Impact of Industry 5.0 on the Construction Industry (Construction 5.0): Systematic Literature Review and Bibliometric Analysis

Abstract

1. Introduction

2. Methodology

2.1. Methods

2.2. Search Strategy

2.3. Inclusion and Exclusion Criteria

- Journal articles and books published between 2022 and 2025 to ensure up-to-date insights.

- Studies explicitly discussing C5.0 technologies and their application in the construction sector.

- Publications from engineering, computer science, technology, and interdisciplinary innovation domains.

- Documents in the English language to ensure accessibility and consistency in analysis.

- Document types: Articles, reviews, book chapters, and books.

- Publication stage: Only final publications were considered.

- Key focus: Studies emphasizing Construction 5.0 and Industry 5.0 applications in construction.

- Relevance to research aim: Studies that contribute significantly to understanding Construction 5.0.

- Studies from non-engineering disciplines, such as arts, medicine, nursing, agriculture, biological sciences, health professions, microbiology, immunology, pharmacology, veterinary science, and dentistry, as they do not contribute to the technical and engineering focus of this review.

- Articles discussing C5.0 technologies in non-construction contexts, such as healthcare or education, unless they provide transferable insights applicable to construction innovation.

- Non-peer-reviewed sources, such as conference papers.

- Non-English publications to ensure consistency in language analysis.

- Conference proceedings were excluded.

- Articles in the press were omitted to ensure only finalized research was considered.

- Studies that do not specifically focus on Construction 5.0 or Industry 5.0 applications in construction were excluded.

- Studies with marginal relevance to the research aim were also eliminated to maintain a highly focused and coherent dataset.

2.4. Qualitative Review

3. Bibliometric Analysis

3.1. Publication Versus Citation

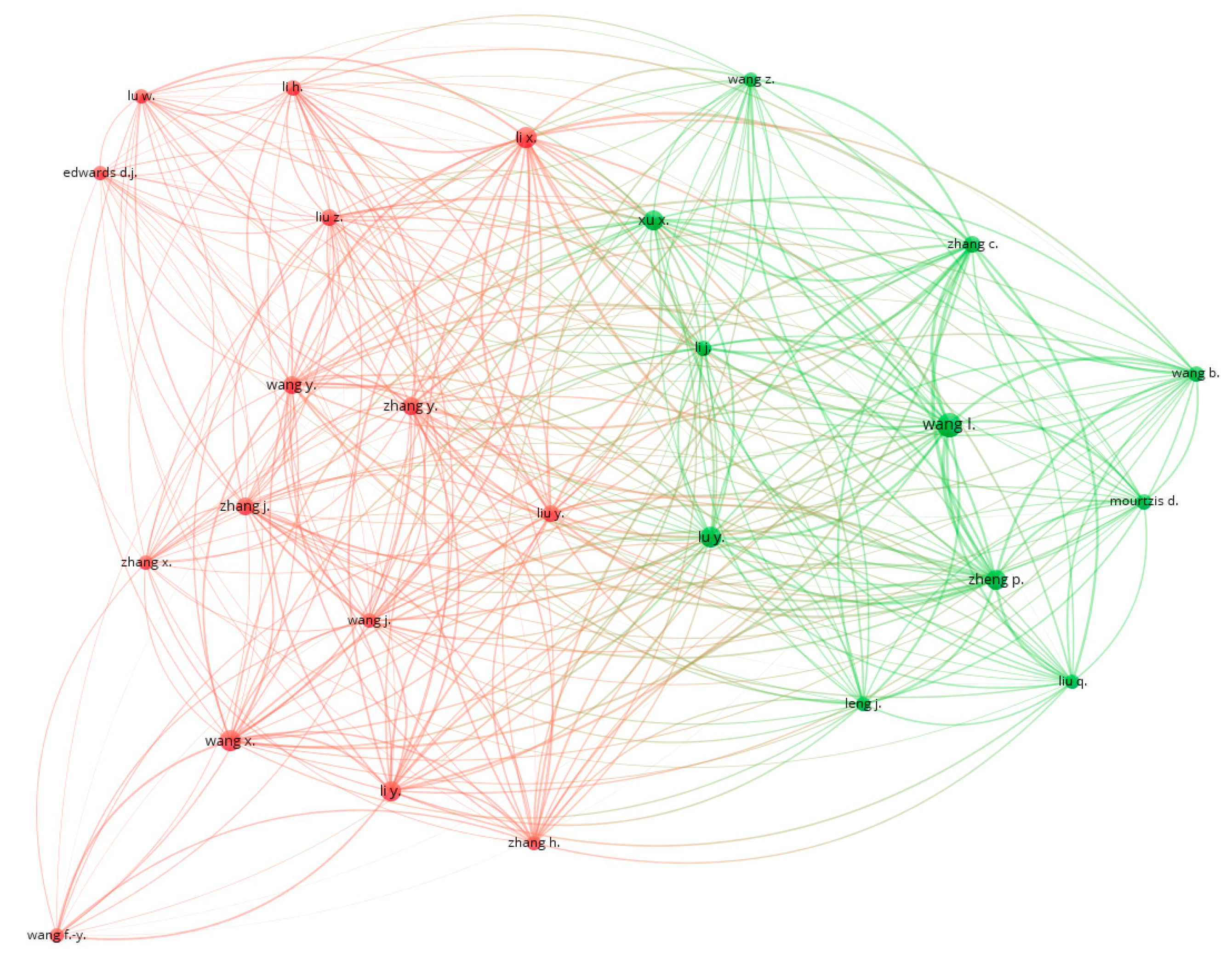

3.2. Co-Citation Analysis

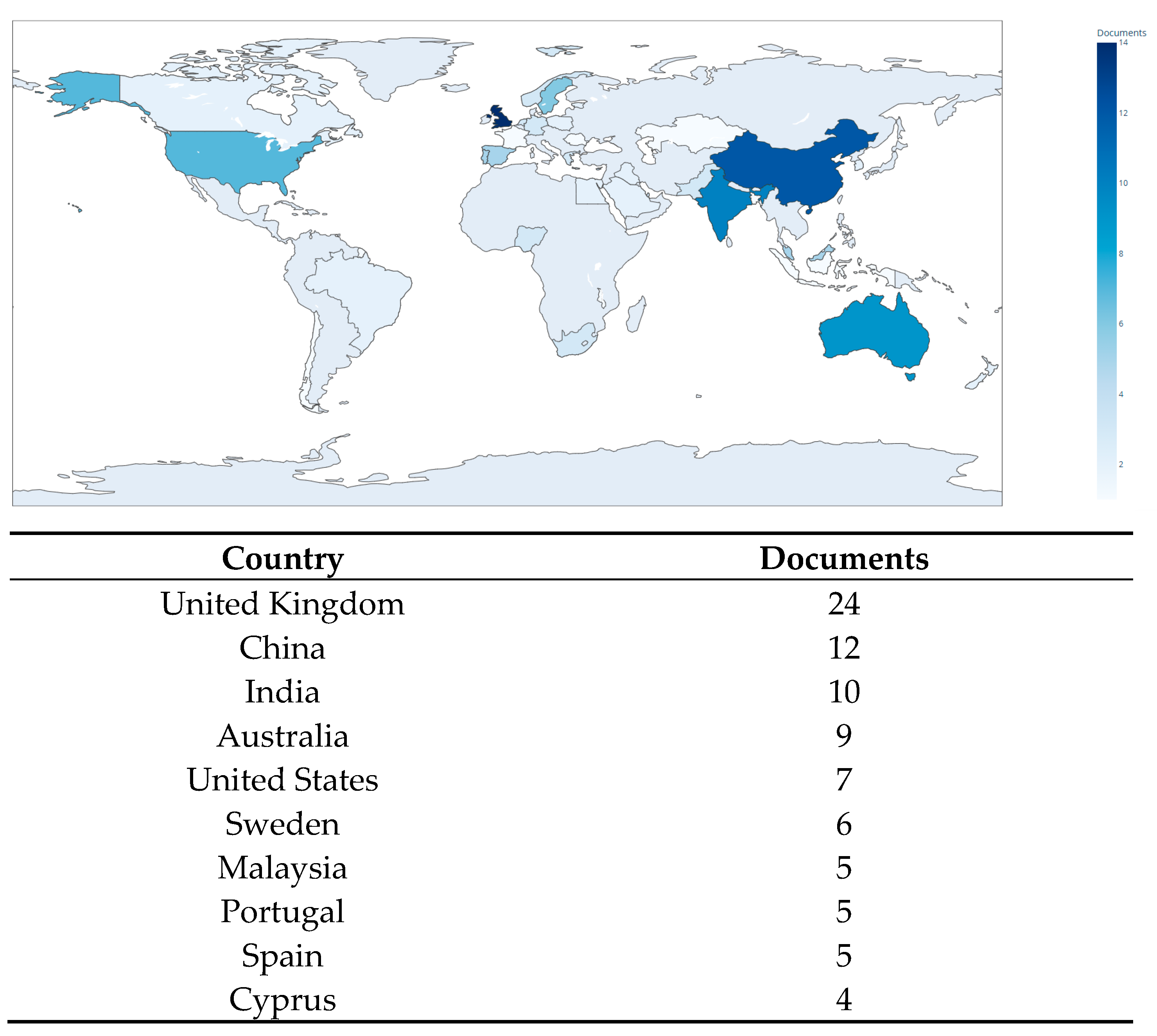

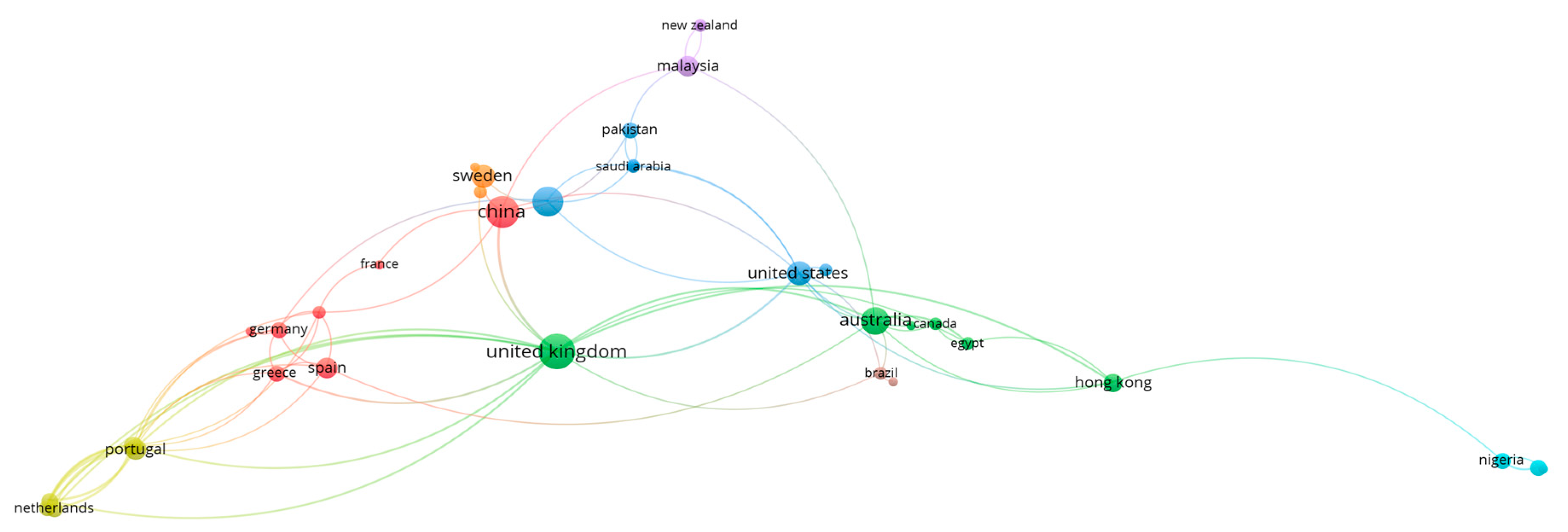

3.3. Multinational Co-Authorship

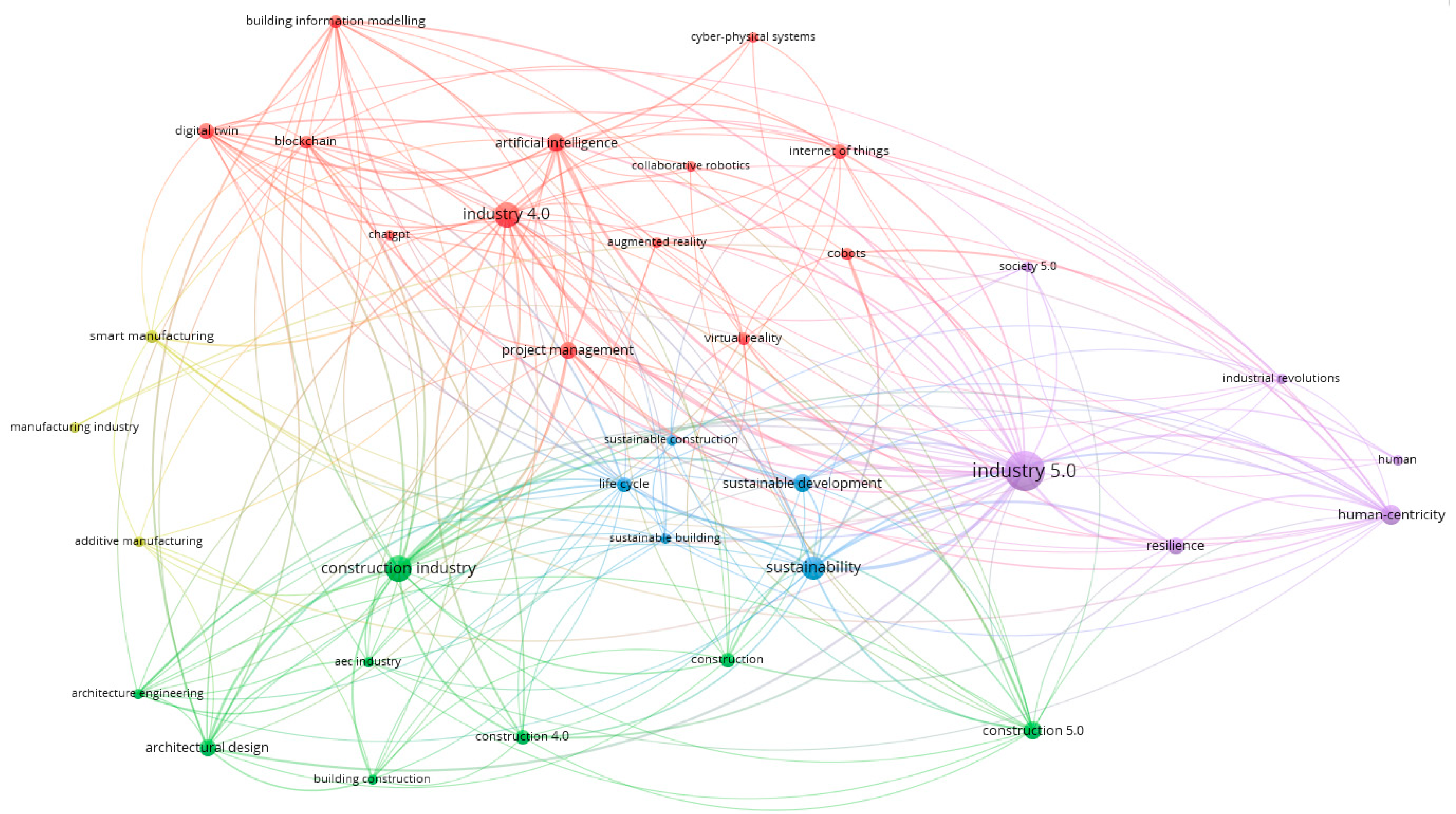

3.4. Keyword-Based Research Cluster Analysis

3.5. Seminal Contributions and Influential Research in Construction 5.0

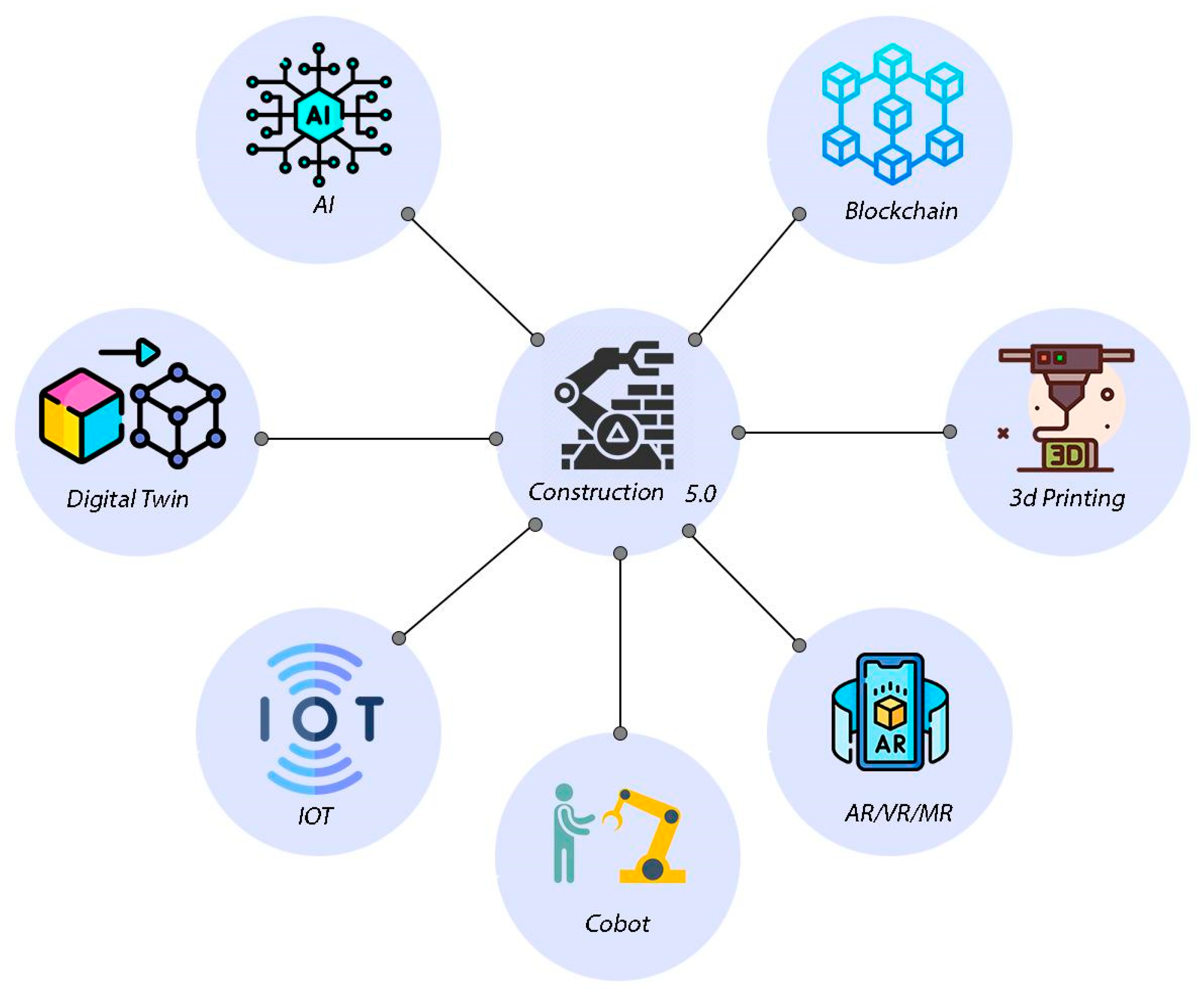

4. Impact of Industrial 5.0 on Construction Industry

4.1. Collaborative Robots

4.2. Blockchain

4.3. Digital Twin (DT)

4.4. Internet of Things (IoT)

4.5. Artificial Intelligence (AI)

4.6. AR/VR/MR

4.7. Three-Dimensional Printing

5. Qualitative Discussion

5.1. Challenges of Construction 5.0

5.2. Future Trends and Gaps in C5.0

6. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Title | Year | Cite |

|---|---|---|

| Enhancing sustainable construction decisions: integrating BIM and VR for circular economy assessment [150] | 2025 | 1 |

| Empowering Sustainable Infrastructure and Sustainable Development Goals Through Industry 5.0 Implementation [151] | 2025 | 0 |

| A Framework for Modeling the Decarbonization of the Economy Based on Energy Innovations in the Context of Industry 5.0 and Sustainable Development: International Perspective [152] | 2025 | 0 |

| A novel human-centered methodology for assessing manual-to-collaborative safe conversion of workstations [153] | 2025 | 1 |

| The Impact of Digital Technology Applications on Construction Industry Project Performance [154] | 2025 | 0 |

| Integrating large language model and digital twins in the context of industry 5.0: Framework, challenges and opportunities [155] | 2025 | 0 |

| Digital Twin Approach in Buildings: Future Challenges via a Critical Literature Review [156] | 2024 | 9 |

| Developing a proof-of-concept curriculum foundation model for industry 5.0: A primary data survey of built environment academics [157] | 2024 | 3 |

| Supply chain resilience in the construction industry: A bibliometric review on operations management practices from Industry 4.0 to Industry 5.0 [158] | 2024 | 0 |

| Resilient Scheduling Heuristic for Single Machine Systems to Minimize Variance of Job Completion Time [159] | 2024 | 0 |

| Facilitating Construction 5.0 for smart, sustainable and resilient buildings: opportunities and challenges for implementation [160] | 2024 | 1 |

| A knowledge empowered graph learning feature selection method based on variation propagation effect representation and analysis for human-centric manufacturing systems | 2024 | 0 |

| Unlocking Blockchain in Construction: A Systematic Review of Applications and Barriers [161] | 2024 | 3 |

| Industry 5.0 and the future of work in manufacturing in Australia [162] | 2024 | 0 |

| Eco epo-seal, versatile ancillary construction material: pathway to circularity in Industry 5.0 [163] | 2024 | 0 |

| Drone swarms in industry 5.0 [164] | 2024 | 0 |

| Ethics-Aware Application of Digital Technologies in the Construction Industry [165] | 2024 | 1 |

| Industry 5.0 concepts and enabling technologies, towards an enhanced conservation practice: systematic literature review protocol [166] | 2024 | 2 |

| Digital Twin Technology and Social Sustainability: Implications for the Construction Industry [167] | 2024 | 2 |

| Integration of Industry 5.0 Principles in Stealth Construction: Leveraging Emerging Technologies for Efficiency and Sustainability [168] | 2024 | 0 |

| ETHNOGRAPHY FOR CONSTRUCTION 5.0 [169] | 2024 | 0 |

| Industry 5.0, towards an enhanced built cultural heritage conservation practice [170] | 2024 | 4 |

| Architecting net zero: from drawings to bytes [171] | 2024 | 1 |

| Metaverse for Industry 5.0 [172] | 2024 | 1 |

| Toward sustainability and resilience with Industry 4.0 and Industry 5.0 [173] | 2024 | 0 |

| Multimodal Perception and Decision-Making Systems for Complex Roads Based on Foundation Models [174] | 2024 | 1 |

| Printing the Future Layer by Layer: A Comprehensive Exploration of Additive Manufacturing in the Era of Industry 4.0 [175] | 2024 | 5 |

| A State-of-the-Art Review and Bibliometric Analysis on the Smart Preservation of Heritages [176] | 2024 | 0 |

| Breaking down to build up: how deconstruction and carbon finance foster sustainable, resilient construction in the industry 5.0 era [177] | 2024 | 0 |

| Bamboo industrialization in the era of Industry 5.0: An exploration of key concepts, synergies and gaps [178] | 2024 | 0 |

| BIM Policy Trends in Europe: Insights from a Multi-Stage Analysis [179] | 2024 | 4 |

| Innovative horizons in drone technology for construction during industry 5.0 [180] | 2024 | 0 |

| Quality Assurance and Control in Welding and Additive Manufacturing [181] | 2024 | 1 |

| ARCHITECTURE, ENGINEERING, AND CONSTRUCTION (AEC) INDUSTRY 4.0 AND BEYOND: Building Construction Automation through 3D Printing and Additive Manufacturing Toward Lower Environmental Impacts [182] | 2024 | 0 |

| Construction 5.0 and Sustainable Neuro-Responsive Habitats: Integrating the Brain–Computer Interface and Building Information Modeling in Smart Residential Spaces [183] | 2024 | 0 |

| Research trends in industry 5.0 and its application in the construction industry [45] | 2024 | 3 |

| Enhancing Drone Operator Competency within the Construction Industry: Assessing Training Needs and Roadmap for Skill Development [184] | 2024 | 3 |

| Human Digital Twin in Industry 5.0: A Holistic Approach to Worker Safety and Well-Being through Advanced AI and Emotional Analytics [185] | 2024 | 11 |

| Towards Enhanced Built Cultural Heritage Conservation Practices: Perceptions on Industry 5.0 Principles and Enabling Technologies [186] | 2024 | 0 |

| Society 5.0: social implications, technoethics, and social acceptance [187] | 2024 | 0 |

| Gender diversity in construction: demystifying the pipeline leaks in Australia, United States, United Kingdom and Brazil [188] | 2024 | 0 |

| Human-robot collaboration for building deconstruction in the context of construction 5.0 [189] | 2024 | 4 |

| Multi-Objective Optimization of an Assembly Layout Using Nature-Inspired Algorithms and a Digital Human Modeling Tool [190] | 2024 | 1 |

| Korea’s Citizen-Centric Smart City Development by Adopting Living Labs and Design Thinking Methodologies and Their Implications for ASEAN Countries [191] | 2023 | 0 |

| Thematic evolution and trends linking sustainability and project management: Scientific mapping using SciMAT [192] | 2023 | 9 |

| From Industry 4.0 to Construction 5.0: Exploring the Path towards Human–Robot Collaboration in Construction [7] | 2023 | 42 |

| Digital Twin Approach for Maintenance Management [193] | 2023 | 4 |

| Explainability as the key ingredient for AI adoption in Industry 5.0 settings [194] | 2023 | 6 |

| Perspectives on Digital Transformation Initiatives in the Mechanical Engineering Industry [195] | 2023 | 0 |

| A Review on the Way Forward in Construction through Industrial Revolution 5.0 [196] | 2023 | 27 |

| Integrated practices in the Architecture, Engineering, and Construction industry: Current scope and pathway towards Industry 5.0 [42] | 2023 | 32 |

| The resurgence of augmented reality and virtual reality in construction: Past, present, and future directions [197] | 2023 | 2 |

| Investigating the Causal Relationships among Enablers of the Construction 5.0 Paradigm: Integration of Operator 5.0 and Society 5.0 with Human-Centricity, Sustainability, and Resilience [43] | 2023 | 21 |

| Investigating the Use of ChatGPT for the Scheduling of Construction Projects [38] | 2023 | 79 |

| Application of artificial intelligence and machine learning for BIM: review [198] | 2023 | 16 |

| Assessing the Accuracy of ChatGPT Use for Risk Management in Construction Projects [199] | 2023 | 10 |

| Building Contract in the Fifth Industrial Revolution: Embedding Sustainable Design and Construction Practices [200] | 2023 | 0 |

| A novel evolution model to investigate the collaborative innovation mechanism of green intelligent building materials enterprises for construction 5.0 [201] | 2023 | 10 |

| University and Education 5.0 for Emerging Trends, Policies and Practices in the Concept of Industry 5.0 and Society 5.0 [202] | 2023 | 12 |

| Artificial Intelligence Enabled Project Management: A Systematic Literature Review [41] | 2023 | 48 |

| A Review on Challenges and Solutions in the Implementation of Ai, IoT and Blockchain in Construction Industry [203] | 2023 | 13 |

| Towards new-generation human-centric smart manufacturing in Industry 5.0: A systematic review [37] | 2023 | 100 |

| On Intelligent Mining with Parallel Intelligence [204] | 2023 | 5 |

| Modelling the adoption of Internet of things (IoT) for sustainable construction in a developing economy [205] | 2023 | 11 |

| Evaluation of Lean Off-Site Construction Literature through the Lens of Industry 4.0 and 5.0 [206] | 2023 | 15 |

| Reviewing and Integrating AEC Practices into Industry 6.0: Strategies for Smart and Sustainable Future-Built Environments [207] | 2023 | 40 |

| Application of BIM Methodology in Public and Private Electricity and Telecommunications Projects in Peru [208] | 2023 | 0 |

| Influence of 3D-printable sustainable concrete and industrial waste on Industry 5.0 [209] | 2022 | 0 |

| Human–Robot Collaboration and Lean Waste Elimination: Conceptual Analogies and Practical Synergies in Industrialized Construction [18] | 2022 | 17 |

| Greening Construction Transport as a Sustainability Enabler for New Zealand: A Research Framework [210] | 2022 | 7 |

| Process View to Innovate the Management of the Social Housing System: A Multiple Case Study [211] | 2022 | 6 |

| Challenges and opportunities of augmented reality during the construction phase [19] | 2022 | 29 |

| BIM Information Integration Based VR Modeling in Digital Twins in Industry 5.0 [39] | 2022 | 73 |

| Comparative Study of Digitalization in the Spanish Ceramic Sector from a Marketing Perspective over the Period 2017–2021 [212] | 2022 | 0 |

| Construction 4.0, Industry 4.0, and Building Information Modeling (BIM) for Sustainable Building Development within the Smart City [40] | 2022 | 70 |

| Achieving stepwise construction of cyber physical systems in EX-MAN component model [213] | 2022 | 0 |

| An optimal construction of smart aged homes based on SDLC using smart sensors and agent networks [214] | 2022 | 2 |

| A Scientometric Analysis of Studies on Risk Management in Construction Projects [215] | 2022 | 24 |

References

- GlobalData. United Kingdom (UK) Construction Market Size, Trend Analysis by Sector, Competitive Landscape and Forecast to 2028—Q3 Update. 2024. Available online: https://www.globaldata.com/store/report/uk-construction-market-analysis/ (accessed on 15 April 2025).

- Statista Research Department. U.S. value added to GDP by construction industry 2000–2023. 2024. Available online: https://www.statista.com/statistics/785445/value-added-by-us-construction/ (accessed on 15 April 2025).

- Adepoju, O. Re-Skilling Human Resources for Construction 4.0: Implications for Industry, Academia and Government; Springer International Publishing: Cham, Switzerland, 2022; pp. 3–16. [Google Scholar]

- Altuwaim, A.; AlTasan, A.; Almohsen, A. Success Criteria for Applying Construction Technologies in Residential Projects. Sustainability 2023, 15, 6854. [Google Scholar] [CrossRef]

- Nowotarski, P.; Paslawski, J. Industry 4.0 Concept Introduction into Construction SMEs. IOP Conf. Ser. Mater. Sci. Eng. 2017, 245, 052043. [Google Scholar] [CrossRef]

- Safura Zabidin, N.; Belayutham, S.; Che Ibrahim, C.K.I. A bibliometric and scientometric mapping of Industry 4.0 in construction. J. Inf. Technol. Constr. 2020, 25, 287–307. [Google Scholar] [CrossRef]

- Marinelli, M. From Industry 4.0 to Construction 5.0: Exploring the Path towards Human–Robot Collaboration in Construction. Systems 2023, 11, 152. [Google Scholar] [CrossRef]

- Renda, A.; Schwaag Serger, S.; Tataj, D.; Morlet, A.; Isaksson, D.; Martins, F.; Mir Roca, M.; Hidalgo, C.; Huang, A.; et al.; Directorate-General for Research and Innovation (European Commission) Industry 5.0, a Transformative Vision for Europe—Governing Systemic Transformations Towards a Sustainable Industry; Publications Office of the European Union: Luxembourg, 2021. [Google Scholar]

- Raja Santhi, A.; Muthuswamy, P. Industry 5.0 or industry 4.0S? Introduction to industry 4.0 and a peek into the prospective industry 5.0 technologies. Int. J. Interact. Des. Manuf. (IJIDeM) 2023, 17, 947–979. [Google Scholar] [CrossRef]

- Alojaiman, B. Technological Modernizations in the Industry 5.0 Era: A Descriptive Analysis and Future Research Directions. Processes 2023, 11, 1318. [Google Scholar] [CrossRef]

- Akundi, A.; Euresti, D.; Luna, S.; Ankobiah, W.; Lopes, A.; Edinbarough, I. State of Industry 5.0—Analysis and Identification of Current Research Trends. Appl. Syst. Innov. 2022, 5, 27. [Google Scholar] [CrossRef]

- Ghobakhloo, M.; Iranmanesh, M.; Tseng, M.-L.; Grybauskas, A.; Stefanini, A.; Amran, A. Behind the definition of Industry 5.0: A systematic review of technologies, principles, components, and values. J. Ind. Prod. Eng. 2023, 40, 432–447. [Google Scholar] [CrossRef]

- Sachsenmeier, P. Industry 5.0—The Relevance and Implications of Bionics and Synthetic Biology. Engineering 2016, 2, 225–229. [Google Scholar] [CrossRef]

- Akhavan, M.; Rashvand, P.; Razzaghi, M.S. An iot-based earthquake early warning system with fuzzy logic for utility control in tehran. Archit. Eng. 2024, 9, 16. [Google Scholar] [CrossRef]

- Forcael, E.; Ferrari, I.; Opazo-Vega, A.; Pulido-Arcas, J.A. Construction 4.0: A Literature Review. Sustainability 2020, 12, 9755. [Google Scholar] [CrossRef]

- El Jazzar, M.; Schranz, C.; Urban, H.; Nassereddine, H. Integrating Construction 4.0 Technologies: A Four-Layer Implementation Plan. Front. Built Environ. 2021, 7, 671408. [Google Scholar] [CrossRef]

- Li, Q.; Shi, J. Dam construction 4.0. Shuili Fadian Xuebao/J. Hydroelectr. Eng. 2015, 34, 1–6. [Google Scholar]

- Marinelli, M. Human–Robot Collaboration and Lean Waste Elimination: Conceptual Analogies and Practical Synergies in Industrialized Construction. Buildings 2022, 12, 2057. [Google Scholar] [CrossRef]

- Kolaei, A.Z.; Hedayati, E.; Khanzadi, M.; Amiri, G.G. Challenges and opportunities of augmented reality during the construction phase. Autom. Constr. 2022, 143, 104586. [Google Scholar] [CrossRef]

- Mongeon, P.; Paul-Hus, A. The journal coverage of Web of Science and Scopus: A comparative analysis. Scientometrics 2016, 106, 213–228. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef]

- Yin, X.; Liu, H.; Chen, Y.; Al-Hussein, M. Building information modelling for off-site construction: Review and future directions. Autom. Constr. 2019, 101, 72–91. [Google Scholar] [CrossRef]

- Hosseini, M.R.; Martek, I.; Zavadskas, E.K.; Aibinu, A.A.; Arashpour, M.; Chileshe, N. Critical evaluation of off-site construction research: A Scientometric analysis. Autom. Constr. 2018, 87, 235–247. [Google Scholar] [CrossRef]

- Jin, R.; Zou, P.X.W.; Piroozfar, P.; Wood, H.; Yang, Y.; Yan, L.; Han, Y. A science mapping approach based review of construction safety research. Saf. Sci. 2019, 113, 285–297. [Google Scholar] [CrossRef]

- Martinez, P.; Al-Hussein, M.; Ahmad, R. A scientometric analysis and critical review of computer vision applications for construction. Autom. Constr. 2019, 107, 102947. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, H.; Kang, S.-C.; Al-Hussein, M. Virtual reality applications for the built environment: Research trends and opportunities. Autom. Constr. 2020, 118, 103311. [Google Scholar] [CrossRef]

- Chavalarias, D.; Cointet, J.-P. Phylomemetic Patterns in Science Evolution—The Rise and Fall of Scientific Fields. PLoS ONE 2013, 8, e54847. [Google Scholar] [CrossRef]

- Zhao, X. A scientometric review of global BIM research: Analysis and visualization. Autom. Constr. 2017, 80, 37–47. [Google Scholar] [CrossRef]

- Small, H. Co-citation in the scientific literature: A new measure of the relationship between two documents. J. Am. Soc. Inf. Sci. 1973, 24, 265–269. [Google Scholar] [CrossRef]

- van Eck, N.J.; Waltman, L. VOSviewer Manual for Version 1.6.15. 2020. Available online: https://www.vosviewer.com/documentation/Manual_VOSviewer_1.6.20.pdf (accessed on 15 April 2025).

- Mir-Nasiri, N.; Siswoyo, H.; Ali, M.H. Portable Autonomous Window Cleaning Robot. Procedia Comput. Sci. 2018, 133, 197–204. [Google Scholar] [CrossRef]

- Perianes-Rodriguez, A.; Waltman, L.; van Eck, N.J. Constructing bibliometric networks: A comparison between full and fractional counting. J. Informetr. 2016, 10, 1178–1195. [Google Scholar] [CrossRef]

- Madsen, D.Ø.; Berg, T.; Di Nardo, M. Bibliometric Trends in Industry 5.0 Research: An Updated Overview. Appl. Syst. Innov. 2023, 6, 63. [Google Scholar] [CrossRef]

- Maskuriy, R.; Selamat, A.; Ali, K.N.; Maresova, P.; Krejcar, O. Industry 4.0 for the Construction Industry—How Ready Is the Industry? Appl. Sci. 2019, 9, 2819. [Google Scholar] [CrossRef]

- Walter, C.; Saenz, J.; Elkmann, N.; Althoff, H.; Kutzner, S.; Stuerze, T. Design considerations of robotic system for cleaning and inspection of large-diameter sewers. J. Field Robot. 2012, 29, 186–214. [Google Scholar] [CrossRef]

- Siebert, S.; Teizer, J. Mobile 3D mapping for surveying earthwork projects using an Unmanned Aerial Vehicle (UAV) system. Autom. Constr. 2014, 41, 1–14. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, Z.; Zhou, G.; Chang, F.; Ma, D.; Jing, Y.; Cheng, W.; Ding, K.; Zhao, D. Towards new-generation human-centric smart manufacturing in Industry 5.0: A systematic review. Adv. Eng. Inform. 2023, 57, 102121. [Google Scholar] [CrossRef]

- Prieto, S.A.; Mengiste, E.T.; García de Soto, B. Investigating the Use of ChatGPT for the Scheduling of Construction Projects. Buildings 2023, 13, 857. [Google Scholar] [CrossRef]

- Wang, W.; Guo, H.; Li, X.; Tang, S.; Li, Y.; Xie, L.; Lv, Z. BIM Information Integration Based VR Modeling in Digital Twins in Industry 5.0. J. Ind. Inf. Integr. 2022, 28, 100351. [Google Scholar] [CrossRef]

- Chen, Y.; Huang, D.; Liu, Z.; Osmani, M.; Demian, P. Construction 4.0, Industry 4.0, and Building Information Modeling (BIM) for Sustainable Building Development within the Smart City. Sustainability 2022, 14, 10028. [Google Scholar] [CrossRef]

- Taboada, I.; Daneshpajouh, A.; Toledo, N.; de Vass, T. Artificial Intelligence Enabled Project Management: A Systematic Literature Review. Appl. Sci. 2023, 13, 5014. [Google Scholar] [CrossRef]

- Ikudayisi, A.E.; Chan, A.P.C.; Darko, A.; Adedeji, Y.M.D. Integrated practices in the Architecture, Engineering, and Construction industry: Current scope and pathway towards Industry 5.0. J. Build. Eng. 2023, 73, 106788. [Google Scholar] [CrossRef]

- Yitmen, I.; Almusaed, A.; Alizadehsalehi, S. Investigating the Causal Relationships among Enablers of the Construction 5.0 Paradigm: Integration of Operator 5.0 and Society 5.0 with Human-Centricity, Sustainability, and Resilience. Sustainability 2023, 15, 9105. [Google Scholar] [CrossRef]

- Baghalzadeh Shishehgarkhaneh, M.; Keivani, A.; Moehler, R.C.; Jelodari, N.; Roshdi Laleh, S. Internet of Things (IoT), Building Information Modeling (BIM), and Digital Twin (DT) in Construction Industry: A Review, Bibliometric, and Network Analysis. Buildings 2022, 12, 1503. [Google Scholar] [CrossRef]

- Tunji-Olayeni, P.; Aigbavboa, C.; Oke, A.; Chukwu, N. Research trends in industry 5.0 and its application in the construction industry. Technol. Sustain. 2023, 3, 1–23. [Google Scholar] [CrossRef]

- Heydari, M.; Shojaei, A. Blockchain applications in the construction supply chain. Autom. Constr. 2025, 171, 105998. [Google Scholar] [CrossRef]

- Valente, M.; Sambucci, M.; Sibai, A. Geopolymers vs. Cement matrix materials: How nanofiller can help a sustainability approach for smart construction applications—A review. Nanomaterials 2021, 11, 2007. [Google Scholar] [CrossRef] [PubMed]

- Adel, A. Future of industry 5.0 in society: Human-centric solutions, challenges and prospective research areas. J. Cloud Comput. 2022, 11, 40. [Google Scholar] [CrossRef]

- Adachi, D.; Kawaguchi, D.; Saito, Y.U. Robots and Employment: Evidence from Japan, 1978–2017; Research Institute of Economy, Trade and Industry (RIETI): Tokyo, Japan, 2020. [Google Scholar]

- Aly, A.; Griffiths, S.; Stramandinoli, F. Metrics and benchmarks in human-robot interaction: Recent advances in cognitive robotics. Cogn. Syst. Res. 2017, 43, 313–323. [Google Scholar] [CrossRef]

- Lattanzi, D.; Miller, G. Review of Robotic Infrastructure Inspection Systems. J. Infrastruct. Syst. 2017, 23, 04017004. [Google Scholar] [CrossRef]

- Halder, S.; Afsari, K. Robots in Inspection and Monitoring of Buildings and Infrastructure: A Systematic Review. Appl. Sci. 2023, 13, 2304. [Google Scholar] [CrossRef]

- Asadi, E.; Li, B.; Chen, I.M. Pictobot: A Cooperative Painting Robot for Interior Finishing of Industrial Developments. IEEE Robot. Autom. Mag. 2018, 25, 82–94. [Google Scholar] [CrossRef]

- Kehoe, B.; Patil, S.; Abbeel, P.; Goldberg, K. A Survey of Research on Cloud Robotics and Automation. IEEE Trans. Autom. Sci. Eng. 2015, 12, 398–409. [Google Scholar] [CrossRef]

- Xiang, S.; Wang, R.; Feng, C. Mobile projective augmented reality for collaborative robots in construction. Autom. Constr. 2021, 127, 103704. [Google Scholar] [CrossRef]

- Kaipa, K.N.; Onal, C.; Jovanovic, V.; Djuric, A.; Luo, M.; Bowers, M.P.; Popovic, M.B. 17—Bioinspired Robotics. In Biomechatronics; Popovic, M.B., Ed.; Academic Press: Cambridge, MA, USA, 2019; pp. 495–541. [Google Scholar]

- Chea, C.P.; Bai, Y.; Pan, X.; Arashpour, M.; Xie, Y. An integrated review of automation and robotic technologies for structural prefabrication and construction. Transp. Saf. Environ. 2020, 2, 81–96. [Google Scholar] [CrossRef]

- Bock, T. The future of construction automation: Technological disruption and the upcoming ubiquity of robotics. Autom. Constr. 2015, 59, 113–121. [Google Scholar] [CrossRef]

- Hamledari, H.; Fischer, M. Construction payment automation using blockchain-enabled smart contracts and robotic reality capture technologies. Autom. Constr. 2021, 132, 103926. [Google Scholar] [CrossRef]

- Dindorf, R.; Wos, P. Challenges of Robotic Technology in Sustainable Construction Practice. Sustainability 2024, 16, 5500. [Google Scholar] [CrossRef]

- Xiao, B.; Chen, C.; Yin, X. Recent advancements of robotics in construction. Autom. Constr. 2022, 144, 104591. [Google Scholar] [CrossRef]

- Dörfler, K.; Dielemans, G.; Lachmayer, L.; Recker, T.; Raatz, A.; Lowke, D.; Gerke, M. Additive Manufacturing using mobile robots: Opportunities and challenges for building construction. Cem. Concr. Res. 2022, 158, 106772. [Google Scholar] [CrossRef]

- Kurien, M.; Kim, M.-K.; Kopsida, M.; Brilakis, I. Real-time simulation of construction workers using combined human body and hand tracking for robotic construction worker system. Autom. Constr. 2018, 86, 125–137. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, T.; Rahman, A.; Zhou, L. Blockchain Applications for Construction Contract Management: A Systematic Literature Review. J. Constr. Eng. Manag. 2023, 149, 03122011. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, T.; Hu, H.; Gong, J.; Ren, X.; Xiao, Q. Blockchain-based framework for improving supply chain traceability and information sharing in precast construction. Autom. Constr. 2020, 111, 103063. [Google Scholar] [CrossRef]

- Dakhli, Z.; Lafhaj, Z.; Mossman, A. The Potential of Blockchain in Building Construction. Buildings 2019, 9, 77. [Google Scholar] [CrossRef]

- Taherdoost, H. Smart Contracts in Blockchain Technology: A Critical Review. Information 2023, 14, 117. [Google Scholar] [CrossRef]

- Rathnayake, I.; Wedawatta, G.; Tezel, A. Smart Contracts in the Construction Industry: A Systematic Review. Buildings 2022, 12, 2082. [Google Scholar] [CrossRef]

- Figueiredo, K.; Hammad, A.W.A.; Haddad, A.; Tam, V.W.Y. Assessing the usability of blockchain for sustainability: Extending key themes to the construction industry. J. Clean. Prod. 2022, 343, 131047. [Google Scholar] [CrossRef]

- Singh, A.K.; Mohandes, S.R.; Awuzie, B.O.; Omotayo, T.; Kumar, V.R.P.; Kidd, C. A roadmap for overcoming barriers to implementation of blockchain-enabled smart contracts in sustainable construction projects. Smart Sustain. Built Environ. 2024. Available online: https://eprints.leedsbeckett.ac.uk/id/eprint/11251/ (accessed on 15 April 2025).

- Dong, Y.; Hu, Y.; Li, S.; Cai, J.; Han, Z. BIM-blockchain integrated automatic asset tracking and delay propagation analysis for prefabricated construction projects. Autom. Constr. 2024, 168. [Google Scholar] [CrossRef]

- Liu, H.; Han, S.; Zhu, Z. Blockchain Technology toward Smart Construction: Review and Future Directions. J. Constr. Eng. Manag. 2023, 149, 03123002. [Google Scholar] [CrossRef]

- Wu, H.; Zhang, P.; Li, H.; Zhong, B.; Fung, I.W.H.; Lee, Y.Y.R. Blockchain Technology in the Construction Industry: Current Status, Challenges, and Future Directions. J. Constr. Eng. Manag. 2022, 148, 03122007. [Google Scholar] [CrossRef]

- Li, J.; Greenwood, D.; Kassem, M. Blockchain in the built environment and construction industry: A systematic review, conceptual models and practical use cases. Autom. Constr. 2019, 102, 288–307. [Google Scholar] [CrossRef]

- Swan, M. Blockchain: Blueprint for a New Economy; O’Reilly Media, Inc.: Sebastopol, CA, USA, 2015. [Google Scholar]

- Al Amin, M.; Nabil, D.H.; Baldacci, R.; Rahman, M.H. Exploring Blockchain Implementation Challenges for Sustainable Supply Chains: An Integrated Fuzzy TOPSIS–ISM Approach. Sustainability 2023, 15, 13891. [Google Scholar] [CrossRef]

- Singh, M.; Fuenmayor, E.; Hinchy, E.; Qiao, Y.; Murray, N.; Devine, D. Digital Twin: Origin to Future. Appl. Syst. Innov. 2021, 4, 36. [Google Scholar] [CrossRef]

- Kineber, A.F.; Singh, A.K.; Fazeli, A.; Mohandes, S.R.; Cheung, C.; Arashpour, M.; Ejohwomu, O.; Zayed, T. Modelling the relationship between digital twins implementation barriers and sustainability pillars: Insights from building and construction sector. Sustain. Cities Soc. 2023, 99, 104930. [Google Scholar] [CrossRef]

- Tuhaise, V.V.; Tah, J.H.M.; Abanda, F.H. Technologies for digital twin applications in construction. Autom. Constr. 2023, 152, 104931. [Google Scholar] [CrossRef]

- Liu, Z.-S.; Meng, X.-T.; Xing, Z.-Z.; Cao, C.-F.; Jiao, Y.-Y.; Li, A.-X. Digital Twin-Based Intelligent Safety Risks Prediction of Prefabricated Construction Hoisting. Sustainability 2022, 14, 5179. [Google Scholar] [CrossRef]

- Lee, D.; Lee, S.H.; Masoud, N.; Krishnan, M.S.; Li, V.C. Integrated digital twin and blockchain framework to support accountable information sharing in construction projects. Autom. Constr. 2021, 127, 103688. [Google Scholar] [CrossRef]

- Moshood, T.D.; Rotimi, J.O.B.; Shahzad, W.; Bamgbade, J.A. Infrastructure digital twin technology: A new paradigm for future construction industry. Technol. Soc. 2024, 77, 102519. [Google Scholar] [CrossRef]

- Jiang, Y.; Li, M.; Guo, D.; Wu, W.; Zhong, R.Y.; Huang, G.Q. Digital twin-enabled smart modular integrated construction system for on-site assembly. Comput. Ind. 2022, 136, 103594. [Google Scholar] [CrossRef]

- Adu-Amankwa, N.A.N.; Pour Rahimian, F.; Dawood, N.; Park, C. Digital Twins and Blockchain technologies for building lifecycle management. Autom. Constr. 2023, 155, 105064. [Google Scholar] [CrossRef]

- Omrany, H.; Al-Obaidi, K.M.; Husain, A.; Ghaffarianhoseini, A. Digital Twins in the Construction Industry: A Comprehensive Review of Current Implementations, Enabling Technologies, and Future Directions. Sustainability 2023, 15, 10908. [Google Scholar] [CrossRef]

- Sepasgozar, S.M.E.; Khan, A.A.; Smith, K.; Romero, J.G.; Shen, X.; Shirowzhan, S.; Li, H.; Tahmasebinia, F. BIM and Digital Twin for Developing Convergence Technologies as Future of Digital Construction. Buildings 2023, 13, 441. [Google Scholar] [CrossRef]

- Modoni, G.E.; Sacco, M. A Human Digital-Twin-Based Framework Driving Human Centricity towards Industry 5.0. Sensors 2023, 23, 6054. [Google Scholar] [CrossRef]

- Meža, S.; Mauko Pranjić, A.; Vezočnik, R.; Osmokrović, I.; Lenart, S. Digital Twins and Road Construction Using Secondary Raw Materials. J. Adv. Transp. 2021, 2021, 8833058. [Google Scholar] [CrossRef]

- Lucchi, E. Digital twins for the automation of the heritage construction sector. Autom. Constr. 2023, 156, 105073. [Google Scholar] [CrossRef]

- Madubuike, O.C.; Anumba, C.J.; Khallaf, R. A review of digital twin applications in construction. J. Inf. Technol. Constr. 2022, 27, 145–172. [Google Scholar] [CrossRef]

- Lee, I.; Lee, K. The Internet of Things (IoT): Applications, investments, and challenges for enterprises. Bus. Horiz. 2015, 58, 431–440. [Google Scholar] [CrossRef]

- Woodhead, R.; Stephenson, P.; Morrey, D. Digital construction: From point solutions to IoT ecosystem. Autom. Constr. 2018, 93, 35–46. [Google Scholar] [CrossRef]

- Zhong, R.Y.; Peng, Y.; Xue, F.; Fang, J.; Zou, W.; Luo, H.; Thomas Ng, S.; Lu, W.; Shen, G.Q.P.; Huang, G.Q. Prefabricated construction enabled by the Internet-of-Things. Autom. Constr. 2017, 76, 59–70. [Google Scholar] [CrossRef]

- Chen, Y. A Survey on Industrial Information Integration 2016–2019. J. Ind. Integr. Manag. 2020, 05, 33–163. [Google Scholar] [CrossRef]

- Al-Obaidi, K.M.; Hossain, M.; Alduais, N.A.M.; Al-Duais, H.S.; Omrany, H.; Ghaffarianhoseini, A. A Review of Using IoT for Energy Efficient Buildings and Cities: A Built Environment Perspective. Energies 2022, 15, 5991. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Singh, R.P.; Suman, R.; Gonzalez, E.S. Understanding the adoption of Industry 4.0 technologies in improving environmental sustainability. Sustain. Oper. Comput. 2022, 3, 203–217. [Google Scholar] [CrossRef]

- Gharbia, M.; Chang-Richards, A.; Lu, Y.; Zhong, R.Y.; Li, H. Robotic technologies for on-site building construction: A systematic review. J. Build. Eng. 2020, 32, 101584. [Google Scholar] [CrossRef]

- Soori, M.; Arezoo, B.; Dastres, R. Internet of things for smart factories in industry 4.0, a review. Internet Things Cyber-Phys. Syst. 2023, 3, 192–204. [Google Scholar] [CrossRef]

- Baduge, S.K.; Thilakarathna, S.; Perera, J.S.; Arashpour, M.; Sharafi, P.; Teodosio, B.; Shringi, A.; Mendis, P. Artificial intelligence and smart vision for building and construction 4.0: Machine and deep learning methods and applications. Autom. Constr. 2022, 141, 104440. [Google Scholar] [CrossRef]

- Chen, F.; Jiao, H.; Han, L.; Shen, L.; Du, W.; Ye, Q.; Yu, G. Real-time monitoring of construction quality for gravel piles based on Internet of Things. Autom. Constr. 2020, 116, 103228. [Google Scholar] [CrossRef]

- Li, R.; Zhao, Z.; Zhou, X.; Ding, G.; Chen, Y.; Wang, Z.; Zhang, H. Intelligent 5G: When Cellular Networks Meet Artificial Intelligence. IEEE Wirel. Commun. 2017, 24, 175–183. [Google Scholar] [CrossRef]

- Tixier, A.J.P.; Hallowell, M.R.; Rajagopalan, B.; Bowman, D. Application of machine learning to construction injury prediction. Autom. Constr. 2016, 69, 102–114. [Google Scholar] [CrossRef]

- Abioye, S.O.; Oyedele, L.O.; Akanbi, L.; Ajayi, A.; Davila Delgado, J.M.; Bilal, M.; Akinade, O.O.; Ahmed, A. Artificial intelligence in the construction industry: A review of present status, opportunities and future challenges. J. Build. Eng. 2021, 44, 103299. [Google Scholar] [CrossRef]

- Zhang, Y.; Teoh, B.K.; Wu, M.; Chen, J.; Zhang, L. Data-driven estimation of building energy consumption and GHG emissions using explainable artificial intelligence. Energy 2023, 262, 125468. [Google Scholar] [CrossRef]

- Rashid, K.M.; Louis, J. Activity identification in modular construction using audio signals and machine learning. Autom. Constr. 2020, 119, 103361. [Google Scholar] [CrossRef]

- Pan, Y.; Zhang, L. Roles of artificial intelligence in construction engineering and management: A critical review and future trends. Autom. Constr. 2021, 122, 103517. [Google Scholar] [CrossRef]

- Li, Y.; Lu, Y.; Chen, J. A deep learning approach for real-time rebar counting on the construction site based on YOLOv3 detector. Autom. Constr. 2021, 124, 103602. [Google Scholar] [CrossRef]

- Piras, G.; Muzi, F.; Ziran, Z. Open Tool for Automated Development of Renewable Energy Communities: Artificial Intelligence and Machine Learning Techniques for Methodological Approach. Energies 2024, 17, 5726. [Google Scholar] [CrossRef]

- Chen, H.-P.; Ying, K.-C. Artificial Intelligence in the Construction Industry: Main Development Trajectories and Future Outlook. Appl. Sci. 2022, 12, 5832. [Google Scholar] [CrossRef]

- Toorajipour, R.; Sohrabpour, V.; Nazarpour, A.; Oghazi, P.; Fischl, M. Artificial intelligence in supply chain management: A systematic literature review. J. Bus. Res. 2021, 122, 502–517. [Google Scholar] [CrossRef]

- Valizadeh, J.; Ghahroudi, A.G.; Soltani, S.; Akhavan, M.; Zaki, A.; Heravi, P. Mathematical modeling for the closed-loop supply chain with consideration of sustainability risks: A hybrid optimization approach. Environ. Dev. Sustain. 2024, 1–36. [Google Scholar] [CrossRef]

- Stecyk, A.; Miciuła, I. Harnessing the Power of Artificial Intelligence for Collaborative Energy Optimization Platforms. Energies 2023, 16, 5210. [Google Scholar] [CrossRef]

- Danish, M.S.S.; Senjyu, T. Shaping the future of sustainable energy through AI-enabled circular economy policies. Circ. Econ. 2023, 2, 100040. [Google Scholar] [CrossRef]

- Fordal, J.M.; Schjølberg, P.; Helgetun, H.; Skjermo, T.Ø.; Wang, Y.; Wang, C. Application of sensor data based predictive maintenance and artificial neural networks to enable Industry 4.0. Adv. Manuf. 2023, 11, 248–263. [Google Scholar] [CrossRef]

- Bouabdallaoui, Y.; Lafhaj, Z.; Yim, P.; Ducoulombier, L.; Bennadji, B. Predictive Maintenance in Building Facilities: A Machine Learning-Based Approach. Sensors 2021, 21, 1044. [Google Scholar] [CrossRef]

- Abdulfattah, B.S.; Abdelsalam, H.A.; Abdelsalam, M.; Bolpagni, M.; Thurairajah, N.; Perez, L.F.; Butt, T.E. Predicting implications of design changes in BIM-based construction projects through machine learning. Autom. Constr. 2023, 155, 105057. [Google Scholar] [CrossRef]

- Wang, X.; Truijens, M.; Hou, L.; Wang, Y.; Zhou, Y. Integrating Augmented Reality with Building Information Modeling: Onsite construction process controlling for liquefied natural gas industry. Autom. Constr. 2014, 40, 96–105. [Google Scholar] [CrossRef]

- Meža, S.; Turk, Ž.; Dolenc, M. Component based engineering of a mobile BIM-based augmented reality system. Autom. Constr. 2014, 42, 1–12. [Google Scholar] [CrossRef]

- Li, X.; Yi, W.; Chi, H.-L.; Wang, X.; Chan, A.P.C. A critical review of virtual and augmented reality (VR/AR) applications in construction safety. Autom. Constr. 2018, 86, 150–162. [Google Scholar] [CrossRef]

- Dodoo, J.E.; Al-Samarraie, H.; Alzahrani, A.I.; Tang, T. XR and Workers’ safety in High-Risk Industries: A comprehensive review. Saf. Sci. 2025, 185, 106804. [Google Scholar] [CrossRef]

- Kamari, A.; Paari, A.; Torvund, H.Ø. BIM-Enabled Virtual Reality (VR) for Sustainability Life Cycle and Cost Assessment. Sustainability 2021, 13, 249. [Google Scholar] [CrossRef]

- Maqsoom, A.; Zulqarnain, M.; Irfan, M.; Ullah, F.; Alqahtani, F.K.; Khan, K.I.A. Drivers of, and Barriers to, the Adoption of Mixed Reality in the Construction Industry of Developing Countries. Buildings 2023, 13, 872. [Google Scholar] [CrossRef]

- Babalola, A.; Manu, P.; Cheung, C.; Yunusa-Kaltungo, A.; Bartolo, P. A systematic review of the application of immersive technologies for safety and health management in the construction sector. J. Saf. Res. 2023, 85, 66–85. [Google Scholar] [CrossRef]

- Ahmed, S. A Review on Using Opportunities of Augmented Reality and Virtual Reality in Construction Project Management. Organ. Technol. Manag. Constr. Int. J. 2019, 11, 1839–1852. [Google Scholar] [CrossRef]

- Miljkovic, I.; Shlyakhetko, O.; Fedushko, S. Real Estate App Development Based on AI/VR Technologies. Electronics 2023, 12, 707. [Google Scholar] [CrossRef]

- Chi, H.-Y.; Juan, Y.-K.; Lu, S. Comparing BIM-Based XR and Traditional Design Process from Three Perspectives: Aesthetics, Gaze Tracking, and Perceived Usefulness. Buildings 2022, 12, 1728. [Google Scholar] [CrossRef]

- Weller, C.; Kleer, R.; Piller, F.T. Economic implications of 3D printing: Market structure models in light of additive manufacturing revisited. Int. J. Prod. Econ. 2015, 164, 43–56. [Google Scholar] [CrossRef]

- Xia, M.; Nematollahi, B.; Sanjayan, J. Printability, accuracy and strength of geopolymer made using powder-based 3D printing for construction applications. Autom. Constr. 2019, 101, 179–189. [Google Scholar] [CrossRef]

- Sotorrío Ortega, G.; Alonso Madrid, J.; Olsson, N.O.E.; Tenorio Ríos, J.A. The Application of 3D-Printing Techniques in the Manufacturing of Cement-Based Construction Products and Experiences Based on the Assessment of Such Products. Buildings 2020, 10, 144. [Google Scholar] [CrossRef]

- Ayyagari, R.; Chen, Q.; García de Soto, B. Quantifying the impact of concrete 3D printing on the construction supply chain. Autom. Constr. 2023, 155, 105032. [Google Scholar] [CrossRef]

- Aghimien, D.; Aigbavboa, C.; Aghimien, L.; Thwala, W.; Ndlovu, L. 3D Printing for sustainable low-income housing in south africa: A case for the urban poor. J. Green Build. 2021, 16, 129–141. [Google Scholar] [CrossRef]

- Shahzad, Q.; Shen, J.; Naseem, R.; Yao, Y.; Waqar, S.; Liu, W. Influence of phase change material on concrete behavior for construction 3D printing. Constr. Build. Mater. 2021, 309, 125121. [Google Scholar] [CrossRef]

- Perkins, I.; Skitmore, M. Three-dimensional printing in the construction industry: A review. Int. J. Constr. Manag. 2015, 15, 1–9. [Google Scholar] [CrossRef]

- Faleschini, F.; Trento, D.; Masoomi, M.; Pellegrino, C.; Zanini, M.A. Sustainable mixes for 3D printing of earth-based constructions. Constr. Build. Mater. 2023, 398, 132496. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Hossain, M.A.; Zhumabekova, A.; Paul, S.C.; Kim, J.R. A Review of 3D Printing in Construction and its Impact on the Labor Market. Sustainability 2020, 12, 8492. [Google Scholar] [CrossRef]

- Jiang, R.; Kleer, R.; Piller, F.T. Predicting the future of additive manufacturing: A Delphi study on economic and societal implications of 3D printing for 2030. Technol. Forecast. Soc. Change 2017, 117, 84–97. [Google Scholar] [CrossRef]

- Pal, U.; Zhang, C.; Haupt, T.; Li, H.; Su, L. The Evolution of Construction 5.0: Challenges and Opportunities for the Construction Industry. Buildings 2024, 14, 4010. [Google Scholar] [CrossRef]

- Gharaibeh, L.; Matarneh, S.; Lantz, B.; Eriksson, K. Quantifying the influence of BIM adoption: An in-depth methodology and practical case studies in construction. Results Eng. 2024, 23, 102555. [Google Scholar] [CrossRef]

- Bayhan, H.G.; Demirkesen, S.; Zhang, C.; Tezel, A. A lean construction and BIM interaction model for the construction industry. Prod. Plan. Control. 2023, 34, 1447–1474. [Google Scholar] [CrossRef]

- Auti, S.; Patil, J. Prefabrication Technology—A Promising Alternative in Construction Industry. Int. J. Sci. Res. 2019, 8, 220–224. [Google Scholar]

- Mannan, M.; Al-Ghamdi, S.G. Environmental impact of water-use in buildings: Latest developments from a life-cycle assessment perspective. J. Environ. Manag. 2020, 261, 110198. [Google Scholar] [CrossRef] [PubMed]

- Alaloul, W.S.; Liew, M.S.; Zawawi, N.A.W.A.; Kennedy, I.B. Industrial Revolution 4.0 in the construction industry: Challenges and opportunities for stakeholders. Ain Shams Eng. J. 2020, 11, 225–230. [Google Scholar] [CrossRef]

- Othman, U.; Yang, E. Human–Robot Collaborations in Smart Manufacturing Environments: Review and Outlook. Sensors 2023, 23, 5663. [Google Scholar] [CrossRef]

- Simões, A.; Pinto, A.; Santos, J.; Pinheiro, S.; Romero, D. Designing Human-Robot Collaboration (HRC) Workspaces in Industrial Settings: A Systematic Literature Review. J. Manuf. Syst. 2022, 62, 28–43. [Google Scholar] [CrossRef]

- Dharmapalan, V.; O’Brien, W.J. Benefits and challenges of automated materials technology in industrial construction projects. Proc. Inst. Civ. Eng. Smart Infrastruct. Constr. 2018, 171, 144–157. [Google Scholar] [CrossRef]

- Datta, S.D.; Islam, M.; Rahman Sobuz, M.H.; Ahmed, S.; Kar, M. Artificial intelligence and machine learning applications in the project lifecycle of the construction industry: A comprehensive review. Heliyon 2024, 10, e26888. [Google Scholar] [CrossRef]

- Pärn, E.; Ghadiminia, N.; García de Soto, B.; Oti-Sarpong, K. A perfect storm: Digital twins, cybersecurity, and general contracting firms. Dev. Built Environ. 2024, 18, 100466. [Google Scholar] [CrossRef]

- Govea, J.; Gaibor-Naranjo, W.; Villegas-Ch, W. Securing Critical Infrastructure with Blockchain Technology: An Approach to Cyber-Resilience. Computers 2024, 13, 122. [Google Scholar] [CrossRef]

- Sahebzamani, E.; Forcada, N. Enhancing sustainable construction decisions: Integrating BIM and VR for circular economy assessment. Build. Res. Inf. 2025, 1–21. [Google Scholar] [CrossRef]

- Daoud, A.; Kineber, A.; Ali, A.; Elseknidy, M. Empowering Sustainable Infrastructure and Sustainable Development Goals Through Industry 5.0 Implementation. Sustain. Dev. 2025, 1–24. [Google Scholar] [CrossRef]

- Kravchenko, M.; Kopishynska, K.; Trofymenko, O.; Pyshnograiev, I.; Boiarynova, K. A Framework for Modeling the Decarbonization of the Economy Based on Energy Innovations in the Context of Industry 5.0 and Sustainable Development: International Perspective. Probl. Ekorozwoju 2025, 20, 207–220. [Google Scholar] [CrossRef]

- Cardoso, A.; Colim, A.; Bicho, E.; Braga, A.C.; Arezes, P. A novel human-centered methodology for assessing manual-to-collaborative safe conversion of workstations. Saf. Sci. 2025, 181, 106685. [Google Scholar] [CrossRef]

- Jiao, W.; Jing, K.T.; Esa, M. The Impact of Digital Technology Applications on Construction Industry Project Performance. J. Adv. Res. Appl. Sci. Eng. Technol. 2025, 53, 311–322. [Google Scholar]

- Chen, C.; Zhao, K.; Leng, J.; Liu, C.; Fan, J.; Zheng, P. Integrating large language model and digital twins in the context of industry 5.0: Framework, challenges and opportunities. Robot. Comput. -Integr. Manuf. 2025, 94, 102982. [Google Scholar] [CrossRef]

- Lauria, M.; Azzalin, M. Digital Twin Approach in Buildings: Future Challenges via a Critical Literature Review. Buildings 2024, 14, 376. [Google Scholar] [CrossRef]

- Posillico, J.J.; Edwards, D.J. Developing a proof-of-concept curriculum foundation model for industry 5.0: A primary data survey of built environment academics. Ind. High. Educ. 2024, 38, 423–444. [Google Scholar] [CrossRef]

- Bello, J.O.; Stephen, S.; Adetoro, P.; Mogaji, I.J. Supply chain resilience in the construction industry: A bibliometric review on operations management practices from Industry 4.0 to Industry 5.0. Benchmarking Int. J. ahead-of-print. 2024. [Google Scholar]

- Madankumar, S.; Raju, R.; Rajendran, C.; Ziegler, H. Resilient Scheduling Heuristic for Single Machine Systems to Minimize Variance of Job Completion Time. In International Conference on Recent Advances in Industrial and Systems Engineering; Springer Nature Singapore: Singapore, 2024; pp. 3–13. [Google Scholar]

- Yitmen, I.; Almusaed, A.; Alizadehsalehi, S. Facilitating Construction 5.0 for smart, sustainable and resilient buildings: Opportunities and challenges for implementation. Smart Sustain. Built Environ. 2024. ahead-of-print. [Google Scholar]

- Celik, B.G.; Abraham, Y.S.; Attaran, M. Unlocking Blockchain in Construction: A Systematic Review of Applications and Barriers. Buildings 2024, 14, 1600. [Google Scholar] [CrossRef]

- Snell, D.; Dean, M.; Rainnie, A. Industry 5.0 and the future of work in manufacturing in Australia. In The Handbook for the Future of Work; Routledge: London, UK, 2024; pp. 225–236. Available online: https://www.taylorfrancis.com/chapters/edit/10.4324/9781003327561-25/industry-5-0-future-work-manufacturing-australia-darryn-snell-mark-dean-al-rainnie (accessed on 15 April 2025).

- Balaji, C.R.; Madurwar, M. Eco epo-seal, an ancillary construction material: Pathway to circularity in Industry 5.0. Green Mater. 2024, 40, 1–27. [Google Scholar] [CrossRef]

- Ranjan, C.; Chakraborty, B.; Srinivas, J.; Kumar, K. Drone Swarms in Industry 5.0; IGI Global: New York, NY, USA, 2024; pp. 31–45. [Google Scholar]

- Khodabakhshian, A. Ethics-Aware Application of Digital Technologies in the Construction Industry. In Improving Technology Through Ethics; Chiodo, S., Kaiser, D., Shah, J., Volonté, P., Eds.; Springer Nature Switzerland: Cham, Switzerland, 2024; pp. 49–64. [Google Scholar]

- Jiménez Rios, A.; Petrou, M.L.; Ramirez, R.; Plevris, V.; Nogal, M. Industry 5.0 concepts and enabling technologies, towards an enhanced conservation practice: Systematic literature review protocol. Open Res. Eur. 2024, 4, 75. [Google Scholar] [CrossRef] [PubMed]

- Omrany, H.; Mehdipour, A.; Oteng, D. Digital Twin Technology and Social Sustainability: Implications for the Construction Industry. Sustainability 2024, 16, 8663. [Google Scholar] [CrossRef]

- Stephen, S.S.; Oke, A.E.; Aigbavboa, C.O. Integration of Industry 5.0 Principles in Stealth Construction: Leveraging Emerging Technologies for Efficiency and Sustainability. In Studies in Systems, Decision and Control; Springer: Cham, Switzerland, 2024; pp. 181–197. [Google Scholar]

- Pink, S. Ethnography for construction 5.0. In Embracing Ethnography: Doing Contextualised Construction Research; Taylor & Francis: Abingdon, UK, 2024; pp. 104–119. [Google Scholar]

- Jiménez Rios, A.; Petrou, M.L.; Ramirez, R.; Plevris, V.; Nogal, M. Industry 5.0, towards an enhanced built cultural heritage conservation practice. J. Build. Eng. 2024, 96, 110542. [Google Scholar] [CrossRef]

- Sajjadian, S.M. Architecting net zero: From drawings to bytes. J. Build. Eng. 2024, 95, 110094. [Google Scholar] [CrossRef]

- Majumder, S.; Dey, N. Metaverse for Industry 5.0. In SpringerBriefs in Applied Sciences and Technology; Springer: Singapore, 2024; pp. 1–70. [Google Scholar]

- Moshood, T.D.; Nawanir, G.; Lee, C.K.; Fauzi, M.A. Toward sustainability and resilience with Industry 4.0 and Industry 5.0. Sustain. Futures 2024, 8, 100349. [Google Scholar] [CrossRef]

- Fan, L.; Wang, Y.; Zhang, H.; Zeng, C.; Li, Y.; Gou, C.; Yu, H. Multimodal Perception and Decision-Making Systems for Complex Roads Based on Foundation Models. IEEE Trans. Syst. Man Cybern. Syst. 2024, 54, 6561–6569. [Google Scholar] [CrossRef]

- Bănică, C.-F.; Sover, A.; Anghel, D.-C. Printing the Future Layer by Layer: A Comprehensive Exploration of Additive Manufacturing in the Era of Industry 4.0. Appl. Sci. 2024, 14, 9919. [Google Scholar] [CrossRef]

- Shehata, A.O.; Noroozinejad Farsangi, E.; Mirjalili, S.; Yang, T.Y. A State-of-the-Art Review and Bibliometric Analysis on the Smart Preservation of Heritages. Buildings 2024, 14, 3818. [Google Scholar] [CrossRef]

- Murali, D.; Suresh, M.; Raman, R. Breaking down to build up: How deconstruction and carbon finance foster sustainable, resilient construction in the industry 5.0 era. Constr. Innov. 2024. ahead-of-print. [Google Scholar]

- Binfield, L.; Nasir, V.; Dai, C. Bamboo industrialization in the era of Industry 5.0: An exploration of key concepts, synergies and gaps. Environ. Dev. Sustain. 2024, 1–32. [Google Scholar] [CrossRef]

- Mitera-Kiełbasa, E.; Zima, K. BIM Policy Trends in Europe: Insights from a Multi-Stage Analysis. Appl. Sci. 2024, 14, 4363. [Google Scholar] [CrossRef]

- Gowda, D.D.; Jagtap, M.; Tarambale, M.; Prasad, K.D.V. Innovative Horizons in Drone Technology for Construction During Industry 5.0. In Drone Applications for Industry 5.0; IGI Global: New York, NY, USA, 2024; pp. 190–203. [Google Scholar]

- Kantumchu, V.C.; Moinuddin, S.Q.; Dewangan, A.K.; Cheepu, M. Quality Assurance and Control in Welding and Additive Manufacturing. In Automation in the Welding Industry: Incorporating Artificial Intelligence, Machine Learning and Other Technologies; John Wiley & Sons: Hoboken, NJ, USA, 2024; pp. 245–262. [Google Scholar]

- Piroozfar, P.; Farr, E. ARCHITECTURE, ENGINEERING, AND CONSTRUCTION (AEC) INDUSTRY 4.0 AND BEYOND: Building Construction Automation through 3D Printing and Additive Manufacturing Toward Lower Environmental Impacts. In The Routledge Companion to Smart Design Thinking in Architecture & Urbanism for a Sustainable, Living Planet; Routledge: London, UK, 2024; pp. 643–651. [Google Scholar]

- Almusaed, A.; Yitmen, I.; Almssad, A.; Myhren, J.A. Construction 5.0 and Sustainable Neuro-Responsive Habitats: Integrating the Brain–Computer Interface and Building Information Modeling in Smart Residential Spaces. Sustainability 2024, 16, 9393. [Google Scholar] [CrossRef]

- Nwaogu, J.M.; Yang, Y.; Chan, A.P.C.; Wang, X. Enhancing Drone Operator Competency within the Construction Industry: Assessing Training Needs and Roadmap for Skill Development. Buildings 2024, 14, 1153. [Google Scholar] [CrossRef]

- Davila-Gonzalez, S.; Martin, S. Human Digital Twin in Industry 5.0: A Holistic Approach to Worker Safety and Well-Being through Advanced AI and Emotional Analytics. Sensors 2024, 24, 655. [Google Scholar] [CrossRef] [PubMed]

- Jiménez Rios, A.; Nogal, M.; Plevris, V.; Ramirez Alvarez de Lara, R.; Petrou, M. Towards Enhanced Built Cultural Heritage Conservation Practices: Perceptions on Industry 5.0 Principles and Enabling Technologies. Hist. Environ. Policy Pract. 2024, 15, 1–27. [Google Scholar] [CrossRef]

- Zheng, P.; Yin, Y.; Wang, T.; Wan, K. Society 5.0: Social implications, technoethics, and social acceptance. In Manufacturing from Industry 4.0 to Industry 5.0; Mourtzis, D., Ed.; Elsevier: Amsterdam, The Netherlands, 2024; pp. 133–178. [Google Scholar]

- Edirisinghe, R.; Jayasuriya, S.; Almulla, J.; Abobakr, M.; Bastos Costa, D.; Alberte, E.; Hastak, M.; Tzortzopoulos, P. Gender diversity in construction: Demystifying the pipeline leaks in Australia, United States, United Kingdom and Brazil. Int. J. Constr. Manag. 2024, 1–15. [Google Scholar] [CrossRef]

- Ohueri, C.C.; Masrom, M.A.N.; Noguchi, M. Human-robot collaboration for building deconstruction in the context of construction 5.0. Autom. Constr. 2024, 167, 105723. [Google Scholar] [CrossRef]

- Lind, A.; Elango, V.; Hanson, L.; Högberg, D.; Lämkull, D.; Mårtensson, P.; Syberfeldt, A. Multi-objective optimization of an assembly layout using nature-inspired algorithms and a digital human modeling tool. IISE Trans. Occup. Ergon. Hum. Factors 2024, 12, 175–188. [Google Scholar] [CrossRef]

- Hwangbo, Y. Korea’s Citizen-Centric Smart City Development by Adopting Living Labs and Design Thinking Methodologies and Their Implications for ASEAN Countries. In Sustainable Development and the Digital Economy: Human-Centricity, Sustainability and Resilience in Asia; Routledge: London, UK, 2023; pp. 244–266. [Google Scholar]

- Gibbin, R.V.; Sigahi, T.F.A.C.; Pinto, J.d.S.; Rampasso, I.S.; Anholon, R. Thematic evolution and trends linking sustainability and project management: Scientific mapping using SciMAT. J. Clean. Prod. 2023, 414, 137753. [Google Scholar] [CrossRef]

- Lauria, M.; Azzalin, M. Digital Twin Approach for Maintenance Management. In Technological Imagination in the Green and Digital Transition; Springer International Publishing: Cham, Switzerland, 2023. [Google Scholar]

- Agostinho, C.; Dikopoulou, Z.; Lavasa, E.; Perakis, K.; Pitsios, S.; Branco, R.; Reji, S.; Hetterich, J.; Biliri, E.; Lampathaki, F.; et al. Explainability as the key ingredient for AI adoption in Industry 5.0 settings. Front. Artif. Intell. 2023, 6, 1264372. [Google Scholar] [CrossRef]

- Miklosik, A.; Krah, A.B. Perspectives on Digital Transformation Initiatives in the Mechanical Engineering Industry. Appl. Sci. 2023, 13, 12386. [Google Scholar] [CrossRef]

- Musarat, M.A.; Irfan, M.; Alaloul, W.S.; Maqsoom, A.; Ghufran, M. A Review on the Way Forward in Construction through Industrial Revolution 5.0. Sustainability 2023, 15, 13862. [Google Scholar] [CrossRef]

- Trivedi, S.; Tiwari, S. 14 The resurgence of augmented reality and virtual reality in construction: Past, present, and future directions. In Augmented and Virtual Reality in Industry 5.0; Richa, G., Sukanta Kumar, B., Tapas, M., Vishal, J., Eds.; De Gruyter: Berlin, Germany, 2023; pp. 275–292. [Google Scholar]

- Bassir, D.; Lodge, H.; Chang, H.; Majak, J.; Chen, G. Application of artificial intelligence and machine learning for BIM: Review. Int. J. Simul. Multidisci. Des. Optim. 2023, 14, 5. [Google Scholar] [CrossRef]

- Aladağ, H. Assessing the Accuracy of ChatGPT Use for Risk Management in Construction Projects. Sustainability 2023, 15, 16071. [Google Scholar] [CrossRef]

- Mat Yaman, K.; Abd Ghadas, Z. Building Contract in the Fifth Industrial Revolution: Embedding Sustainable Design and Construction Practices. In From Industry 4.0 to Industry 5.0: Mapping the Transitions; Springer Nature Switzerland: Cham, Switzerland, 2023; pp. 947–956. [Google Scholar]

- Hu, C.; Liu, P.; Yang, H.; Yin, S.; Ullah, K. A novel evolution model to investigate the collaborative innovation mechanism of green intelligent building materials enterprises for construction 5.0. AIMS Math. 2023, 8, 8117–8143. [Google Scholar] [CrossRef]

- Carayannis, E.G.; Morawska, J. University and Education 5.0 for Emerging Trends, Policies and Practices in the Concept of Industry 5.0 and Society 5.0. In Industry 5.0: Creative and Innovative Organizations; Springer Nature: Berlin/Heidelberg, Germany, 2023; pp. 1–25. [Google Scholar]

- V Prabhakar, V.; Belarmin Xavier, C.S.; Abubeker, K.M. A Review on Challenges and Solutions in the Implementation of Ai, IoT and Blockchain in Construction Industry. Mater. Today Proc. 2023, in press. [CrossRef]

- Yang, J.; Huang, Q.; Ge, S.; Wang, X.; Chen, L.; Guo, Y.; Gui, T. On Intelligent Mining With Parallel Intelligence. IEEE Trans. Intell. Veh. 2023, 8, 4296–4300. [Google Scholar] [CrossRef]

- Dosumu, O.; Uwayo, S. Modelling the adoption of Internet of things (IoT) for sustainable construction in a developing economy. Built Environ. Proj. Asset Manag. 2023, 13, 394–411. [Google Scholar] [CrossRef]

- Hadi, A.; Chenug, F.; Adjei, S.; Dulaimi, A. Evaluation of Lean Off-Site Construction Literature through the Lens of Industry 4.0 and 5.0. J. Constr. Eng. Manag. 2023, 149, 03123007. [Google Scholar] [CrossRef]

- Almusaed, A.; Yitmen, I.; Almssad, A. Reviewing and Integrating AEC Practices into Industry 6.0: Strategies for Smart and Sustainable Future-Built Environments. Sustainability 2023, 15, 13464. [Google Scholar] [CrossRef]

- Traverso-Frisancho, A.; Romero-Alva, V. Application of BIM Methodology in Public and Private Electricity and Telecommunications Projects in Peru. Int. J. Eng. Trends Technol. 2023, 71, 67–74. [Google Scholar] [CrossRef]

- Uddin, M. Greater influence of 3D-printable sustainable concrete and industrial waste on Industry 5.0. In Implications of Industry 5.0 on Environmental Sustainability; IGI Global: New York, NY, USA, 2022; p. 36. [Google Scholar]

- Dhawan, K.; Tookey, J.; Ghaffarianhoseini, A.; Ghaffarianhoseini, A. Greening Construction Transport as a Sustainability Enabler for New Zealand: A Research Framework. Front. Built Environ. 2022, 8, 871958. [Google Scholar] [CrossRef]

- Mangialardi, G.; Corallo, A.; Lazoi, M.; Scozzi, B. Process View to Innovate the Management of the Social Housing System: A Multiple Case Study. Sustainability 2022, 14, 8294. [Google Scholar] [CrossRef]

- Callarisa, L.; Sanchez, J.; Moliner, M.A.; Rodriguez, R.M.; Fandos, J.C. Comparative Study of Digitalization in the Spanish Ceramic Sector from a Marketing Perspective over the Period 2017–2021. CFI Ceram. Forum Int. 2022, 99, E44–E53. [Google Scholar]

- Rana, T.; Maqbool, A.; Rana, T.A.; Mirza, A.; Iqbal, Z.; Khan, M.A.; Alhaisoni, M.; Alqahtani, A.; Kim, Y.J.; Chang, B. Achieving stepwise construction of cyber physical systems in EX-MAN component model. J. King Saud Univ. Comput. Inf. Sci. 2022, 34, 10319–10338. [Google Scholar] [CrossRef]

- Subha, R.; Zhang, J. An optimal construction of smart aged homes based on SDLC using smart sensors and agent networks. Int. J. Intell. Netw. 2022, 3, 138–142. [Google Scholar] [CrossRef]

- Osei-Kyei, R.; Narbaev, T.; Ampratwum, G. A Scientometric Analysis of Studies on Risk Management in Construction Projects. Buildings 2022, 12, 1342. [Google Scholar] [CrossRef]

| Construction 5.0 |

|---|

| “Construction 5.0”OR (“Operator 5.0” and “construction”) OR(“Industry 5.0” OR “Industrial 5.0”) AND (“Construction industry” OR “Human-Centric in Construction” OR “HRC in Construction” OR “Robot in Construction” OR “Building” OR “AEC industry” OR “Resilience in Construction” OR “sustainability in Construction” OR “Automation in Construction” OR “3D printing in construction” OR “Blockchain in construction” OR “Digital twins in construction” OR “IoT in construction” OR “Augmented reality in construction” OR “Virtual reality in construction” OR “Mixed reality in construction” OR “Machine learning in construction” OR “machine learning in construction” OR “cloud computing in construction” OR “metaverse in construction” OR “AI in construction”) |

| Journal Title | Documents |

|---|---|

| Sustainability (Switzerland) | 8 |

| Buildings | 7 |

| Applied Sciences (Switzerland) | 4 |

| Journal of Building Engineering | 3 |

| Studies in Systems, Decision and Control | 2 |

| Automation in Construction | 2 |

| SpringerBriefs in Applied Sciences and Technology | 2 |

| Drone Applications for Industry 5.0 | 2 |

| Environment, Development and Sustainability | 1 |

| CFI Ceramic Forum International | 1 |

| Names | Total Link Strength | Citations |

|---|---|---|

| Zheng P. | 2836 | 50 |

| Wang L. | 2668 | 70 |

| Zhang C. | 2591 | 35 |

| Li X. | 2277 | 53 |

| Wang Y. | 1665 | 37 |

| Li Y. | 1651 | 48 |

| Xu X. | 1638 | 48 |

| Liu Y. | 1617 | 34 |

| Lu Y. | 1610 | 53 |

| Li J. | 1496 | 28 |

| Wang B. | 1488 | 30 |

| Zhang Y. | 1481 | 40 |

| Label | Cluster | Links | Total Link Strength | Occurrences | Avg. Citations |

|---|---|---|---|---|---|

| Industry 5.0 | 5 | 41 | 118 | 37 | 12.1 |

| Construction industry | 2 | 27 | 65 | 16 | 17.7 |

| Industry 4.0 | 1 | 33 | 61 | 15 | 21.9 |

| Sustainability | 3 | 23 | 48 | 13 | 5.2 |

| Human centricity | 5 | 26 | 44 | 9 | 10 |

| Artificial intelligence | 1 | 23 | 39 | 8 | 25.5 |

| Life cycle | 3 | 24 | 38 | 5 | 45.4 |

| Architectural design | 2 | 18 | 34 | 7 | 26.5 |

| Blockchain | 1 | 20 | 34 | 4 | 37 |

| Project management | 1 | 19 | 31 | 7 | 26 |

| Digital twin | 1 | 19 | 30 | 6 | 21.8 |

| Building information modeling | 1 | 20 | 26 | 4 | 30.5 |

| Construction 5.0 | 2 | 19 | 24 | 8 | 20.1 |

| Resilience | 5 | 9 | 24 | 7 | 3.9 |

| Title | Year | Cite |

|---|---|---|

| Towards new-generation human-centric smart manufacturing in Industry 5.0: A systematic review [37] | 2023 | 100 |

| Investigating the Use of ChatGPT for the Scheduling of Construction Projects [38] | 2023 | 79 |

| BIM Information Integration Based VR Modeling in Digital Twins in Industry 5.0 [39] | 2022 | 73 |

| Construction 4.0, Industry 4.0, and Building Information Modeling (BIM) for Sustainable Building Development within the Smart City [40] | 2022 | 70 |

| Artificial Intelligence Enabled Project Management: A Systematic Literature Review [41] | 2023 | 48 |

| From Industry 4.0 to Construction 5.0: Exploring the Path towards Human–Robot Collaboration in Construction [7] | 2023 | 42 |

| Integrated practices in the Architecture, Engineering, and Construction industry: Current scope and pathway towards Industry 5.0 [42] | 2023 | 32 |

| Challenges and opportunities of augmented reality during the construction phase [19] | 2022 | 29 |

| Investigating the Causal Relationships among Enablers of the Construction 5.0 Paradigm: Integration of Operator 5.0 and Society 5.0 with Human-Centricity, Sustainability, and Resilience [43] | 2023 | 21 |

| Human–Robot Collaboration and Lean Waste Elimination: Conceptual Analogies and Practical Synergies in Industrialized Construction [18] | 2022 | 17 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akhavan, M.; Alivirdi, M.; Jamalpour, A.; Kheradranjbar, M.; Mafi, A.; Jamalpour, R.; Ravanshadnia, M. Impact of Industry 5.0 on the Construction Industry (Construction 5.0): Systematic Literature Review and Bibliometric Analysis. Buildings 2025, 15, 1491. https://doi.org/10.3390/buildings15091491

Akhavan M, Alivirdi M, Jamalpour A, Kheradranjbar M, Mafi A, Jamalpour R, Ravanshadnia M. Impact of Industry 5.0 on the Construction Industry (Construction 5.0): Systematic Literature Review and Bibliometric Analysis. Buildings. 2025; 15(9):1491. https://doi.org/10.3390/buildings15091491

Chicago/Turabian StyleAkhavan, Mahdi, Mahsa Alivirdi, Amirhossein Jamalpour, Mohammad Kheradranjbar, Abolfazl Mafi, Reza Jamalpour, and Mehdi Ravanshadnia. 2025. "Impact of Industry 5.0 on the Construction Industry (Construction 5.0): Systematic Literature Review and Bibliometric Analysis" Buildings 15, no. 9: 1491. https://doi.org/10.3390/buildings15091491

APA StyleAkhavan, M., Alivirdi, M., Jamalpour, A., Kheradranjbar, M., Mafi, A., Jamalpour, R., & Ravanshadnia, M. (2025). Impact of Industry 5.0 on the Construction Industry (Construction 5.0): Systematic Literature Review and Bibliometric Analysis. Buildings, 15(9), 1491. https://doi.org/10.3390/buildings15091491