Abstract

Innovative approaches in the Portland cement industry, aligned with circular economy principles, offer a promising solution to reduce the environmental impacts. These methods can initially target the architectural elements with lower structural demands, such as urban furniture and paving, before being applied to areas with higher cement usage. Alkali-activated binders (AABs) made from secondary resources present a sustainable alternative to Portland cement (PC), promoting resource recovery, conservation, and a low-carbon economy. Incinerator bottom ash (IBA), traditionally landfilled, has shown potential as a precursor for AABs due to its aluminosilicate content. Repurposing IBA for urban furniture and paving transforms it into a valuable secondary resource. Accordingly, this is the first study to utilize IBA as the sole precursor for urban furniture or paving applications. Research, including state-of-the-art studies and proof of concept developed in this work, demonstrates that IBA-based AABs can produce cast concrete suitable for non-structural urban elements, meeting the technical, environmental, and ecotoxicological standards. Using IBA in AAB formulations not only reduces the reliance on primary raw materials but also contributes to significant energy savings in binder production and lowers greenhouse gas (GHG) emissions, resulting in a reduced carbon footprint. Furthermore, producing concrete from local residual resources, such as IBA, facilitates the reintegration of municipal waste into the production cycle at its point of origin, fostering a sustainable approach to urban development and supporting the circular economy.

1. Introduction

The construction industry is pivotal in driving regional economic growth, catering to both the infrastructure demands of industries, such as factories, ports, and roads, and the societal needs for housing, hospitals, and urban transportation. Despite its considerable economic impact, contributing 13% to the global GDP in 2020 and anticipated to exceed 13.5% by 2030 [1], the sector also has significant environmental consequences. It utilizes up to 60% of all raw materials extracted globally and is a major source of CO2 emissions, responsible for about 50% of emissions during the conversion of raw materials into construction products [2].

In the construction industry, Portland cement (PC) stands out as one of the most widely produced materials worldwide. Currently, the global annual production capacity for cement surpasses 4100 million metric tons [3]. The PC industry is currently the third-largest consumer of industrial energy, using 12 to 15% of the total. It is also the second-largest industrial emitter of CO2 globally, responsible for 25 to 27% of the industry’s total emissions [4]. The significant energy consumption and CO2 emissions in the Portland cement industry are primarily due to the large volumes of cement produced and the energy-intensive thermal processes involved. Recent data for the European Union (EU27) indicate that cement production reached approximately 180 million metric tons in 2023 [5]. Each ton of cement produced requires 60 to 130 kg of fuel oil or its equivalent, depending on the type of cement and manufacturing process, and about 110 kWh of electricity. This production accounts for 5% of the total CO2 emissions in the EU [6].

The construction sector is vital for developing urban amenities and enhancing public spaces. As housing and infrastructure projects grow, the demand for urban furnishings and amenities rises to meet the needs of expanding communities, thereby improving the esthetics and functionality of urban areas. This sector’s growth not only drives residential and infrastructural development but also creates significant opportunities for the urban furnishings market and the paving of public spaces. Urban furniture, such as benches, litter bins, and lighting, enhances the functionality and visual appeal of public spaces. Meanwhile, urban pavement, including roads, sidewalks, and plazas, plays a crucial role in ensuring safety and accessibility.

Today, traditional materials such as metals and their alloys, wood, natural stone, concrete, and plastics remain the primary choices for urban furniture [7]. For paving urban areas, especially sidewalks, concrete is a popular option due to its durability and ability to create decorative patterns. Additionally, its lower technical requirements allow for the increased use of recycled materials without sacrificing performance. As a result, modern urban designs emphasize sustainability by incorporating recycled materials [8], aiming to reduce the extraction of natural resources and mitigate the environmental impact associated with high Portland cement emissions.

In recent years, alternative Portland binders for urban construction materials have gained significant attention due to the growing demand for sustainable and eco-friendly building practices. These alternatives support the development of environmentally conscious urban infrastructure and promote the creation of sustainable cities and communities. As a result, researchers and industry professionals are actively seeking binders that minimize the environmental impact while maintaining strong mechanical properties.

One promising alternative is alkali-activated binders (AABs), which can be made from aluminosilicate-rich industrial waste or natural resources like fly ash and volcanic ash [9,10]. AABs are notable for their potential to significantly reduce carbon emissions due to their lower production temperatures and energy requirements. Additionally, the concept of a circular economy, which emphasizes reusing and transforming waste and by-products into new materials, has gained popularity as a means to lessen the environmental impact of human activities. Moreover, AABs offer mechanical properties that are comparable to or even better than those of Portland cement. As a result, AABs support the EU 2050 energy efficiency strategic policy, promoting a low-carbon economy and the efficient use of natural resources.

This approach allows for the use of various industrial wastes and locally sourced aluminosilicate-rich materials as precursors for AABs, promoting the creation of sustainable binders within a circular economy framework and reducing the reliance on natural resource extraction. Additionally, this approach offers several benefits, including lowering transportation-related carbon emissions and creating new job opportunities within the local community. Therefore, discovering innovative ways to repurpose local waste is essential for sustainable development, especially in urban construction materials.

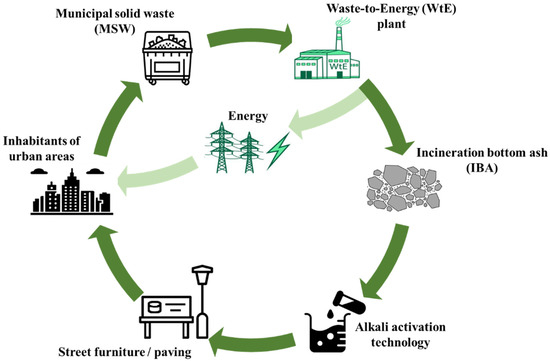

This paper aims to evaluate the strategy of using local aluminosilicate-rich waste to formulate alkali-activated binders for producing urban amenities, particularly street furniture and paving. Given its composition and the substantial annual generation of waste, IBA emerges as a promising candidate for exploration as a sole precursor material for AABs. The research seeks to validate its feasibility for this purpose, assess its environmental performance across different particle sizes, and establish a technical route to produce non-structural precast components. Drawing from global bibliographic studies, it is essential to evaluate the aspects of circularity and sustainability, alongside the mechanical and environmental constraints, to determine its suitability for the proposed applications.

2. Waste-to-Energy: A Key Process for Municipal Solid Waste Treatment

The significant amount of residue generated globally has raised concerns about the management of municipal solid waste (MSW). This issue is primarily due to the increased industrial and economic activities in both developed and emerging economies, leading to population growth and higher living standards, among other factors [11]. According to the latest data from Eurostat, the Statistical Office of the EU, the European Union (EU-27) produced approximately 235 million tons of MSW in 2021 [12]. This quantity translates to an average of 527 kg of MSW per capita, accounting for about 10% of the total waste generated in the EU [13,14].

In response to the increasing generation of MSW, the EU’s waste framework directive emphasizes maximizing the value of products, materials, and resources by promoting their extended use, thereby advancing a circular economy [15,16]. The directive also introduces a waste treatment hierarchy, prioritizing treatments that enhance waste valorization and minimize the environmental impact, with landfilling being the least preferred option. When the reuse or recycling of waste materials is not feasible, energy recovery in waste-to-energy (WtE) plants is a preferable alternative before landfilling, significantly reducing the volume (up to 90%) and weight (up to 75%) of MSW [17]. Despite the increase in waste generation within the EU, there has been a notable decrease in the amount of municipal waste being landfilled. This trend aligns with the EU’s target to limit landfilling to 10% by 2030 [18]. According to the latest data on MSW treatment from Eurostat [12], in 2021, 23% of MSW was landfilled, 26% was treated in WtE incineration plants, 31% was recycled, 18% was composted, and 2% was managed through other processes.

It is noteworthy that energy recovery through WtE processes, despite being just one step above landfill disposal in the waste treatment hierarchy, is on the rise. Many EU countries view municipal solid waste incineration (MSWI) in WtE facilities as a valuable opportunity for energy recovery. According to data from the Confederation of European Waste-to-Energy Plants [19] and national sources, there were 504 operational WtE plants in Europe in 2020, which incinerated a total of 101 million tons of MSW. Therefore, promoting MSWI is crucial for advancing a sustainable economy that relies on alternative energy sources and the repurposing of MSW.

The treatment of municipal solid waste (MSW) in WtE plants not only facilitates energy recovery but also significantly reduces the CO2 emissions associated with electricity generation. As early as 2003, the International Energy Agency [20] highlighted the net reduction in CO2 emissions when MSW is incinerated, compared to generating an equivalent amount of energy through coal combustion and disposing of MSW in landfills without methane capture. Their analysis indicated a net reduction of 1982 kg of CO2-equivalent emissions per ton of MSW incinerated.

3. Incineration Bottom Ash as a Secondary Raw Material

The combustion of MSW produces two types of residues [21]: (i) incineration bottom ash (IBA) and (ii) air pollution control residues (APCrs). APCrs include fly ash from the combustion process and neutralization products from flue gases. The mass ratio of these residues typically ranges from 6:1 to 10:1, depending on the specific combustion process and pollution control technology used. IBA is considered non-hazardous and suitable for secondary resource utilization, while APCrs, due to their high levels of soluble salts and heavy metals, are classified as hazardous waste and require landfill management [22].

Before final disposal, fresh IBA undergoes pre-treatment to recover valuable metals like ferrous materials and aluminum using electromagnets and Eddy current devices, respectively. In countries where reusing IBA as a secondary resource is feasible, the mineral fraction is then stockpiled outdoors for 2–3 months. This weathering process helps immobilize heavy metals through carbonation, pH stabilization, metal oxidation, and hydration of the mineral phases within the IBA. The resulting material, known as weathered IBA, is classified as non-hazardous waste under the European Waste Catalogue (EWC 190112) based on its hazardous substance content and is recommended for reuse as a secondary resource.

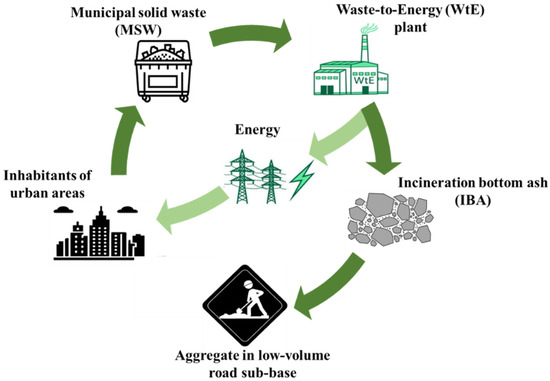

The potential applications of weathered IBA in engineering are extensive and varied. Its primary appeal lies in its particle size distribution and composition, which includes glass, ceramics, stone, brick, concrete, and melting products [23]. Despite its high heterogeneity, weathered IBA is considered a silica-rich material with significant amounts of calcium and aluminum, making it comparable to natural sand or gravel [24]. Its main use is in civil and construction engineering, where it serves as a secondary aggregate material for road construction [25,26], embankments [27,28], pavements [29], land leveling, landfill cover, and the restoration of areas degraded by extractive activities, as well as for concrete filling [30]. Due to its high glass content and brittle ceramics, IBA has a relatively low mechanical strength as a secondary aggregate. Consequently, its use in construction and civil engineering is limited to applications with minimal performance requirements, such as sub-base layers for low-volume roads or industrial park streets, typically located away from urban centers (Figure 1).

Figure 1.

Circularity of IBA as a secondary aggregate in low-volume road sub-base applications.

Additionally, on a smaller scale and in experimental stages, weathered IBA has been used in high-temperature sintering processes (above 1000 °C) to produce ceramics [31], glass-ceramics [32], bricks [33], and tiles [34].

4. Incineration Bottom Ash as an Alkali-Activated Binder Precursor

IBA has been extensively studied in the civil and building engineering sectors to explore its potential for full valorization. However, its use is often limited by technical and environmental challenges, including its glassy nature and the presence of heavy metals and metalloids. Furthermore, the absence of standardized regulations for IBA utilization results in significant disparities: some countries achieve nearly 100% valorization, while others primarily dispose of it in landfills [13,22].

In recent decades, the valorization of IBA through alkali activation has gained attention as a way to address its limitations. Using weathered IBA as a precursor for alkali-activated binders offers a viable alternative to its conventional use as a secondary aggregate, thanks to its rich composition of SiO2, Al2O3, and CaO, key components for alkali-activated binders [35]. However, the chemical composition of IBA is highly heterogeneous, influenced by factors such as local population practices, seasonal variations, particle size, and specific recovery processes in WtE plants [36]. Despite this variability, studies show that the average contents of SiO2 (36.8 ± 9.1), Al2O3 (10.5 ± 4.9), and CaO (26.4 ± 8.6) in IBA highlight its potential as a cementing material for alkali activation technologies. Additionally, forming a cement-based matrix can immobilize heavy metals from IBA, reducing their toxicity. Thus, the alkali activation of weathered IBA supports the circular economy by promoting the zero-waste principle and offering a greener, more sustainable alternative to Portland cement production.

To quantitatively evaluate the relevance of using IBA as a precursor in the formulation of AABs and to contextualize the conducted research, a bibliometric study was performed, covering the period from 2013 to mid-2024. These studies use mathematical and statistical methods to assess the impact and progression of scientific research through various indicators, involving a quantitative analysis of publications. The methodology used in this bibliometric study extends the approach previously developed by the authors in earlier research [37]. Several keywords and phrases were identified to determine the appropriate search terms for this study. The main keywords were: “MSW”, “bottom ash”, “alkali cement”, “alkali binder”, and “geopolymer”. The review includes all publications focusing on the alkali activation of IBA for developing building materials, such as pastes, mortars, and aggregate-based materials. The data source selected for this study was Scopus from Elsevier. Additionally, only scientific articles and conference proceedings were included when filtering the results from these databases. The search results were manually sorted by title and abstract.

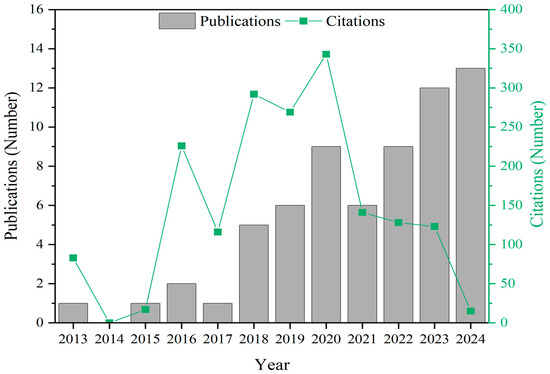

Figure 2 depicts the trend in publications and citations concerning the use of IBA for AAB formulation. Starting in 2018, there is a noticeable upward trend in the annual number of publications, indicating growing interest in this area. Citations also increase over time, peaking in 2020. However, after 2020, citations level off to around 125 per year, likely because the publications have not yet reached their full citation potential.

Figure 2.

Publication and citation evolution about the use of incineration bottom ash in the formulation of alkali-activated binders.

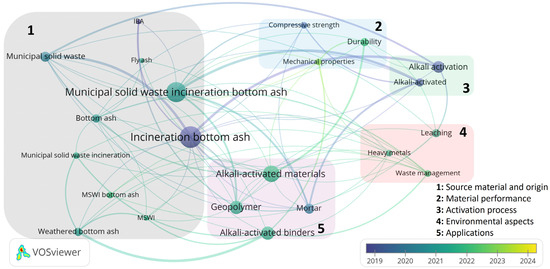

The map of keyword co-occurrences, as defined by the authors in the analyzed publications, illustrates the relationships between the various keywords (Figure 3). The size of each circle indicates the number of articles in which the keyword appears, while the lines connecting the circles represent the co-occurrence of the keywords. The thickness of each line is proportional to the number of documents that use both keywords. Alongside the keywords related to the materials generated during the incineration process, such as “municipal solid wastes incineration bottom ash” and “incineration bottom ash”, the four most significant keywords in the publication are “alkali-activated materials”, “geopolymer”, “alkali activation”, and “alkali-activated binders”. The co-occurrence of these keywords underscores the extensive use of IBA as a precursor in the formulation of AABs. Additionally, the absence of the keywords indicative of advanced technological stages typically associated with industrial implementation highlights the low Technology Readiness Level (TRL) of the current research. Most investigations have been conducted primarily at the laboratory scale, focusing on the critical parameters influencing the formulation of AABs. Special attention has been given to microstructural analysis using advanced characterization techniques, including scanning electron microscopy coupled with energy-dispersive X-ray spectroscopy (SEM-EDS), Fourier transform infrared spectroscopy (FT-IR), X-ray diffraction (XRD), and thermogravimetric analysis (TGA). Furthermore, the mechanical performance of these materials has been extensively evaluated in most studies, mainly through the determination of compressive strength.

Figure 3.

Keywords co-occurrence map.

4.1. Incineration Bottom Ash as a Partial Precursor

The use of IBA in the formulation of AABs can present challenges, primarily due to the presence of heavy metals and metalloids, which may be released more readily in highly alkaline environments. To address this issue, IBA is often investigated as a partial precursor mixed with other silica-rich materials to mitigate the potential release of these elements. Table 1 summarizes the studies focused on the formulation of AABs using IBA as a partial precursor in combination with other well-researched materials. The table includes bibliographic references of studies that concentrate on the formulation of pastes and mortars for potential construction applications. It does not cover studies related to the formulation of aggregate materials, which are included in Figure 2.

The summary indicates that IBA is often combined with materials like slaked lime (SL), ground granulated blast furnace slag (GBFS), metakaolin (MK), fly ash from coal power plants (FA), and Portland cement (PC). These materials are chosen for their calcium- and aluminosilicate-rich composition and well-documented properties in binder systems. Additionally, less conventional co-precursors such as incineration fly ash (IFA), phosphogypsum (PG), drinking water treatment residue (DWTR), ladle slag (LS), aluminum recycling waste (PV), limestone and calcined clay (LC2), coal gangue (CG), and waste glass (WG) have also been used in combination with IBA. Most studies incorporate IBA as a partial replacement for other precursors, with some using up to 100% IBA, typically utilizing the entire fraction (EF) of IBA. The particle size of powdered IBA typically ranges from 20 to 425 μm, making it a key parameter that affects multiple factors, including workability, the liquid-to-solid (L/S) ratio, and the mechanical properties of AAB pastes. Additionally, it plays a crucial role in the expansion and foaming behavior of mortars [38].

The most frequently used alkaline activators are combinations of sodium silicate (water glass, WG) and NaOH in various proportions, typically ranging from 1:1 to 5:1, with the 5:1 ratio being the most common. The molarity of NaOH usually falls between 5M and 12M, with 5M and 8M being the most used concentrations. Additionally, the L/S ratio, also known as the alkaline activator-to-precursor ratio, generally varies between 0.4 and 0.8. For the curing of AABs, most studies were conducted under similar temperature and relative humidity (RH) conditions [39], typically maintaining samples at room temperature with the RH around 95% ± 5% until testing.

In terms of mechanical performance, the results showed that AABs or mortars could be formulated for both non-structural and structural applications, depending on the choice of precursors and the amount of IBA used. The highest mechanical performances, with compressive strengths reaching up to 50–60 MPa, were achieved using GBFS and SL, with around a 60 wt.% IBA content. However, some studies reported lower mechanical performance due to the reaction between metallic aluminum and NaOH, which generates hydrogen gas, increasing the porosity and significantly reducing the mechanical strength. Other factors affecting the compressive strength included the L/S ratio, the SiO2/Na2O ratio of the alkaline activator solution (also known as the silicate modulus), and the NaOH concentration. High compressive strengths were observed with L/S ratios ranging from 0.45 to 0.6 and silicate modulus values between 2 and 2.5.

4.2. Incineration Bottom Ash as a Sole Precursor

The literature on using IBA as the sole precursor for AABs is significantly smaller compared to studies exploring its use as a partial precursor. Table 2 summarizes the research on the alkali activation of IBA as a sole precursor. Most of these studies have been published in the last decade, underscoring the unconventional nature of this approach in alkali activation technology. The limited number of studies is likely due to the inherent heterogeneity of IBA and the presence of metallic aluminum and heavy metals. These challenges have created uncertainty in the scientific community, which tends to favor more homogeneous and higher-purity raw materials for such applications.

Various investigations utilized different fractions of IBA to formulate AABs, with one study specifically using the glass fraction of IBA to enhance the mechanical properties of AABs. The particle size of powdered IBA typically ranged from 20 to 200 µm, depending on the study. The alkaline activators employed were mixtures of WG and NaOH (generally 8M) in a mass ratio of 2:1. Only two studies adopted a one-part alkali activation method by mixing water with Ca(OH)2 to produce IBA-based AABs [40,41]. It is noteworthy that studies using IBA as the sole precursor often applied higher L/S ratios. This approach is likely due to the low reactivity of IBA, which hinders the dissolution of calcium aluminosilicate phases in IBA powder, thereby reducing the workability of the mixtures.

Regarding the curing of the samples, the temperature and RH conditions varied significantly from those described when IBA was used as a co-precursor. Studies utilizing the entire fraction (EF) of IBA employed dry curing methods, maintaining temperatures above 75 °C. In contrast, other studies using IBA cured the samples at room temperature or relatively lower temperatures, with RH conditions ranging from 50% to 98%. To prevent excessive evaporation and drying shrinkage, all samples were sealed in plastic bags. The IBA-based AABs were characterized both chemically and mechanically after 3, 7, or 28 days of curing.

The investigations demonstrated the feasibility of producing AABs using IBA as the sole precursor for non-structural purposes, due to their low or intermediate compressive strength values. This is primarily attributed to the porosity of the samples, caused by the reaction between metallic Al and NaOH, which leads to H2 formation. However, the porosity and mechanical behavior of the binders can vary depending on the particle size fraction of IBA used as the sole precursor. Maldonado-Alameda et al. [42] demonstrated that binders formulated with the coarse fractions of IBA exhibit a higher mechanical strength compared to those using the EF. Previous research by Chimenos et al. [43] and del Valle-Zermeño et al. [23] found that the content of glass cullet and fired ceramics varies with particle size, with the coarse fractions (>8 mm) showing the highest concentrations of silicate- and aluminosilicate-rich materials. Consequently, Maldonado-Alameda et al. [44] also confirmed that the highest availability of silica and alumina for forming cementitious gels is associated with the coarser fractions of IBA.

Table 1.

Studies related to the use of IBA as a partial precursor.

Table 1.

Studies related to the use of IBA as a partial precursor.

| Study | Raw Materials Parameters | Curing Conditions | Mechanical Characterization | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Author/s | Year | Type | Co-Precursors | Alkaline Activator/s | Fraction of IBA Used (mm) | L/S Ratio | IBA Content (%) | Powder Size of IBA (µm) | T (°C) | RH (%) | Time (d) | Comp. Strength (σc; MPa) |

| Polettini et al. [45] | 2004 | P | IBA/PC | WG/NaOH/Na2SO4/CaCl22H2O | EF | 0.4 | 10–80 | <150 | 20/40 | 90 | 1,7, 28,56 90 | 6–43 |

| Onori et al. [46] | 2011 | P | IBA/MK | WG/NaOH | EF | 0.3 | 20–80 | <425 | 75 | room | 7 | 0.1–7 |

| Krausova et al. [47] | 2012 | P | IBA/IFA/WG | WG/NaOH | EF | 1.2 | 15–20 | n.r. | 700 | 30 | 7 | n.r. |

| Lancellotti et al. [48] | 2013 | P | IBA/MK | WG/NaOH | 0.2–1 | 0.5–0.7 | 50–80 | 75 | room | room | 15, 30 | n.r. |

| Lancellotti et al. [49] | 2014 | P | IBA/MK/LS | WG/NaOH | EF | 0.5–0.8 | 70 | 75 | room | 70 | 30 | n.r. |

| Song et al. [50] | 2015 | P | IBA/FA/PC | Water/Ca(OH)2 | EF | 0.7 | 5–30 | 23 | 185 | n.r. | 7 | 3–9 |

| Garcia-Lodeiro et al. [51] | 2016 | M | IBA/IFA/PC | Water/Ca(OH)2 | EF | 0.5 | 33 | 45 | room | 99 | 2,28 | 5–30 |

| Wongsa et al. [52] | 2017 | M | IBA/FA/PC | WG/NaOH | EF | 0.7 | 0–100 | 45 | 60 | 50 | 7.28 | 10–53 |

| Zhu et al. [53] | 2018 | P | IBA/MK | WG/NaOH | EF | 1.0–1.2 | 15–30 | <150 | 28 | 80 | 3 | 5–11 |

| Huang et al. [54] | 2018 | C | IBA/GBFS/SL/PC | WG/NaOH | EF | 0.6 | 27–60 | 45 | 20 | 95 | 14, 28, 60 | n.r. |

| Huang et al. [55] | 2018 | C | IBA/GBFS/SL | WG/NaOH | EF | 0.6 | 50 | 45 | 20 | 95 | 14, 28, 60 | 18–50 |

| Xuan et al. [56] | 2019 | C | IBA/WG | NaOH | 0–2.36 | 0.4–0.8 | 0–100 | 20 | 80 | 95 | 1, 7, 28 | 1–21 |

| Huang et al. [57] | 2019 | M | IBA/GBFS/PC | WG/NaOH | EF | 0.6 | 12–60 | 45 | 20 | 95 | 3, 28, 60 | 13–56 |

| Huang et al. [58] | 2019 | M | IBA/GBFS | WG/NaOH | EF | 0.5–0.6 | 60 | 45 | 20 | 95 | 3, 28, 60 | 15–52 |

| Ji and Pei. [59] | 2019 | P | IBA/DWTR | WG/NaOH | EF | 0.7 | 60–100 | 75 | 80 | room | 7, 14, 28 | 1–24 |

| Biswal et al. [60] | 2020 | P | IBA/MK | WG/NaOH | EF | 0.6 | 20 | <300 | room | room | 28 | n.r. |

| Cristelo et al. [61] | 2020 | P | IBA/IFA/PC | WG/NaOH | EF | 0.4–0.5 | 70–100 | 63 | 30 | 25 | 7 | 1–12 |

| Manzi et al. [62] | 2020 | P | IBA/MK | WG/NaOH | EF | 0.3–0.4 | 25–50 | <100 | 25 | 98 | 28 | 28–32 |

| Huang et al. [38] | 2020 | M | IBA/GBFS/SL | WG/NaOH | EF | 0.6 | 60–100 | n.r. | 20 | 95 | 3, 28, 60 | 2–60 |

| Huang et al. [63] | 2020 | M | IBA/GBFS | WG/NaOH | EF | 0.5–0.7 | 60 | n.r. | 20 | 95 | 3, 28, 60 | 5–50 |

| Maldonado-Alameda et al. [64] | 2021 | P | IBA/PV | WG/NaOH | >8 | 0.6 | 90–98 | <80 | 25 | 95 | 28 | 12–26 |

| Jin et al. [65] | 2021 | M | IBA/GBFS | WG/NaOH | EF | 0.5 | 60 | 49 | room | 95 | 3, 28, 60 | 1–30 |

| Vaičiukynienė et al. [66] | 2021 | P | IBA/PG | NaOH | EF | 0.3 | 80–100 | 39 | 60 | n.r. | 28 | 2.-4 |

| Maldonado-Alameda et al. [42] | 2022 | P | IBA/MK | WG/NaOH | >8 | 0.6–1.0 | 25–100 | <80 | 25 | 50 | 3, 28, 60 | 1–62 |

| Avila et al. [67] | 2022 | M | IBA/IFA | WG/NaOH | EF | 0.4 | 0–100 | <120 | 80 | n.r. | 7, 28, 91, 182 | 5–61 |

| Irshidat et al. [68] | 2022 | M | IBA/FA | WG/NaOH | EF | 0.6 | 5–20 | 100–1000 | 80 | n.r. | 28 | 26–40 |

| Liu et al. [69] | 2022 | P | IBA/FA/LC2 | WG/NaOH | 4-8 | 0.4 | 68–100 | <100 | room | 90 | 3, 7, 14, 28 | 2–17 |

| Suescum-Morales et al. [70] | 2022 | M | IBA/FA | WG/NaOH | EF | 0.4 | 15–30 | <100 | 70 | 60 | 7, 17, 28 | 27–46 |

| Feng et al. [71] | 2023 | P | IBA/IFA/CG | WG/NaOH | EF | 0.5 | 20–40 | <75 | n.r. | n.r. | 3, 7, 14, 28 | 0.5–4 |

| Feng et al. [72] | 2023 | P | IBA/GBFS | WG/NaOH | EF | 0.5 | 30 | <75 | 20 | 98 | 3, 7, 14, 28 | 0.1–27 |

| Liu et al. [73] | 2023 | P | IBA/IFA | WG/NaOH | <15 | 0.5 | 25–75 | n.r. | 25 | 90 | 3, 7, 28, 56 | 1–9 |

| Wang et al. [74] | 2023 | P | IBA/GBFS | WG/NaOH | EF | 0.5 | 25–100 | <200 | 25 | 90 | 3, 7, 28 | 1–16 |

| Zhang et al. [75] | 2023 | P | IBA/GBFS | WG/NaOH | EF | 0.4 | 3–12 | <50 | 25 | 95 | 28 | 60 |

| Deng et al. [76] | 2024 | P | IBA/GBFS | WG/NaOH | EF | 0.5 | 6–39 | <200 | room | room | 3, 28 | 10–70 |

| Feng et al. [77] | 2024 | P | IBA/CG | WG/NaOH | <15 | 0.5–0.7 | 10–40 | <75 | n.r. | n.r. | 3, 7, 14, 28 | 1–17 |

| Jian et al. [78] | 2024 | P | IBA/GBFS | WG/NaOH | EF | 0.4–0.5 | 30–60 | <125 | 20 | 95 | 7, 28 | 6–42 |

| Liu et al. [79] | 2024 | M | IBA/GBFS | WG/NaOH | EF | 0.5 | 5–25 | <75 | n.r. | n.r. | 7, 28, 56 | 2–40 |

| Wang et al. [80] | 2024 | M | IBA/GBFS | WG/NaOH | EF/0–2 | 0.4 | 60 | <75 | room | room | 28 | 44–54 |

| Xie et al. [81] | 2024 | P | IBA/GBFS | WG/NaOH/Ca(OH)2 | 2–4/4–8/8–16 | 0.4 | 70 | <100 | 20 | 90 | 3, 7, 14, 28 | 22–36 |

| Yang et al. [82] | 2024 | P | IBA/VT | WG/NaOH | EF | n.r. | 5–100 | <100 | 60 | n.r. | 3, 7, 14, 28 | 5–27 |

P—paste; M—mortar; C—concrete; EF—entire fraction; n.r.—not reported.

Table 2.

Studies related to the use of IBA as a sole precursor.

Table 2.

Studies related to the use of IBA as a sole precursor.

| Study | Raw Materials Parameters | Curing Conditions | Mechanical Characterization | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Author/s | Year | Type | Co-Precursors | Alkaline Activator/s | Fraction of IBA Used (mm) | L/S Ratio | Powder Size of IBA (µm) | T (°C) | RH (%) | Time (d) | Comp. Strength (σc; MPa) |

| Qiao et al. [40] | 2008 | P | IBA | Ca(OH)2 | 0–14 | 0.5 | <200 | 20 | 98 | 3, 7, 28 | 0.5–3 |

| Qiao et al. [41] | 2008 | P | IBA | Ca(OH)2 | 0–14 | 0.5 | <200 | 20 | 98 | 7, 28 | 0.5–15 |

| Yamaguchi et al. [83] | 2013 | P | IBA | WG/NaOH | EF | 0.4 | 63 | 80 | 100 | 2 | n.r. |

| Chen et al. [84] | 2016 | P | IBA | WG/NaOH | EF | 0.6–1.1 | 20 | 75 | n.r. | 3 | 1.0–2.8 |

| Zhu et al. [85] | 2016 | P | IBA | WG/NaOH | EF | 1.0 | <150 | 75 | n.r. | 3 | 2.8 |

| Giro-Paloma et al. [86] | 2017 | P | IBA | WG/NaOH | 0–2 | 1.3–1.4 | 80 | 23 | 50 | 7, 30, 90 | n.r. |

| Zhu et al. [87] | 2018 | P | IBA | WG/NaOH | EF | 1.0 | <150 | 75 | n.r. | 3 | 2.8 |

| Zhu et al. [35] | 2019 | P | IBA | WG/NaOH | EF | 1.0 | <150 | 75 | n.r. | 3 | n.r. |

| Chen et al. [88] | 2020 | P | IBA | WG/NaOH | 4–11 | 0.5 | 63 | 40 | n.r. | 7,28 | 8 |

| Maldonado-Alameda et al. [89] | 2020 | P | IBA | WG/NaOH | EF | 1.0 | <80 | 25 | 95 | 28 | 4–7 |

| Casanova et al. [90] | 2021 | M | IBA | NaOH | EF | 0.7 | 100 | n.r. | 70/90 | 7, 28, 56, 91, 121 | 2–28 |

| Carvalho et al. [91] | 2021 | M | IBA | WG/NaOH | EF | 0.65 | <45 | 70–90 | n.r. | 7, 28, 56, 90, 120 | 0.7–6.5 |

| Maldonado-Alameda et al. [44] | 2022 | P | IBA | WG/NaOH | >8 | 0.8 | <80 | 25 | 95 | 28 | 19–23 |

| Maldonado-Alameda et al. [92] | 2023 | P | IBA | WG/NaOH | EF | 0.8–1.2 | <80 | 70 | n.r. | 28 | 6–11 |

P—paste; M—mortar; EF—entire fraction; n.r.—not reported.

Regarding the curing conditions, there is some debate about which factors, such as the L/S ratio, powdered precursor particle size, or activator concentration, have the greatest influence on the final properties. However, it is clear that L/S ratios close to one are essential. Additionally, the silicate modulus should range between 2.0 and 2.5, rather than the 1.0 to 1.5 range suggested for other types of alkali-activated binders.

4.3. Environmental and Toxicological Performance

Over the past decades, growing concerns about the environmental impact of industrial activities have led to the implementation of policies and regulations designed to protect both the population and the environment from harmful effects. These measures also apply to the building and civil engineering sectors, requiring all construction projects to be designed and executed in a manner that does not endanger the safety of people, domestic animals, or property, nor harm the environment, as mandated by Regulation 305/2011 of the European Parliament [93]. One key requirement is the environmental analysis of construction products, which includes assessing the release of hazardous substances into water systems and soils. In this context, certain precursors used in the formulation of AABs can significantly increase the environmental impact of the resulting materials. This is due to their complex and potentially hazardous composition, as well as the aggressive conditions created by the highly alkaline nature of the activator solution, which can release trace metal(loid)s and other toxic elements into the environment.

Considering the origin of IBA, the ongoing debate about its potential reuse as a secondary resource, and the absence of standardized legislation on its reuse [13,22], it is crucial to conduct studies on the environmental and toxicological performance of IBA-based AABs to verify their environmental viability.

Environmental analyses can be performed using assessment techniques such as harmonized leaching tests. Consequently, many of the studies referenced in Table 1, which explore the use of IBA as a co-precursor, include an environmental evaluation of the investigated formulations. Typically, this evaluation is carried out using standardized leaching tests for granular wastes, such as EN-12457 [42,61,79,94] or the Toxicity Characteristic Leaching Procedure (TCLP) [59,69,71,72], which assess the materials at the end of their lifecycle and which are intended for landfill disposal. These tests measure the concentration of metal(loid)s in the leachate, comparing the results with those of the precursor materials and/or the regulatory thresholds for classification as inert, non-hazardous, or hazardous waste. The findings consistently show that the concentration of metal(loid)s released from the formulated AABs is lower than that of the precursors, thereby confirming the effective immobilization of metal(loid)s within the cementitious matrix. However, the impact of IBA is diluted due to the presence of other co-precursors, many of which are either naturally derived or exhibit initial characteristics of non-hazardous waste.

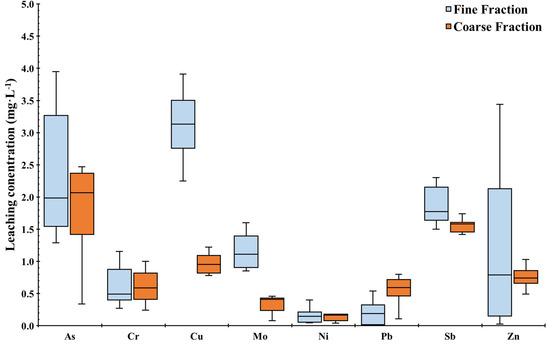

For AABs formulated solely with IBA as the precursor (Table 2), where the environmental performance is entirely determined by the release of pollutants from the IBA, it is consistently observed that the release of metal(loid)s is lower in the formulated AABs than in the precursors, due to the immobilizing effect of the cementitious matrix. Except for Sb and As, all other metal(loid)s are well below the regulatory limits for non-hazardous materials, and in most cases, below the thresholds for inert materials. Notably, a significant reduction in metal(loid) leaching is observed when using coarser fractions compared to finer or entire fractions (see Figure 4), with the coarser fractions exhibiting substantially lower leaching concentrations [44,69,95].

Figure 4.

Leaching concentration (mg·L−1) of AABs formulated using the fine or coarse fraction of IBA as a sole precursor, according to EN 12457 leaching test.

The finer fractions of IBA typically contain higher levels of heavy metals, chlorides, and soluble salts. In contrast, glass and synthetic ceramic materials tend to accumulate in the coarser fractions (e.g., >8 mm), making these fractions richer in aluminosilicates [23,43,95]. As a result, excluding the finer fractions and using only the coarser fractions as precursors reduces the content of heavy metals while increasing the availability of Si and Al, which are crucial for forming cementitious gels.

Further insights into mobility mechanisms were obtained using the monolithic leaching test CEN/TS 16637-2 [94]. The release behavior of most metal(loid)s proved unpredictable, except for those present in low concentrations or governed by a depletion mechanism. The surface release of most metal(loid)s was likely controlled by a mixed mechanism involving both diffusion and dissolution. Additionally, a higher availability of SiO2 and Al2O3 was observed to promote the formation of the reaction products, thereby reducing the open porosity and increasing the tortuosity of the cementitious matrix.

However, although these leaching tests are valuable for evaluating the leaching potential of specific compounds, they do not fully replicate real-world conditions due to the complexity of certain construction products and the experimental limitations that affect the test conditions [96]. To address these challenges, the European Committee for Standardization (CEN), via Technical Committee 351 (CEN/TC 351), released a technical report (CEN/TR 17105) focused on creating modular, horizontal, standardized eco-toxicity tests for construction products. These tests facilitate the evaluation of potential environmental impacts through bioassays, especially when the composition of leachates or their interactions with the environment are uncertain.

Bioassays of AABs made with by-products and waste are essential for validating their suitability as building materials and assessing their potential hazards. However, to the best of the authors’ knowledge, only three studies have used eco-toxicity bioassays to evaluate AABs formulated with IBA as a precursor [60,94,97]. These studies confirm the physical and/or chemical immobilization of metal(loid)s within the cementitious matrix. Additionally, bioassays on leachates from the EN 12457 test, under the conditions designed to enhance metal(loid) release and simulate worst-case scenarios, reveal a significant difference in eco-toxicity between AABs formulated with the entire fraction of IBA, including finer fractions, and those formulated with coarser fractions of IBA (e.g., >8 mm). Notably, the latter demonstrated moderate-to-low acute eco-toxicity, comparable to that of AABs formulated with MK.

5. Urban Furniture and Paving: Advancing a Circular Economy Framework

The concept of a circular economy, which focuses on reusing and transforming waste and by-products into new materials, has gained significant attention as a strategy to reduce the environmental impact of human activities. A key aspect of the circular economy is the “0 km” or “local sourcing” approach, which involves using waste and by-products generated locally to create new materials or products. This approach offers several benefits, including reducing the transportation needs and associated carbon emissions, creating local jobs, and promoting the sustainable use of local raw materials. In the construction industry, reusing waste and by-products to develop new building materials can significantly reduce the sector’s environmental footprint [98]. Consequently, exploring and advancing innovative methods for reusing locally sourced waste and by-products is increasingly seen as a crucial element of sustainable development.

Urban furniture includes a wide range of features and amenities installed in public spaces to serve various functions. These items include benches, waste bins, bicycle racks, planters, public restrooms, lighting systems, and other elements that enhance the usability and visual appeal of urban environments. The design, placement, and maintenance of urban furniture greatly influence the identity and atmosphere of a location, while promoting the safety, comfort, and opportunities for social interaction among residents and visitors. With a growing emphasis on sustainable and environmentally conscious urban development, there is increasing interest in repurposing recycled materials and waste to create urban furniture [99]. Such initiatives not only meet community needs but also align with the principles of environmental conservation and circular economy practices. Exploring innovative and creative approaches to designing urban furniture represents a promising avenue for enhancing sustainability and the quality of life in cities and towns.

Urban pavement, or street pavement, covers roads, sidewalks, plazas, and other public spaces in cities. Besides providing a safe and comfortable surface for pedestrians and vehicles, pavement also enhances the character and identity of urban areas. Various materials, such as concrete, asphalt, stone, and brick, are used for urban pavement, each with its own benefits and limitations. With a growing emphasis on sustainable urban development, there is increasing interest in exploring new, environmentally friendly, durable, and visually appealing materials and design strategies for pavement [100,101]. Notably, the use of secondary resources as substitutes for natural materials in the formulation of non-structural and low-performance architectural concrete is gaining significant attention.

Urban pavements or paving blocks precast with alkali-activated binders, incorporating secondary resources from industrial or agro-industrial origins, have been documented in various research studies [102,103,104,105,106]. The results indicate that integrating secondary resources into AAB formulations enables the production of precast concretes that meet the required performance standards for urban pavement applications. However, particular attention must be given to the workability during precast operations. Despite these considerations, AABs formulated with secondary resources offer notable economic and environmental advantages while contributing to the development of more sustainable materials. Nevertheless, all the resources examined in these studies originate from industrial or agro-industrial activities, typically located far from major urban centers, where these pavements are ultimately implemented.

As discussed earlier, using IBA as a precursor in the development of AABs offers a sustainable and viable alternative to PC. This method leverages the availability of waste materials and significantly reduces the carbon footprint associated with binder production. Additionally, the insights gained from laboratory research can be applied to the development of non-structural architectural concrete, incorporating advanced technological considerations to enhance its potential. However, the physicochemical properties of IBA vary depending on its source, so its use as a precursor in AAB formulation should prioritize local sourcing to minimize the energy impact of transportation. Furthermore, within the circular economy framework, it is beneficial for sustainable AABs made with IBA to be used in municipal construction projects, such as street furniture or urban pavement slabs. This approach would close the loop by reintegrating IBA into a productive cycle near its origin (Figure 5).

Figure 5.

Circularity of IBA as a precursor of AABs in the production of street furniture and/or urban paving.

Using IBA as a precursor in the formulation of AABs and the production of architectural concrete for urban elements provides several environmental benefits. These include the following: (i) repurposing waste as a secondary resource to create an alternative binder to PC, thus integrating it into a new production cycle; (ii) achieving significant energy savings in binder production; (iii) reducing greenhouse gas (GHG) emissions, thereby lowering the carbon footprint of the material; and (iv) producing architectural concrete from a local residual resource (kilometer zero), allowing municipal waste to be reintegrated at its point of origin through its application in non-structural urban elements.

6. Contribution to the Reduction in the Impacts on the Urban Environment

The production of PC has a significant global environmental impact, contributing substantially to GHG emissions. Within the European Union (EU), the negative effects of these emissions are widely felt, underscoring the urgent need for sustainable alternatives to traditional cementitious materials. Addressing this challenge is crucial for advancing environmental sustainability, promoting the circular economy principles, and achieving the global climate goals. Accordingly, the aim of the World Cement Association for its WCA Annual Conference 2021 was “Accelerating the Cement & Concrete Industry’s Path to Net Zero”, urging the global cement industry to continue its efforts towards carbon neutrality. During the recent Climate Change Conference (COP26) in Glasgow, Ian Riley (World Cement Association CEO) encouraged the faster adoption of low-carbon technologies, indicating that measures can be implemented at low cost as well as stimulating the innovation and rapid scaling of new technologies, whilst directing governments to focus on the cement and concrete industry as a great place to start reducing emissions.

AABs offer a promising alternative to PC, significantly reducing the environmental impact. Their use in construction as substitutes for PC is a key strategy to minimize the sector’s environmental footprint. Within the circular economy framework, AABs made from industrial by-products and waste materials provide an innovative pathway for creating more sustainable and less polluting construction materials.

In urban precast materials, using IBA as a precursor in AAB formulations establishes a productive cycle where raw materials come from MSW. This approach reduces the reliance on virgin resources and creates a closed-loop system, transforming urban waste into valuable construction products like precast pavements and urban furniture. Incorporating IBA enhances cement sustainability, valorizes waste materials, and improves the overall waste management efficiency.

Additionally, using IBA as a precursor in AABs significantly contributes to natural resource conservation, aligning with the European Commission’s Directive 2008/98/EC on waste management. This method extends the lifecycle of waste materials, reduces environmental burdens, and strengthens the local resource utilization by repurposing urban waste for local construction applications.

Aligned with the United Nations Sustainable Development Goals (SDGs), particularly SDG 13 (Climate Action), developing alkali-activated cements from waste materials directly addresses climate change mitigation. By significantly reducing the carbon emissions associated with cement production, this approach supports sustainable urban development and contributes to global environmental targets.

The main environmental and technological benefits of this approach are summarized in Table 3.

Table 3.

Impact of the circular economy approach of using IBA in the formulation of AABs for urban furniture/pavement.

7. Proof of Concept

The Technology Readiness Level (TRL) framework is an essential tool for advancing innovative technologies, especially in moving from laboratory-scale concepts to practical, real-world applications. Within this framework, the proof of concept is critical, acting as the bridge between theoretical principles and the practical implementation of technological innovations.

For developing AABs using IBA as the sole precursor, the proof of concept is crucial. It not only confirms the material’s technical feasibility but also validates its mechanical performance and environmental sustainability. This stage offers a thorough platform for assessing the efficiency of alkaline activation processes, ensuring the stability of material mixtures, and measuring the potential impacts on waste reduction and carbon footprint mitigation. Additionally, the proof of concept provides essential data for optimizing component ratios and predicting the material performance in larger-scale applications. Advancing the TRL reduces the technical uncertainties, improves decision making, and builds confidence in the material’s readiness for wider use. In this study, the proof of concept serves as a bridge between theoretical research and practical application. Demonstrating a proof of concept at an early stage (TRL 3-4) is essential for building confidence and securing support for further development. In summary, conducting a proof of concept for AABs utilizing IBA as the sole precursor establishes a robust foundation for scalability and integration into sustainable urban furniture and pavement applications, fostering innovative approaches aligned with the circular economy principles.

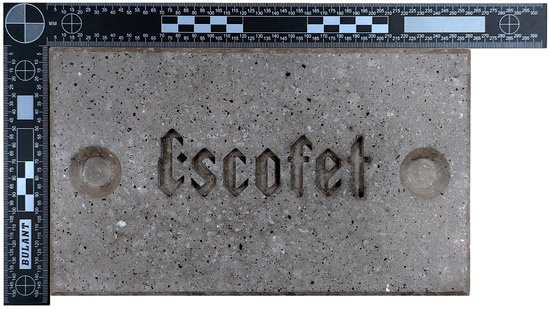

To validate the concept, a cast concrete paver was developed in collaboration with Escofet by Molins (www.escofet.com/en; accessed on 6 May 2025), a global leader in the design and industrialization of urban elements and architectural concrete. The cementitious paste was prepared by adapting the methodology previously described by Maldonado-Alameda et al. [42], using IBA with a particle size greater than 10 mm as the sole precursor. The aim was to obtain a paste sufficiently workable to include the granitic aggregates commonly used by the Escofet company for the formulation of architectural concrete.

For the proof of concept, and the prior optimization of the cementitious paste and concrete formulation, 24 tons of weathered IBA was sourced from the WtE plant in Mataró (Barcelona, Spain). From this, approximately 6 tons of the IBA fraction larger than 10 mm, used as the sole precursor, was first subjected to ferrous and non-ferrous metal removal using electromagnets and Eddy current separation, respectively. The material was then ground to achieve a particle size below 90 µm. Table 4 shows the major elements of IBA used as the precursor, analyzed via X-ray fluorescence (XRF) using a spectrophotometer Panalytical Philips PW 2400 sequential X-ray equipped with the software UniQuant®V5.0 (Malvern Panalytical, Almelo, The Netherlands). As expected, the chemical composition of IBA confirms that SiO2, CaO, and Al2O3 are the main compounds.

Table 4.

Composition of major elements (wt.%) in powdered IBA with particle size greater than 10 mm.

The alkali-activator solution used was composed of a water glass (Na2SiO3) and NaOH mixture. The waterglass solution, with 26.0 wt.% of SiO2 and 8.0 wt.% of Na2O (ρ = 1.35–1.37 g·cm−3) was provided by Industrias Químicas del Ebro company (Zaragoza, Spain). NaOH solutions were prepared by dissolving NaOH pearls (purity > 98%), supplied by Labbox Labware S.L. (Barcelona, Spain), in water. In addition, to improve the workability of the mixture, Chronos VF202, an aqueous polymer-based superplasticizer provided by Mapei (Santa Perpétua de Mogoda, Spain), was added. This adjustment extended the casting time in the mold and improved the vibration efficiency.

Following multiple optimization trials, the proportions of materials used in the formulation of the AABs, along with the aggregates incorporated to produce the cast concrete paver, are presented in Table 5 below.

Table 5.

Proportions of materials used for the formulation of AABs with IBA as the sole precursor, demonstrated through the production of cast concrete paver as proof of concept. Dosage details for each cast concrete paver are provided.

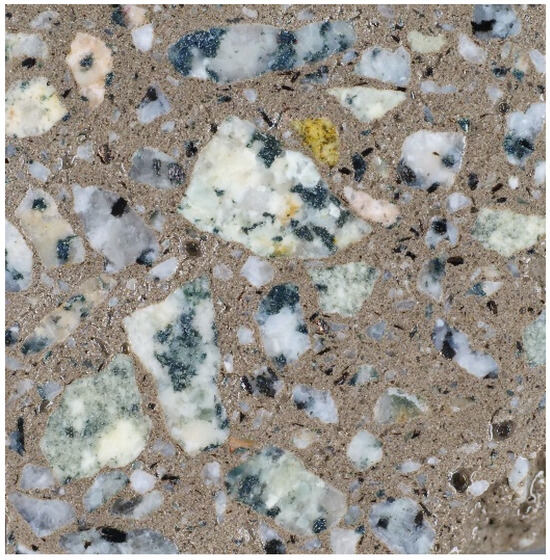

The proof of concept involved the formulation and molding of several cast concrete pavers (245 × 145 × 40 mm), as illustrated in Figure 6. The result was a cast concrete with high compactness, excellent aggregate distribution within the alkali-activated binder matrix, and high homogeneity (Figure 7). A very good bond between the aggregates and the cementitious matrix was observed, which will contribute to improved structural integrity, durability, and the overall performance.

Figure 6.

Cast concrete paver formulated from an alkali-activated binder using incineration bottom ash (IBA) as the sole precursor, and granitic aggregates.

Figure 7.

Cross-sectional image of the cast concrete paver formulated for the proof of concept.

After a 28-day curing period in a climatic chamber (20 °C, 95% RH), the tested specimens exhibited a compressive strength between 13 and 17 MPa, which meets the requirements established for this type of material in urban paving applications.

Although the proof-of-concept results are promising, scalability remains a critical challenge. This is largely due to the workability limitations when increasing the material volumes and the extended processing times typical of precast concrete production. Increasing the water content in the activating solution adversely affects both the mechanical performance and strength requirements. Consequently, further research is necessary, either through the use of co-precursors to improve the workability or the development of tailored additives, to optimize concrete formulations suitable for pilot-scale and industrial casting applications.

8. Conclusions

Innovative approaches aligned with a circular economy can transform the Portland cement (PC) industry, allowing concrete to maintain its crucial role in urbanization while significantly reducing its environmental impact. Consequently, advancements in the construction sector, one of the most environmentally impactful industries, could enhance the environmental and societal well-being. The initial applications of these innovations could focus on architectural elements with lower structural demands, such as urban furniture and paving. From there, adoption could expand to areas with higher cement usage, including pavements, architectural concrete panels, and civil infrastructure.

Among the alternatives to PC, alkali-activated binders (AABs) made from secondary resources offer a sustainable option that aligns with the circular economy principles. Promoting a circular economy through the recovery and reuse of waste materials extends their lifecycle, conserves resources, and significantly contributes to building a sustainable, low-carbon, resource-efficient, and competitive economy.

In the context of manufacturing urban furniture or paving, using IBA in AAB formulations, either as the sole precursor or as a substitute for other secondary or natural materials, has proven to be a viable and attractive solution. This approach revalorizes a secondary resource rich in aluminosilicates, which has predominantly been disposed of in landfills until now. Additionally, reusing IBA in urban furniture or paving not only repurposes a locally sourced secondary resource (kilometer zero) but also completes the waste cycle by reintegrating IBA into a productive process near its point of origin. This method enables the creation of construction materials designed for use by the very citizens who generated the municipal waste.

Research studies by various authors, along with the proof of concept developed in this work, confirm the potential of IBA as a precursor in AAB formulations. These binders can be used to produce cast concrete suitable for manufacturing street furniture and paving. In this context, the cementitious material and the formulated cast concrete meet the technical, environmental, and ecotoxicological requirements.

While the results are promising, several key parameters remain unaddressed in this study, including long-term durability, permeability, and the regional variability of IBA depending on its MSW composition, all of which warrant further investigation. Additionally, aspects such as workability and the incorporation of additives to extend the setting time should be carefully considered in future validation studies conducted in pilot plants.

Author Contributions

Conceptualization, J.M.C. and L.F.C.; methodology, J.M.C., J.R.R. and L.F.C.; validation, J.M.C., F.C. and A.M.-A.; formal analysis, F.C. and A.M.-A.; investigation, F.C., A.M.-A., J.M. and A.A.; resources, G.F.; data curation, A.M.-A. and A.A.; writing—original draft preparation, J.M.C.; writing—review and editing, A.M.-A., J.M., J.R.R., A.A. and L.F.C.; visualization, A.M.-A.; supervision, J.M.C.; project administration, J.M.C. and G.F.; funding acquisition, J.M.C and G.F. All authors have read and agreed to the published version of the manuscript.

Funding

This work is partially supported by the Spanish Government with the TED2021-129718B–I00, funded by MICIU/AEI/10.13039/501100011033, by the “European Union NextGenerationEU/PRTR”, and by Grant ACE051/22/000011 funded by ACCIÓ, the Catalan Government’s Agency for Business Competitiveness. The Catalan Government also contributed via the Grants 2021 SGR 00708 and 2021 SGR 01615 through the Agency for Management of University and Research Grants (AGAUR). This work is also partially supported by ICREA under the ICREA Academia program.

Data Availability Statement

The data supporting this study are available from the corresponding author upon request.

Acknowledgments

The authors of the University of Barcelona and the University of Lleida would like to thank the Catalan Government for the quality accreditation given to their research group DIOPMA (2021 SGR 00708) and GREiA (2021 SGR 01615). DIOPMA and GREiA are certified agents TECNIO in the category of technology developers from the Government of Catalonia. The authors acknowledge the support of CYTED Network ECoEICo-Circular Economy as a Strategy for a More Sustainable Construction Industry and the COST Action CircularB-Implementation of a Circular Economy in the Built Environment.

Conflicts of Interest

Author Gerard Faneca was employed by the company Escofet 1886 S.A. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| AABs | Alkali-activated binders |

| APCr | Air pollution control residues |

| CG | Coal gangue |

| DWTR | Drinking water treatment residue |

| EF | Entire fraction |

| GBFS | Ground granulated blast furnace slag |

| IBA | Incineration bottom ash |

| IBA | Incinerator bottom ash |

| IFA | Fly ash from waste-to-energy plants |

| LC2 | Limestone and calcined clay |

| LS | Ladle slag |

| MK | Metakaolin |

| MSW | Municipal solid waste |

| MSWI | Municipal solid waste incineration |

| PC | Portland cement |

| PG | Phosphogypsum |

| PV | Aluminum recycling waste |

| RH | Relative humidity |

| SL | Slaked lime |

| WG | Waste glass |

| WtE | Waste-to-energy |

References

- Oxford Economics. Future of Construction a Global Forecast for Construction to 2030; Oxford Economics: London, UK, 2021. [Google Scholar]

- San-José Lombera, J.-T.; Garrucho Aprea, I. A System Approach to the Environmental Analysis of Industrial Buildings. Build. Environ. 2010, 45, 673–683. [Google Scholar] [CrossRef]

- Reilly, J.F. Mineral Commodity Summaries 2020; U.S. Geological Survey: Reston, VA, USA, 2020.

- Ali, M.B.; Saidur, R.; Hossain, M.S. A Review on Emission Analysis in Cement Industries. Renew. Sustain. Energy Rev. 2011, 15, 2252–2261. [Google Scholar] [CrossRef]

- The European Cement Association CEMBUREAU. CEMBUREAU Key Facts & Figures; The European Cement Association CEMBUREAU: Brussels, Belgium, 2023. [Google Scholar]

- Lympeti, A.; Karampinis, M. 100% Renewable Energies for Energy Intensive Industries. EEIs Sector Status in Europe; WIP Renewable Energies: Munich, Germany, 2022. [Google Scholar]

- Grabiec, A.M.; Łacka, A.; Wiza, W. Material, Functional, and Aesthetic Solutions for Urban Furniture in Public Spaces. Sustainability 2022, 14, 16211. [Google Scholar] [CrossRef]

- Sánchez-Roldán, Z.; Martín-Morales, M.; Valverde-Espinosa, I.; Zamorano, M. Technical Feasibility of Using Recycled Aggregates to Produce Eco-Friendly Urban Furniture. Constr. Build. Mater. 2020, 250, 118890. [Google Scholar] [CrossRef]

- Provis, J.L. Geopolymers and Other Alkali Activated Materials: Why, How, and What? Mater. Struct. 2014, 47, 11–25. [Google Scholar] [CrossRef]

- Provis, J.L.; van Deventer, J.S.J. Alkali Activated Materials: State-of-the-Art Report, RILEM TC 224-AAM; RILEM State-of-the-Art Reports; Springer: Dutch, The Netherlands, 2013; ISBN 9789400776722. [Google Scholar]

- Song, Q.; Li, J.; Zeng, X. Minimizing the Increasing Solid Waste through Zero Waste Strategy. J. Clean. Prod. 2015, 104, 199–210. [Google Scholar] [CrossRef]

- Eurostat–European Statistical Office Waste Statistics. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Waste_statistics (accessed on 4 February 2025).

- Bandarra, B.S.; Pereira, J.L.; Martins, R.C.; Maldonado-Alameda, A.; Chimenos, J.M.; Quina, M.J. Opportunities and Barriers for Valorizing Waste Incineration Bottom Ash: Iberian Countries as a Case Study. Appl. Sci. 2021, 11, 9690. [Google Scholar] [CrossRef]

- Dri, M.; Canfora, P.; Antonopoulos, I.S.; Gaudillat, P. Best Environmental Management Practice for the Waste Management Sector; Publications Office of the European Union: Luxembourg, 2018. [Google Scholar]

- European Commission. Report from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. Off. J. Eur. Union 2017, COM(2017), 1–14.

- European Parliament—European Union. Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives; Publications Office of the European Union: Luxembourg, 2008; Available online: https://eur-lex.europa.eu/legal-content/ES/TXT/?uri=celex%3A32008L0098 (accessed on 5 April 2025).

- Cheng, H.; Hu, Y. Municipal Solid Waste (MSW) as a Renewable Source of Energy: Current and Future Practices in China. Bioresour. Technol. 2010, 101, 3816–3824. [Google Scholar] [CrossRef]

- European Commission. Directive of the European Parlament and of the Council-Amending Directive 2008/98/EC on Waste 2015; Publications Office of the European Union: Luxembourg, 2015; pp. 1–5. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex:52015PC0595 (accessed on 5 April 2025).

- CEWEP—Confederation of European Waste-to-energy Plants Waste-to-Energy Plants in Europe in 2020. Available online: https://www.cewep.eu/waste-to-energy-plants-in-europe-in-2020/ (accessed on 4 February 2025).

- IEA Bioenergy. Municipal Solid Waste and Its Role in Sustainability; IEA Bioenergy: Rotorua, New Zealand, 2003; Available online: https://www.ieabioenergy.com/wp-content/uploads/2013/10/40_IEAPositionPaperMSW.pdf (accessed on 5 April 2025).

- Tian, Y.; Dai, S.; Wang, J. Environmental Standards and Beneficial Uses of Waste-to-Energy (WTE) Residues in Civil Engineering Applications. Waste Dispos. Sustain. Energy 2023, 5, 323–350. [Google Scholar] [CrossRef]

- Blasenbauer, D.; Huber, F.; Lederer, J.; Quina, M.J.; Blanc-Biscarat, D.; Bogush, A.; Bontempi, E.; Blondeau, J.; Chimenos, J.M.; Dahlbo, H.; et al. Legal Situation and Current Practice of Waste Incineration Bottom Ash Utilisation in Europe. Waste Manag. 2020, 102, 868–883. [Google Scholar] [CrossRef]

- del Valle-Zermeño, R.; Gómez-Manrique, J.; Giro-Paloma, J.; Formosa, J.; Chimenos, J.M. Material Characterization of the MSWI Bottom Ash as a Function of Particle Size. Effects of Glass Recycling over Time. Sci. Total Environ. 2017, 581–582, 897–905. [Google Scholar] [CrossRef] [PubMed]

- Kurda, R.; Silva, R.V.; de Brito, J. Incorporation of Alkali-Activated Municipal Solid Waste Incinerator Bottom Ash in Mortar and Concrete: A Critical Review. Materials 2020, 13, 3428. [Google Scholar] [CrossRef]

- Cioffi, R.; Colangelo, F.; Montagnaro, F.; Santoro, L. Manufacture of Artificial Aggregate Using MSWI Bottom Ash. Waste Manag. 2011, 31, 281–288. [Google Scholar] [CrossRef] [PubMed]

- Hjelmar, O.; Holm, J.; Crillesen, K. Utilisation of MSWI Bottom Ash as Sub-Base in Road Construction: First Results from a Large-Scale Test Site. J. Hazard. Mater. 2007, 139, 471–480. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Wang, L.; Wu, T.; Liu, W.; Tang, Q. Mechanical Properties and Heavy Metal Leaching Behaviors of Municipal Solid Waste Incineration Bottom Ash as Road Embankment Fillings. J. Clean. Prod. 2023, 394, 136355. [Google Scholar] [CrossRef]

- Pecqueur, G.; Crignon, C.; Quénée, B. Behaviour of Cement-Treated MSWI Bottom Ash. Waste Manag. 2001, 21, 229–233. [Google Scholar] [CrossRef]

- Toraldo, E.; Saponaro, S.; Careghini, A.; Mariani, E. Use of Stabilized Bottom Ash for Bound Layers of Road Pavements. J. Environ. Manag. 2013, 121, 117–123. [Google Scholar] [CrossRef]

- Ginés, O.; Chimenos, J.M.; Vizcarro, A.; Formosa, J.; Rosell, J.R. Combined Use of MSWI Bottom Ash and Fly Ash as Aggregate in Concrete Formulation: Environmental and Mechanical Considerations. J. Hazard. Mater. 2009, 169, 643–650. [Google Scholar] [CrossRef]

- Cheeseman, C.R.; Monteiro da Rocha, S.; Sollars, C.; Bethanis, S.; Boccaccini, A.R. Ceramic Processing of Incinerator Bottom Ash. Waste Manag. 2003, 23, 907–916. [Google Scholar] [CrossRef]

- Andreola, F.; Barbieri, L.; Hreglich, S.; Lancellotti, I.; Morselli, L.; Passarini, F.; Vassura, I. Reuse of Incinerator Bottom and Fly Ashes to Obtain Glassy Materials. J. Hazard. Mater. 2008, 153, 1270–1274. [Google Scholar] [CrossRef] [PubMed]

- Andreola, F.; Barbieri, L.; Lancelloti, I.; Pozzi, P. Recycling Industrial Waste in Brick Manufacture. Part 1. Mater. Constr. 2005, 55, 5–16. [Google Scholar] [CrossRef]

- Barbieri, L.; Corradi, A.; Lancellotti, I.; Manfredini, T. Use of Municipal Incinerator Bottom Ash as Sintering Promoter in Industrial Ceramics. Waste Manag. 2002, 22, 859–863. [Google Scholar] [CrossRef]

- Zhu, W.; Chen, X.; Struble, L.J.; Yang, E.H. Quantitative Characterization of Aluminosilicate Gels in Alkali-Activated Incineration Bottom Ash through Sequential Chemical Extractions and Deconvoluted Nuclear Magnetic Resonance Spectra. Cem. Concr. Compos. 2019, 99, 175–180. [Google Scholar] [CrossRef]

- Šyc, M.; Simon, F.G.; Hykš, J.; Braga, R.; Biganzoli, L.; Costa, G.; Funari, V.; Grosso, M. Metal Recovery from Incineration Bottom Ash: State-of-the-Art and Recent Developments. J. Hazard. Mater. 2020, 393, 122433. [Google Scholar] [CrossRef]

- Mañosa, J.; Calderón, A.; Salgado-Pizarro, R.; Maldonado-Alameda, A.; Chimenos, J.M. Research Evolution of Limestone Calcined Clay Cement (LC3), a Promising Low-Carbon Binder—A Comprehensive Overview. Heliyon 2024, 10, 25117. [Google Scholar] [CrossRef]

- Huang, G.; Yang, K.; Chen, L.; Lu, Z.; Sun, Y.; Zhang, X.; Feng, Y.; Ji, Y.; Xu, Z. Use of Pretreatment to Prevent Expansion and Foaming in High-Performance MSWI Bottom Ash Alkali-Activated Mortars. Constr. Build. Mater. 2020, 245, 118471. [Google Scholar] [CrossRef]

- Tortora, P.C.D.; Maldonado-Alameda, A.; Mañosa, J.; Quintero-Payan, A.C.; Leonelli, C.; Lancellotti, I.; Chimenos, J.M. Effect of Temperature and Humidity on the Synthesis of Alkali-Activated Binders Based on Bottom Ash from Municipal Waste Incineration. Sustainability 2022, 14, 1848. [Google Scholar] [CrossRef]

- Qiao, X.C.; Tyrer, M.; Poon, C.S.; Cheeseman, C.R. Characterization of Alkali-Activated Thermally Treated Incinerator Bottom Ash. Waste Manag. 2008, 28, 1955–1962. [Google Scholar] [CrossRef]

- Qiao, X.C.; Tyrer, M.; Poon, C.S.; Cheeseman, C.R. Novel Cementitious Materials Produced from Incinerator Bottom Ash. Resour. Conserv. Recycl. 2008, 52, 496–510. [Google Scholar] [CrossRef]

- Maldonado-Alameda, A.; Giro-Paloma, J.; Andreola, F.; Barbieri, L.; Chimenos, J.M.; Lancellotti, I. Weathered Bottom Ash from Municipal Solid Waste Incineration: Alkaline Activation for Sustainable Binders. Constr. Build. Mater. 2022, 327, 126983. [Google Scholar] [CrossRef]

- Chimenos, J.M.; Segarra, M.; Fernández, M.A.; Espiell, F. Characterization of the Bottom Ash in Municipal Solid Waste Incinerator. J. Hazard. Mater. 1999, 64, 211–222. [Google Scholar] [CrossRef]

- Maldonado-Alameda, A.; Giro-Paloma, J.; Mañosa, J.; Formosa, J.; Chimenos, J.M. Alkali-Activated Binders Based on the Coarse Fraction of Municipal Solid Waste Incineration Bottom Ash. Bol. Soc. Esp. Ceram. Vidr. 2022, 61, 313–324. [Google Scholar] [CrossRef]

- Polettini, A.; Pomi, R.; Carcani, G. The Effect of Na and Ca Salts on MSWI Bottom Ash Activation for Reuse as a Pozzolanic Admixture. Resour. Conserv. Recycl. 2005, 43, 403–418. [Google Scholar] [CrossRef]

- Onori, R.; Will, J.; Hoppe, A.; Polettini, A.; Pomi, R.; Boccaccini, A.R. Bottom Ash-Based Geopolymer Materials: Mechanical and Environmental Properties. Ceram. Eng. Sci. Proc. 2011, 32, 71–82. [Google Scholar] [CrossRef]

- Krausova, K.; Cheng, T.W.; Gautron, L.; Dai, Y.S.; Borenstajn, S. Heat Treatment on Fly and Bottom Ash Based Geopolymers: Effect on the Immobilization of Lead and Cadmium. Int. J. Environ. Sci. Dev. 2012, 3, 350–353. [Google Scholar] [CrossRef]

- Lancellotti, I.; Ponzoni, C.; Barbieri, L.; Leonelli, C. Alkali Activation Processes for Incinerator Residues Management. Waste Manag. 2013, 33, 1740–1749. [Google Scholar] [CrossRef] [PubMed]

- Lancellotti, I.; Ponzoni, C.; Bignozzi, M.C.; Barbieri, L.; Leonelli, C. Incinerator Bottom Ash and Ladle Slag for Geopolymers Preparation. Waste Biomass Valorization 2014, 5, 393–401. [Google Scholar] [CrossRef]

- Song, Y.; Li, B.; Yang, E.H.; Liu, Y.; Ding, T. Feasibility Study on Utilization of Municipal Solid Waste Incineration Bottom Ash as Aerating Agent for the Production of Autoclaved Aerated Concrete. Cem. Concr. Compos. 2015, 56, 51–58. [Google Scholar] [CrossRef]

- Garcia-Lodeiro, I.; Carcelen-Taboada, V.; Fernández-Jiménez, A.; Palomo, A. Manufacture of Hybrid Cements with Fly Ash and Bottom Ash from a Municipal Solid Waste Incinerator. Constr. Build. Mater. 2016, 105, 218–226. [Google Scholar] [CrossRef]

- Wongsa, A.; Boonserm, K.; Waisurasingha, C.; Sata, V.; Chindaprasirt, P. Use of Municipal Solid Waste Incinerator (MSWI) Bottom Ash in High Calcium Fly Ash Geopolymer Matrix. J. Clean. Prod. 2017, 148, 49–59. [Google Scholar] [CrossRef]

- Zhu, W.; Hong, X.; Liu, Y.; Yang, E. Lightweight Aerated Metakaolin-Based Geopolymer Incorporating Municipal Solid Waste Incineration Bottom Ash as Gas-Forming Agent. J. Clean. Prod. 2018, 177, 775–781. [Google Scholar] [CrossRef]

- Huang, G.; Ji, Y.; Li, J.; Hou, Z.; Jin, C. Use of Slaked Lime and Portland Cement to Improve the Resistance of MSWI Bottom Ash-GBFS Geopolymer Concrete against Carbonation. Constr. Build. Mater. 2018, 166, 290–300. [Google Scholar] [CrossRef]

- Huang, G.; Ji, Y.; Zhang, L.; Li, J.; Hou, Z. Advances in Understanding and Analyzing the Anti-Diffusion Behavior in Complete Carbonation Zone of MSWI Bottom Ash-Based Alkali-Activated Concrete. Constr. Build. Mater. 2018, 186, 1072–1081. [Google Scholar] [CrossRef]

- Xuan, D.; Tang, P.; Poon, C.S. MSWIBA-Based Cellular Alkali-Activated Concrete Incorporating Waste Glass Powder. Cem. Concr. Compos. 2019, 95, 128–136. [Google Scholar] [CrossRef]

- Huang, G.; Yuan, L.; Ji, Y.; Liu, B.; Xu, Z. Cooperative Action and Compatibility between Portland Cement and MSWI Bottom Ash Alkali-Activated Double Gel System Materials. Constr. Build. Mater. 2019, 209, 445–453. [Google Scholar] [CrossRef]

- Huang, G.; Ji, Y.; Li, J.; Zhang, L.; Liu, X.; Liu, B. Effect of Activated Silica on Polymerization Mechanism and Strength Development of MSWI Bottom Ash Alkali-Activated Mortars. Constr. Build. Mater. 2019, 201, 90–99. [Google Scholar] [CrossRef]

- Ji, Z.; Pei, Y. Geopolymers Produced from Drinking Water Treatment Residue and Bottom Ash for the Immobilization of Heavy Metals. Chemosphere 2019, 225, 579–587. [Google Scholar] [CrossRef]

- Biswal, B.K.; Zhu, W.; Yang, E.H. Investigation on Pseudomonas Aeruginosa PAO1-Driven Bioleaching Behavior of Heavy Metals in a Novel Geopolymer Synthesized from Municipal Solid Waste Incineration Bottom Ash. Constr. Build. Mater. 2020, 241, 118005. [Google Scholar] [CrossRef]

- Cristelo, N.; Segadães, L.; Coelho, J.; Chaves, B.; Sousa, N.R.; de Lurdes Lopes, M. Recycling Municipal Solid Waste Incineration Slag and Fly Ash as Precursors in Low-Range Alkaline Cements. Waste Manag. 2020, 104, 60–73. [Google Scholar] [CrossRef]

- Manzi, S.; Lancellotti, I.; Masi, G.; Saccani, A. Alkali-Activated Binders From Waste Incinerator Bottom Ashes and Metakaolin Reinforced by Recycled Carbon Fiber Composites. Front. Mater. 2020, 7, 583400. [Google Scholar] [CrossRef]

- Huang, G.; Yang, K.; Sun, Y.; Lu, Z.; Zhang, X.; Zuo, L.; Feng, Y.; Qian, R.; Qi, Y.; Ji, Y.; et al. Influence of NaOH Content on the Alkali Conversion Mechanism in MSWI Bottom Ash Alkali-Activated Mortars. Constr. Build. Mater. 2020, 248, 118582. [Google Scholar] [CrossRef]

- Maldonado-Alameda, A.; Mañosa, J.; Giro-Paloma, J.; Formosa, J.; Chimenos, J.M. Alkali-Activated Binders Using Bottom Ash from Waste-to-Energy Plants and Aluminium Recycling Waste. Appl. Sci. 2021, 11, 3840. [Google Scholar] [CrossRef]

- Jin, L.; Huang, G.; Li, Y.; Zhang, X.; Ji, Y.; Xu, Z. Positive Influence of Liquid Sodium Silicate on the Setting Time, Polymerization, and Strength Development Mechanism of Mswi Bottom Ash Alkali-Activated Mortars. Materials 2021, 14, 1927. [Google Scholar] [CrossRef] [PubMed]

- Vaičiukynienė, D.; Tamošaitis, G.; Kantautas, A.; Nizevičienė, D.; Pupeikis, D. Porous Alkali-Activated Materials Based on Municipal Solid Waste Incineration Ash with Addition of Phosphogypsum Powder. Constr. Build. Mater. 2021, 301, 123962. [Google Scholar] [CrossRef]

- Avila, Y.; Silva, R.V.; de Brito, J. Alkali-Activated Materials with Pre-Treated Municipal Solid Waste Incinerator Bottom Ash. Appl. Sci. 2022, 12, 3535. [Google Scholar] [CrossRef]

- Irshidat, M.R.; Al-Nuaimi, N.; Rabie, M. Sustainable Alkali-Activated Binders with Municipal Solid Waste Incineration Ashes as Sand or Fly Ash Replacement. J. Mater. Cycles Waste Manag. 2022, 24, 992–1008. [Google Scholar] [CrossRef]

- Liu, J.; Liang, Z.; Jin, H.; Kastiukas, G.; Tang, L.; Xing, F.; Ren, J. Alkali-Activated Binders Based on Incinerator Bottom Ash Combined with Limestone-Calcined Clay or Fly Ash. Constr. Build. Mater. 2022, 320, 126306. [Google Scholar] [CrossRef]

- Suescum-Morales, D.; Silva, R.V.; Bravo, M.; Jiménez, J.R.; Fernández-Rodríguez, J.M.; de Brito, J. Effect of Incorporating Municipal Solid Waste Incinerated Bottom Ash in Alkali-Activated Fly Ash Concrete Subjected to Accelerated CO2 Curing. J. Clean. Prod. 2022, 370, 133533. [Google Scholar] [CrossRef]

- Feng, D.; Wang, J.; Wang, Y.; Xiao, X.; Hou, W.; Liang, S. Alkali-Activated Geopolymer Materials Prepared from Coal Gangue and Municipal Solid Waste Incineration Byproducts. J. Build. Eng. 2023, 80, 108074. [Google Scholar] [CrossRef]

- Feng, D.; Wang, J.; Wang, Y.; Liang, S. Experimental Study on Solidification/Stabilisation of High-Salt Sludge by Alkali-Activated GGBS and MSWI Bottom Ash Cementitious Materials. Case Stud. Constr. Mater. 2023, 19, e02417. [Google Scholar] [CrossRef]

- Liu, J.; Xie, G.; Wang, Z.; Zeng, C.; Fan, X.; Li, Z.; Ren, J.; Xing, F.; Zhang, W. Manufacture of Alkali-Activated Cementitious Materials Using Municipal Solid Waste Incineration (MSWI) Ash: Immobilization of Heavy Metals in MSWI Fly Ash by MSWI Bottom Ash. Constr. Build. Mater. 2023, 392, 131848. [Google Scholar] [CrossRef]

- Wang, Z.; Xie, G.; Zhang, W.; Liu, J.; Jin, H.; Xing, F. Co-Disposal of Municipal Solid Waste Incineration Bottom Ash (MSWIBA) and Steel Slag (SS) to Improve the Geopolymer Materials Properties. Waste Manag. 2023, 171, 86–94. [Google Scholar] [CrossRef] [PubMed]

- Zhang, B.; Ma, Y.; Yang, Y.; Zheng, D.; Wang, Y.; Ji, T. Improving the High Temperature Resistance of Alkali-Activated Slag Paste Using Municipal Solid Waste Incineration Bottom Ash. J. Build. Eng. 2023, 72, 106664. [Google Scholar] [CrossRef]

- Deng, J.; Wu, G.; Xia, Y.; Liu, L. Preparation and Hydration Properties of Sodium Silicate-Activated Municipal Solid Waste Incineration Bottom Ash Composite Ground-Granulated Blast Furnace Slag Cementitious Materials. Materials 2024, 17, 2406. [Google Scholar] [CrossRef]

- Feng, D.; Yu, Y.; Wang, J.; Liang, S. Experimental Study on Municipal Solid Waste Incineration Bottom Ash as a Component of Alkali-Activated Coal Gangue–Based Geopolymer. Environ. Sci. Pollut. Res. 2024, 31, 26153–26169. [Google Scholar] [CrossRef]

- Jian, H.; Wang, C.; Dou, G.; Zhong, X. Research on Composite Municipal Solid Waste Incineration Bottom Ash and Granulated Blast Furnace Slag Based Geopolymers with Sodium Alginate for Sealing Coal Seam Gas Drainage Boreholes. Fuel 2024, 358, 130278. [Google Scholar] [CrossRef]

- Liu, T.; Tang, Y.; Ling, X.; Stapper, J.L.; Kunther, W.; Yu, Q. NaAlO2 Activated Slag and MSWI Bottom Ash: Phase Assemblages and Thermodynamic Assessment of Long-Term Leaching Behavior. Cem. Concr. Compos. 2024, 152, 105634. [Google Scholar] [CrossRef]

- Wang, C.; Zhao, X.; Zhang, X.; Zhao, Y.; Wang, Y.; Zhao, J. Effects of Alkali Equivalent and Polypropylene Fibres on Performance of Alkali-Activated Municipal Waste Incineration Bottom Ash-Slag Mortar. J. Build. Eng. 2024, 84, 108496. [Google Scholar] [CrossRef]

- Xie, G.; Zhang, W.; Liu, J.; Liang, Z.; Xing, F. Recovery Potential of Municipal Solid Waste Incineration Bottom Ash Graded by Particle Size in an Alkali-Activated Cementitious Material System: Curing Properties and Environmental Leaching Risk. Constr. Build. Mater. 2024, 448, 138237. [Google Scholar] [CrossRef]

- Yang, Y.; Luo, Z.; Huang, F.; Ni, C.; Wu, J.; Zheng, B. Utilizing Municipal Solid Waste Incineration Bottom Ash and Volcanic Tuff to Produce Geopolymer Materials. Constr. Build. Mater. 2024, 425, 136015. [Google Scholar] [CrossRef]