Enhancing the Performance of Ultra-High Performance Concrete Using Expansive Agent and Pre-Wetted Biochar to Produce a Synergistic Effect

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Mixing Proportion and Sample Preparation

2.3. Test Methods

2.3.1. Setting Time

2.3.2. Fluidity of Mortars

2.3.3. Compressive Strength

2.3.4. Hydration Products Analysis

2.3.5. Internal Relative Humidity (IRH)

2.3.6. Autogenous Shrinkage

2.3.7. Mercury Intrusion Porosimetry (MIP)

2.3.8. Microstructure Analysis

2.3.9. Nanoindentation Test

3. Results and Discussions

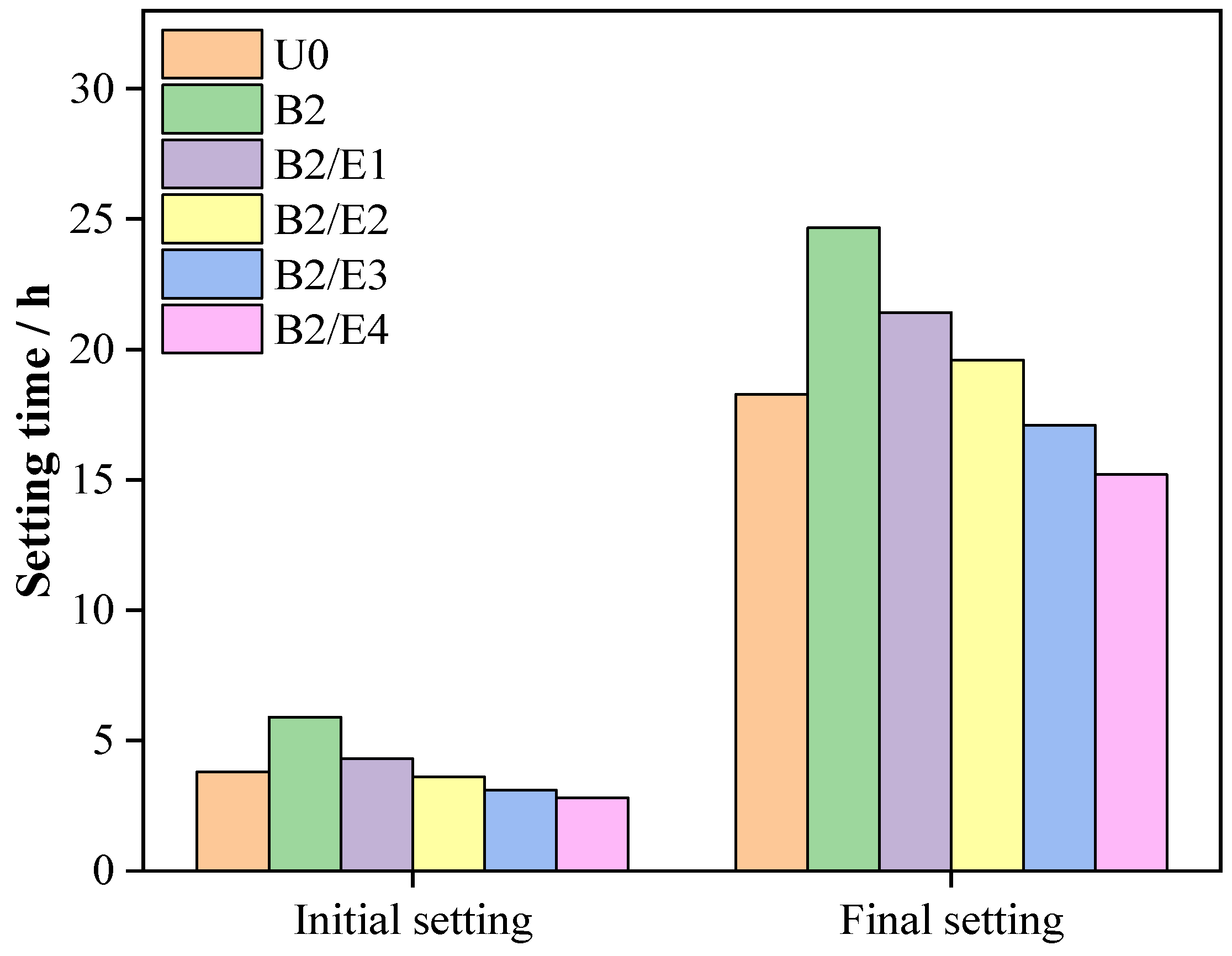

3.1. Setting Time

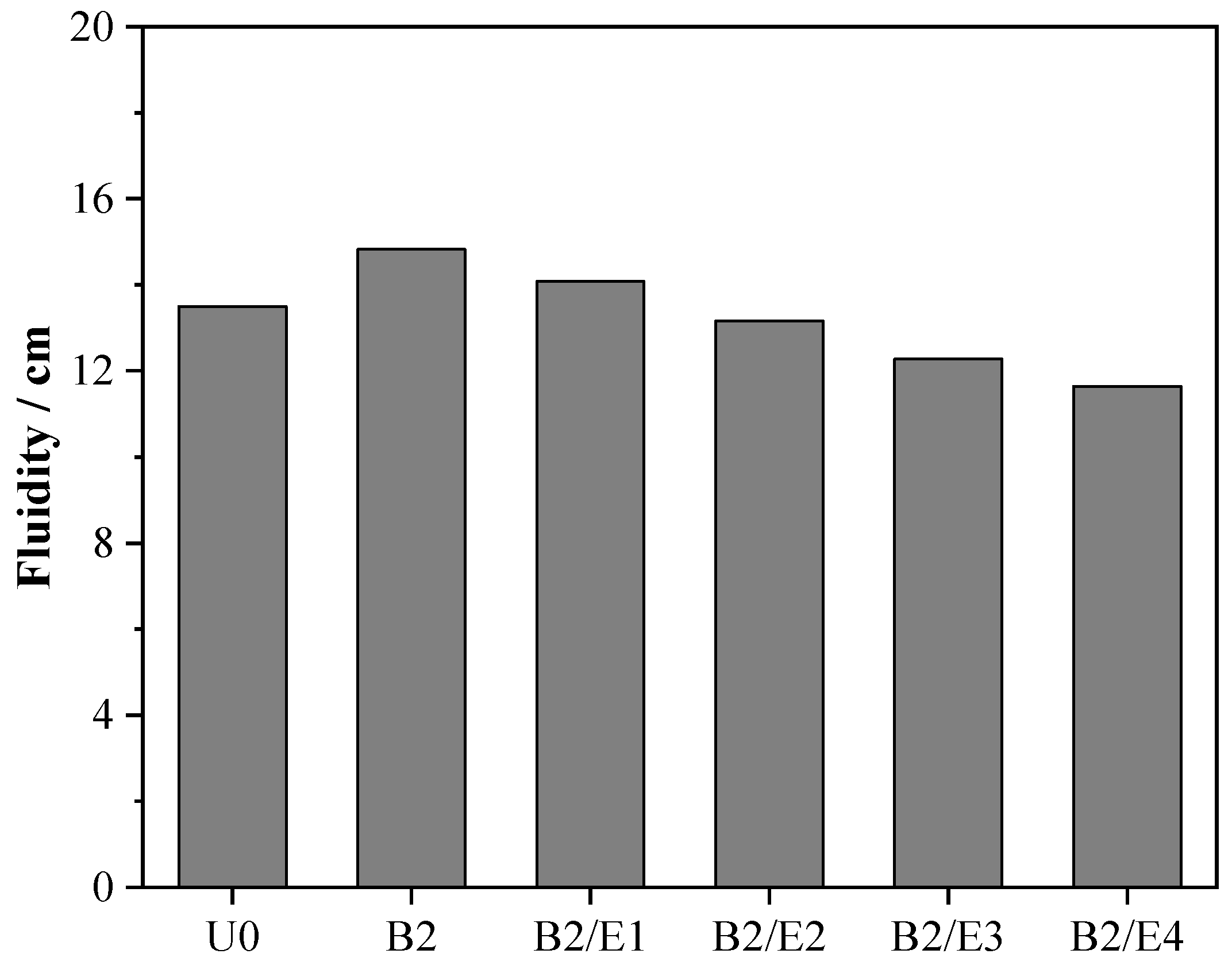

3.2. Fluidity

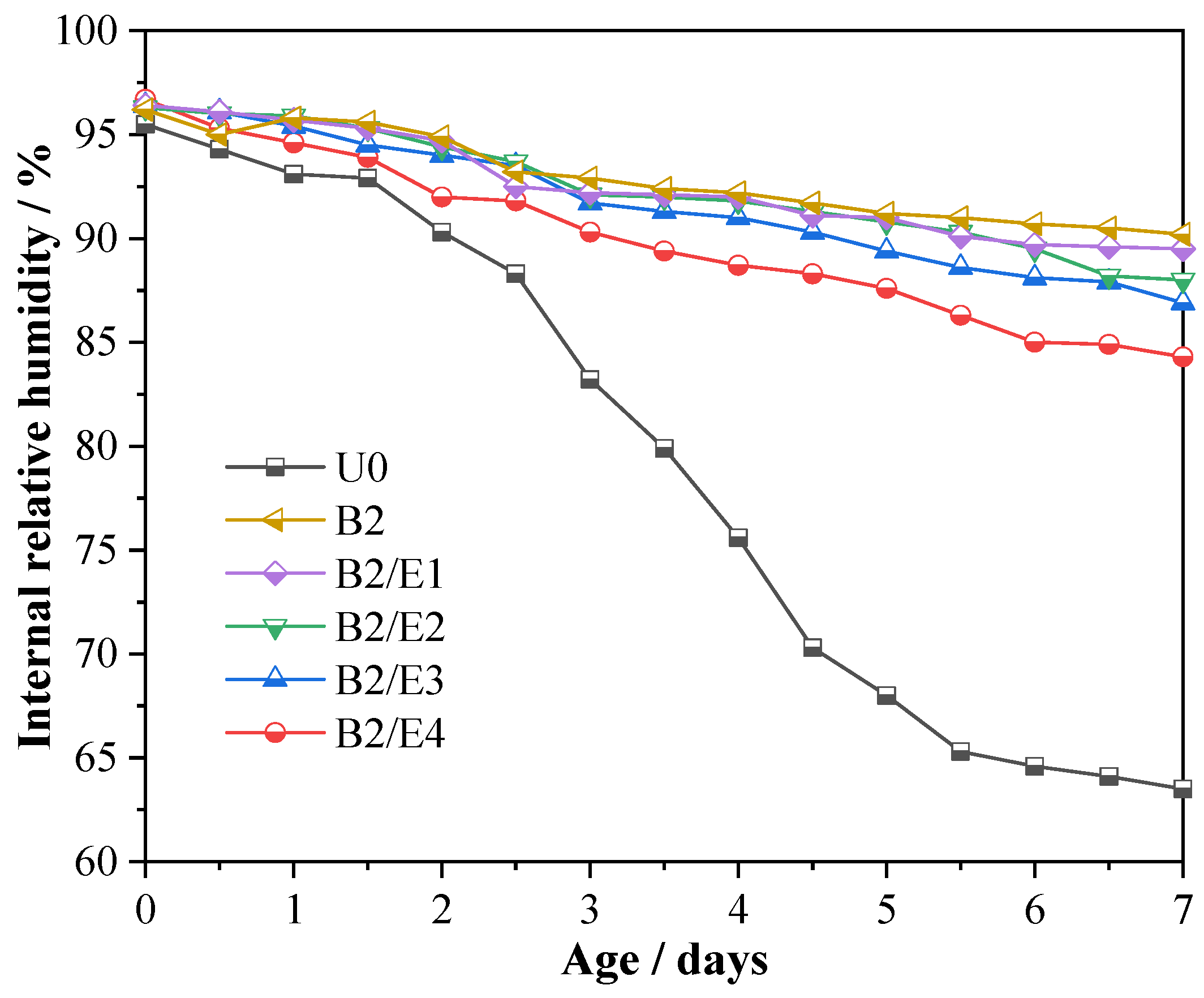

3.3. IRH

3.4. Autogenous Shrinkage

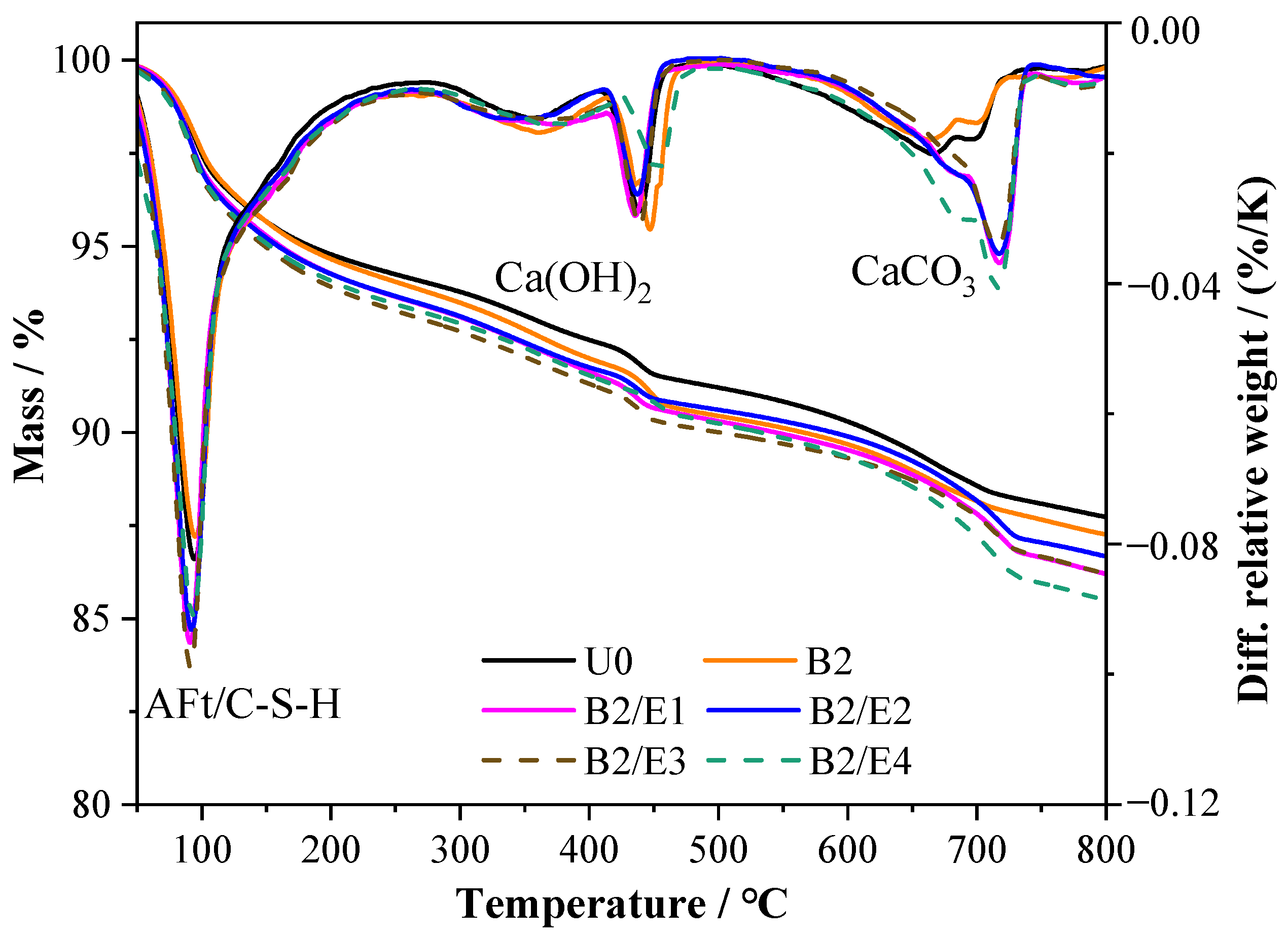

3.5. TG-DTG Analysis

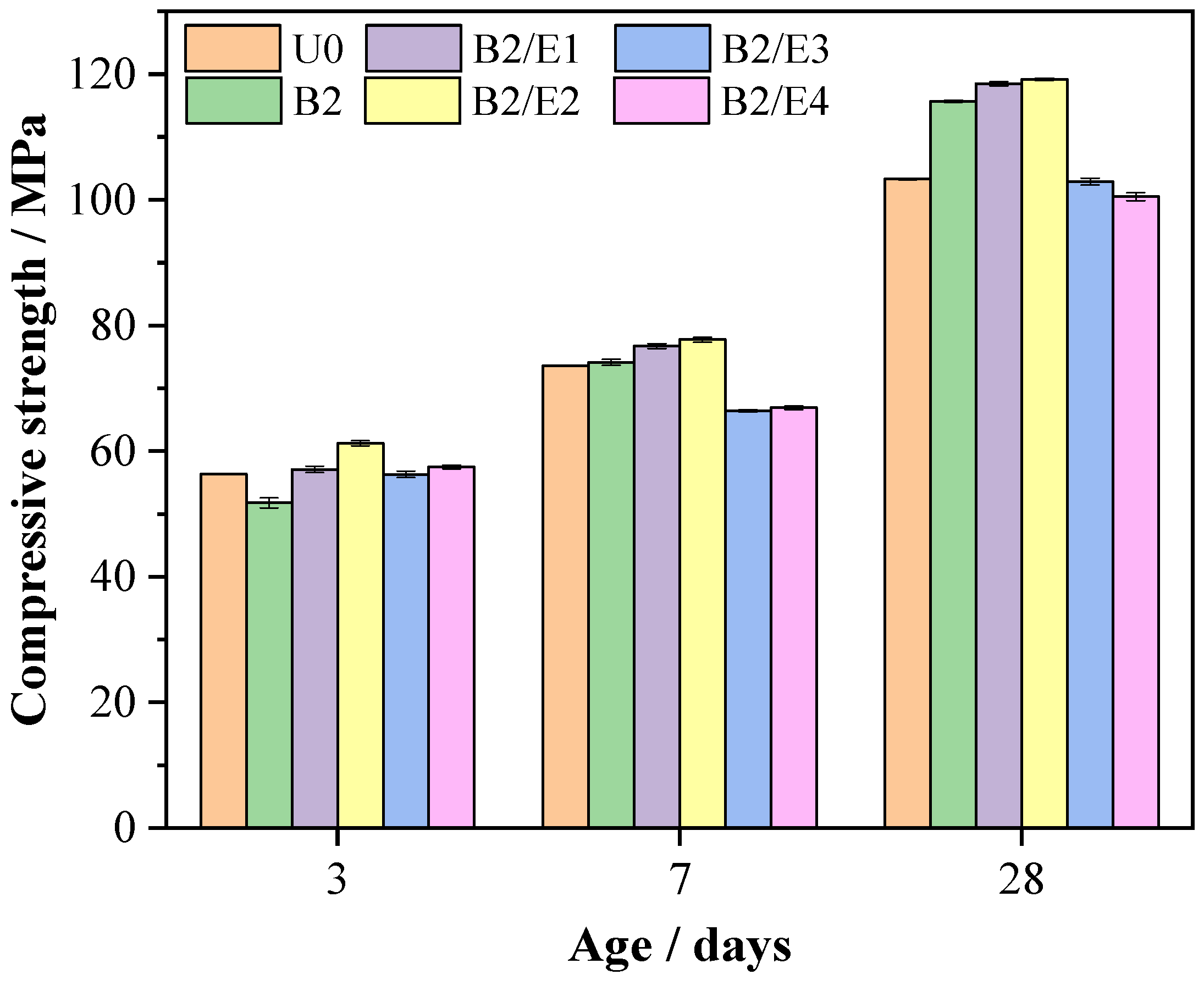

3.6. Compressive Strength

3.7. Pore Structure

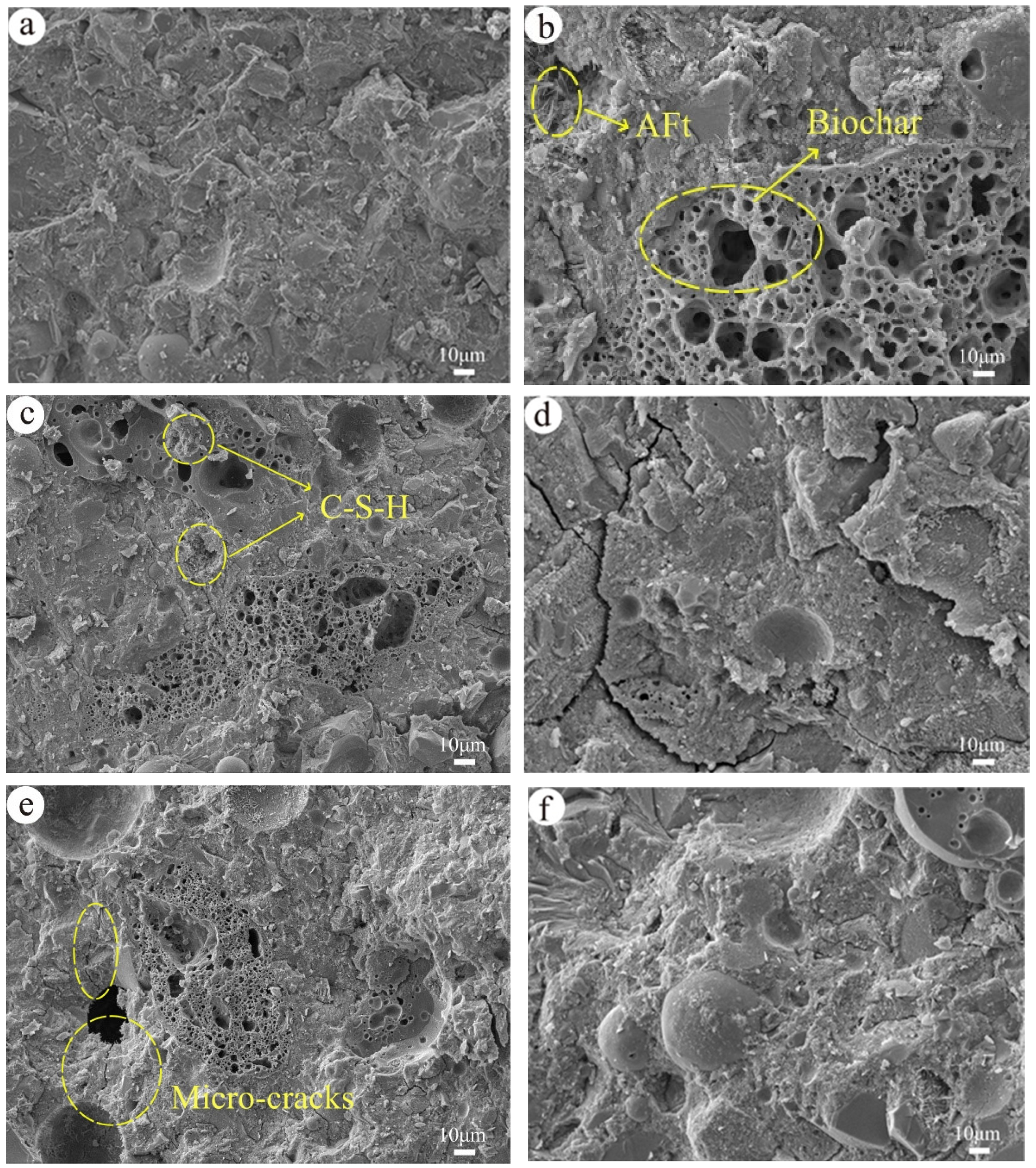

3.8. Microstructure Analysis

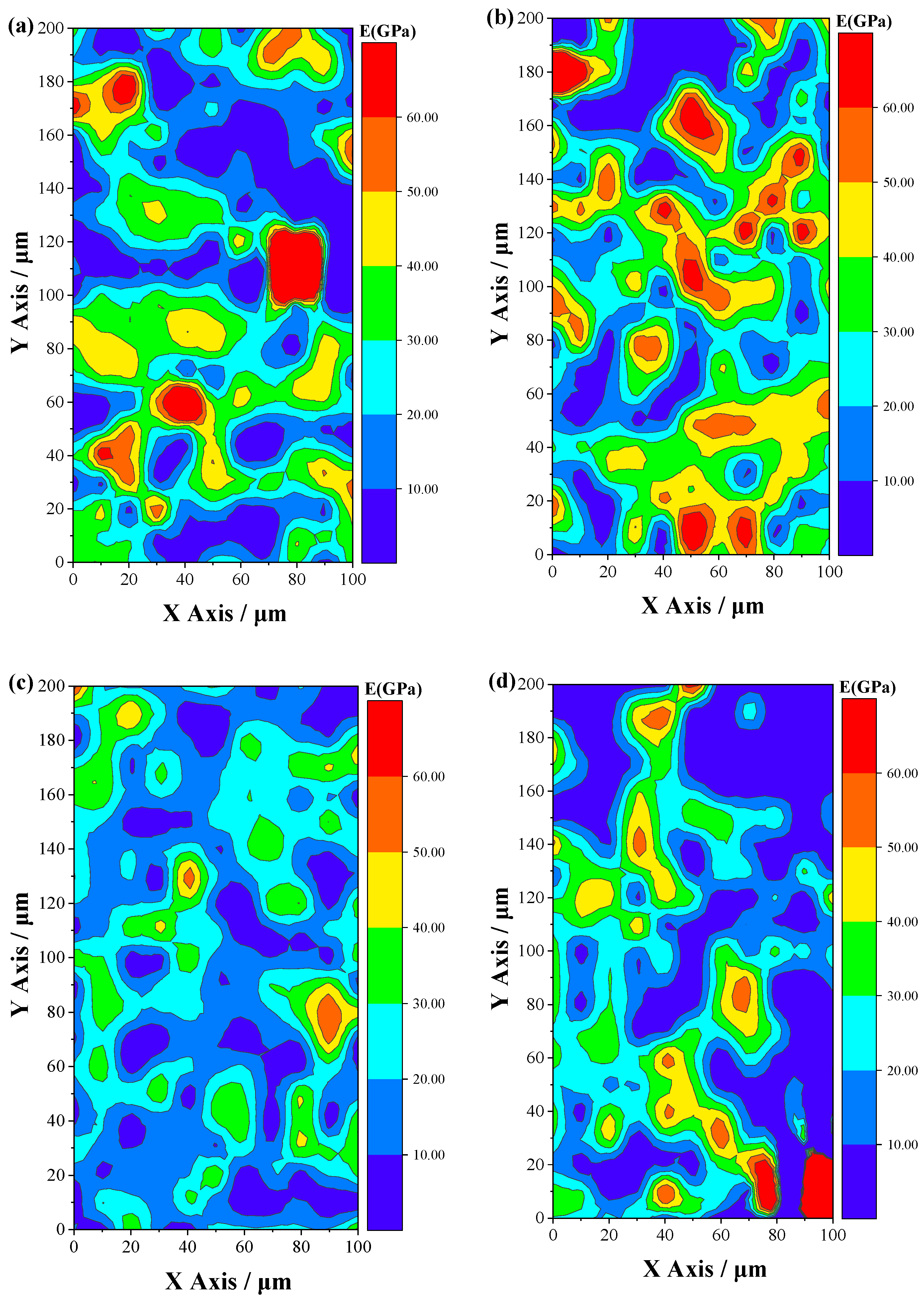

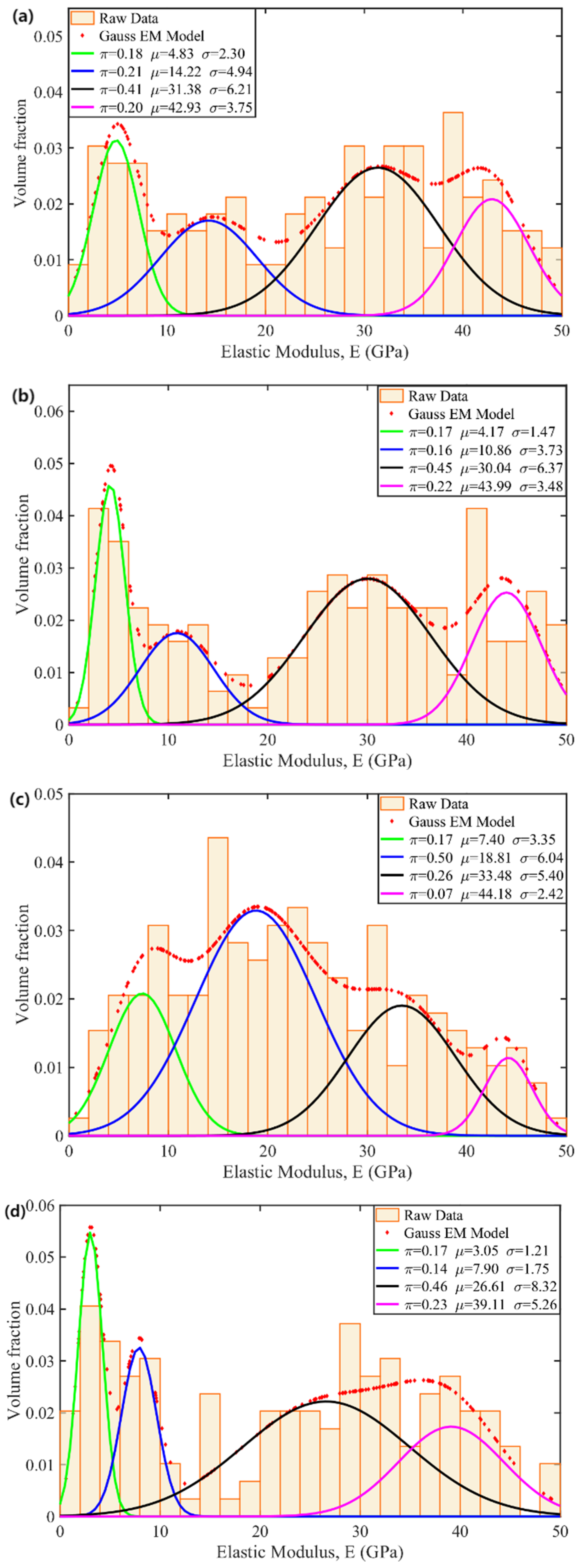

3.9. Micro-Mechanical Properties

4. Conclusions

- The hydration of EA, which consumed water and generated expansive products rapidly, accelerated the setting process of internally cured UHPC. This mitigated the prolonged setting time caused by the leakage of internal curing water from pre-wetted biochar. For example, adding 1–4% EA reduced the initial and final setting times by 27.1–52.5% and 13.2–38.4%, respectively, compared to the reference sample (B2). However, the initial fluidity of internally cured UHPC decreased with the addition of EA.

- Internal curing with pre-wetted biochar significantly increased the IRH of UHPC compared to the control sample (U0). Although the rapid hydration of EA slightly lowered the IRH, it remained above 70% in all EA-modified mixtures. As a result, the 7 d autogenous shrinkage of B2 was reduced by 35.7% compared to U0. Furthermore, incorporating 1–4% EA further decreased autogenous shrinkage by 6.8–30.3% relative to B2.

- TG-DTG analysis revealed that adding EA to UHPC with biochar increased the total quantity of hydration products. This suggested that a portion of the internal curing water contributed to EA hydration in addition to cement hydration. This dual hydration process created a synergistic effect, refining the pore structure through EA-induced expansion and enhanced cement hydration facilitated by the internal curing water.

- The inclusion of pre-wetted biochar slightly improved the 7 d and 28 d compressive strengths of UHPC, highlighting the effectiveness of this internal curing approach. The addition of EA initially enhanced these strengths, peaking at a 2% EA dosage, before declining with higher EA content. Additionally, EA incorporation led to a more uniform and refined elastic modulus distribution, indicating improved matrix densification due to accelerated hydration kinetics.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Alkaysi, M.; El-Tawil, S.; Liu, Z.; Hansen, W. Effects of silica powder and cement type on durability of ultra high performance concrete (Uhpc). Cem. Concr. Compos. 2016, 66, 47–56. [Google Scholar] [CrossRef]

- He, Z.-H.; Zhu, H.-N.; Zhang, M.-Y.; Shi, J.-Y.; Du, S.-G.; Liu, B. Autogenous shrinkage and nano-mechanical properties of UHPC containing waste brick powder derived from construction and demolition waste. Constr. Build. Mater. 2021, 306, 124869. [Google Scholar] [CrossRef]

- Zhu, J.Y.; Chen, F.X.; Dai, X.Q.; Tan, Y.Z.; Duan, L.Q.; Zhang, Z.W.; Leng, Y.; Wang, S.Y.; Yin, T.Y.; Yu, R. Development of a novel ultra-high performance concrete (Uhpc) suitable for underwater operation: Design and performance evaluation. J. Build. Eng. 2023, 75, 107030. [Google Scholar] [CrossRef]

- Justs, J.; Wyrzykowski, M.; Bajare, D.; Lura, P. Internal curing by superabsorbent polymers in ultra-high performance concrete. Cem. Concr. Res. 2015, 76, 82–90. [Google Scholar] [CrossRef]

- Liu, K.; Long, Y.; Chen, L.; Ling, X.; Yu, R.; Shui, Z.; Fei, S.; Yu, W.; Li, C.; Ge, K. Mechanisms of autogenous shrinkage for Ultra-High Performance Concrete (Uhpc) prepared with pre-wet porous fine aggregate (PFA). J. Build. Eng. 2022, 54, 104622. [Google Scholar] [CrossRef]

- Liu, L.; Chen, H.; He, Z.; Wang, P.; Cui, J.; Cai, X.; Sun, Y. Effect and mechanism of compound expansive agent on rheological, mechanical, and shrinkage properties of Uhpc. Constr. Build. Mater. 2024, 444, 137730. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, X.; Cheng, S.; Li, S.; Bao, M.; Qiao, L. Mechanical properties, hydration behavior and shrinkage deformation of ultra-high performance concrete (Uhpc) incorporating MgO expansive agent. J. Build. Eng. 2024, 96, 110529. [Google Scholar] [CrossRef]

- Li, S.; Mo, L.; Deng, M.; Cheng, S. Mitigation on the autogenous shrinkage of ultra-high performance concrete via using MgO expansive agent. Constr. Build. Mater. 2021, 312, 125422. [Google Scholar] [CrossRef]

- Cao, F.; Yan, P. The influence of the hydration procedure of MgO expansive agent on the expansive behavior of shrinkage-compensating mortar. Constr. Build. Mater. 2019, 202, 162–168. [Google Scholar] [CrossRef]

- Jiang, F.; Mao, Z.; Yu, L. Hydration and Expansion Characteristics of MgO Expansive Agent in Mass Concrete. Materials 2022, 15, 8028. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, G.; Ding, Q.; Yang, J.; Zhu, J.; Qi, D. Effect of expansive agent on lightweight micro-expansive ultra-high performance concrete: Properties, microstructure, and interfacial bonding in concrete-filled steel tube. Constr. Build. Mater. 2025, 462, 139996. [Google Scholar] [CrossRef]

- Zhang, Z.; Shao, H.; Cao, W.; Yin, S.; Liu, S. Understanding synergistic effects between MgO expansive agents and hydrophilic nano-silica in UHPC. J. Build. Eng. 2024, 95, 110049. [Google Scholar] [CrossRef]

- Hamada, H.; Alattar, A.; Tayeh, B.; Yahaya, F.; Almeshal, I. Influence of different curing methods on the compressive strength of ultra-high-performance concrete: A comprehensive review. Case Stud. Constr. Mater. 2022, 17, e01390. [Google Scholar] [CrossRef]

- Liu, J.; Farzadnia, N.; Khayat, K.H.; Shi, C. Effects of SAP characteristics on internal curing of Uhpc matrix. Constr. Build. Mater. 2021, 280, 122530. [Google Scholar] [CrossRef]

- Zhang, Q.; Dong, S.; Wu, F.; Cai, Y.; Xie, L.; Huang, C.; Zhao, J.; Yang, S.; Xu, F.; Zhu, Z.; et al. Investigation of the macro performance and mechanism of biochar modified ultra-high performance concrete. Case Stud. Constr. Mater. 2024, 21, e03595. [Google Scholar] [CrossRef]

- Dixit, A.; Gupta, S.; Pang, S.D.; Kua, H.W. Waste Valorisation using biochar for cement replacement and internal curing in ultra-high performance concrete. J. Clean. Prod. 2019, 238, 117876. [Google Scholar] [CrossRef]

- Du, J.; Wang, Y.; Bao, Y.; Sarkar, D.; Meng, W. Valorization of wasted-derived biochar in ultra-high-performance concrete (Uhpc): Pretreatment, characterization, and environmental benefits. Constr. Build. Mater. 2023, 409, 133839. [Google Scholar] [CrossRef]

- Kheir, J.; Klausen, A.; Hammer, T.A.; De Meyst, L.; Hilloulin, B.; Van Tittelboom, K.; Loukili, A.; De Belie, N. Early age autogenous shrinkage cracking risk of an ultra-high performance concrete (Uhpc) wall: Modelling and experimental results. Eng. Fract. Mech. 2021, 257, 108024. [Google Scholar] [CrossRef]

- De Maio, U.; Gaetano, D.; Greco, F.; Luciano, R.; Pranno, A. Degradation analysis of dynamic properties for plain concrete structures under mixed-mode fracture conditions via an improved cohesive crack approach. Fract. Struct. Integr. 2024, 18, 422–439. [Google Scholar] [CrossRef]

- Gong, B.; Li, H. A couple Voronoi-RBSM modeling strategy for RC structures. Struct. Eng. Mech. 2024, 91, 239–250. [Google Scholar]

- Long, X.; Mao, M.-H.; Su, T.-X.; Su, Y.-T.; Tian, M.-K. Machine learning method to predict dynamic compressive response of concrete-like material at high strain rates. Def. Technol. 2023, 23, 100–111. [Google Scholar] [CrossRef]

- Long, X.; Li, H.; Iyela, P.M.; Kang, S.-B. Predicting the bond stress–slip behavior of steel reinforcement in concrete under static and dynamic loadings by finite element, deep learning and analytical methods. Eng. Fail. Anal. 2024, 161, 108312. [Google Scholar] [CrossRef]

- Hua, H.; Li, M.; Yuan, Y.; Bai, H. Experimental research on the seismic performance of precast concrete frame with replaceable artificial controllable plastic hinges. J. Struct. Eng. 2023, 149, 04022222. [Google Scholar]

- Jie, W.; Liu, X.; Zhang, Z.; Liu, Y. Synergistic utilization, critical mechanisms, and environmental suitability of bauxite residue (red mud) based multi-solid wastes cementitious materials and special concrete. J. Environ. Manag. 2024, 361, 121255. [Google Scholar]

- ASTM C191-08; Standard Test Methods for Time of Setting of Hydraulic Cement by Vicat Needle. ASTM International: West Conshohocken, PA, USA, 2008.

- ASTM C1437; Standard Test Method for Flow of Hydraulic Cement Mortar. ASTM International: West Conshohocken, PA, USA, 2007.

- ASTM C 192/C 192M; Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory. ASTM International: West Conshohocken, PA, USA, 2007.

- ASTM C1698-09; Standard Test Method for Autogenous Strain of Cement Paste and Mortar. ASTM International: West Conshohocken, PA, USA, 2009.

- Fang, Y.; Wang, J.; Ma, H.; Wang, L.; Qian, X.; Qiao, P. Performance enhancement of silica fume blended mortars using bio-functionalized nano-silica. Constr. Build. Mater. 2021, 312, 125467. [Google Scholar] [CrossRef]

- Fang, J.; Xie, J.; Wang, Y.; Tan, W.; Ge, W. Alkali-activated slag materials for bulk disposal of waste waterglass foundry sand: A promising approach. J. Build. Eng. 2023, 63, 105422. [Google Scholar] [CrossRef]

- Qian, X.; Li, M.; Wang, J.; Wang, L.; Chen, P.; Fang, Y.; Wang, X.; Yang, F. A bio-inspired, plant-derived admixture for metakaolin blended cement mortars. Constr. Build. Mater. 2022, 354, 129185. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Ze, Z.; Guo, F.; Gao, J.; Deng, E.; Kong, J.; Zhang, L. Seismic performance of an innovative prefabricated bridge pier using rapid hardening ultra-high performance concrete. Structures 2025, 74, 108558. [Google Scholar]

- Meng, W.; Khayat, K. Effects of saturated lightweight sand content on key characteristics of ultra-high-performance concrete. Cem. Concr. Res. 2017, 101, 46–54. [Google Scholar] [CrossRef]

- Zhutovsky, S.; Kovler, K.; Bentur, A. Influence of cement paste matrix properties on the autogenous curing of high-performance concrete. Cem. Concr. Compos. 2004, 26, 499–507. [Google Scholar] [CrossRef]

- Henkensiefken, R.; Castro, J.; Bentz, D.; Nantung, T.; Weiss, J. Water absorption in internally cured mortar made with water-filled lightweight aggregate. Cem. Concr. Res. 2009, 39, 883–892. [Google Scholar] [CrossRef]

- Scrivener, K.; Snellings, R.; Lothenbach, B. A Practical Guide to Microstructural Analysis of Cementitious Materials; CRC Press: Boca Raton, FL, USA, 2016; Volume 540. [Google Scholar]

- Yang, G.; Wang, H.; Wan-Wendner, R.; Hu, Z.; Liu, J. Cracking behavior of ultra-high strength mortar with CaO-based expansive agent and superabsorbent polymer. Constr. Build. Mater. 2022, 357, 129281. [Google Scholar] [CrossRef]

- Das, B.B.; Kondraivendhan, B. Implication of pore size distribution parameters on compressive strength, permeability and hydraulic diffusivity of concrete. Constr. Build. Mater. 2012, 28, 382–386. [Google Scholar] [CrossRef]

- Zhang, S.; Qiu, S.; Jiang, Q.; Yan, C.; Zhou, L.; Li, X. Modeling damage evolution in granite under temperature using a thermo-mechanical grain-based FDEM model. Comput. Geotech. 2024, 169, 106198. [Google Scholar] [CrossRef]

- Zhang, W.; Xue, M.; Lin, H.; Duan, X.; Jin, Y.; Su, F. Effect of polyether shrinkage reducing admixture on the drying shrinkage properties of alkali-activated slag. Cem. Concr. Compos. 2023, 136, 104865. [Google Scholar] [CrossRef]

- Němecek, J.; Smilauer, V.; Kopecky, L.; Německová, J. Nanoindentation of alkali-activated fly ash. Transp. Res. Rec. 2010, 2141, 36–40. [Google Scholar] [CrossRef]

- Fang, Y.; Wang, J.; Qian, X.; Wang, L.; Chen, P.; Qiao, P. A renewable admixture to enhance the performance of cement mortars through a pre-hydration method. J. Clean. Prod. 2022, 332, 130095. [Google Scholar] [CrossRef]

- Kim, J.J.; Foley, E.M.; Taha, M.M.R. Nano-mechanical characterization of synthetic calcium–silicate–hydrate (C–S–H) with varying CaO/SiO2 mixture ratios. Cem. Concr. Compos. 2013, 36, 65–70. [Google Scholar] [CrossRef]

| SiO2 | CaO | Fe2O3 | Al2O3 | MgO | K2O | Others | |

|---|---|---|---|---|---|---|---|

| Cement | 25.32 | 53.11 | 4.01 | 5.63 | 3.81 | 0.83 | 7.29 |

| Silica fume | 97.1 | 0.43 | 0.61 | 0.93 | 0.35 | 0.19 | 0.39 |

| Fly ash | 59.3 | 3.38 | 3.83 | 25.19 | 1.1 | 1.1 | 6.1 |

| Expansive agent | 4.28 | 73.81 | 0.89 | 5.55 | 1.32 | 0.23 | 13.92 |

| U0 | B2 | B2/E1 | B2/E2 | B2/E3 | B2/E4 | |

|---|---|---|---|---|---|---|

| Cement | 971 | 971 | 971 | 971 | 971 | 971 |

| Silica fume | 155 | 155 | 155 | 155 | 155 | 155 |

| Fly ash | 169 | 148 | 148 | 148 | 148 | 148 |

| Quartz sand | 997 | 997 | 997 | 997 | 997 | 997 |

| Water | 171 | 171 | 171 | 171 | 171 | 171 |

| Expansive agent | 0 | 0 | 9.71 | 19.42 | 29.13 | 38.84 |

| Biochar | 0 | 21 | 21 | 21 | 21 | 21 |

| Steel fiber | 187 | 187 | 187 | 187 | 187 | 187 |

| Superplasticizer | 25 | 25 | 25 | 25 | 25 | 25 |

| Total binder * | 1295 | 1295 | 1304.71 | 1314.42 | 1324.13 | 1333.84 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, C.; Zong, Z.; Chen, P. Enhancing the Performance of Ultra-High Performance Concrete Using Expansive Agent and Pre-Wetted Biochar to Produce a Synergistic Effect. Buildings 2025, 15, 1348. https://doi.org/10.3390/buildings15081348

Huang C, Zong Z, Chen P. Enhancing the Performance of Ultra-High Performance Concrete Using Expansive Agent and Pre-Wetted Biochar to Produce a Synergistic Effect. Buildings. 2025; 15(8):1348. https://doi.org/10.3390/buildings15081348

Chicago/Turabian StyleHuang, Congbin, Zijian Zong, and Peiyuan Chen. 2025. "Enhancing the Performance of Ultra-High Performance Concrete Using Expansive Agent and Pre-Wetted Biochar to Produce a Synergistic Effect" Buildings 15, no. 8: 1348. https://doi.org/10.3390/buildings15081348

APA StyleHuang, C., Zong, Z., & Chen, P. (2025). Enhancing the Performance of Ultra-High Performance Concrete Using Expansive Agent and Pre-Wetted Biochar to Produce a Synergistic Effect. Buildings, 15(8), 1348. https://doi.org/10.3390/buildings15081348