Exploring Uncharted Territories in a Vertical Greening System: A Systematic Literature Review of Design, Performance, and Technological Innovations for Urban Sustainability

Abstract

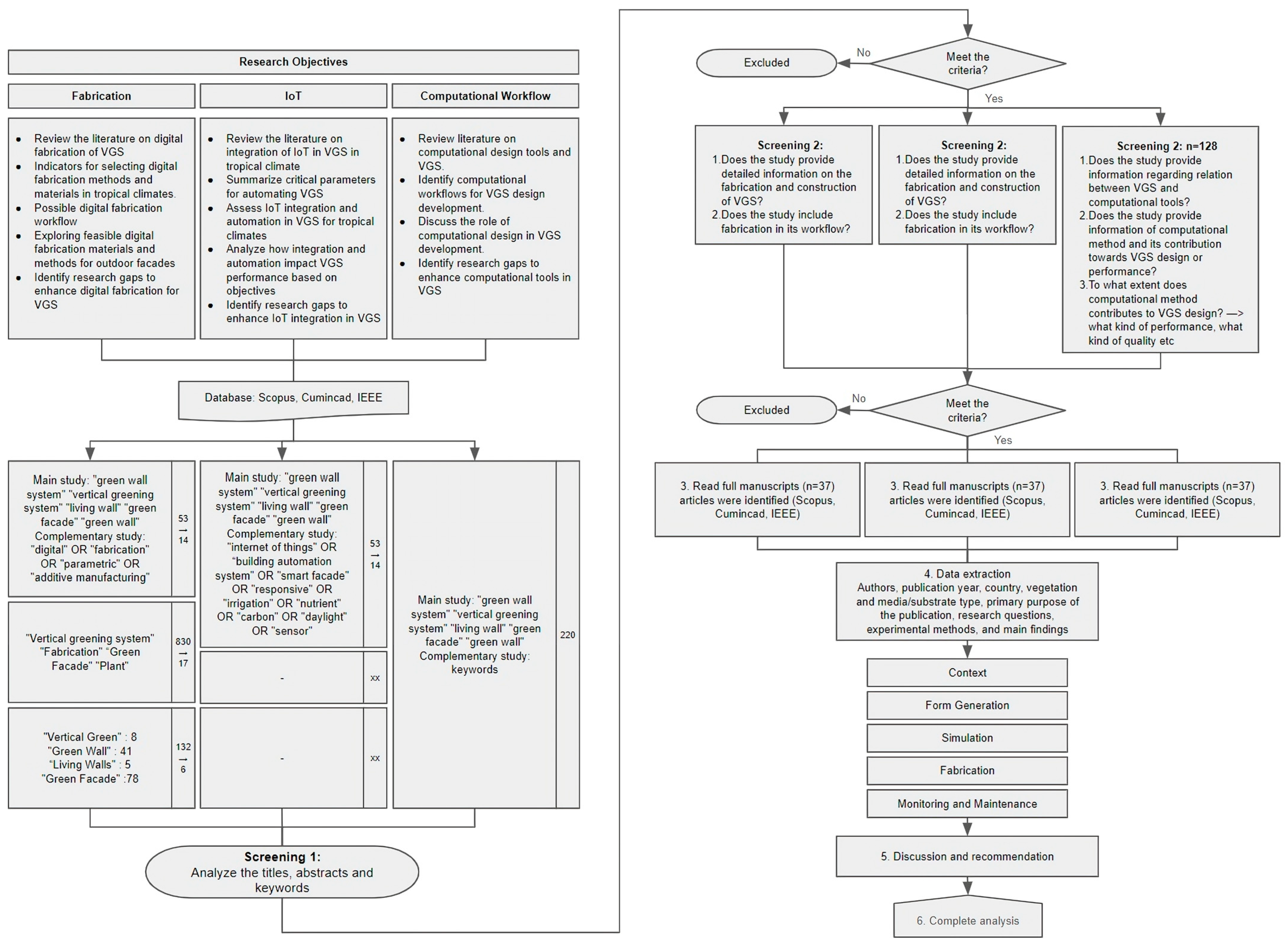

1. Introduction

1.1. Background

1.2. Research Objectives

- To identify technological advancements and how they are used in creating VGS as a facade.

- To evaluate how current VGS research optimizes its performance and functional efficiency.

- To establish a comprehensive framework and method of VGS design until fabrication and maintenance.

- Providing a novel perspective on VGS design methods by addressing the full framework from design to maintenance.

- Establishing future research directions by identifying research gaps at each stage of VGS development.

- Offering references for technical aspects at each stage, such as computational tools for performance simulation and materials suitable for tropical building facades.

2. Methods

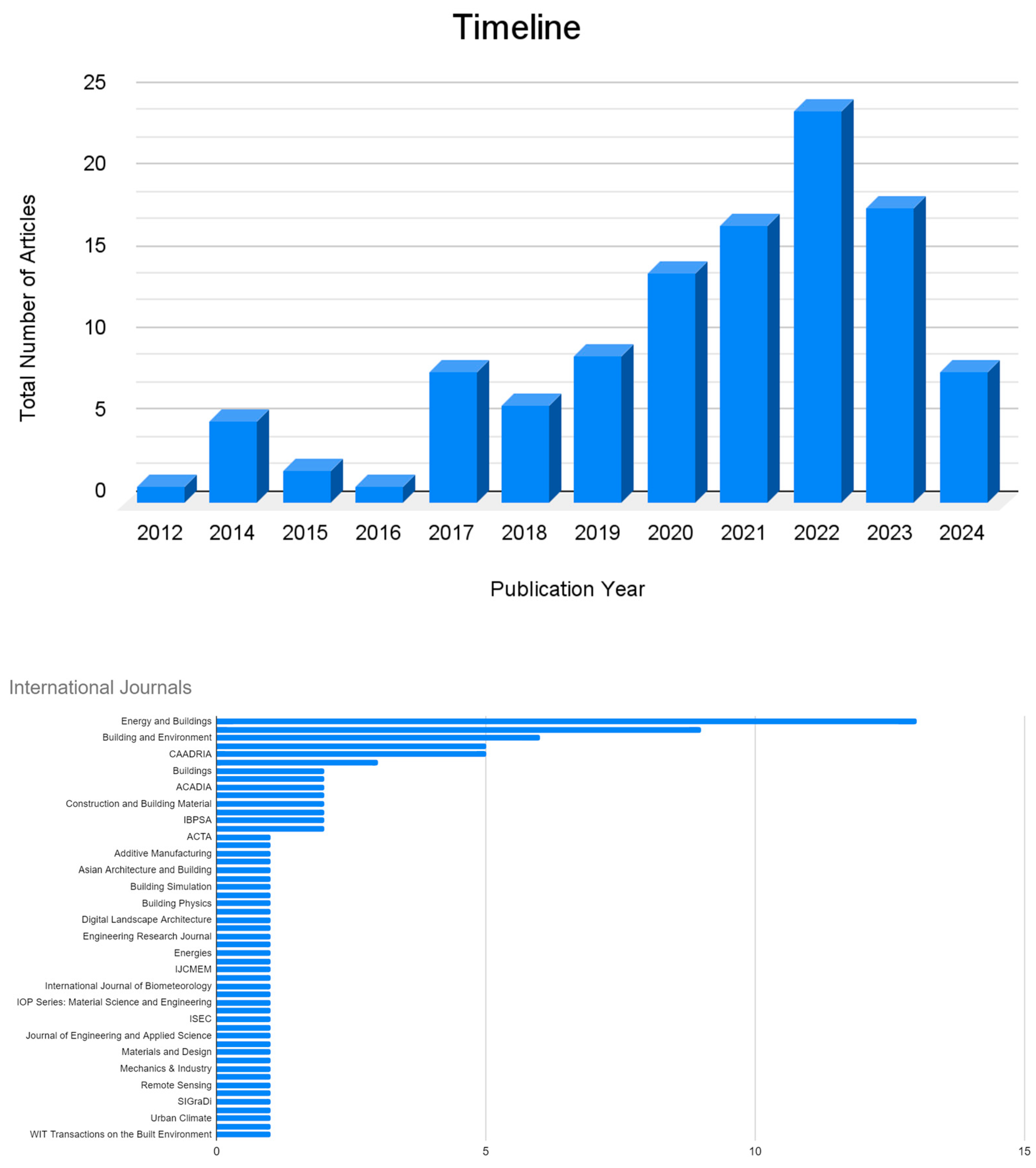

3. Publication Trends and VGS Development Stages

4. Result

4.1. Context

4.2. Form Generation

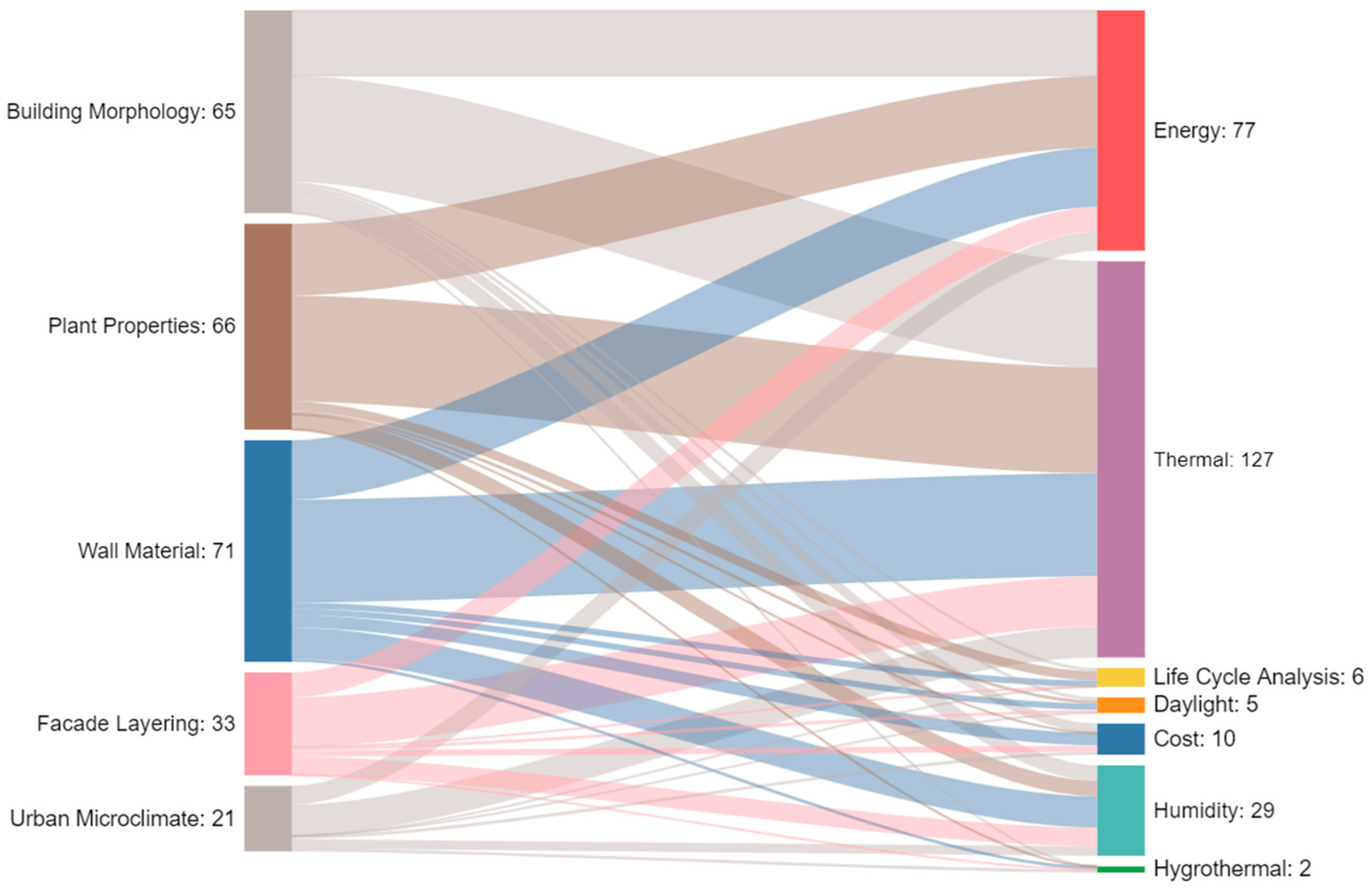

4.3. Simulation

- Previous VGS simulation literature has not addressed the iterative process of design–simulation–optimization, as most research focuses solely on the simulation phase.

- Performance objectives have primarily centered on thermal and energy aspects, while other quantifiable parameters—such as acoustics, economic feasibility, and life cycle assessment—remain underexplored

- The types of simulation and optimization tools used for VGS performance evaluation have not been comprehensively discussed despite their importance in ensuring accurate and valid results.

4.3.1. Relations Between Performance Objectives and Design Variables

4.3.2. Computational Tools

4.4. Fabrication

4.4.1. Digital Fabrication Tools in VGS

4.4.2. Material Advantages and Disadvantages

4.4.3. Material Selection Parameter

4.4.4. Relationship Between Tools and Performance

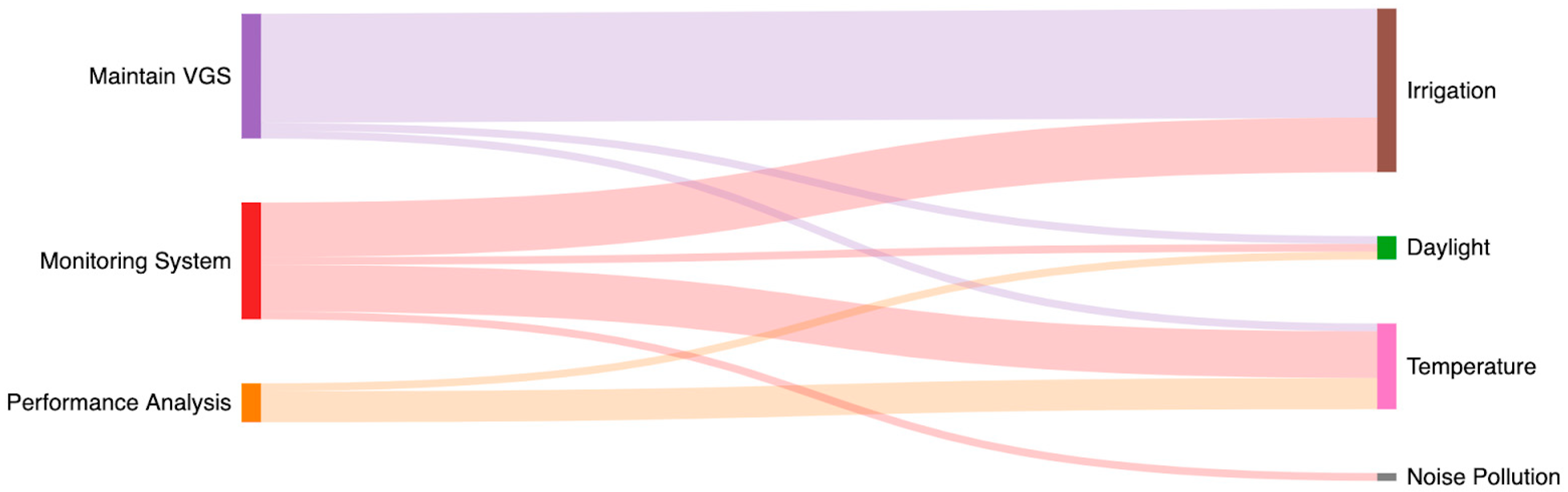

4.5. Monitoring and Maintenance

4.5.1. Function of Internet of Things in VGS

4.5.2. Relation of IoT Functions and Growth-Influencing Factors

4.5.3. IoT Tools for VGS

4.5.4. Advantages and Disadvantages of IoT

5. Discussion

6. Conclusions

- Technological advancements in computational tools and simulation enable the analysis and optimization of VGS performance in relation to climate and microclimate conditions. These tools help design more effective VGS systems tailored to specific environmental conditions.

- While research on form generation is limited, integrating this stage with simulation and optimization processes can generate more diverse and adaptable VGS forms. Technological advancements allow for the exploration of a wider range of VGS forms, enhancing the overall design flexibility.

- Computational tools enable detailed simulation of VGS performance, helping to predict its effectiveness in various climatic conditions. These advancements aid in optimizing the design before physical construction, ensuring better performance.

- Technological improvements in fabrication allow for the efficient production and precise construction of VGS elements. These advancements ensure that VGS systems can be implemented at scale while maintaining accuracy and reliability in their application to facades.

- IoT technology is increasingly utilized for the automation and maintenance of living vegetation within VGS. Real-time monitoring and automated care ensure the sustainability and long-term functionality of the system, reducing the need for manual intervention.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| EAHEs | Earth Air Heat Exchangers. |

| IoT | Internet of Things. |

| UHI | Urban heat island. |

| VGS | Vertical Greening System. |

Appendix A

Appendix A.1

| No. | Software | Plugin | Computational Tools | Use in Study | Design Variables | Performance | Reference | ||

|---|---|---|---|---|---|---|---|---|---|

| 3D Modeler | Performance Simulation | Optimization | |||||||

| 1 | Autodesk Green Building Studio | v | v | Run building performance simulation by estimating building energy use and operating cost | Building Morphology, Facade Layering | Cost, Energy, Thermal | [6,129] | ||

| 2 | ANSYS | v | Simulate Computational Fluid Dynamics (CFDs) to investigate temperature distribution and flow uniformity | Wall Material, Building Morphology, Plant Properties | Energy, Thermal, Humidity, Cost | [10,29,33,44,130] | |||

| 3 | Design Modeler | v | CAD model and meshing | Plant Properties | Thermal | [130] | |||

| 4 | ENVI Met | v | v | Model and simulate the effect of VGS and surrounding environmental elements. Simulate outdoor microclimate and thermal comfort | Plant Properties, Wall Material, Building Morphology, Facade Layering | Humidity, Thermal, LCA, Urban Microclimate | [2,8,32,42,43,47,49,50,52,53,62,63,68,74,131,132,133] | ||

| 5 | Biomet | v | Calculate human thermal comfort from ENVI-met tools, including PET and UTCI | Wall Material | Thermal | [52] | |||

| 6 | CE3X | v | Calculate energy simulation to estimate energy demand | Building Morphology, Wall Material | Energy, Cost | [72] | |||

| 7 | Delphin | v | Calculate coupled heat and moisture in building materials | Facade Layering, Wall Material | Thermal, Humidity | [42,43] | |||

| 8 | Design Builder | v | v | Analyze using Computational Fluid Dynamics to investigate building performance. Used to create 3D models and simulate thermal and energy analysis. However, there are limitations in VGS modeling. Connected to EnergyPlus as a calculation engine | Building Morphology, Plant Properties, Wall Material, Facade Layering, Urban Microclimate | Thermal, Energy, Humidity, Cost | [7,13,29,30,33,48,49,53,54,56,57,64,66,67,71,134,135,136,137,138] | ||

| 9 | Energy Plus | Building energy simulation program to analyze thermal and energy use by calculating building component and material | Facade Layering, Wall Material, Plant Properties, Building Morphology, Urban Microclimate | Energy, Thermal, Cost, Humidity | [29,30,31,48,49,51,53,55,56,58,60,61,63,66,71,134,138,139,140] | ||||

| 10 | FDS | v | To study fire spread along VGS | Plant Properties | Fire Spread | [1] | |||

| 11 | Rhinoceros | v | 3D Modeling | Plant Properties, Wall Material, Building Morphology | Thermal | [69,73,123,124] | |||

| 12 | Grasshopper | v | v | Generate building geometry and computational simulation | Plant Properties, Wall Material, Building Morphology | Thermal | [69,73,107,123,124] | ||

| 13 | Honeybee | v | Simulations to evaluate human thermal comfort. Assign material characteristics to geometry to connect Grasshopper and Energyplus | [6] | |||||

| 14 | Ladybug | v | Import and create weather data analysis | Plant Properties | [10] | ||||

| 15 | DIVA-for Rhino | v | Modeling plug-in for Rhinoceros | [69] | |||||

| 16 | Galapagos | v | Optimize a fitness function that produces numeric value | Plant Properties | Thermal | [73] | |||

| 17 | IES VE | v | v | Predict thermal efficiency of VGS facade | Wall Material | Daylight, Energy, Thermal | [6] | ||

| 18 | ODEON | v | Predict the acoustic effect of vegetation | Wall Material | Acoustic | [14] | |||

| 19 | Rayman Pro | v | To calculate PET from ENVI-met input data | Wall Material, Building Morphology | Thermal, Humidity | [74] | |||

| 20 | Revit | v | v | Three-dimensional modeling and simulation | Building Morphology, Facade Layering, Wall Material | Daylight, Humidity, Thermal, Cost, Energy, LCA | [66,124,136,137] | ||

| 21 | Revit Tally | v | Evaluate environmental impact from material selection and design | Wall Material | LCA | [2] | |||

| 22 | TRNSYS | v | Simulate transient system, such as thermal and energy | Plant Properties, Urban Microclimate, Wall Material, Building Morphology | Energy, Cost, Thermal | [11,12,29,34] | |||

| 23 | USEPA SWMM 5.1 | v | Stormwater management | Plant Properties | [45] | ||||

Appendix A.2

| Tools | Material Category | Materials | Advantages | Disadvantages |

|---|---|---|---|---|

| Robotic Arm | Soil-based | Clay and sand [78] Sand [79] Clay [15,36,80,91,111] | • Offers balance of workability, low shrinkage rate, good cohesion, and low carbon impact, widely available and low carbon impact [78] • Potential for load-bearing structures and plant germination, efficient scaling up, and porosity behavior for effective water distribution and evaporative cooling [79] • Consistent performance with stable or improving fluorescence yield [80] • High plasticity and drying performance [111] • Improved material removability [91] | • Lower durability and weather resistance without additional reinforcement [78] • Repetition of drying cycles weakens structural strength; changes in soil–water characteristics affect watering schedule [36] • Inherent material irregularities and non-linear behavior during wet conditions [111] |

| 3D Printers | Bio-materials | Algae filament [106] Bio-material substrate [17] Nylon [141] | • Improves thermal performance, reduces carbon emissions and energy production, enhances water quality, and minimizes material waste [107] • Widely available in Middle East [106] | • Need for annual tube maintenance costs and cleaning tube parts, costly for construction [107] |

| Concrete | Concrete [16] Sulfur concrete mix, cork concrete [142] Portland cement [125] | •Enable the production of building components with detailed designs, offers aesthetic appeal and energy-saving features, provides soundproofing and thermal insulation, and maintains structural performance [16] • Improves energy efficiency [142] • Enhances plant growth with higher porosity and lower alkalinity cement [125] | • Larger aggregate mixture decreases mechanical strength, high alkalinity hinders plant growth, and higher porosity supports growth but reduces structural integrity [125] | |

| Foam | Foam [24,108] Cement-free, geopolymer-based mineral foam, Industrial fly ash [24] | • Simple foaming process and applicability at construction scale [104] • No need for sintering process; UHPFRC is high-performance load-bearing material, less energy-intensive than sintering, allowing for fabrication of larger elements with lower densities [104] • Light-weighted, environmentally friendly, recycled materials, low embodied carbon, and convenient to replace and assemble [24] | • Labor-intensive, time-consuming, and less accurate [104] | |

| Plastics | PETG [109] | • Lightweight, versatile, enables high-performance envelope solutions, energy-saving benefits, reduces construction industry carbon footprint, durable, and hard-wearing components [109] | • Derives from non-renewable resources [109] | |

| Laser Cut | Wood | MDF [110] | • Fast, high precision for intricate design, and no manual adjustments needed. Clean process without coolants or lubricants [143,144] | •Burning risk in Laser Settings, improper adjustment can lead to burning, and toxic fumes can be produced during process [143,144] |

| Steel | CNC extruded cells, steel, water-jet milled frame [145] | • Strength and versatility, ideal for convoluted designs, laser cut supports customization, provides precision and accuracy [146] | • High initial costs, energy consumption, noise, vibration during cutting, and environmental concerns [146] | |

| Foam | EPS blocks foam [147] | • Supports precision and customization of design form, lightweight, easy installation, high-performance building materials for sound and thermal insulation [126,127] | • Fungibility and weather resistance issues, poor life cycle performance, and limited structural integrity [126,127] |

Appendix A.3

| No | Material/Form | Material Selection Parameters | Vegetation Parameters | Form Design Parameters | Form Categories | References | ||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mechanical Strength | Solar Radiation | Availability | Indoor Air Quality | Porosity | Permeability | Thermal Behavior | Design Flexibility | Aesthetic Functionality | Energy Consumption | Life Cycle | Cost Production | Printing Scale | Non-Toxic | Environmentally Friendly | Plant Growth | Alkalinity | Weather resistance | Moisture | Water reservoir | Evaporative surface | Structural elements | Water vessel | Printability | Vernacular Architecture | Basic Geometric | Curve Geometric | Complex/Irregular | |||

| 1 | Clay and sand cylindrical | v | v | v | v | v | v | v | v | v | [78] | |||||||||||||||||||

| 2 | Sand Dome | v | v | v | v | v | v | [79] | ||||||||||||||||||||||

| 3 | Clay Piramidal | v | v | [80] | ||||||||||||||||||||||||||

| 4 | Clay Irregular | v | v | v | v | v | v | v | v | v | [36] | |||||||||||||||||||

| 5 | Clay Interlocking masonry units | v | v | v | [111] | |||||||||||||||||||||||||

| 6 | Clay Blocks with elliptical concave | v | v | v | v | v | v | v | v | [91] | ||||||||||||||||||||

| 7 | Clay Extrusion of an equilateral hyperbolic paraboloid (hypar) | v | v | v | [15] | |||||||||||||||||||||||||

| 8 | Algae filament Spiral | v | v | v | v | v | v | v | v | v | v | [106] | ||||||||||||||||||

| 9 | Bio algae Spiral | v | v | v | v | v | v | v | v | v | v | [107] | ||||||||||||||||||

| 10 | Biomaterial substrate Modular block with concave and convex shapes | v | v | v | v | v | v | v | [17] | |||||||||||||||||||||

| 11 | Nylon Triangular tiles mesh | v | v | v | v | v | [141] | |||||||||||||||||||||||

| 12 | Concrete Sinusoidal | v | v | v | v | v | v | v | [16] | |||||||||||||||||||||

| 13 | Sulfur concrete mix Rectangular | v | v | v | v | [142] | ||||||||||||||||||||||||

| 14 | Low-Alkalinity Sulphoaluminate Cement (LSAC) Rectangular | v | v | v | v | v | v | v | v | [125] | ||||||||||||||||||||

| 15 | Fly ash mixture Circle based cellular patterns | v | v | v | v | [108] | ||||||||||||||||||||||||

| 16 | Foam Isostatic lines based on strength analysis | v | v | v | v | v | [108] | |||||||||||||||||||||||

| 17 | Cement-free, geopolymer-based m-neral foam. Industrial fly ash. Alcove-like geometry | v | v | v | v | [24] | ||||||||||||||||||||||||

| 18 | PETG Pod with voronoi pattern | v | v | v | v | v | v | v | v | v | [109] | |||||||||||||||||||

| 19 | Laser cut MDF components Pigeonholes | v | v | v | v | v | v | [110] | ||||||||||||||||||||||

| 20 | CNC extruded cells, steel, water-jet milled frame Hexagonal | v | v | v | v | v | v | [145] | ||||||||||||||||||||||

| 21 | EPS blocks (Foam) Penrose tiling | v | v | v | v | v | [147] | |||||||||||||||||||||||

Appendix A.4

| No | IoT Function | Tools | Tools | Categories | Parameter Input (V)/Output (X) Data | Referensi | |||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Performance Analysis | Monitoring System | Maintain VGS | Sensor | Record | Actuator/Robot | Controller/Programming | Photovoltaic | Hardware | Software | Irrigation | Temperature | Daylight | Noise Pollution | Air Pollution/Carbon Sequestration | Fertilization | Water | Water Flow | Water Preassure | Water Volume | Water Speed | Water Frequency | Light Intensity | Solar Radiation | Duration of Light Exposure | Air Felocity/Wind Speed | Surface Temperature | Air Temperature | Room Temperature | Humidity | Pressure | Soil Density | Soil Moisture | Soil Substrate | Orientation | Location | Vegetation Type | Rain drops | CO2 | Leaf Transpiration | Evapotranspiration | Spectral | LAI | Infrared - Spectroscopy | Air Quality | Energy Efficient | PM Mittigation | |||

| 1 | v | AGRI|gen Analysis | v | v | v | v | v | v | v | v | v | v | [122] | ||||||||||||||||||||||||||||||||||||

| 2. | v | Thermocube | v | v | v | [120] | |||||||||||||||||||||||||||||||||||||||||||

| 3. | v | Globe Thermometer | v | v | |||||||||||||||||||||||||||||||||||||||||||||

| 4. | v | SpecimIQ hyperspectral camera | v | v | v | ||||||||||||||||||||||||||||||||||||||||||||

| 5. | v | Air Temperature sensor | v | v | v | ||||||||||||||||||||||||||||||||||||||||||||

| 6. | v | 2 Onset® Silicon Pyranometer Smart Sensor (Part # S-LIB-M003) | v | v | v | v | [148] | ||||||||||||||||||||||||||||||||||||||||||

| 7. | v | 2 HOBO® U20 Fresh Water Level Data Logger 13 feet—U20-001-04 | v | v | v | v | |||||||||||||||||||||||||||||||||||||||||||

| 8. | v | T/RH sensors of Xiaomi | v | v | v | [115] | |||||||||||||||||||||||||||||||||||||||||||

| 9. | v | LI-6800, LiCOR | v | v | v | v | v | ||||||||||||||||||||||||||||||||||||||||||

| 10. | v | LI-600, LiCOR | v | v | v | v | v | ||||||||||||||||||||||||||||||||||||||||||

| 11. | v | FLIR T560 | v | v | v | v | v | ||||||||||||||||||||||||||||||||||||||||||

| 12. | v | LI-3100 Leaf Area Meter | v | v | v | v | v | [149] | |||||||||||||||||||||||||||||||||||||||||

| 13. | v | Automated drip irrigation | v | v | v | v | v | v | x | x | x | x | [150] | ||||||||||||||||||||||||||||||||||||

| 14. | v | Soil moisture sensor | v | v | v | v | |||||||||||||||||||||||||||||||||||||||||||

| 15. | v | v | Control devices | v | v | v | v | v | v | v | x | x | x | x | v | v | v | ||||||||||||||||||||||||||||||||

| 16. | v | Automatic irrigation sprayer | v | v | v | v | v | v | v | x | x | x | x | v | v | v | [151] | ||||||||||||||||||||||||||||||||

| 17. | v | Temperature sensor | v | v | v | [114] | |||||||||||||||||||||||||||||||||||||||||||

| 18. | v | Agronic | v | v | v | ||||||||||||||||||||||||||||||||||||||||||||

| 19. | Two-meter sensor | v | v | v | v | ||||||||||||||||||||||||||||||||||||||||||||

| 20 | v | DHT22 | v | v | v | v | v | v | [19] | ||||||||||||||||||||||||||||||||||||||||

| 21. | v | pH Sensor | v | v | |||||||||||||||||||||||||||||||||||||||||||||

| 22. | v | Acoustic sensor | v | v | [152] [129] | ||||||||||||||||||||||||||||||||||||||||||||

| 23. | v | Smart Citizen kit v2.0 SCK | v | v | v | x | x | x | x | x | x | v | |||||||||||||||||||||||||||||||||||||

| 24. | v | INMET Weather Station | v | v | v | v | v | x | v | x | [119] | ||||||||||||||||||||||||||||||||||||||

| 25. | v | Onset HOBO weatherproof temperature logger | v | v | v | v | v | x | [153] | ||||||||||||||||||||||||||||||||||||||||

| 26. | v | Rope driven robot | v | v | v | v | x | x | x | x | x | x | x | v | v | v | |||||||||||||||||||||||||||||||||

| 27. | v | v | v | v | v | v | [118] | ||||||||||||||||||||||||||||||||||||||||||

| 28. | v | v | v | v | v | v | v | v | x | x | x | [154] | |||||||||||||||||||||||||||||||||||||

| 29. | v | RS 485 RTU-Modbus | v | v | v | v | x | v | [20] | ||||||||||||||||||||||||||||||||||||||||

| 30. | v | Wireless sensor nodes | v | v | v | v | v | v | x | x | x | [155] | |||||||||||||||||||||||||||||||||||||

| 31. | v | Electronic automatic programmer | v | v | v | x | x | x | x | v | [23] | ||||||||||||||||||||||||||||||||||||||

| 32. | v | Campbell CS215 | v | v | v | v | x | x | x | x | v | v | [38] | ||||||||||||||||||||||||||||||||||||

| 33. | v | v | v | v | x | [117] | |||||||||||||||||||||||||||||||||||||||||||

| 34. | v | nRF52840-based Wireless sensor node | v | v | v | v | v | x | [116] | ||||||||||||||||||||||||||||||||||||||||

| 35. | v | Arduino UNO | v | v | v | v | [121] | ||||||||||||||||||||||||||||||||||||||||||

| 36. | v | Integrated Development Environment (IDE) | v | v | v | ||||||||||||||||||||||||||||||||||||||||||||

| 37. | v | ThingSpeak | v | v | v | v | v | v | v | v | v | ||||||||||||||||||||||||||||||||||||||

| 38. | v | The FC-28 | v | v | v | v | v | x | |||||||||||||||||||||||||||||||||||||||||

| 39. | v | The DHT22 | v | v | v | vx | vx | ||||||||||||||||||||||||||||||||||||||||||

| 40. | v | Light Dependent Resistor (LDR) Photo-Resistor | v | v | v | vx | |||||||||||||||||||||||||||||||||||||||||||

| 41. | v | The YL-83 | v | v | v | x | v | ||||||||||||||||||||||||||||||||||||||||||

| 42. | v | The YF-S402 | v | v | v | v | x | ||||||||||||||||||||||||||||||||||||||||||

References

- Karunaratne, T.L.W.; Chow, C.L. Fire spread along vertical greenery systems from window ejected flame: A study based on a fire dynamic simulator model. J. Build. Eng. 2022, 62, 105359. [Google Scholar] [CrossRef]

- Kio, P.; Ali, A.K. In situ experimental evaluation of a novel modular living wall system for industrial symbiosis. Energy Build. 2021, 252, 111405. [Google Scholar] [CrossRef]

- Bakhshoodeh, R.; Ocampo, C.; Oldham, C. Exploring the evapotranspirative cooling effect of a green façade. Sustain. Cities Soc. 2022, 81, 103822. [Google Scholar] [CrossRef]

- Pichlhöfer, A.; Korjenic, A.; Sulejmanovski, A.; Streit, E. Influence of Facade Greening with Ivy on Thermal Performance of Masonry Walls. Sustainability 2023, 15, 9546. [Google Scholar] [CrossRef]

- Vujovic, S.; Haddad, B.; Karaky, H.; Sebaibi, N.; Boutouil, M. Urban Heat Island: Causes, Consequences, and Mitigation Measures with Emphasis on Reflective and Permeable Pavements. CivilEng 2021, 2, 459–484. [Google Scholar] [CrossRef]

- Bagheri Moghaddam, F.; Fort Mir, J.M.; Navarro Delgado, I.; Redondo Dominguez, E. Evaluation of Thermal Comfort Performance of a Vertical Garden on a Glazed Façade and Its Effect on Building and Urban Scale, Case Study: An Office Building in Barcelona. Sustainability 2021, 13, 6706. [Google Scholar] [CrossRef]

- Bano, P.; Dervishi, S. The impact of vertical vegetation on thermal performance of high-rise office building facades in Mediterranean climate. Energy Build. 2021, 236, 110761. [Google Scholar] [CrossRef]

- Peng, L.L.H.; Jiang, Z.; Yang, X.; He, Y.; Xu, T.; Chen, S.S. Cooling effects of block-scale facade greening and their relationship with urban form. Build. Environ. 2020, 169, 106552. [Google Scholar] [CrossRef]

- Kim, H.; Oh, K.; Yoo, I. Analysis of Spatial Characteristics Contributing to Urban Cold Air Flow. Land 2023, 12, 2165. [Google Scholar] [CrossRef]

- Lin, H.; Ni, H.; Xiao, Y.; Zhu, X. Couple simulations with CFD and ladybug + honeybee tools for green façade optimizing the thermal comfort in a transitional space in hot-humid climate. J. Asian Archit. Build. Eng. 2023, 22, 1317–1342. [Google Scholar] [CrossRef]

- Libessart, L.; Kenai, M.A. Measuring thermal conductivity of green-walls components in controlled conditions. J. Build. Eng. 2018, 19, 258–265. [Google Scholar] [CrossRef]

- Djedjig, R.; El Ganaoui, M.; Belarbi, R.; Bennacer, R. Thermal effects of an innovative green wall on building energy performance. Mech. Ind. 2017, 18, 104. [Google Scholar] [CrossRef]

- Rupasinghe, H.T.; Halwatura, R.U. Benefits of implementing vertical greening in tropical climates. Urban For. Urban Green. 2020, 53, 126708. [Google Scholar] [CrossRef]

- Kim, M.-J.; Yang, H.-S.; Kang, J. A case study on controlling sound fields in a courtyard by landscape designs. Landsc. Urban Plan. 2014, 123, 10–20. [Google Scholar] [CrossRef]

- Xu, W.; Huang, Z. Robotic Fabrication of Sustainable Hybrid Formwork with Clay and Foam for Concrete Casting. In Proceedings of the 24th Conference of the Iberoamerican Society of Digital Graphic, Online, 18–20 November 2020; pp. 377–383. [Google Scholar]

- He, Y.; Zhang, Y.; Zhang, C.; Zhou, H. Energy-saving potential of 3D printed concrete building with integrated living wall. Energy Build. 2020, 222, 110110. [Google Scholar] [CrossRef]

- Urroz, C.; Yousif, S. A Method for Designing a Breathing Modular Wall. In Proceedings of the 29th International Conference of the Association for Computer-Aided Architectural Design Research in Asia (CAADRIA), Singapore, 24–26 April 2024; pp. 253–262. Available online: http://papers.cumincad.org/cgi-bin/works/paper/caadria2024_548 (accessed on 3 February 2025).

- Holschemacher, D.; Müller, C.; Helbig, M.; Weisel, N. Large-Scale, Rope-Driven Robot for the Automated Maintenance of Urban Green Facades. Proc. Int. Struct. Eng. Constr. 2022, 9. Available online: https://www.isec-society.org/ISEC_PRESS/EURO_MED_SEC_04/xml/SUS-12.xml (accessed on 24 January 2025).

- Dungca, D.M.R.; Larioza, M.D.M.; Mondonedo, P.M.M.; Orence, H.F.A.; Sigue, A.-L.F.; Medina, O.A.; Soriano, A.J.; Mandayo, E.A. Innovating Green Wall: A Sustainable Way of Enhancing the Vertical Planting System. In Proceedings of the 2021 IEEE 13th International Conference on Humanoid, Nanotechnology, Information Technology, Communication and Control, Environment, and Management (HNICEM), Manila, Philippines, 28–30 November 2021; pp. 1–6. Available online: https://ieeexplore.ieee.org/document/9731929/ (accessed on 23 January 2025).

- Nicolini, E.; Germanà, M.L.; Marcon, G.; Chiodi, M.; Gutiérrez, Á.; Olivieri, F. Monitoring of the effect of solar radiation and rain on the building envelope with integrated vertical vegetation. Build. Environ. 2022, 226, 109731. [Google Scholar] [CrossRef]

- Xu, L.; Wang, J.; Xiao, F.; EI-Badawy, S.; Awed, A. Potential strategies to mitigate the heat island impacts of highway pavement on megacities with considerations of energy uses. Appl. Energy 2021, 281, 116077. [Google Scholar] [CrossRef]

- Irfeey, A.M.M.; Chau, H.-W.; Sumaiya, M.M.F.; Wai, C.Y.; Muttil, N.; Jamei, E. Sustainable Mitigation Strategies for Urban Heat Island Effects in Urban Areas. Sustainability 2023, 15, 10767. [Google Scholar] [CrossRef]

- Santi, G.; Bertolazzi, A.; Croatto, G.; Turrini, U. Vertical Turf for Green Façades: A Vertical Greenery Modular System Integrated to the Building Envelope. J. Green Build. 2019, 14, 111–132. [Google Scholar] [CrossRef]

- Bedarf, P.; Jeoffroy, E.; FenX, A.G.; Dillenburger, B. A Lightweight and Insulating Monolithic Wall System made with Mineral Foam 3D Printing. 2023, pp. 16–24. Available online: https://www.researchgate.net/profile/Patrick-Bedarf/publication/375115929_Airlements_A_Lightweight_and_Insulating_Monolithic_Wall_System_made_with_Mineral_Foam_3D_Printing/links/65414f690426ef6369edea12/Airlements-A-Lightweight-and-Insulating-Monolithic-Wall-System-made-with-Mineral-Foam-3D-Printing.pdf (accessed on 23 March 2025).

- Bustami, R.A.; Belusko, M.; Ward, J.; Beecham, S. Vertical greenery systems: A systematic review of research trends. Build. Environ. 2018, 146, 226–237. [Google Scholar] [CrossRef]

- Fernando, D.; Navaratnam, S.; Rajeev, P.; Sanjayan, J. Study of Technological Advancement and Challenges of Façade System for Sustainable Building: Current Design Practice. Sustainability 2023, 15, 14319. [Google Scholar] [CrossRef]

- Bianchi, S.; Andriotis, C.; Klein, T.; Overend, M. Multi-criteria design methods in façade engineering: State-of-the-art and future trends. Build. Environ. 2024, 250, 111184. [Google Scholar] [CrossRef]

- Chew, M.Y.L.; Conejos, S.; Azril, F.H.B. Design for maintainability of high-rise vertical green facades. Build. Res. Inf. 2019, 47, 453–467. [Google Scholar] [CrossRef]

- Dabaieh, M.; Serageldin, A.A. Earth air heat exchanger, Trombe wall and green wall for passive heating and cooling in premium passive refugee house in Sweden. Energy Convers. Manag. 2020, 209, 112555. [Google Scholar] [CrossRef]

- Karimi, K.; Farrokhzad, M.; Roshan, G.; Aghdasi, M. Evaluation of effects of a green wall as a sustainable approach on reducing energy use in temperate and humid areas. Energy Build. 2022, 262, 112014. [Google Scholar] [CrossRef]

- Carlos, J.S. Simulation assessment of living wall thermal performance in winter in the climate of Portugal. Build. Simul. 2015, 8, 3–11. [Google Scholar] [CrossRef]

- Charif, O.; El Bat, A.M.; Romani, Z.; Draoui, A. Impact of Aspect Ratio and Green Surfaces on the outdoor Thermal Comfort of the Street Canyon under Mediterranean Climate. In Proceedings of the 2021 9th International Renewable and Sustainable Energy Conference (IRSEC), Morocco, 23–27 November 2021; pp. 1–6. Available online: https://ieeexplore.ieee.org/document/9741167/ (accessed on 21 February 2025).

- Cortês, A.; Almeida, J.; Tadeu, A.; Ramezani, B.; Fino, M.R.; De Brito, J.; Silva, C.M. The effect of cork-based living walls on the energy performance of buildings and local microclimate. Build. Environ. 2022, 216, 109048. [Google Scholar] [CrossRef]

- Djedjig, R.; Bozonnet, E.; Belarbi, R. Modeling green wall interactions with street canyons for building energy simulation in urban context. Urban Clim. 2016, 16, 75–85. [Google Scholar] [CrossRef]

- Zhao, S.; De Angelis, E. Performance-based Generative Architecture Design: A Review on Design Problem Formulation and Software Utilization. J. Integr. Des. Process Sci. 2019, 22, 55–76. [Google Scholar] [CrossRef]

- Bae, J.; Park, D. Weeping Brick: The Modular Living Wall System Using 3D Printed Porous Ceramic Materials. In Computer-Aided Architectural Design. “Hello, Culture”; Lee, J.-H., Ed.; Communications in Computer and Information Science; Springer: Singapore, 2019; Volume 1028, pp. 399–409. ISBN 978-981-13-8409-7. Available online: http://link.springer.com/10.1007/978-981-13-8410-3_28 (accessed on 28 October 2024).

- Shan, R.; Junghans, L. Multi-Objective Optimization for High-Performance Building Facade Design: A Systematic Literature Review. Sustainability 2023, 15, 15596. [Google Scholar] [CrossRef]

- Medl, A.; Stangl, R.; Florineth, F. Vertical greening systems—A review on recent technologies and research advancement. Build. Environ. 2017, 125, 227–239. [Google Scholar] [CrossRef]

- Pérez-Urrestarazu, L.; Fernández-Cañero, R.; Franco-Salas, A.; Egea, G. Vertical Greening Systems and Sustainable Cities. J. Urban Technol. 2015, 22, 65–85. [Google Scholar] [CrossRef]

- Su, M.; Jie, P.; Li, P.; Yang, F.; Huang, Z.; Shi, X. A review on the mechanisms behind thermal effect of building vertical greenery systems (VGS): Methodology, performance and impact factors. Energy Build. 2024, 303, 113785. [Google Scholar] [CrossRef]

- Raji, B.; Tenpierik, M.J.; Van Den Dobbelsteen, A. The impact of greening systems on building energy performance: A literature review. Renew. Sustain. Energy Rev. 2015, 45, 610–623. [Google Scholar] [CrossRef]

- Alsaad, H.; Hartmann, M.; Voelker, C. The effect of a living wall system designated for greywater treatment on the hygrothermal performance of the facade. Energy Build. 2022, 255, 111711. [Google Scholar] [CrossRef]

- Alsaad, H.; Voelker, C. Heat and moisture transport through a living wall system designated for greywater treatment. In Proceedings of the Building Simulation 2021: 17th Conference of IBPSA, Bruges, Belgium, 1–3 September 2021; Available online: https://publications.ibpsa.org/conference/paper/?id=bs2021_30146 (accessed on 21 February 2025).

- Lin, H.; Xiao, Y.; Musso, F.; Lu, Y. Green Façade Effects on Thermal Environment in Transitional Space: Field Measurement Studies and Computational Fluid Dynamics Simulations. Sustainability 2019, 11, 5691. [Google Scholar] [CrossRef]

- Lau, J.T.; Mah, D.Y.S. Green wall for retention of stormwater. Pertanika J. Sci. Technol. 2018, 26, 283–298. [Google Scholar]

- Pérez, G.; Escolà, A.; Rosell-Polo, J.R.; Coma, J.; Arasanz, R.; Marrero, B.; Cabeza, L.F.; Gregorio, E. 3D characterization of a Boston Ivy double-skin green building facade using a LiDAR system. Build. Environ. 2021, 206, 108320. [Google Scholar] [CrossRef]

- Iaria, J.; Susca, T. Analytic Hierarchy Processes (AHP) evaluation of green roof- and green wall- based UHI mitigation strategies via ENVI-met simulations. Urban Clim. 2022, 46, 101293. [Google Scholar] [CrossRef]

- Bevacqua, M.; Grossi, G.; Fionda, M.P.; Arcuri, N. Passive Cooling Techniques for Less Energy Consumption in Buildings a Comparative Study on Green Surfaces. In Proceedings of the 2018 IEEE International Conference on Environment and Electrical Engineering and 2018 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Palermo, Italy, 12–15 June 2018; pp. 1–6. Available online: https://ieeexplore.ieee.org/document/8494625/ (accessed on 21 February 2025).

- Fahmy, M.; El-Hady, H.; Mahdy, M.; Abdelalim, M.F. On the green adaptation of urban developments in Egypt; predicting community future energy efficiency using coupled outdoor-indoor simulations. Energy Build. 2017, 153, 241–261. [Google Scholar] [CrossRef]

- Zhu, Z.; Zhou, D.; Wang, Y.; Ma, D.; Meng, X. Assessment of urban surface and canopy cooling strategies in high-rise residential communities. J. Clean. Prod. 2021, 288, 125599. [Google Scholar] [CrossRef]

- Cascone, S.; Evola, G.; Leone, C.; Sciuto, G. Vertical greenery systems for the energy retrofitting of buildings in Mediterranean climate: A case study in Catania, Italy. IOP Conf. Ser. Mater. Sci. Eng. 2018, 415, 012054. [Google Scholar] [CrossRef]

- Tseliou, A.; Melas, E.; Mela, A.; Tsiros, I. Evaluating the effects of green roofs and green façade as an urban heat island adaptation strategy. E3S Web Conf. 2023, 436, 01018. [Google Scholar] [CrossRef]

- Li, Z.; Chow, D.H.C.; Yao, J.; Zheng, X.; Zhao, W. The effectiveness of adding horizontal greening and vertical greening to courtyard areas of existing buildings in the hot summer cold winter region of China: A case study for Ningbo. Energy Build. 2019, 196, 227–239. [Google Scholar] [CrossRef]

- Shah, I.; Lau, S.-K.; Sekaran, V.; Ghahramani, A. Porous plant form-induced amplification of evapotranspiration for enhanced cooling in vertical greenery systems. Build. Environ. 2023, 245, 110904. [Google Scholar] [CrossRef]

- De Masi, R.F.; De Rossi, F.; Ruggiero, S.; Vanoli, G.P. Numerical optimization for the design of living walls in the Mediterranean climate. Energy Convers. Manag. 2019, 195, 573–586. [Google Scholar] [CrossRef]

- Assimakopoulos, M.-N.; De Masi, R.F.; De Rossi, F.; Papadaki, D.; Ruggiero, S. Green Wall Design Approach Towards Energy Performance and Indoor Comfort Improvement: A Case Study in Athens. Sustainability 2020, 12, 3772. [Google Scholar] [CrossRef]

- Safikhani, T.; Abdullah, A.M.; Ossen, D.R.; Baharvand, M. Thermal Impacts of Vertical Greenery Systems. Environ. Clim. Technol. 2014, 14, 5–11. [Google Scholar] [CrossRef]

- Jiang, C.; Zhou, Y.; Li, K.; Wei, D. Impact of green roof and green facade on building thermal performance and carbon sequestration in subtropical climate of China. J. Build. Phys. 2023, 46, 602–629. [Google Scholar] [CrossRef]

- Habibi, A.; Kahe, N. Evaluating the Role of Green Infrastructure in Microclimate and Building Energy Efficiency. Buildings 2024, 14, 825. [Google Scholar] [CrossRef]

- García, M.; Vera, S.; Rouault, F.; Gironás, J.; Bustamante, W. Cooling potential of greenery systems for a stand-alone retail building under semiarid and humid subtropical climates. Energy Build. 2022, 259, 111897. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, L.; Meng, Q. Dynamic heat transfer model of vertical green façades and its co-simulation with a building energy modelling program in hot-summer/warm-winter zones. J. Build. Eng. 2022, 58, 105008. [Google Scholar] [CrossRef]

- Erdener, H.; Edis, E. The effect of orientation and plant type on the thermal behaviour of living wall systems in buildings. In Proceedings of the 10th World Construction Symposium 2022; Building Economics and Management Research Unit (BEMRU), Colombo, Sri Lanka, 24–26 June 2022; University of Moratuwa: Moratuwa, Sri Lanka, 2022; pp. 845–856. Available online: http://dl.lib.uom.lk/handle/123/19934 (accessed on 21 February 2025).

- Bakhtyari, V.; Fattahi, K.; Movahed, K.; Franz, A. Investigating the Effect of Living Walls on Cooling Energy Consumption in Various Urban Microclimates, Building Heights, and Greenery Coverage Areas. Sustainability 2024, 16, 920. [Google Scholar] [CrossRef]

- Galagoda, R.U.; Jayasinghe, G.Y.; Halwatura, R.U.; Rupasinghe, H.T. The impact of urban green infrastructure as a sustainable approach towards tropical micro-climatic changes and human thermal comfort. Urban For. Urban Green. 2018, 34, 1–9. [Google Scholar] [CrossRef]

- Coma, J.; Pérez, G.; De Gracia, A.; Burés, S.; Urrestarazu, M.; Cabeza, L.F. Vertical greenery systems for energy savings in buildings: A comparative study between green walls and green facades. Build. Environ. 2017, 111, 228–237. [Google Scholar] [CrossRef]

- Bahdad, A.A.S.; Fadzil, S.F.S.; Onubi, H.O. Assessment of the Thermal Performance of Vertical Green Walls Using Overall Thermal Transfer Value Based BIM Simulation Method: Case Study of Residential Buildings in Sub-Tropics. J. Daylighting 2021, 8, 294–312. [Google Scholar] [CrossRef]

- Pragati, S.; Shanthi Priya, R.; Pradeepa, C.; Senthil, R. Simulation of the Energy Performance of a Building with Green Roofs and Green Walls in a Tropical Climate. Sustainability 2023, 15, 2006. [Google Scholar] [CrossRef]

- Gao, Y.; Farrokhirad, E.; Pitts, A. The Impact of Orientation on Living Wall Façade Temperature: Manchester Case Study. Sustainability 2023, 15, 11109. [Google Scholar] [CrossRef]

- Li, X.S.; Byrne, U.; Kesik, T. Experimental Design of Energy Performance Simulation for Building Envelopes Integrated with Vegetation. In A. Symposium on Simulation for Architecture and Urban Design; SimAUD: Tampa, FL, USA, 2014. [Google Scholar]

- Attal, E.; Dubus, B.; Leblois, T.; Cretin, B. An optimal dimensioning method of a green wall structure for noise pollution reduction. Build. Environ. 2021, 187, 107362. [Google Scholar] [CrossRef]

- Ramadhan, A.M.; Mahmoud, A.H. Evaluating the efficiency of a living wall facade as a sustainable energy-saving alternative in hot arid regions. J. Eng. Appl. Sci. 2023, 70, 96. [Google Scholar] [CrossRef]

- Martínez-Rocamora, A.; Pulselli, R.M.; Solís-Guzmán, J.; Marrero, M.; Bastianoni, S. Vertical Greenery Systems as sustainable solutions for building retrofitting: A case study. In Proceedings of the ERES 2025, Edinburgh, UK, 11–13 June 2025; pp. 127–135. Available online: http://library.witpress.com/viewpaper.asp?pcode=ARC14-012-1 (accessed on 21 February 2025).

- Olivieri, F.; Grifoni, R.C.; Redondas, D.; Sánchez-Reséndiz, J.A.; Tascini, S. An experimental method to quantitatively analyse the effect of thermal insulation thickness on the summer performance of a vertical green wall. Energy Build. 2017, 150, 132–148. [Google Scholar] [CrossRef]

- Katsoulas, N.; Antoniadis, D.; Tsirogiannis, I.L.; Labraki, E.; Bartzanas, T.; Kittas, C. Microclimatic effects of planted hydroponic structures in urban environment: Measurements and simulations. Int. J. Biometeorol. 2017, 61, 943–956. [Google Scholar] [CrossRef] [PubMed]

- Leschok, M.; Cheibas, I.; Piccioni, V.; Seshadri, B.; Schlüter, A.; Gramazio, F.; Kohler, M.; Dillenburger, B. 3D printing facades: Design, fabrication, and assessment methods. Autom. Constr. 2023, 152, 104918. [Google Scholar] [CrossRef]

- Agustí-Juan, I.; Müller, F.; Hack, N.; Wangler, T.; Habert, G. Potential benefits of digital fabrication for complex structures: Environmental assessment of a robotically fabricated concrete wall. J. Clean. Prod. 2017, 154, 330–340. [Google Scholar] [CrossRef]

- Tay, Y.W.D.; Panda, B.; Paul, S.C.; Noor Mohamed, N.A.; Tan, M.J.; Leong, K.F. 3D printing trends in building and construction industry: A review. Virtual Phys. Prototyp. 2017, 12, 261–276. [Google Scholar] [CrossRef]

- Curth, A.; Alvarez, E.G.; Sass, L.; Norford, L.; Mueller, C. Additive Energy: 3D printing thermally performative building elements with low carbon earthen materials. In 3D Printing for Construction in the Transformation of the Building Industry; CRC Press: Boca Raton, FL, USA, 2023. [Google Scholar] [CrossRef]

- Barnes, S.; Kirssin, L.; Needham, E.; Baharlou, E.; Carr, D.E.; Ma, J. 3D printing of ecologically active soil structures. Addit. Manuf. 2022, 52, 102670. [Google Scholar] [CrossRef]

- Crawford, A.; In-na, P.; Caldwell, G.; Armstrong, R.; Bridgens, B. Clay 3D printing as a bio-design research tool: Development of photosynthetic living building components. Archit. Sci. Rev. 2022, 65, 185–195. [Google Scholar] [CrossRef]

- Shi, Z.; Fonseca, J.A.; Schlueter, A. A review of simulation-based urban form generation and optimization for energy-driven urban design. Build. Environ. 2017, 121, 119–129. [Google Scholar] [CrossRef]

- Marchant, W.; Tosunoglu, S. Robotic implementation to automate a vertical farm system. In Proceedings of the 30th Florida Conference on Recent Advances in Robotics, Boca Raton, FL, USA, 11–12 May 2017. [Google Scholar]

- Phillips, B.T.; Becker, K.P.; Kurumaya, S.; Galloway, K.C.; Whittredge, G.; Vogt, D.M.; Teeple, C.B.; Rosen, M.H.; Pieribone, V.A.; Gruber, D.F.; et al. A Dexterous, Glove-Based Teleoperable Low-Power Soft Robotic Arm for Delicate Deep-Sea Biological Exploration. Sci. Rep. 2018, 8, 14779. [Google Scholar] [CrossRef]

- Sepulveda, A.J.; Birch, J.M.; Barnhart, E.P.; Merkes, C.M.; Yamahara, K.M.; Marin, R.; Kinsey, S.M.; Wright, P.R.; Schmidt, C. Robotic environmental DNA bio-surveillance of freshwater health. Sci. Rep. 2020, 10, 14389. [Google Scholar] [CrossRef]

- Yeo, M.S.K.; Samarakoon, S.M.B.P.; Ng, Q.B.; Muthugala, M.A.V.J.; Elara, M.R. Design of Robot-Inclusive Vertical Green Landscape. Buildings 2021, 11, 203. [Google Scholar] [CrossRef]

- Li, K.; Huo, Y.; Liu, Y.; Shi, Y.; He, Z.; Cui, Y. Design of a lightweight robotic arm for kiwifruit pollination. Comput. Electron. Agric. 2022, 198, 107114. [Google Scholar] [CrossRef]

- Gren, R. Agile Robotic Arm for Vertical Applications—Evaluation, Design and Development. Master’s Thesis, Lund University, Lund, Sweden, 2023. Available online: http://lup.lub.lu.se/student-papers/record/9124135 (accessed on 23 March 2025).

- Naselli, G.A.; Scharff, R.B.N.; Thielen, M.; Visentin, F.; Speck, T.; Mazzolai, B. A Soft Continuum Robotic Arm with a Climbing Plant-Inspired Adaptive Behavior for Minimal Sensing, Actuation, and Control Effort. Adv. Intell. Syst. 2024, 6, 2300537. [Google Scholar] [CrossRef]

- Hamm, J.; Lim, S.; Park, J.; Kang, J.; Lee, I.; Lee, Y.; Kang, J.; Jo, Y.; Lee, J.; Lee, S.; et al. A Modular Robotic Platform for Biological Research: Cell Culture Automation and Remote Experimentation. Adv. Intell. Syst. 2024, 6, 2300566. [Google Scholar] [CrossRef]

- Jamšek, M.; Sajko, G.; Krpan, J.; Babič, J. Design and Control of a Climbing Robot for Autonomous Vertical Gardening. Machines 2024, 12, 141. [Google Scholar] [CrossRef]

- Xu, W.; Jin, C.; Qian, X.; Jin, Z. Mass-customization of Integrated Green Wall Building Blocks through Clay Printing Formwork. In Proceedings of the 29th International Conference of the Association for Computer-Aided Architectural Design Research in Asia (CAADRIA), Singapore, 24–26 April 2024; pp. 329–338. Available online: http://papers.cumincad.org/cgi-bin/works/paper/caadria2024_253 (accessed on 7 February 2025).

- Arefin, A.M.E.; Khatri, N.R.; Kulkarni, N.; Egan, P.F. Polymer 3D Printing Review: Materials, Process, and Design Strategies for Medical Applications. Polymers 2021, 13, 1499. [Google Scholar] [CrossRef]

- Sarakinioti, M.V.; Turrin, M.; Konstantinou, T.; Tenpierik, M.; Knaack, U. Developing an integrated 3D-printed façade with complex geometries for active temperature control. Mater. Today Commun. 2018, 15, 275–279. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Maniadi, A.; Koudoumas, E.; Vairis, A.; Kechagias, J. Sustainable Additive Manufacturing: Mechanical Response of Acrylonitrile-Butadiene-Styrene over Multiple Recycling Processes. Sustainability 2020, 12, 3568. [Google Scholar] [CrossRef]

- Gomaa, M.; Jabi, W.; Veliz Reyes, A.; Soebarto, V. 3D printing system for earth-based construction: Case study of cob. Autom. Constr. 2021, 124, 103577. [Google Scholar] [CrossRef]

- Wolf, A.; Rosendahl, P.L.; Knaack, U. Additive manufacturing of clay and ceramic building components. Autom. Constr. 2022, 133, 103956. [Google Scholar] [CrossRef]

- Lakhdar, Y.; Tuck, C.; Binner, J.; Terry, A.; Goodridge, R. Additive manufacturing of advanced ceramic materials. Prog. Mater. Sci. 2021, 116, 100736. [Google Scholar] [CrossRef]

- Adams, T.; Vollpracht, A.; Haufe, J.; Hildebrand, L.; Brell-Cokcan, S. Ultra-lightweight foamed concrete for an automated facade application. Mag. Concr. Res. 2019, 71, 424–436. [Google Scholar] [CrossRef]

- Prasittisopin, L.; Pongpaisanseree, K.; Jiramarootapong, P.; Snguanyat, C. Thermal and Sound Insulation of Large-Scale 3D Extrusion Printing Wall Panel. In Second RILEM International Conference on Concrete and Digital Fabrication; Bos, F.P., Lucas, S.S., Wolfs, R.J.M., Salet, T.A.M., Eds.; RILEM Bookseries; Springer International Publishing: Cham, Switzerland, 2020; Volume 28, pp. 1174–1182. ISBN 978-3-030-49915-0. Available online: http://link.springer.com/10.1007/978-3-030-49916-7_111 (accessed on 28 October 2024).

- Liu, W.V.; Apel, D.B.; Bindiganavile, V.S. Thermal properties of lightweight dry-mix shotcrete containing expanded perlite aggregate. Cem. Concr. Compos. 2014, 53, 44–51. [Google Scholar] [CrossRef]

- Van Der Putten, J.; Van Olmen, A.; Aerts, M.; Ascione, E.; Beneens, J.; Blaakmeer, J.; De Schutter, G.; Van Tittelboom, K. 3D Concrete Printing on Site: A Novel Way of Building Houses? In Second RILEM International Conference on Concrete and Digital Fabrication; Bos, F.P., Lucas, S.S., Wolfs, R.J.M., Salet, T.A.M., Eds.; RILEM Bookseries; Springer International Publishing: Cham, Switzerland, 2020; Volume 28, pp. 712–719. ISBN 978-3-030-49915-0. Available online: http://link.springer.com/10.1007/978-3-030-49916-7_71 (accessed on 28 October 2024).

- Frazier, W.E. Metal Additive Manufacturing: A Review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Colorado, H.A.; Velásquez, E.I.G.; Monteiro, S.N. Sustainability of additive manufacturing: The circular economy of materials and environmental perspectives. J. Mater. Res. Technol. 2020, 9, 8221–8234. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Zhang, Y.; Bose, S. Recent developments in metal additive manufacturing. Curr. Opin. Chem. Eng. 2020, 28, 96–104. [Google Scholar] [CrossRef]

- Galjaard, S.; Hofman, S.; Ren, S. New Opportunities to Optimize Structural Designs in Metal by Using Additive Manufacturing. In Advances in Architectural Geometry 2014; Block, P., Knippers, J., Mitra, N.J., Wang, W., Eds.; Springer International Publishing: Cham, Switzerland, 2015; pp. 79–93. ISBN 978-3-319-11417-0. Available online: https://link.springer.com/10.1007/978-3-319-11418-7_6 (accessed on 28 October 2024).

- El-Mahdy, D.; Youssef, A.K. Wastewater Matter: From Algae to Bio-Algae Plastic 3D Printed Façade Element. In Proceedings of the HPSM/OPTI 2025, Edinburgh, UK, 10–12 June 2025; pp. 153–165. Available online: http://library.witpress.com/viewpaper.asp?pcode=MC21-017-1 (accessed on 28 October 2024).

- El-Mahdy, D.; Youssef, A.K. Optimization of an Adaptive Algae Facade Based on Solar Radiation Simulation. Int. J. Comput. Methods Exp. Meas. 2022, 10, 314–328. [Google Scholar]

- Bedarf, P.; Szabo, A.; Zanini, M.; Heusi, A.; Dillenburger, B. Robotic 3D Printing of Mineral Foam for a Lightweight Composite Concrete Slab. In Proceedings of the 27th International Conference of the Association for Computer-Aided Architectural Design Research in Asia (CAADRIA), Sydney, Australia, 9–15 April 2022; pp. 61–70. Available online: http://papers.cumincad.org/cgi-bin/works/paper/caadria2022_357 (accessed on 28 October 2024).

- Zidek, J.; Aman, L.; Li, X.; Elhashemi, J.; Aghaei Meibodi, M. Integrative Green Building Envelope: Large Scale Robotic Additive Manufacturing. In Proceedings of the ACADIA 2022, Philadelphia, PA, USA, 27–29 October 2022. [Google Scholar]

- Khoo, C.K.; Wee, H. PIXELGREENa Hybrid Green Media Wall for Existing High-Rise Buildings. In Proceedings of the 24th Annual Conference of the Association for Computer-Aided Architectural Design Research in Asia (CAADRIA 2019), Wellington, New Zealand, 15–18 April 2019. [Google Scholar]

- Shi, J.; Cho, Y.; Taylor, M.; Correa, D. Guiding Instability A craft-based approach for modular 3D clay printed masonry screen units. In Proceedings of the 37 eCAADe and XXIII SIGraDi Joint Conference, Porto, Portugal, 11–13 September 2019; pp. 477–484. Available online: http://www.proceedings.blucher.com.br/article-details/34204 (accessed on 28 October 2024).

- Borgia, E. The Internet of Things vision: Key features, applications and open issues. Comput. Commun. 2014, 54, 1–31. [Google Scholar] [CrossRef]

- Halgamuge, M.N.; Bojovschi, A.; Fisher, P.M.J.; Le, T.C.; Adeloju, S.; Murphy, S. Internet of Things and autonomous control for vertical cultivation walls towards smart food growing: A review. Urban For. Urban Green. 2021, 61, 127094. [Google Scholar] [CrossRef]

- Sarfraz, I.; Rizzo, A.; Masi, F.; Sebastiani, L. Estimating evapotranspiration rate in greywater-irrigated pilot living green wall using sensor-derived temperature data from three different orientations. In Proceedings of the 2023 IEEE International Workshop on Metrology for Agriculture and Forestry (MetroAgriFor), Pisa, Italy, 6–8 November 2023; pp. 31–35. Available online: https://ieeexplore.ieee.org/document/10424369/ (accessed on 22 January 2025).

- Helman, D.; Yungstein, Y.; Mulero, G.; Michael, Y. High-Throughput Remote Sensing of Vertical Green Living Walls (VGWs) in Workplaces. Remote Sens. 2022, 14, 3485. [Google Scholar] [CrossRef]

- Castillo-Atoche, A.; Vazquez-Castillo, J.; Osorio-de-la-Rosa, E.; Heredia-Lozano, J.C.; Vinas, J.A.; Cetina, R.Q.; Estrada-Lopez, J.J. An Energy-Saving Data Statistics-Driven Management Technique for Bio-Powered Indoor Wireless Sensor Nodes. IEEE Trans. Instrum. Meas. 2021, 70, 9507010. [Google Scholar] [CrossRef]

- Gamal, A.; Eleinen, O.A.; Eltarabily, S.; Elgheznawy, D. Enhancing urban resilience in hot humid climates: A conceptual framework for exploring the environmental performance of vertical greening systems (VGS). Front. Archit. Res. 2023, 12, 1260–1284. [Google Scholar] [CrossRef]

- Heród, A.; Malik, M. Effect of Daily Light Integral on Physiological and Morphological Quality of Indoor Plants in Vertical Garden. Acta Sci. Pol. Hortorum Cultus 2022, 21, 121–130. [Google Scholar] [CrossRef]

- Fensterseifer, P.; Gabriel, E.; Tassi, R.; Piccilli, D.G.A.; Minetto, B. A year-assessment of the suitability of a green façade to improve thermal performance of an affordable housing. Ecol. Eng. 2022, 185, 106810. [Google Scholar] [CrossRef]

- Liang, T.C.; Hien, W.N.; Jusuf, S.K. Effects of vertical greenery on mean radiant temperature in the tropical urban environment. Landsc. Urban Plan. 2014, 127, 52–64. [Google Scholar] [CrossRef]

- Rivas-Sánchez, Y.A.; Moreno-Pérez, M.F.; Roldán-Cañas, J. Environment Control with Low-Cost Microcontrollers and Microprocessors: Application for Green Walls. Sustainability 2019, 11, 782. [Google Scholar] [CrossRef]

- Ghazal, I.; Mansour, R.; Davidová, M. AGRI|gen: Analysis and Design of a Parametric Modular System for Vertical Urban Agriculture. Sustainability 2023, 15, 5284. [Google Scholar] [CrossRef]

- Zheng, Y.; Keeffe, G.; Mariotti, J. Nature-Based Solutions for Cooling in High-Density Neighbourhoods in Shenzhen: A Case Study of Baishizhou. Sustainability 2023, 15, 5509. [Google Scholar] [CrossRef]

- Hollands, J.; Korjenic, A. Evaluation and Planning Decision on Façade Greening Made Easy—Integration in BIM and Implementation of an Automated Design Process. Sustainability 2021, 13, 9387. [Google Scholar] [CrossRef]

- Lyu, Q.; Wang, Y.; Dai, P. Multilayered plant-growing concrete manufactured by aggregate-bed 3D concrete printing. Constr. Build. Mater. 2024, 430, 136453. [Google Scholar] [CrossRef]

- Fernandes De Oliveira, H.; Dos Santos Mota, O.; Rocha Pinto, F.; Barbosa De Alencar, D.; Santos Fontineles, F.H.; Dos Santos Santarém, S.; Samuel Dias Maia, D. Descriptive Analysis of Advantages and Disadvantages of Expanded Polystyrene Monolytic Panels—EPS. Int. J. Innov. Educ. Res. 2019, 7, 159–168. [Google Scholar] [CrossRef]

- Ogundiran, I.A.; Adedeji, Y.M.D. Sustainable Construction: Comparative Advantages of ExpandedPolystyrene (EPS) Fascia in Housing Delivery in Nigeria. Civ. Environ. Res. 2014, 6, 66–75. [Google Scholar]

- Anghel, A.A.; Mohora, I.; Frigura-Iliasa, F.M.; Giurea, D.; Preda, A.-D.; Milincu, C. Smart Responsive Green Walls for Public Transportation Areas in Timisoara. In Proceedings of the 2019 IEEE International Conference on Environment and Electrical Engineering and 2019 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Genova, Italy, 11–14 June 2019; pp. 1–4. Available online: https://ieeexplore.ieee.org/document/8783698/ (accessed on 19 March 2025).

- Farinea, C.; Awad, L.; Dubor, A.; Atab, M.E. Integrating biophotovoltaic and cyber-physical technologies into a 3D printed wall. In Proceedings of the 38th International Conference on Education and Research in Computer Aided Architectural Design in Europe (eCAADe), Berlin, Germany, 14–18 September 2020; Volume 2, pp. 463–472. [Google Scholar]

- Báez-García, W.G.; Simá, E.; Chagolla-Aranda, M.A.; Carlos Sandoval Herazo, L.; Carreto-Hernandez, L.G. Numerical-experimental study of the thermal behavior of a green facade in a warm climate in Mexico. Energy Build. 2024, 311, 114156. [Google Scholar] [CrossRef]

- Perera, T.A.N.T.; Jayasinghe, G.Y.; Halwatura, R.U.; Rupasinghe, H.T. Modelling of vertical greenery system with selected tropical plants in urban context to appraise plant thermal performance. Ecol. Indic. 2021, 128, 107816. [Google Scholar] [CrossRef]

- Yanardag Erdener, H.M.; Edis, E. The effect of living wall systems’ variables on the energy consumption of buildings. Built Environ. Proj. Asset Manag. 2024, 14, 333–348. [Google Scholar] [CrossRef]

- Ornam, K.; Triyadi, S.; Wonorahardjo, S.; Sutjahja, I.M.; Martonohadi, P.; Assegaf, S.; Kimsan, M. Thermal Environment Control of Buildings using Installation of Plants and Metal Panels on Brick Walls. IOP Conf. Ser. Earth Environ. Sci. 2021, 738, 012001. [Google Scholar] [CrossRef]

- Banti, N.; Ciacci, C.; Di Naso, V.; Bazzocchi, F. Green Walls as Retrofitting Measure: Influence on Energy Performance of Existing Industrial Buildings in Central Italy. Buildings 2023, 13, 369. [Google Scholar] [CrossRef]

- Poddar, S.; Park, D.; Chang, S. Energy performance analysis of a dormitory building based on different orientations and seasonal variations of leaf area index. Energy Effic. 2017, 10, 887–903. [Google Scholar] [CrossRef]

- Freewan, A.A.; Jaradat, N.M.; Amaireh, I.A. Optimizing Shading and Thermal Performances of Vertical Green Wall on Buildings in a Hot Arid Region. Buildings 2022, 12, 216. [Google Scholar] [CrossRef]

- Abdeen, N.; Rafaat, T. Assessing vertical green walls for indoor corridors in educational buildings and its impact outdoor: A field study at the universities of Canada in Egypt. Results Eng. 2024, 21, 101838. [Google Scholar] [CrossRef]

- Shaheen, A.M.A.; Sabry, H.M.K.; Faggal, A.A.E.D. Double Skin Green Facade in Workplace for Enhancing Thermal Performance in Greater Cairo. Eng. Res. J. 2020, 168, 1–12. [Google Scholar] [CrossRef]

- Wang, L.; Witte, M.J. Integrating building energy simulation with a machine learning algorithm for evaluating indoor living walls’ impacts on cooling energy use in commercial buildings. Energy Build. 2022, 272, 112322. [Google Scholar] [CrossRef]

- Daemei, A.B.; Shafiee, E.; Chitgar, A.A.; Asadi, S. Investigating the thermal performance of green wall: Experimental analysis, deep learning model, and simulation studies in a humid climate. Build. Environ. 2021, 205, 108201. [Google Scholar] [CrossRef]

- Wortmann, T.; Tuncer, B. Performative Design and Fabrication of a Parametric Wall Screen for Tropical Climates—A Modular Approach. In Proceedings of the 33rd International Conference on Education and research in Computer Aided Architectural Design in Europe, Vienna, Austria, 16–18 September 2015; pp. 521–530. Available online: http://papers.cumincad.org/cgi-bin/works/paper/ecaade2015_318 (accessed on 21 February 2025).

- Alkhalidi, A.; Hatuqay, D. Energy efficient 3D printed buildings: Material and techniques selection worldwide study. J. Build. Eng. 2020, 30, 101286. [Google Scholar] [CrossRef]

- McClements, D. Advantages and Disadvantages of Laser Cutting 2022. Available online: https://www.xometry.com/resources/sheet/laser-cutting-advantages/ (accessed on 23 March 2025).

- Harrison, N. Laser Cutting: Examining Advantages and Disadvantages of Laser Technology 2022. Available online: https://www.rapiddirect.com/blog/advantages-and-disadvantages-of-laser-cutting/ (accessed on 20 February 2025).

- Briscoe, D. Living Wall—Information Workflow and Collaboration. In Proceedings of the eCAADe 2018: Computing for a Better Tomorrow, Łódź, Poland, 19–21 September 2018; pp. 207–212. Available online: http://papers.cumincad.org/cgi-bin/works/paper/ecaade2018_135 (accessed on 20 February 2025).

- Jayawardane, H.; Davies, I.J.; Gamage, J.R.; John, M.; Biswas, W.K. Investigating the ‘techno-eco-efficiency’ performance of pump impellers: Metal 3D printing vs. CNC machining. Int. J. Adv. Manuf. Technol. 2022, 121, 6811–6836. [Google Scholar] [CrossRef]

- Stavric, M.; Kaftan, M. Robotic Fabrication of Modular Formwork for Non-Standard Concrete Structures. In Proceedings of the 30th eCAADe Conference, Prague, Czech Republic, 12–14 September 2012; pp. 431–437. Available online: http://papers.cumincad.org/cgi-bin/works/paper/ecaade2012_319 (accessed on 20 February 2025).

- Nagle, L.; Echols, S.; Tamminga, K. Food Production on a Living Wall: Pilot Study. J. Green Build. 2017, 12, 23–38. [Google Scholar] [CrossRef]

- Charoenkit, S.; Yiemwattana, S. The performance of outdoor plants in living walls under hot and humid conditions. Landsc. Ecol. Eng. 2021, 17, 55–73. [Google Scholar] [CrossRef]

- Wang, C.; Wood, L.C.; Teo, L.T. Tropical Vertical Greenery Systems: Irrigation Systems, Biophysical Characteristics, and Influential Criteria. J. Green Build. 2016, 11, 57–90. [Google Scholar] [CrossRef]

- Yan, Z. Vertical Greening Engineering Technology Research Based on Experimental Analysis. In Proceedings of the 2018 International Conference on Engineering Simulation and Intelligent Control (ESAIC), Changsha, China, 10–11 August 2018; pp. 319–322. Available online: https://ieeexplore.ieee.org/document/8530423/ (accessed on 19 March 2025).

- Vazquez-Castillo, J.; Castillo-Atoche, A.; Estrada-Lopez, J.; Osorio-de-la-Rosa, E.; Becerra-Nunez, G.; Heredia-Lozano, J.; Atoche-Ensenat, R.; Sandoval-Curmina, V. Energy-Saving Techniques for Urban Noise WSN with Kalman-Based State Estimation and Green Facade Energy Harvester. IEEE Trans. Instrum. Meas. 2022, 71, 9502110. [Google Scholar] [CrossRef]

- Anderson, V.; Gough, W.A. Nature-based cooling potential: A multi-type green infrastructure evaluation in Toronto, Ontario, Canada. Int. J. Biometeorol. 2022, 66, 397–410. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Hu, K.; Liu, Y.; Wang, Z.; Dong, K.; Lv, P.; Shi, X. Optimisation of Building Green Performances Using Vertical Greening Systems: A Case Study in Changzhou, China. Sustainability 2023, 15, 4494. [Google Scholar] [CrossRef]

- Srbinovska, M.; Andova, V.; Mateska, A.K.; Krstevska, M.C.; Cundeva-Blajer, M.; Kutirov, M.; Majstoroski, M. Quantifying the impact of meteorological factors and green infrastructure location on particulate matter (PM) mitigation in Republic of North Macedonia using sensor collected data. Meas. Sens. 2023, 27, 100819. [Google Scholar] [CrossRef]

| Search Within Title, Abstract, Keyword | Database | Number of Studies |

|---|---|---|

| Main study: “green wall system” OR “vertical greening system” OR “living wall” OR “green facade” OR “green wall” Complementary study: “digital” OR “fabrication” OR “parametric” OR “additive manufacturing” | Scopus | 53 |

| IEEE | 132 | |

| Cumincad | 830 | |

| Main study: “green wall system” OR “vertical greening system” OR “living wall” OR “green facade” OR “green wall” Complementary study: “internet of things” OR “building automation system” OR “smart facade” OR “responsive” “irrigation” OR “nutrient” OR “carbon” OR “daylight” OR “sensor” | Scopus | 228 |

| IEEE | 15 | |

| Main study: “green wall system” OR “vertical greening system” OR “living wall” OR “green facade” OR “green wall” Complementary study: “computational” OR “simulation” OR “optimization” OR “form-finding” OR “parameter” AND “computational” OR “simulation” OR “optimization” OR “form-finding” OR “parameter” | Scopus | 1015 |

| IEEE | 42 | |

| Cumincad | 9 |

| Design Stages | Existing Studies | Research Gaps | Future Directions |

| Context | Focus on VGS cooling performance, with limited research on its effectiveness in heating load reduction [29,30,31]. |

|

|

| Studies primarily evaluate the performance of VGS in Subtropical and Mediterranean climates [7,8,10,13,16,58,60,61]. |

| ||

| Form Generation | Weeping Brick system, which demonstrates the potential of parametric adjustments in VGS design but rarely explores iterative form generation involving design variables, parameters, and performance indicators [36,67]. |

|

|

| Simulation |

|

| |

| Existing research primarily evaluates VGS performance based on thermal and energy efficiency metrics [11,66,67,69]. |

| ||

| Using Grasshopper to generate building geometry and computational simulation [69,73,107,123,124]. |

| ||

| Fabrication | Material selection in several studies focuses on performance, environmental impact, design, and production (cost and scale) [36,78,107]. |

|

|

| There are few studies that have examined material properties like porosity, alkalinity, and thermal behavior on plant growth [125]. |

| ||

| Several studies highlight scalability as a key issue and require further experimentation and collaboration due to budget constraints [78,79]. |

| ||

| There are only a few studies that have assessed the environmental impact of VGS materials by evaluating their life cycle and carbon sequestration [58,126,127]. |

| ||

| Monitoring and Maintenance | Existing studies have not throughly reviewed the benefits of using IoT for maintaining and monitoring system [128]. |

|

|

| Existing studies primarily focus on using IoT for monitoring, maintaining, and analyzed the performance of VGS [114]. |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alkadri, M.F.; Yuliana; Hadini, M.H.; Jonatan, S.A.; Yolanda, A.; Desiana, P.A.; Sa’diah, N.F.; Susanto, D.; Istiani, N.F.F.; Suryanegara, M. Exploring Uncharted Territories in a Vertical Greening System: A Systematic Literature Review of Design, Performance, and Technological Innovations for Urban Sustainability. Buildings 2025, 15, 1102. https://doi.org/10.3390/buildings15071102

Alkadri MF, Yuliana, Hadini MH, Jonatan SA, Yolanda A, Desiana PA, Sa’diah NF, Susanto D, Istiani NFF, Suryanegara M. Exploring Uncharted Territories in a Vertical Greening System: A Systematic Literature Review of Design, Performance, and Technological Innovations for Urban Sustainability. Buildings. 2025; 15(7):1102. https://doi.org/10.3390/buildings15071102

Chicago/Turabian StyleAlkadri, Miktha Farid, Yuliana, Muthiah Hakim Hadini, Stefanie Aylien Jonatan, Aprilia Yolanda, Putri Alifia Desiana, Nur Fitriatus Sa’diah, Dalhar Susanto, Noor Fajrina Farah Istiani, and Muhammad Suryanegara. 2025. "Exploring Uncharted Territories in a Vertical Greening System: A Systematic Literature Review of Design, Performance, and Technological Innovations for Urban Sustainability" Buildings 15, no. 7: 1102. https://doi.org/10.3390/buildings15071102

APA StyleAlkadri, M. F., Yuliana, Hadini, M. H., Jonatan, S. A., Yolanda, A., Desiana, P. A., Sa’diah, N. F., Susanto, D., Istiani, N. F. F., & Suryanegara, M. (2025). Exploring Uncharted Territories in a Vertical Greening System: A Systematic Literature Review of Design, Performance, and Technological Innovations for Urban Sustainability. Buildings, 15(7), 1102. https://doi.org/10.3390/buildings15071102