Performance Analysis of Model-Based Control for Thermoelectric Window Frames

Abstract

1. Introduction

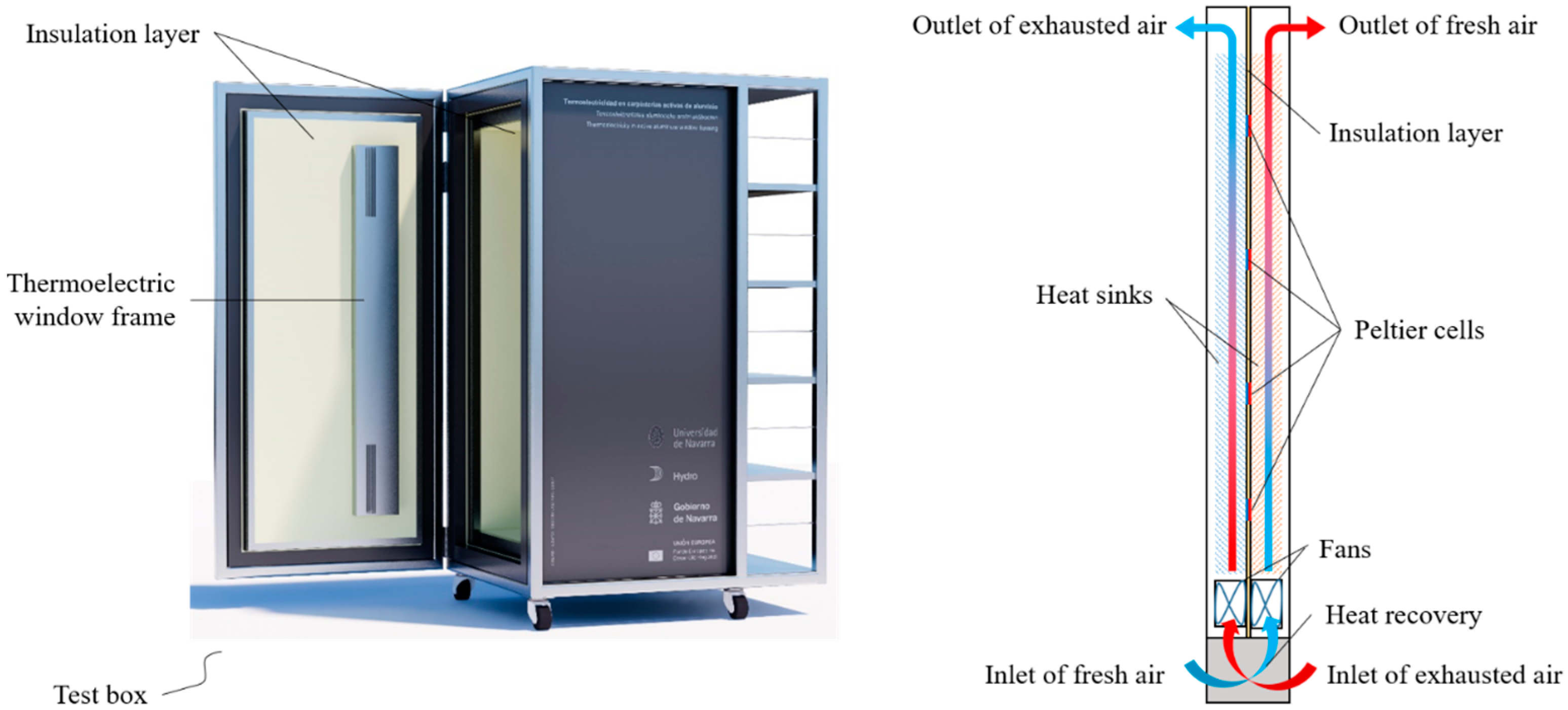

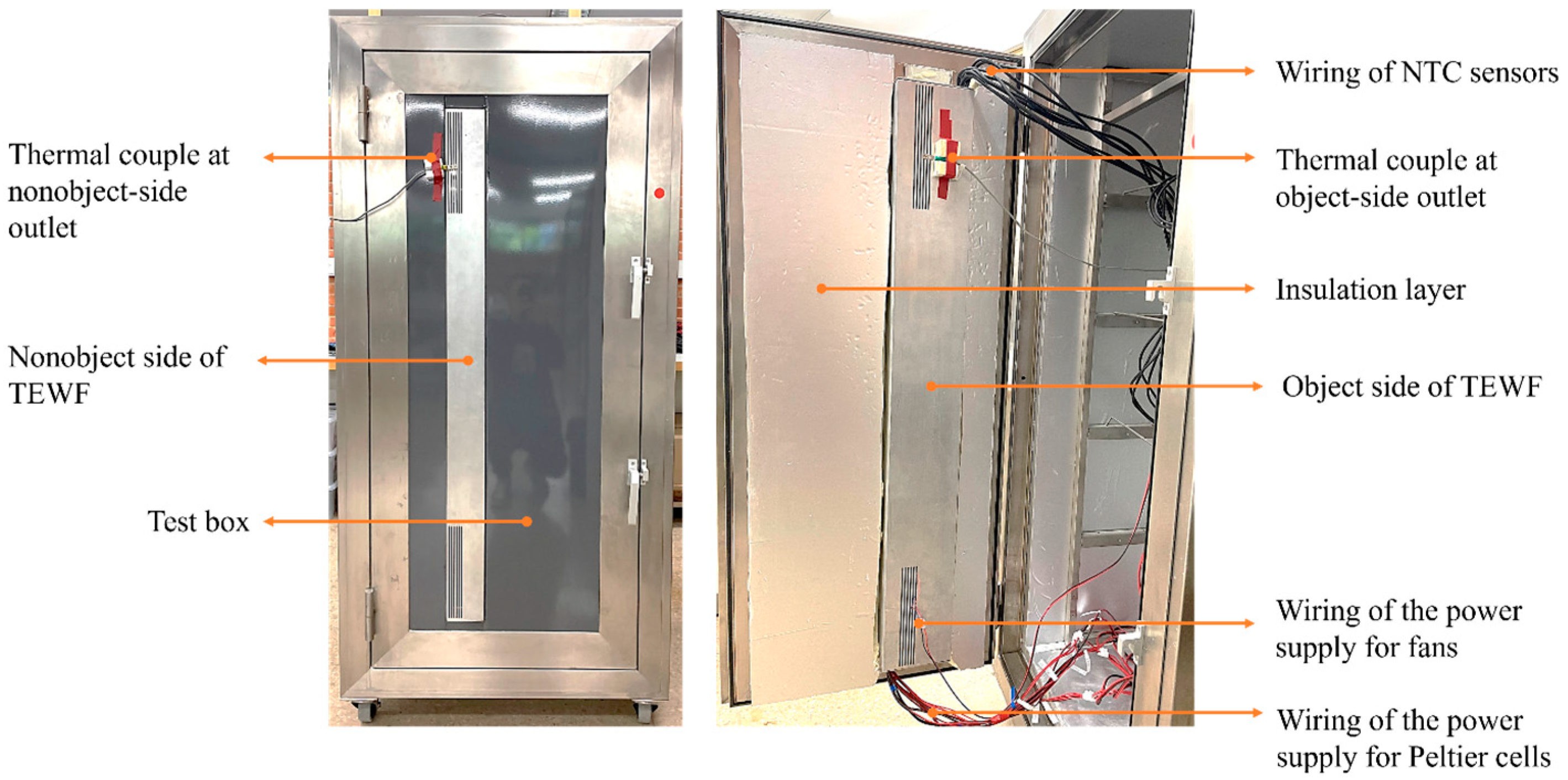

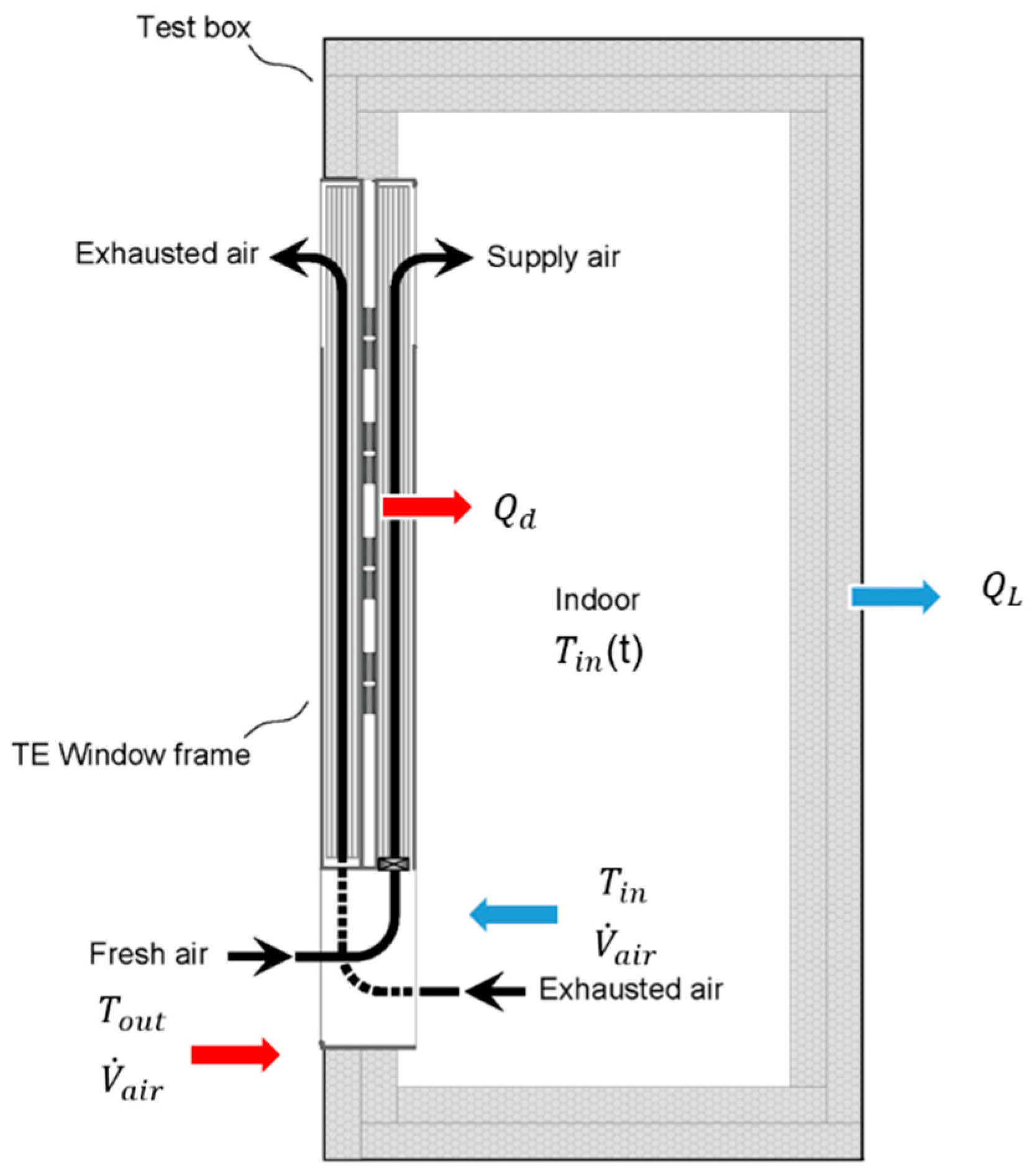

2. System Description

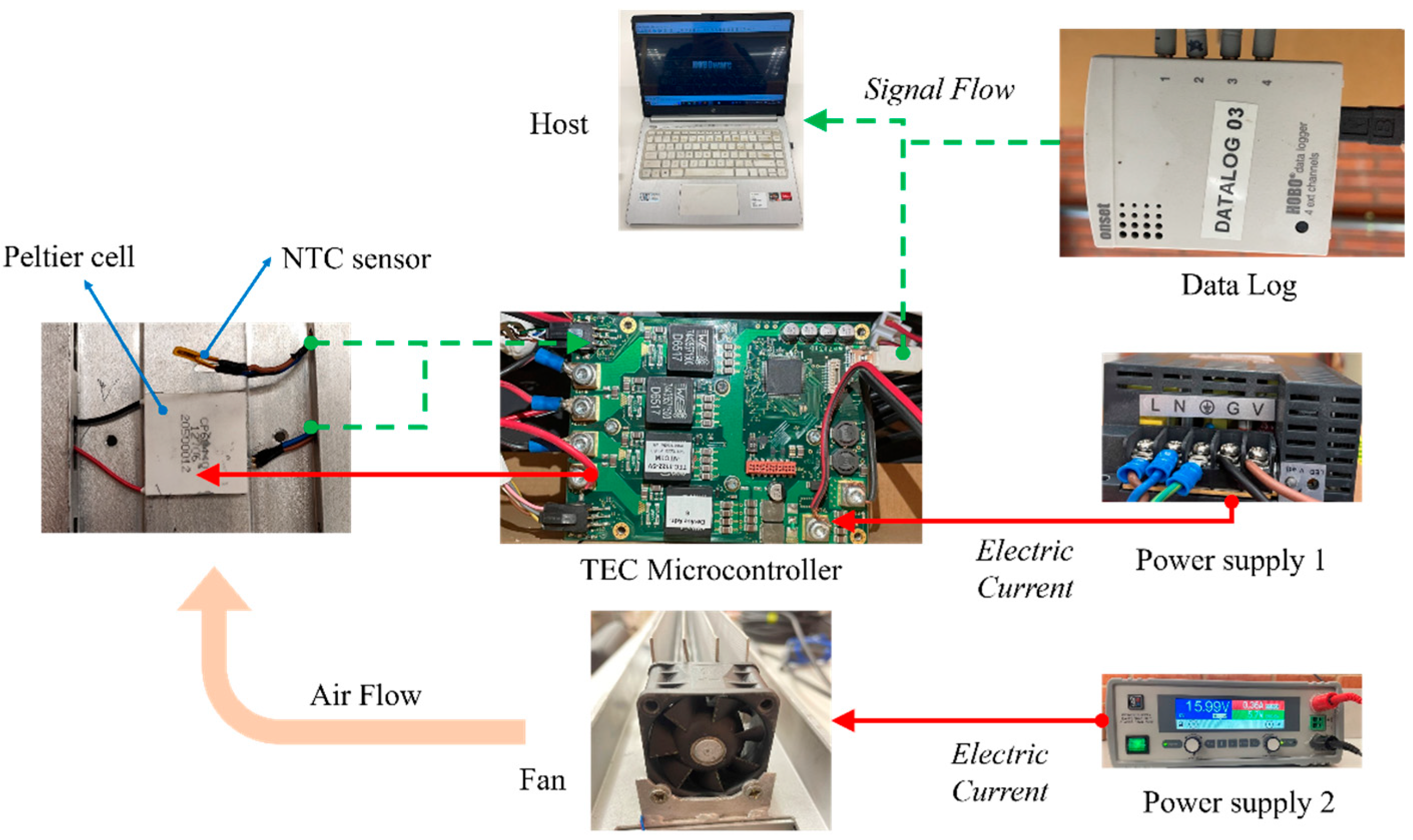

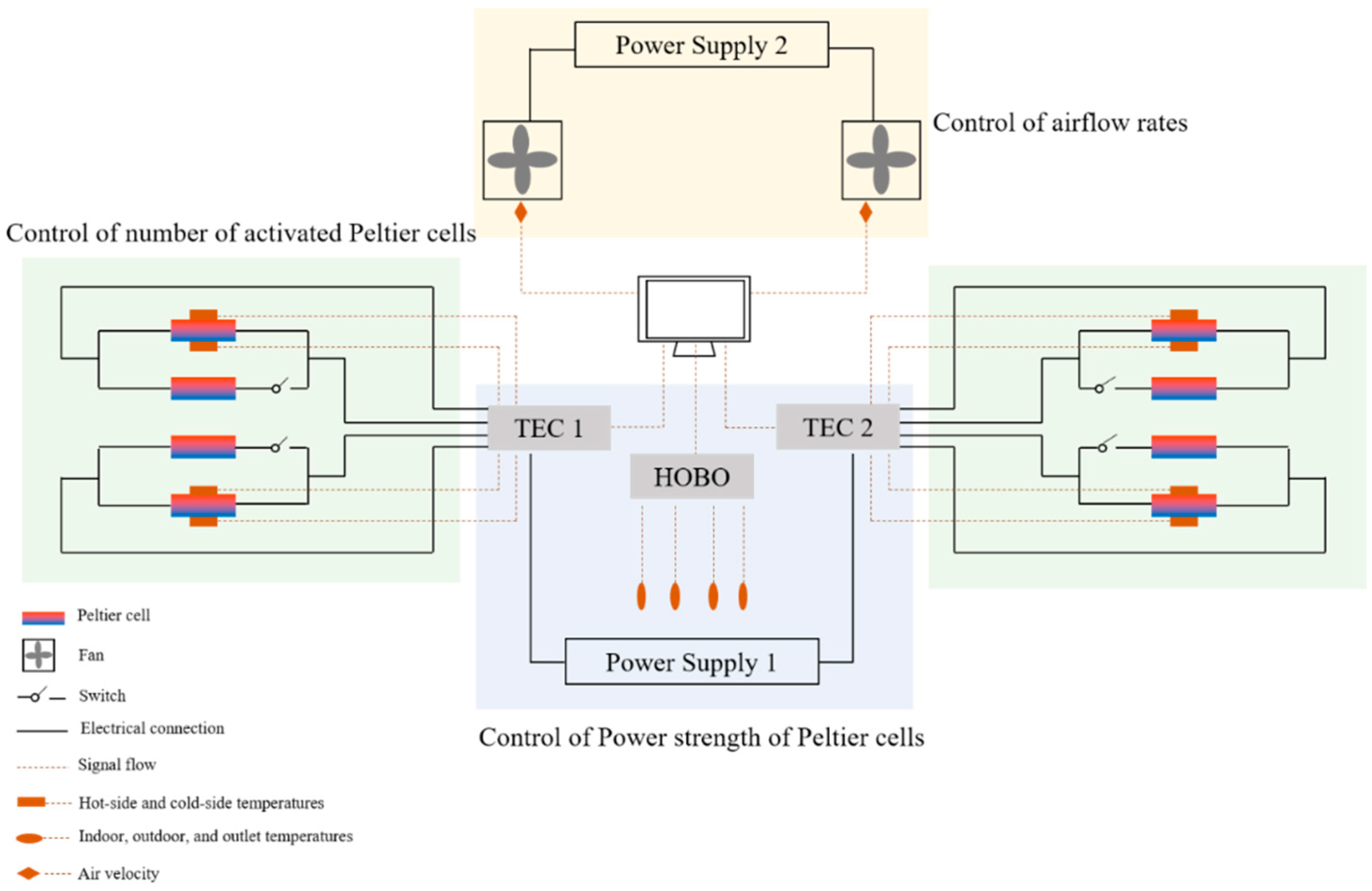

2.1. Experimental System

2.2. Experimental Setup

3. System Modeling

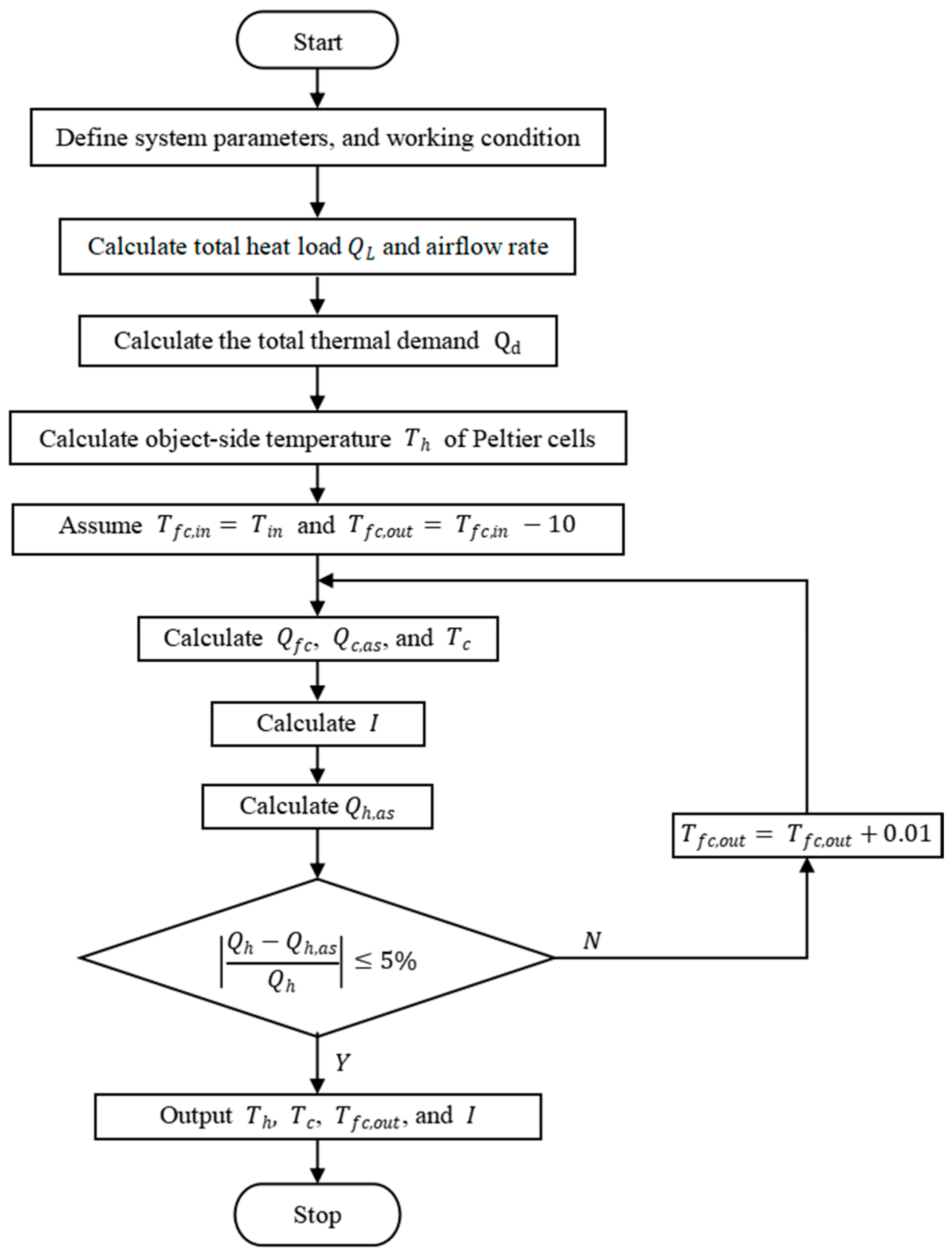

3.1. Computational Model

3.2. Transient Model

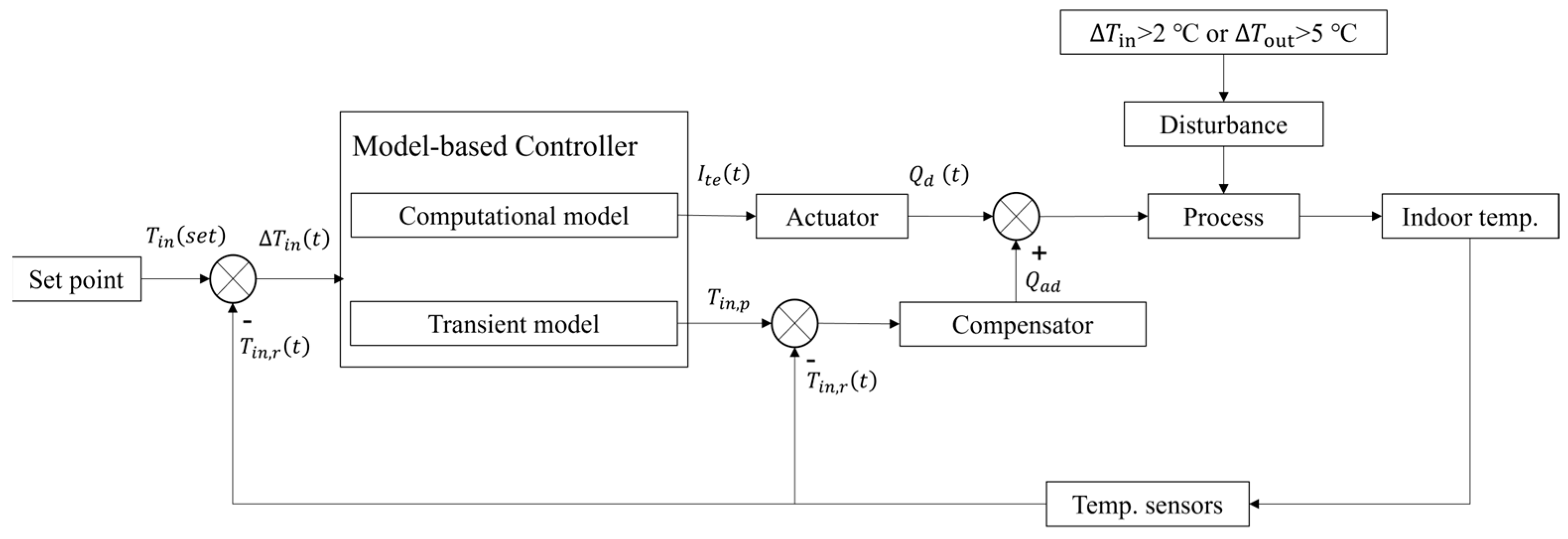

3.3. Control Methodology

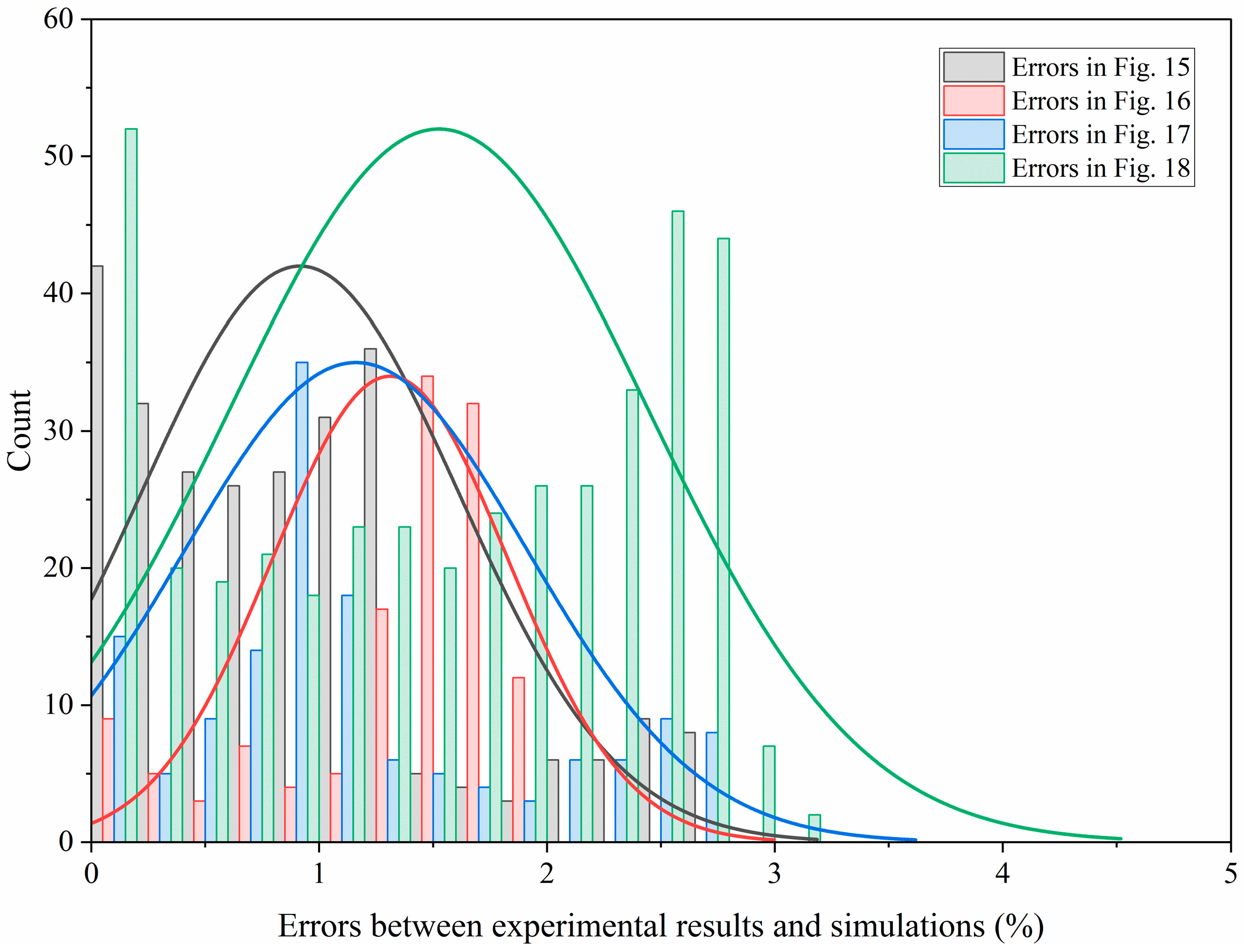

4. Results Analysis and Discussion

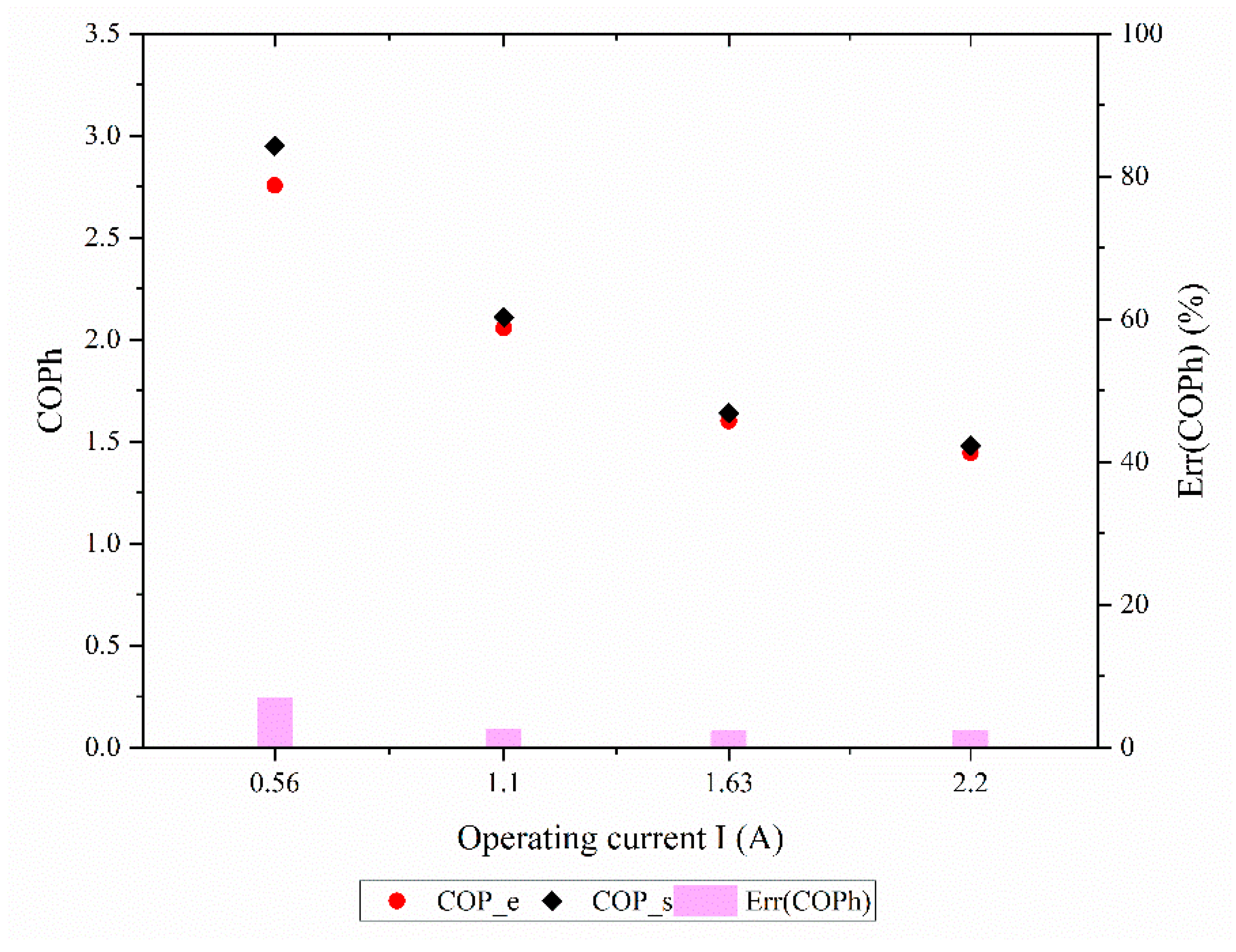

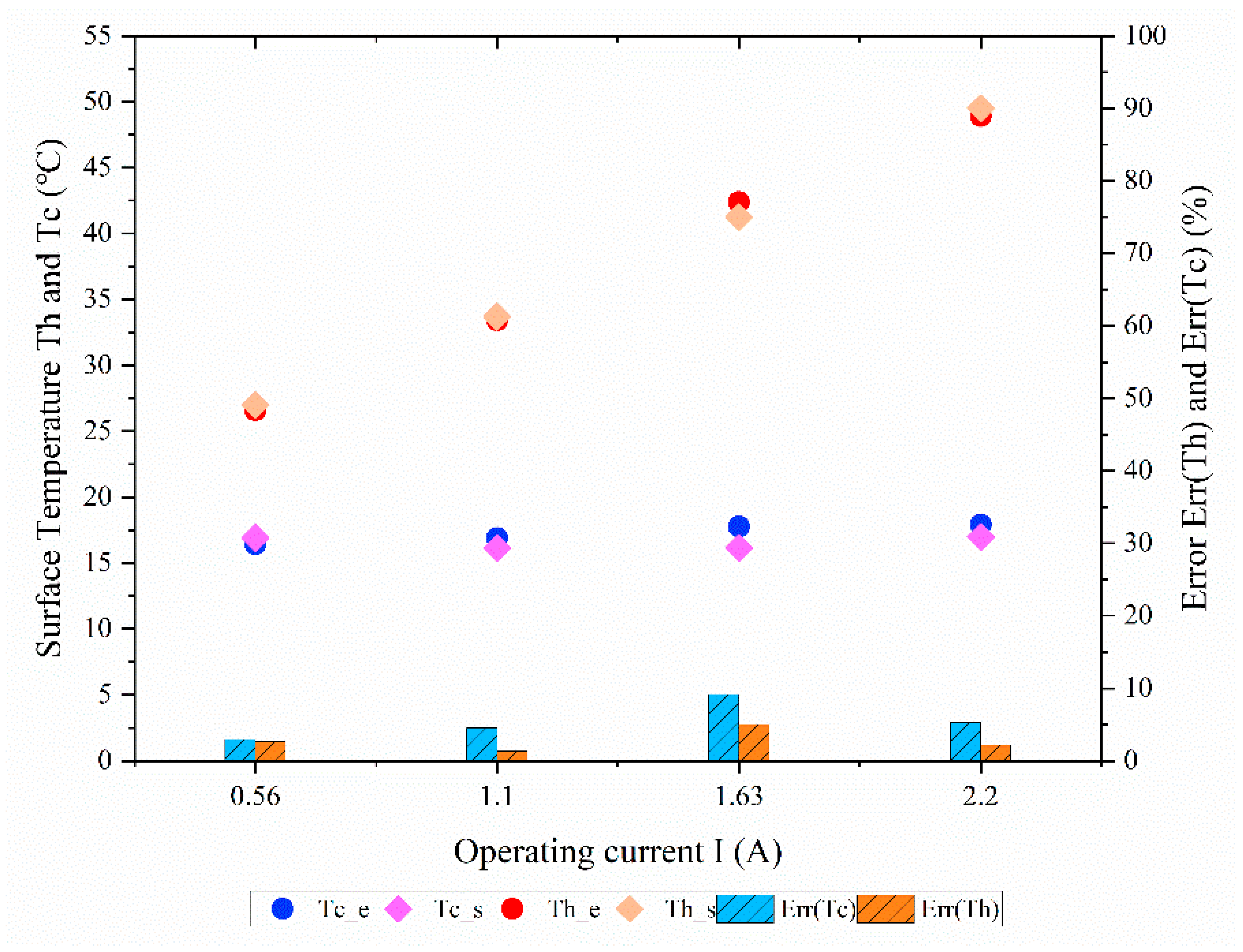

4.1. Operating Current

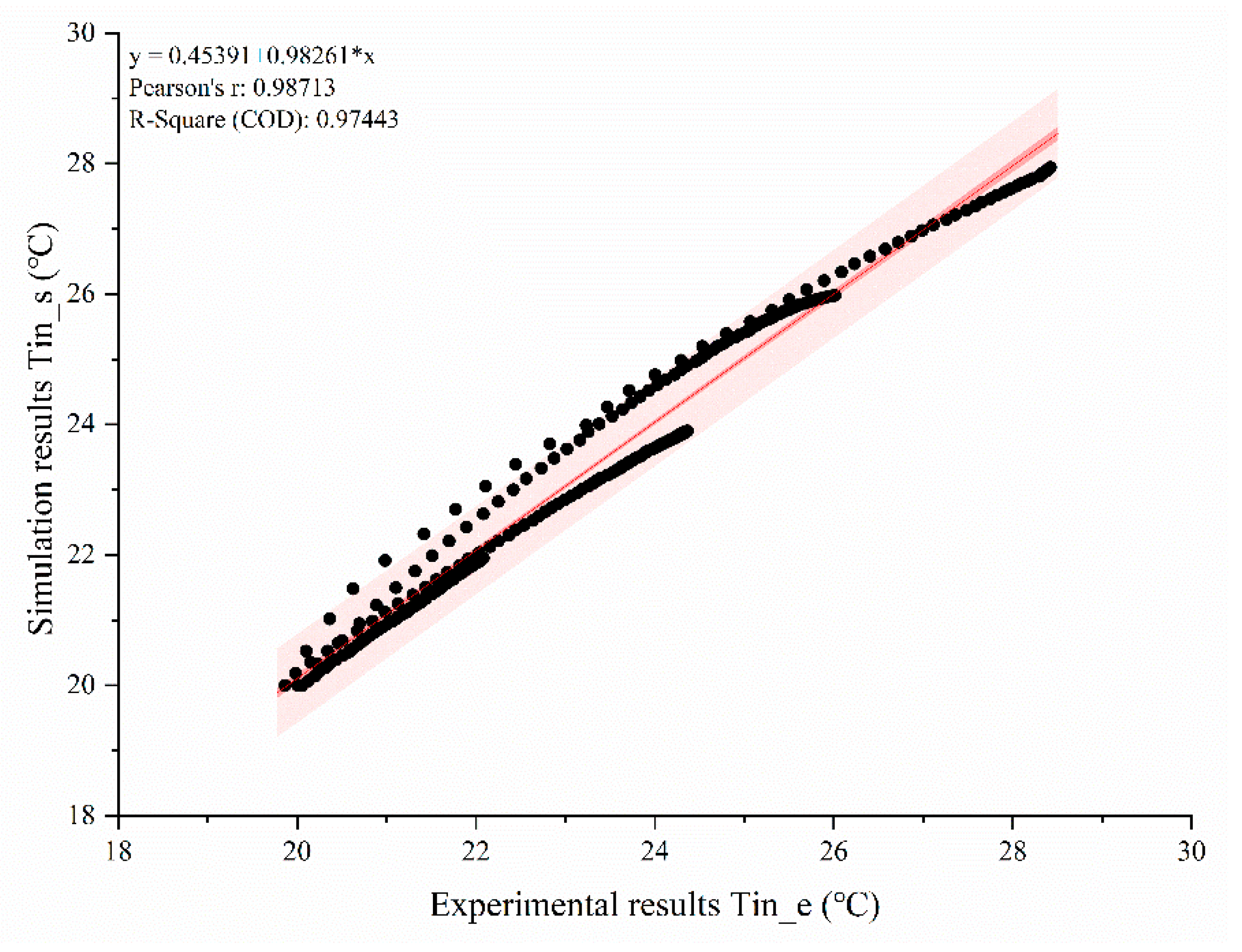

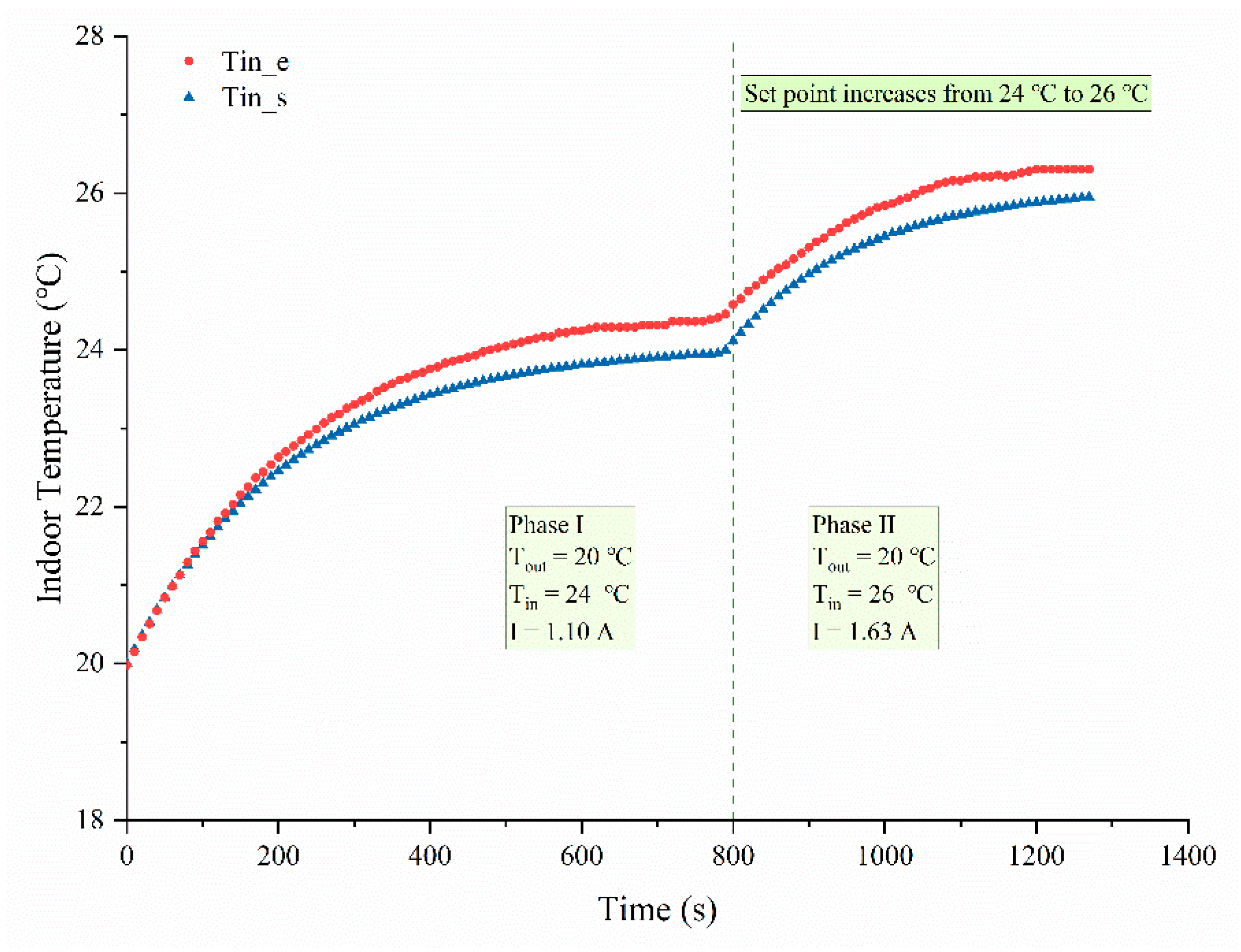

4.2. Indoor Temperature Profile

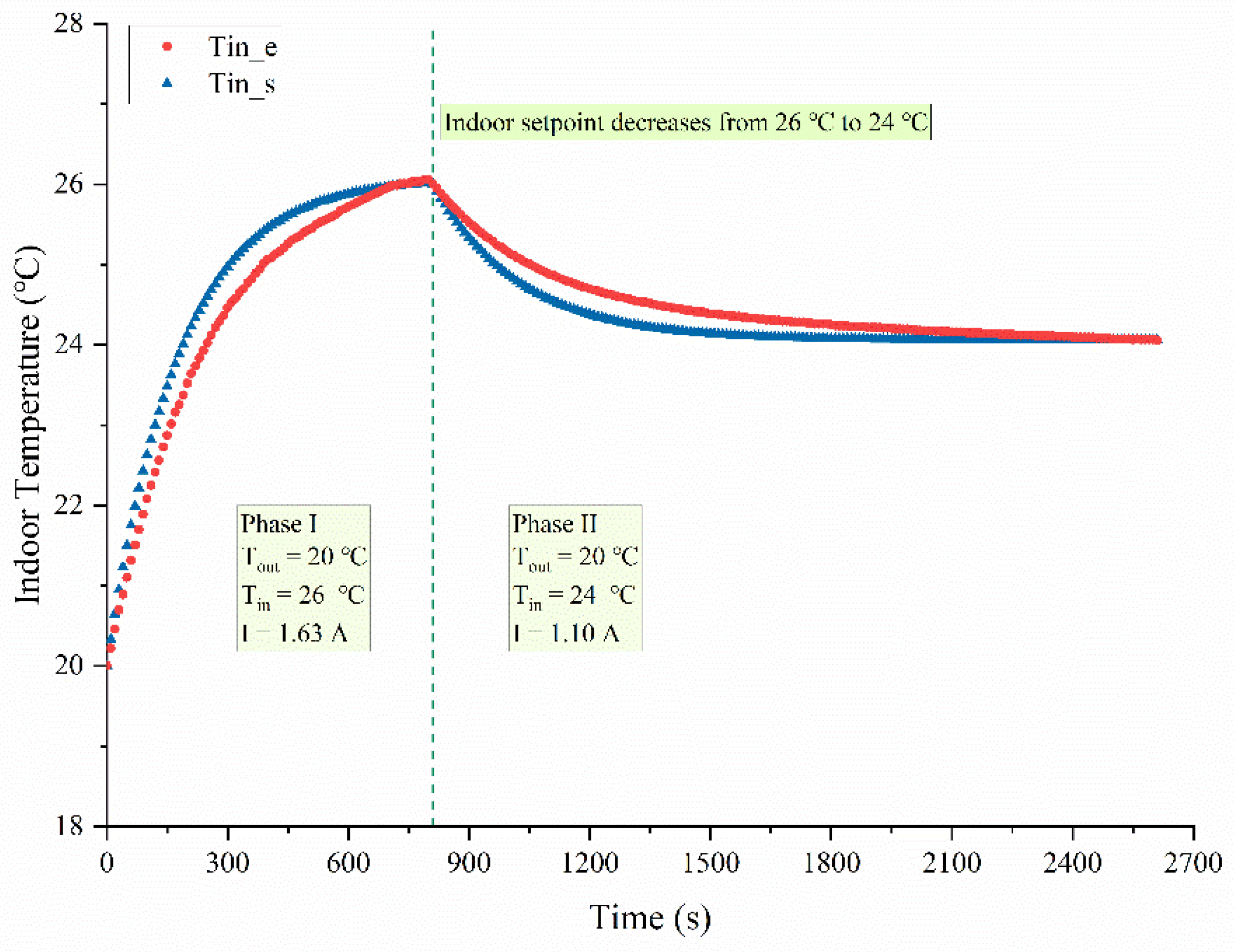

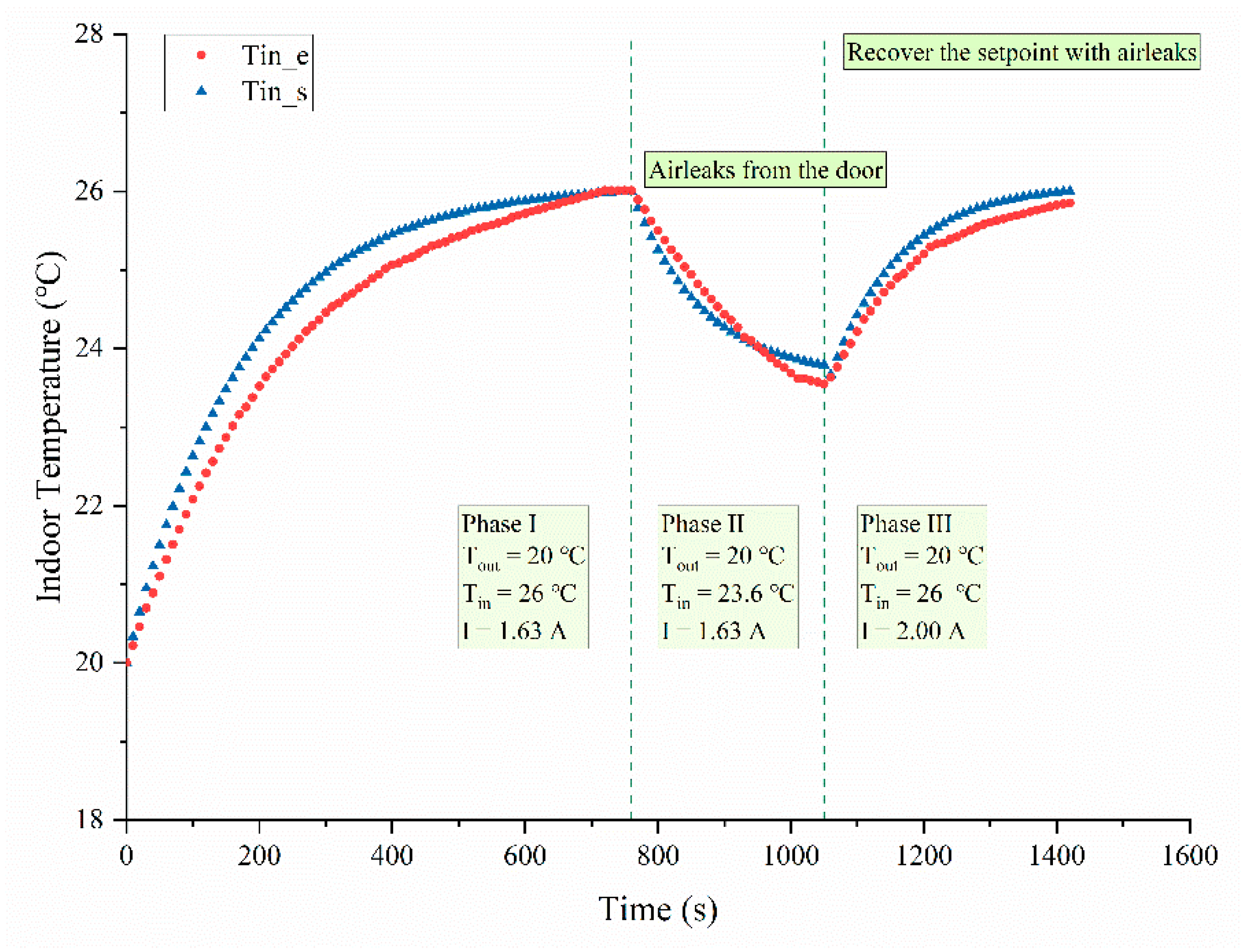

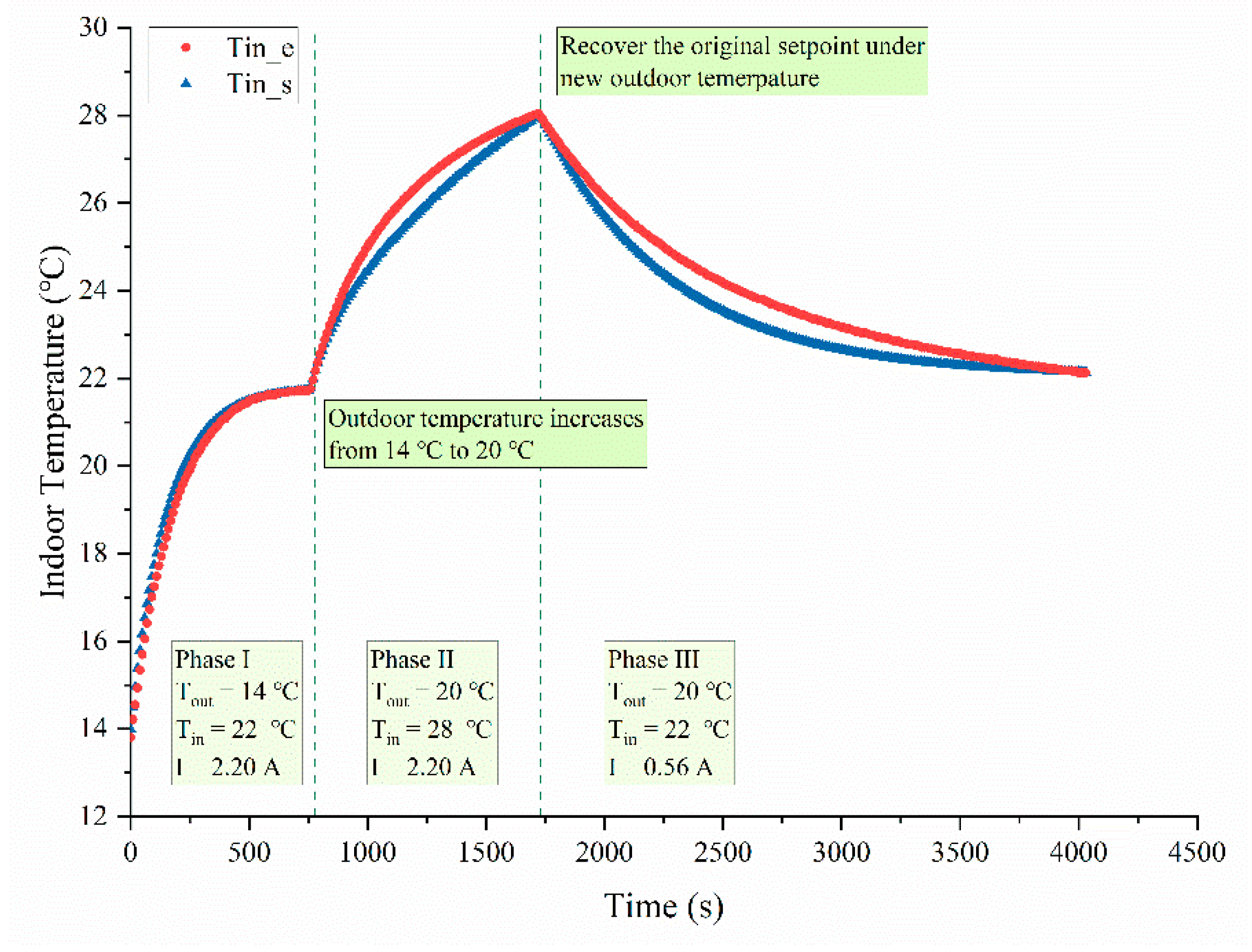

4.3. Responses to Interferences

5. Conclusions

- (a)

- Regarding the construction of the prototype, due to the existence of the temperature sensors, there is still interspace between Peltier cells and the heat sink, which easily results in extreme surface temperatures and large temperature differences between the hot and cold sides, then negatively affects the COP;

- (b)

- The experimental booth cannot appropriately simulate the temperature distribution in a real room scale, but the local area near the window;

- (c)

- This research applies the model-based control to stabilize the indoor temperature with interferences. However, the performance of model-based control heavily depends on the accuracy of the TEWF model. In case that components, such as Peltier cells, fans, or electric elements, wear out over time, the model may need frequent recalibration.

- (a)

- Structural optimization. The metal bolts and aluminum frames will be replaced by low-conductivity materials, such as high strength plastic. Additionally, placing strategically sensors for measuring the surface temperature of Peltier cells directly in the subplates (creating dedicated openings for the sensors) will eliminate the space between the subplates and Peltier cells as far as possible. Furthermore, implementing superior insulation between the heat sinks would serve to mitigate heat loss.

- (b)

- Control method. Several other control methods, including PID control, adaptive PID control, fuzzy logic control, and other model-free control, could be applied and compared with the model-based control method. This comparison would help identify the optimal control strategy for TE systems in buildings.

- (c)

- Building-scale application. Building-scale experiments of the TEWF can be conducted to assess its actual heating and cooling potential for practical applications. The solutions to decrease non-uniform indoor temperature distribution in the room and increase the thermal capacity of the TEWF should be explored, for example, integrating with a background independent air-conditioning system or TE systems integrated with other construction parts (wall, ceiling, etc.).

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Nomenclature | |||

| Acronyms | |||

| COP | Coefficient of Performance | cp | Specific heat capacity (J/kg·K) |

| CV | Coefficient of Variation | k | Coefficient of thermal transfer (W/K) |

| HVAC | Heating, Ventilation, and Air-conditioning | Re | Electric resistance (Ω) |

| NTC | Negative Temperature Coefficient | α | Seebeck coefficient (V/K) |

| PID | Proportional, Integral, Differential | ρ | Density (kg/m3) |

| RMSE | Root Mean Square Error | Subscripts | |

| TE | Thermoelectric | air | Air |

| TEC | Thermoelectric Cooler | ad | additional |

| TEWF | Thermoelectric Window Frame | as | Values based on assumption |

| Variables | box | Test box | |

| Err | Error (%) | c | Cold side |

| I | Operating current (A) | d | Demand or desire |

| m | Air flow mass rate (kg/s) | e | Experimental result |

| N | Number of working Peltier cells | fh | Airflow at the hot side |

| P | Electric power (W) | fc | Airflow at the cold side |

| Q | Thermal capacity (W) | h | Hot side |

| T | Temperature (K or ℃) | in | Indoor or incoming |

| t | Time (s) | L | Heat load |

| U | Thermal resistance (K/W) | m | Average value |

| V | Air flow volume rate (m3/h) or volume (m3) | out | Outdoor or outgoing |

| ΔT | Temperature difference | r | Real-time value |

| η | Thermal efficiency | s | Simulation result |

| Constants | set | Set point | |

| A | Area (m2) | p | Predictive value |

References

- Beretta, D.; Neophytou, N.; Hodges, J.M.; Kanatzidis, M.G.; Narducci, D.; Martin-Gonzalez, M.; Beekman, M.; Balke, B.; Cerretti, G.; Tremel, W.; et al. Thermoelectrics: From history, a window to the future. Mater. Sci. Eng. R Rep. 2019, 138, 210–255. [Google Scholar] [CrossRef]

- Mannella, G.A.; La Carrubba, V.; Brucato, V. Peltier cells as temperature control elements: Experimental characterization and modeling. Appl. Therm. Eng. 2014, 63, 234–245. [Google Scholar] [CrossRef]

- Luo, Y.; Zhang, L.; Liu, Z.; Wang, Y.; Meng, F.; Wu, J. Thermal performance evaluation of an active building integratedphotovoltaic thermoelectric wall system. Appl. Energy 2016, 177, 25–39. [Google Scholar] [CrossRef]

- Martín-Gómez, C.; Zuazua-Ros, A.; Del Valle de Lersundi, K.; Sánchez Saiz-Ezquerra, B.; Ibáñez-Puy, M. Integration development of a ventilated active thermoelectric envelope (VATE): Constructive optimization and thermal performance. Energy Build. 2021, 231, 110593. [Google Scholar] [CrossRef]

- Wang, P.; Liu, Z.; Chen, D.; Li, W.; Zhang, L. Experimental study and multi-objective optimisation of a novel integral thermoelectric wall. Energy Build. 2021, 252, 111403. [Google Scholar] [CrossRef]

- Birthwright, R.-S.; Messac, A.; Harren-Lewis, T.; Rangavajhala, S. Heat compensation in buildings using thermoelectric windows: An energy efficient window technology. In Proceedings of the ASME 2008 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Brooklyn, NY, USA, 3–6 August 2008; pp. 977–987. [Google Scholar] [CrossRef]

- Xu, X.; Van Dessel, S. Evaluation of an active building envelope window-system. Build Environ. 2008, 43, 1785–1791. [Google Scholar] [CrossRef]

- Luo, Y.; Zhang, L.; Liu, Z.; Wang, Y.; Meng, F.; Xie, L. Modeling of the surface temperature field of a thermoelectric radiant ceiling panel system. Appl. Energy 2016, 162, 675–686. [Google Scholar] [CrossRef]

- Seyednezhad, M.; Najafi, H. Numerical analysis and parametric study of a thermoelectric-based radiant ceiling panel for building cooling applications. In Proceedings of the ASME 2020 International Mechanical Engineering Congress and Exposition, Online, 16–19 November 2020; Volume 8. [Google Scholar] [CrossRef]

- Diaz de Garayo, S.; Martínez, A.; Astrain, D. Optimal combination of an air-to-air thermoelectric heat pump with a heat recovery system to HVAC a passive house dwelling. Appl. Energy 2022, 309, 118443. [Google Scholar] [CrossRef]

- Zuazua-Ros, A.; Martín-Gómez, C.; Ibañez-Puy, E.; Vidaurre-Arbizu, M.; Gelbstein, Y. Investigation of the thermoelectric potential for heating, cooling and ventilation in buildings: Characterization options and applications. Renew. Energy 2019, 131, 229–239. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, L.; Gong, G.; Luo, Y.; Meng, F. Evaluation of a prototype active solar thermoelectric radiant wall system in winter conditions. Appl. Therm. Eng. 2015, 89, 36–43. [Google Scholar] [CrossRef]

- Cheng, T.-C.; Cheng, C.-H.; Huang, Z.-Z.; Liao, G.-C. Development of an energy-saving module via combination of solar cellsand thermoelectric coolers for green building applications. Energy 2011, 36, 133–140. [Google Scholar] [CrossRef]

- Seyednezhad, M.; Najafi, H. Solar-powered thermoelectric-based cooling and heating system for building applications: A parametric study. Energies 2021, 14, 5573. [Google Scholar] [CrossRef]

- Diaz-Londono, C.; Enescu, D.; Ruiz, F.; Mazza, A. Experimental modeling and aggregation strategy for thermoelectric refrigeration units as flexible loads. Appl. Energy 2020, 272, 115065. [Google Scholar] [CrossRef]

- Duan, M.; Sun, H.; Lin, B.; Wu, Y. Evaluation on the applicability of thermoelectric air cooling systems for buildings with thermoelectric material optimization. Energy 2021, 221, 119723. [Google Scholar] [CrossRef]

- Khire, R.A.; Messac, A.; Van Dessel, S. Optimization based design of thermoelectric heat pump unit of active building envelope systems. In Proceedings of the ASME 2005 International Mechanical Engineering Congress and Exposition, Orlando, Fl, USA, 5–11 November 2005; pp. 161–173. [Google Scholar] [CrossRef]

- Kim, Y.W.; Ramousse, J.; Fraisse, G.; Dalicieux, P.; Baranek, P. Optimal sizing of a thermoelectric heat pump (THP) for heatingenergy-efficient buildings. Energy Build. 2014, 70, 106–116. [Google Scholar] [CrossRef]

- He, Z.; Zuazua-Ros, A.; Martín-Gómez, C. Thermoelectric system applications in buildings: A review of key factors and control methods. J. Build. Eng. 2023, 78, 107658. [Google Scholar] [CrossRef]

- He, Z.; Zuazua-Ros, A.; Martín-Gómez, C. Current-dependent temperature change model of a thermoelectric window frame. Appl. Therm. Eng. 2024, 247, 123081. [Google Scholar] [CrossRef]

- Keshtkar, A.; Arzanpour, S. An adaptive fuzzy logic system for residential energy management in smart grid environments. Appl. Energy 2017, 186, 68–81. [Google Scholar] [CrossRef]

- Güler, N.F.; Ahiska, R. Design and testing of a microprocessor-controlled portable thermoelectric medical cooling kit. Appl. Therm. Eng. 2002, 22, 1271–1276. [Google Scholar] [CrossRef]

- Chojecki, A.; Ambroziak, A.; Borkowski, P. Fuzzy controllers instead of classical pids in hvac equipment: Dusting off a well-known technology and today’s implementation for better energy efficiency and user comfort. Energies 2023, 16, 2967. [Google Scholar] [CrossRef]

- Li, Y.; Bian, J.; Zhang, N.; Li, J. Experimental study on intelligent control scheme for fan coil air-conditioning system. Adv. Mech. Eng. 2013, 5, 481213. [Google Scholar] [CrossRef]

- Işik, H.; Saraçoğlu, E. The design of thermoelectric footwear heating system via fuzzy logic. J. Med. Syst. 2007, 31, 521–527. [Google Scholar] [CrossRef] [PubMed]

- Ahiska, R.; Yavuz, A.H.; Kaymaz, M.; Güler, I. Control of a thermoelectric brain cooler by adaptive neuro-fuzzy inference system. Instrum. Sci. Technol. 2008, 36, 636–655. [Google Scholar] [CrossRef]

- Wang, J.; Wang, Y.; Qiu, D.; Su, H.; Strbac, G.; Gao, Z. Resilient energy management of a multi-energy building under low-temperature district heating: A deep reinforcement learning approach. Appl. Energy 2025, 378, 124780. [Google Scholar] [CrossRef]

- Wang, Y.; Qiu, D.; Sun, X.; Bie, Z.; Strbac, G. Coordinating multi-energy microgrids for integrated energy system resilience: A multi-task learning approach. IEEE Trans. Sustain. Energy 2024, 15, 920–937. [Google Scholar] [CrossRef]

- Luo, J.; Lee, J. Machine learning-assisted thermoelectric cooling for on-demand multi-hotspot thermal management. J. Appl. Phys. 2024, 135, 244503. [Google Scholar] [CrossRef]

- Kishore, M.; Sharma, B.; Pillai, B.M.; Suthakorn, J. Model predictive control-based thermoelectric cooling for rough terrain rescue robots. IEEE Access 2021, 9, 167652–167662. [Google Scholar] [CrossRef]

- Wang, R.; Zhang, H.; Chen, J.; Ding, R.; Luo, D. Modeling and model predictive control of a battery thermal management system based on thermoelectric cooling for electric vehicles. Energy Technol. 2024, 12, 2301205. [Google Scholar] [CrossRef]

- Kajgaard, M.U.; Mogensen, J.; Wittendorff, A.; Veress, A.T.; Biegel, B. Model predictive control of domestic heat pump. In Proceedings of the 2013 American Control Conference, Washington, DC, USA, 17–19 June 2013. [Google Scholar] [CrossRef]

- He, Z.; Zuazua-Ros, A.; Martín-Gómez, C. Optimizing a thermoelectric window frame for heating and cooling: A cross-validated simulation study. Build. Simul. 2024, 17, 2355–2372. [Google Scholar] [CrossRef]

- Arias-Salazar, P.; Zuazua-Ros, A.; Sacristán-Fernández, J.A.; He, Z.; Vidaurre-Arbizu, M.; Martín-Gómez, C. Thermoelectric active window frame: Constructive integration and preheating analysis. J. Build. Eng. 2024, 94, 109888. [Google Scholar] [CrossRef]

- Meerstetter. TEC Controllers|Peltier Controllers n.d. Available online: https://www.meerstetter.ch/products/tec-controllers (accessed on 15 September 2024).

- HOBO. Temperature Data Loggers n.d. Available online: https://www.onsetcomp.com/products/data-loggers-sensors/temperature (accessed on 15 September 2024).

- Mills, A.F. Heat Transfer; CRC Press: Boca Raton, FL, USA, 1992. [Google Scholar]

- Afram, A.; Janabi-Sharifi, F. Black-box modeling of residential HVAC system and comparison of gray-box and black-box modeling methods. Energy Build. 2015, 94, 121–149. [Google Scholar] [CrossRef]

- Shailza. Energy modeling of multi-storied residential buildings—A manual calibration approach. In Proceedings of the 2018 Building Performance Analysis Conference and SimBuild Co-Organized by ASHRAE and IBPSA-USA, Roorkee, India, 26–28 September 2018; pp. 550–557. [Google Scholar]

| Equipment | Type | Range | Accuracy |

|---|---|---|---|

| Temperature sensor | Film NTC thermistor | −30 °C to 120 °C | ±1% |

| Temperature sensor | TMCx-HE U12 | −40 °C to 50 °C | ±0.25 °C |

| Power supply | PSI5040-10A | 0 A to 10 A | ≤0.2% |

| Data logger | HOBO U12-006 | 0 to 10 V | ±2.5% ± 2 mV |

| Hot-wire anemometry | Testo 405i | 0 to 30 m/s | ±3% ± 0.1 m/s |

| Microcontroller | TEC-1122 | −40 °C to 90 °C | <0.01 °C |

| 0 A to ±10 A | <1% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, Z.; Martín-Gómez, C.; Zuazua-Ros, A. Performance Analysis of Model-Based Control for Thermoelectric Window Frames. Buildings 2025, 15, 1364. https://doi.org/10.3390/buildings15081364

He Z, Martín-Gómez C, Zuazua-Ros A. Performance Analysis of Model-Based Control for Thermoelectric Window Frames. Buildings. 2025; 15(8):1364. https://doi.org/10.3390/buildings15081364

Chicago/Turabian StyleHe, Zhineng, César Martín-Gómez, and Amaia Zuazua-Ros. 2025. "Performance Analysis of Model-Based Control for Thermoelectric Window Frames" Buildings 15, no. 8: 1364. https://doi.org/10.3390/buildings15081364

APA StyleHe, Z., Martín-Gómez, C., & Zuazua-Ros, A. (2025). Performance Analysis of Model-Based Control for Thermoelectric Window Frames. Buildings, 15(8), 1364. https://doi.org/10.3390/buildings15081364