1. Introduction

Full-face rock Tunnel Boring Machines (TBMs) are special tunnel excavation machinery suitable for construction operations under hard-rock geological conditions. Their working principle involves the use of a specific cutting device to fragment the rock and quickly transporting the crushed rock through a dedicated transport system. Compared to traditional blasting excavation methods, TBMs offer rapid construction speeds, significantly shortening project duration, especially when tunneling long distances in stable rock formations [

1,

2]. Zhang et al. [

3] have compared TBM methods with traditional drill-and-blast techniques, highlighting TBMs’ advantages such as faster excavation, reduced environmental impact, and enhanced safety, despite their higher costs and lower adaptability, while AI enhances their predictive accuracy and the Metaverse enables immersive infrastructure solutions. Furthermore, the TBM method allows for the precise control of the excavation section, ensuring accurate tunnel dimensions and shapes, optimizing the support work required, and enhancing engineering quality [

4,

5,

6,

7]. These advantages have led to the widespread adoption of the TBM method in modern tunnel construction, including highway tunnels, railway tunnels, and tunnels for large-scale water conservancy, hydropower, and water diversion projects.

The TBM tunneling process inevitably generates enormous amounts of sandstone waste, which is often not effectively managed. Most of the residue is discarded and piled up, occupying valuable land resources and polluting soil and water. Therefore, exploring recycling pathways for the sandstone waste from TBM tunneling has become particularly urgent. Among the various recycling approaches, utilizing the sandstone waste from TBM tunneling to produce fine aggregate concrete demonstrates significant advantages and potential [

8,

9]. Fine aggregate concrete, a high-performance building material, is widely used in various civil engineering projects. Recycling the sandstone waste from TBM tunneling to produce fine aggregate concrete can not only effectively address the disposal issue of sandstone waste, but also provide quality building materials for related projects, thereby achieving a win–win situation by reducing resource waste, conserving natural concrete aggregate resources, and lowering engineering costs, yielding significant economic and social benefits.

Numerous scholars have studied the characteristics of Tunnel Boring Machine (TBM) excavation materials and analyzed the feasibility of recycling them as concrete aggregates. The results indicate that TBM excavation materials can be utilized as concrete aggregates after appropriate treatment. Olbrecht and Studer [

10] have recycled six types of TBM excavation materials with different properties and used them as coarse aggregates to produce concrete with a cubic compressive strength of 30 MPa. Their results indicate that, compared with ordinary concrete, concrete prepared with TBM aggregates exhibits higher shrinkage and a relatively lower elastic modulus. Alnuaim et al. [

11] have analyzed the engineering properties of TBM-excavated material and its potential as a concrete aggregate through various mechanical and thermal processing methods. Their results showed that, while the compressive strength of TBM aggregate-based concrete is slightly lower than that of control mixtures, thermal treatment can mitigate this strength loss. The porosity and chloride diffusivity of TBM aggregate-based concrete were somewhat higher; the aggregate processing method had a negligible impact on strength and durability, especially at lower aggregate contents. Additionally, predictive models have been developed to forecast the strength and durability of TBM aggregate-based concrete, aiding in future material utilization and design optimization. Alnuaim et al. [

12] assessed the performance of different mixtures of TBM-crushed limestone and granular materials to explore the feasibility of utilizing limestone crushed by Tunnel Boring Machines (TBMs) as a building material based on dynamic and static strength testing. Their results indicate that TBM-crushed limestone powder is feasible as a road-based material by conducting screening operations at the site and adding 3/8-inch aggregate at a ratio of 5–10% to the limestone powder. Tokgöz et al. [

13] conducted laboratory testing of the physical and mechanical properties of TBM-excavated materials, which provided a detailed analysis of the geological structure, classification, and characteristics of the excavated materials, and proposed a design scheme for utilizing them as fill in abandoned quarry reservoirs.

Priyadharshini et al. [

14] investigated the influence of thermal treatment on the properties of excavated soil as a fine aggregate in cement mortar. The thermal treatment of these soils at temperatures ranging from 200 °C to 1000 °C was conducted, and changes in their mineralogy and physical properties were analyzed using thermogravimetric analysis (TGA) and X-ray diffraction (XRD). The results showed that, as fine aggregate in cement mortar, thermally treated soils reduced water demand, increased dry density, and enhanced compressive strength; furthermore, this process can transform high-plasticity excavated soil into a suitable fine aggregate for cement mortar, with property improvements depending on soil mineralogy and treatment conditions. The drying shrinkage of the mixed mortar was significantly reduced, and its permeable pore volume decreased, improving durability. Voit and Zimmermann [

15] examined the mechanical properties of concrete utilizing various tunnel excavation materials as aggregates in combination with different cement types, measured the parameters of both freshly mixed and hardened concrete, along with factors related to concrete fracture, and also conducted a comparison between the characteristics of plain concrete and fiber-reinforced concrete that incorporated aggregates sourced from tunnel excavation materials. Their results showed that washing the aggregate resulted in a 20% increase in compressive strength, which was attributed to the removal of adhering fines. Adding admixtures and hydraulically active additives enhanced the workability of the concrete, whereas it caused a decrease in density and compressive strength. Notably, adding fibers could improve the concrete’s fire resistance and mechanical properties.

Existing studies have demonstrated that the morphological characteristics of coarse aggregates and stone powder content in machine-made sand substantially influence concrete’s mechanical performance and workability [

16,

17,

18]. Nevertheless, existing research exhibits notable limitations in addressing TBM-excavated materials. Despite the well-documented challenges posed by TBM-generated aggregates, particularly their inherently high flakiness indices and elevated stone powder concentrations, current research efforts remain inadequate in providing an optimized particle size distribution that comprehensively accounts for these material-specific characteristics. While partial investigations have explored the incorporation of recycled TBM tunnel excavation materials as coarse aggregate blends with conventional aggregates, critical knowledge gaps persist regarding their application as fine aggregates (manufactured sand). Therefore, in this study, the recycled TBM-excavated materials underwent mechanical processing involving crushing and multi-stage screening. This treatment effectively reshaped irregular rock fragments into geometrically favorable coarse aggregates for sprayed concrete while eliminating undersized particles. Then, blending the graded fine aggregates (obtained from the crushed flaky TBM aggregates) with pre-screened fine aggregates in a critical ratio produced machine-made sand with an optimized particle gradation and controlled stone powder content. Eventually, through systematic mix design optimization trials and rebound resistance assessments, this investigation elucidated the parametric interdependencies between composition variables (water–binder ratio, sand fraction, fly ash dosage, fiber reinforcement, and accelerator concentration) and the resultant concrete performance metrics—encompassing fresh-state workability, hardened-state mechanical properties (compressive/flexural strength), and spraying efficiency. The study concurrently formulated mitigation strategies for rebound control while establishing an evidence-based framework for engineering applications using TBM-excavated geomaterials as sustainable concrete aggregates.

4. Conclusions

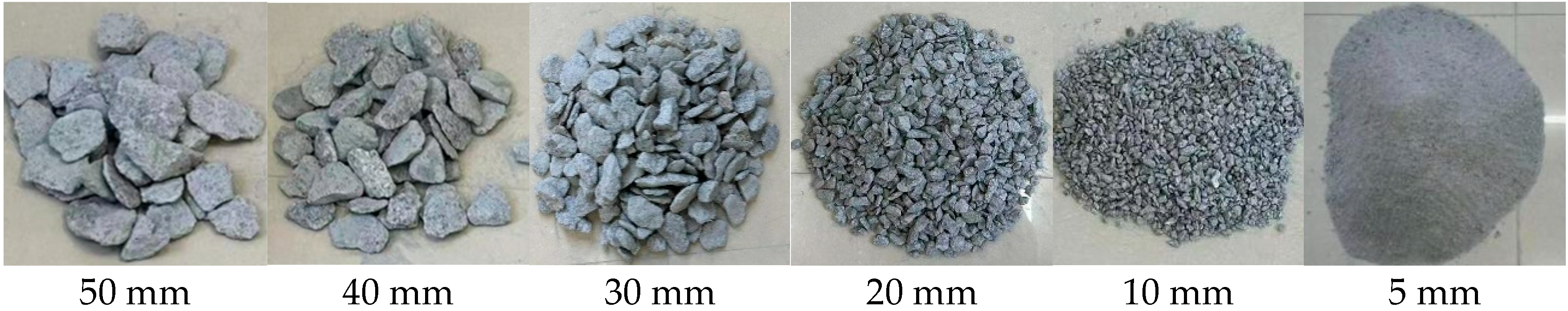

The 5–10 mm particles obtained from recycled TBM tunnel excavation materials exhibit low elongated and flaky contents (4%), making them suitable for concrete production. The manufactured sand initially screened from TBM tunnel excavation materials shows a poor particle size distribution and excessive stone powder content of around 40%. Crushing TBM-excavated flaky rocks above 10 mm in size and blending the screened particles below 5 mm with the manufactured sand in a 4:1 ratio can optimize the gradation distribution of the manufactured sand while reducing its stone powder content to a suitable level (18%), thus meeting the requirements for shotcrete preparation.

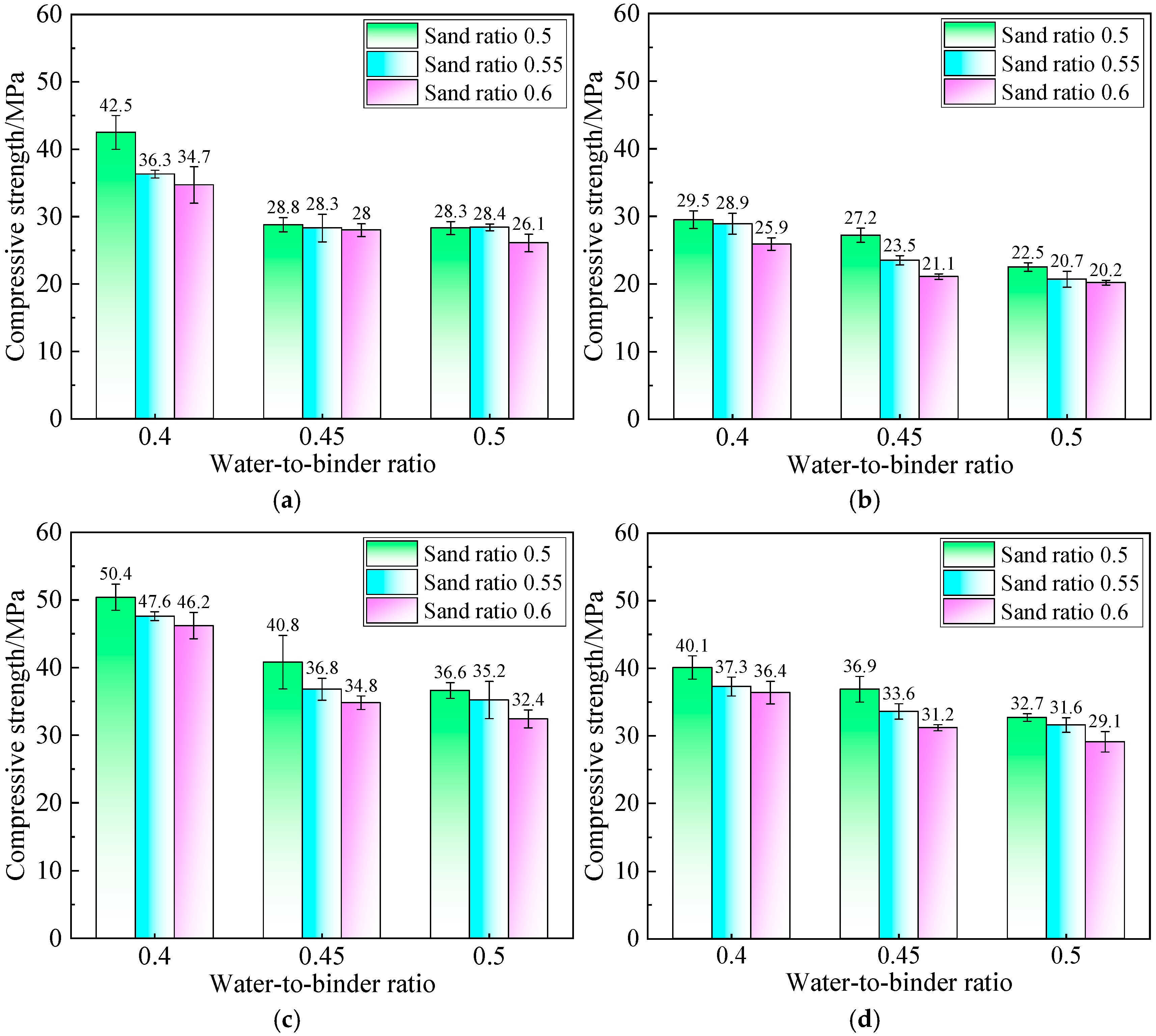

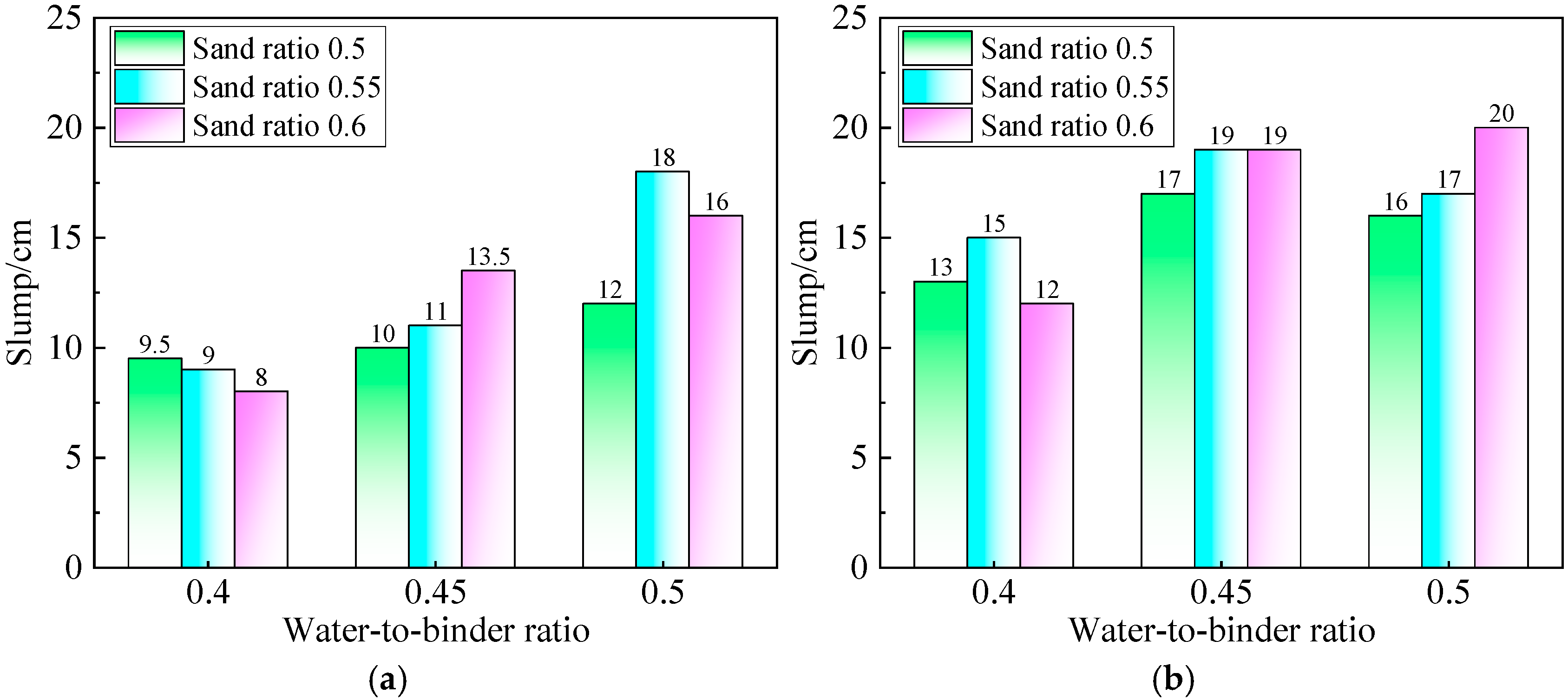

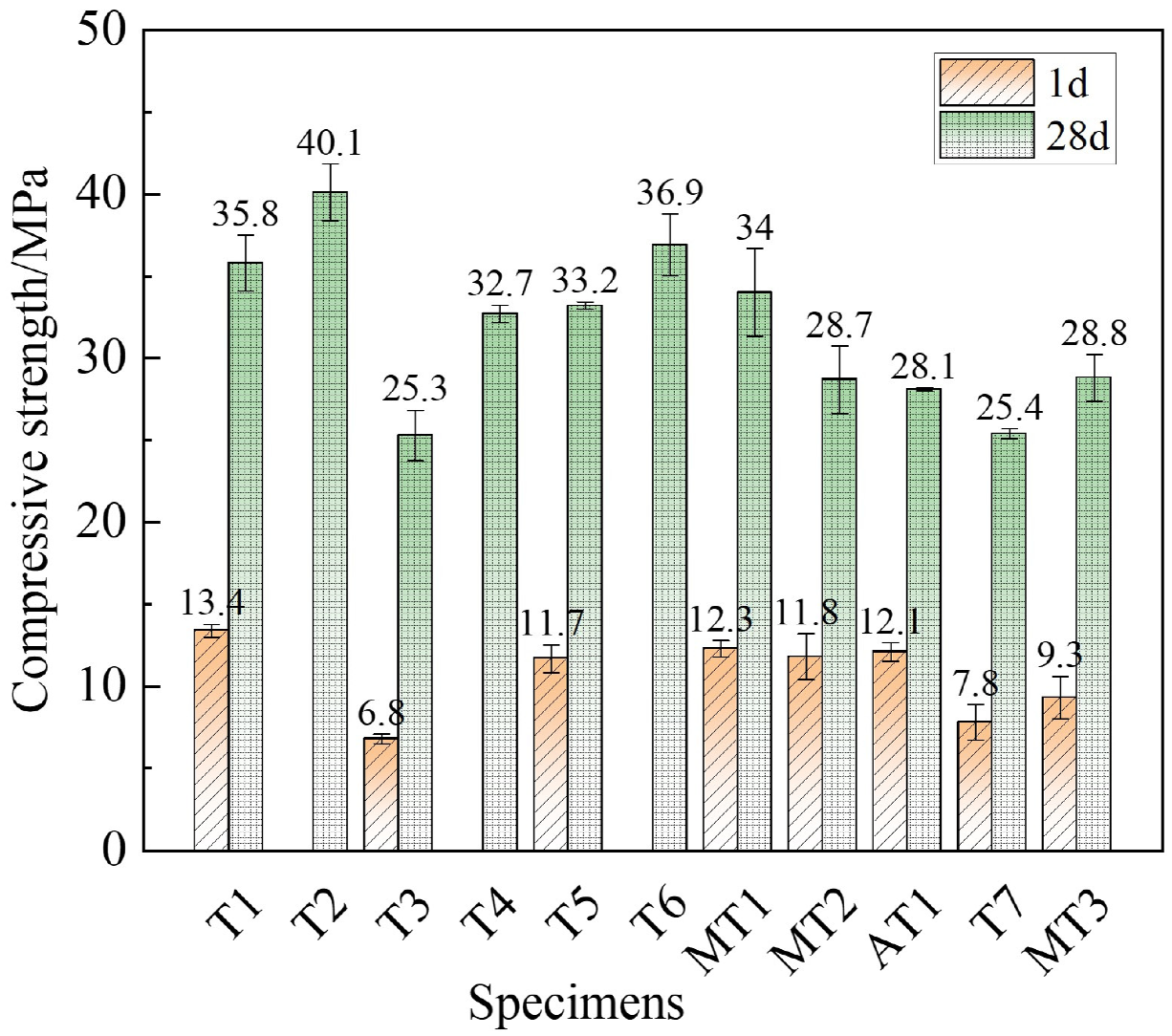

The strength characteristics of TBM concrete demonstrate significant sensitivity to variations in the water-to-binder ratio and fly ash content. It also exhibits a moderate sensitivity to the sand ratio; increasing it from 0.5 to 0.6 caused around an 8–15% strength reduction (28-day) in the concrete mixes, regardless of fly ash incorporation. An increase in the water-to-binder ratio from 0.4 to 0.5 resulted in divergent 28–day strength responses: the non-fly-ash concrete experienced a 26–29% strength decline, while the fly-ash-modified concrete showed a mitigated 15–20% reduction. Specifically, substituting 20% of the cement with fly ash induced distinct strength effects across water-to-binder ratios: a 20% reduction at a 0.4 ratio versus approximately 10% reductions at 0.45 and 0.5. By systematically optimizing key parameters, such as water-to-binder ratio and aggregate proportioning, engineers can design TBM fine aggregate concrete mixtures that meet C25, C30, and C35 strength requirements while ensuring excellent workability.

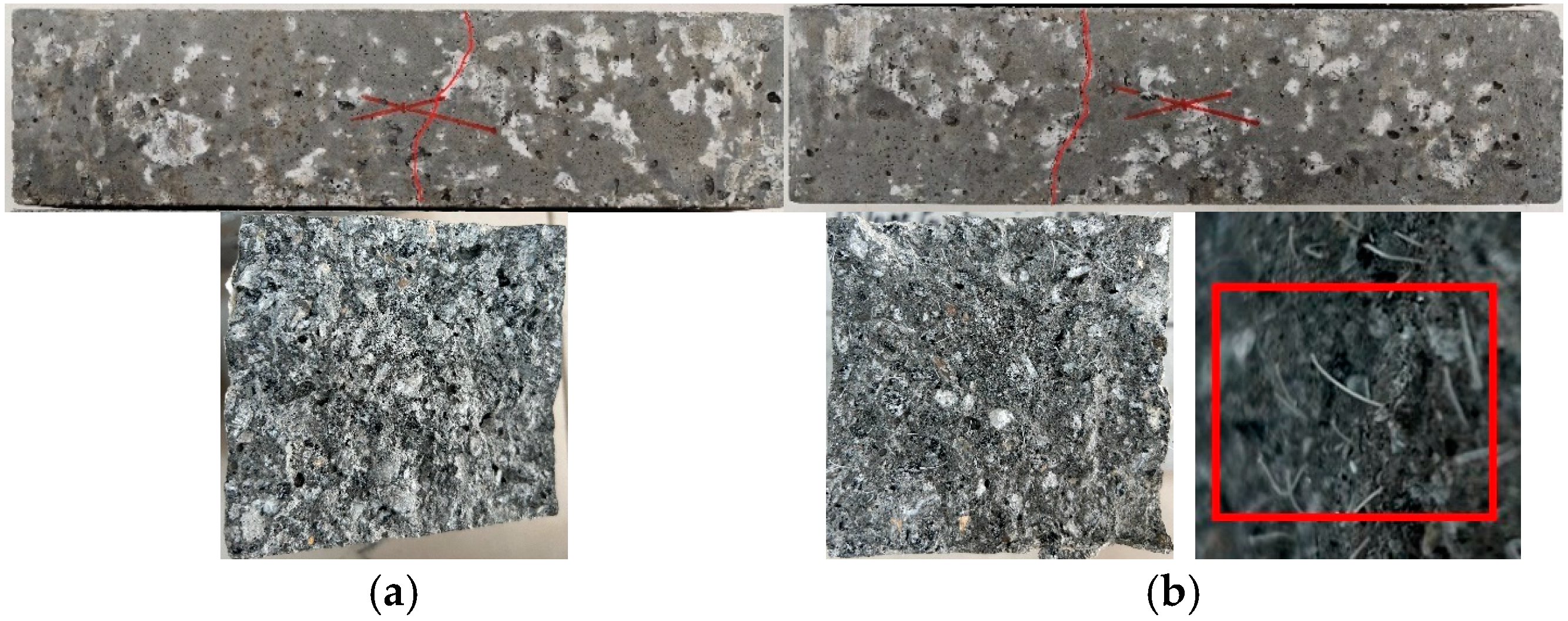

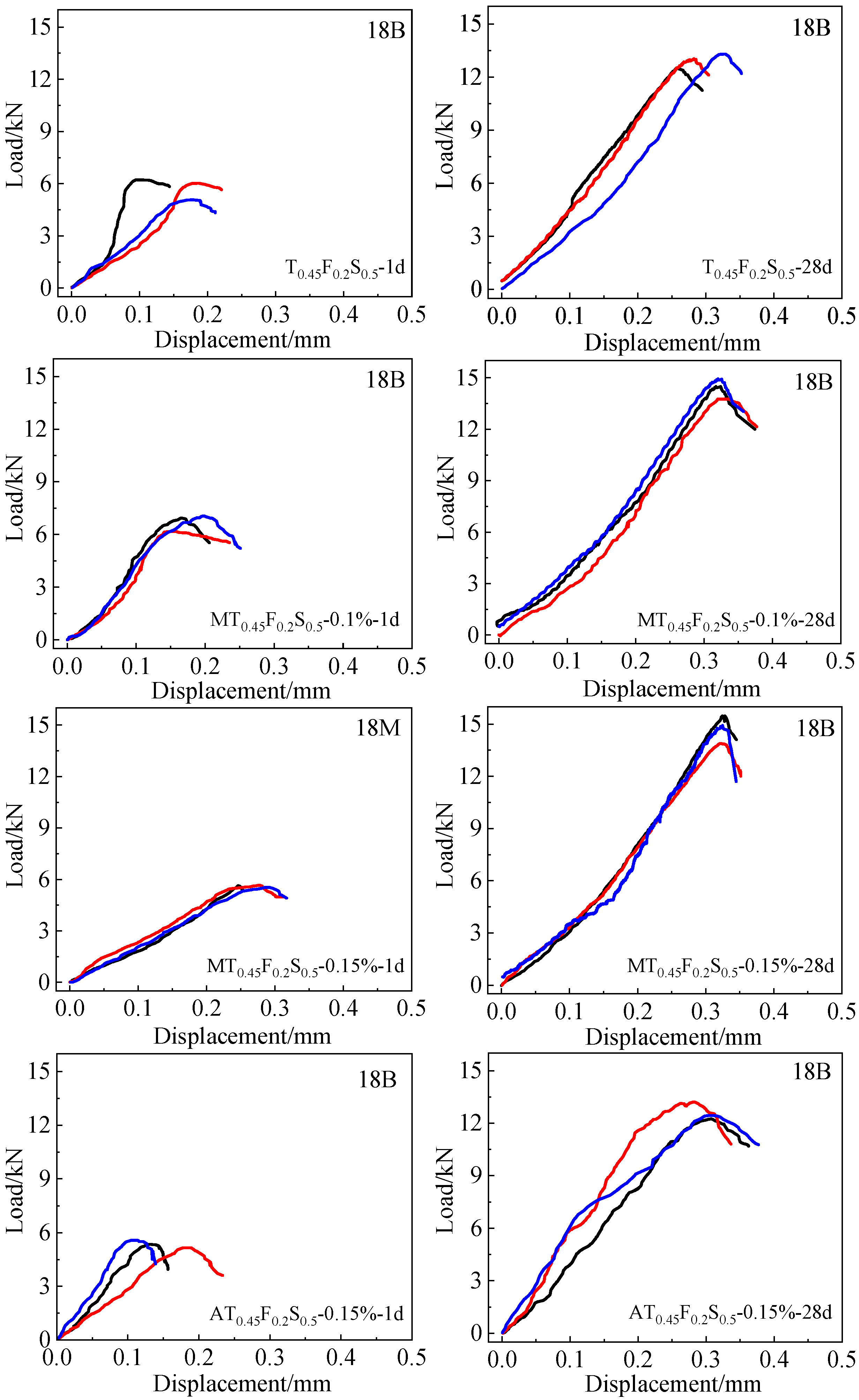

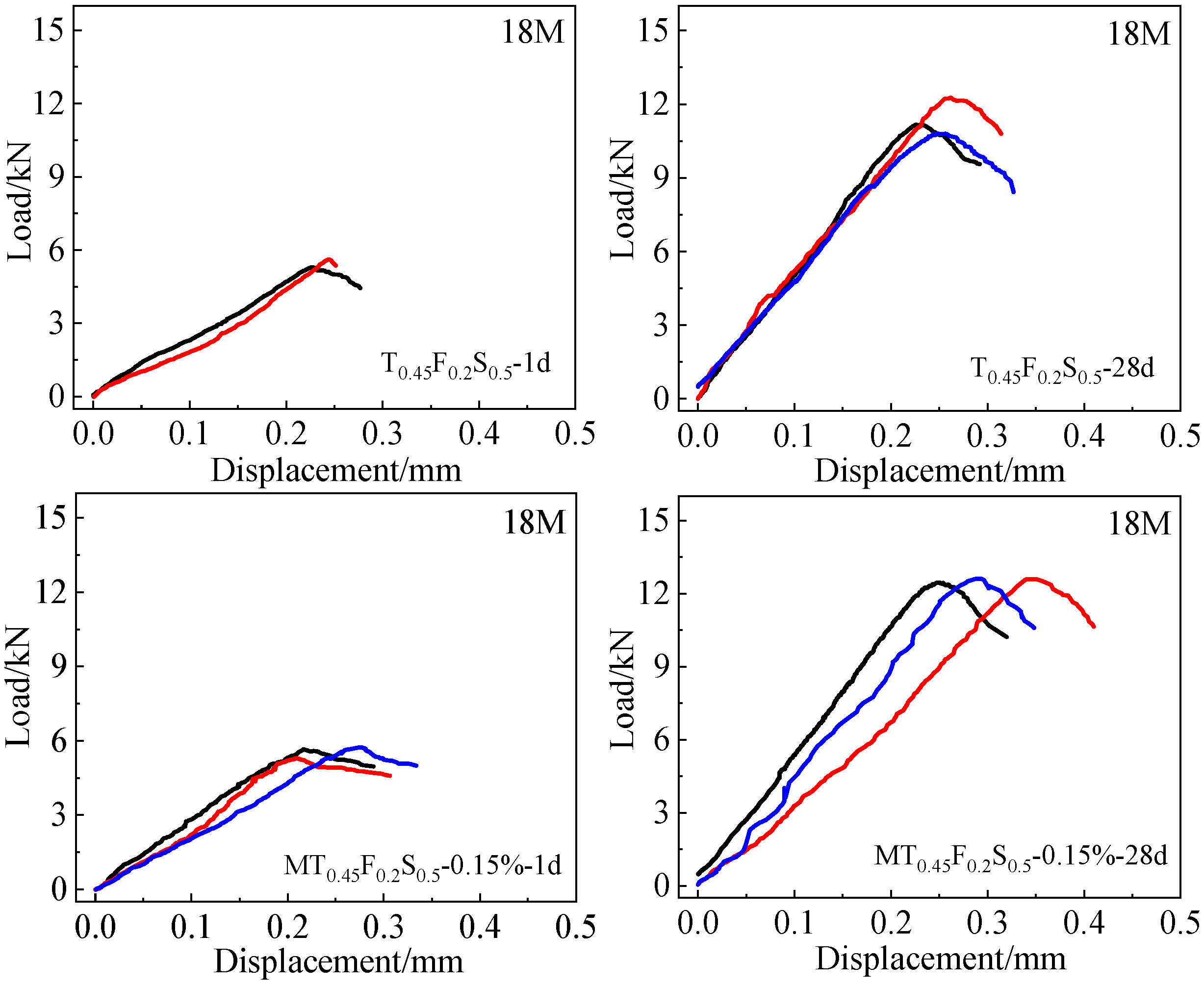

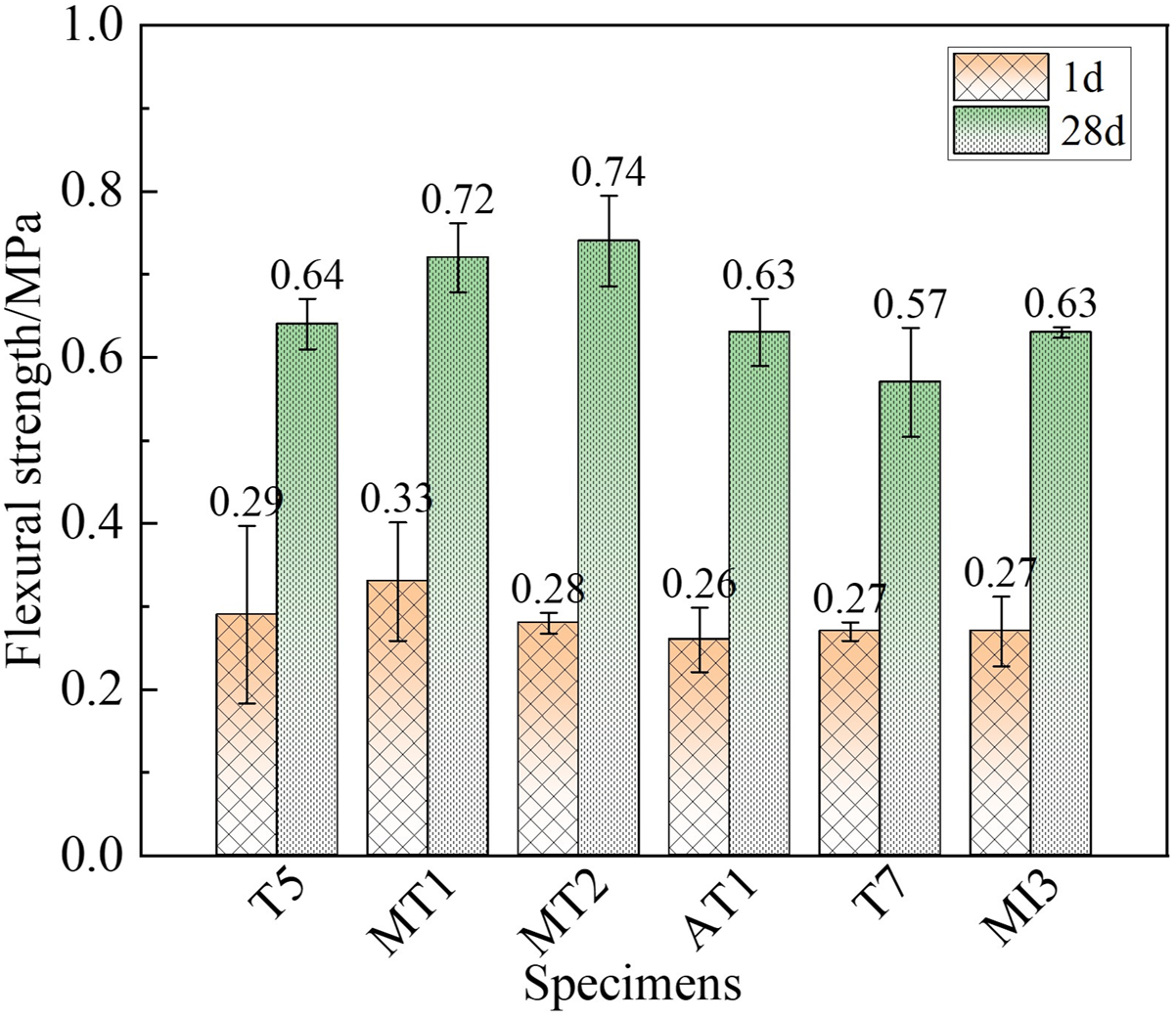

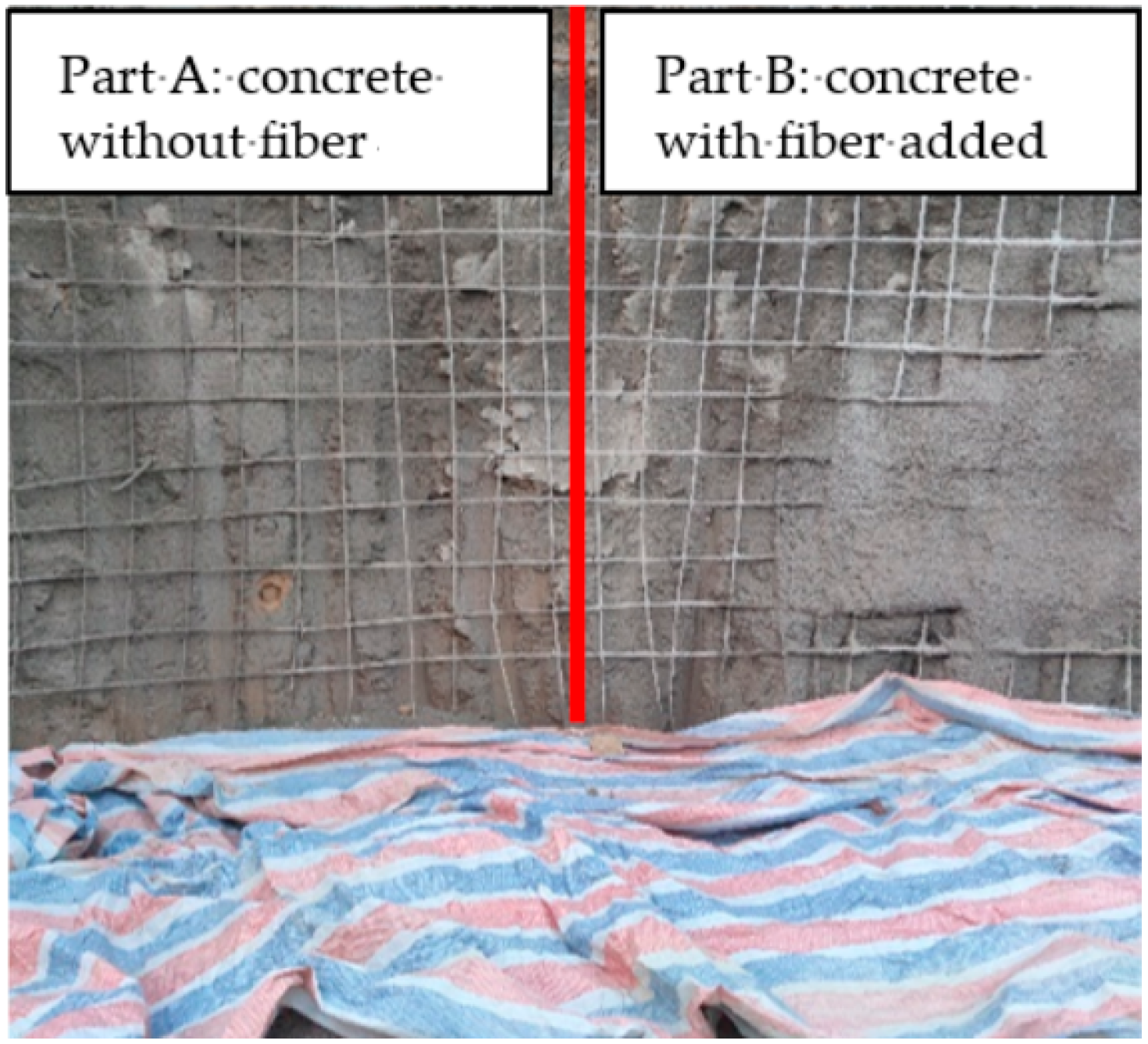

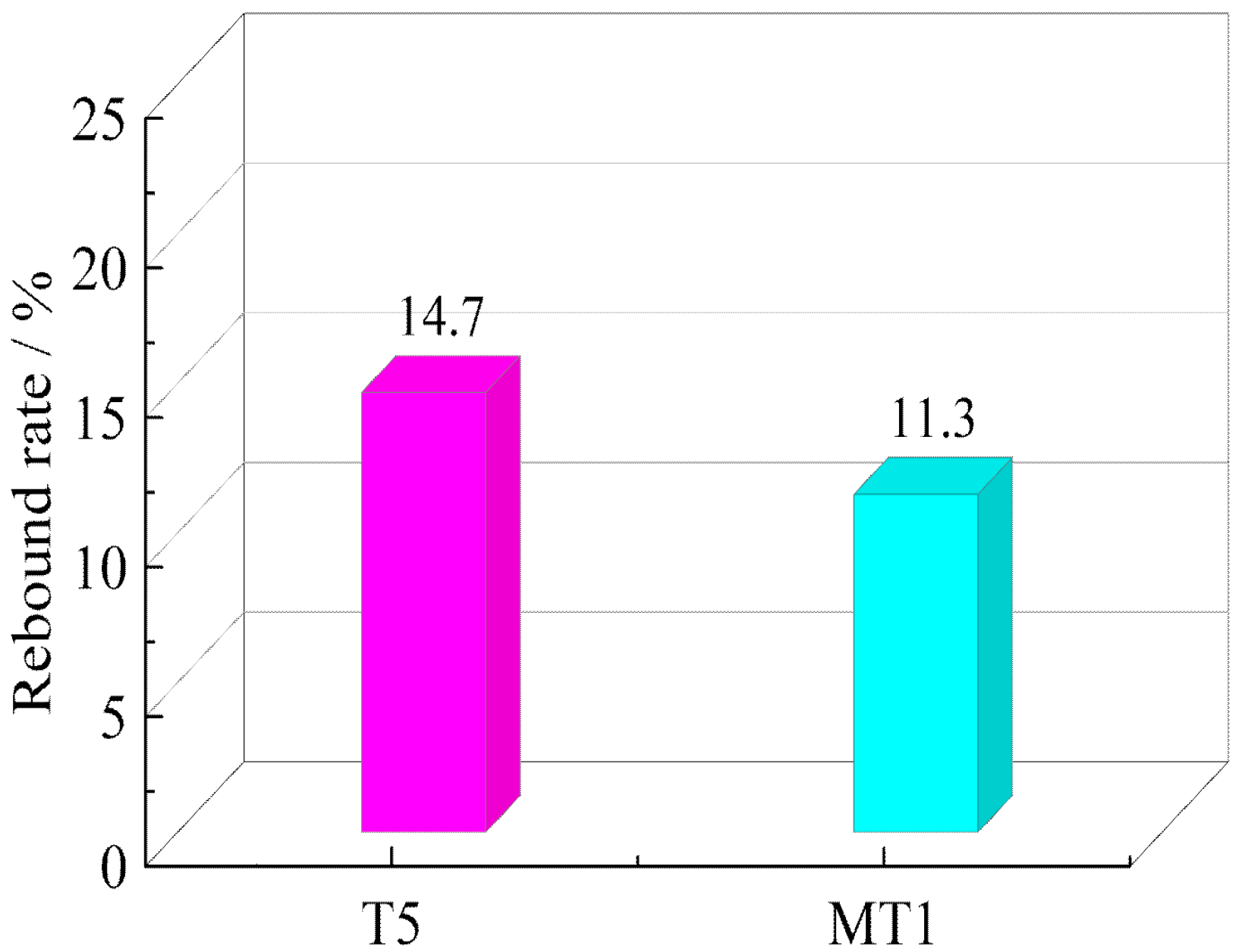

An accelerator can significantly shorten the setting time of concrete and increase its early strength. However, it caused the cement particles to be consumed rapidly in a short time, thus affecting the long-term strength development of the concrete and resulting in a reduction of around 30% in the 28d compressive strength of the concrete. Incorporating POM fibers at a volume fraction of 0.1% had little impact on the mechanical performance of the concrete while enhancing its cohesion and tensile strength, enabling the concrete to better resist its own weight and external impact forces during spraying or casting and thereby significantly reducing the rebound rate of the concrete. The prepared TBM shotcrete with a 0.15% volume fraction and a liquid-state alkali-free setting accelerator (8% dosage) had a moderate rebound rate of 11.3%.

Recycled TBM tunnel-excavated sand and aggregates demonstrate broad application prospects in concrete production, particularly for metro systems, railway construction, highway engineering, and hydraulic projects. However, the absence of comprehensive durability indices and the high processing costs of recycled sand and aggregates limit their large-scale application. Furthermore, this research focused solely on short-term performance (strength) and primary lining applications in tunnels, with insufficient systematic research on long-term durability (freeze–thaw resistance, permeability). Therefore, future research should prioritize optimizing shotcrete mix designs, improving durability, developing multifunctional materials, reducing processing costs, and evaluating environmental performance.

The applicability of recycled TBM-excavated materials is contingent upon the availability and quality of the aggregates at TBM construction sites. Although this research employed aggregates with particular mineralogical compositions and mechanical properties, it is recognized that geological heterogeneity can result in variations in aggregate characteristics across different TBM projects. In regions where comparable high-quality aggregates are accessible, the methodology and conclusions presented can serve as a reliable reference. However, when using alternative aggregate types, additional testing is recommended to address potential variations in material properties. Future studies should incorporate multi-source aggregate datasets and establish region-specific adjustment coefficients to enhance the generalizability of their findings for diverse TBM locations.