1. Introduction

The circular economy (CE) in the construction industry aims to reduce waste, with the objective of gradually decreasing the impacts of climate change on the planet [

1]. According to the Australian Bureau of Statistics [

2], waste is a considerable issue within the construction industry and costs the Australian economy AUD 2 billion in services. Within this figure, it is estimated that 76% of all construction and demolition waste is recycled [

3]. This is a positive revelation as the industry strives to implement more sustainable practices. However, ‘recycling’ is only R approach that can be applied at the end of life of a built asset. The 10R model aims to improve sustainability by applying the CE throughout a building’s life cycle (pre-, during and post-construction) [

4].

Modular construction (MC) is a process whereby a building is constructed off-site. These modular buildings are cost-effective and time-efficient when compared to traditional in situ buildings [

5]. According to Garusinghe, Perera and Weerapperuma [

4], MC provides 50% reduced construction time compared to traditional builds and can also reduce costs by 20%. MC is also beneficial for the housing industry as it provides safe manufacturing and increased quality control. Specifically, the method of prefabricating buildings off-site minimises disruption to surrounding communities, the public and shareholders. Furthermore, the customisable component of modular construction ensures that the needs of clients are met [

6]. Choi, Chen and Kim [

7] conducted a survey that confirmed the effectiveness of implementing modular construction compared to in situ builds as a method to enhance quality standards, improve safety, shorten construction timelines and minimise waste.

Hence, the application of CE principles in MC would lead to the further minimisation of waste. However, a study conducted by Yang et al. [

8] suggests that MC, particularly the feasibility of utilising the CE, is ‘not well understood’, despite the popularity of MC due to its time and cost efficiency. Garusinghe, Perera and Weerapperuma [

4] further confirm the need for further research into this crucial intersection. Their study attempts to identify common issues in MC and suggests that the 9R CE principles can mitigate these issues. However, they do not focus on investigating to what extent the R principles are currently applied in MC. The few other studies that investigate the CE in MC in real-life cases only consider a few R strategies. The identification of this specific research gap motivated us to undertake this study. Accordingly, this study aimed to investigate how the CE principles, particularly the 10Rs, can be applied within the Australian modular construction industry. This research specifically explores which 10R strategies are currently implemented, identifies barriers to their adoption, and evaluates their potential to improve sustainable outcomes. By providing empirical insights from expert interviews and case studies, this study seeks to inform industry professionals and policymakers on effective sustainability strategies within modular construction.

This paper is structured in seven sections. Following

Section 1, the

Section 2 offers a deeper literature review of the 10R principles and modular construction. The

Section 3 sets forth the research method of this study. The

Section 4 and

Section 5 present the research findings from the expert interviews and secondary case studies, respectively. The

Section 6 discusses the findings by triangulating the data gathered, while the

Section 7 prioritises the conclusions of this study.

2. Literature Review

The traditional linear economy, characterised by a ‘cradle-to-grave’ material flow, is unsustainable. Raw materials are transformed into products, used, and then disposed of, often ending up in landfills. This linear approach contrasts sharply with the circular economy (CE), which promotes a ‘cradle-to-cradle’ approach, enabling the circulation of materials and products in the economy up to their maximum use. The concept of the CE emerged in the 1970s and initially focused on reducing input consumption in industrial production [

9]. The Ellen MacArthur Foundation [

10], the recent pioneering body for the CE, defines the CE as a restorative and regenerative industrial system by intention and design. They [

10] outline three core CE principles: eliminate waste and pollution; circulate products and materials; and regenerate nature. These principles form a cyclical flow model aimed at minimising environmental impacts [

11]. The ReSOLVE framework [

12] further elaborates on these principles, encompassing strategies to regenerate, share, optimise, loop, virtualise, and exchange. This framework is not a perfect solution for the creation of a CE on its own [

13]. The 10R model, on the other hand, offers a holistic approach to CE implementation and is often referred to in CE implementations. Hence, this study mainly focuses on the application of the 10R principles in creating a CE in construction. The evolution of the CE is evident in the expansion of the R principles. Starting with the 3Rs (reduce, reuse, recycle), it has grown to include 6Rs (adding recover, redefine/rethink, and remanufacture) and subsequently 9Rs (adding refurbish, repair, and refuse). While Khaw-ngern et al. [

14] highlight this progression, they omit repurpose, which is a key element in the most recent 10R principles. Garusinghe, Perera and Weerapperuma [

4] emphasise the pivotal role of the 10R principles in offering strategies to reduce resource depletion and minimise waste and, thereby, providing a comprehensive approach to the CE. The 10R model is a dynamic framework that has evolved over time. Its flexibility allows for adaptation to individual business needs and budgets.

Table 1 summarises the 10R principles, drawing from Reike, Vermeulen and Witjes [

15].

Several methods exist for the categorisation of the 10R principles. For example, Potting et al. [

16] propose a three-category system based on the level of circularity, from efficient product use to maximising material usefulness. This study adopts the ‘short, medium, and long loop’ categorisation [

15], which focuses on the proximity of a material to its original value and the influence of key parties.

In the short loop, material remains close to its original value, focusing on smart product use. The Rs in the short loop are refuse, rethink, reduce, reuse, and repair (R1–R5).

In the medium loop, material is less valuable, re-involved in other R stages, extending its lifespan. Refurbish, remanufacture, and repurpose (R6–R8) are considered in the medium loop. These loops are employed when the short loop options are exhausted.

In the long loop, the product loses its original function, focusing on creating new solutions for material use. Recycle and recovery (R9 and R10) are included in the long loop. These are the least desirable options, employed when other avenues are exhausted. For example, they would use technology to extract materials and energy for new products and can be expensive.

Modular construction (MC) is becoming a fast competitor for the construction of residential and commercial buildings compared to traditional builds due to its significant cost, time, quality, and environmental benefits [

17,

18]. In terms of sustainable benefits, resource efficiency through MC involves not only reducing the extraction of virgin and non-renewable resources, but also reductions in production waste and energy and the prolongation of a product’s life [

18,

19,

20]. These sustainable benefits, coupled with MC’s features, such as flexibility, adaptability, easy disassembly, and easy reconfiguration [

21], naturally help with a circular economic approach. To fully realise the CE, the 10R principles can be applied in MC with intention.

The synergy between the circular economy (CE) principles and modular construction (MC) presents a powerful opportunity to revolutionise the building industry. Garusinghe, Perera and Weerapperuma [

4] point out the need for further research by suggesting how the 9R CE principles help in solving the common MC issues that they discovered in their research. The inherent characteristics of MC, such as standardisation and controlled environments, create ideal conditions for the implementation of CE principles effectively. The potential to design for disassembly in MC projects is a prime example of how these two concepts can work together. By carefully considering the deconstruction process during the design phase, MC buildings can be easily taken apart at the end of their initial use, allowing components to be reused, repurposed, or recycled. This ‘design for deconstruction’ philosophy is a cornerstone of the CE.

Several studies and real-world examples illustrate the potential of integrating the CE and MC. Wuni and Shen [

22], in their study of MC in Hong Kong, focused on the 3R principles (reduce, reuse, recycle). They found that reusing materials during the design and planning stages was particularly effective in minimising waste. While recycling presented challenges due to potential material contamination, the study highlighted the potential for MC to create closed-loop systems for materials, thereby reducing waste and maximising value. Furthermore, the Modular Building Institute [

23] showcases a real-world example of sustainable MC in California. An office building was constructed in just 70 days using reused modules from previous projects. This approach not only significantly reduced the construction time but also earned the project ‘Cal Green’ certification and Title 24 energy recognition, demonstrating its commitment to sustainability.

As Weerakoon, Wimalasena and Zvirgzdins [

24] insist, implementing CE principles is a ‘must rather than a choice’ and would lead to a ‘a sustainable circular economy’ [

25]. Given the few studies and examples of the merging of the CE and MC, as discussed above, the application of the 10R principles in MC remains largely under-researched. While the potential benefits are clear, there are also challenges to overcome and strategies to be discovered. The identification of this specific research gap motivated us to undertake the current study.

3. Research Method

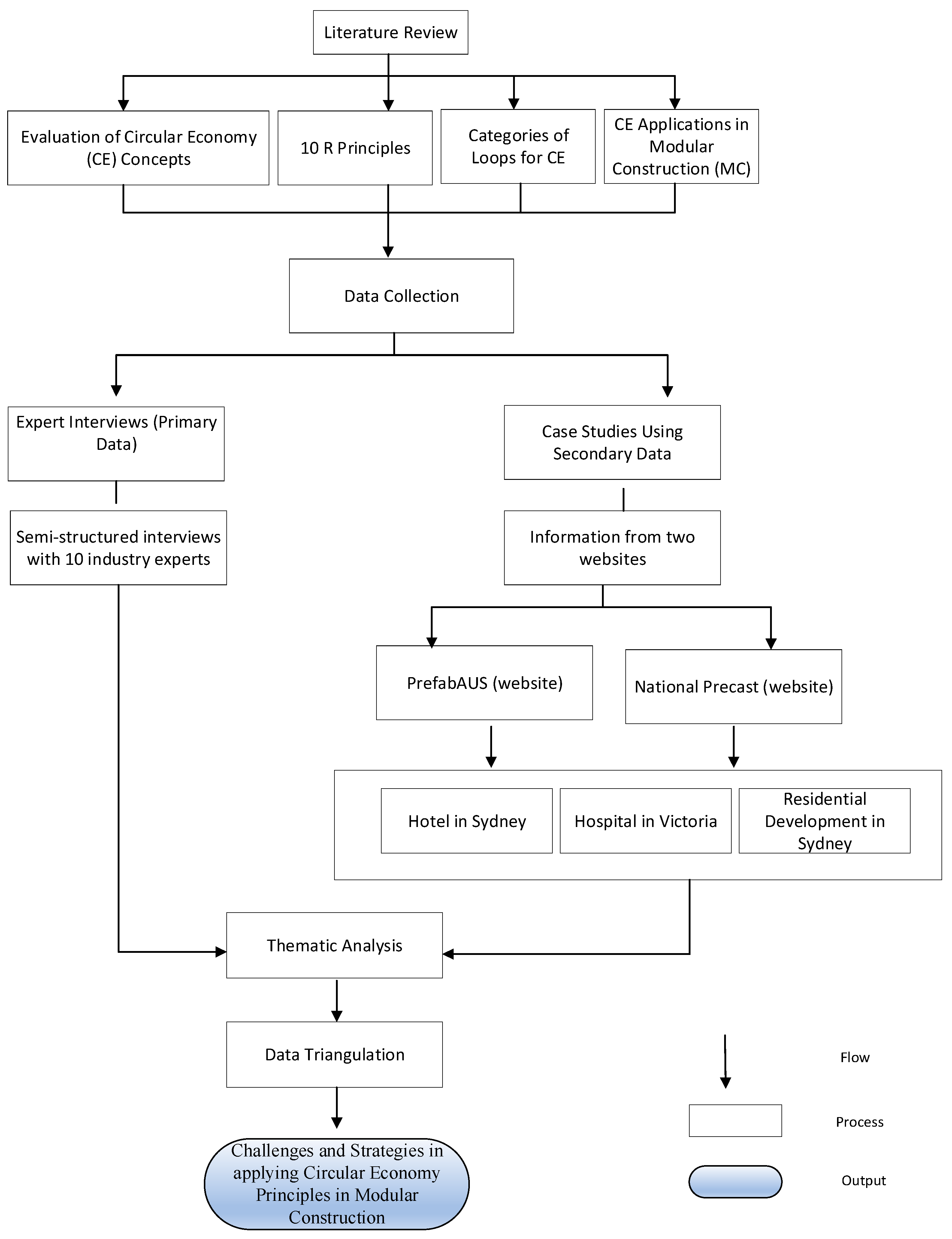

This study employed qualitative research methods to investigating sustainability in modular construction (MC) and assess the applicability of circular economy (CE) principles, particularly the 10R framework. As depicted in

Figure 1 below, the research design comprised a comprehensive literature review and two data collection methods—expert interviews (EIs) and case studies using secondary data (CSs)—and used thematic analysis to derive insights into challenges and strategies in applying circular economy principles in modular construction.

Expert interviews (EIs) were identified as the most suitable method for the collection of primary data, offering in-depth insights from industry professionals on the implementation of circular economy (CE) principles in modular construction (MC). Semi-structured interviews were conducted with experts to ensure a diverse range of perspectives. Participants were selected based on their expertise in the construction industry, particularly in MC, with a minimum of three years of experience. Prefab AUS [

26], a leading industry body for prefabricated construction, provides a member directory. This directory served as a valuable resource in initially identifying and contacting potential expert interview participants. To ensure geographic representation, professionals from across Australia were included. To maximise participation and accessibility, the interviews were conducted online via Microsoft Teams, offering flexibility in scheduling, including evening sessions. All interviews were recorded, transcribed verbatim, and anonymised for confidentiality. The interview questions were categorised into three sections, with 25 questions in total, to cover general information, an understanding of the relevant terms and 10R loops, and challenges and strategies in applying 10R in MC. Participants were provided with the questionnaire in advance to facilitate informed responses. Relevant human ethics approval was obtained to conduct this research from the authors’ institution. Informed consent was secured from all participants, ensuring compliance with ethical guidelines.

Case studies were completed using secondary data to triangulate the interview data. This study analysed exiting and completed jobs to find suitable circular economy principles implemented in selected MC projects. The projects were screened using details available on the National Precast [

27] website, which is limited to precast construction. The criteria for selection included MC projects that utilised some CE, 10R, or sustainability practices.

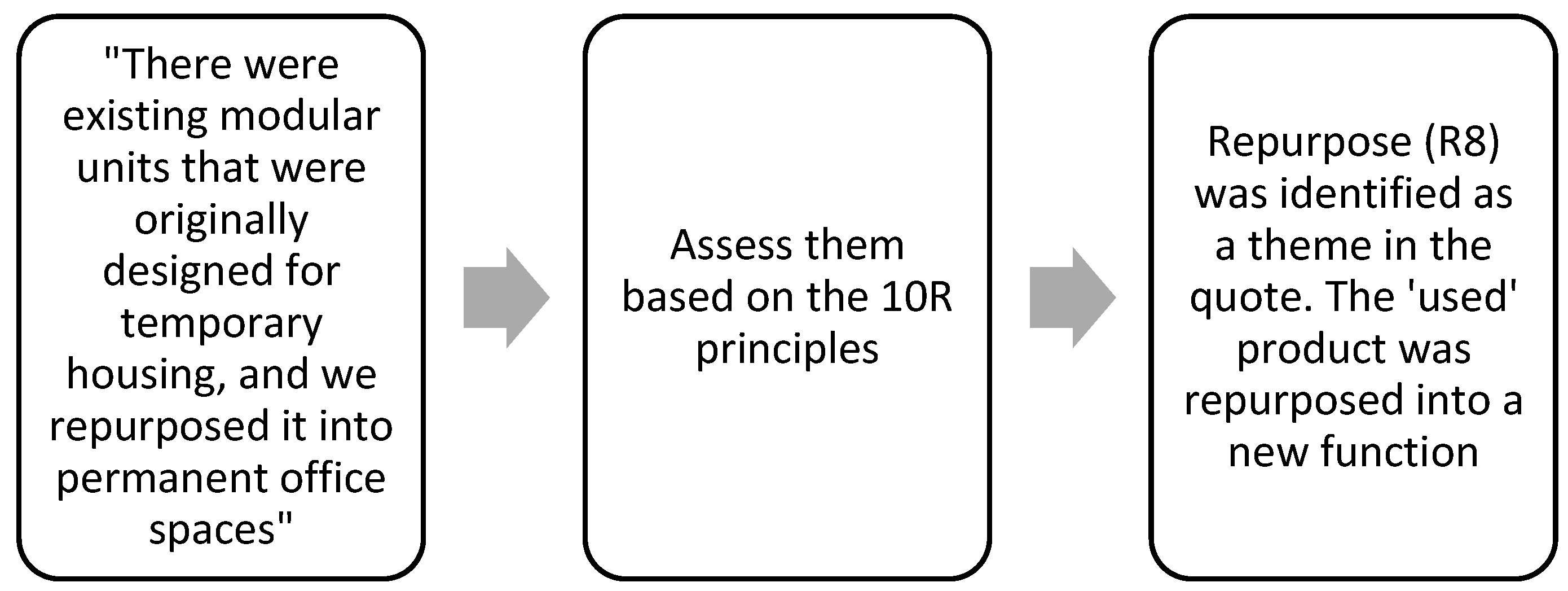

The collected data were analysed using thematic analysis following the framework of Lester, Cho and Lochmiller [

28]. This method involves seven key steps to ensure effective data analysis and meaningful findings. These steps include data organisation, where data are structured for easy access, followed by data transcription to ensure verbatim accuracy. Next, initial familiarisation involves a preliminary review and note taking, while memoing and reflection help to capture insights and identify potential biases. The coding process categorises data through a structured system, leading to the development of themes from the codes to form broader interpretations. Finally, ensuring transparency verifies the findings and helps to present the results clearly, with

Figure 2 illustrating how quotes are categorised into themes. In this way, the thematic analysis enabled the identification of key challenges and strategies in implementing the 10R principles in MC.

4. Research Findings from Expert Interviews

The expert interviews were completed with six participants. The initial goal was to conduct them with 8–10 professionals. However, the availability of professionals willing to participate was minimal, and, initially, 18 were approached. During the first six interviews, it was found that there were similar responses and patterns arising, which indicated theoretical saturation [

29]. Furthermore, according to Gilbert and Prion [

30], in areas where it is difficult to find experts, it is adequate to use 5–10. Therefore, the panel consisted of six (6) experts. To ensure that the study was completed appropriately, all participants needed to sign the consent form and return it within 2 weeks of the initial contact. The participants were coded as P1–P6. This ensured compliance with the confidentiality agreement and allowed for an efficient analysis.

Table 2 outlines the professionals’ ages, the type of business that they worked for, their specific roles within such a workplace, whether they were Prefab AUS members, and their experience in the industry. It should be noted that there was a mixture of males and females who participated in the study. In order to conduct successful expert interviews, the professionals selected had to vary in age, experience, and business role. The average time of each interview was 30 min, recorded and conducted over a 4-week period, and we utilised Microsoft Teams to record and then transcribe the quotes (verbatim). The data collected were then cross-checked to ensure the complete accuracy of the responses.

4.1. Familiarity with the Terminology and R Applications

The initial questions asked the professionals about their personal understanding of the terms ‘sustainability and circular economy’. It was found that 100% knew both terms. This percentage suggests that the industry has good knowledge of general sustainability. Additionally, the participants were posed the question, ‘do you know the terms ‘reduce (R3), reuse (R4), recycle (R9)?’ All of the professionals (100%) knew these terms, and some also stated that they had ‘been around for a decade‘ (P2) and were ‘very common terms’ (P4). When the participants were asked about the 10R principles specifically, 17% knew the terms and 50% were familiar with the terms, but 33% did not know additional details. This figure highlights the lack of understanding regarding in-depth knowledge associated with CE principles.

The three looping systems were discussed throughout the expert interviews. The professionals had varied responses, which highlighted their lack of awareness. The professionals were all asked if they agreed with the definition of the looping system, after providing them with the definitions. It was found that 67% of the participants understood and agreed with the definitions, whereas 33% did not comprehend the definitions provided. This revelation suggests that the short, medium, and long loops are not commonly considered in the construction industry, which further stresses the importance of generating more awareness and educating the industry in attempts to increase the sustainable practices of the 10R model. The looping system directly correlates with the 10R model; however, in order of importance, the main focus still remains the 10R principles. Consequently, the participants were questioned to identify specific uses of 10R applications after explaining each term. They were able to provide certain examples of 10R applications within their previous and existing employment during the interviews.

It was a common theme amongst all six professionals that recycling (R9) was a key initiative taken within their professional settings in attempts to create a more sustainable business. For example, according to P6, ‘everything’s recycled’. However, the extent to which recycling was applied varied. To elaborate, P2 stated that they ‘stockpile any waste that can be recycled and that goes to the waste recovery centre’. P3 also stated that their company separates their rubbish into ‘carboard bins and waste bins’ and is considering a ‘timber bin’ to limit its environmental impact. P4 showed an application of the recycling principle at the input end as they used ‘car batteries and car bumper bars that are recycled from car waste in the manufacturing of their modular products’.

The repurpose (R8), remanufacture (R7), and refurbishment (R6) principles were also observed through the interview findings. For example, P1 stated, ‘in one project we repurposed our products. There were existing modular units that were originally designed for temporary housing, and we repurposed it into permanent office spaces’. P3 also implemented the R7 principle as their company ‘used some leftover cladding material and steel to create an insulation shed’. P5 also encouraged clients to purchase refurbished modular units compared to replacing them with new units.

There was some evidence of repair (R5) and reuse (R4) applications. For example, P5 demonstrated that their company reused products compared to single use to minimise their waste, saying, ‘we (re)use all our temporary flashings/bracing and walkway temp flooring for every project’. This initiative aligns with the R5 principle of repair, as P5 stated, ‘we repair a few times all our transit bracing prior to disposing of these when they are unable to be reused again’. This company aimed to extend the lifecycle of the bracing without compromising the structural integrity. P6 also reused ‘leftover materials’ to limit disposable waste and increase the materials’ lifecycles.

Reduce (R3) and refuse (R1) applications were the least observed, while rethink (R2) was unconsciously considered in modular construction as modular units are designed for durability and future use. The participants strongly emphasised the importance of these Rs. P2 stated that ‘using the R model values to really think about how you’re going to use that product in the future and then it’s going to get recycled again’. P1 mentioned, ‘We often try to rethink how traditional building methods could be used because they do most of the time aligned with sustainability practises…aim to minimise material usage the way we design buildings with fewer resources’. This professional highlighted that, if companies wish to achieve greater sustainability, they should rethink their designs and material choices. P5 agreed that the ideal method for the implementation of the 10R principles to create a circular economy is refusing a material based on its environmental impact.

In summary, all professionals described some sustainable initiatives that were related to the 10R principles. R10 was not evident in the findings. However, the long and medium loops were more evident compared to practical applications of short loops, except in the case of the rethink principle, which seems to be inherent in modular construction. Most of the professionals lacked an understanding of the 10R model, so they did not directly involve practices related to the principles. Consequently, these findings support the literature review in suggesting that there is a gap in both academia and the industry in the application of the 10R principles within modular construction.

4.2. Challenges in Implementing 10R Principles in Modular Construction

These findings illustrate the suitability of implementing the 10R principles within modular construction, as 100% of the industry professionals agreed that they could do ‘more’ to improve the company’s circular economy. P2 specifically highlighted that they did not have a specific team dedicated to sustainability but there were underlying morals and values in the business that encouraged sustainable approaches. This situation was also reflected by P4, as they did not have enough staff to have a sustainability team, but the principles were at the forefront among all team members. Essentially, small to medium enterprises did not have enough staff, resources, or funds to provide a dedicated sustainability team/person. However, the businesses were all aware that sustainable practices were important to implement in order to reduce waste and create a more circular economy.

In order to implement the 10R principles within the construction industry, one must look at the possible challenges that might be associated. The interviews highlighted the current barriers facing the modular construction industry, which include, but are not limited to, financial challenges, customisation and design, a lack of resources, and a lack of industry awareness.

Financial Issues: It was found that all six professionals agreed that the financial challenges associated with implementing sustainable practices—specifically the 10R principles—were a large deterrent. This result was not a surprise, as it is extremely common for businesses to not advance in their practices if there is a large associated cost and the return on investment is not high. This ideology was illustrated by P2, who stated that the sustainable route could be a ‘financial burden, so you have to make financial choices overlaid with your moral choices’. This comment highlights the need to create a balance between costs and values. Additionally, P1 stated that there are high initial costs because ‘sustainable materials often come with a higher price tag’, which can be a barrier in a cost-sensitive market. This statement was supported by P5, who discussed the ‘costs associated with materials’, as clients are driven by the cheapest price, which impacts their business decisions. P1 further elaborated on this, sharing an experience in a previous project involving the design of 220 modular residential apartments. This project was solely designed using sustainable materials, but the ‘developers scrapped it because of the price difference’ (between traditional and sustainable materials and practices). This decision to reject the proposal occurred after the drawings and bill of quantities were created. Thus, the project was not feasible for the company as the return on investment did not allow for a high enough profit margin to proceed with the works. This example highlights the industry’s hesitation to build sustainable modular complexes as they have not been cost-effective and realistic in the past.

Customisation and Design: P3 identified another challenge that they faced that limits the implementation of sustainable practices, namely the clients’ specifications for the design. This professional stated that ‘the biggest challenge to be able to implement these would be that we’re really building custom to order, client specification’. Therefore, the company struggled in applying some of the 10R principles, such as ‘reuse’ (R4), because clients do not want ‘used’ products but rather ‘brand new’ ones. Furthermore, customised designs also limit the ability to apply other R principles, such as ‘refurbish’ (R1), as the business completes the order as per the direction of the client.

Lack of Resources: P2 suggested that they had a lack of formal suitable council within this business, which was due to them being ‘small’ compared to the more established companies. However, this professional was adamant that sustainable principles were considered during their works but not formally recognised. This lack of body was also highlighted by P4, who stated that ‘to have a dedicated team or something like that, now we don’t have the money to do that’. This barrier related to a lack of resources coexists with the financial burden of implementing sustainable practices.

Lack of Awareness: Another challenge that was extremely prevalent in this study was the lack of industry awareness of the 10R principles. Although MC is a more sustainable building practice compared to traditional builds, there are still areas for improvement. The expert interviews also showed this lack of industry awareness.

4.3. Strategies to Implement 10R Principles Within Modular Construction

During the expert interviews, to overcome the barriers identified above, a few strategies were highlighted by the participants, covering government grants/incentives, policies/schemes, and the updating of codes.

Government grants and incentives: The idea of grants and incentives was discussed as a method to better implement the 10R principles within the modular construction industry. Specifically, P4 stated that they had been conducting research on ‘recycled products for near 15 years’, and this research, investment in technology, and time spent cost the business ‘thousands of dollars’ and they ‘haven’t received a cent from the government’. This revelation suggests that professionals are willing to improve their practices and increase their sustainability; however, this comes at a cost to them, without reimbursement. P4 also highlighted their negative attitude regarding the absence of government support regarding sustainability and the lack of investment in future technologies.

Government policies and schemes: P1 encouraged the implementation of government policies such as ‘tax breaks and subsidies’, as they would reduce the main challenge in implementing the 10R principles in MC, namely the cost. They also stated that this initiative would likely ‘attract more people towards circular economy’, as previous schemes that were declared by the government generated high visibility among developers who wished to implement the strategies. This highlights the importance of introducing incentives as a method to create a shift in the industry and move toward more sustainable practices that implement the 10R principles.

Updated standards: In overcoming the barriers of limited information, the interviewees suggested updating standards to reflect R practices. The lack of public information raises concerns about the industry-wide awareness and adoption of CE principles. Prefab AUS [

26] emphasises the need for improved construction codes, standards, and planning laws specific to modular construction and sustainable practices.

5. Research Findings from Secondary Case Studies

This section presents a review of selected case studies using secondary data and explores the implementation of sustainable and CE practices, particularly the 10R principles, in modular construction. These data complement the primary data collected through the expert interviews and allow us to compare, contrast, and expand upon the interview findings.

Critically for this research, National Precast [

27] provides extensive publicly accessible information about projects, including details about implemented sustainable practices. Accordingly, three case studies from the National Precast website were examined to explore the practical application of sustainable principles in projects, mainly involving precast concrete components.

Hospital in Victoria: Bendigo Hospital, designed by Bates Smart and Silver Thomas Hanley and built by Lendlease, exemplifies the rethink (R2) principle through innovative design strategies, including the integration of green spaces such as courtyards, gardens, and a 1000 m2 green roof to enhance its environmental sustainability. The project utilised precast concrete systems for its multi-level car park and conference centre, incorporating a specially designed concrete mix that reduced the maintenance costs. The precast modular wall systems facilitated rapid installation, exceeding expectations and delivering the project within five months, significantly reducing the construction time and costs. Additionally, modular patient rooms and flexible clinical areas were incorporated to improve the long-term adaptability. The hospital also demonstrated the refuse (R1) principle by using materials with environmentally friendly certifications, such as FSC-certified wood and low-carbon concrete. As part of the redevelopment process, it applied the reuse (R4) principle, incorporating reclaimed materials such as bricks and metal from the previous structure. The recycle (R9) principle was evident through a comprehensive recycling program, successfully saving and recycling 1 tonne of curtain waste from disposal. In addition to these sustainability measures, the hospital significantly reduced its environmental footprint by installing 770 solar panels, allowing the building to function largely on natural energy. A rainwater harvesting system was implemented, leading to a 50% reduction in potable water consumption, further enhancing the resource efficiency. The project also achieved an 80% diversion rate of total construction waste from landfill, reinforcing its commitment to sustainable construction. This award-winning hospital serves as a strong example of the practical application of multiple 10R principles, although a fully holistic 10R approach was not entirely evident.

Hotel Complex in Sydney: The Ribbon, a 30-storey hotel complex in Darling Harbour, Sydney, exemplifies the application of the circular economy principles, particularly rethink (R2) and recycle (R9). The project incorporated precast glass-reinforced concrete (GRC) components, which were composed of recyclable materials and required less energy-intensive production processes, thereby minimising the carbon footprint. Manufactured domestically by Asurco, the use of GRC significantly reduced the emissions associated with transportation. In addition to the sustainable use of GRC, the W Sydney Hotel integrated several eco-friendly features. The hotel partnered with Genesis Motors to offer electrified vehicles for VIP transport, promoting the use of electric vehicles among guests. Furthermore, the installation of electric vehicle chargers on-site encourages environmentally respectful travel to and from the hotel. The interior design also reflects a commitment to sustainability. Guest rooms feature Dreamscape wall coverings with custom prints of Australia’s flora and fauna. These low-VOC vinyl coverings enhance the indoor air quality while showcasing environmental responsibility. While these initiatives demonstrate the project’s dedication to sustainable practices, specific quantitative data on the economic or environmental impacts of applying the 10R principles in the Ribbon project are not readily available. Further research and data collection would be necessary to provide detailed metrics regarding the waste reduction, energy savings, or resource efficiency achieved through these initiatives.

Residential Development in Sydney: The EKO Residential Development in Sydney exemplifies the application of several 10R principles, particularly rethink (R2), reduce (R3), and recycle (R9), to achieve notable economic and environmental benefits. By integrating Ultrafloor precast flooring systems, the project achieved a reduction in concrete and reinforcement material usage by up to 50% compared to traditional construction methods, leading to significant cost savings and a shortened construction timeline. Additionally, the incorporation of sustainable features such as solar power installations, rainwater capture systems, and water recycling initiatives contributed to a substantial decrease in the development’s carbon footprint and operational costs. These strategies collectively demonstrate a commitment to sustainable building practices, resulting in both economic efficiencies and environmental stewardship. These three case studies consistently demonstrate the partial implementation of the 10R principles in modular construction projects, primarily focusing on rethink (R2) and some aspects of recycle (R9) and the other Rs. However, there is a clear lack of comprehensive application of the full 10R framework. This outcome aligns with the findings from the expert interviews, where the limited understanding and application of the 10R principles was observed.

6. Discussion and Recommendations

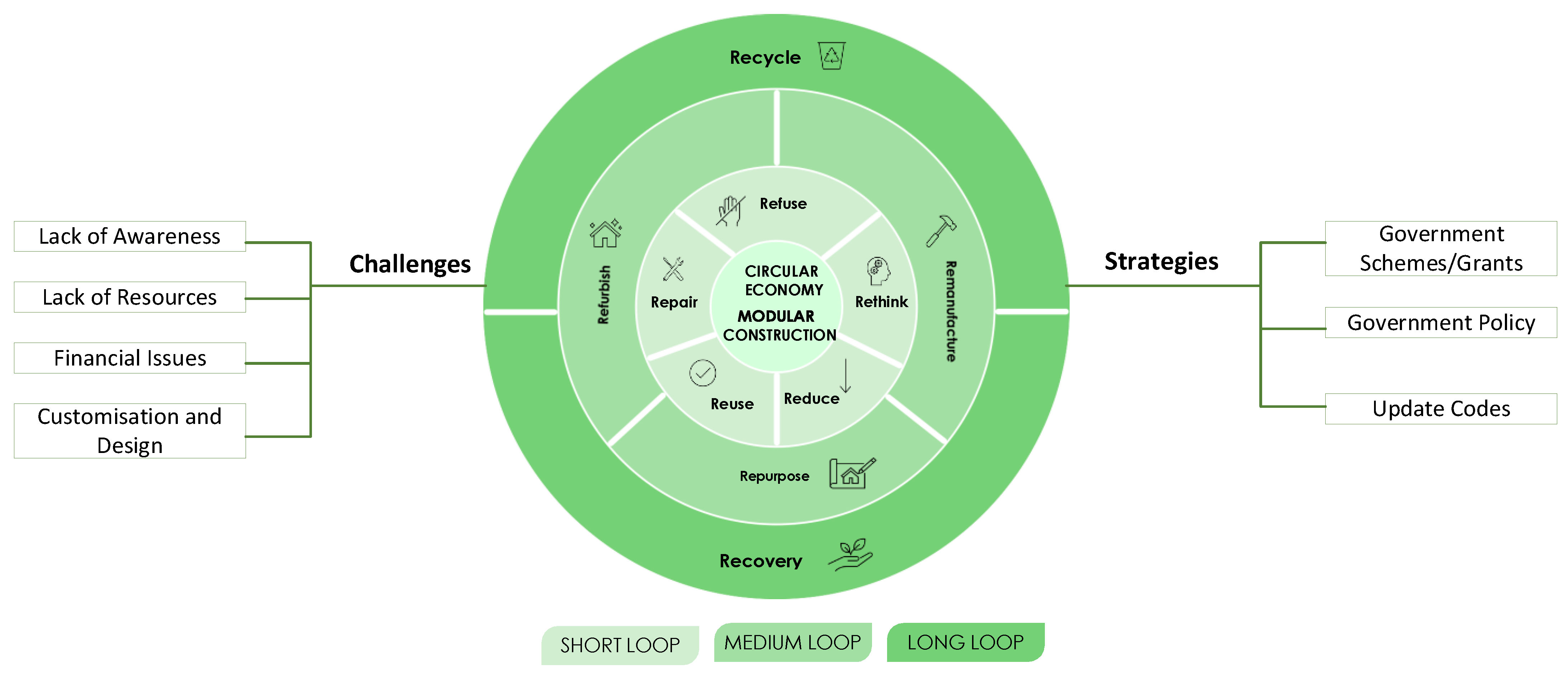

The expert interviews and case studies present some evidence of circular economy applications in modular buildings. There are fewer attempts at explicit circular economy implementation, as observed in this study. Even though modular construction, in comparison to traditional construction, offers superior sustainability benefits and an easy path to the implementation of circular construction, the current research findings indicate that a more comprehensive and strategic approach to applying the 10R principles is needed to maximise the circularity and sustainability of modular construction. The findings of this study are summarised in

Figure 3 below. The findings from the interviews on the challenges and strategies that were discussed in

Section 4.3 are summarised in

Figure 3 below.

In

Figure 3, the loops are shown in the key at the bottom, with the lightest green indicating the short loop, the darker green the medium loop, and the darkest green the long loop. The left-hand side highlights the challenges associated with implementing the 10Rs, whereas the right-hand side highlights the strategies suggested by the expert interviews and document review to combat these barriers. This study highlights the critical challenges, including insufficient awareness, limited resources, financial barriers, and customised design, in implementing circular economy practices in modular construction. To address these challenges, this research identified strategies such as the development of policies, incentives, and standards.

While modular construction companies have successfully implemented certain principles, such as R2 (rethink) and R9 (recycle), the adoption of other principles, including R1 (refuse), R3 (reduce), R4 (reuse), R5 (repair), R6 (refurbish), R7 (remanufacture), R8 (repurpose), and R10 (recovery), remains limited. This gap suggests significant opportunities for improvement within the industry. Several recommendations are proposed, as listed below.

Companies should train employees on sustainable practices and establish dedicated teams to focus on environmental considerations.

Collaboration with suppliers is essential to source materials that can be reused from previous projects.

Incorporating renewable energy solutions, such as solar panels, can help to reduce the carbon footprint of modular buildings.

Raising awareness through informative posters and other initiatives can encourage a broader commitment to sustainable practices.

Raising awareness through the integration of MC into education, construction-specific information, and attitude formation.

Leveraging technology such as building information modeling (BIM) can optimise designs and minimise waste.

These measures aim to foster a more sustainable workplace and environmentally responsible project outcomes, while also promoting the adoption of the 10R principles across the industry. However, achieving these goals will require time, effort, and sustained commitment from all stakeholders, as meaningful change is a long-term process.

7. Conclusions

The aim of this study was to explore applications of circular economy principles—specifically, the 10R principles—within modular construction in Australia. Following a literature review, the study revealed the importance of applying the 10R principles to modular construction. It is well recognised in multiple research studies that there is insufficient awareness and discussion surrounding the 10R principles and how they can be applied to modular construction to increase sustainability and create a circular economy. The literature revealed that the 10R principles related to CE implementation are comprehensive and cover approaches such as R1 (refuse), R2 (rethink), R3 (reduce), R4 (reuse), R5 (repair), R6 (refurbish), R7 (remanufacture), R8 (repurpose), R9 (recycle), and R10 (recovery), which could be categorised into short (R1 to R5), medium (R6–R8), and long loops (R9 and R10) based on the proximity of a material to its original value and the influence of key parties. The effective implementation of the proposed 10R principles would reduce waste by refusing and reducing resource consumption; rethinking would allow for better designs; reuse, repair, and refurbishment can repurpose unwanted materials; products’ lifespans can be extended through remanufacturing and repurposing; and recycling and recovery can be performed more effectively, with a commitment to ongoing change. While modular construction already exhibits some of these sustainable benefits, it can be further enhanced with strategic intervention. Furthermore, previous studies have suggested that the R principles could mitigate the current common issues in MC. However, there is a lack of studies investigating the extent of the application of these Rs in modular construction. This study focused on addressing this specific research gap and explored the application of the 10R CE principles in MC through expert interviews and case studies.

Both the expert interviews and case studies demonstrated the existing industry’s experience with sustainable and modular construction. There is an overall lack of awareness of the 10R principles in modular construction, which was initially highlighted in the literature review and further supported in the interview findings and case studies. The study found that there were some challenges regarding the implementation of the 10R principles, as the industry professionals interviewed during the study believed that the associated direct and ongoing costs of sustainable projects posed deterrents to their business. Furthermore, the lack of grants and schemes to subsidise the costs of businesses that implement the 10R sustainable principles is another challenge. An interesting finding was that the rethink (R2) principle was observed as inherent in modular construction, with modular designs considering durability and future use aspects. Recycling was another widely noticed approach. However, there was a lack of other R applications and a comprehensive holistic approach. The findings of this research highlight the pressing need for the construction industry to adopt more sustainable practices to strengthen the circular economy with the initiation of relevant government policies, standards, and grants. Industry-wide education initiatives for capacity building and fostering collaboration between stakeholders are imperative to align efforts toward sustainability. Ultimately, the key points from this research suggest that, in order to improve sustainability and create a circular economy in modular construction, changes must be made.

This study faced several limitations that may have influenced its outcomes. A key challenge was the reliance on expert interviews and case studies for data collection, constrained by time and participant availability. Another limitation was the focus on professionals from small to medium enterprises, potentially restricting the study’s applicability to larger companies with more extensive resources and advanced sustainable practices. These limitations highlight areas for future research to enhance the scope and applicability of the findings. Future research could investigate the implementation of the 10R principles in larger modular construction companies, both within Australia and internationally. Additionally, exploring government policies, legislation, and standards and their roles in offering clear guidelines and actions to promote sustainability in the construction industry could drive industry-wide change.

Overall, this study provides a valuable contribution to research and practice on sustainable principles in the Australian modular construction industry, shedding light on key challenges and offering recommended strategies. This study aligns with the United Nations’ 17 Sustainable Development Goals, particularly Goal 9 (Industry, Innovation, and Infrastructure), Goal 11 (Sustainable Cities and Communities), and Goal 12 (Responsible Consumption, and Production), as they emphasise reducing construction waste through innovation, fostering sustainable communities, and promoting responsible resource use. These goals serve as global benchmarks for sustainability, reinforcing this study’s focus on advancing a circular economy.