Abstract

The developments in building information modeling (BIM) technology provide a new approach for remote real-time visualized bridge health monitoring and structural damage detection, but so far, there are scarcely any application cases of a BIM-based SHM system for butterfly arch bridges around the world. This paper reviewed the recent progress on the butterfly arch bridge and its requirements for the integration between SHM and BIM. Based on an actual project in southwest China, work on the spatial mechanical properties, the analysis of monitoring requirements, and the design of functional modules of SHM are elaborately conducted. Subsequently, the lightweight BIM is established and integrated into the web client-side of the SHM system with the skeleton-template method, CATIA platform, and sensor data. With the implementation of user-defined virtual sensor parameter linkage, the design of the specific databases is accomplished in the SQL server environment. Based on one actual incident that saw an overweight/oversize vehicle (with the weight of 80 t, 2015) pass over the arch bridge, the fuzzy relation synthesis and data cleaning method were improved to compare the standard deviation with the threshold value of the correlation degree, and a method is adopted to evaluate the structural operation behavior of the bridge and the service condition of the BIM-based SHM system after the ultra-limit accident. The study results evince the validity and efficiency of the BIM-based SHM system, which could lay a foundation for the visualized assessment and early warning system of long-span bridges.

1. Introduction

1.1. Progress in Structural Health Monitoring (SHM) for Bridges

The operational safety of in-service bridges is an important worldwide problem, and is also a hot issue and continuous challenge focused on at present by international scholars of bridge engineering, particularly for long-span bridge structures [1]. Due to the severe and complicated service conditions, long-span bridges are inevitably subjected to long-term vehicle cyclic loading and heavy loads, suffer from long-term environmental erosions such as sunshine exposure, high temperature, strong rain, corrosion, freeze–thaw cycles, and experience extreme loads such as earthquakes, typhoons, and collisions [2,3,4,5,6]. Therefore, it is imperative to carry out periodical inspection and structural health monitoring of bridge structures regularly. In the past century, there have been numerous safety accidents regarding in-service bridges domestically and overseas due to unreasonable structural design, construction defects, natural disasters, inadequate management, and other reasons [7,8,9,10,11,12,13,14,15,16], and the safety and durability of bridge operation is becoming increasingly important and has become a hot issue and the focus of researchers.

SHM systems for bridges have achieved extensive development and application over the past four decades since they were first put forward in the 1980s. After the accident of the Silver Bridge collapse in 1967, the United States specially formulated the national bridge monitoring standard, which later became the first SHM-related standard and laid a foundation for the health monitoring and detection of bridge structures. On that basis, a series of bridge health monitoring system applications have been carried out since the middle of the 1980s [17,18,19]. In 2009, the University of Illinois Urbana-Champaign organized research into the deployment of the SHM system for the Jindo Bridge in Korea, where they collaboratively designed an SHM system with a total of 70 monitoring nodes and 113 sensor instruments and achieved data acquisition for the cable force status, main tower deviation, and stress distribution of main girder using real-time wireless network transmission [20]. The research and construction of bridge SHM systems in China date back to the SHM systems on Tsing Ma Bridge, Kap Shui Mun Bridge, and Ting Kau bridge in Hong Kong. A complete SHM system, one of the largest bridge SHM systems in the world at the time [21], was built for real-time dynamic tracing of bridge conditions during its service life. Since then, a majority of other SHM systems have been developed and installed in long-span bridges [22,23,24,25,26,27]. In addition, some super long-span bridges, such as the Pingtan Strait Rail-cum-Road Bridge, which is under construction (the longest rail-cum-road sea-crossing bridge in the world), and the Wufengshan Yangtze River Bridge [28] (the first modern suspension bridge for high-speed railway) are also actively building refined SHM systems. These SHM systems advance our understanding of the development of long-term monitoring systems. Much more importantly, the data acquired from the SHM systems can be utilized for evaluating the serviceability, safety, and sustainability of long-span or super long-span bridges [29,30,31,32].

1.2. Building Information Modeling Technology in Structural Health Monitoring Systems

Along with the continuous development of bridge span, structural type, and construction materials, the requirements for bridge SHM are also becoming higher and stricter [33]. Meanwhile, there still exist some obvious problems in the traditional SHM system of bridges, such as the lag of monitoring results, its insufficiency in reflecting damage location and damage condition directly, the lack of effective indicators for evaluating real-time bridge structural health status, etc.

Due to the distinct advantages of its information visualization, the real-time coordination, and its interdisciplinary metamodeling [34], BIM has been increasingly gaining popularity in architecture, the construction industry, and machinery manufacturing [35]. Seam et al. [36] combined BIM with real-time monitoring of structural health and damage assessment methods, which evidenced that this could provide a robust and intelligent system for managing modern modular building. Rio et al. [37] revealed that accomplishing a dynamic monitoring system for the structural behavior of a building to provide sensor data for BIM is not part of the BIM functionality and is still a challenge. Sternal and Dragos [38] proposed a BIM-based modeling of wireless SHM systems using the industry foundation class (IFC) standard. Smarsly and Tauscher [39] proposed a conceptual monitoring information modeling built on the IFC standard to present monitoring-related digital information. Wang et al. [40] found that applying BIM in SHM can improve the effectiveness of monitoring processes and decision making in construction informatics applications. Del Grosso et al. [41] attempted to explore the idea of integrating 6D digital models with SHM systems, but the study mainly focused on creating and modeling the sensor system in the BIM software application and did not provide the linkage to sensor data or facilitate visualization. Valinejadshoubi et al. [42] drew out a preliminary scheme for utilizing BIM to assess the seismic risk of nonstructural components in buildings. Mojtaba Valinejadshoubi et al. [42,43] attempted to design a BIM-based prototype SHM system using the extended IFC schema and then explored an integrated strain-based monitoring system framework in a BIM environment.

Despite the fact that BIM has clear advantages and potential benefits in the application of SHM systems, there still exist some noticeable challenges and choke points, and few attempts have been made to integrate BIM technology into bridge structural health monitoring, especially for long-span bridges. The engineering application examples of BIM technology in bridges at present are mainly focused on the design, engineering construction, evaluation management, and so on [44,45,46,47]. Nonetheless, the existing BIM implementation of SHM and relevant research work in the field of bridge SHM are still relatively lacking and usually limited to small-scale structures [48,49,50,51,52].

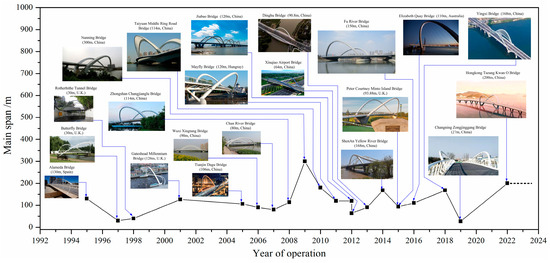

1.3. Butterfly Arch Bridge and Its Requirements for SHM

The butterfly arch bridge is a novel arch structure characteristic of a couple of outward-inclined arch ribs, different from the paralleled upright ones in conventional arch bridges. Jan Bobrowski and partners designed the first typical butterfly arch bridge in the world, designated as Butterfly Bridge, which is a pedestrian bridge over the River Great Ouse in England. Ever since then, the Rotherhithe Tunnel Bridge in Britain, the Seri Empangan Bridge in Malaysia, etc., were established successively. In some cases, one arch rib of the butterfly arch bridge is upright, whereas the other one is outward-inclined, such as the Alameda Bridge in Spain [53] and the Gateshead Millennium Bridge in Yorkshire [54]. With the rapid development of China’s urbanization in the past few years, numerous cities embark on planning and building individual landmark bridges. Due to the impressive design and graceful appearance, the butterfly arch bridge schemes have been increasingly realized and even become a landmark architecture in some regions (Figure 1). More than ten outward-inclined butterfly arch bridges have been built in China so far, such as the Dagu Bridge in Tianjin Municipality [55], which is China’s first butterfly arch bridge with span arrangement of (24 + 106 + 24) m. Another representative engineering project is Nanning Bridge [56], which is the first long-span curved-girder asymmetric butterfly arch bridge in the world. Beyond those, a few more butterfly arch bridges are being planned, designed and constructed, such as Luxi River Bridge in Sichuan, Foshan Guipanhai Bridge in Guangdong, etc. Compared to traditional ones, the component and mechanical features of butterfly arch bridges are more complicated and ambiguous. And this makes the structural health monitoring (SHM) for butterfly arch bridges more necessary and urgent, especially under the background of increasing traffic load, vehicle overloading and more frequent natural disasters.

Figure 1.

Major development history of butterfly arch bridges worldwide.

In this study, the recent progress of bridge SHM systems and previous research on BIM-based SHM are reviewed. Aiming at the existing problems in traditional bridge SHM systems, the Internet+ and BIM technologies are introduced to overcome these disadvantages and accomplish the real-time visual surveillance and scientific management of monitoring data, which could display the damage position and service conditions intuitively. This paper investigates the integration between BIM and SHM through three-dimensional information modeling technology and sensor monitoring data, and realizes a feasible and effective informationalized visual scheme for long-span bridge structural health monitoring. The main contents of this paper include Requirements Analysis of the SHM System for Butterfly Arch Bridges, Implementation of the SHM System for Butterfly Arch Bridge in BIM Environment, Monitoring Results Analysis of Butterfly Arch Bridges, and Challenges and Development Trends of BIM-based SHM Systems for Long-span Bridges.

2. Requirements Analysis of the SHM System for Butterfly Arch Bridges

2.1. Requirement Analysis of Monitoring Items

2.1.1. Spatial Mechanical Properties of Butterfly Arch Bridges

The force balance of the butterfly arch bridge structure system is attained primarily through the interactions among the main girder, arch rib, suspenders, tied-bars, etc. The mechanical characteristics of butterfly arch bridges mainly manifest in the following parts:

- Highly statically indeterminate feature of the structure system.

- Obvious spatial force distribution of arch ribs. The arch ribs are not only subjected to tensile forces of suspenders and end cross beams, but also bear internal forces such as the biaxial bending moment, torsion, compressive axial force, shearing force, and out-of-plane bending moment under dead loads. Therefore, the eccentric center should be set between suspenders and the arch plane to balance arch ribs’ overturning moment.

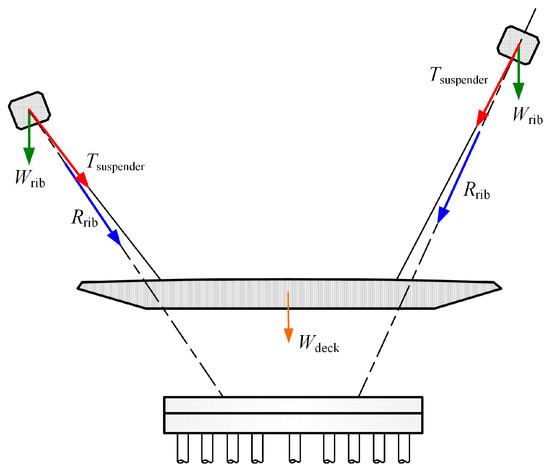

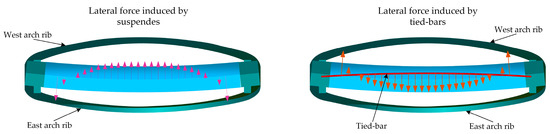

- Large lateral displacement of arch ribs. Large lateral displacement could appear when the outward-inclined arch ribs are subjected to external loads, leading to distinct changes in the geometrical shape of butterfly arch bridges. By and large, the spatial forces and lateral displacements depend on the arch geometric shape and the mutual matching relation of the gravity load and overall stiffness of bridge components (Figure 2). Hence, monitoring of the displacement and stress state becomes particularly important.

Figure 2. Integral form-finding schematic diagram of the butterfly arch bridges.

Figure 2. Integral form-finding schematic diagram of the butterfly arch bridges. - Complicated mechanical characteristics of the main girder. In addition to the vehicle loads and pedestrian loads, the main girder will also bear the uneven lateral force component induced by axial forces in suspenders. Moreover, the pushing force and lateral force components of other loads also act on the main girder.

- Complicated mechanical characteristics of the suspender. The suspenders need to be spatially arranged to provide enough constraints to avoid the buckling of outward-inclined arch ribs. Since the vertical component is certain, the force of suspenders is closely related to the inclination angle of arch ribs, and all the equilibrium relationships (such as the out-of-plane equilibrium of the arch) differ from conventional ones (Figure 3).

Figure 3. Representative spatial mechanical schematic diagram of the butterfly arch bridges.

Figure 3. Representative spatial mechanical schematic diagram of the butterfly arch bridges.

2.1.2. Pivotal Monitoring Items

Based on the spatial mechanical features of the butterfly arch bridges, the impacts that are focused on during the SHM measurements are listed as follows:

(1). Environmental Monitoring of the Bridge Site

- Ambient Humidity Monitoring. The effect of alternate wetting and drying (AWD), in general, is quite detrimental to the durability of steel bridges.

- Ambient Temperature Monitoring. The ambient temperature will give rise to the temperature difference and local temperature gradient among different components of the bridge structure, and then produce secondary internal forces in local member bars of the main girder. Of the above considerations, the structural temperature of cross-sections on main girder and arch ribs should be monitored meticulously.

(2). Overall Structural Performance Monitoring of the Bridge

- Geometric Alignment Monitoring. The bridge axial alignment is directly influenced by the concrete creep, support settlement, temperature variation, and the overall structural stiffness of the bridge. Hence, it is crucially important to monitor the static displacement, dynamic displacement, settlement, inclination and so on to guarantee the structural operation safety during service life.

- Structural Vibration Monitoring. Once the damage or other abnormal cases appear in bridge structures, dynamic properties will change with it accordingly. So, primary monitoring items of the structural vibration include dynamic deflection, dynamic strain, transverse acceleration, and so on.

- Load-carrying Member Monitoring. The monitoring of primary load-carrying members, such as the main girder stress and main arch rib stress, is very essential.

(3). Local Structural Performance Monitoring of the Bridge

Local structural performance monitoring items mainly aim at special parts of the bridge, such as the suspender stress and tied-bar stress, whose abrupt change of stress conditions could be an important indication of local buckling.

(4). Traffic Safety Monitoring

The moving vehicle loads and its time-histories are acquired by means of remote real-time monitoring and recording, which could provide the load data for structural self-diagnostic analysis and reliability analysis.

2.2. Requirement Analysis of SHM System Function

By installing the testing equipment on representative key cross-sections and positions of the bridge, the variation of the environment, loads, and responses will be transformed into digital–analog signals such as electric current and voltage through built-in sensor circuits. Furthermore, the environmental parameters, vehicle load parameters, video monitoring information, and structural responses could be eventually gained using an analog/digital converter (ADC). The requirements for realizing the functions of the structural health monitoring are presented in the following.

- Automatic continuous acquisition and remote transmission of monitoring data.

- Effective disposal and control management of mass data.

- Data analysis and structural health evaluation.

- Comprehensive display of user interface (UI).

- Information sharing and collaborative linkage.

2.3. Requirement Analysis of SHM System Capability for Butterfly Arch Bridges

As a vital operation, administration, and maintenance (OAM) system for the butterfly arch bridge, some other indispensable capabilities are also demanded when developing and utilizing SHM system, mainly including the versatility and extendibility, the safety and stability, the quick response ability, the easy maintenance, the self-diagnosis and error resilience ability as well as the hierarchical protective ability of the SHM system.

2.4. Requirement for BIM-Based SHM Data Management System in Butterfly Arch Bridge

Based on the review of the SHM literature and analysis of spatial mechanical characteristics of butterfly arch bridges, requirements for BIM technology in the SHM system of the butterfly arch bridge are presented in the following.

- Due to complicated loading states of butterfly arch bridges, it is difficult to carry out routine maintenance. Until now, there have only been a few studies on the SHM system for butterfly arch bridges domestically and overseas, and scarcely any studies concerning the developing and utilization of BIM-based SHM system on butterfly arch bridges.

- The large-scale SHM system of complicated bridges will produce mass monitoring data, which could result in the problem of poor interface interaction ability and ineffective data management. The powerful information management ability of BIM technology needs to be applied to accomplish 3D visualization and better disposal efficiency.

- The whole BIM model of bridge structures is generally large-sized. There still exist unavoidable problems such as low database query speed, bad display effect, and poor efficiency of user information sharing. Hence, the lightweight disposal of the BIM model is of great importance to achieve more convenient and efficient database querying.

- The function of video monitoring is usually not abundant for bridge SHM systems, and the exceedance event of monitoring data should be supervised through the linkage between the video monitoring system and SHM subsystem.

3. Implementation of the SHM System for Butterfly Arch Bridges in BIM Environment

3.1. General Description of the Butterfly Arch Bridge

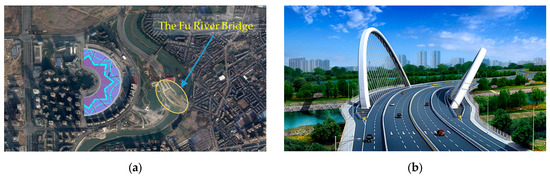

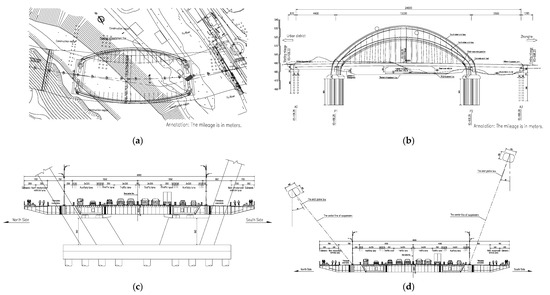

- Geographical Location: The Fu River Bridge is located over the Fu River, which is to the east of the new Convention and Exhibition Center, Chengdu, China (Figure 4). The construction of this bridge was started in 2012 and finished within three years.

Figure 4.

Geographic location and scenery of the Fu River Bridge: (a) vertical view; (b) front view.

- General Layout: The bridge is designed as an asymmetric butterfly arch structure, with a span arrangement of 44.00 + 150.00 + 55.00 m and a total length of 264.65 m. The scheme of a two-way five-lane urban expressway is adopted, with a total width of 69.00 m (Figure 5). The main span is within the horizontal curve, with the northern and southern arch ribs located in their respective inclined planes. The two arch ribs have different inclined angles, bound up with each other under the main girder, and there are no transverse connections between the two arch ribs over the deck.

Figure 5.

General layout and dimensions of the Fu River Bridge (unit: cm): (a) plan view; (b) elevation view; (c) standard cross-section at the main pier; (d) standard cross-section in the midspan.

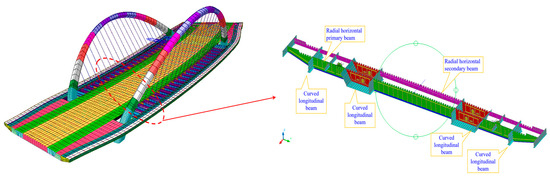

- Main Girder: The main girder consists of a three-span continuous beam and the cross-section is composed of a double longitudinal box-girder. The deck system is composed of the radial horizontal beam and curved longitudinal beam (see Figure 5a,b,d and Figure 6). The lateral force is dominant in the horizontal beam for the main span, while the longitudinal force is dominant for the side span. In addition, the orthotropic steel bridge deck is adopted in the design.

Figure 6.

Spatial structural finite element model and detailed subassemblies of main girder.

- Arch Rib: The arch ribs consist of the steel-box arch rib segment and concrete arch rib segment (see Figure 5b,d). In each arch plane, the arch axis of the steel-box arch rib is the catenary line, and that of the concrete arch rib is composed of the circular curve and straight line. The calculated span and calculated rise of the southern arch rib are 154.772 m and 57.706 m, respectively. Those of the northern ones are 145.951 m and 47.919 m, respectively. Furthermore, the angles between the planes of the south and north arch rib and the horizontal plane are 72° and 60°, respectively.

- Suspenders: The suspender projection is along the radial direction. There are 20 suspenders with intervals of 6 m along the arch length (see Figure 5a,b and Figure 6). The transverse double-cable system is adopted to make the cable replacement construction at the operation stage more convenient. The lengths of the suspenders range between 13.0 m and 42.0 m. The low-relaxation epoxy-coated strand and the extruded whole-bundle anchorage method are employed in the bridge.

- Abutments and Piers: The gravity abutment and the plate-type pier are adopted during the design of the abutments and piers, respectively (see Figure 5c).

- Tied-Bar Cables: There are 12 bundles of tie bar cables arranged on the bridge in total. They are divided into the south group and the north group. Each of them has six bundles. All the tied-bar cables are anchored on the anchor seat of the concrete arch rib by the steering gear, which is located at the bottom of the steel-box girder.

- Technical standard: The bridge design followed Chinese bridge design standards in general, supplemented with American Association of Highway and Transportation Officials (AASHTO) design criteria to better address the special features and requirements of this bridge. The road grade is designed to be an urban expressway, and the design speeds of the main lane and auxiliary lane are 60 km/h and 30 km/h, respectively. The design value of the vehicle load and pedestrian load are urban Level A and 3.0 kPa, respectively. The design flood level is 482.06 m (once in two centuries). The design basic wind speed is 24.5 m/s. The channel grade is VI, and the maximum navigable water level is 479.76 m. The design characteristic period of ground motion is 0.4 s and the basic seismic intensity is VII. In addition, the design reference period is 100 years and the design security level is Level I.

3.2. Location and Category Determining of Physical Transducers and Instruments

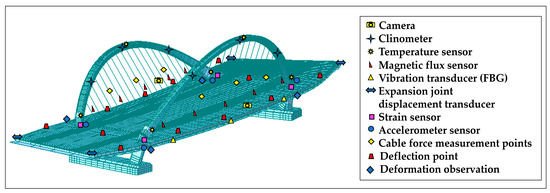

Based on the construction blueprints, the professional software midas Civil was adopted to analyze the spatial mechanical characteristics and ascertain the key parameter positions of the Fu River Bridge (such as the maximum deflection, maximum stress, maximum vibration acceleration and so on). According to the analysis results and site environment, the main monitoring items and measuring sensor arrangement are depicted in Figure 7 and Table 1.

Figure 7.

Sensor arrangement of the SHM system of the Fu River Bridge.

Table 1.

Types, specifications and quantity of the sensors of SHM system of the bridge.

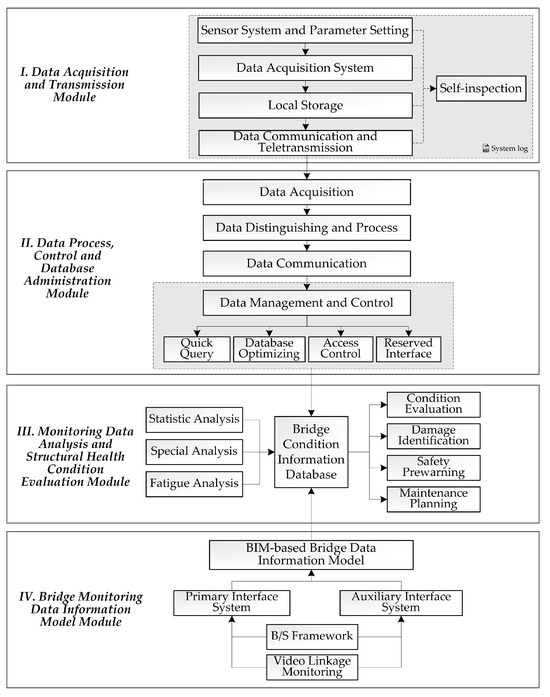

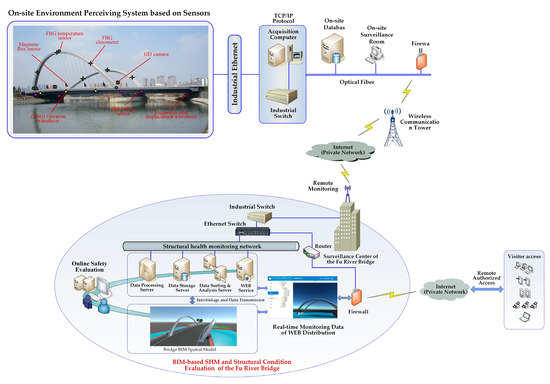

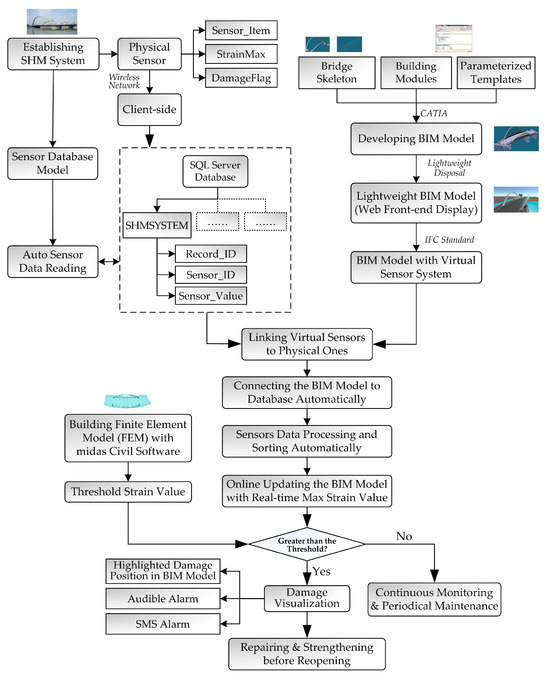

The above SHM system is designed to focus on the bridge deflection, stress condition of key cross-sections in the arch rib and main girder, the vibration acceleration of the arch rib, the cable force variation of suspenders and tied-bars, structural temperature, and traffic loads. The monitoring data from each sensor are acquired and stored on the on-site acquisition PC, transmitted to the surveillance center by use of the wireless communication and remote monitoring techniques. The supervisor PC then retrieves, processes, displays and analyzes these data, and provides the real-time safety evaluation for the bridge operation. The integral design architecture of the BIM-based SHM system for the Fu River Bridge is shown in Figure 8, and the flowchart of BIM-based SHM and structural monitoring and evaluation system is shown in Figure 9.

Figure 8.

The integrated design architecture of the BIM-based SHM system for this bridge.

Figure 9.

The flowchart of BIM-based SHM and structural monitoring and evaluation system.

3.3. Integrated Design of the Structural Health Monitoring System in the Fu River Bridge

According to the structural features of the Fu River Bridge, the structural health monitoring system is designed to include four primary modules, and the integrated design architecture of the BIM-based SHM system in the Fu River Bridge is depicted in Figure 8.

3.3.1. Data Information Acquisition and Transmission Module

The data information acquisition and transmission module is set in the outstation of the bridge site, and equipped with local storage, data telecommunication and continuous transferring from breakpoint. In addition, the module could realize automatic maintenance through the self-inspection and running log system, in order to guarantee the stability of the data collection and transmission.

Based on the features of physical variables to be monitored, multifarious intelligent sensors (including the stress and strain transducer, acceleration transducer, wind speed transducer, and high-definition camera) are adopted to acquire and record the monitoring data of the bridge. The raw data collected through this module are stored locally by means of scrolling storage, and the caching technology is introduced to ensure the storage efficiency and reduce the failure rate of the storage medium. The data exchange and transmission are accomplished based on TCP/IP protocol, and the data are sent to the remote datacenter in a packet, capable of data compression and decompression (Figure 9).

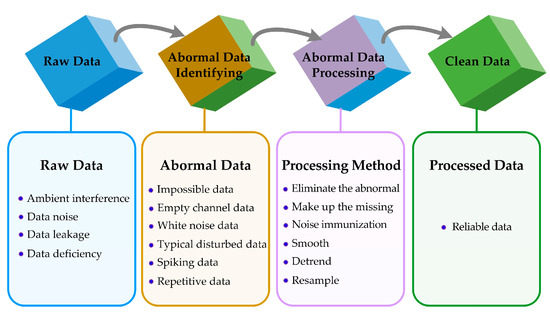

3.3.2. Data Processing, Control and Database Administration Module

- Data Processing and Control: Due to the influence of various uncontrollable environmental factors, the raw monitoring data generally contain noisy ingredients, and sometimes even data leakage, fragmentation, and distortion, which is detrimental to the effective and accurate evaluation of the bridge condition. In view of this, the data cleaning method was adopted to distinguish and dispose of the raw monitoring data to obtain reliable data that could reflect the real service status of the bridge structure. In the practice of monitoring, the abnormal data mainly consist of the incredible data, empty channel data, white noise data, typical disturbed data, spiking data, repetitive data, and duplicate data. Aiming at these abnormal data, some indispensable data mending measures, such as elimination, makeup, noise immunization, smoothing, and resampling, were introduced to the monitoring data processing and control, and its flow diagram (Figure 10) is presented as follows.

Figure 10.

The flowchart of the monitoring data processing and control in this study.

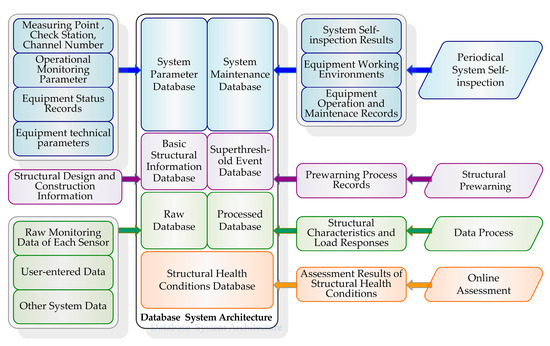

- Database Administration Module: The SHM system of the butterfly arch bridge will produce mass data through 24 h continuous online monitoring of numerous sensors. Due to diverse data sources and complex data formats, it is necessary to implement an integrated proper strategy of data reorganization before storage in the database. Therefore, seven databases are logically constructed, including the system parameter database, structural information database, raw database, processed database, structural health conditions database, suprathreshold event database, and system maintenance database. By means of modular design, the database tables could be stored on different hard disks, which will increase the access speed (Figure 11).

Figure 11.

The schematic diagram of the database system architecture.

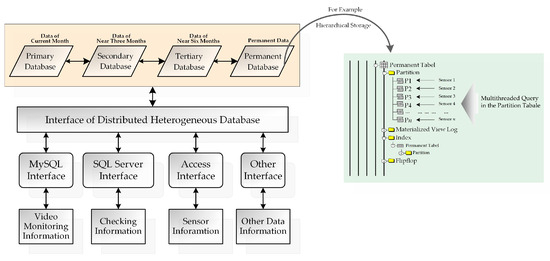

In order to adapt to the mass data collected from the SHM system, a few effective measures, such as hierarchical caching, partition storage, and search index, are taken to improve the efficiency of the data access and index. The hierarchical caching divides a group of data into several database tables: the Primary Database, which stores the data in just the last month; the Secondary Database, which stores the data in the last three months; the Tertiary Database, which stores the data in the last six months; the Permanent Database, which stores the data in the last ten months and before. The partition storage divides a big table into several minor table spaces and thereby promotes the performance of the table maintenance, backup, recovery, query, and physical-layer manageability. The data search could index the target data in a related database table according to acquisition time. The target data in the near term could be queried promptly from the minor database table. In addition, strict user authorization management and high-intensity encryption algorithm, aiming at the client side and server side, should be executed to ensure the security of data storage and transmission. Meanwhile, relevant data interfaces are reserved to realize the convenience of data interaction of the exterior and interior system (Figure 12).

Figure 12.

The schematic diagram of the partition and hierarchical storage.

3.3.3. Monitoring Data Analysis and Structural Health Condition Evaluation Module

The fundamental function of this module is to obtain the bridge vibration indicator and deformation indicator through sensing equipment. Afterwards, safety precautions, condition assessments, and the relevant maintenance scheme could be implemented through the SHM system and bridge engineer’s analysis.

- Data Statistical Analysis: Based on the time-series data analysis, the statistical results of monitoring data, such as maximum and minimum value, mean value, mean square value, and aggregate value, will be properly stored in the database.

- Data Specific Analysis: This module consists of loads and environmental monitoring data analysis (vehicle load analysis, temperature analysis, etc.), whole structural response monitoring analysis (structural deformation analysis, beam end displacement, and acceleration analysis) as well as the local structural response monitoring analysis (strain time-history analysis, tied-bar force time-history analysis, etc.).

- Real-time Safety Prewarning: The safety prewarning system of this bridge consists of two levels: Yellow Alert and Red Alert. Yellow Alert indicates situations including a gross vehicle weight equal to or greater than the 150% of designed vehicle load, suspender, arch rib or main girder stress equal to or greater than 95% of designed stress, and displacement or deformation equal to or greater than 80% of the designed value. In the case of Yellow Alert, more focus and close observations should be implemented on the environment, loads, whole structural responses, and local structural responses. Red Alert indicates situations including a gross vehicle weight equal to or greater than 200% of designed vehicle load, suspender, arch rib or main girder stress equal to or greater than designed stress (or more than ten yellow alerts in one month), and displacement or deformation equal to or greater than 80% of the designed value (or more than ten yellow alerts in one month). In the case of Red Alert, more focus and closer observations should be implemented on the environment, loads, whole structural responses and local structural responses. And what is more, the alarm reasons need to be immediately traced, and emergency management and safety evaluation measures should be promptly taken to guarantee the safe operation of the bridge structure.

- Online Safety Evaluation: The bridge operation conditions are directly influenced by various factors, such as the design, construction technology, building materials, operation load, environment, and maintenance status, which also cause difficulty in assessing the bridge’s structural health because of the mutual interactions and effects among the above factors. In view of these facts, the fuzzy analytic hierarchy process (FAHP) is introduced to evaluate the raw data gathered from the various sensors of the SHM system. Based on the fuzzy relation synthesis, this method could realize quantification of those indicators which are hard to quantify, establish the weight vectors of different evaluation indices via building comparative judgment matrix and iterative computation, and then accomplish the quantitative calculation of various indices and the assessment of bridge health conditions. The assessment system of the butterfly arch bridge consists of the bottom index (to evaluate conditions of the foundation settlement, line shape of main girder, main girder stress, etc.), middle index (to evaluate the conditions of the substructure, main girder, arch rib, suspender and ancillary facilities) and top index (to evaluate the overall operation conditions of the bridge), in which the determination of every index weight plays a crucial role in the process of bridge condition assessment.

Assume that the weight vector is a subset of the evaluation index factor set, which represents the importance degree of every evaluation index factor when evaluating the bridge’s operation conditions. And there are index factors in the evaluating layer of the bottom index, and thereby the comparative judgment matrix could be constructed, where the symbol represents the i-th objective’s relative importance to the j-th objective.

Before utilizing the iterative computation method to obtain the objective weight vector, the elements of the fuzzy judgment matrix should first be normalized, and then we have:

And then follows the computational vector , where the calculated expression of each element can be depicted as below:

Thereupon, each element of the weight vector matrix is expressed as:

We introduce the membership degree set to represent the evaluation index factor set incidence relationship to the evaluation membership degree set, that is:

where the above elements manifest the i-th element’s membership degree to the j-th element. And the lower the value of , the lower the membership degree, and vice versa.

In this paper, the lower semi-trapezoid distribution function is adopted to represent the membership degree function, that is:

where is the absolute value of the i-th factor; and are the maximum value and minimum value of the γ-th factor index, respectively.

On the basis of obtaining the membership degree function, the scores of evaluation indices could be subsequently figured out, of which the score of the bottom index should be obtained through specialized persons according to industry standards. Furthermore, the fuzzy evaluation set of the middle index could be calculated, that is:

where and represent the weight vector and the membership degree set of the bottom index, respectively.

After obtaining the evaluation set of the middle index, the score of the top index will be calculated, and then the final overall score of the bridge structural health conditions could be accomplished, that is:

3.3.4. Bridge Monitoring Data Information Model Module

The information model system of the bridge monitoring data is a whole life-cycle information model system based on BIM technology, which could provide fundamental data for the construction and structural health monitoring of bridges. It runs throughout the planning stage, design stage, construction stage and especially the operation maintenance stage. The engineering data information, inspection information, equipment information, and sensor information of the bridge BIM environment could offer fundamental data files for the comprehensive evaluation of bridge structural health conditions.

3.4. BIM Application in the SHM System of the Fu River Bridge

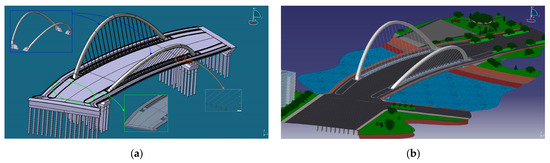

In order to achieve functions such as data and file collaboration, 3D visualization, quick positioning of monitoring points, and visual presentation of monitoring data in the Fu River Bridge, the building information model (BIM) technology is integrated into the establishment of the structural health monitoring (SHM) system. Considering the actual design style of the Fu River butterfly arch bridge and strict requirements for curve lines, curved surfaces, and spatial design capabilities, CATIA software, developed by French Dassault System, is eventually adopted to act as the BIM operating platform, and the three-dimensional modeling technique of the skeleton-template method is applied when constructing the primary component of the butterfly arch bridge (such as the foundation, arch rib, bridge deck, cable, and bridge bearing) and the local parameterized components.

3.4.1. Establishment of the Bridge Skeleton

According to the basic constitution and characteristics of butterfly arches, the longitudinal centerline of the main girder is set as the X-axis, the horizontal centerline of the main girder is set as the Y-axis, and the Z-axis is defined by the line that is vertical to the X-Y plane. During the establishment of the skeleton of the butterfly arch bridge, key points, lines, and surfaces elements (such as the road centerline, spring line of arch rib, arch support, pier, cushion cap, etc.) are first built. And then, by means of CATIA’s issuing function, these key points, lines, and surfaces elements could be issued so that other products could establish the bridge model with these issued modeling components. Meanwhile, related virtual strain transducers in the BIM model should be created corresponding to physical ones in the SHM system. Through this method of establishing the model, a certain part of the bridge can be accessed conveniently. Simultaneously, a hidden function could also be applied and hide the structural components that are not required to be displayed in the hidden storage space.

3.4.2. Parametric Design of the Modeling Template

In the course of building the butterfly arch bridge model, the design knowledge and technological process can be integrated into the user feature, powercopy, and document template, by which new bridge models can be established easily and conveniently, with only some parameter alterations to the referenced elements. After creating skeletons of each related subject, the parameterized and functional design of the bridge components is urgently required to realize the fast inquiry and attribute change of the model components. Furthermore, aiming at the vital factors (including the structural dimension, material property, spatial position, etc.) of the important bridge components, such as the arch rib, main girder and suspender, the structural templates and parameterized components for the butterfly arch bridge modeling are finally set up through the User-defined Feature (UDF) function in the Knowledge Engineering module. As for the spatial components with complicated shapes, equations of higher order and complex equations are usually introduced to control and construct the model edge lines. Selecting key points, lines, and surfaces of the butterfly arch bridge skeleton as the locating information and inserting modeling templates of parameterized components according to the above locating information, the information models of components could be established. Based on the above method, information models of the main girder, arch ribs and so on are created sequentially, and the rendered initial model could be eventually obtained, as shown in Figure 13.

Figure 13.

The BIM model of the Fu River Bridge: (a) initial BIM model of the butterfly arch bridge (including detail structures); (b) render of BIM model of the butterfly arch bridge (without lightweight disposal).

3.4.3. Lightweight Disposal of the BIM Model

The complete BIM model established by the CATIA platform could describe all the engineering information of the bridge structure with pinpoint accuracy. However, it needs a huge number of calculations and memory storage to divide the complete model into a polygonal mesh when displayed on the web client side, which leads to an inordinately long time for model loading and latency. Furthermore, there also exist other serious problems, such as an excess of redundant information, inferior model compatibility, hysteretic nature, etc. Meanwhile, considering that the complete BIM model includes sensitive design information such as the modeling process and characteristic parameters, there is a big risk of damage and property loss once the sensitive information is used in other aspects. All of the above problems have hampered the application of BIM technology in the SHM system sharing to some extent. In view of the actual demand of this bridge SHM system, lightweight disposal measures are adopted in the complete BIM mode of the butterfly arch bridge, including the following.

- Simplifying the Model Properties: Set the document template properties according to the actual demand of the web client side.

- Reducing the Model Resolution: Adopt low model resolution in the non-critical regions for the fast browsing of the model.

- Compressing the Normal Vector Data: Compress the normal vector data of the CATIA model.

- Constructing the Model Flows: Adopt the display mode of Model Flows, by which users could watch real-time data downloaded from the web, and those which have a large effect on the display will be preferentially downloaded and shown.

3.4.4. Interlinkage and Data Transmission Between BIM Model and SHM System

As for the large spatial structural health monitoring system, there is an urgent need for the clear, explicit, and visual display of collected monitoring data, especially when the structure is complicated and the monitoring items are multitudinous. Therefore, aiming at the interlinkage and data transmission between the BIM model and SHM system of this butterfly arch bridge, the IFC (Industry Foundation Classes) standard, which is an open source, structured, and object-based information exchange format, is adopted to expand the user-defined property set of strain sensors. Then, during the lightweight disposal of the BIM model, the virtual sensor and its parameters (such as the sensor ID, strain value, damage diagnosis, etc.) are simultaneously taken into account and connected to the designated positions of the BIM model.

After constructing the lightweight BIM model, specific databases are designed in the SQL Server environment, so as to store and update the monitoring data acquired from physical sensors in the SHM system. The subsystem called SHMSYSTEM is created in the database module beforehand, and some basic parameters such as Sensor_Item, Sensor_Value, Record_ID, and so on are defined, of which the Record_ID parameter is set as the principal linkage. These monitoring data from physical sensor systems should be preprocessed before being imported into the databases in bulk, in order to obtain the maximum strain values at each monitoring time, and mark these values using the virtual parameter StrainMaxPoint and display structural health conditions with the virtual parameter DamageFlag. After that, user-defined virtual sensor parameters in the BIM model are correspondingly linked to physical sensor parameters in the SQL Server database, the automatic access and reading of the monitoring data of physical sensors stored in SQL Server databases are accomplished, and then the related real-time value of the parameter StrainMaxPoint in the BIM model will be automatically updated. Once these most adverse strain values exceed the predefined threshold value (the theoretical strain calculated by professional software such as midas Civil and Dr. Bridge V4.0), the SHM system could identify the components with the impaired parameter DamageFlag, and highlight the damaged position in the BIM model, which could visualize the damage location exactly when safety alerts occur (Figure 14). All of the above can provide beneficial references and decision making for the operation and maintenance management of the butterfly arch bridge.

Figure 14.

The hierarchy of research steps adopted in this study.

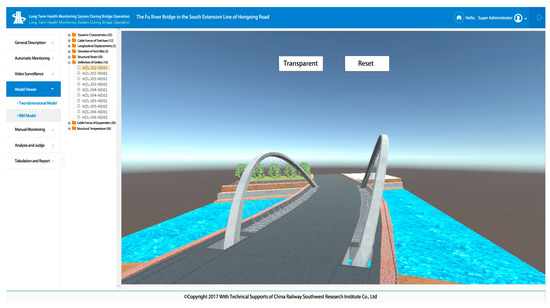

The final browser-based lightweight BIM model for bridge structural health monitoring and its web front-end display effect are depicted below (Figure 15).

Figure 15.

The final browser-based lightweight BIM model for the Fu River Bridge.

4. Monitoring Results Analysis of Butterfly Arch Bridges

The long-term and real-time monitoring method is adopted during the monitoring process of key structural parameters. As a consequence, the system will produce vast quantities of monitoring data on a daily basis. In order to explore the valuable information, obtain the actual operation conditions, and estimate the structural service life, a few necessary analysis methods need to be introduced when analyzing and utilizing the data collected from the BIM-based SHM system. In this section, based on numerous monitoring data from the BIM-based SHM system of the Fu River Bridge, the immediate evaluation method, statistical analysis method, grey relational analysis (GRA) and so on are adopted in monitoring results analysis, to evaluate the structural operation behavior of the bridge and the service condition of the BIM-based SHM system.

4.1. Structural Operation Condition Analysis

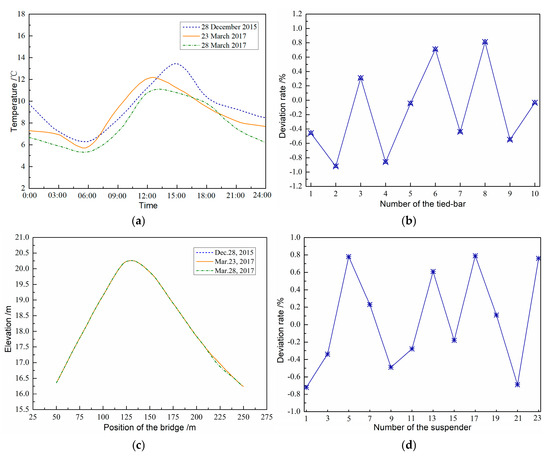

4.1.1. Structural Condition Evaluation Under Dead Loads

Considering the complex structural features, bridge deck deflection, forces of tied-bars and suspenders, and the arch rib deformation are adopted as the evaluation indexes to reflect structural conditions under dead loads. The statistical comparative diagnosis method based on static identifications is used to analyze the measured value and the deviation, which could manifest the performance evolution of bridge structural components. In order to eliminate the interference of environment temperature and vehicle loading to the utmost extent, the appropriate night time is chosen as the analysis period, which is characterized by a stable temperature field (the temperature difference is within 1.5 °C) and less traffic flow. Meanwhile, statistical fitting formulas are used to eliminate the influence of the temperature dependency on monitoring data. Based on the above considerations, three representative time domains at different service periods are selected to analyze and evaluate the structural conditions under dead loads. Concretely, a period in the initial operation of the BIM-based SHM system (02:00~05:00 a.m., 28 December 2015, set as the initial state), and two periods before (02:00~05:00 a.m., 23 March 2017) and after (02:00~05:00 a.m., 28 March 2017) the actual incident that an overweight/oversize vehicle (with a weight of 80 t) passed over the arch bridge are selected. Through the analysis of mass data obtained from the three representative time domains, some valuable measured curves and deviation curves could be depicted as follows (Figure 16a–d). The definition of “deviation rate” is “(Vmaximum measured value – Vinitial value)/Vinitial value × 100%”, where the “Vmaximum measured value” represents the maximum measured value of the internal forces of suspenders and internal forces of tied-bars under dead loads, selected from the maximum measured value at the three representative time domains at different service periods.

Figure 16.

Measured values and corresponding deviation values of representative monitoring indexes: (a) measured temperature data in steel-box girders; (b) deviations of the internal forces of suspenders under dead loads; (c) measured deflections of the bridge deck; (d) deviations of the internal forces of tied-bars under dead loads.

The above figures show that deviation values of representative monitoring indexes under dead loads are relatively small compared to the initial state. During the overweight/oversize vehicle incident, the bridge deck deformation ranged between −10 mm and 6 mm, the deviations of the internal forces of tied-bars and suspenders were within 1%, and the deviation of the arch rib deflection was no more than 12″ (i.e., 0.0033°), which indicates that the integral stiffness, internal force distribution and material performance did not change noticeably. Furthermore, no monitoring index increaseed distinctly after the overweight/oversize vehicle incident, which also shows that the incident did not bring about irreversible damage to the bridge.

4.1.2. Structural Dynamic Performance Evaluation Under Live Loads

Bridge dynamic characteristics are the basis for the structural health condition evaluation. In this study, the immediate evaluation method is used to assess the arch bridge’s dynamic performances based on the period maximum parameter selected from the measured dynamic response parameters of the main girder and arch ribs, such as the vibration acceleration, vibration frequency, vibration amplitude, etc. Meanwhile, threshold values for different levels of evaluation indexes, such as Calculated Value, Normal Value and Safety Value Threshold, are set according to the bridge characteristics. With a view to the representativeness of the evaluation, the acceleration data were taken as an example to explain the evaluation method. In the specific implementation process, the monitoring data of specific periods are first obtained after preprocessing procedures, such as eliminating abnormal values and gross error. Afterwards, the absolute measured maximum acceleration data are compared with the calculated maximum acceleration data and then divided into a few evaluation intervals according to the analysis method mentioned in Section 3.3.3 of this manuscript. The evaluation hierarchy consists of four grades (Grade-A, Grade-B, Grade-C, Grade-D), which represents the sequence of evaluation conclusions from good to bad. Five key positions of this bridge, including two arch apexes, two side spans and the midspan, are selected to evaluate the measured acceleration data using the immediate evaluation method mentioned above. The sampling frequencies of acceleration transducers in each direction are 100 Hz, and the measured time-history data are preprocessed using 10 Hz Low-Pass Filtering (LPF). According to the needs of the bridge dynamic analysis, the typical three-minute lower-traffic period and typical three-minute traffic rush period are chosen, respectively, to extract the absolute measured maximum acceleration data, and then compared with the corresponding threshold values. As for our specific work, threshold values for different hierarchy evaluation indexes (such as Calculated Value, Normal Value, and Safety Value Threshold) were set according to the bridge characteristics (Table 2). As such, the Calculated Value is calculated from the results of vehicle–bridge coupled vibration analysis, the Normal Value is the threshold value set for guaranteeing the good operation of the bridge, and the Safety Value Threshold is the threshold value set for guaranteeing the structural bearing capacity safety of the bridge.

Table 2.

Evaluation criteria for the measured maximum accelerations.

As shown in Table 2, the most unfavorable value of the measured acceleration data is 22.42 mm/s2, which is less than the corresponding Calculated Value, Normal Value and Safety Threshold. The corresponding evaluation grades are predominantly Grade-A except for a few Grade-B cases, which indicates that the live-load responses do not exceed the design threshold values and the whole dynamic performances of the bridge are good.

4.1.3. Fatigue Damage Estimation Analysis of the Suspender and Tied-Bar

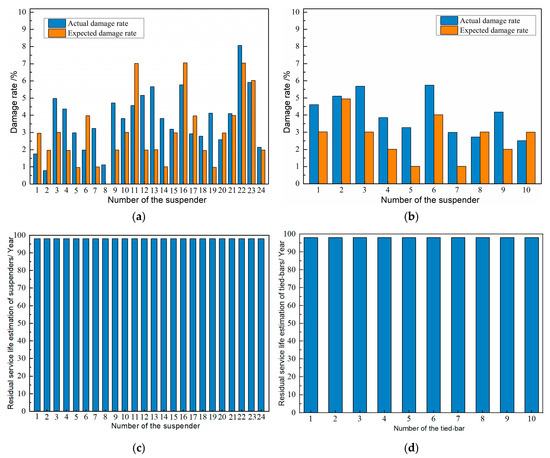

The fatigue damage of bridge structures is mainly caused by reciprocal actions of various vehicles, which is a fatigue-cumulative damage process. In this study, fiber strain-induced sensors are installed on the controlling sections of suspenders and tied-bars. Based on the time-history curves of stress collected from the representative period, the fatigue stress spectrum, variable amplitude stress and corresponding equivalent stress were obtained sequentially by use of the rainflow-counting algorithm. Meanwhile, through a mass of data processing, the fatigue damage ratio and the residual service life of the monitored suspenders and tied-bars were calculated and assessed (Figure 17a–d) based on the Miner linear cumulative damage criterion and the fatigue strength curves. According to the analysis, there is no induced fatigue damage of the suspenders and tied-bars, which also reflects good whole dynamic performances of this bridge.

Figure 17.

The damage condition assessment and the service life estimation of representative monitoring indexes: (a) the damage rate of suspenders during the design service life period; (b) the damage rate of tied-bars during the design service life period; (c) residual service life estimation of suspenders; (d) residual service life estimation of tied-bars.

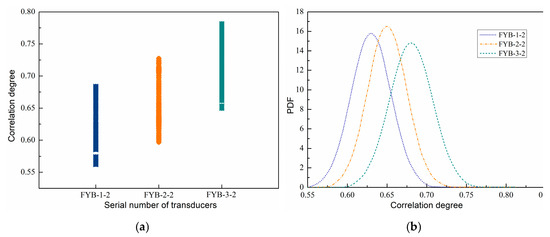

4.2. Performance Evaluation of the BIM-Based SHM System

The good operation of BIM-based SHM Systems depends on the reasonability of monitoring data. During the practical application, data exceptions will sometimes happen due to ambient interference, system malfunction, network communication quality and so on, which mainly includes Data missing, Data distortion, and Data recurrence. In order to identify the exceptional situations and evaluate operating performances of the system, the grey relational analysis method was adopted to identify the compliance between the monitoring data and structural mechanical properties [51,52,53]. The basic strategy is as follows. Based on the collected monitoring data from the sensors of the same type and similar position, the correlation calculation is carried out using the grey relational analysis method, the standard deviation is compared with the threshold value of correlation degree, and then the operating performances of the SHM system are evaluated. Taking the strain data as an example, two symmetrical longitudinal fiber strain-induced sensors were selected for each quartile cross-section of the bridge. One set of data served as the reference data, and the other set served as the comparative data, denoted as FYB-i-1 and FYB-i-2, respectively (where, i = 1, 2, 3 represent the 1/4 cross-section, 1/2 cross-section and 3/4 cross-section in sequence). A total of 300 datasets (unit: 10 min) were selected to carry out the correlation analysis, and the corresponding results are shown in Figure 18a,b.

Figure 18.

The correlation degree and corresponding probability distribution functions: (a) the correlation degree of the monitoring strain data; (b) the corresponding probability distribution functions of the correlation degree.

As shown in the figures above, the standard deviations of the correlation probability of monitoring data from strain sensors #1 and #2, both in the 1/4 cross-section and in 1/2 cross-section, are δ1 = 2.45 × 10−2 and δ2 = 2.53 × 10−2, respectively, which are both less than the threshold value (δ = 2.66 × 10−2) and reflect the good digital correlation and service performance of the sensors. Nevertheless, the standard deviation of the correlation probability of monitoring data from strain sensors #1 and #2 in the 3/4 cross-section is δ3 = 2.72 × 10−2 (greater than the threshold value of 2.66 × 10−2), which indicates poor digital correlation, and one of the sensors may be abnormal.

Through the analysis on the monitoring data collected from the establishment of the system to the end of April, 2017, the missing rate, distortion rate and recurrence rate of the monitoring data for the monitoring subsystems and the overall system are obtained. On this basis, the corresponding abnormal rate is defined as follows: Abnormal Rate = (∑Missing Rate + ∑Distortion Rate + ∑Recurrence Rate)/3. The system can be evaluated as Fine, Good, Normal and Poor, corresponding to the situation in which the Abnormal Rate is in the range of [0, 5%), [5%, 10%), [10%, 25%) and [25%, 100%], respectively. This is depicted in Table 3.

Table 3.

The evaluation of the BIM-based structural health monitoring system of the bridge.

It can be concluded from Table 3 that all the abnormal rate values of the system are within 5%, which demonstrates that the system has a high integration level of software and hardware, stable running performances and reliable data quality. Until now, nearly ten years later, this BIM-based collaboration system for structural damage condition assessment in the asymmetric butterfly arch bridge is still in good condition and runs well.

5. Challenges and Development Trends of BIM-Based SHM Systems for Long-Span Bridges

Structural health monitoring (SHM) is now developing rapidly, and its integration with BIM technology is becoming a new trend and hot research topic at present [47,57,58]. Meanwhile, there still exist many challenges which need further improvement and optimization [59,60], especially for an increasing number of long-span and complicated bridges with economic and social development. The existing challenges and development trends are summarized as follows.

- The applications of BIM-based model establishment software remain immature. The construction of 3D and nD BIM models is mainly accomplished by means of 2D patterning imported into the BIM-related software, which always brings about the trouble of building conflict and format conversion problems. The entire process of the BIM model construction must be accomplished using a variety of software with a great deal of operation time and money. Furthermore, the evaluation of LoD (Levels of Detail) must be executed before model construction, which therefore requires more time, cost and staff.

- With regard to BIM application in long-span bridge SHM systems, there are still some obstacles or even resistance from quite a few project construction companies, contractor companies and maintenance companies. Most of them reckon that the introduction of BIM will lead to a reduction in work efficiency and productivity, and they also believe that the BIM will push them to spend more money and time on staff training, change their software use habits, and that BIM application in BIM is too arduous to make a stable return against its cost.

- The long-term real-time monitoring of long-span bridges in the BIM environment will still produce massive data, though some lightweight disposals are being explored and tried. Furthermore, during the data transmission and remote access to BIM models among different stakeholders through the internet, cybersecurity also poses a real challenge; it could become a serious concern considering the possibility of online unauthorized access and copyright infringement.

- A lack of standards and technical hurdles still exist in the implementation of BIM-based SHM systems. In the absence of uniform standards, new “isolated islands of information” will arise and cause the severe loss of information resources. BIM users in the SHM field may only use the BIM technology in pilot projects instead of applying BIM widely to achieve a ‘scale of economy’ under these circumstances. Furthermore, BIM users may unavoidably have to undertake extra R&D to develop the codes or standards from scratch, such as the relevant standards regarding how BIM and SHM evaluation can cooperate together, which cannot possibly be shared across the entire industry.

- Legal and contractual issues, associated with long-span BIM-based SHM system implementation, will be experienced during the pursuit of seamless collaboration between all stakeholders, which could obfuscate the responsibility level amongst individual stakeholders and their liability assignment. Furthermore, BIM application in long-span bridge SHM systems will also be affected by cultural challenges, such as different understandings of BIM programs and applications, especially for trans-provincial or transnational bridge projects.

In the future deployment of BIM-based long-span bridge SHM systems, computational BIM and cloud BIM technologies should be further explored and implemented, and the relevant superior functions should be developed to assist the efficient integration between BIM and SHM. Moreover, AI and machine learning technologies, intensive digital reality capture technology, and BIM as well as big data technology should be further studied, which may resolve the challenges mentioned above, and eventually, distinct work efficiency and productivity will be achieved and even reshape the current bridge SHM systems at large.

6. Conclusions

In this study, recent applications of SHM technologies in long-span bridges are summarized and studies on SHM systems in the BIM environment are reviewed in detail. After carrying out the monitoring requirements analysis, the specific BIM framework and functional modules are evaluated, and the corresponding lightweight BIM model, integrated into the web client side of SHM system, is subsequently established. Thereafter, the representative monitoring results are elaborately analyzed and evaluated, and challenges and trends of BIM-based SHM systems for long-span bridges are also investigated. Several major conclusions can be drawn from this work accordingly.

- Based on spatial mechanical calculations and monitoring requirement analysis of the butterfly arch bridge, a comprehensive and feasible SHM system, including pivotal modules (such as Data Acquisition and Transmission Module, Data Process and Control Module, Data Analysis and Evaluation Module, etc.), could be built.

- As for the established BIM model, the utilization of lightweight disposal methods (such as simplifying the model properties, reducing the model resolution, compressing the normal vector data, etc.) could solve the problem of slow data access, poor display effects and inefficient and ineffective information sharing, and then promote the integrated management level of the BIM-based structural health monitoring system.

- The design of the specific databases is accomplished in the SQL Server environment to store and update the monitoring data collected from the physical sensors in the SHM system, to which the user-defined virtual sensor parameters in the BIM model could be correspondingly linked. Thus, real-time maximum values in the BIM environment could be automatically updated, and the damage location could be visualized exactly when safety alerts occur.

- The research results show that the overweight /oversize vehicle incident did not cause irreversible damage to this bridge. The bridge whole stiffness, internal force distribution and material properties do not vary noticeably. Furthermore, the structural responses under live loads do not exceed design threshold values, and the whole dynamic performances of the bridge are good. Moreover, induced fatigue damage of the suspenders and tied-bars are not present, and measuring results show that the BIM-based SHM system is valid and efficient in visualized assessment and early warning.

- The challenges of BIM technologies in long-span bridges, such as the immature establishing software, unstable return against its cost, massive data production, lack of standards, legal issues and so on, are systematically summarized. Meanwhile, some representative developing trends and important BIM-based techniques, which need to be developed and further explored, are discussed and investigated.

Author Contributions

Conceptualization, H.Q. and C.D.; methodology, H.Q., Y.C. and A.H.; Validation, C.D., H.Q., X.L. and C.Z.; formal analysis, H.Q. and C.D.; data curation, Y.C., H.Q., A.T. and C.D.; writing—original draft preparation, H.Q. and C.D.; writing—review and editing, H.Q., C.D. and X.L.; supervision, H.Q., C.D. and A.H.; project administration, C.D.; funding acquisition, H.Q. and X.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by [the Scientific Research Foundation of Hunan Provincial Education Department] grant number [No. 22B0270]; [the Science and Technology Program of Hunan Provincial Department of Transportation] grant number [No. 202309]; and [the National and Hunan Province Innovation and Entrepreneurship Training Program for College Students] grant number [No. S202310538017]. The authors also would like to thank Mr. Zhonghe Du for providing valuable suggestions.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

Authors Changjun Deng, Yang Chen, Chunrong Zou and Anqing Hu were employed by the company China Railway Southwest Research Institute Co., Ltd. Author Ao Tang was employed by the company Hunan Zhongda Digital Innovation Technology Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- He, X.H.; Wu, T.; Zou, Y.F.; Chen, Y.F.; Guo, H.; Yu, Z.W. Recent developments of high-speed railway bridges in China. Struct. Infrastruct. Eng. 2017, 13, 1584–1595. [Google Scholar] [CrossRef]

- Chu, X.; Cui, W.; Zhao, L.; Cao, S.; Ge, Y. Probabilistic flutter analysis of a long-span bridge in typhoon-prone regions considering climate change and structural deterioration. J. Wind Eng. Ind. Aerod. 2021, 215, 104701. [Google Scholar] [CrossRef]

- Pang, Y.T.; Wei, K.; Yuan, W.C. Life-cycle seismic resilience assessment of highway bridges with fiber- reinforced concrete piers in the corrosive environment. Eng. Struct. 2020, 222, 111120. [Google Scholar] [CrossRef]

- Liu, W.S.; Dai, G.L.; Yu, Z.W.; Chen, Y.F.; He, X.H. Interaction between continuous welded rail and long-span steel truss arch bridge of a high-speed railway under seismic action. Struct. Infrastruct. Eng. 2018, 14, 1051–1064. [Google Scholar] [CrossRef]

- Fan, W.; Zhong, Z.W.; Wang, J.J.; Xia, Y. Vessel-bridge Collisions: Accidents, Analysis, and Protection. China J. Highw. Transp. 2024, 37, 38–66. [Google Scholar]

- Chen, L.K.; Qin, H.X.; Jiang, L.Z.; Xu, L. A near fault vertical scenario earthquakes based generic simulation framework for elastoplastic seismic analysis of light rail vehicle viaduct system. Vehicle Syst. Dyn. 2020, 58, 181–207. [Google Scholar] [CrossRef]

- Hou, W.; Zhang, G.; He, S.H. Fire resistance tests on prestressed concrete box girder with intumescent fire-retardant coatings. Fire Technol. 2021, 58, 107–131. [Google Scholar] [CrossRef]

- Feldman, B.J. The Collapse of the I-35W Bridge in Minneapolis. Phys. Teach. 2010, 48, 541–542. [Google Scholar] [CrossRef]

- Lu, Y.E.; Zhang, L.M. Progressive collapse of a drilled-shaft bridge foundation under vessel impact. Ocean Eng. 2013, 66, 101–112. [Google Scholar] [CrossRef]

- Wang, J.J.; Wang, W. Estimation of vessel-bridge collision probability for complex navigation channels. J. Bridge Eng. 2015, 20, 608–614. [Google Scholar] [CrossRef]

- Emily Pollock. Italy’s Morandi Bridge Collapse—Why Do We Know? Available online: https://www.engineering.com/italys-morandi-bridge-collapse-what-do-we-know/ (accessed on 23 August 2018).

- Zhou, J.T.; Li, X.G.; Xia, R.C.; Yang, J.; Zhang, H. Health monitoring and evaluation of long-span bridges based on sensing and data analysis: A survey. Sensors 2017, 17, 603. [Google Scholar] [CrossRef] [PubMed]

- Ye, X.W.; Su, Y.H.; Xi, P.S. Statistical analysis of stress signals from bridge monitoring by FBG system. Sensors 2018, 18, 491. [Google Scholar] [CrossRef] [PubMed]

- Yi, T.H.; Li, H.N.; Gu, M. Clustering number determination for sparse component analysis during output-only modal identification. J. Eng. Mech-ASCE 2019, 145, 04018122. [Google Scholar] [CrossRef]

- Deng, L.; Yan, W.; Li, S. Computer Modeling and Weight Limit Analysis for Bridge Structure Fatigue Using OpenSEES. J. Bridge Eng. 2019, 24, 4019081. [Google Scholar] [CrossRef]

- Mario, S.; Ana, S.; Pablo, R.; Carlos, P.; Pedro, A.; Belén, R. Review of Laser Scanning Technologies and Their Applications for Road and Railway Infrastructure Monitoring. Infrastructure 2019, 4, 58. [Google Scholar]

- Sloan, T.D.; Thompson, A.; Kirkpatrick, J.; Boyd, J.W. Monitoring the Inservice Behaviour of the Foyle Bridge. Struct. Eng. 1992, 70, 130–134. [Google Scholar]

- Catbas, F.N.; Grimmelsman, K.A.; Aktan, A.E. Structural identification of Commodore Barry Bridge. In Nondestructive Evaluation of Highways, Utilities, and Pipelines IV; SPIE: Bellingham, WA, USA, 2000; Volume 3995. [Google Scholar]

- Butcher, A.M.; Newhook, J.P. Long-Term Monitoring of the Confederation Bridge. In Proceedings of the 4th International Conference on Structural Health Monitoring of Intelligent Infrastructure (SHMII-4), Zurich, Switzerland, 22–24 July 2009. [Google Scholar]

- Jang, S.; Jo, H.; Cho, S.; Mechitov, K.; Rice, J.A.; Sim, S.-H.; Jung, H.-J.; Yun, C.-B.; Spencer, B.F., Jr.; Agha, G. Structural health monitoring of a cable stayed bridge using smart sensor technology: Deployment and evaluation. Smart. Struct. Syst. 2010, 6, 439–459. [Google Scholar] [CrossRef]

- Xia, Y.; Chen, B.; Zhou, X.Q.; Xu, Y.L. Field monitoring and numerical analysis of Tsing Ma Suspension Bridge temperature behavior. Struct. Control Health Monit. 2013, 20, 560–575. [Google Scholar] [CrossRef]

- Rainieri, C.; Fabbrocino, G. Development and validation of an automated operational modal analysis algorithm for vibration-based monitoring and tensile load estimation. Mech. Syst. Signal Proc. 2015, 60, 512–534. [Google Scholar] [CrossRef]

- Zhou, G.D.; Yi, T.H. Recent developments on wireless sensor networks technology for bridge health monitoring. Math. Probl. Eng. 2013, 2013, 947867. [Google Scholar] [CrossRef]

- He, X.; Qin, H.; Tao, T.Y.; Liu, W.S.; Wang, H. Measurement of Non-Stationary Characteristics of a Landfall Typhoon at the Jiangyin Bridge Site. Sensors 2017, 17, 2186. [Google Scholar] [CrossRef] [PubMed]

- Ding, Y.; An, Y.; Wang, C. Field monitoring of the train-induced hanger vibration in a high-speed railway steel arch bridge. Smart Struct. Syst. 2016, 17, 1107–1127. [Google Scholar] [CrossRef]

- Wang, H.; Tao, T.; Li, A.; Zhang, Y. Structural health monitoring system for sutong cable-stayed bridge. Smart Struct. Syst. 2016, 18, 317–334. [Google Scholar] [CrossRef]

- He, X.H.; Shi, K.; Wu, T. An integrated structural health monitoring system for the Xijiang high-speed railway arch bridge. Smart Struct. Syst. 2018, 21, 611–621. [Google Scholar]

- Shi, Z.; Ji, F.; Yang, S.L.; Lv, D.C. Research on Risk Assessment during the Construction Phase of Wufengshan Yangtze River Bridge. Railw. Stand. Des. 2020, 64, 71–78. [Google Scholar]

- Sun, Z.; Santos, J.; Caetano, E. Data-driven prediction and interpretation of fatigue damage in a road-rail suspension bridge considering multiple loads. Struct. Control Health Monit. 2022, 29, e2997. [Google Scholar] [CrossRef]

- Ding, Y.; Ye, X.W.; Guo, Y. Data set from wind, temperature, humidity and cable acceleration monitoring of the Jiashao bridge. J. Civ. Struct. Health 2023, 13, 579–589. [Google Scholar] [CrossRef]

- Du, Q.; Li, D.D.; Jie, Z. Research on Health Status Assessment Method of Long span Bridges Based on Monitoring Data Analysis. Sci. Technol. Innov. 2023, 153–156. [Google Scholar] [CrossRef]

- Cetindemir, O.; Zuelfikar, A.C.; Apaydin, N.M. Dynamic Modal Identification of a Long-Span Suspension Bridge Using Measured Acceleration Data during a Storm. J. Struct. Eng. 2023, 149, 05023004. [Google Scholar] [CrossRef]

- Li, H.N.; Li, D.S.; Ren, L.; Yi, T.H.; Jia, Z.G.; Li, K.P. Structural health monitoring of innovative civil engineering structures in mainland China. Struct. Monit. Maint. 2016, 3, 1–32. [Google Scholar] [CrossRef]

- Michael, T.; Kay, S. IFC Monitor—An IFC schema extension for modeling structural health monitoring systems. Adv. Eng. Inform. 2018, 37, 54–65. [Google Scholar]

- Rafael Sacks, R.; Eastman, C.; Lee, G.; Teicholz, P. BIM Handbook: A Guide to Building Information Modeling for Owners, Designers, Engineers, Contractors, and Facility Managers, 3rd ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2018; pp. 18–31. [Google Scholar]

- Seam, A.; Zheng, T.; Lu, Y.; Usmani, A.; Laurenson, D. BIM integrated workflow management and monitoring system for modular buildings. Int. J. 3-D Inf. Model. IJ3DIM 2013, 2, 17–28. [Google Scholar] [CrossRef]

- Rio, J.; Ferreira, B.; Pocas-Martins, J. Expansion of IFC Model with Structural Sensors. Inf. Constr. 2013, 65, 219–228. [Google Scholar] [CrossRef]

- Sternal, M.; Dragos, M. BIM-Based modeling of structural health monitoring systems using the IFC standard. In Proceedings of the 28th Forum Bauinformatik, Hanover, Germany, 19–21 September 2016; Leibniz Universität Hannover: Hanover, Germany, 2016. [Google Scholar]

- Smarsly, K.; Tauscher, E. Monitoring information modeling for semantic mapping of structural health monitoring systems. In Proceedings of the 16th International Conference on Computing in Civil and Building Engineering, Osaka, Japan, 6–8 July 2016; ICCCBE2016 Organizing Committee: Osaka, Japan, 2016. [Google Scholar]

- Wang, J.; Fu, Y.; Yang, X. An integrated system for building structural health monitoring and early warning based on an Internet of things approach. Int. J. Distrib. Sens. Netw. 2017, 13, 1–14. [Google Scholar] [CrossRef]

- Del Grosso, A.; Basso, P.; Ruffini, L.; Figini, F.; Cademartori, M. Infrastructure management integrating SHM and BIM procedures. In Proceedings of the SMAR 2017-4th Conference on Smart Monitoring Assessment and Rehabilitation of Civil Structures, Zurich, Switzerland, 13–15 September 2017; Istanbul Technical University: Istanbul, Turkey, 2017. [Google Scholar]

- Valinejadshoubi, M.; Bagchi, A.; Moselhi, O. Identifying at-risk non-structural elements in buildings using BIM: A case study application. J. Earthq. Eng. 2018, 24, 869–880. [Google Scholar] [CrossRef]

- Valinejadshoubi, M.; Bagchi, A.; Moselhi, O. Development of a BIM-Based Data Management System for Structural Health Monitoring with Application to Modular Buildings: Case Study. J. Comput. Civil Eng. 2019, 33, 05019003. [Google Scholar] [CrossRef]

- Shim, C.S.; Yun, N.R.; Song, H.H. Application of 3D bridge information modeling to design and construction of bridges. Procedia Eng. 2011, 14, 95–99. [Google Scholar] [CrossRef]

- Marzouk, M.M.; Hisham, M. Bridge information modeling in sustainable bridge management. In Proceedings of the ICSDC 2011: Integrating Sustainability Practices in the Construction Industry, Kansas City, MO, USA, 23–25 March 2011. [Google Scholar]

- Fanning, B. Impacts and Benefits of Implementing BIM on Bridge and Infrastructure Projects. Master’s Thesis, Colorado State University, Fort Collins, CO, USA, 2014. [Google Scholar]

- Chan, B.; Guan, H.; Hou, L.; Jo, J.; Blumenstein, M.; Wang, J. Defining a conceptual framework for the integration of modeling and advanced imaging for improving the reliability and efficiency of bridge assessments. J. Civ. Struct. Health 2016, 6, 703–714. [Google Scholar] [CrossRef]

- McGuire, B.M. Using Building Information Modeling to Track and Assess the Structural Condition of Bridges. Master’s Thesis, Colorado State University, Fort Collins, CO, USA, 2014. [Google Scholar]

- Delgado, J.M.D.; Brilakis, I.; Middleton, C. Modelling, management, and visualization of structural performance monitoring data on BIM. In Transforming the Future of Infrastructure through Smarter Information, Proceedings of the International Conference on Smart Infrastructure and Construction, Cambridge, UK, 27–29 June 2016; ICE Publishing: New York, NY, USA, 2016; pp. 543–549. [Google Scholar]

- Delgado, J.M.D.; Butler, L.J.; Gibbons, N.; Brilakis, I.; Elshafie, M.; Middleton, C. Management of structural monitoring data of bridges using BIM. Proc. Inst. Civ. Eng.-Bridge Eng. 2016, 170, 204–218. [Google Scholar] [CrossRef]

- Banfia, F.; Barazzettia, L.; Previtali, M.; Roncoronib, F. Historic BIM: A new repository for structural health monitoring. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2017, XLII-5/W1, 269–274. [Google Scholar]

- Boddupalli, C.; Sadhu, A.; Azar, E.R.; Pattyson, S. Improved visualization of infrastructure monitoring data using building information modeling. Struct. Infrastruct. Eng. 2019, 15, 1247–1263. [Google Scholar] [CrossRef]

- Moreira; José, C.F. Project for a Road Bridge Between the Cities of Porto and Gaia. Master’s Thesis, Universidade do Porto, Porto, Portugal, 2012. [Google Scholar]

- Dimelow, M.T. Temporary Uses, Critical Praxis and Urban Water Spaces: A Case Study. Ph.D. Thesis, The University of Manchester, Manchester, UK, 2023. [Google Scholar]

- Xu, Q. Construction Monitoring and Control of Tied Arch Bridge with Asymmetrical Arch Ribs. Master’s Thesis, Tianjin University, Tianjin, China, 2008. [Google Scholar]

- Cheng, K.M.; Ketchum, M.A.; Drouillard, F. Nanning butterfly tied arch bridge over the Yong River in China. Struct. Eng. Int. 2010, 20, 308–311. [Google Scholar] [CrossRef]

- Thomson, C.; Boehm, J. Automatic Geometry Generation from Point Clouds for BIM. Remote Sens. 2015, 7, 11753–11775. [Google Scholar] [CrossRef]

- Zou, Y.; Kiviniemi, A.; Stephen, W.J. Developing a tailored RBS linking to BIM for risk management of bridge projects. Eng. Constr. Archit Ma. 2016, 23, 727–750. [Google Scholar] [CrossRef]

- Xue, F.; Lu, W.S.; Chen, K.; Webster, C.J. BIM reconstruction from 3D point clouds: A semantic registration approach based on multimodal optimization and architectural design knowledge. Adv. Eng. Inform. 2019, 42, 100965. [Google Scholar] [CrossRef]

- Zheng, L.; Lu, W.S.; Chen, K.; Chau, W.K. Benefit sharing for BIM implementation: Tackling the moral hazard dilemma in inter-firm cooperation. Int. J. Proj. Manag. 2017, 35, 393–405. [Google Scholar] [CrossRef]