afshan, S.; Rossetto, T.; Varum, H.; Arêde, A. Experimental and numerical investigation of the cyclic response of stainless steel reinforced concrete columns. Eng. Struct. 2022, 252, 113607. [Google Scholar] [CrossRef]

- Melo, J.o.s.é.; Triantafyllidis, Z.; Rush, D.; Bisby, L.; Rossetto, T.; Arêde, A.; Varum, H.; Ioannou, I. Cyclic behaviour of as-built and strengthened existing reinforced concrete columns previously damaged by fire. Eng. Struct. 2022, 266, 114584. [Google Scholar] [CrossRef]

- Plioplys, L.; Antonovič, V.; Boris, R.; Kudžma, A.; Gribniak, V. Investigating the high-temperature bonding performance of refractory castables with ribbed stainless-steel bars. Materials 2024, 17, 2916. [Google Scholar] [CrossRef]

- Wang, H.; Qian, D.; Wang, F.; Dong, Z.; Chen, J. Predictive mechanical property and fracture behavior in high-carbon steel containing high-density carbides via artificial RVE modeling. Mater. Des. 2024, 247, 113383. [Google Scholar] [CrossRef]

- Garrison, W.M.; Maloney, J.L. Sulfide Stability, Void Nucleation and the Toughness of Ultra High Strength Steels. MRS Proc. 1990, 186, 407. [Google Scholar] [CrossRef]

- Cai, G.; Zheng, X.; Gao, W.; Guo, J. Self-extinction characteristics of fire extinguishing induced by nitrogen injection rescue in an enclosed urban utility tunnel. Case Stud. Therm. Eng. 2024, 59, 104478. [Google Scholar] [CrossRef]

- Hua, L.; Du, Y.; Qian, D.; Sun, M.; Wang, F. Influence of prior cold rolling on bainite transformation of high carbon bearing steel. Metall. Mater. Trans. A 2024, 56, 640–654. [Google Scholar] [CrossRef]

- Li, R.; Song, X.; Duan, Z.; Hao, Z.; Yang, Y.; Han, Y.; Ran, X.; Liu, Y. Improving the high-temperature ductility of γ-TiAl matrix composites by incorporation of AlCoCrFeNi high entropy alloy particles. J. Alloys Compd. 2025, 1012, 178515. [Google Scholar] [CrossRef]

- Xie, M.; Xu, F.; Wang, Z.; Yin, L.; Wu, X.; Xu, M.; Li, X. Investigating fire collapse early warning systems for portal frames. Buildings 2025, 15, 296. [Google Scholar] [CrossRef]

- Platt, S.; Harries, K.A. Geometry, material properties and bond performance of prototype titanium reinforcing bars. Constr. Build. Mater. 2018, 187, 1253–1266. [Google Scholar] [CrossRef]

| Keywords | Search Date | Database Used |

|---|---|---|

| A615, Structural steel, Quenched, Hypoeutectic steel, Strength, Ductility “A615” Or “Structural steel” Or “Quenched*” Or “Hypoeutectic steel” And “Strength*”And “Ductility” | 7 June 2024 | Google Scholar, Web of Science, Scopus |

| Fire, Structural steel, Quenched, Hypoeutectic steel, Strength, Ductility “Fire” And “Structural steel” Or “Quenched*” Or “Hypoeutectic steel” And “Strength*” And “Ductility” | 17 June 2024 8 July 2024 | Google Scholar, Web of Science, Scopus |

| A955, Structural stainless steel, Quenched, Hypoeutectic, strength, ductility “A955” Or “structural steel” Or “quenched*” Or “Hypoeutectic steel” And “strength*” And “ductility” | 16 April 2025 | Google Scholar, Web of Science, Scopus |

| “Stainless steel” AND “fire” AND “buildings” AND “concrete” | 16 April 2025 | Google Scholar, Web of Science, Scopus |

| “Carbon steel” AND “fire” AND “buildings” AND “concrete” and “rebars” | 16 April 2025 | Google Scholar, Web of Science, Scopus |

| Reason of Exclusion | Articles (Year) |

|---|---|

| Studies that are not written in English. | Kostina, et al. (2023) [41] |

| Studies that do not provide chemical composition. | Maraveas, et al. (2017) [42] |

| Chi and Peng (2017) [43] | |

| Aziz and Kodur (2016) [44] | |

| Jeong et al. (2020) [45] | |

| Zhou et al. (2022) [46] | |

| Studies that do not specify the type of steel. | Huang, et al. (2023) [47] |

| Chou et al. (2023) [48] | |

| Studies that do not provide the temperature. | Koo (2021) [49] |

| Kamil et al. (2019) [50] | |

| Ronanki et al. (2018) [51] | |

| Ismail (2020) [52] | |

| Studies that are not indexed in SCOPUS, Web of Science, or Google Scholar journals. | Choi and Chung (2016) [53] |

| Taufik et al. (2018) [54] | |

| Tang et al. (2015) [55] | |

| Pons et al. (2022) [56] | |

| Tseng et al. (2017) [57] | |

| Medium-high carbon content. | Hussein et al. (2016) [58] |

| Liu et al. (2020) [59] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leal Matilla, A.; Ferrández, D.; Prieto Barrio, M.I.; Varum, H. Systematic Review on the Behaviour of Carbon and Stainless Steel Reinforcing Bars in Buildings Under High Temperatures. Buildings 2025, 15, 1539. https://doi.org/10.3390/buildings15091539

Leal Matilla A, Ferrández D, Prieto Barrio MI, Varum H. Systematic Review on the Behaviour of Carbon and Stainless Steel Reinforcing Bars in Buildings Under High Temperatures. Buildings. 2025; 15(9):1539. https://doi.org/10.3390/buildings15091539

Chicago/Turabian StyleLeal Matilla, Alberto, Daniel Ferrández, Maria Isabel Prieto Barrio, and Humberto Varum. 2025. "Systematic Review on the Behaviour of Carbon and Stainless Steel Reinforcing Bars in Buildings Under High Temperatures" Buildings 15, no. 9: 1539. https://doi.org/10.3390/buildings15091539

APA StyleLeal Matilla, A., Ferrández, D., Prieto Barrio, M. I., & Varum, H. (2025). Systematic Review on the Behaviour of Carbon and Stainless Steel Reinforcing Bars in Buildings Under High Temperatures. Buildings, 15(9), 1539. https://doi.org/10.3390/buildings15091539