Interaction Analysis of the Synchronous Excavations of Deep Foundation Pit and Adjacent Underground Channel

Abstract

1. Introduction

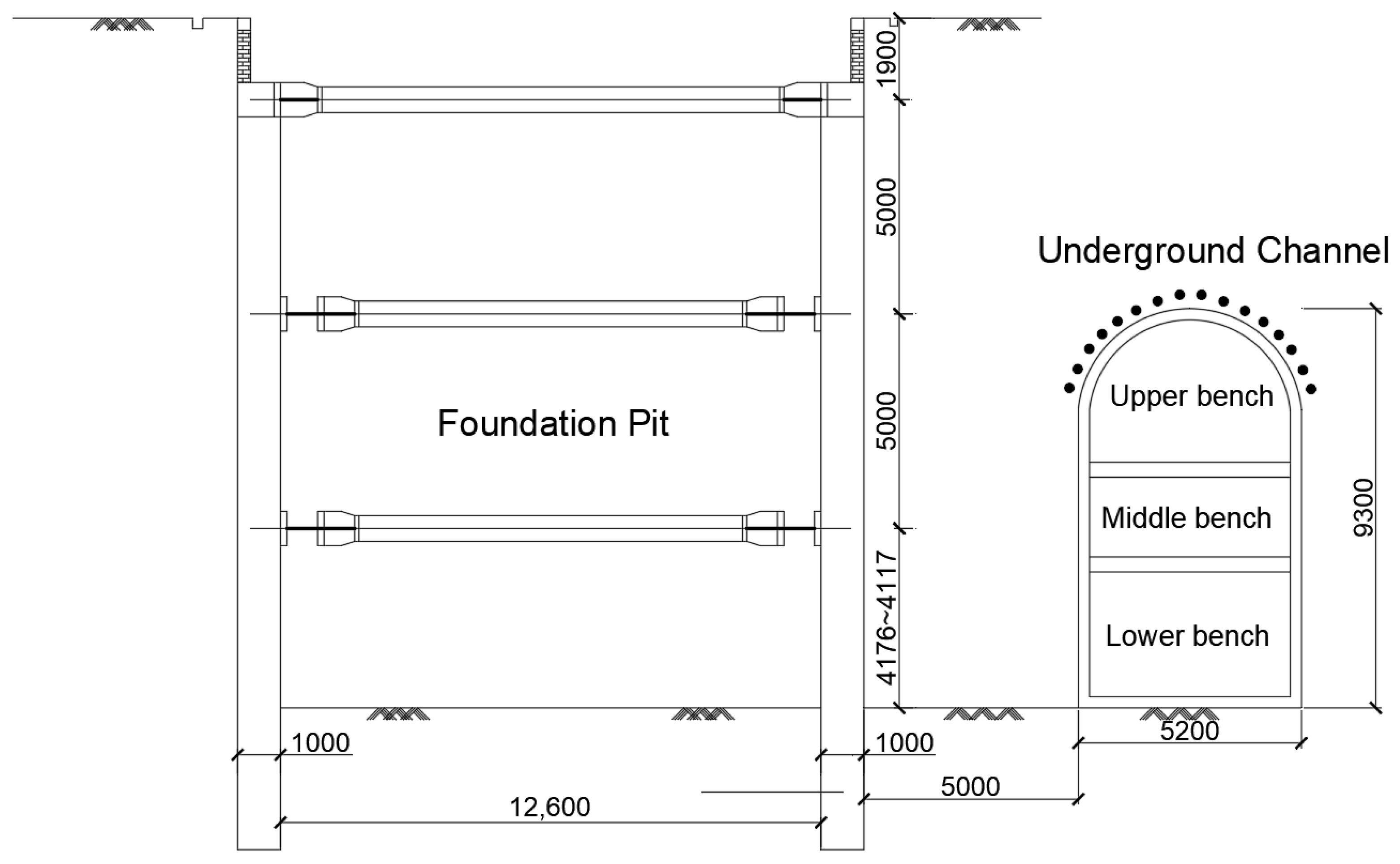

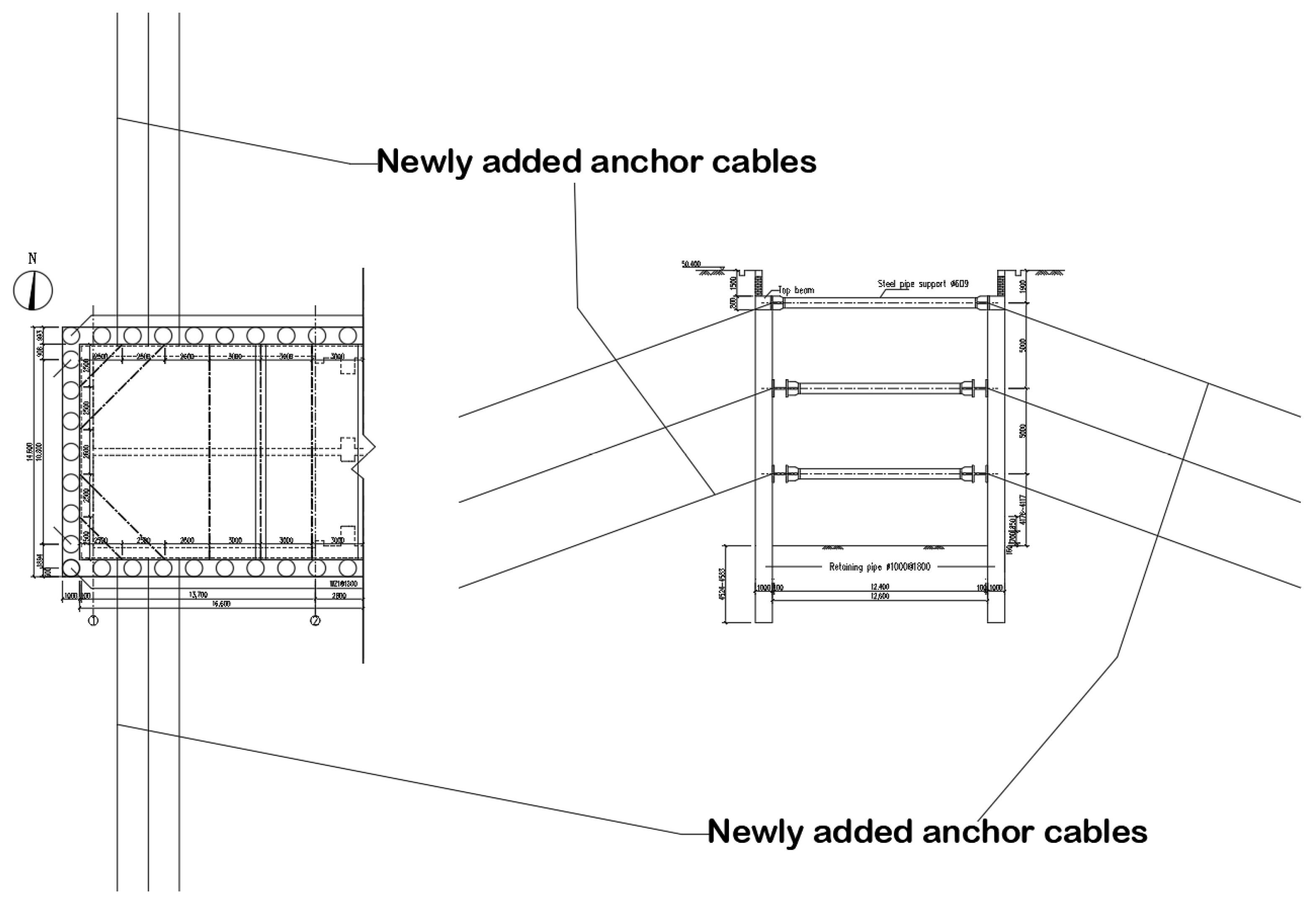

2. Engineering Background

2.1. Project Description

2.2. Soil Conditions

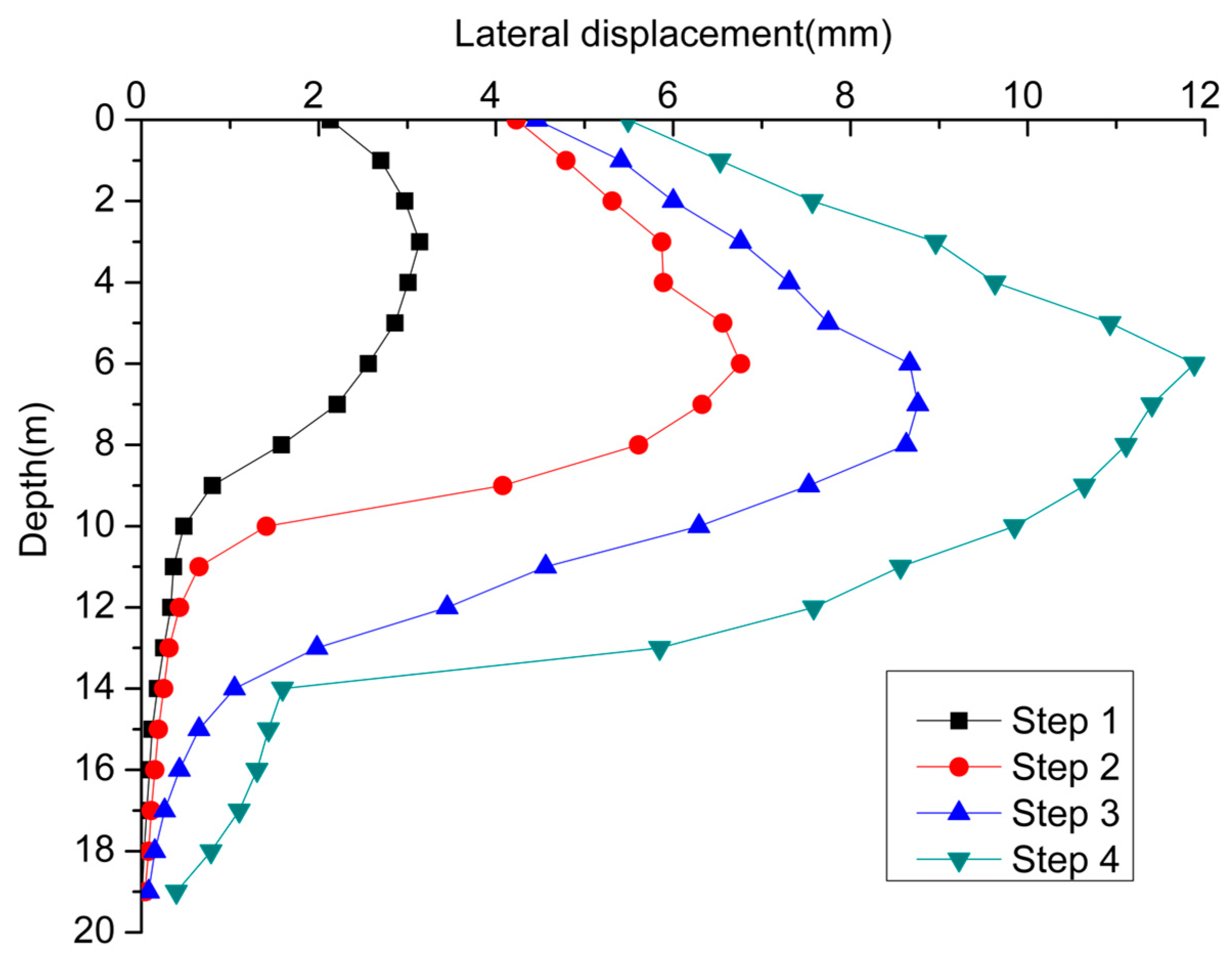

3. On-Site Monitoring

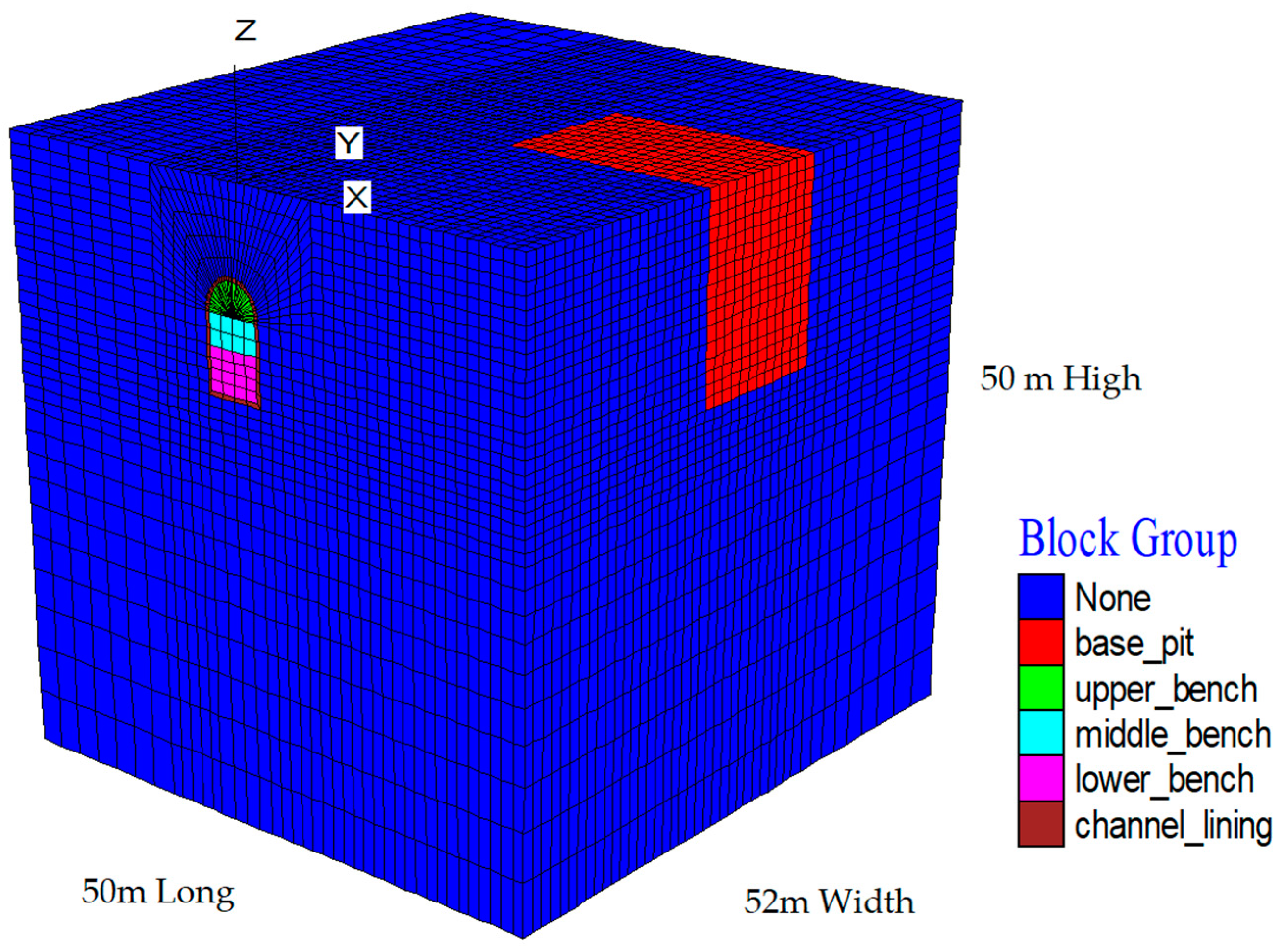

4. Numerical Simulation and Analysis

4.1. Modeling

4.2. Implementation

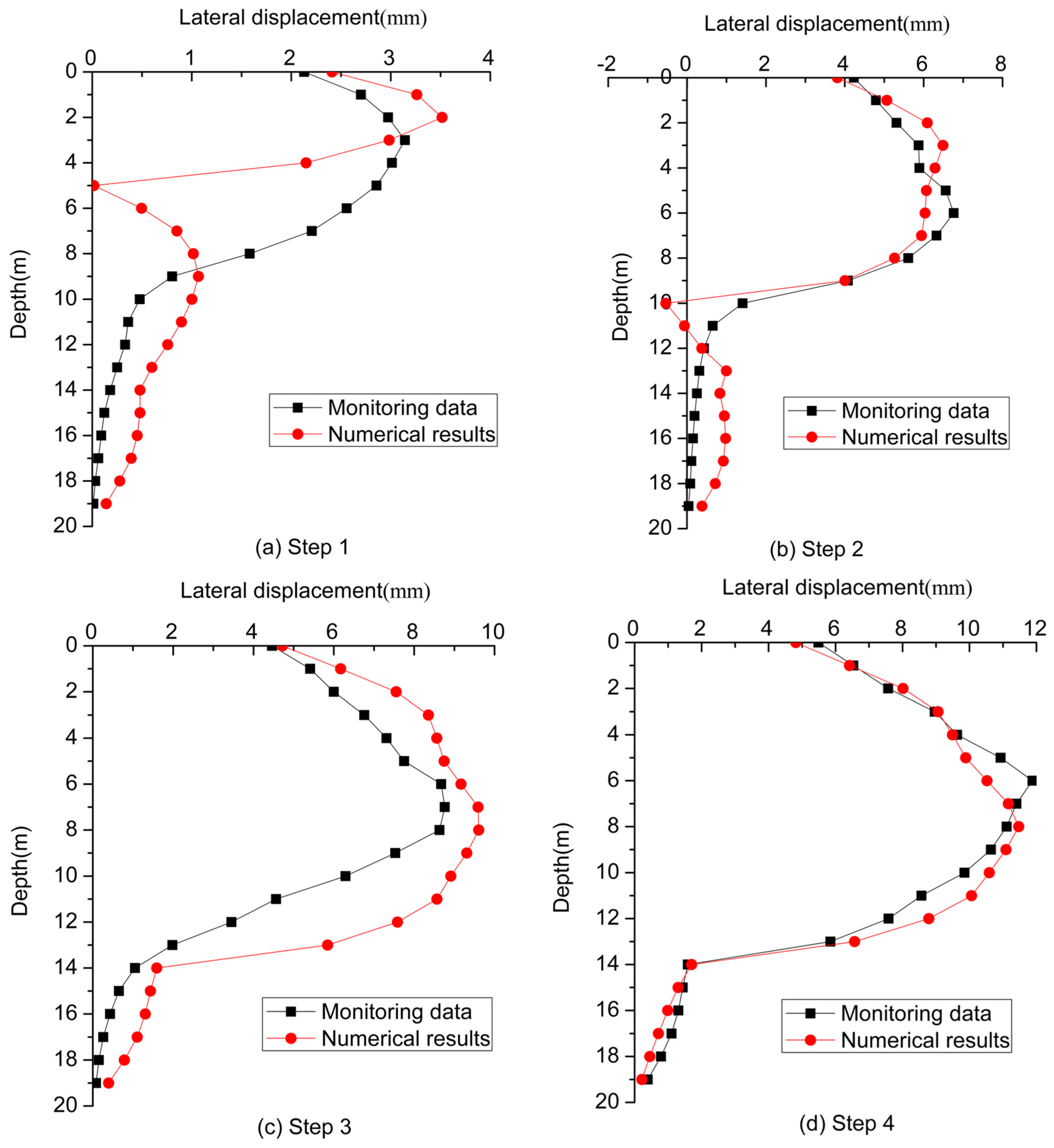

4.3. Validation

4.4. Case Study

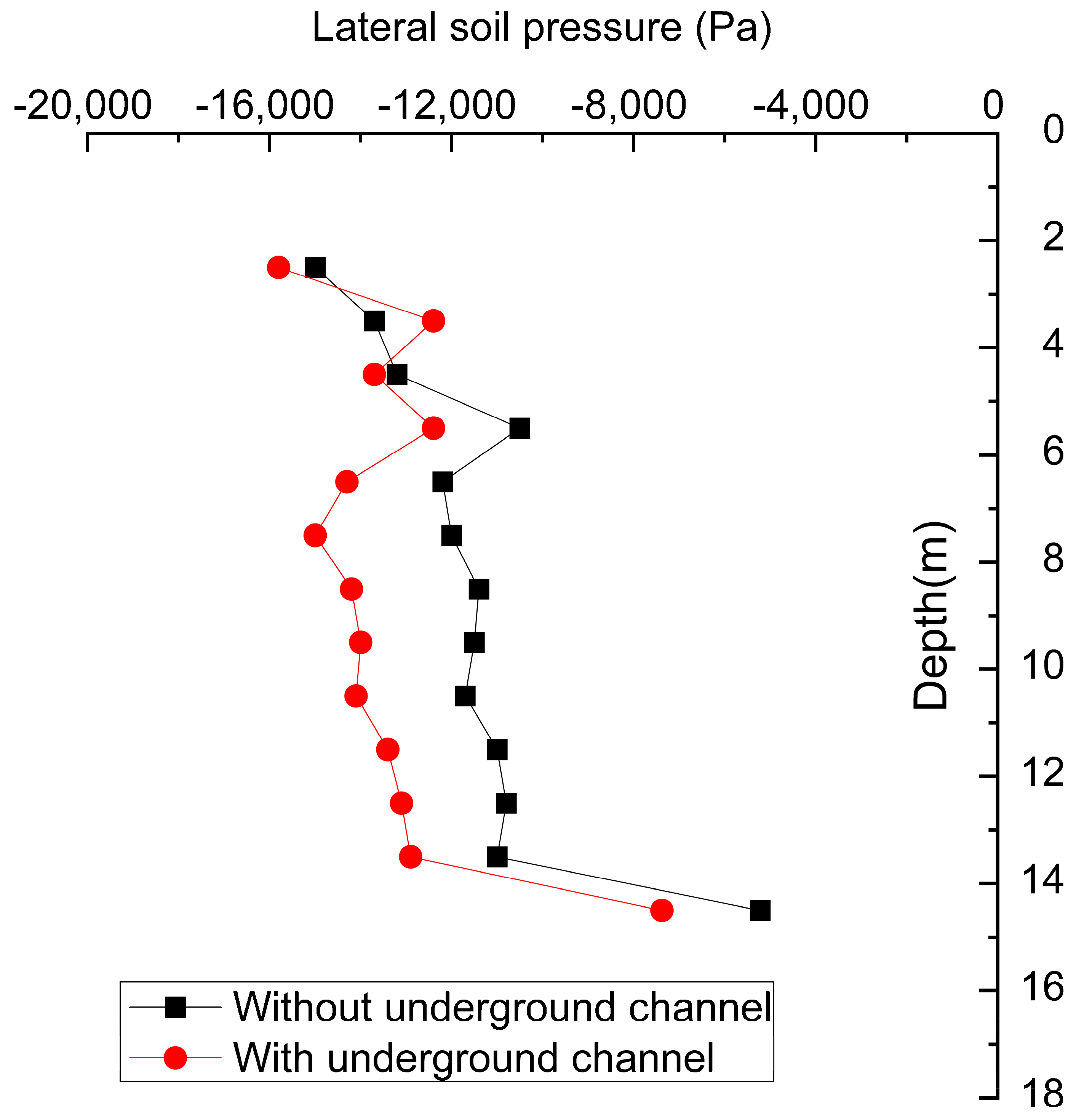

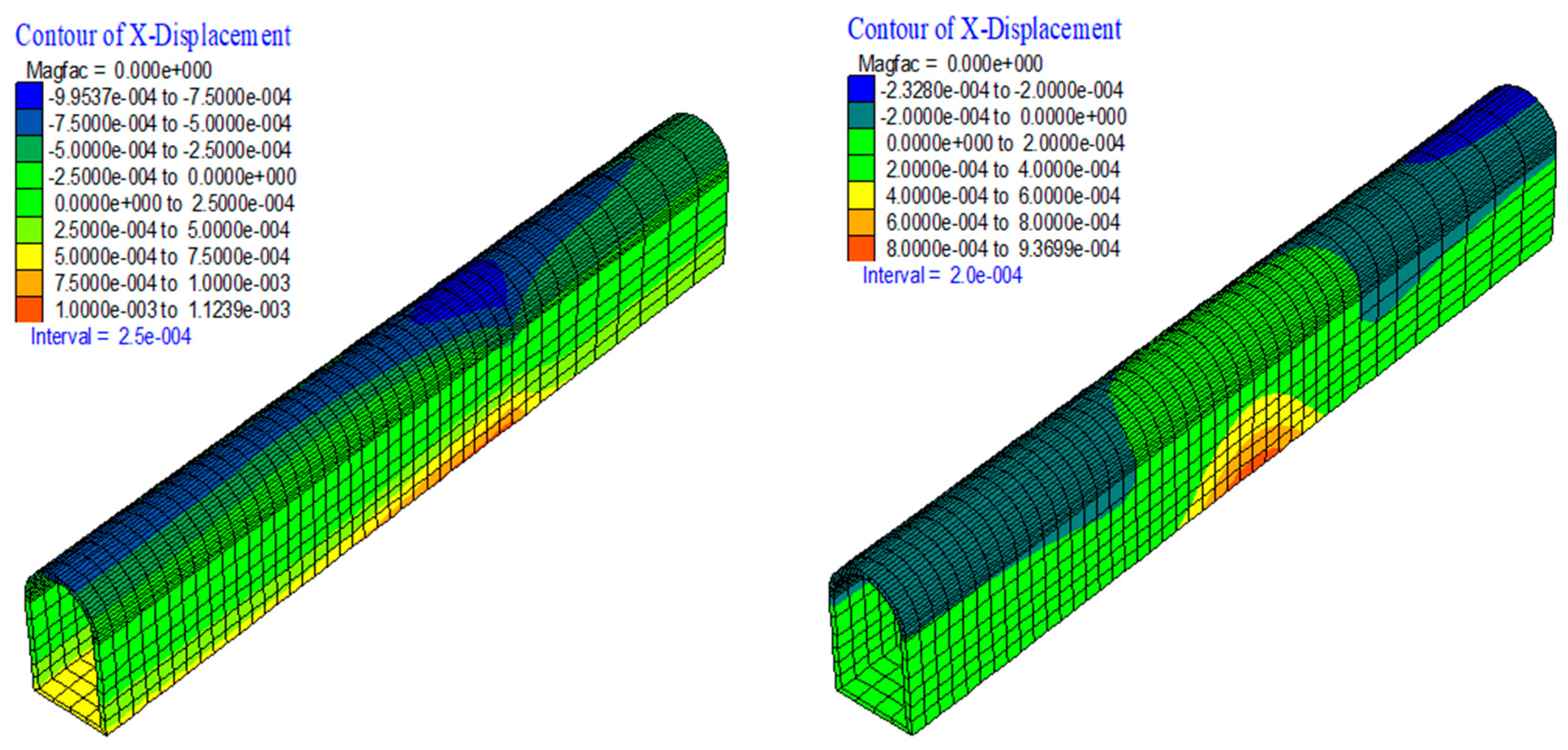

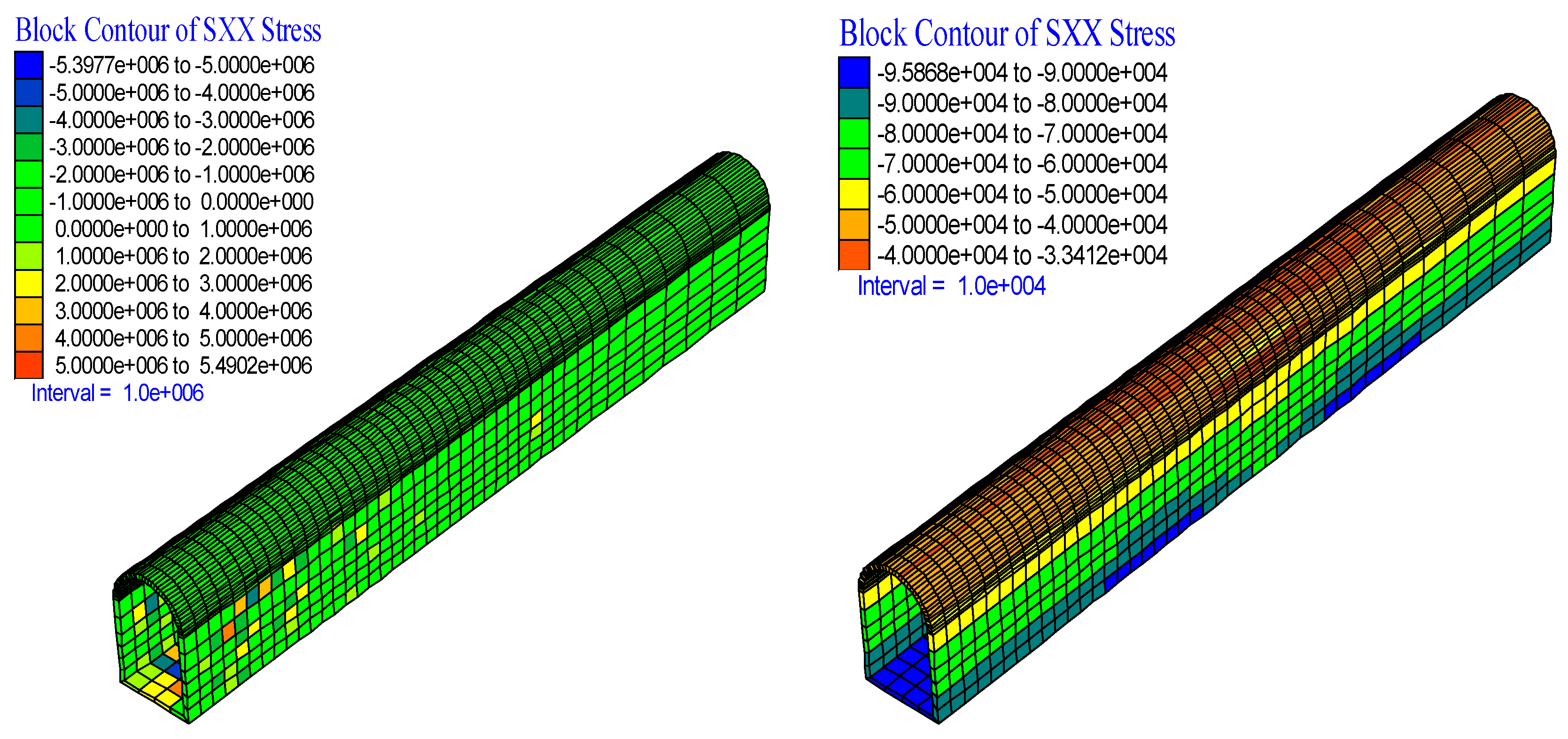

4.4.1. Excavation of the Foundation Pit with Versus Without Adjacent Underground Channel

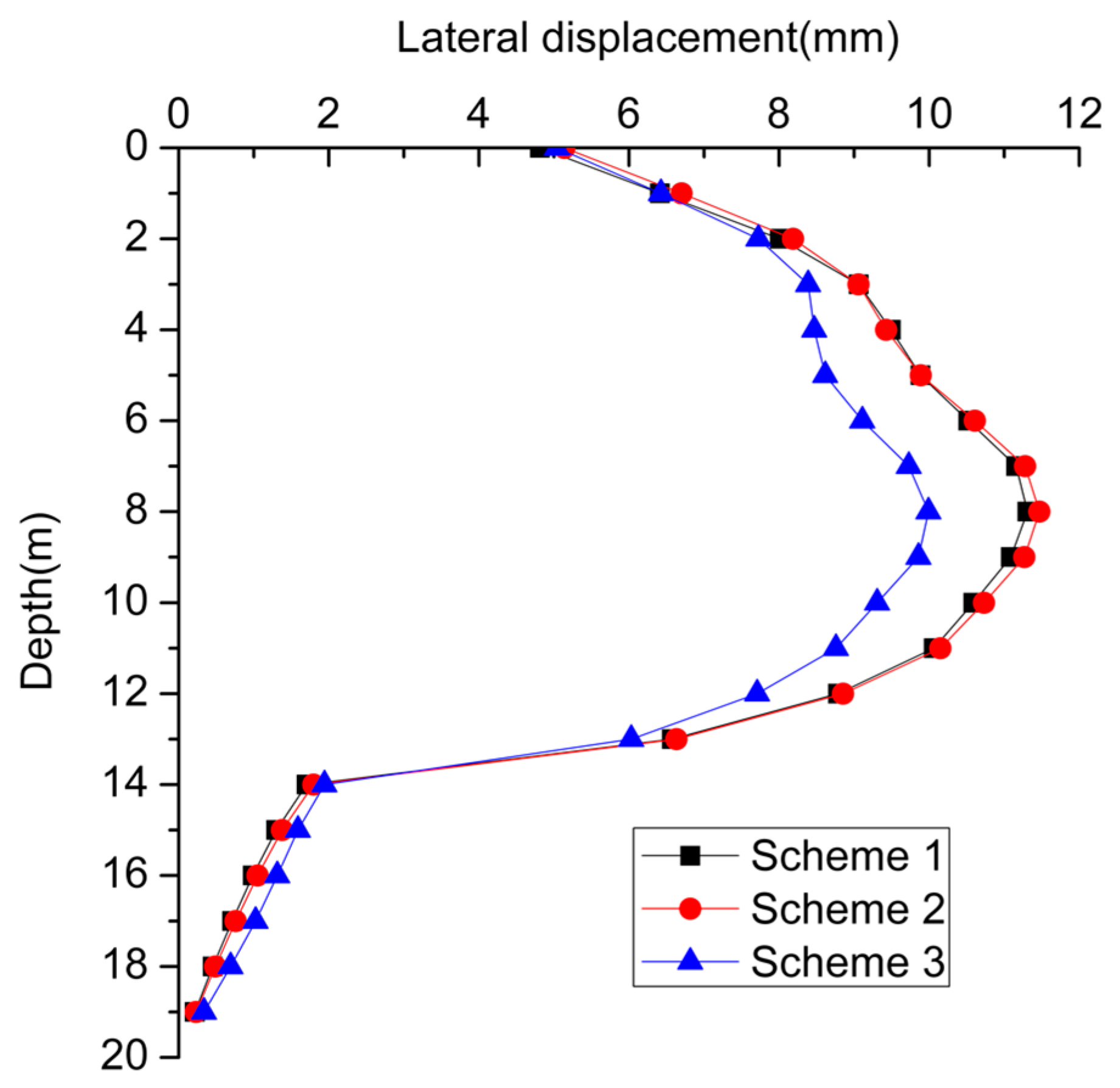

4.4.2. Effect of Excavation Sequences

4.4.3. Effect of the Spacing

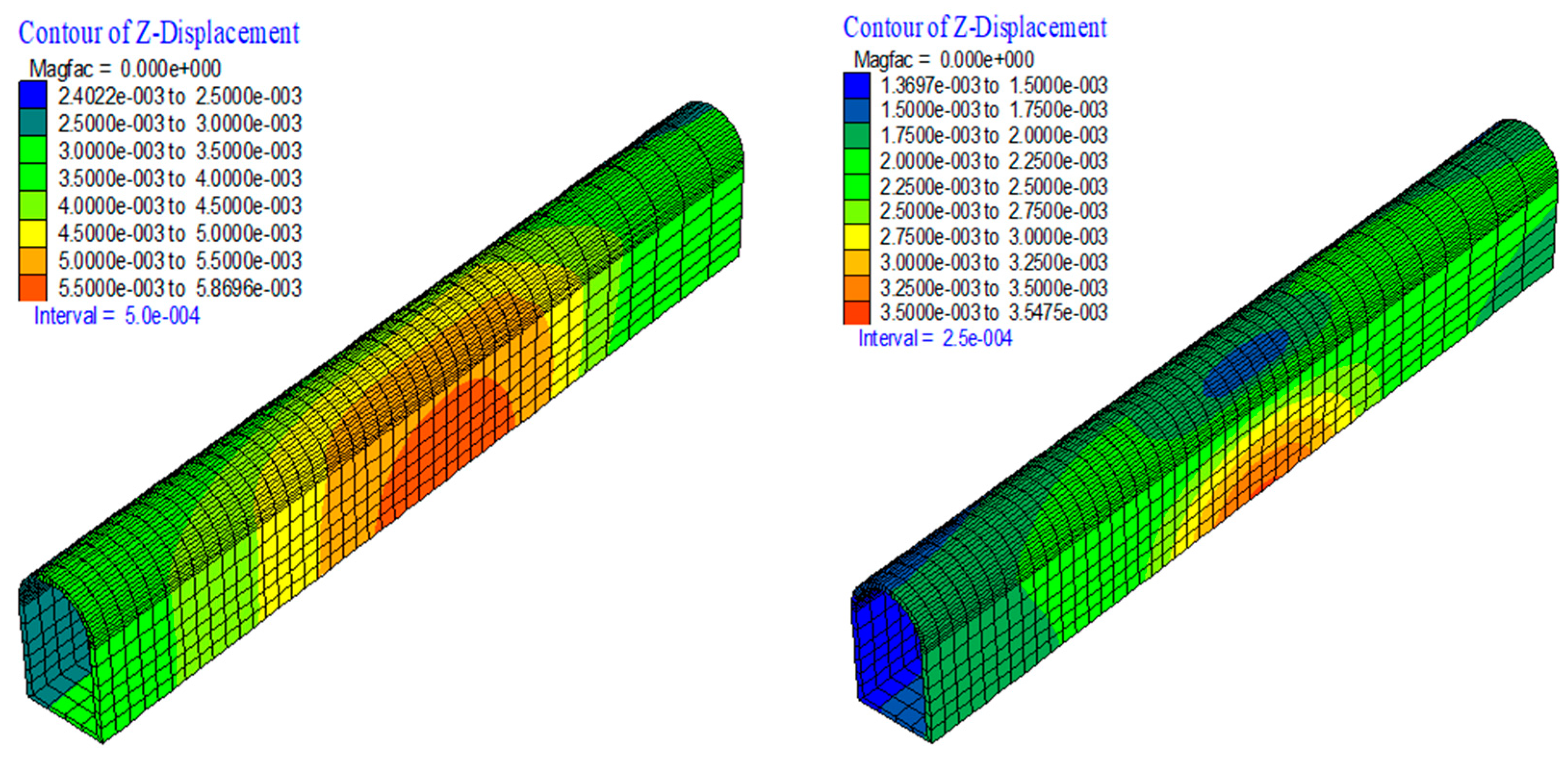

4.4.4. Effect of Existing Underground Channel on the Foundation Pit Excavation

5. Conclusions

- -

- The underground channel excavation disrupts the soil structure around the channel and foundation pit on a larger scale, which affects the formation of soil arch behind the retaining pile and thus increased the lateral pile displacement, and the addition of anchor cables is unnecessary;

- -

- If conditions permit, it is the safest to excavate the underground channel first and then the foundation pit;

- -

- The primary interaction spacing between the two adjacent excavations is at the same depth the foundation pit depth, and when the spacing increases to twice the foundation pit depth, there is basically no interaction;

- -

- Compared to the solid and heavy soil, the adjacent existing underground channel is like a “hollow, elastic, light” tube and more sensitive to the foundation pit excavation, whose uplift and deformation rebound could exert a force on the surrounding soil and then enlarge the lateral pile displacement.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, Z.F.; Yang, K.W.; Xu, X.B.; Yang, Y.J.; Jiang, Y.X.; Tong, L.; Chen, Y.M. Investigation of metro tunnel response to multiple adjacent large excavations in soft soils. Tunn. Undergr. Space Technol. 2024, 152, 105935. [Google Scholar]

- Zhao, X.; Wang, H.X.; Li, Z.W.; Dai, G.L.; Yin, Z.W.; Cao, S.N.; Zhou, J.L. Numerical study on the deformation of tunnels by excavation of foundation pit adjacent to the subway. Appl. Sci. 2022, 12, 4752. [Google Scholar] [CrossRef]

- Ma, F.H.; Li, S.L.; Wang, Q.Y. Study on the Impact of Deep Foundation Excavation of Reclaimed Land on the Deformation of Adjacent Subway Tunnels. Buildings 2024, 14, 1771. [Google Scholar] [CrossRef]

- Zhuang, Y.; Cui, X.Y.; Hu, S.L. Numerical simulation and simplified analytical method to evaluate the displacement of adjacent tunnels caused by excavation. Tunn. Undergr. Space Technol. 2023, 132, 104879. [Google Scholar]

- Qiu, J.T.; Jiang, J.; Zhou, X.J.; Zhang, Y.F.; Pan, Y.D. Analytical solution for evaluating deformation response of existing metro tunnel due to excavation of adjacent foundation pit. J. Cent. South Univ. 2021, 28, 1888–1900. [Google Scholar] [CrossRef]

- Liang, R.Z.; Xia, T.D.; Huang, M.S.; Lin, C.G. Simplified analytical method for evaluating the effects of adjacent excavation on shield tunnel considering the shearing effect. Comput. Geotech. 2017, 81, 167–187. [Google Scholar]

- Feng, G.H.; Xu, C.J.; Liang, L.J.; Tey, M.W.; Chi, M.L.; Ge, S.Q. Simplified method for evaluating the response of existing tunnel induced by adjacent excavation. Int. J. Numer. Anal. Methods Geomech. 2023, 47, 54–81. [Google Scholar]

- Ou, X.F.; Zhang, X.M.; Feng, H.; Zhang, C.; Wang, S.Y.; Zhou, X.S.; Wang, Z.X. Response of Metro Tunnels to Adjacent Diaphragm Wall Construction in Shenzhen Granite Residual Soil. Int. J. Geomech. 2023, 23, 05023004. [Google Scholar]

- Liu, B.; Shao, C.M.; Wang, N.N.; Zhang, D.W. Influenced zone of deep excavation and a simplified prediction method for adjacent tunnel displacement in thick soft soil. Appl. Sci. 2023, 13, 4647. [Google Scholar] [CrossRef]

- Wang, L.; Zheng, G. Protection of cement-soil reinforced regions for adjacent running tunnels during pit excavation. Chin. J. Rock Mech. Eng. 2018, 37, 3674–3685. [Google Scholar]

- Zheng, G.; Pan, J.; Cheng, X.S.; Bai, R.B.; Du, Y.M.; Diao, Y.; Ng, C.W.W. Use of Grouting to Control Horizontal Tunnel Deformation Induced by Adjacent Excavation. J. Geotech. Geoenviron. Eng. 2020, 146, 05020004. [Google Scholar] [CrossRef]

- Yang, Y.B.; Chen, C.Y.; Liu, C.; Huang, L.T.; Chen, W.; Lin, N.Y.; Cui, J.; Xie, W.D. Performance of a deep excavation and the influence on adjacent piles: A case history in karst region covered by clay and sand. Ugd. Space 2023, 8, 45–60. [Google Scholar] [CrossRef]

- Zhang, R.H.; Zhang, W.G.; Goh, A.T.C. Numerical investigation of pile responses caused by adjacent braced excavation in soft clays. Inter. J. Geotech. Eng. 2018, 15, 1–15. [Google Scholar]

- Liu, J.W.; Shi, C.H.; Cao, C.Y.; Lei, M.F.; Wang, Z.X. Improved analytical method for pile response due to foundation pit excavation. Comput. Geotech. 2020, 123, 103609. [Google Scholar]

- Liu, B.; Wu, W.W.; Lu, H.P.; Chen, S.; Zhang, D.W. Effect and control of foundation pit excavation on existing tunnels: A state-of-the-art review. Tunn. Undergr. Space Tech 2024, 147, 105704. [Google Scholar]

- Zhou, Z.; Zhen, Y.D.; Hu, J.F.; Yang, H.; Gong, C.J. Deformation analysis of shield undercrossing and vertical paralleling excavation with existing tunnel in composite stratum. J. Centr South Univ. 2023, 30, 3127–3144. [Google Scholar]

- Zheng, W. Analytical solution for evaluating the responses of existing pile caused by adjacent tunnel excavation. Environ. Earth Sci. 2024, 83, 495. [Google Scholar]

- Wu, T.H.; Gao, Y.T.; Huang, C.F.; Jin, A.B.; Zhou, Y.; Li, J.W. Horizontal mechanical responses of single pile induced by adjacent tunneling considering the effect of multiple factors based on Timoshenko Beam-Kerr foundation model. Appl. Math. Model. 2025, 140, 115885. [Google Scholar]

- Qi, W.Q.; Yang, Z.Y.; Jiang, Y.S.; Yang, X.; Shao, X.K.; An, H.B. Investigation on ground displacements induced by excavation of overlapping twin shield tunnels. Geomech. Eng. 2022, 28, 531–546. [Google Scholar]

- Liu, X.; Zhang, R.; Fang, Q.; Li, Q.Q.; Jiang, A.N.; Li, K.-C. Subgrade settlements of existing railway lines and operational parameters of shield machine induced by twin shield tunnel excavations: A case study. J. Cent. South Univ. 2024, 31, 272–287. [Google Scholar]

- Rodríguez, C.A.; Rodríguez-Pérez, Á.M.; López, R.; Hernández-Torres, J.A.; Caparrós-Mancera, J.J. A Finite Element Method Integrated with Terzaghi’s Principle to Estimate Settlement of a Building Due to Tunnel Construction. Buildings 2023, 13, 1343. [Google Scholar] [CrossRef]

- Stewart, B.R. Active and passive wall pressure induced by sorghum grain in a shallow bin. Trans. Amer. Soc. Agric. Engrs. 1972, 15, 121–125. [Google Scholar]

- Yue, S.Q.; Zuo, R.Y.; Lu, Z. A method for calculating active earth pressure of soil piece with a finite width between adjacent foundation pits. Rock Soil Mech. 2016, 37, 2063–2069. [Google Scholar]

- Shao, P.; Zhu, C.B.; Pan, J.J.; Liu, N.W. Study on the Interaction of Limited Earth Pressure and Supporting Structure between Deep Foundation Pits. Chin. J. Ugd. Space Eng. 2021, 17, 187–195. [Google Scholar]

- Li, S.H.; Huang, C.F.; Yao, T.J.; Li, P.F. The Influence of Non-synchronous Excavation of Twin Curved Shield Tunnels. KSCE J. Civil Eng. 2022, 26, 2456–2467. [Google Scholar]

- Dai, B.; Hu, Y.; Wang, H.S. Analysis and practice of influence of synchronous excavation of adjacent foundation pits in Shanghai area. Chin. J. Geotech. Eng. 2021, 43, 129–132. [Google Scholar]

- Shi, H.Y.; Ge, C.L.; Liu, Z.; Tang, J. Study on Interaction of Two Adjacent Excavations Constructed Simultaneously. Chin. J. Ugd. Space Eng. 2015, 11, 183–188. [Google Scholar]

- Shi, H.; Jia, Z.L.; Wang, T.; Cheng, Z.Q.; Zhang, D.; Bai, M.Z.; Yu, K. Deformation Characteristics and Optimization Design for Large-Scale Deep and Circular Foundation Pit Partitioned Excavation in a Complex Environment. Buildings 2022, 12, 1292. [Google Scholar] [CrossRef]

- Wang, S.J.; Wang, W.T.; Yang, H.; Zhao, D.B.; Liu, Y. Study on the influence of adjacent double deep foundation pit excavation sequence on existing tunnel deformation based on HSS constitutive model. Appl. Sci. 2024, 14, 3626. [Google Scholar] [CrossRef]

- Tan, Y.; Lu, Y.; Wang, D.L. Synchronous-cross zoned excavation of the oversized basement of Shanghai International Financial Centre by combination of bottom-up and top-down methods: Structural and geotechnical behaviors. Tunn. Undergr. Space Tech. 2024, 153, 106023. [Google Scholar]

- Tan, Y.; Lu, Y.; Wang, D.L. Interactive behaviors of four closely spaced mega excavations in soft clays: Case study on an excavation group in Shanghai, China. Tunn. Undergr. Space Technol. 2023, 138, 105186. [Google Scholar] [CrossRef]

- Beijing Municipal Commission of Housing and Urban-Rural Development. Technical Code for Monitoring Measurement of Subway Engineering(DB11/490-2007)[S]; China Communications Press: Beijing, China, 2007.

Disclaimer/Publisher’s Note: The statements, opinions, and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions, or products referred to in the content. |

| Soil | Thickness (m) | Density (g/cm3) | Bulk Modulus (Mpa) | Shear Modulus (Mpa) | Internal Friction Angle (°) | Cohesion (kPa) |

|---|---|---|---|---|---|---|

| Earth fill | 3 | 1.80 | 6.67 | 3.08 | 10 | 15 |

| Silty fine sand | 2 | 2.02 | 17.36 | 9.92 | 30 | 0 |

| Pebble | 14 | 2.10 | 32.74 | 22.54 | 45 | 0 |

| Silty clay | 3 | 1.95 | 7.94 | 3.88 | 22 | 20 |

| Pebble | 10 | 2.15 | 37.63 | 29.41 | 52 | 0 |

| Structural Units | Density (kg/cm3) | Elastic Modulus (GPa) | Poisson’s Ratio |

|---|---|---|---|

| RC retaining pile | 2500 | 30 | 0.2 |

| Lining of underground channel | 2500 | 10.5 | 0.25 |

| Steel pipe support | 7800 | 200 | 0.3 |

| Crown and waist beams | 2500 | 30 | 0.2 |

| Foundation pit bottom plate | 2500 | 30 | 0.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhong, H.; Zheng, L.; Liu, B.; Li, T.; Cao, B. Interaction Analysis of the Synchronous Excavations of Deep Foundation Pit and Adjacent Underground Channel. Buildings 2025, 15, 1110. https://doi.org/10.3390/buildings15071110

Zhong H, Zheng L, Liu B, Li T, Cao B. Interaction Analysis of the Synchronous Excavations of Deep Foundation Pit and Adjacent Underground Channel. Buildings. 2025; 15(7):1110. https://doi.org/10.3390/buildings15071110

Chicago/Turabian StyleZhong, Hai, Liqun Zheng, Bo Liu, Tao Li, and Bo Cao. 2025. "Interaction Analysis of the Synchronous Excavations of Deep Foundation Pit and Adjacent Underground Channel" Buildings 15, no. 7: 1110. https://doi.org/10.3390/buildings15071110

APA StyleZhong, H., Zheng, L., Liu, B., Li, T., & Cao, B. (2025). Interaction Analysis of the Synchronous Excavations of Deep Foundation Pit and Adjacent Underground Channel. Buildings, 15(7), 1110. https://doi.org/10.3390/buildings15071110