Dynamic Modeling, Trajectory Optimization, and Linear Control of Cable-Driven Parallel Robots for Automated Panelized Building Retrofits †

Abstract

1. Introduction

- Dynamic modeling of six–degrees of freedom (6DOF) CDPRs: We model the dynamics of the CDPR used for installing prefabricated panels. Our analysis highlights the critical role of damping in system behavior, an aspect often overlooked in prior studies.

- Trajectory optimization for efficient handling of heavy loads: We formulate a trajectory optimization problem using nonlinear programming techniques to directly minimize objectives of interest, such as minimum effort. Notably, our framework can generate optimal open-loop trajectories over extended durations (e.g., 20 s) for a 6DOF CDPR, a capability that has not been widely demonstrated in prior studies to the best of our knowledge.

- Feedback control strategies for high-precision trajectory tracking: We apply the well-established Linear Quadratic Gaussian (LQG) control framework to estimate the full states and track the optimal trajectory. Although the LQG framework provides a foundation for control, achieving the high-precision requirements of the panel installation process in the construction industry remains challenging. To address this, we evaluate different sensors for state estimation and examine their effectiveness in mitigating external disturbances. Our study offers insights into designing feedback control strategies that integrate optimal control with state estimation, ensuring accurate trajectory tracking despite uncertainties and environmental factors.

2. Related Work

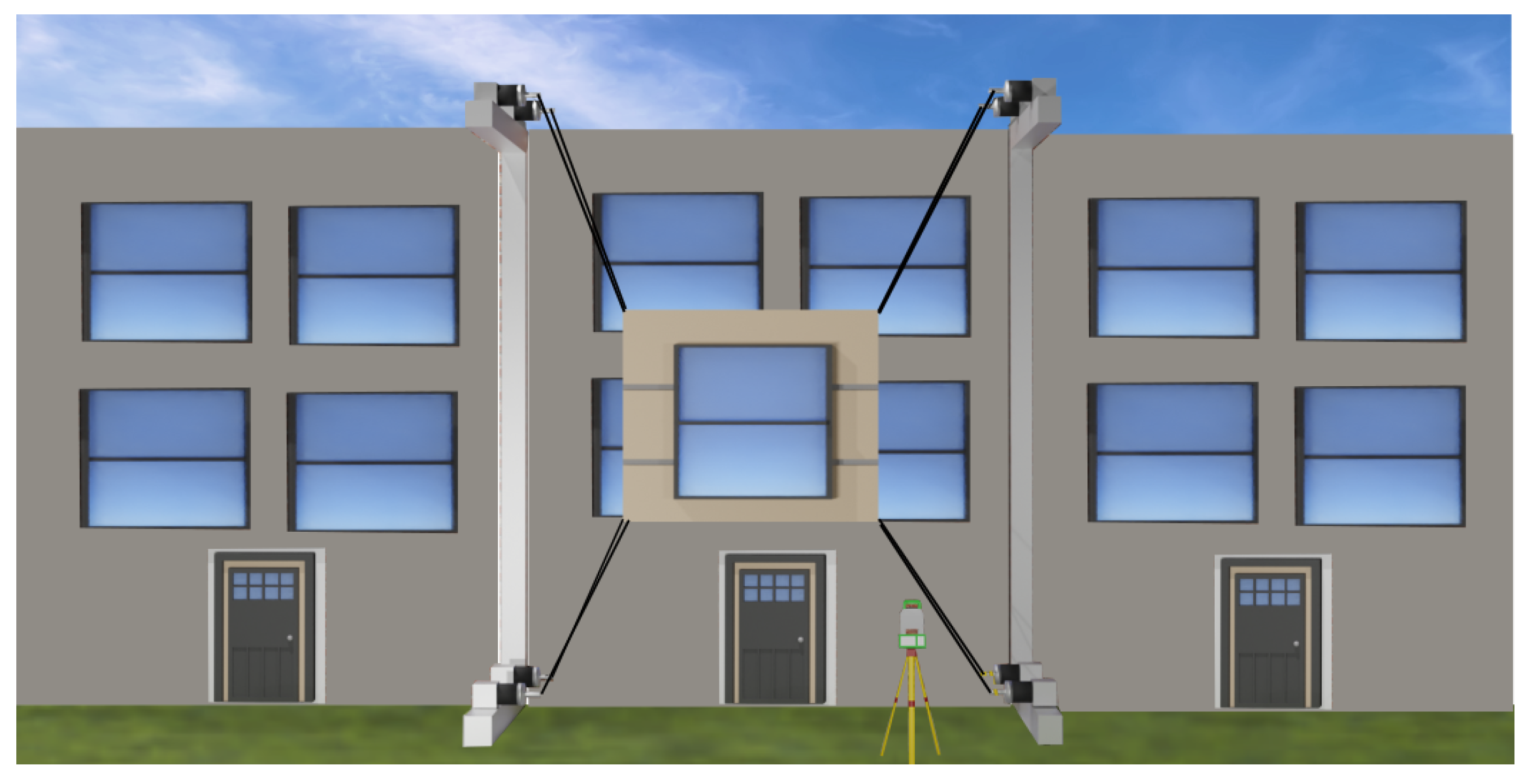

2.1. CDPRs in Robotic Construction

2.2. CDPR Trajectory Planning

2.3. CDPR Controllers

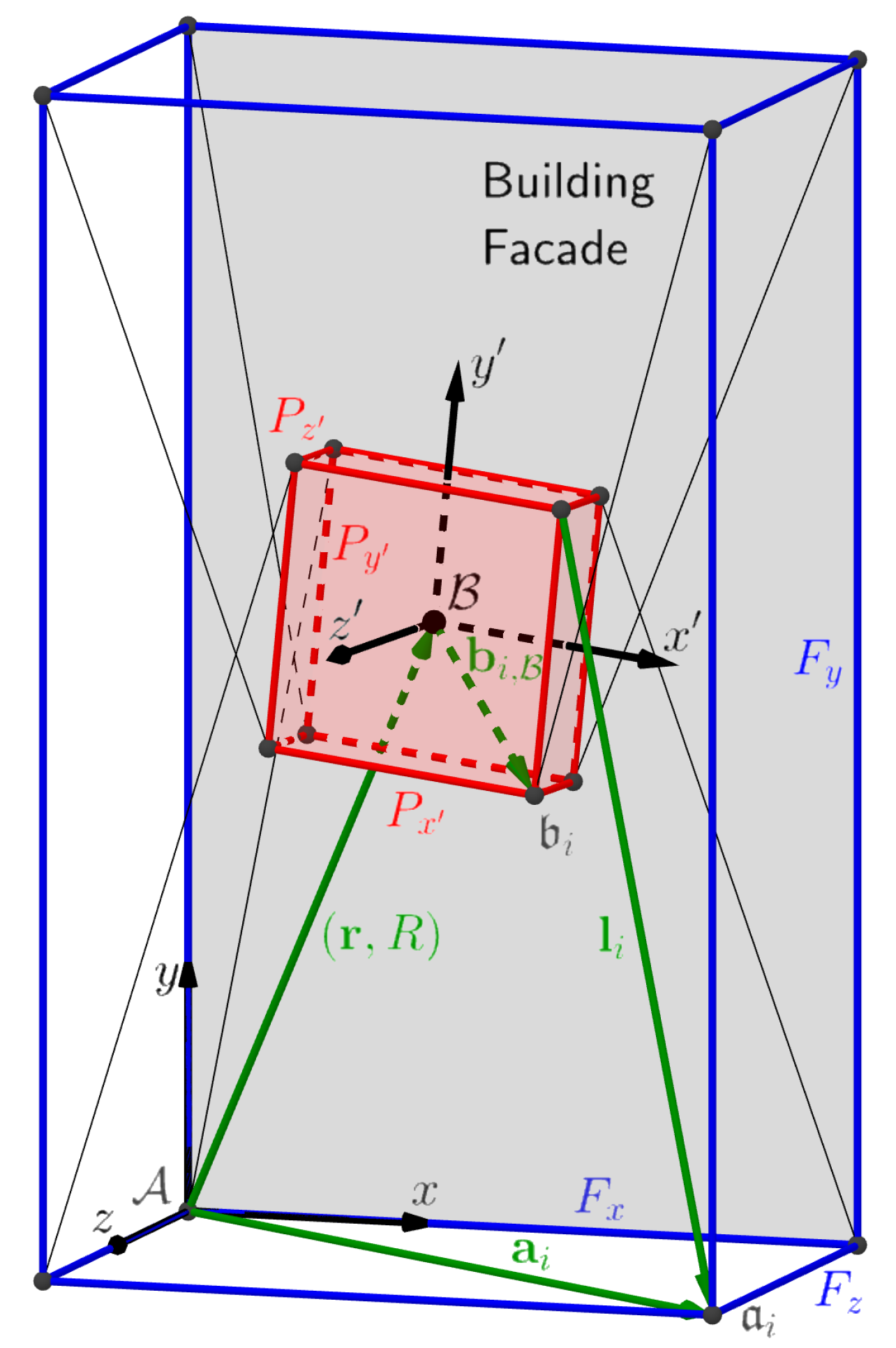

3. CDPR Dynamic Modeling and Analysis

3.1. Dynamic Model

- The constant vectors denote the proximal anchor points in the frame with respect to .

- The constant vectors denote the distal anchor points in the panel with respect to .

- The pose is defined by the location of the panel’s center of mass relative to and the orientation of the panel’s frame of reference relative to , denoted by the rotation matrix .

- The cable vectors are functions of the panel pose calculated relative to .

- The cable forces have tension acting on the cables ( denotes the Euclidean norm).

3.2. Jacobian Linearization

3.3. CDPR Configurations, Poles, and Damping

4. Trajectory Optimization

- Dynamic constraints: these constraints span from the starting time to terminal time :

- Force bounds: the lower bound prevents the cable from sagging, and the upper bound maintains the cable tension below the rupture limit:

- Path constraints: the path constraints guarantee that the panel always remains inside the CDPR frame and impose limits on both the linear and angular velocities:

- Initial conditions: These equality constraints ensure that the trajectory starts from the pickup pose at a stationary state . Let be the cable vectors at . Then, the Newton–Euler Equations (2) and (3) at the initial pickup pose becomewhere and are the initial state and control at . Equation (23) can be written in a compact matrix-vector form as , where is referred to as the structure matrix and is the stationary wrench [3].

- Terminal conditions: These equality constraints ensure that the robot comes to a complete stop at the target pose at time . Static balance guarantees that when the robot ceases movement, the motors experience minimal stress during the stopping process:Here, , , and are the terminal state, terminal control, and structure matrix evaluated at , respectively.

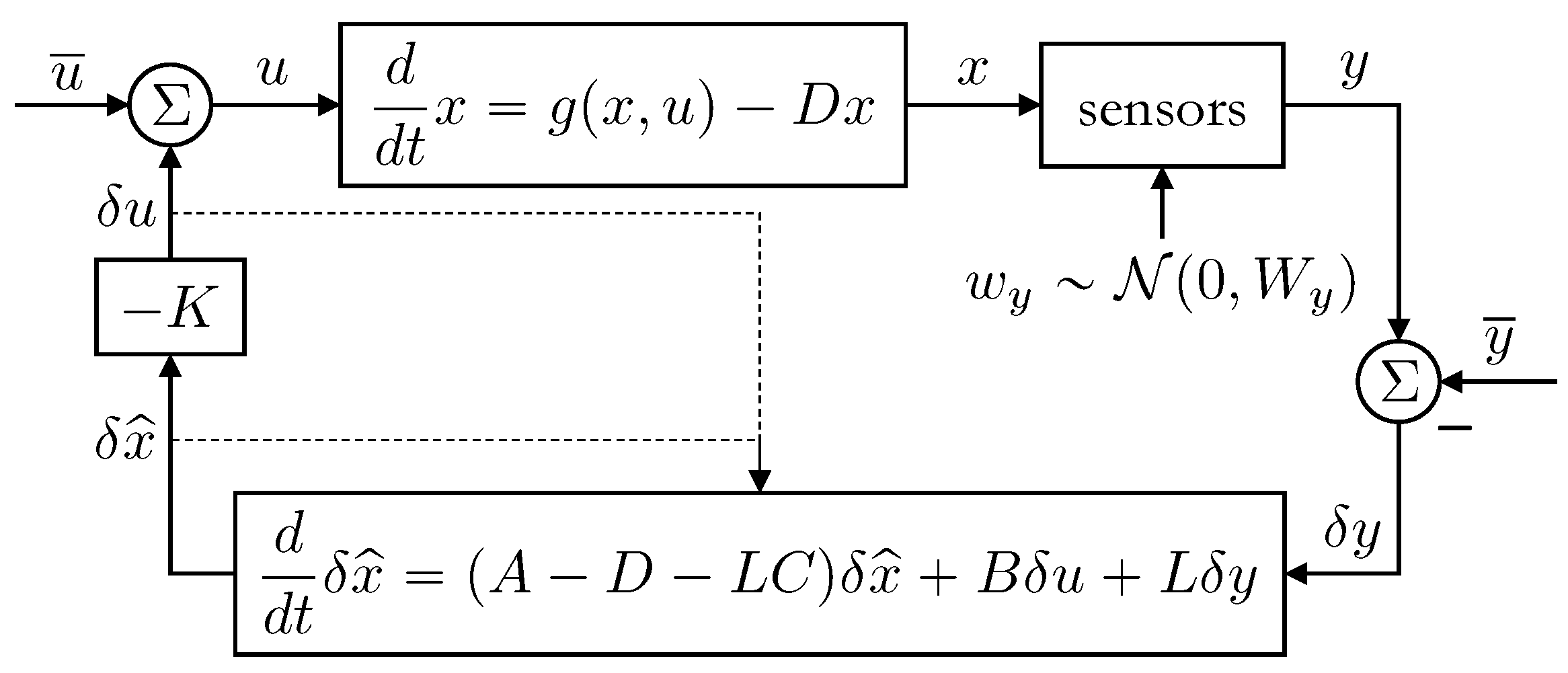

5. Linear Quadratic Gaussian (LQG) Control

5.1. LQG Controller

5.2. Observations

6. Simulation Results

6.1. Implementation Details

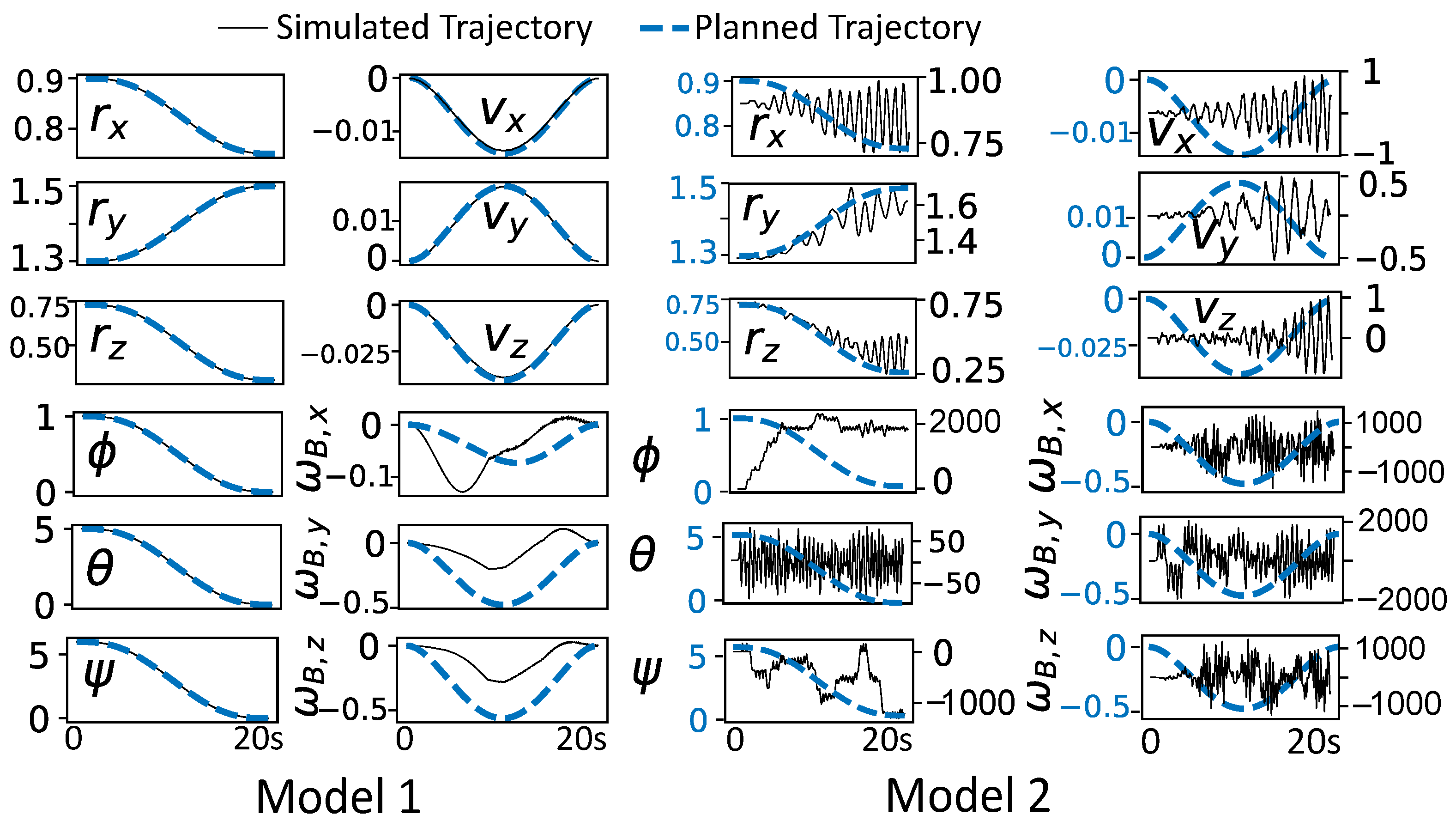

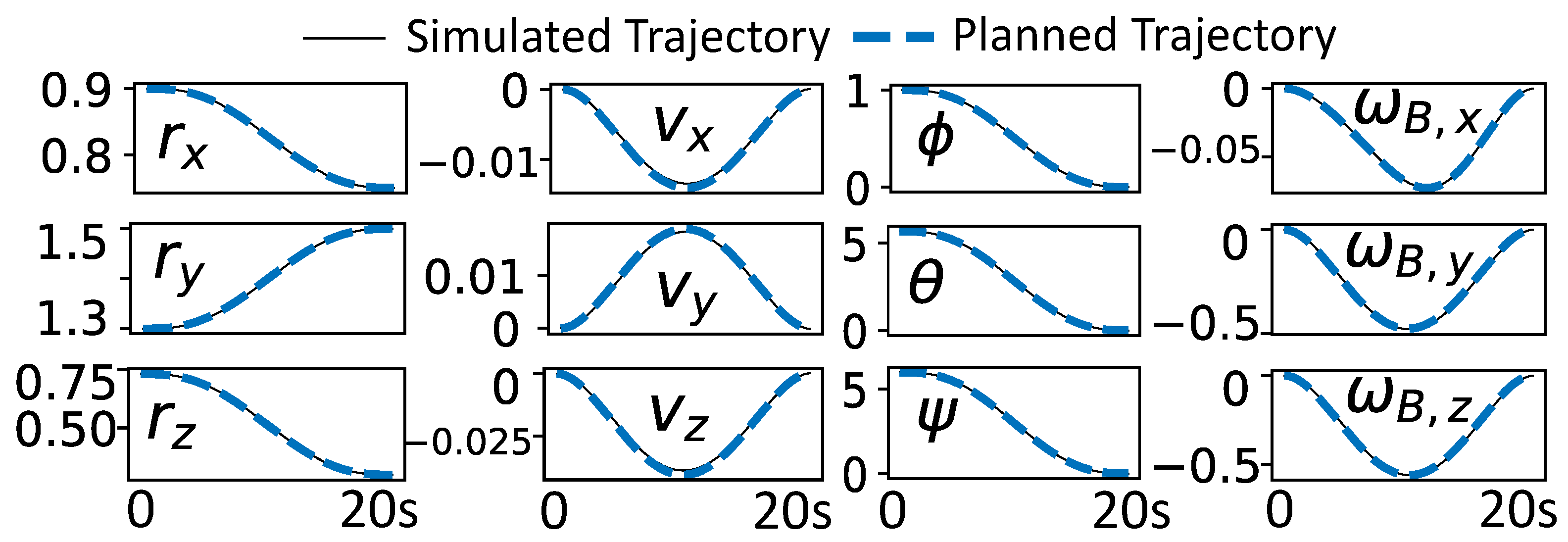

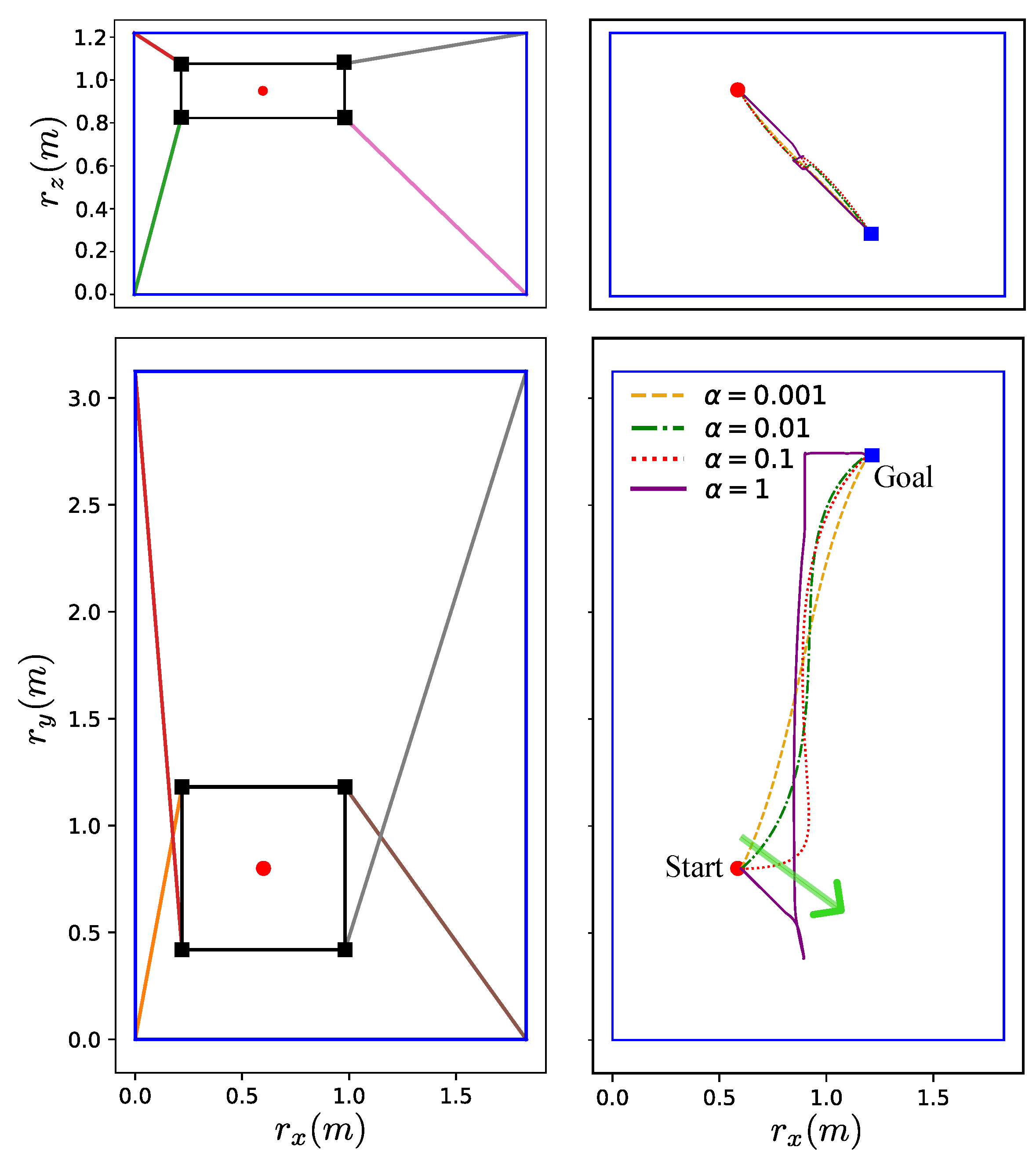

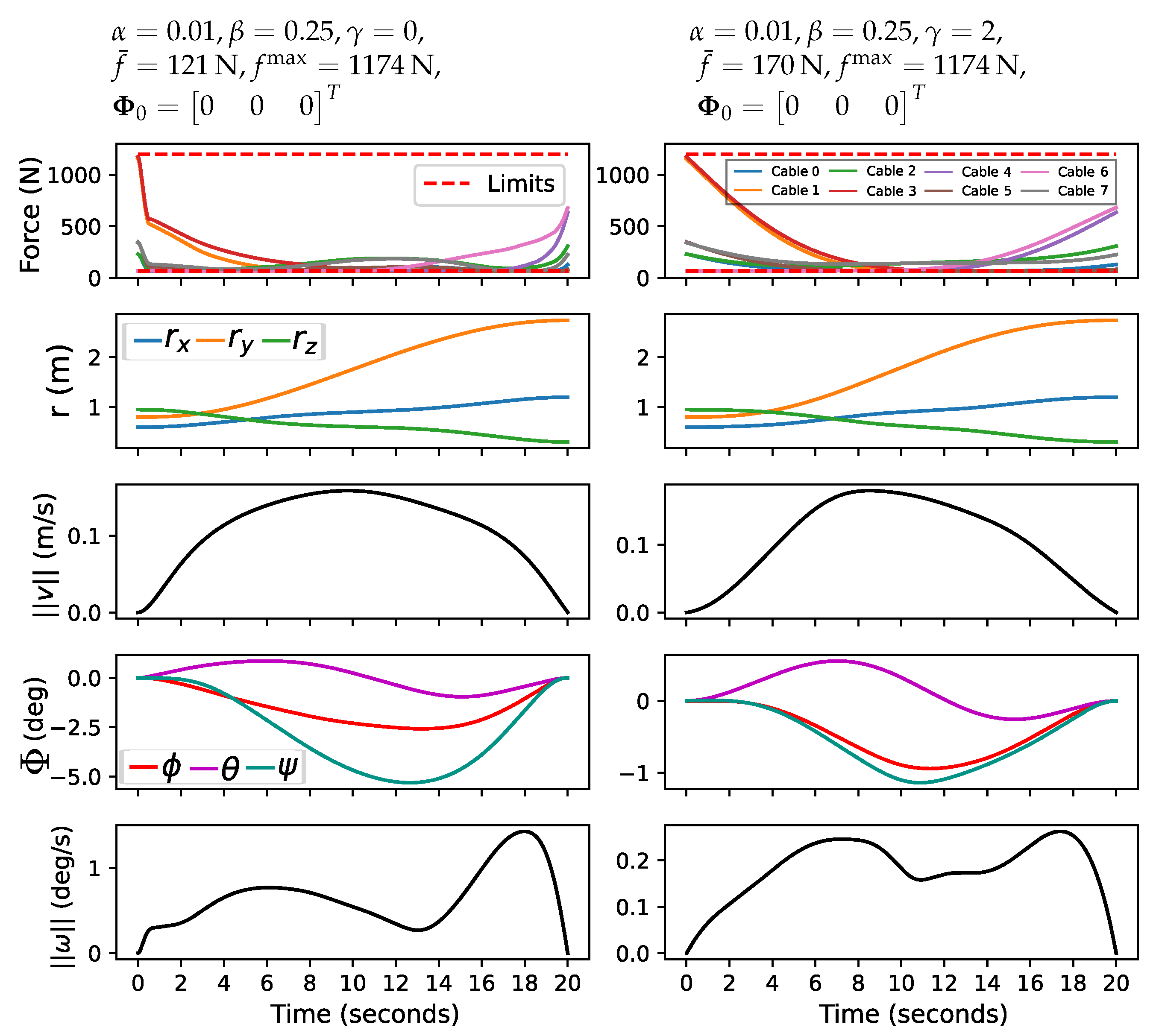

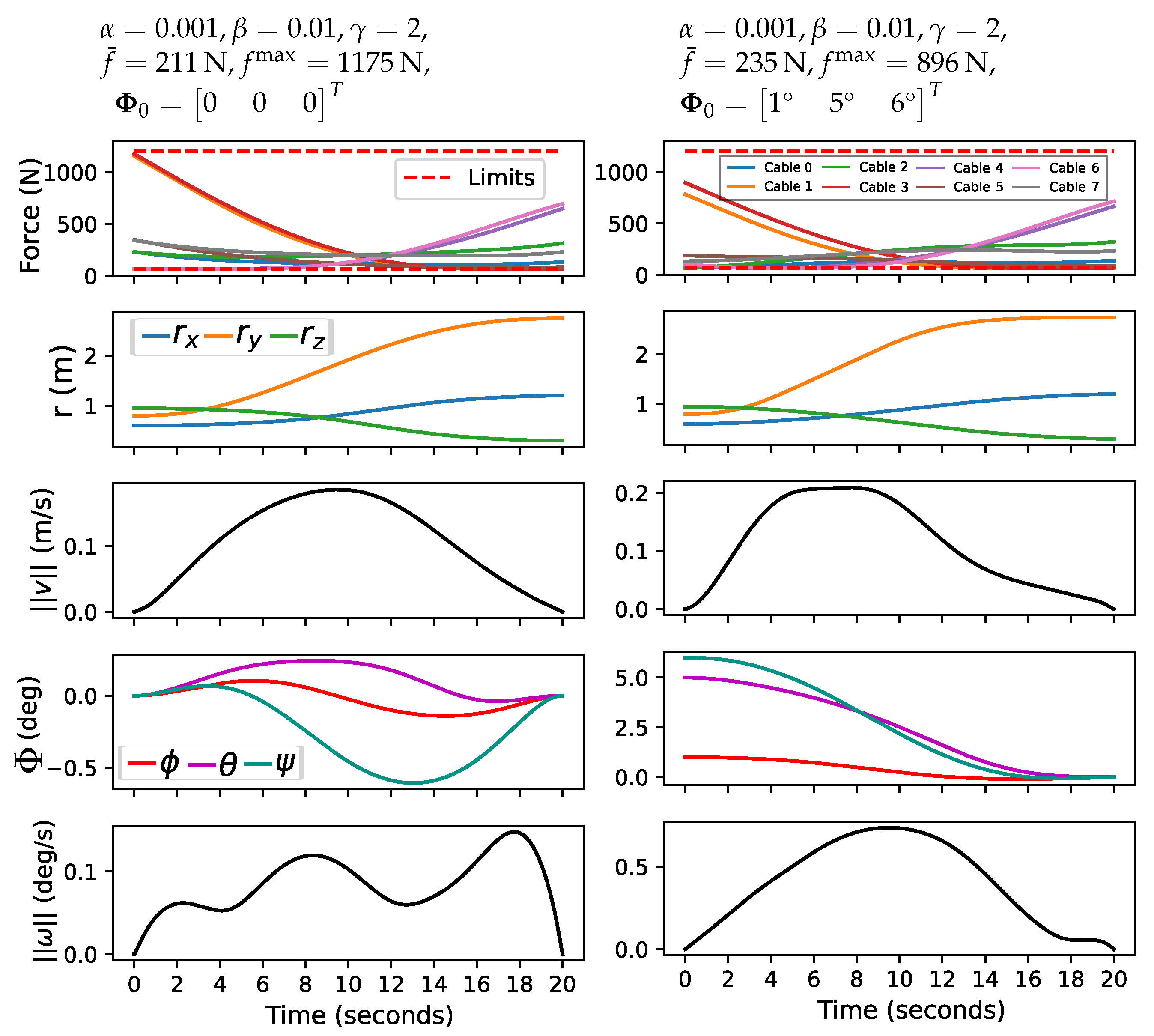

6.2. Trajectory Optimization Results

6.2.1. Sensitivity of Control Effort

6.2.2. Sensitivity of State Jerk

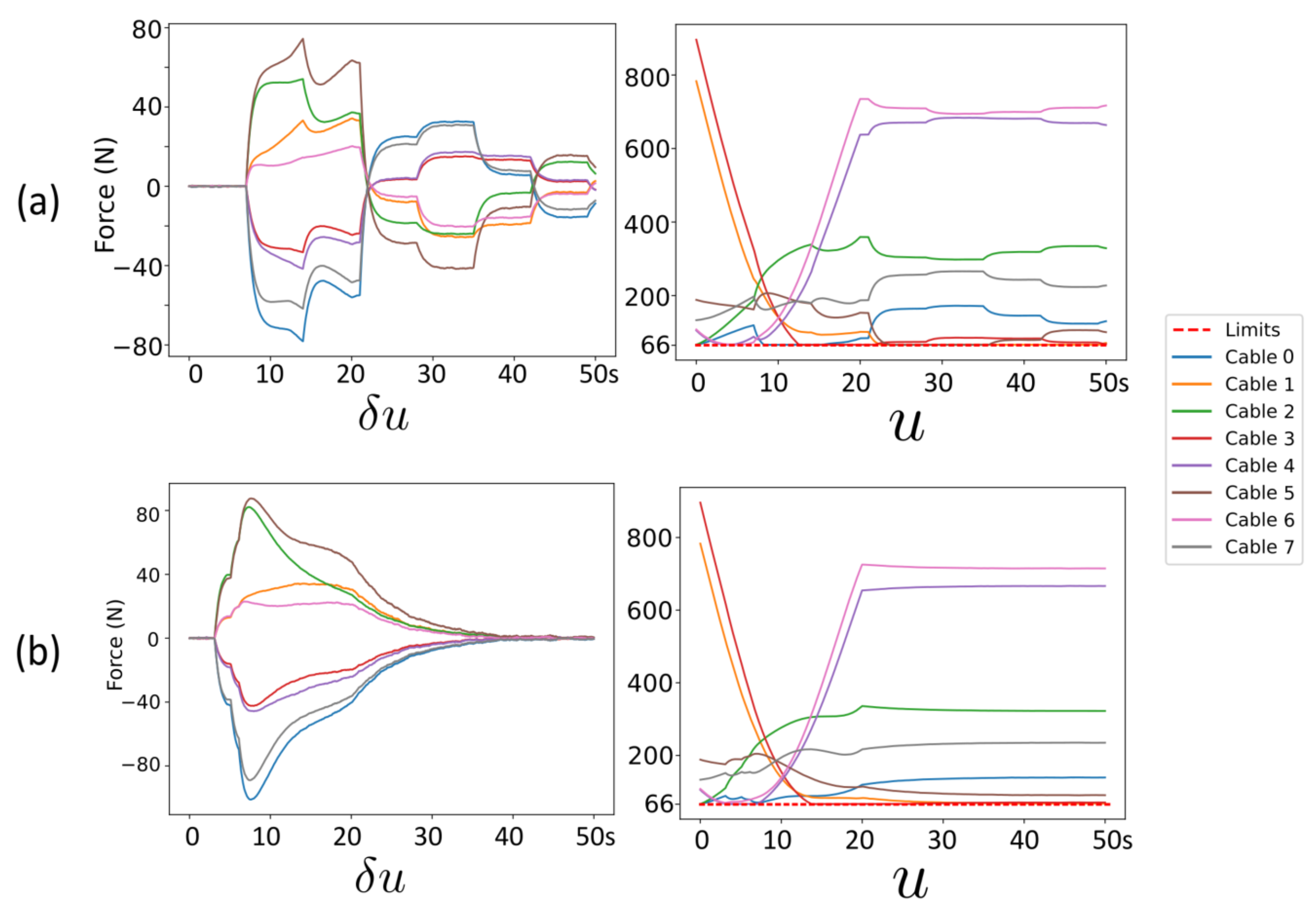

6.2.3. Sensitivity of Force Jerk

6.2.4. Sensitivity of Initial Panel Orientation

6.2.5. Discussion

- Impact of increasing the force penalty: One of the main lessons learned from this study is that the more the force penalty increases, the more the trajectory resembles a vertical lift. When only the force penalty is considered in the cost function, the optimal trajectory initially uses gravity to bring the panel to the central vertical axis of the -plane. Then, the system lifts the panel straight up to a desired height before moving it horizontally to its final destination. This lift-like behavior highlights a key characteristic of a minimum-effort optimal controller: leveraging gravity to assist with horizontal displacement to minimize the force required during this process, followed by prioritizing the most energy-efficient vertical lift.

- Effect of the state jerk penalty: Our analysis indicates that increasing the state jerk penalty reduces the magnitude of rotational movement while maintaining smooth transitions. However, this comes with the cost of an increased average force.

- Effect of the force jerk penalty: Another critical finding relates to the force jerk and its impact on the actuator system. Although introducing the force jerk penalty slightly increases the average effort required, it can effectively reduce stress on the actuators by reducing sudden changes in control commands. This trade-off suggests that although the system may require marginally more energy, it operates more smoothly, which could lead to more reliable execution, extend the longevity of the actuators, and reduce maintenance needs.

- Influence of initial orientation on force distribution: The simulation results show that the initial orientation of the panel plays an important role in determining how forces are allocated and managed at the beginning of the trajectory. Variations in initial orientation lead to different patterns of force distribution. This insight is particularly relevant for applications in which initial conditions are variable or difficult to control because it suggests that careful consideration of initial orientation can optimize force usage and overall system performance.

- Influence of trajectory orientation on force distribution: Even when the initial and terminal orientations are zero, the optimal trajectory still rotates the panel during the transition. The rotation acts as a mechanism to optimize the trajectory in a way that meets all the imposed constraints while minimizing the cost function. Even with zero initial and terminal orientations, allowing some degree of rotation during the transition can help distribute forces more evenly and reduce peak loads. Thus, the rotation effect during the trajectory reflects a complex trade-off aimed at achieving the most efficient overall motion profile, considering all aspects of the control objectives.

6.3. LQG Results

7. Conclusions and Future Development Plan

7.1. Conclusions

7.2. Future Development of a Real-World CDPR System

- Obtain the digital twin of the robot;

- Develop a dynamic model of the physical robot;

- Implement a PI-based torque controller to regulate cable forces;

- Deploy the LQG control strategy.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Salonvaara, M.; Aldykiewicz, A., Jr.; Hun, D.E.; Desjarlais, A.O. Cost Assessment of Building Envelope Retrofits; Technical Report; Oak Ridge National Lab.: Oak Ridge, TN, USA, 2020. [Google Scholar]

- Liu, Y.; Zhang, R.; Hayes, N.; Hun, D.E.; Maldonado Puente, B. Cable-Driven Parallel Robot (CDPR) for Panelized Envelope Retrofits: Feasible Workspace Analysis. In Proceedings of the International Symposium on Automation and Robotics in Construction, Lille, France, 3–5 June 2024; 2024; Volume 41, pp. 1081–1088. [Google Scholar]

- Pott, A.; Bruckmann, T. Cable-Driven Parallel Robots; Springer: Cham, Switzerland, 2013. [Google Scholar]

- Wu, Y.; Cheng, H.H.; Fingrut, A.; Crolla, K.; Yam, Y.; Lau, D. CU-brick cable-driven robot for automated construction of complex brick structures: From simulation to hardware realisation. In Proceedings of the 2018 IEEE International Conference on Simulation, Modeling, and Programming for Autonomous Robots (SIMPAR), Brisbane, Australia, 16–19 May 2018; pp. 166–173. [Google Scholar]

- Bruckmann, T.; Reichert, C.; Meik, M.; Lemmen, P.; Spengler, A.; Mattern, H.; König, M. Concept Studies of Automated Construction Using Cable-Driven Parallel Robots. In Cable-Driven Parallel Robots; Gosselin, C., Cardou, P., Bruckmann, T., Pott, A., Eds.; Springer: Cham, Switeland, 2018; pp. 364–375. [Google Scholar]

- Bosscher, P.; Williams, R.L.; Bryson, L.S.; Castro-Lacouture, D. Cable-suspended robotic contour crafting system. Autom. Constr. 2007, 17, 45–55. [Google Scholar] [CrossRef]

- Qian, S.; Li, C.; Zhao, Z.; Zi, B. Modeling and Experimental Validation of a Cable-Driven Robot for Three-Dimensional Printing Construction. J. Mech. Robot. 2025, 17, 061002. [Google Scholar] [CrossRef]

- Pott, A.; Meyer, C.; Verl, A. Large-scale assembly of solar power plants with parallel cable robots. In Proceedings of the ISR 2010 (41st International Symposium on Robotics) and ROBOTIK 2010 (6th German Conference on Robotics), Munich, Germany, 7–9 June 2010; VDE: Berlin, Germany, 2010; pp. 1–6. [Google Scholar]

- Murphy, K.; Soares, J.C.; Yim, J.K.; Nottage, D.; Soylemezoglu, A.; Ramos, J. Cooperative Modular Manipulation with Numerous Cable-Driven Robots for Assistive Construction and Gap Crossing. arXiv 2024, arXiv:2403.13124. [Google Scholar]

- Izard, J.B.; Gouttefarde, M.; Baradat, C.; Culla, D.; Sallé, D. Integration of a Parallel Cable-Driven Robot on an Existing Building Façade. In Cable-Driven Parallel Robots; Bruckmann, T., Pott, A., Eds.; Springer: Berlin/Heidelberg, Germany, 2013; pp. 149–164. [Google Scholar]

- Iturralde, K.; Feucht, M.; Illner, D.; Hu, R.; Pan, W.; Linner, T.; Bock, T.; Eskudero, I.; Rodriguez, M.; Gorrotxategi, J.; et al. Cable-driven parallel robot for curtain wall module installation. Autom. Constr. 2022, 138, 104235. [Google Scholar] [CrossRef]

- Badrikouhi, M.; Bamdad, M. Design, modelling, implementation, and trajectory planning of a 3-DOF cable driven parallel robot. Appl. Math. Model. 2024, 125, 210–229. [Google Scholar] [CrossRef]

- Bamdad, M. Time-energy optimal trajectory planning of cable-suspended manipulators. In Cable-Driven Parallel Robots; Springer: Berlin/Heidelberg, Germany, 2012; pp. 41–51. [Google Scholar]

- Hasan, M.; Haque, M.A.; Mominuzzaman, S.M.; Troyee, T.G. Optimization of CDPR Path Planning using a Branch and Bound Algorithm. In Proceedings of the 2023 6th International Conference on Electrical Information and Communication Technology (EICT), Khulna, Bangladesh, 7–9 December 2023; pp. 1–6. [Google Scholar]

- Rasheed, T.; Long, P.; Roos, A.S.; Caro, S. Optimization based trajectory planning of mobile cable-driven parallel robots. In Proceedings of the 2019 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Macau, China, 3–8 November 2019; pp. 6788–6793. [Google Scholar]

- Behzadipour, S.; Khajepour, A. Time-optimal trajectory planning in cable-based manipulators. IEEE Trans. Robot. 2006, 22, 559–563. [Google Scholar] [CrossRef]

- Qian, S.; Bao, K.; Zi, B.; Zhu, W. Dynamic trajectory planning for a three degrees-of-freedom cable-driven parallel robot using quintic B-splines. J. Mech. Des. 2020, 142, 073301. [Google Scholar] [CrossRef]

- Korayem, M.; Zehfroosh, A.; Tourajizadeh, H.; Manteghi, S. Optimal motion planning of non-linear dynamic systems in the presence of obstacles and moving boundaries using SDRE: Application on cable-suspended robot. Nonlinear Dyn. 2014, 76, 1423–1441. [Google Scholar] [CrossRef]

- Korayem, M.; Tourajizadeh, H.; Jalali, M.; Omidi, E. Optimal path planning of spatial cable robot using optimal sliding mode control. Int. J. Adv. Robot. Syst. 2012, 9, 168. [Google Scholar] [CrossRef]

- Santos, J.C.; Chemori, A.; Gouttefarde, M. Redundancy resolution integrated model predictive control of CDPRs: Concept, implementation and experiments. In Proceedings of the 2020 IEEE International Conference on Robotics and Automation (ICRA), Paris, France, 31 May–31 August 2020; pp. 3889–3895. [Google Scholar]

- Aflakian, A.; Safaryazdi, A.; Masouleh, M.T.; Kalhor, A. Experimental study on the kinematic control of a cable suspended parallel robot for object tracking purpose. Mechatronics 2018, 50, 160–176. [Google Scholar] [CrossRef]

- Le Nguyen, V.; Caverly, R.J. Cable-driven parallel robot pose estimation using extended Kalman filtering with inertial payload measurements. IEEE Robot. Autom. Lett. 2021, 6, 3615–3622. [Google Scholar] [CrossRef]

- Santos, J.C. Model Predictive Tracking Control of Cable-Driven Parallel Robots: From Concept to Real-Time Validation. Ph.D. Thesis, Université Montpellier, Montpellier, France, 2020. [Google Scholar]

- Chen, G.; Hutchinson, S.; Dellaert, F. Locally optimal estimation and control of cable driven parallel robots using time varying linear quadratic gaussian control. In Proceedings of the 2022 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Kyoto, Japan, 23–27 October 2022; pp. 7367–7374. [Google Scholar]

- Hibbeler, R.C. Engineering Mechanics Dynamics, 11th ed.; Pearson: Upper Saddle River, NJ, USA, 2007. [Google Scholar]

- McGhee, R.; Bachmann, E.R.; Zyda, M.J. Rigid Body Dynamics, Inertial Reference Frames, and Graphics Coordinate Systems: A Resolution of Conflicting Conventions and Terminology; Naval Postgraduate School: Monterey, CA, USA, 2000. [Google Scholar]

- Mamidi, T.K.; Bandyopadhyay, S. Forward dynamic analyses of cable-driven parallel robots with constant input with applications to their kinetostatic problems. Mech. Mach. Theory 2021, 163, 104381. [Google Scholar] [CrossRef]

- Miermeister, P.; Pott, A. Modelling and real-time dynamic simulation of the cable-driven parallel robot IPAnema. In New Trends in Mechanism Science: Analysis and Design; Springer: Dordrecht, The Netherlands, 2010; pp. 353–360. [Google Scholar]

- Zi, B.; Duan, B.; Du, J.; Bao, H. Dynamic modeling and active control of a cable-suspended parallel robot. Mechatronics 2008, 18, 1–12. [Google Scholar] [CrossRef]

- Lamaury, J.; Gouttefarde, M. Control of a large redundantly actuated cable-suspended parallel robot. In Proceedings of the 2013 IEEE International Conference on Robotics and Automation, Karlsruhe, Germany, 6–10 May 2013; pp. 4659–4664. [Google Scholar]

- Sheng, Z.; Park, J.H.; Stegall, P.; Agrawal, S.K. Analytic determination of wrench closure workspace of spatial cable driven parallel mechanisms. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Boston, MA, USA, 2–5 August 2015; American Society of Mechanical Engineers: New York City, NY, USA, 2015; Volume 57144. [Google Scholar]

- Ratiu, M.; Prichici, M.A. Industrial robot trajectory optimization-a review. In MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2017; Volume 126, p. 02005. [Google Scholar]

- Hayes, N.W.; Maldonado, B.P.; Hun, D.; Wang, P. Real-time evaluator to optimize and automate crane installation of prefabricated components. In Proceedings of the 40th International Symposium on Automation and Robotics in Construction, Chennai, India, 3–9 July 2023; pp. 192–199. [Google Scholar] [CrossRef]

- Tang, M.; Hayes, N.; Maldonado Puente, B.; Hun, D.E. Component Pose Reconstruction Using a Single Robotic Total Station for Panelized Building Envelopes; Technical Report; Oak Ridge National Laboratory (ORNL): Oak Ridge, TN, USA, 2024. [Google Scholar]

- Andersson, J.A.E.; Gillis, J.; Horn, G.; Rawlings, J.B.; Diehl, M. CasADi—A software framework for nonlinear optimization and optimal control. Math. Program. Comput. 2019, 11, 1–36. [Google Scholar] [CrossRef]

| Variable | Value | Description |

|---|---|---|

| m | 13.6 kg | Panel mass |

| m | Frame dimensions | |

| m | Panel dimensions | |

| 100 | Linear friction coefficient | |

| 3500 | Angular friction coefficient | |

| 66 N | Cable sagging minimum force | |

| 1200 N | Cable rupture maximum force | |

| 20° | Euler angle orientation limit | |

| 0.2 m/s | Linear velocity limit | |

| 2 deg/s | Angular velocity limit | |

| 20 s | Terminal time | |

| N | 2000 | Samples per trajectory |

| 0.01 | Force balance slack at | |

| 0.0001 | Moment balance slack at | |

| Panel pickup position | ||

| Panel final position |

| r | v | Matrix C | |||

|---|---|---|---|---|---|

| RTE | 10 Hz | Hz | NA | NA | diag |

| RTE+IMU | 10 Hz | 10 Hz | NA | 10 Hz | diag |

| Full state | 10 Hz | 10 Hz | 10 Hz | 10 Hz |

| Observations | (mm) | (deg) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 3 s | 20 s | Feedforward | −16.367 | −10.914 | −44.314 | −11.734 | 0.404 | 7.066 | −1.770 | −3.607 | −6.558 | −1.896 | 0.035 | 0.781 |

| RTE | −2.895 | −3.101 | −3.694 | 0.319 | −0.134 | −0.499 | 4.445 | −9.679 | −2.020 | 0.361 | 0.030 | −0.267 | ||

| 3 s | 20 s | RTE + IMU | −1.138 | −1.789 | −3.716 | −0.294 | −0.183 | 0.185 | 0.561 | −4.777 | 0.585 | 0.052 | 0.024 | −0.024 |

| Full state | −1.065 | −1.822 | −3.663 | −0.278 | −0.182 | 0.163 | 0.628 | −4.858 | 0.926 | 0.048 | 0.024 | −0.026 | ||

| RTE ME | −10.155 | −37.155 | −4.521 | 0.098 | −0.150 | 0.361 | 4.955 | −10.367 | −1.634 | 0.396 | 0.031 | −0.373 | ||

| 3 s | 20 s | RTE + IMU ME | −3.183 | −12.814 | −3.873 | −0.352 | −0.196 | 0.440 | 1.153 | −3.937 | 0.505 | 0.052 | 0.025 | −0.047 |

| Full state ME | −3.108 | −12.860 | −3.929 | −0.351 | −0.195 | 0.429 | 1.481 | −4.692 | −0.336 | 0.059 | 0.025 | −0.044 | ||

| RTE | 0.680 | −0.918 | 0.231 | 0.137 | 0.014 | −0.306 | 0.847 | 1.829 | 1.254 | 0.043 | −0.002 | −0.023 | ||

| 3 s | 50 s | RTE + IMU | −0.115 | −0.019 | 0.021 | −0.006 | −0.002 | 0.012 | 0.062 | −0.013 | −0.083 | 0.002 | 0.001 | 0.000 |

| Full state | −0.028 | 0.115 | 0.133 | 0.002 | −0.001 | −0.003 | 0.285 | −0.015 | −0.459 | −0.001 | 0.001 | 0.002 | ||

| RTE ME | −1.550 | −7.458 | −0.787 | −0.084 | 0.030 | 0.021 | 0.997 | 3.286 | 0.144 | 0.038 | −0.004 | −0.070 | ||

| 3 s | 50 s | RTE + IMU ME | −0.175 | −0.225 | −0.060 | −0.014 | −0.001 | 0.020 | −0.084 | −0.687 | 0.166 | 0.002 | 0.000 | −0.001 |

| Full state ME | −0.157 | 0.207 | 0.136 | 0.004 | −0.001 | 0.013 | 0.123 | −0.145 | −0.318 | −0.003 | 0.001 | −0.005 | ||

| RTE | −13.288 | −3.441 | −11.905 | 0.152 | −0.513 | −1.183 | 5.763 | −11.776 | 1.002 | 0.947 | 0.139 | −0.912 | ||

| 3, 5, 6 s | 20 s | RTE + IMU | −7.036 | −0.680 | −11.874 | −1.175 | −0.627 | 0.732 | 5.087 | −9.273 | −1.727 | 0.188 | 0.106 | −0.131 |

| Full state | −6.943 | −0.707 | −11.702 | −1.149 | −0.626 | 0.727 | 5.095 | −9.179 | −1.736 | 0.187 | 0.105 | −0.127 | ||

| RTE | −1.978 | −4.565 | −3.228 | −0.351 | 0.083 | −0.156 | 2.789 | 0.984 | 0.565 | 0.074 | −0.013 | −0.185 | ||

| 3, 5, 6 s | 50 s | RTE + IMU | −0.075 | −0.069 | −0.083 | −0.015 | −0.009 | 0.013 | −0.245 | 0.294 | 0.271 | 0.002 | 0.001 | 0.002 |

| Full state | −0.080 | 0.049 | 0.028 | −0.005 | −0.007 | 0.011 | −0.019 | 0.100 | 0.003 | 0.001 | 0.001 | 0.004 | ||

| RTE ME | −10.435 | −17.273 | 0.513 | −0.520 | 0.233 | 1.936 | 0.984 | 0.185 | −4.596 | −0.058 | −0.018 | −0.093 | ||

| 3, 5, 6 s | 50 s | RTE + IMU ME | −0.342 | −0.233 | −0.100 | −0.022 | −0.007 | 0.048 | 0.031 | −0.799 | 0.021 | −0.002 | 0.001 | −0.008 |

| Full state ME | −0.380 | −0.118 | 0.077 | −0.001 | −0.006 | 0.050 | −0.040 | −0.513 | −0.133 | −0.002 | 0.001 | −0.009 | ||

| RTE | −32.4 | −230.3 | 57.6 | 2.816 | 0.588 | 2.711 | 2.295 | 98.480 | −11.332 | −0.344 | 0.028 | 0.143 | ||

| Sustained | 50 s | RTE + IMU | −0.270 | −0.279 | −0.439 | −0.038 | −0.025 | 0.044 | −0.237 | −0.040 | 0.365 | 0.006 | 0.003 | −0.001 |

| 3 to 8 s | Full state | −0.240 | −0.312 | −0.361 | −0.026 | −0.025 | 0.022 | −0.148 | −0.241 | −0.270 | 0.012 | 0.004 | −0.005 | |

| 3 to 8 s | 80 s | RTE | 1.598 | −0.254 | 4.519 | 0.459 | 0.041 | −0.228 | −0.298 | −1.035 | 0.705 | −0.040 | −0.002 | 0.115 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Maldonado, B.P. Dynamic Modeling, Trajectory Optimization, and Linear Control of Cable-Driven Parallel Robots for Automated Panelized Building Retrofits. Buildings 2025, 15, 1517. https://doi.org/10.3390/buildings15091517

Liu Y, Maldonado BP. Dynamic Modeling, Trajectory Optimization, and Linear Control of Cable-Driven Parallel Robots for Automated Panelized Building Retrofits. Buildings. 2025; 15(9):1517. https://doi.org/10.3390/buildings15091517

Chicago/Turabian StyleLiu, Yifang, and Bryan P. Maldonado. 2025. "Dynamic Modeling, Trajectory Optimization, and Linear Control of Cable-Driven Parallel Robots for Automated Panelized Building Retrofits" Buildings 15, no. 9: 1517. https://doi.org/10.3390/buildings15091517

APA StyleLiu, Y., & Maldonado, B. P. (2025). Dynamic Modeling, Trajectory Optimization, and Linear Control of Cable-Driven Parallel Robots for Automated Panelized Building Retrofits. Buildings, 15(9), 1517. https://doi.org/10.3390/buildings15091517