Influence of Self-Emulsifying Waterborne Epoxy Resin with Novel Hardeners on Pore Structure and Permeability of Cement-Based Materials

Abstract

1. Introduction

2. Materials and Methods

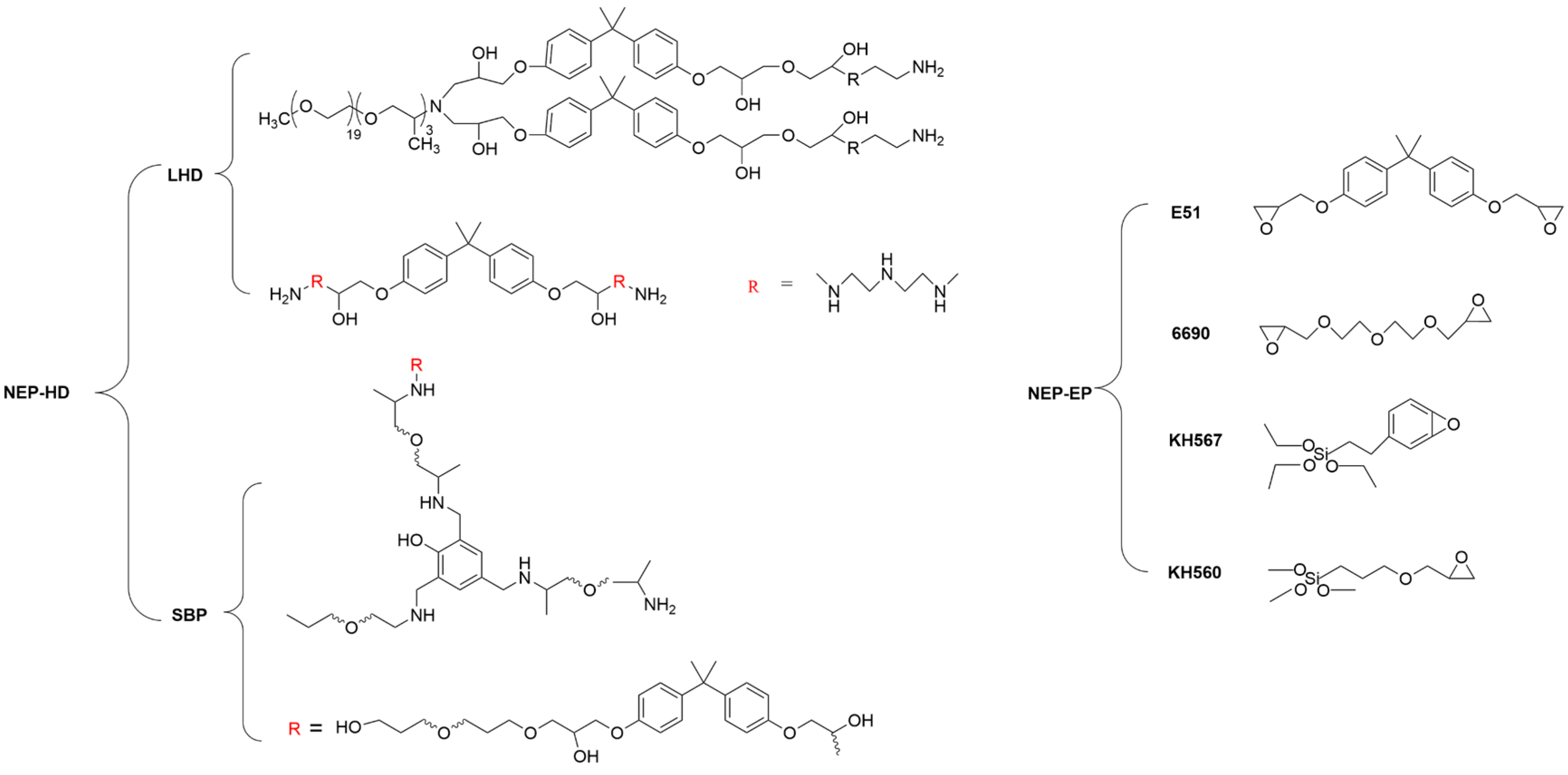

2.1. Materials

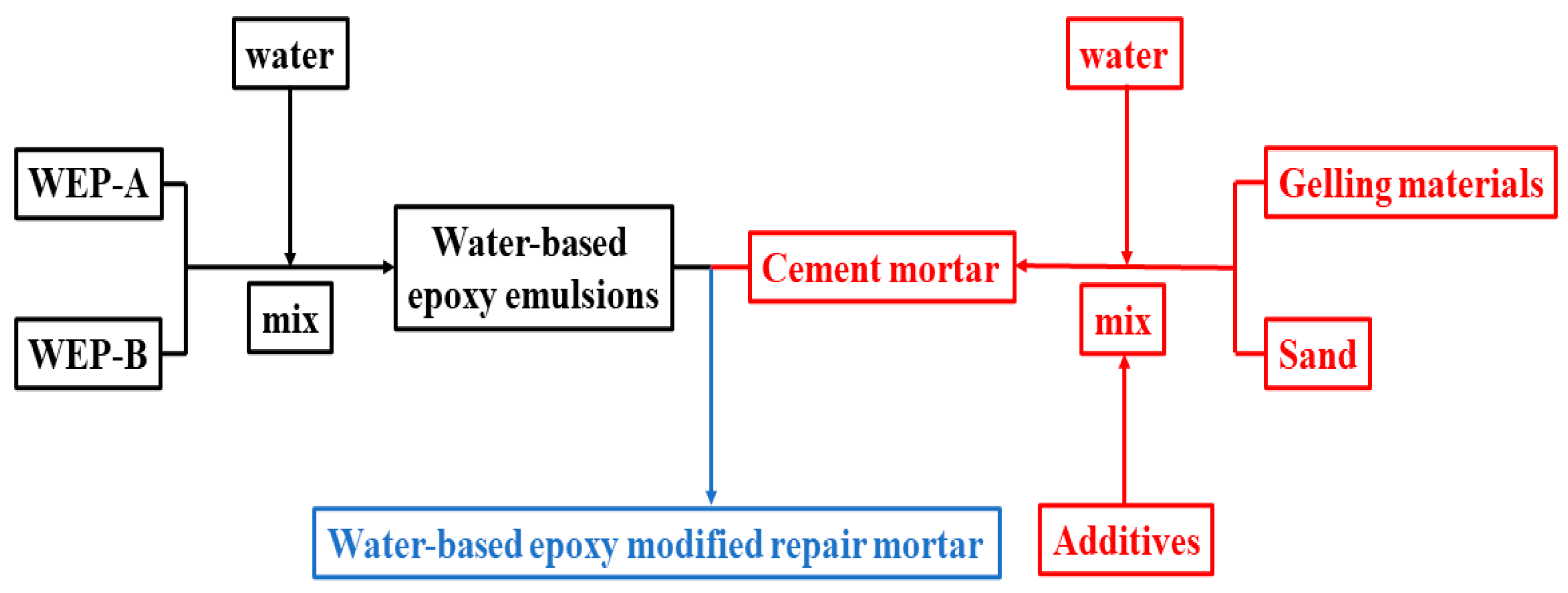

2.2. Preparation of WEP and WEP–Cement Repair Materials

2.2.1. Preparation of WEP

2.2.2. Preparation of WEP–Cement Repair Materials

2.3. Fourier Transform Infrared Spectra (FTIR)

2.4. Microstructure Characterization (SEM)

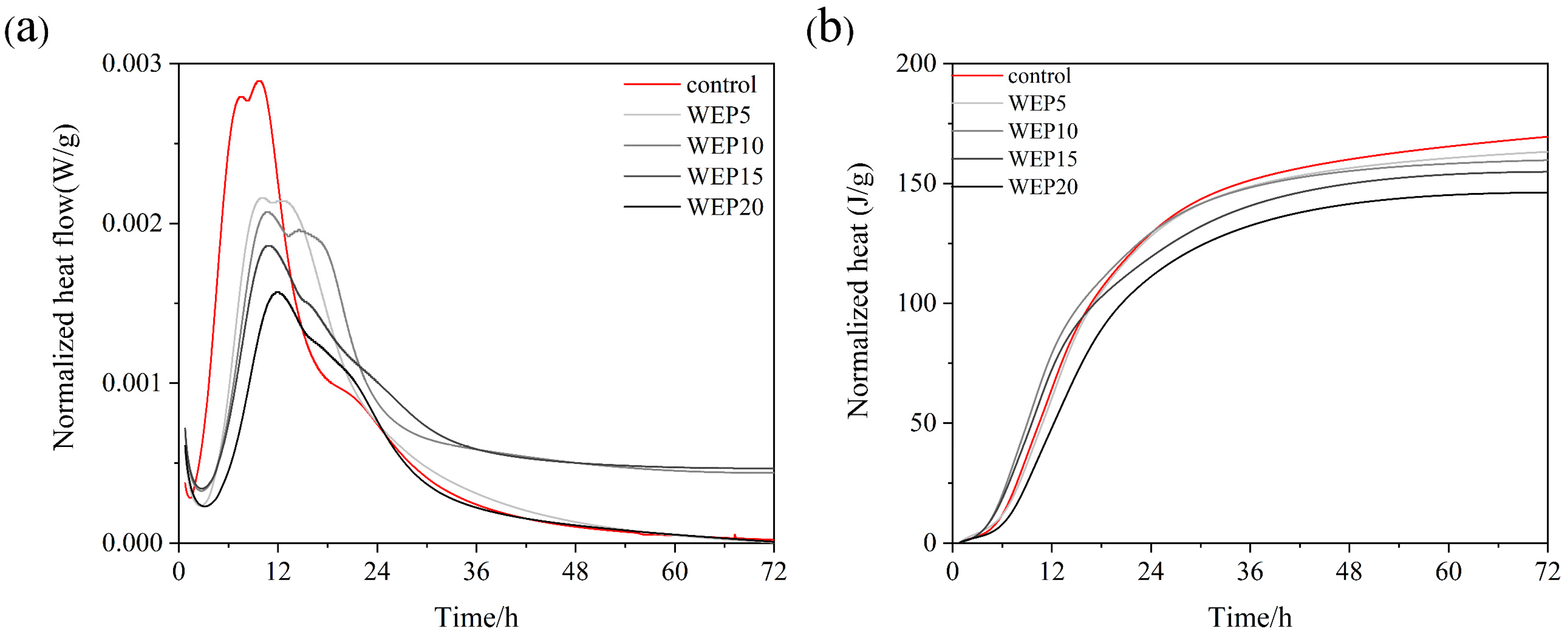

2.5. Exothermic Analysis of Hydration

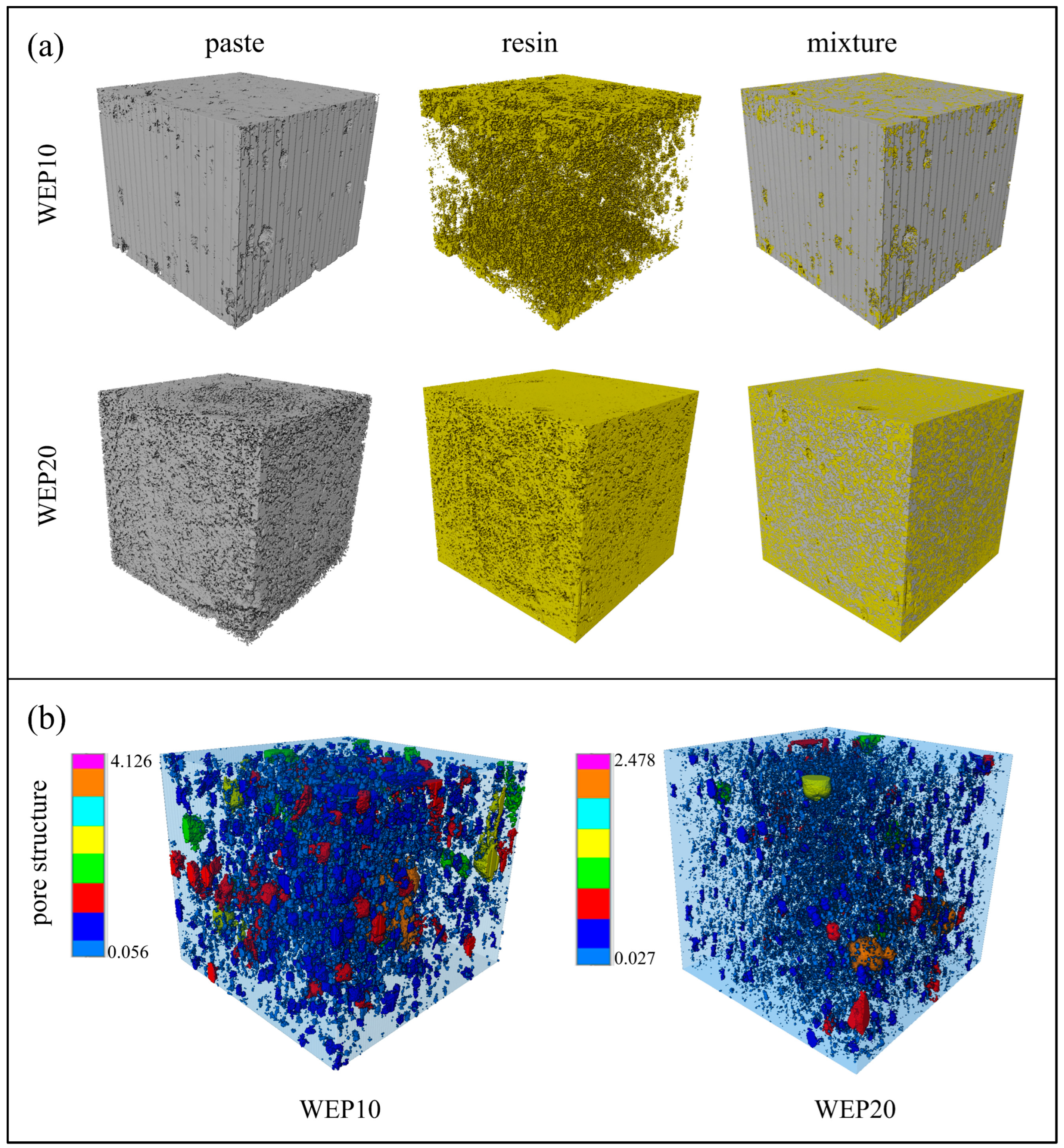

2.6. Three-Dimensional Structure Analysis

2.7. Mechanical Property

2.7.1. Compressive Strength

2.7.2. Flexural Strength

2.7.3. Bonding Strength

2.7.4. Tensile Stress‒Strain Test

2.8. Durability

2.8.1. Carbonation Resistance

2.8.2. Freeze–Thaw Resistance

3. Results and Discussion

3.1. FTIR Analysis

3.2. SEM and EDS Analysis

3.3. Exothermic Analysis of Hydration

3.4. X-CT and Pore Structure Analysis

3.5. Mechanical Property Results

3.5.1. Compressive Strength

3.5.2. Flexural Strength

3.5.3. Bond Strength

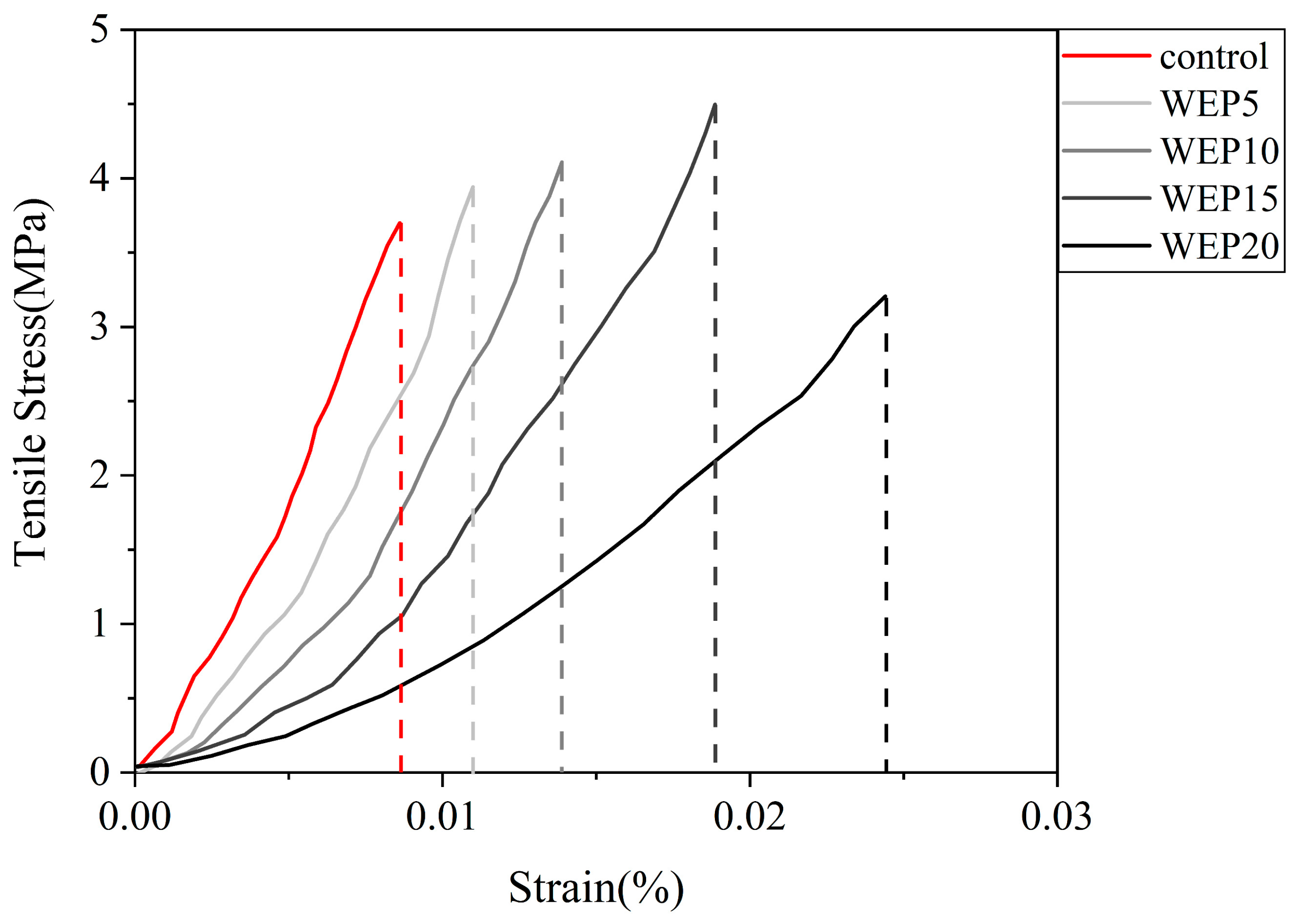

3.5.4. Tensile Stress‒Strain Test

3.6. Durability Performance Analysis

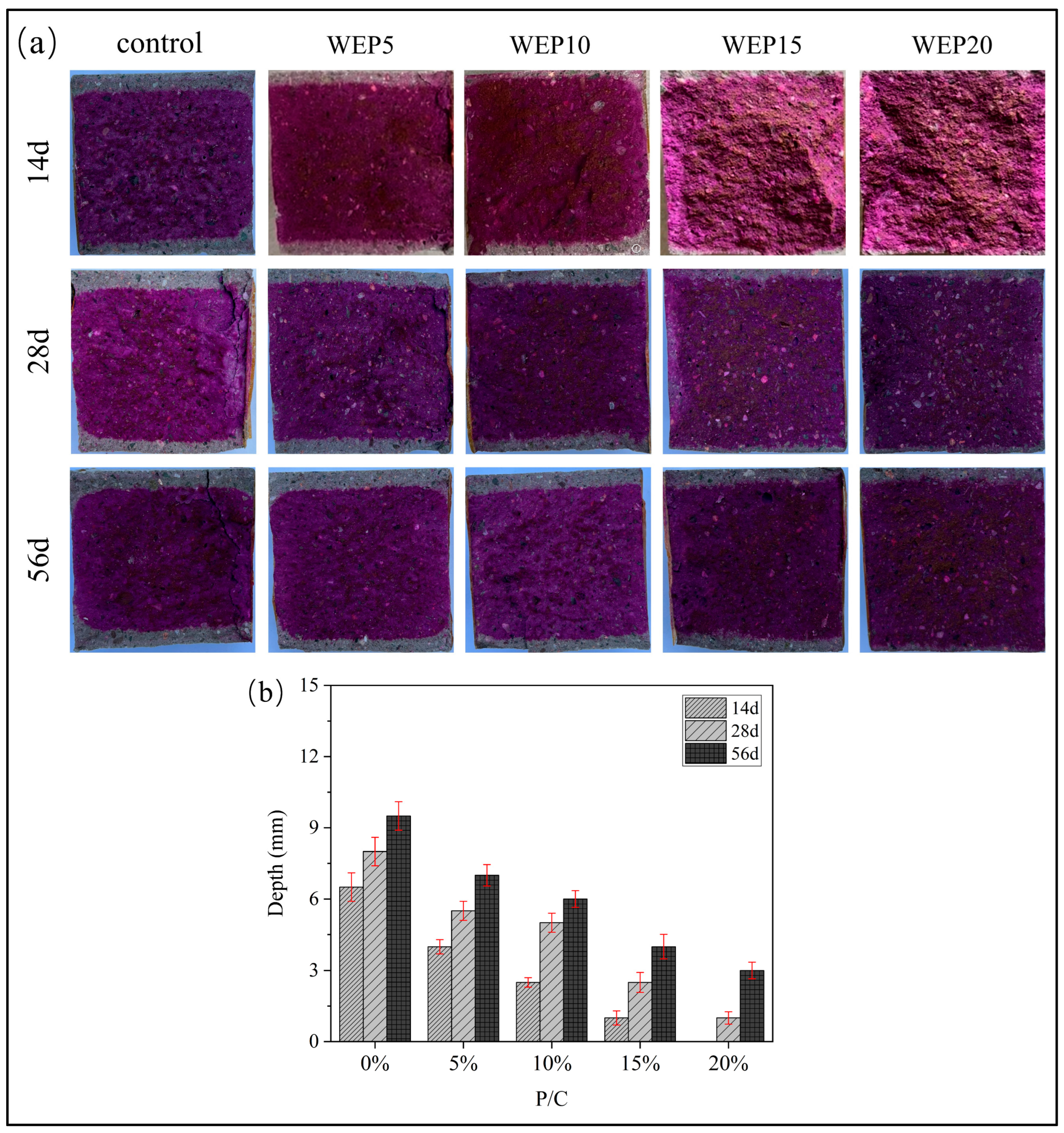

3.6.1. Carbonation Resistance

3.6.2. Freeze–Thaw Resistance

4. Summary and Conclusions

- (1)

- The WEP forms a cross-linked network with cement hydration products, significantly refining pore structure, improving material toughness, and retarding cement hydration.

- (2)

- Optimal mechanical performance was achieved at 10% WEP incorporation, with a 28-day flexural strength of 12.9 MPa (30% increase over control) and a tensile strain capacity of 0.024% (compared to 0.008% for control), demonstrating substantially enhanced material flexibility.

- (3)

- The bond strength improvement (58% increase in tensile bond strength and 74% increase in shear bond strength at 10% WEP) results from the polymer’s high viscosity and chemical interaction between epoxy groups and cement hydration products. The covalent Ca-O-C bonds formed at the interface provide stronger connection points than physical adhesion alone, while coordination bonds between amine groups and calcium ions create chemical anchoring points that enhance structural integrity during loading.

- (4)

- WEP significantly enhanced durability, with the carbonation depth at 56 days reduced from 9.5 mm to 3 mm at 20% WEP incorporation and mass loss after 200 freeze–thaw cycles reduced from 15% to 4%.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, X.L. Study on the Protective Performance of Concrete Coating Under the Action of Marine Environment. Master’s Thesis, Qingdao University of Technology, Qingdao, China, 2016. [Google Scholar]

- Jin, Z.; Li, M.; Pang, B.; Yang, L.; Chen, Y.; Wang, D. Internal superhydrophobic marine concrete: Interface modification based on slag microstructure regulation. J. Build. Eng. 2024, 86, 108769. [Google Scholar] [CrossRef]

- Guo, S.-Y.; Zhang, X.; Chen, J.-Z.; Mou, B.; Shang, H.-S.; Wang, P.; Zhang, L.; Ren, J. Mechanical and interface bonding properties of epoxy resin reinforced Portland cement repairing mortar. Constr. Build. Mater. 2020, 264, 120715. [Google Scholar] [CrossRef]

- U.S. Department of Transportation, Federal Highway Administration. Chapter 7—Capital Investment Scenarios—Highways. In Status of the Nation’s Highways, Bridges, and Transit Conditions and Performance Report, 23rd ed.; U.S. DOT: Washington, DC, USA, 2021. [Google Scholar]

- Pang, B.; Zhou, Z.; Hou, P.; Du, P.; Zhang, L.; Xu, H. Autogenous and engineered healing mechanisms of carbonated steel slag aggregate in concrete. Constr. Build. Mater. 2016, 107, 191–202. [Google Scholar] [CrossRef]

- Pang, B.; Zhou, Z.; Xu, H. Utilization of carbonated and granulated steel slag aggregate in concrete. Constr. Build. Mater. 2015, 84, 454–467. [Google Scholar] [CrossRef]

- Pang, B.; Yang, C.; Wang, P.; Tian, L.; Mei, B.; Song, X. Cement-based ductile rapid repair material modified with self-emulsifying waterborne epoxy. J. Build. Eng. 2023, 79, 107864. [Google Scholar] [CrossRef]

- Sun, C.; Liu, H.; Liu, L.; Zhao, P.; Huang, Y.; Lu, L. Effect of polymer to cement ratio on seawater corrosion resistance of polymer modified cementitious coatings. In Proceedings of the 2018 IEEE International Conference on Advanced Manufacturing (ICAM), Yunlin, China, 16–18 November 2018; pp. 451–454. [Google Scholar]

- Wang, R.; Xu, Y.D. Effect of curing temperature on the physical and mechanical properties of styrene butadienzene emulsionthioaluminate cement mortar. J. Chin. Ceram. Soc. 2017, 45, 227–234. [Google Scholar]

- Yang, Z.; Zhang, X.; Liu, X.; Guan, X.; Zhang, C.; Niu, Y. Flexible and stretchable polyurethane/waterglass grouting material. Constr. Build. Mater. 2018, 138, 240–246. [Google Scholar] [CrossRef]

- Fan, J.; Li, G.; Deng, S.; Deng, C.; Wang, Z.; Zhang, Z. Effect of Carbon Nanotube and Styrene-Acrylic Emulsion Additives on Microstructure and Mechanical Characteristics of Cement Paste. Materials 2020, 13, 2807. [Google Scholar] [CrossRef]

- Pang, B.; Zhang, Y.; Liu, G. Study on the effect of waterborne epoxy resins on the performance and microstructure of cement paste. Constr. Build. Mater. 2018, 167, 831–845. [Google Scholar] [CrossRef]

- Pang, B. Study on the Design, Preparation and Mechanism of Water-Based Epoxy-Concrete Composite Repair Materials. Ph.D. Thesis, Southeast University, Nanjing, China, 2021. [Google Scholar]

- Ying, G.-G.; Song, C.; Ren, J.; Guo, S.-Y.; Nie, R.; Zhang, L. Mechanical and durability-related performance of graphene/epoxy resin and epoxy resin enhanced OPC mortar. Constr. Build. Mater. 2021, 282, 122644. [Google Scholar] [CrossRef]

- Popvics, S.; Tamas, F. Investigation on Portland cement pastes and mortars modified by the addition of epoxy. Spec. Publ. 1978, 58, 357–366. [Google Scholar]

- Beeldens, A.; Van Gemert, D.; Schorn, H.; Ohama, Y.; Czarnecki, L. From microstructure to macrostructure: An integrated model of structure formation in polymer-modified concrete. Mater. Struct. 2005, 38, 601–607. [Google Scholar]

- Liu, J.; Farzadnia, N.; Shi, C. Effects of superabsorbent polymer on interfacial transition zone and mechanical properties of ultra-high performance concrete. Constr. Build. Mater. 2020, 231, 117142. [Google Scholar]

- Zhang, Z.; Zhang, H.; Lv, W.; Zhang, J.; Wang, N. Micro-structure characteristics of unsaturated polyester resin modified concrete under fatigue loads and hygrothermal environment. Constr. Build. Mater. 2021, 296, 123766. [Google Scholar]

- Wang, M.; Wang, R.; Yao, H.; Farhan, S.; Zheng, S.; Wang, Z.; Du, C.; Jiang, H. Research on the mechanism of polymer latex modified cement. Constr. Build. Mater. 2016, 111, 710–718. [Google Scholar]

- Betioli, A.; Filho, J.H.; Cincotto, M.; Gleize, P.; Pileggi, R. Chemical interaction between EVA and Portland cement hydration at early-age. Constr. Build. Mater. 2009, 23, 3332–3336. [Google Scholar]

- Li, P.; Jiang, Z.; An, X.; Maekawa, K.; Du, S. Time-dependent retardation effect of epoxy latexes on cement hydration: Experiments and multi-component hydration model. Constr. Build. Mater. 2022, 320, 126282. [Google Scholar] [CrossRef]

- Zheng, Z.; Li, Y.; He, S.; Ma, X.; Zhu, X.; Li, S. High density and high strength cement-based mortar by modification with epoxy resin emulsion. Constr. Build. Mater. 2019, 197, 319–330. [Google Scholar] [CrossRef]

- DL/T 5126-2021; Technical Specification for Polymer Modified Cement Mortar. China Electricity Council: Beijing, China, 2021.

- ASTM C882/C882M; Standard Test Method for Bond Strength of Epoxy-Resin Systems Used with Concrete By Slant Shear. ASTM International: West Conshohocken, PA, USA, 2020.

- GB/T 50082-2009; Standard for Test Methods of Long-term Performance and Durability of Ordinary Concrete. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2009.

- JG/T 243; Technical Specification for Concrete Freeze-Thaw Test Equipment. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2009.

- Hou, D.; Yu, J.; Wang, P. Molecular dynamics modeling of the structure, dynamics, energetics and mechanical properties of cement-polymer nanocomposite. Compos. Part B Eng. 2019, 162, 433–444. [Google Scholar]

- Hua, W.D.; Jiang, H.Y.; Zhou, Z.X. Research on Nitric Acid Corrosion Resistance of Latex Modified Ordinary Portland Cement Mortar. Adv. Mater. Res. 2012, 485, 262–265. [Google Scholar] [CrossRef]

- Xu, A.; Zhang, J.L.; Zeng, L. Research status and prospects of polymeric grouting material. Concrete 2014, 10, 141–144. [Google Scholar]

- Ukrainczyk, N.; Rogina, A. Styrene–butadiene latex modified calcium aluminate cement mortar. Cem. Concr. Compos. 2013, 41, 16–23. [Google Scholar]

- Wong, W.G.; Fang, P.; Pan, J.K. Dynamic properties impact toughness and abrasiveness of polymer-modified pastes by using nondestructive tests. Cem. Concr. Res. 2003, 33, 1371–1374. [Google Scholar]

- Zhang, C.; Kong, X.; Yu, J.; Jansen, D.; Pakusch, J.; Wang, S. Correlation between the adsorption behavior of colloidal polymer particles and the yield stress of fresh cement pastes. Cem. Concr. Res. 2022, 152, 106668. [Google Scholar]

- Pang, B.; Zhou, Z.; Cheng, X.; Du, P.; Xu, H. ITZ properties of concrete with carbonated steel slag aggregate in salty freeze-thaw environment. Constr. Build. Mater. 2016, 114, 162–171. [Google Scholar]

- Kong, X.; Emmerling, S.; Pakusch, J.; Rueckel, M.; Nieberle, J. Retardation effect of styrene-acrylate copolymer latexes on cement hydration. Cem. Concr. Res. 2015, 75, 23–41. [Google Scholar]

- Taylor, H.F.W. Cement Chemistry, 2nd ed.; Thomas Telford Publishing: London, UK, 1997. [Google Scholar]

- Chen, B.; Qiao, G.; Hou, D.; Wang, M.; Li, Z. Cement-based material modified by in-situ polymerization: From experiments to molecular dynamics investigation. Compos. Part B Eng. 2020, 194, 108036. [Google Scholar] [CrossRef]

- Kim, J.H.; Robertson, R.E.; Naaman, A.E. Structure and properties of poly(vinyl alcohol)-modified mortar and concrete. Cem. Concr. Res. 1999, 29, 407–415. [Google Scholar] [CrossRef]

- Kim, J.H.; Robertson, R.E. Prevention of air void formation in polymer-modified cement mortar by pre-wetting. Cem. Concr. Res. 1997, 27, 171–176. [Google Scholar]

- Shi, C.; Zou, X.; Wang, P. Influences of ethylene-vinyl acetate and methylcellulose on the properties of calcium sulfoaluminate cement. Constr. Build. Mater. 2018, 193, 474–480. [Google Scholar] [CrossRef]

- Fang, X.; Chen, Z.; Jiao, Z.; Xiao, G.; Shao, L. Study on microstructure, rheology and thermal stability of cement epoxy asphalt mortar multiphase materials. Mag. Concr. Res. 2013, 65, 475–485. [Google Scholar] [CrossRef]

- Li, L.; Wang, R.; Lu, Q. Influence of polymer latex on the setting time, mechanical properties and durability of calcium sulfoaluminate cement mortar. Constr. Build. Mater. 2018, 169, 911–922. [Google Scholar] [CrossRef]

- Knapen, E.; Van Gemert, D. Polymer film formation in cement mortars modified with water-soluble polymers. Cem. Concr. Compos. 2015, 58, 23–28. [Google Scholar] [CrossRef]

- Gwon, S.; Jang, S.Y.; Shin, M. Microstructure evolution and strength development of ultra rapid hardening cement modified with redispersible polymer powder. Constr. Build. Mater. 2018, 192, 715–730. [Google Scholar] [CrossRef]

- Bi, J.X. Study on the Design, Preparation and Performance of Waterborne Polyurethane-Cement-Based Composite Repair Materials. Master’s Thesis, Southeast University, Nanjing, China, 2022. [Google Scholar]

- Albidah, A.; Abadel, A.; Alrshoudi, F.; Altheeb, A.; Abbas, H.; Al-Salloum, Y. Bond strength between concrete substrate and metakaolin geopolymer repair mortars at ambient and elevated temperatures. J. Mater. Res. Technol. 2020, 9, 10732–10745. [Google Scholar] [CrossRef]

- Sadrmomtazi, A.; Khoshkbijari, R.K. Determination and Prediction of Bonding Strength of Polymer Modified Concrete (PMC) as the Repair Overlay on the Conventional Concrete Substrate. KSCE J. Civ. Eng. 2019, 23, 1141–1149. [Google Scholar] [CrossRef]

- Wang, R.; Wang, P. Function of styrene-acrylic ester copolymer latex in cement mortar. Mater. Struct. 2009, 43, 443–451. [Google Scholar] [CrossRef]

- Shi, C.; Zou, X.; Yang, L.; Wang, P.; Niu, M. Influence of humidity on the mechanical properties of polymer-modified cement-based repair materials. Constr. Build. Mater. 2020, 261, 119928. [Google Scholar] [CrossRef]

- Li, H.; Ni, D.; Liang, G.; Guo, Y.; Dong, B. Mechanical performance and microstructure of cement paste/mortar modified by VAEC dispersible powder cured under different temperatures. Constr. Build. Mater. 2021, 278, 122446. [Google Scholar] [CrossRef]

- Pang, B.; Jia, Y.; Zhang, Y.; Ni, H.; Liu, G.; She, W.; Yang, L.; Qian, R. Effect of the combined treatment with inorganic and organic agents on the surface hardening and adhesion properties of cement-based materials. Mater. Des. 2019, 169, 107673. [Google Scholar] [CrossRef]

- Shaker, F.; El-Dieb, A.; Reda, M. Durability of Styrene-Butadiene latex modified concrete. Cem. Concr. Res. 1997, 27, 711–720. [Google Scholar] [CrossRef]

- Wang, M.; Wang, R.; Zheng, S.; Farhan, S.; Yao, H.; Jiang, H. Research on the chemical mechanism in the polyacrylate latex modified cement system. Cem. Concr. Res. 2015, 76, 62–69. [Google Scholar] [CrossRef]

- Shen, A.; Lin, S.; Guo, Y.; He, T.; Lyu, Z. Relationship between flexural strength and pore structure of pavement concrete under fatigue loads and Freeze-thaw interaction in seasonal frozen regions. Constr. Build. Mater. 2018, 174, 684–692. [Google Scholar] [CrossRef]

| CaO | SiO2 | Al2O3 | Fe2O3 | MgO | Na2O | LOI | ||

|---|---|---|---|---|---|---|---|---|

| 49.27 | 26.36 | 10.62 | 4.49 | 3.24 | 1.27 | 0.53 | 2.01 | 3.71 |

| Property | Appearance | Solid Content | Bulk Density | pH Value (20% Solution) | Chloride Ion Content |

|---|---|---|---|---|---|

| Value | White powder | ≥99% | 0.40–0.60 g/cm3 | 7–9 | 0.02–0.25% |

| Property | Bulk Density (kg/m3) | Apparent Density (kg/m3) | Void Ratio (%) | Fineness Modulus | Grading Zone |

|---|---|---|---|---|---|

| Value | 1450 | 2660 | 43 | 2.69 | Zone II |

| Polymer Type | Exterior | Solid Content (%) | Viscosity (mPa·s) | pH Value | Density (g/cm3) |

|---|---|---|---|---|---|

| WEP-A | Milky liquid | 50 | 1105 | 7.8 | 1.1~1.0 |

| WEP-B | Pale yellow liquid | 50 | 900 | 9.4 | 1.0 |

| Mark | Polymer-to-Cement Ratio (P/C) | Water-to-Cement Ratio (W/C) | Cement-to-Sand Ratio (C/S) | Superplasticizer Dosage (SP/%) |

|---|---|---|---|---|

| WEP0 | 0 | 0.31 | 0.5 | 0.05 |

| WEP5 | 0.05 | 0.31 | 0.5 | 0.05 |

| WEP10 | 0.1 | 0.31 | 0.5 | 0.05 |

| WEP15 | 0.15 | 0.31 | 0.5 | 0.05 |

| WEP20 | 0.2 | 0.31 | 0.5 | 0.05 |

| Mixture | Tensile Strength (MPa) | Ultimate Strain (%) |

|---|---|---|

| Control | 3.7 | 0.008 |

| WEP5 | 4.0 | 0.011 |

| WEP10 | 4.2 | 0.014 |

| WEP15 | 4.5 | 0.018 |

| WEP20 | 3.2 | 0.024 |

| Mixture | Initial Compressive Strength (MPa) | Residual Compressive Strength (MPa) | Retention Rate (%) | Initial Flexural Strength (MPa) | Residual Flexural Strength (MPa) | Retention Rate (%) |

|---|---|---|---|---|---|---|

| WEP0 | 60.3 | 35.0 | 58 | 9.9 | 5.0 | 51 |

| WEP5 | 48.3 | 30.4 | 63 | 10.7 | 6.6 | 62 |

| WEP10 | 45.2 | 32.5 | 72 | 12.9 | 10.1 | 78 |

| WEP15 | 42.6 | 34.1 | 80 | 10.1 | 8.1 | 80 |

| WEP20 | 38.7 | 32.9 | 85 | 9.2 | 8.0 | 87 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, F.; Zhang, Y.; Song, X.; Liu, L.; Sun, X.; Sun, P. Influence of Self-Emulsifying Waterborne Epoxy Resin with Novel Hardeners on Pore Structure and Permeability of Cement-Based Materials. Buildings 2025, 15, 997. https://doi.org/10.3390/buildings15070997

Wang F, Zhang Y, Song X, Liu L, Sun X, Sun P. Influence of Self-Emulsifying Waterborne Epoxy Resin with Novel Hardeners on Pore Structure and Permeability of Cement-Based Materials. Buildings. 2025; 15(7):997. https://doi.org/10.3390/buildings15070997

Chicago/Turabian StyleWang, Feifei, Yunsheng Zhang, Xiaoyun Song, Lirong Liu, Xianglin Sun, and Peifeng Sun. 2025. "Influence of Self-Emulsifying Waterborne Epoxy Resin with Novel Hardeners on Pore Structure and Permeability of Cement-Based Materials" Buildings 15, no. 7: 997. https://doi.org/10.3390/buildings15070997

APA StyleWang, F., Zhang, Y., Song, X., Liu, L., Sun, X., & Sun, P. (2025). Influence of Self-Emulsifying Waterborne Epoxy Resin with Novel Hardeners on Pore Structure and Permeability of Cement-Based Materials. Buildings, 15(7), 997. https://doi.org/10.3390/buildings15070997