Environmental Risk Mitigation via Deep Learning Modeling of Compressive Strength in Green Concrete Incorporating Incinerator Ash

Abstract

1. Introduction

2. Methodology

2.1. Convolutional Neural Network (CNN)

2.2. MVO Algorithm

2.3. Data Collection

3. Laboratory Program

Benefits of Using Waste Incineration Ash in Concrete

4. Numerical Modeling Using Deep Learning Methods

4.1. Implementation of Deep Learning Method

4.1.1. Convolutional Neural Network (CNN) Configuration

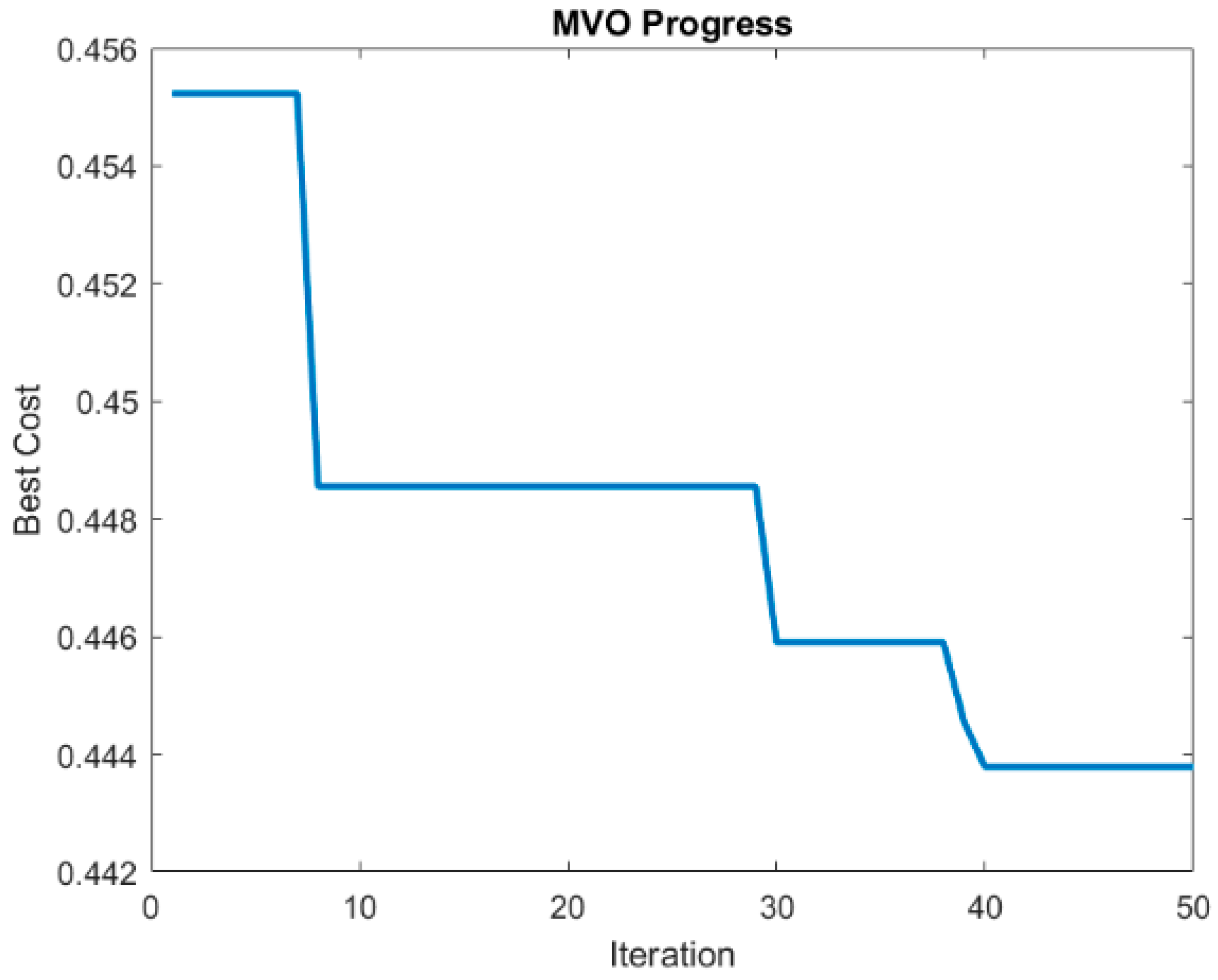

4.1.2. Multi-Verse Optimizer (MVO) Configuration

- Number of Variables (nVar): 5;

- Variable Range (VarMin, VarMax): 0 to 1;

- Maximum Iterations (MaxIt): 100;

- Population Size (nPop): 50;

- Wormhole Existence Probability (WEP) Range: WEP_Max = 1, WEP_Min = 0.2;

- Traveling Distance Rate (TDR): decreases over iterations as TDR = 1 − ((it)1/6/(MaxIt)1/6)

5. Sensitivity Analysis

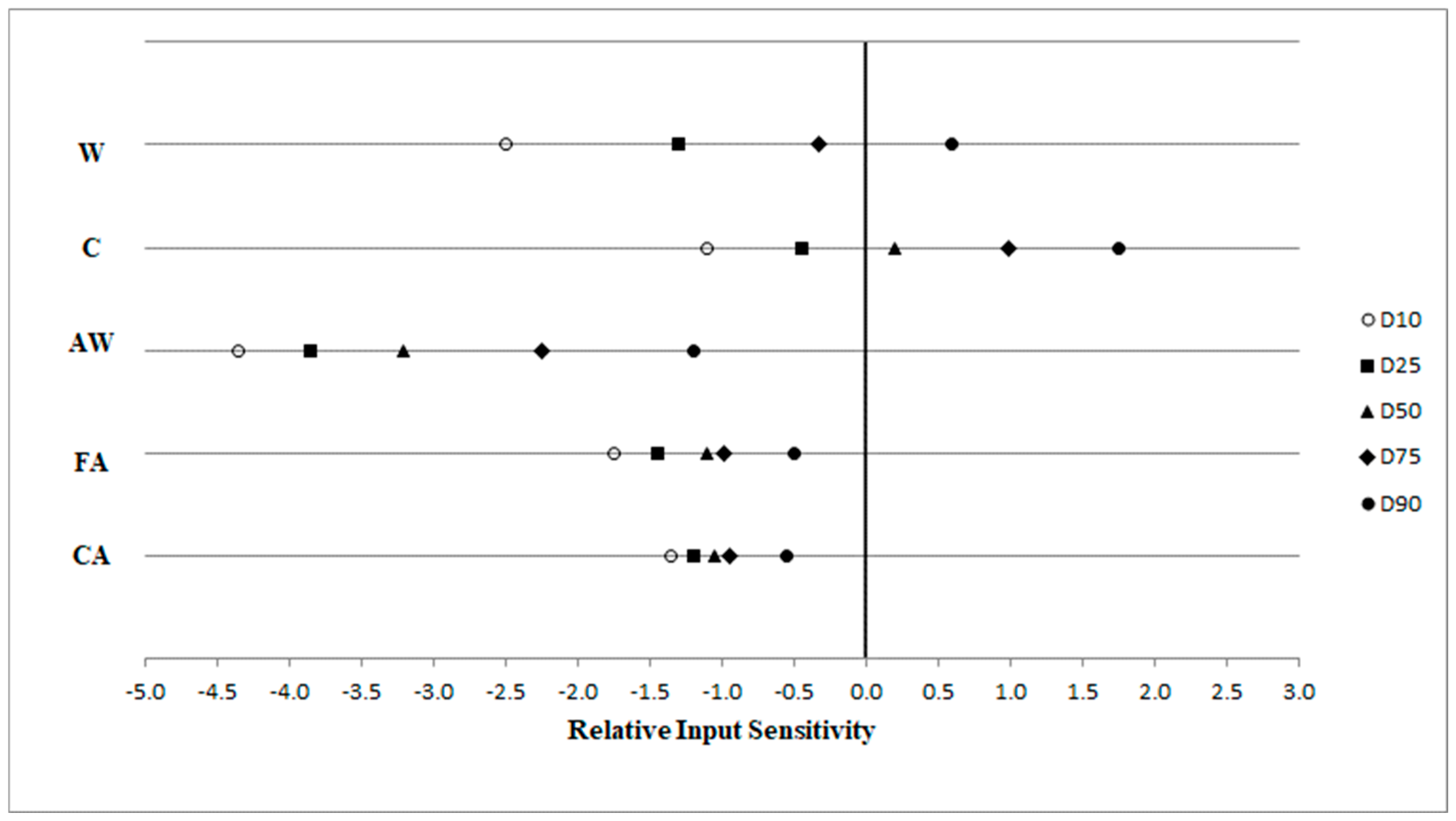

Interpretation of Sensitivity Analysis Results

- D10 represents a relative sensitivity value where 90% of the values are above this value and 10% are below this value. Therefore, if D10 is positive, it indicates that there is a greater than 90% chance that the relative sensitivity is positive. In other words, there is a greater than 90% chance that the output will increase as the input increases [20].

- D90 represents a relative sensitivity value where 90% of the values are below this value and 10% are above this value. Therefore, if D90 is negative, it indicates that there is a greater than 90% probability that the output will decrease as the input increases [20].

- D25 and D75: The explanations for D25 and D75 are similar to those for D10 and D90 [21].

- D50: When this value is at the baseline (zero sensitivity), it indicates that there is a 50% chance that the output will either increase or decrease as the input increases [21].

6. Discussion and Conclusions

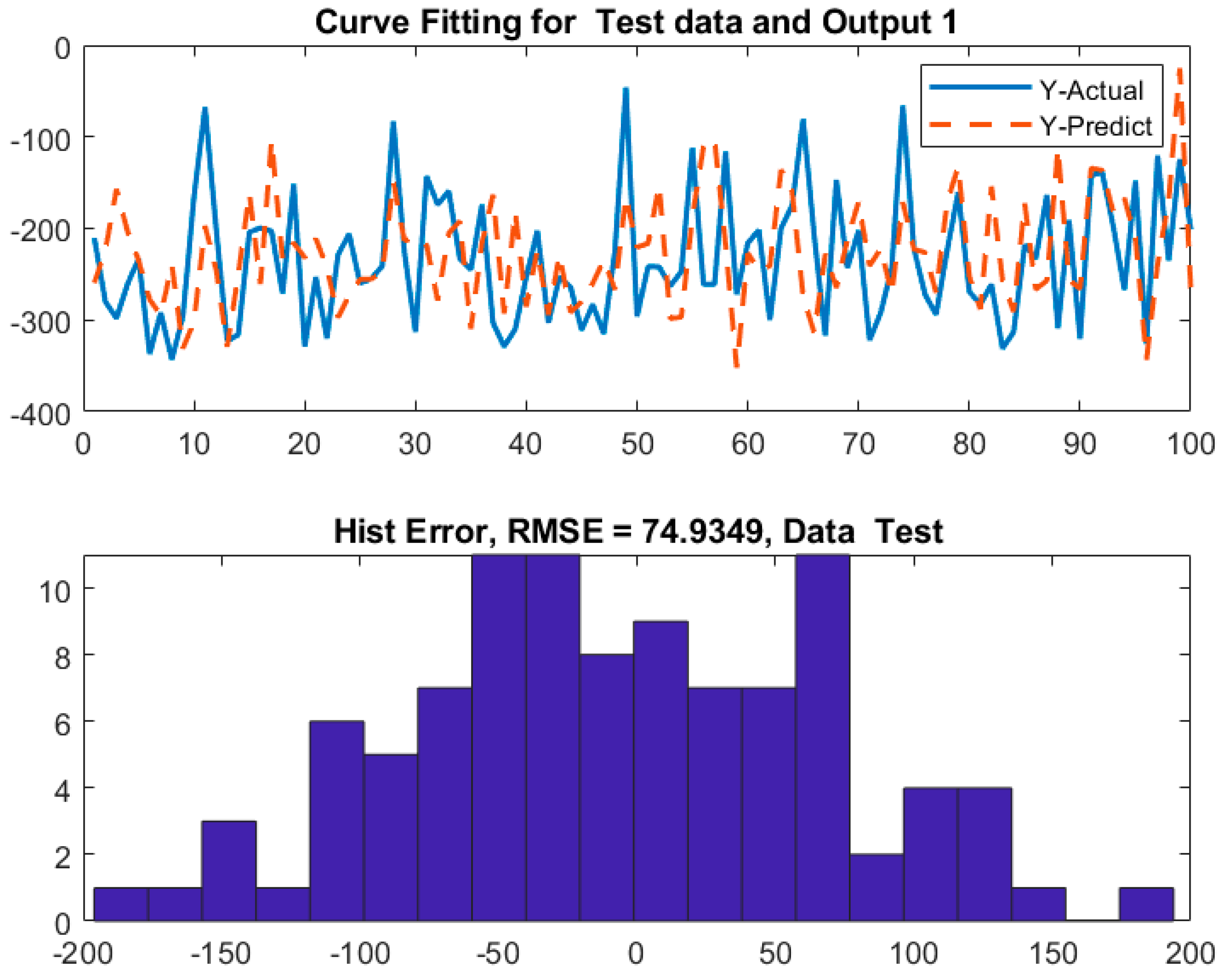

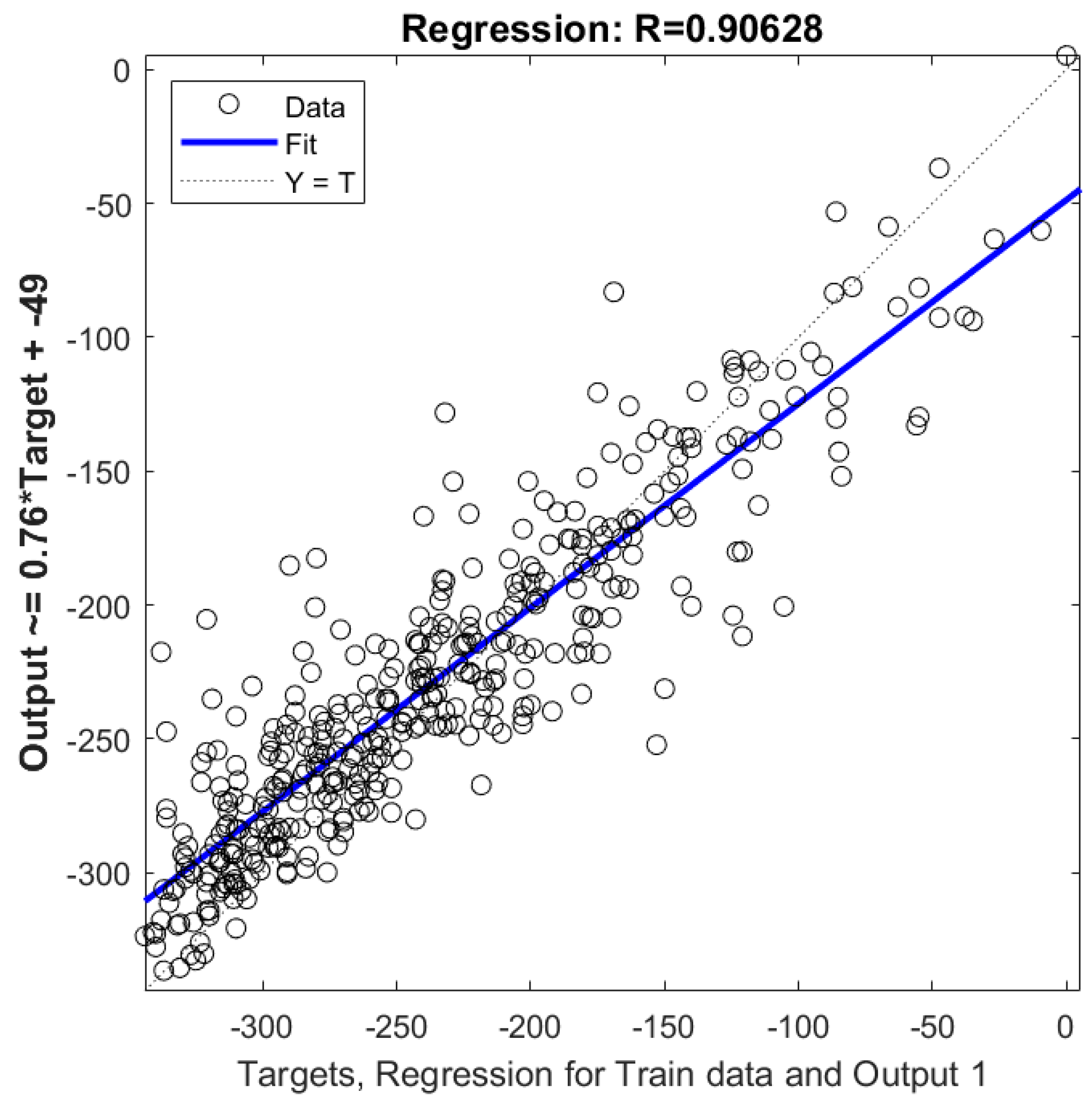

- The regression coefficient (R) of 90% in these models indicates the effectiveness of the deep learning method in modeling the present mix design.

- The applied deep learning method demonstrated the best performance based on the regression coefficient across the three datasets: training, testing, and evaluation.

- The error metric, specifically the root mean squared error (RMSE), demonstrates that the two-layer perceptron network with eight neurons exhibited optimal performance, with an average RMSE of 0.14.

- The error index (RMSE) prior to the integration of the MVO algorithm with the artificial neural network was approximately 30, which diminished to 0.14 following the implementation of this algorithm.

- The most salient result of this research concerns the sensitivity analysis of the optimized model. It was observed that the most negative values in relative sensitivity belong to the incineration ash weight, indicating the greatest decrease in compressive strength. Similarly, the weights of coarse aggregate and fine aggregate also have negative relative sensitivity values, showing that an increase in their amounts leads to a decrease in compressive strength. The impact of fine aggregate is particularly more significant. A comparative analysis of the effects of these five input parameters on compressive strength reveals that cement weight has the most significant influence.

- Implementation of the deep learning modeling method developed in this study for the purpose of predicting the compressive strength of concrete.

- Implementation of the current study’s mix design in concrete projects and economic analysis of the proposed mix design in comparison to analogous designs.

- Utilization of alternative machine learning methods for modeling in the present research and comparison of the results thereof.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gharshasbi, R.; Zare Nejad, H. Applications of Incineration Ash. In Proceedings of the Fifth National Environmental Engineering Conference, Tehran, Tehran, Iran, 21–22 November 2011; Available online: https://civilica.com/doc/122065 (accessed on 14 February 2025).

- Gheskin Tabrizi, M.R.; Maknoon, R.; Ebadi, T.; Nikravan, M. Review and Analysis of Research on Urban Incineration Ash Management Methods with Emphasis on Stabilization and Solidification. In Proceedings of the Twelfth National Civil Engineering Congress, Tabriz, Tabriz, Iran, 27 May 2020; Available online: https://civilica.com/doc/1120332 (accessed on 14 February 2025).

- Saeidi, F.; Abedini Karshk, M. Technology of Lightweight Concrete Made from Incineration Ash. In Proceedings of the National Conference on Human, Environment, and Sustainable Development, Hamadan, Iran, 10 March 2010; Available online: https://civilica.com/doc/106687 (accessed on 14 February 2025).

- Sahraei Karam Basti, M.; Divandari, H.; Abolfathi, B. Feasibility of Using Fly Ash and Bottom Ash from Incineration in Concrete and Asphalt Pavements. 2019. Available online: https://civilica.com/doc/1006682 (accessed on 14 February 2025).

- Divandari, H.; Hosein Janzadeh, H.; Sahraei Karam Basti, M. Evaluation of Hot Asphalt Performance with Incineration Ash Additive. In Proceedings of the Thirteenth National Conference and Exhibition on Asphalt, Bitumen, and Machinery, Tehran, Iran, 24–26 October 2021; Available online: https://civilica.com/doc/1360885 (accessed on 14 February 2025).

- Akhoundi, M.; Ramset, M.H.; Pour Rostam, T.; Golsorkh Pehlaviani, A. A New Method for Producing Eco-Friendly Concrete Using Waste PET Plastic and Silica Fume and Evaluating Its Mechanical Properties and Durability in Roller Compacted Concrete Pavement. Amirkabir J. Civ. Eng. 2021, 53, 1107–1116. [Google Scholar] [CrossRef]

- Naqipour, M.; Ahmadi, S.; Gorji Nejad, F. Investigating the Effect of Coal Waste on the Mechanical Behavior of Green Concrete. 2021. Available online: https://civilica.com/doc/1995308 (accessed on 14 February 2025).

- Chakravarthy, H.G.N.; Seenappa, K.M.; Naganna, S.R.; Pruthviraja, D. Machine Learning Models for the Prediction of the Compressive Strength of Self-Compacting Concrete Incorporating Incinerated Bio-Medical Waste Ash. Sustainability 2023, 15, 13621. [Google Scholar] [CrossRef]

- Li, J. Municipal Solid Waste Incineration Ash-Incorporated Concrete: One Step towards Environmental Justice. Buildings 2021, 11, 495. [Google Scholar] [CrossRef]

- Altuncı, Y.T. A Comprehensive Study on the Estimation of Concrete Compressive Strength Using Machine Learning Models. Buildings 2024, 14, 3851. [Google Scholar] [CrossRef]

- Onyelowe, K.C.; Kontoni, D.-P.N.; Ebid, A.M.; Dabbaghi, F.; Soleymani, A.; Jahangir, H.; Nehdi, M.L. Multi-Objective Optimization of Sustainable Concrete Containing Fly Ash Based on Environmental and Mechanical Considerations. Buildings 2022, 12, 948. [Google Scholar] [CrossRef]

- Emami Korende, M.; Nourbakhsh, S.N. Optimization of Steel Structure Weight Using Artificial Neural Network Method. New Approaches Civ. Eng. 2020, 4, 63–77. [Google Scholar]

- Mostofi Nejad, D. Technology and Mix Design of Concrete, 22nd ed.; Arkan Danesh: Tehran, Iran, 2010. [Google Scholar]

- Adding Fly Ash to Concrete; Iran Concrete Technology and Specialty Clinic: Tehran, Iran, 2015.

- Shafabakhsh, G.; Mohammadi Janaki, A. Evaluation of mechanical properties and durability of geopolymer concrete pavement fly ash and siflica fume. Q. J. Transp. Eng. 2021, 12, 855–872. [Google Scholar] [CrossRef]

- Emami, M. Modelling and Prediction of Coarse Grained Alluvium Behavior by Pressuremeter Test Results and Laboratory Chamber. Doctoral Dissertation, Tarbiat Modares University, Tehran, Iran, 2014. [Google Scholar]

- Emami, M. Application of Artifitial Neural Networks in Pressuremeter Test Results. Master of Science Thesis, Tarbiat Modares University, Tehran, Iran, 2009. [Google Scholar]

- Lu, M.; Abourizk, S.M.; Hermann, U.H. Sensitivity Analisys of neural networks in spool fabrication productivity studies. J. Comp. Civ. Eng. 2001, 15, 299–308. [Google Scholar]

- Emami, M.; Yasrobi, S.S. Modeling and interpretation of pressuremeter test results with artificial neural networks. Geotech. Geol. Eng. 2014, 32, 375–389. [Google Scholar]

- Yasrebi, S.S.; Emami, M. Application of Artificial Neural Networks (ANNs) in prediction and interpretation of pressuremeter test results. In Proceedings of the 12th International Conference of International Association for Computer Methods and Advances in Geomechanics (IACMAG), Goa, India, 1–6 October 2008; pp. 1634–1638. [Google Scholar]

- Farahani, J.N.; Shafigh, P.; Mahmud, H.B. Production of A Green Lightweight Aggregate Concrete by Incorporating High Volume Locally Available Waste Materials. Procedia Eng. 2017, 184, 778–783. [Google Scholar] [CrossRef]

- Emami, M.; Yasrobi, S.S. Modelling of pressuremeter tests with artifitial neural networks. Sharif J. Civ. Eng. 2012, 2, 25–36. [Google Scholar]

- Alderete, N.M.; Joseph, A.M.; Van den Heede, P.; Matthys, S.; De Belie, N. Effective and sustainable use of municipal solid waste incineration bottom ash in concrete regarding strength and durability. Resour. Conserv. Recycl. 2021, 167, 105356. [Google Scholar]

- Wu, M.H.; Lin, C.L.; Huang, W.C.; Chen, J.W. Characteristics of pervious concrete using incineration bottom ash in place of sandstone graded material. Constr. Build. Mater. 2016, 111, 618–624. [Google Scholar]

| Materials | C30F20 | C30F15 | C30F10 | C30F5 | C30F0 |

|---|---|---|---|---|---|

| Cement | 3.84 | 3.77 | 3.7 | 3.99 | 4.2 |

| Ash | 0.768 | 0.566 | 0.42 | 0.21 | 0 |

| Gravel | 10.04 | 10.19 | 10.39 | 10.30 | 10.30 |

| Sand | 12.76 | 12.97 | 13.2 | 13.11 | 13.11 |

| Water | 2.544 | 2.4 | 2.24 | 2.4 | 2.4 |

| Superplasticizer | 0.115 | 0.111 | 0.124 | 0.11 | 0.11 |

| Ash Percent | 20% | 15% | 10% | 5% | 0% |

| Materials | C60F20 | C60F15 | C60F10 | C60F5 | C60F0 |

|---|---|---|---|---|---|

| Cement | 4.61 | 4.9 | 5.18 | 5.47 | 5.76 |

| Ash | 1.15 | 0.86 | 0.58 | 0.29 | 0 |

| Gravel | 9.32 | 9.48 | 9.53 | 9.53 | 9.53 |

| Sand | 11.86 | 12.06 | 12.13 | 12.13 | 11.77 |

| Water | 1.84 | 1.84 | 1.84 | 1.84 | 1.84 |

| Superplasticizer | 0.144 | 0.144 | 0.144 | 0.144 | 0.144 |

| Ash Percent | 20% | 15% | 10% | 5% | 0% |

| Output Parameter | Input Parameters | ||||

|---|---|---|---|---|---|

| Fc (kg/cm2) | W (kg) | C (kg) | AW (kg) | FA (kg) | CA (kg) |

| 115 | 2.58 | 1.92 | 0.35 | 14.11 | 11.05 |

| 105 | 2.55 | 1.95 | 0.38 | 14.15 | 11.08 |

| 125 | 2.56 | 2.04 | 0.32 | 14.08 | 11.04 |

| 116 | 2.61 | 2.18 | 0.35 | 14.12 | 11.08 |

| 128 | 2.48 | 2.27 | 0.31 | 14.13 | 11.12 |

| 123 | 2.54 | 2.42 | 0.36 | 14.15 | 11.06 |

| 118 | 2.55 | 2.35 | 0.33 | 14.21 | 11.07 |

| 119 | 2.63 | 1.98 | 0.31 | 14.16 | 11.10 |

| 305 | 2.55 | 3.85 | 0.798 | 12.95 | 10.08 |

| 312 | 2.54 | 3.75 | 0.78 | 12.85 | 10.15 |

| 318 | 2.45 | 3.78 | 0.58 | 12.88 | 10.18 |

| 325 | 2.56 | 3.76 | 0.58 | 12.91 | 10.23 |

| 331 | 2.23 | 3.68 | 0.46 | 13.23 | 10.38 |

| 326 | 2.35 | 3.73 | 0.45 | 13.15 | 10.45 |

| 315 | 2.38 | 3.75 | 0.25 | 13.23 | 10.33 |

| 310 | 2.48 | 4.02 | 0.23 | 13.15 | 10.35 |

| 316 | 2.53 | 4.20 | 0 | 13.26 | 10.38 |

| Output | FC | ||||

|---|---|---|---|---|---|

| Input | W | C | AW | FA | CA |

| Relative Mean | −0.928 | 0.246 | −2.920 | −1.165 | −1.015 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Amraee, A.; Hosseini, S.A.; Farokhizadeh, F.; Haeri, M.H. Environmental Risk Mitigation via Deep Learning Modeling of Compressive Strength in Green Concrete Incorporating Incinerator Ash. Buildings 2025, 15, 1103. https://doi.org/10.3390/buildings15071103

Amraee A, Hosseini SA, Farokhizadeh F, Haeri MH. Environmental Risk Mitigation via Deep Learning Modeling of Compressive Strength in Green Concrete Incorporating Incinerator Ash. Buildings. 2025; 15(7):1103. https://doi.org/10.3390/buildings15071103

Chicago/Turabian StyleAmraee, Amin, Seyed Azim Hosseini, Farshid Farokhizadeh, and Mohammad Hassan Haeri. 2025. "Environmental Risk Mitigation via Deep Learning Modeling of Compressive Strength in Green Concrete Incorporating Incinerator Ash" Buildings 15, no. 7: 1103. https://doi.org/10.3390/buildings15071103

APA StyleAmraee, A., Hosseini, S. A., Farokhizadeh, F., & Haeri, M. H. (2025). Environmental Risk Mitigation via Deep Learning Modeling of Compressive Strength in Green Concrete Incorporating Incinerator Ash. Buildings, 15(7), 1103. https://doi.org/10.3390/buildings15071103