1. Introduction

In an era where global energy demand is on an upward trajectory, largely propelled by the rapid economic development seen in emerging economies [

1], buildings stand out as major energy consumers, accounting for up to 45% of the total energy consumption [

2,

3]. Among the significant energy expenditures lie heating, ventilation, and air conditioning (HVAC), which devour nearly 40% of the energy used within buildings [

4]. This situation highlights the urgent need to design and implement strategies to reduce the energy consumption of buildings while maintaining an adequate level of comfort for occupants. Two complementary approaches are emerging in this quest for energy efficiency: the active approach, which is based on optimizing existing technical systems such as heating, ventilation, and air-conditioning equipment by integrating intelligent technologies and advanced energy management solutions; and the passive approach, which favors the use of architectural concepts, material innovations, and design techniques aimed at minimizing the intrinsic energy demand of buildings. This includes improving the thermal and hygric performance of the building envelope [

5,

6].

The building envelope, which is constantly subject to temperature and humidity gradients, plays a fundamental role in thermal and hygric exchanges between the interior and exterior. These dynamic processes have a direct impact on the building’s energy requirements, as well as on the thermal and hygrometric comfort of its occupants. Understanding and controlling the hygrothermal behavior of the building envelope is therefore becoming a priority in the context of the energy transition. In this context, increasing attention is being paid to biobased buildings. A recent study [

7] examined the use of biologically sourced construction materials, highlighting their properties, recommended applications, and performance expectations. Biobased materials, derived from animal or plant biomass, have garnered increasing interest in recent decades [

8]. These materials not only offer multiphysical performances comparable to, or even superior to, those of traditional materials [

9] but they also have the advantage of carbon storage, thus contributing to the reduction in greenhouse gas emissions [

10]. Röhlen et al. [

11] demonstrated that the soil’s absorption and evaporation capacity help harmonize temperatures by regulating atmospheric humidity and moderating temperature fluctuations. Moreover, this capacity aids in air filtration by trapping particles and removing pollutants, thus improving the surrounding air quality. From a hygrothermal standpoint, raw earth behaves as a thermal and hygrometric regulator, slowing and attenuating heat waves and stabilizing indoor relative humidity more quickly than other building materials [

8]. Extensive studies have shown that compressed earth blocks outperform adobe materials in terms of durability [

12,

13], while offering equivalent or superior thermal performance to concrete in hot climates [

12,

14,

15,

16]. Neya et al. [

17] examined the impact of insulation and wall thickness on the thermal performance of compressed earth buildings located in hot and dry regions. They constructed a test cell using cement-stabilized compressed earth blocks and modeled its thermal performance using EnergyPlus software. The results showed that adding thermal insulation reduced heat transmission, while wall thickness influenced thermal lag and occupant comfort. This research underscores the importance of striking a balance between insulation, wall thickness, and durability to design buildings suited to hot and dry climatic conditions. Desogus et al. [

18] examined monitoring and simulation comparisons for an earthen residential building in Sardinia (Italy) during summertime. Their research confirmed the high thermal inertia of an adobe wall and demonstrated internal temperature values within the comfort range. The authors concluded that roofs are the limiting factor, causing local discomfort due to radiant asymmetry. Additionally, they emphasized that these findings underscore the need for careful attention to roof design to ensure optimal thermal comfort in earthen buildings. Martín et al. [

19] conducted a field monitoring study in Navapalos, Spain, comparing the thermal performance of traditional and non-traditional houses. Their findings revealed significant disparities in thermal behavior. During summer, when temperatures averaged 23 °C with peaks reaching 35.7 °C, the indoor temperature of a traditional adobe house with 40 cm thick walls remained within the comfort zone. Palme et al. [

20] presented monitoring and simulation studies on four houses constructed with various materials in a desert climate during winter in San Pedro de Atacama, Chile. The study examined adobe, rammed earth, wood, and concrete as building materials. Their results indicated that earthen constructions outperformed wood and concrete in terms of thermal decrement, thermal lag, insulation properties, and solar radiation gain. Another interesting study for earthen constructions was performed by Miño et al. [

21], who selected two residences to assess the impact of key envelope parameters on indoor thermal performance in a rural region of the Ecuadorian Andes. One residence comprised compressed stabilized earth blocks (CSEBs) and concrete tiles, while the other was a typical, uninsulated lightweight structure utilizing hollow concrete blocks and zinc sheet roofing. Their findings from monitoring and simulation revealed that the roof, floor, and airtightness significantly influenced indoor thermal conditions. Notably, the traditional dwelling exhibited greater thermal stability, with a 4.7 °C reduction in total temperature fluctuation compared to the alternative structure.

Phase-change materials (PCMs) are another innovative solution for reducing energy consumption in buildings [

22]. These materials have the ability to absorb or release large quantities of thermal energy as they transition between solid and liquid states, thus stabilizing indoor temperature fluctuations and reducing the sensitive load imposed on air-conditioning systems [

23,

24]. They fall into three main categories—organic, inorganic, and eutectic—and cover a wide range of melting points and are used in both passive and active thermal storage systems. Their efficiency is particularly marked when their melting point is within the range of human thermal comfort, between 15 °C and 30 °C. This enables them to efficiently store and release heat or coolness, providing better thermal regulation for occupants. PCMs can be integrated into various elements of building envelopes, such as walls, floors, suspended ceilings, roofs, and windows [

25,

26,

27,

28]. By increasing the thermal mass of structures, they promote passive heating and cooling while limiting the dependence on mechanical ventilation systems. Their high latent heat of fusion also contributes to more efficient heat and moisture transfer management within buildings.

While extensive research has been conducted on the thermal performance of biobased walls, the scientific literature remains limited regarding an in-depth analysis of the integration of phase-change materials (PCMs) into these construction systems. Indeed, most existing studies have focused on the thermophysical properties of materials individually, without systematically exploring the potential synergies between biobased walls and PCMs. The combination of technological innovations such as phase-change materials (PCMs) and solutions based on biobased materials represent a promising response to today’s energy challenges. These approaches combine the modernity of advanced materials with the sustainability of natural resources, fully in line with the objectives of sustainable development. In buildings using traditional materials such as cob, the integration of PCMs can significantly improve thermal performance while maintaining the authenticity and low ecological footprint of these structures. Two main integration methods have been explored. The first, direct immersion, involves impregnating the building material with PCMs. Although this approach enables immediate and effective thermal interaction, it can lead to leakage risks when the PCMs enter a liquid state, thus limiting their practical application. The second technique, micro-encapsulation, represents a more reliable and durable alternative. This method involves encapsulating the PCMs in small protective structures, thus avoiding problems associated with changes in state and guaranteeing greater stability within the material. By integrating PCMs in a micro-encapsulated form, cob constructions can benefit from optimized thermal regulation while retaining the material’s natural hygroscopic properties. In this work, the impact of incorporating PCM into biobased materials, particularly in enhancing both the energy and hygrothermal performances of buildings, was investigated. The heat storage process within the biobased material and their influence on moisture transfer were analyzed.

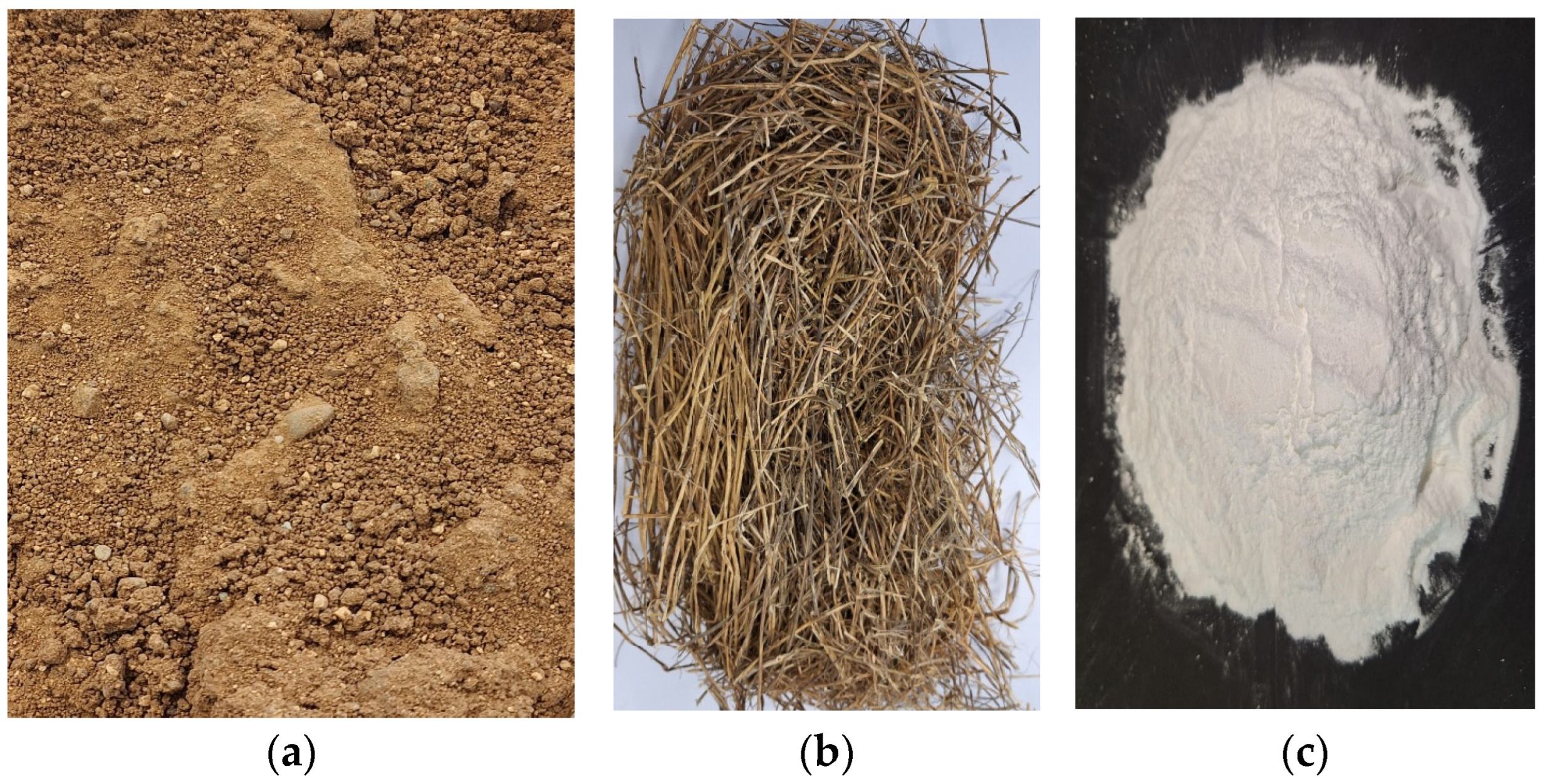

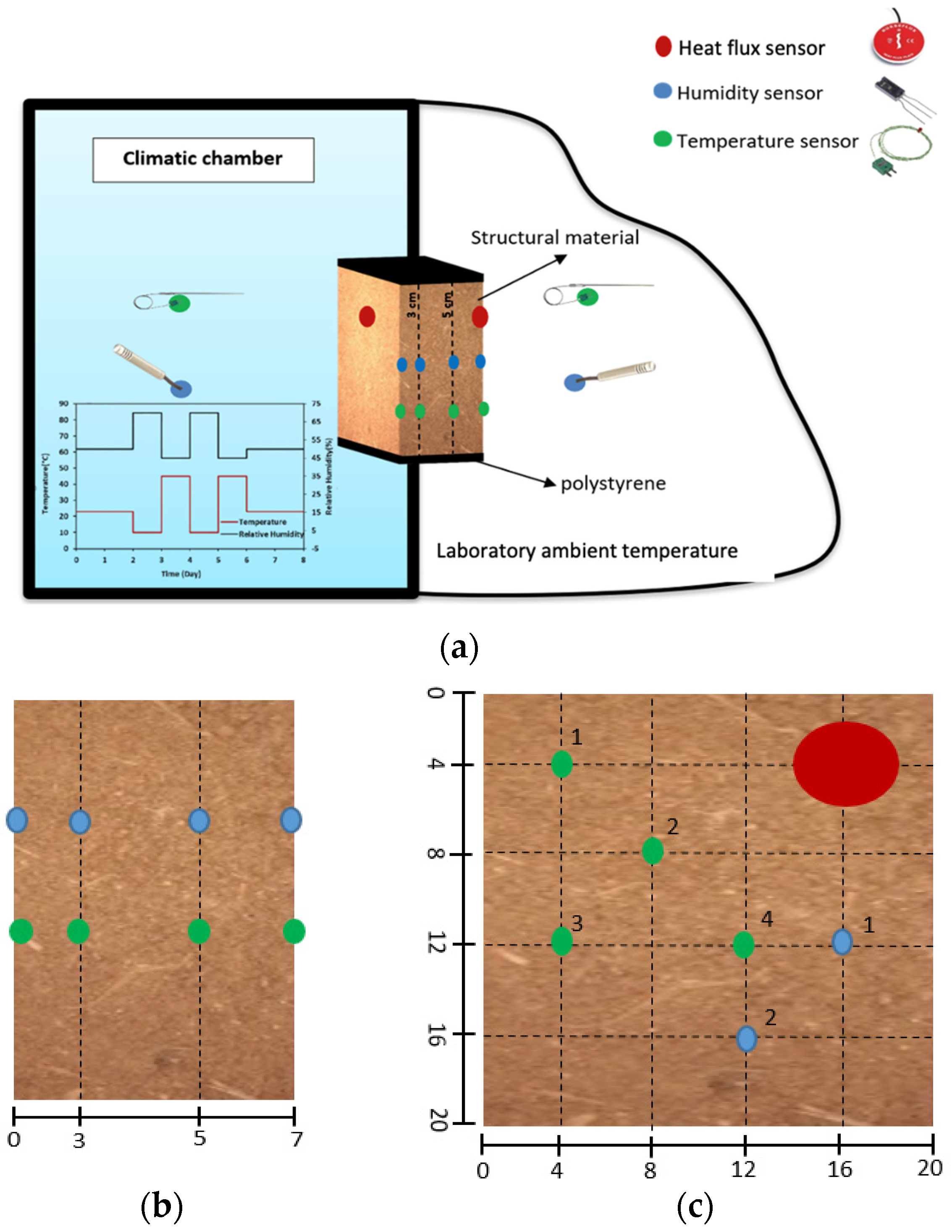

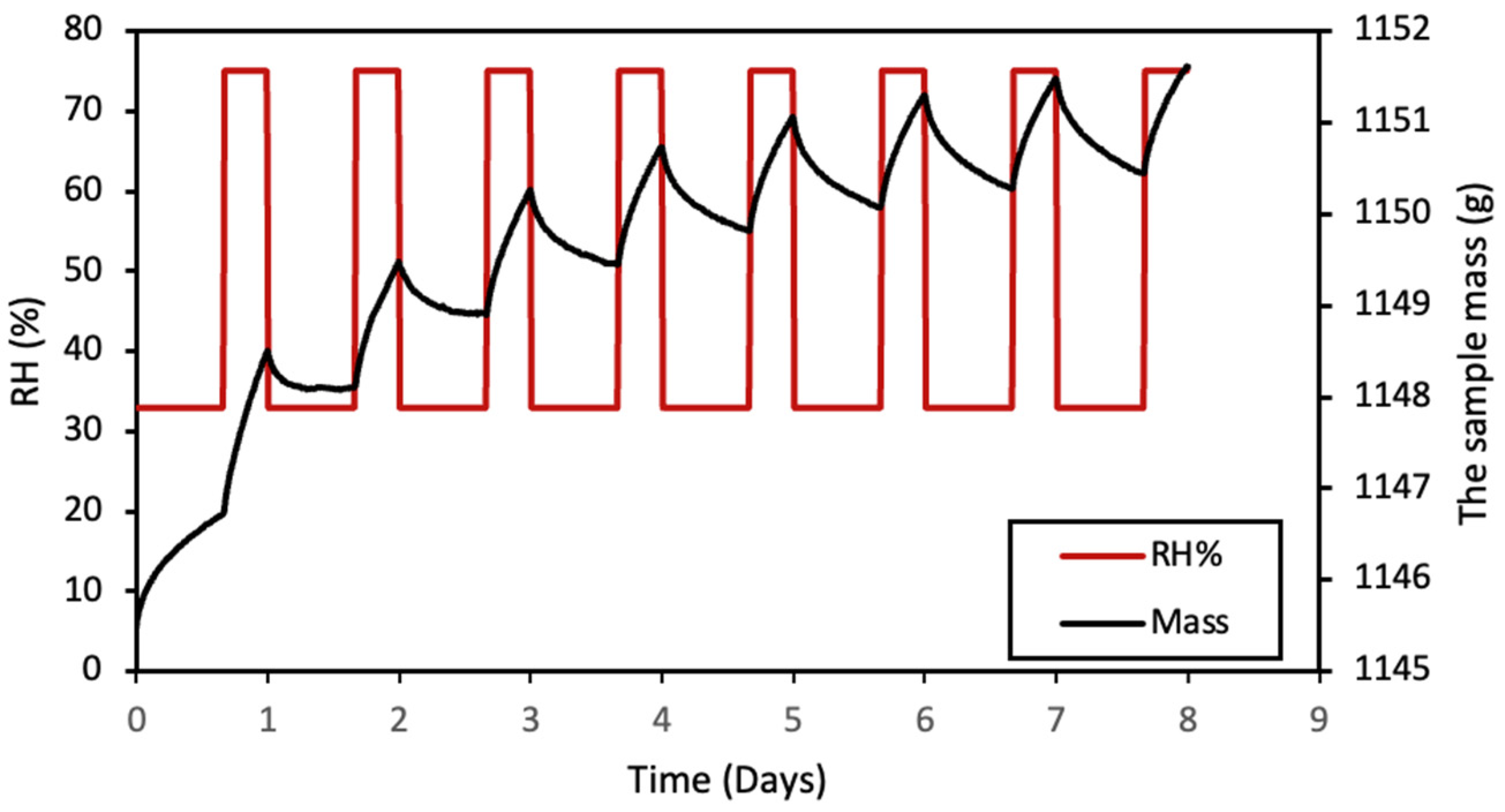

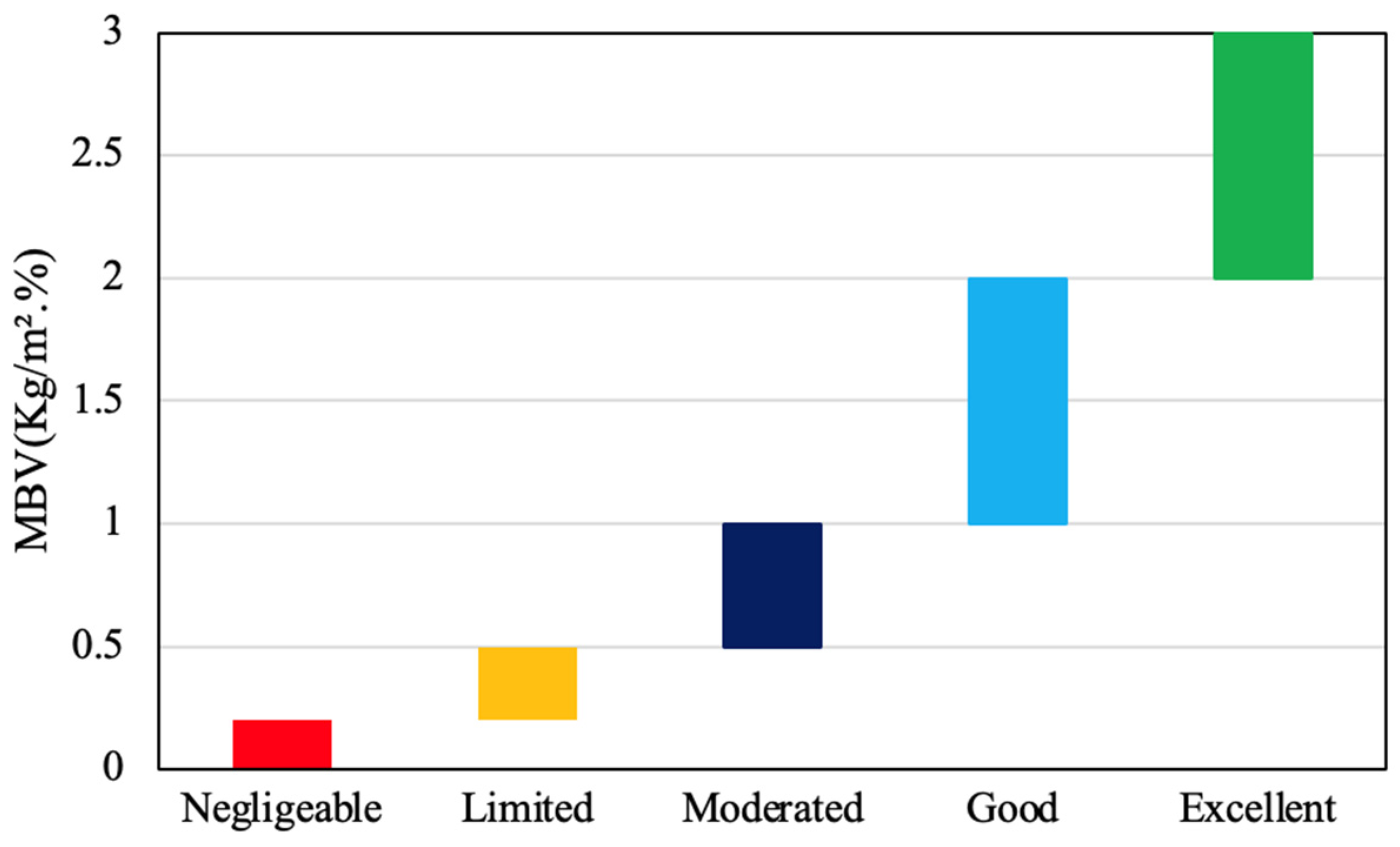

In light of the previous analyses, the present study investigates the hygrothermal properties via an experimental study for biobased materials based on soil and plant fibers. French soil is used for the preparation of the tested material as it contains a strong composition of soil and a low fiber content, provides structural performance, and can withstand significant loads. Our testing of moisture buffering values was inspired by the Nordtest project [

29], which represents their ability to dampen variations in indoor relative humidity due to their moisture buffering capacity. The objective of this article is to examine the effect of integrating PCMs into cob material on its thermal and hygroscopic behavior by studying two materials: cob and cob with 20% microencapsulated PCMs. The experimental results shed light on the thermal and hygroscopic variations induced by the incorporation of PCMs into this traditional building material. A simulation was carried out to study the impact of wall materials on the building’s thermal performance using the transient heat equation. The numerical model, developed in MATLAB, employs the alternating direction implicit (ADI) finite difference method, solving the transient heat equation. Real outdoor temperature data, extracted for summer and winter conditions, serve as boundary conditions, with an internal temperature fixed at 20 °C. This study compares three wall configurations: a cob wall, a cob wall incorporating PCM, and a conventional multi-layer wall. The model considers homogeneous material properties, effective thermal conductivity, and latent heat storage effects for PCM integration. The simulation tracks heat conduction, convection, and phase transition dynamics, evaluating energy efficiency, heat flux regulation, and indoor temperature stability under seasonal variations. Heat losses and gains are quantified through an integral formulation of the global heat flux, assessing each wall’s capacity to mitigate temperature fluctuations and improve indoor comfort.

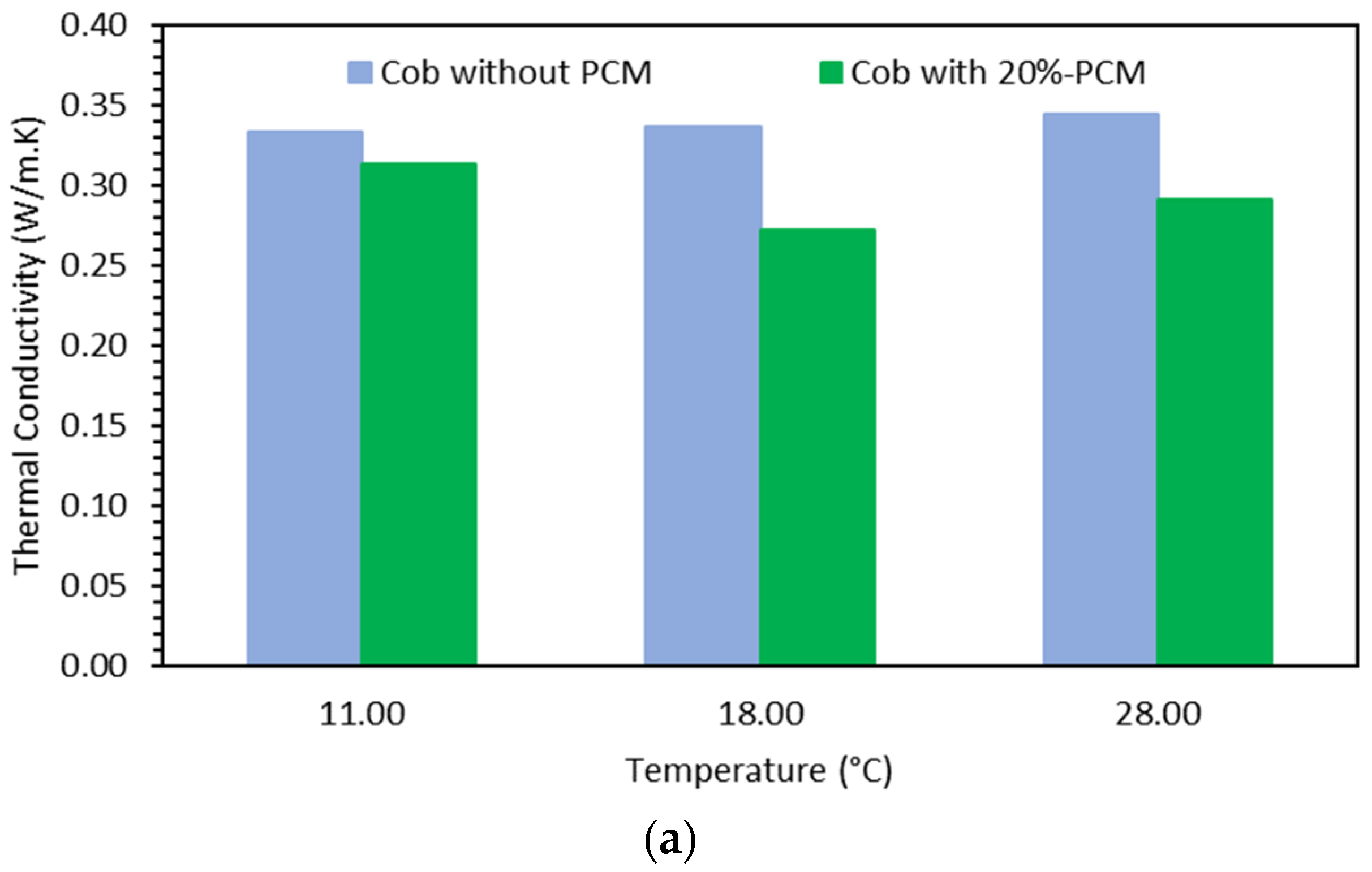

4. Impact of Microencapsulated PCM on the Thermal Behavior of the Cob Material

As part of this study, the thermal conductivity and specific heat capacity of the two materials studied (cob without and with PCM) were determined using the HFM 436 Lambda. The thermal conductivity of the cob, as well as that of the cob incorporating PCM, was measured at three distinct temperatures: 11 °C, 18 °C, and 28 °C. These temperatures were carefully selected to assess thermal conductivity within the phase transition range of PCM (18 °C) and outside this range (11 °C and 28 °C). At 11 °C, PCM is entirely in the solid state, while at 28 °C, it is completely in the liquid state, enabling us to study the impact of different physical states on thermal properties.

Figure 17a illustrates the evolution of thermal conductivity as a function of temperature for cob with and without PCM. In the case of cob material without PCM, thermal conductivity increases with temperature, following a classic thermal behavior, with an average value of 0.34 W/(m·K), in line with data reported in the literature [

38]. On the other hand, for cob containing 20% PCM, an overall decrease in thermal conductivity is observed, attributed to the low intrinsic thermal conductivity of PCM (around 0.12 W/(m·K)). This reduction is particularly pronounced around the phase-transition temperature (18 °C), where PCM absorbs latent thermal energy, slowing heat transfer. This behavior underscores the positive effect of integrating PCM on thermal regulation, in comparison with cribbing without PCM.

The evolution of the mass heat capacity of the two cob mixes, with and without PCM, as a function of temperature is shown in

Figure 17b. Measurements were carried out at three specific temperatures corresponding to the different physical states of INERTEK 18 PCM: at 10 °C, when the PCM is entirely in the solid state; at 18 °C, during the solid–liquid phase transition; and at 50 °C, when the PCM is entirely in the liquid state. These measurement points enable us to assess the impact of phase change on the thermal mass capacity of the composite material.

INERTEK 18 PCM has a significantly higher thermal capacity by mass than the cob material. This characteristic enables its incorporation to significantly improve the thermal properties of the mixture. Indeed, analysis of the results reveals an overall increase in thermal mass capacity thanks to the presence of PCM. Before the phase transition, at 10 °C, the heat capacity of the mixture containing MCP is around 2.2 times greater than that of the cob sample. This effect is explained by the specific properties of MCP in the solid state, which contribute to better heat storage. During the phase transition, at 18 °C, an even more significant increase is observed. The heat capacity reaches a value some 2.6 times higher than that of the cob without PCM. This sharp rise is due to the latent energy absorbed by the PCM during its solid–liquid phase change. This phenomenon considerably increases the energy storage capacity of the composite material at this key temperature. After the phase transition, at 50 °C, although the effect is more moderate, the heat capacity by mass of the mixture containing PCM remains higher than that of the cob sample without PCM. An increase of around 1.3% is recorded, reflecting the thermal properties of PCM in the liquid state. Although this contribution is less pronounced, it nevertheless maintains an advantage over the unmodified material.

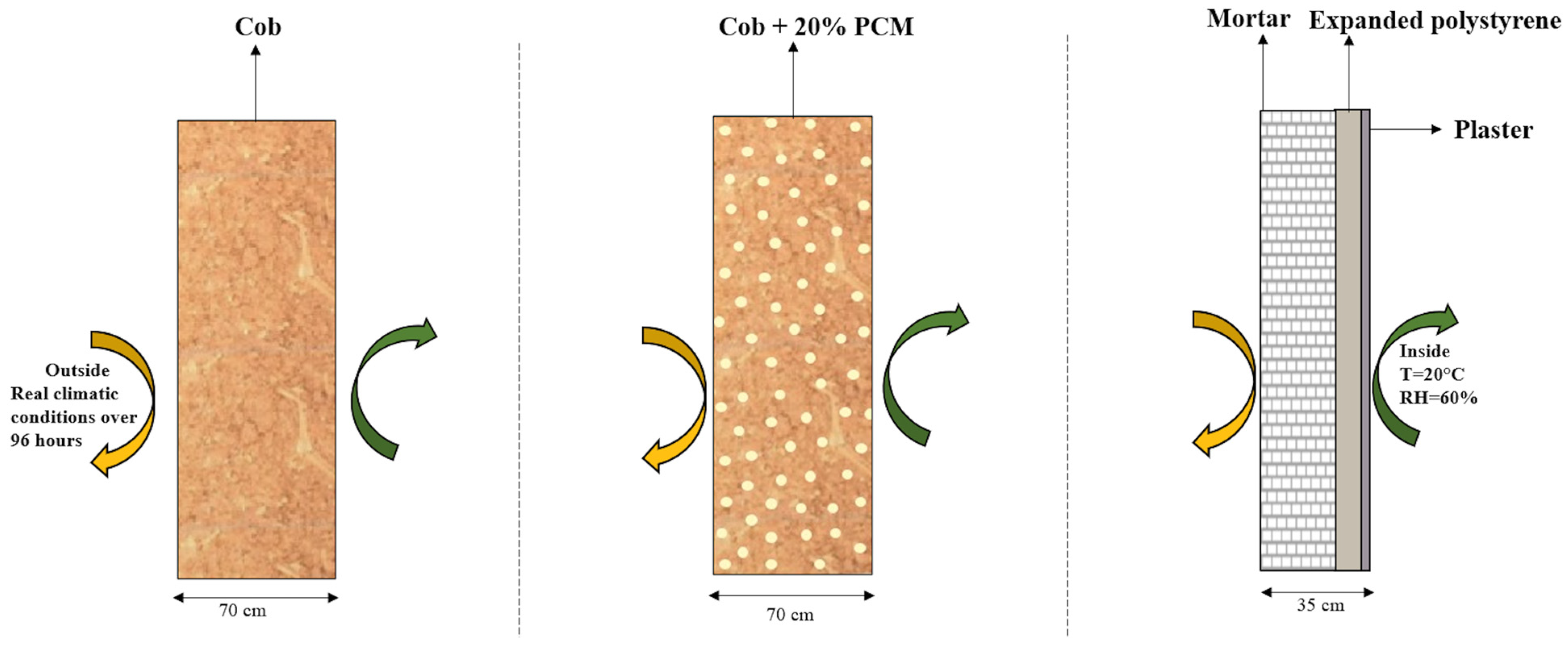

A simulation is conducted to study the impact of wall materials on thermal performance, considering the transient heat equation using real outdoor temperature data for two scenarios—summer (first four days of August 2023) and winter (first four days of January 2024). The data were extracted from Wunderground for the Normandy region in France. The study initially examines a 70 cm thick wall made entirely of structural biobased material. Secondly, it analyzes a 70 cm wall made of structural biobased material with 20% of its mass replaced by PCM. Lastly, a conventional multi-layer wall following a 35 cm standard is studied, consisting of 25 cm of concrete mortar, 8 cm of polystyrene, and 2 cm of plaster,

Figure 18. This conventional wall, studied by Ferroukhi et al. [

39], considers coupled heat and moisture transfer, with the thermal transfer coefficients extracted from the book Moisture Analysis and Condensation Control in Building Envelopes [

40], complying with EN 12939 and ISO 6946 standards, which outline the measurement of thermal properties and the calculation method for the thermal performance of multilayer walls. The thermal properties of the conventional materials composing the studied wall are summarized in

Table 4.

A fairer comparison of wall performance considers both thermal transmittance (U-value) and specific heat capacity rather than thickness alone. The 35 cm conventional multi-layer wall, designed for strength, thermal efficiency, and cost-effectiveness, has a U-value of 0.36 W/m2K, with internal insulation often used in retrofitting to prevent moisture condensation. In contrast, the 70 cm cob wall, selected in the CobBauge project to enhance thermal inertia and structural stability, shares the same U-value of 0.36 W/m2K, while the addition of PCM lowers it to 0.31 W/m2K, improving insulation. The higher thermal inertia of cob construction, linked to its greater specific heat capacity, contributes to better temperature regulation and energy efficiency.

The modeled transient heat equation represents the energy conservation principle in a mortar wall containing 20% phase-change material (PCM), capturing the combined effects of heat conduction and latent heat exchange during phase transitions:

where

and

represent the effective density and specific heat capacity, with

as the effective thermal conductivity. The term

incorporates the latent heat of fusion of the 20% presented PCM’s density in the material, which varies with the melting fraction

. The melting fraction is described by a linear model

The model includes convection as boundary conditions. The convective heat transfer at the surface of the mortar wall is expressed as:

where

represents the surface temperature of the wall,

is the external air temperature, which depends on real climatic conditions,

is the internal air temperature fixed at 20 °C,

(17 W/m

2K) is the convective heat transfer coefficient at the exterior surface, and

(8 W/m

2K) is the convective heat transfer coefficient at the internal surface. The model allows us to simulate the PCM’s ability to store heat during melting and release it during solidification, stabilizing the wall temperature. The model considers several hypotheses. simplifying the physical system to make the model computationally manageable:

- (1)

The PCM distribution within the mortar is homogeneous, ensuring uniform thermal properties.

- (2)

The effective thermal conductivity , density , and specific heat capacity are constant and averaged over the composite.

- (3)

The phase-change process occurs over a specific temperature range with a linear dependence of the melting fraction.

- (4)

Heat transfer is modeled exclusively via conduction and convection, neglecting radiative effects within the wall.

- (5)

Thermal equilibrium is assumed between the PCM and the structural material matrix at all times.

The numerical resolution of the heat transfer equation, programmed in version 9.0 of MATLAB using the ADI finite difference method, was performed with a time step of 1 s and a spatial step of 1 cm. The model incorporates real climatic data from the Normandy region as external boundary conditions, representing the temperature variations and environmental interactions accurately. The time-dependent global heat flux equation simplifies to an integral along the length of the domain in terms of heat conduction. It can be expressed as:

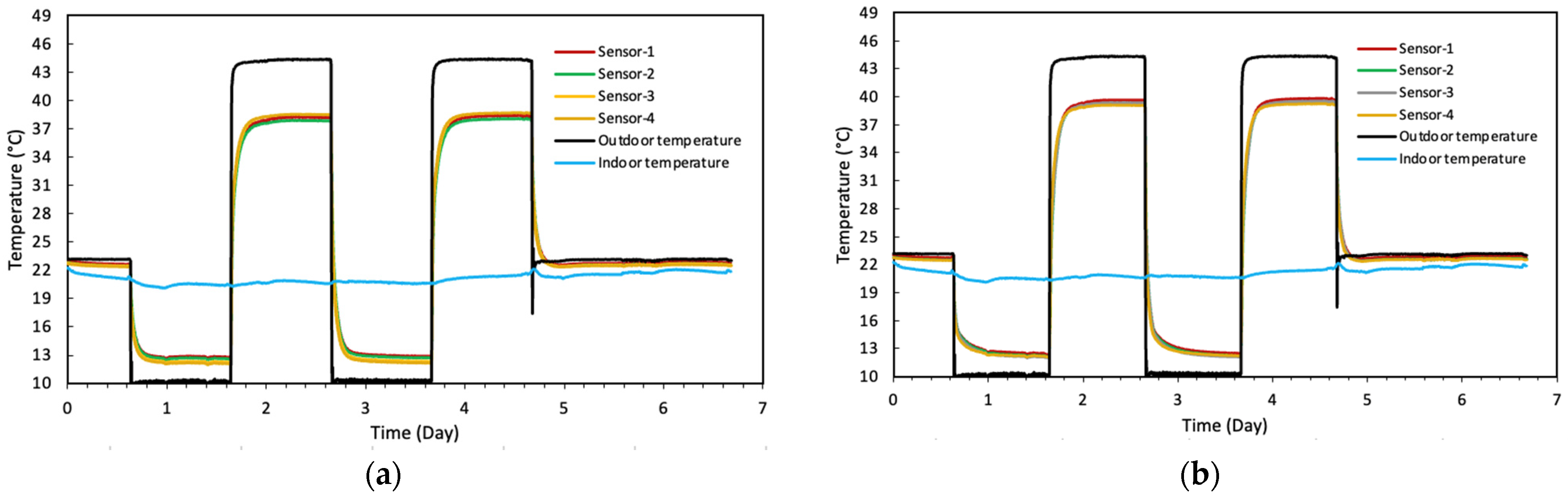

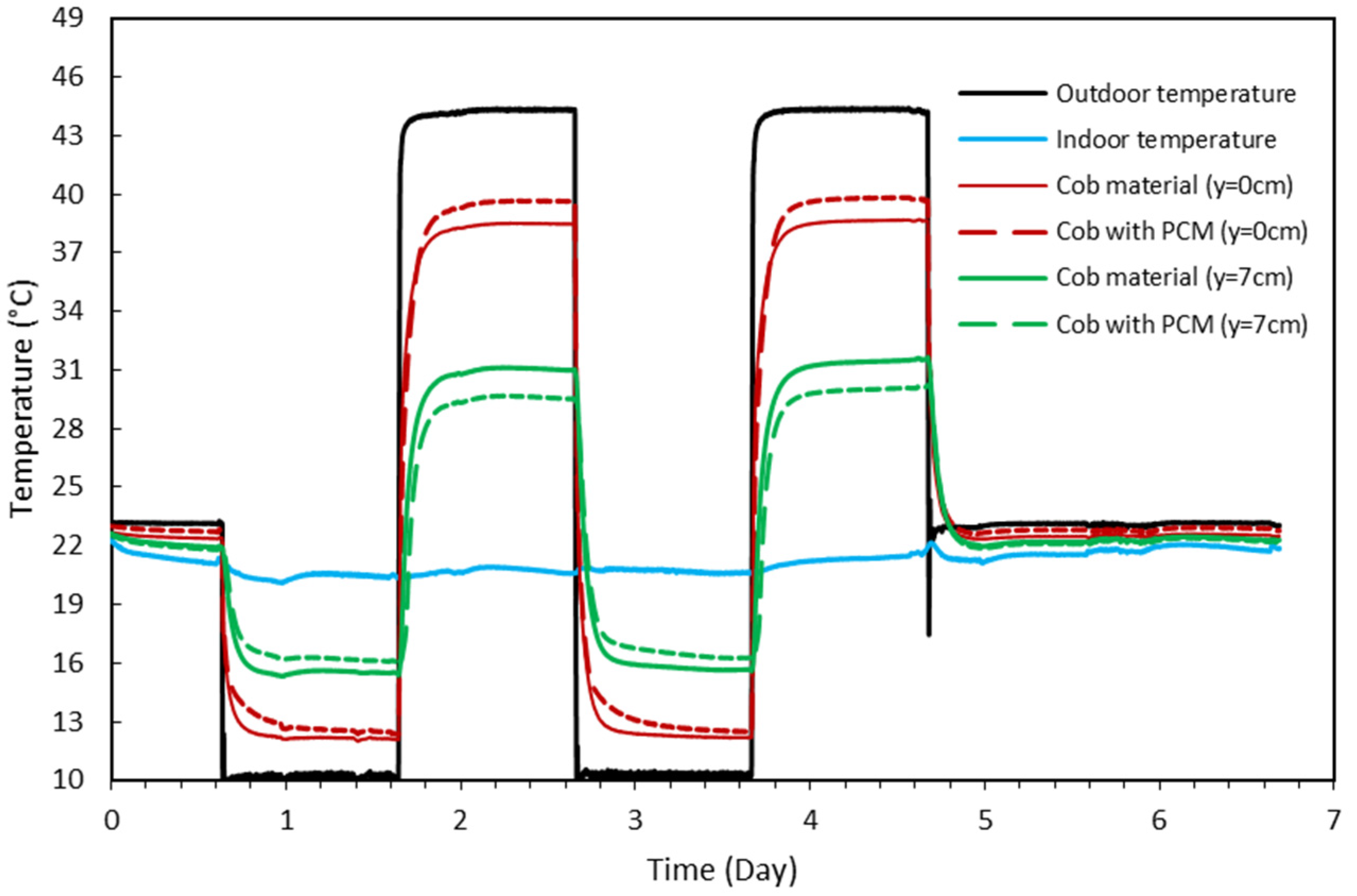

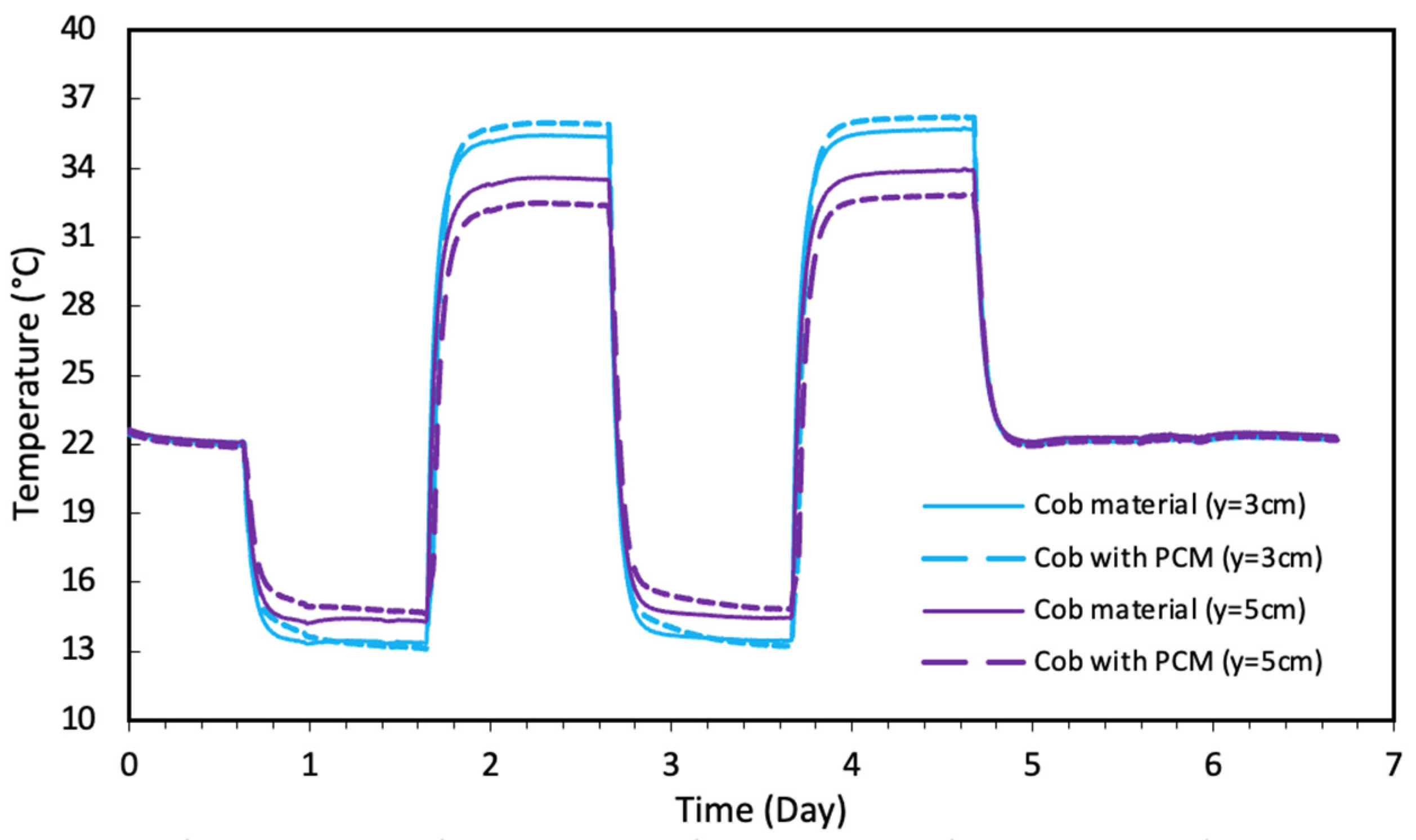

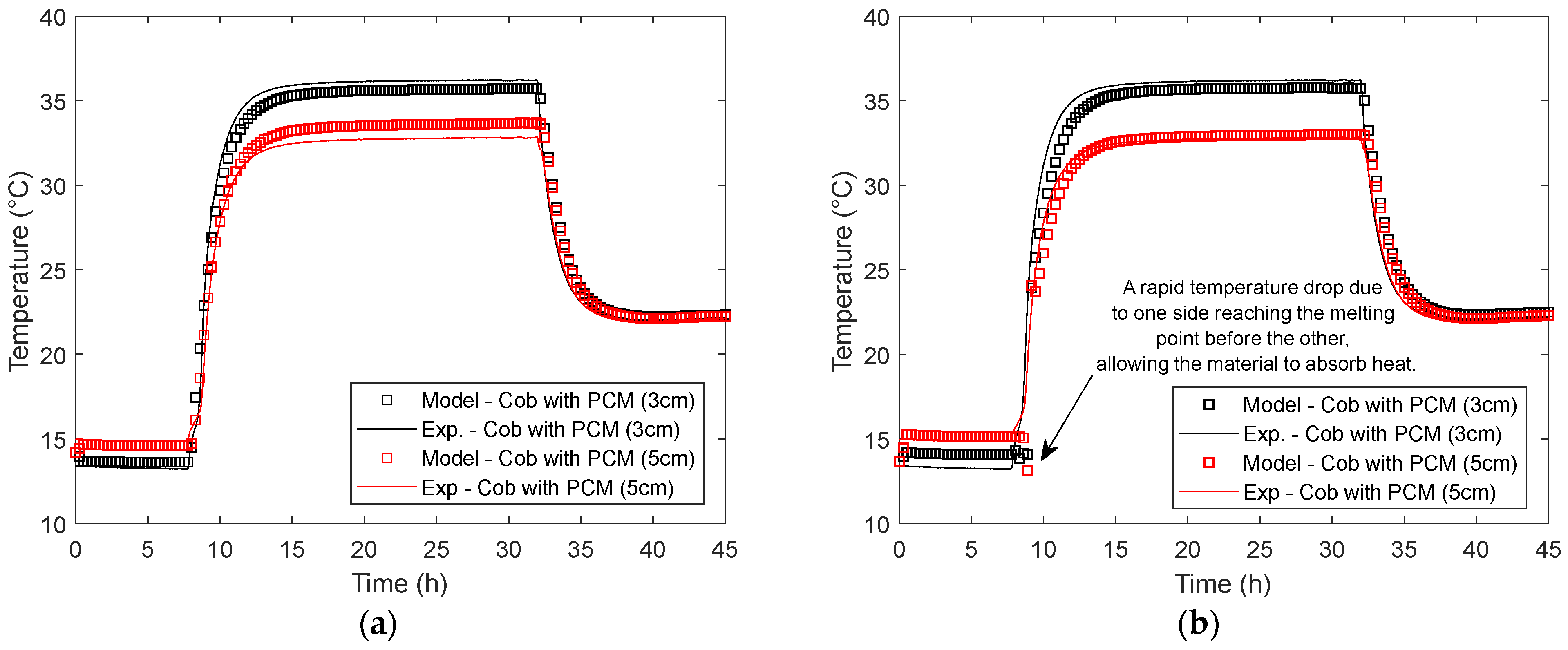

Figure 19 provides a numerical validation of cob material with and without PCM under boundary conditions imposed by the climatic chamber in the experimental of the present study. The model considers 7 cm of thickness, and the initial state corresponds to the mean of all initial measurements.

Figure 19a (cob without PCM) shows a rapid temperature rise and decline, with the model capturing conductive heat transfer with minor deviations due to material inhomogeneities. In

Figure 19b (cob with PCM), the simulation shows a rapid temperature drop at the transition phase (9 h) due to asymmetric heat absorption, as the 3 cm PCM layer reaches its melting temperature of 18 °C first, creating a localized heat sink and causing a sudden thermal gradient. The effect is less pronounced in thicker PCM layers.

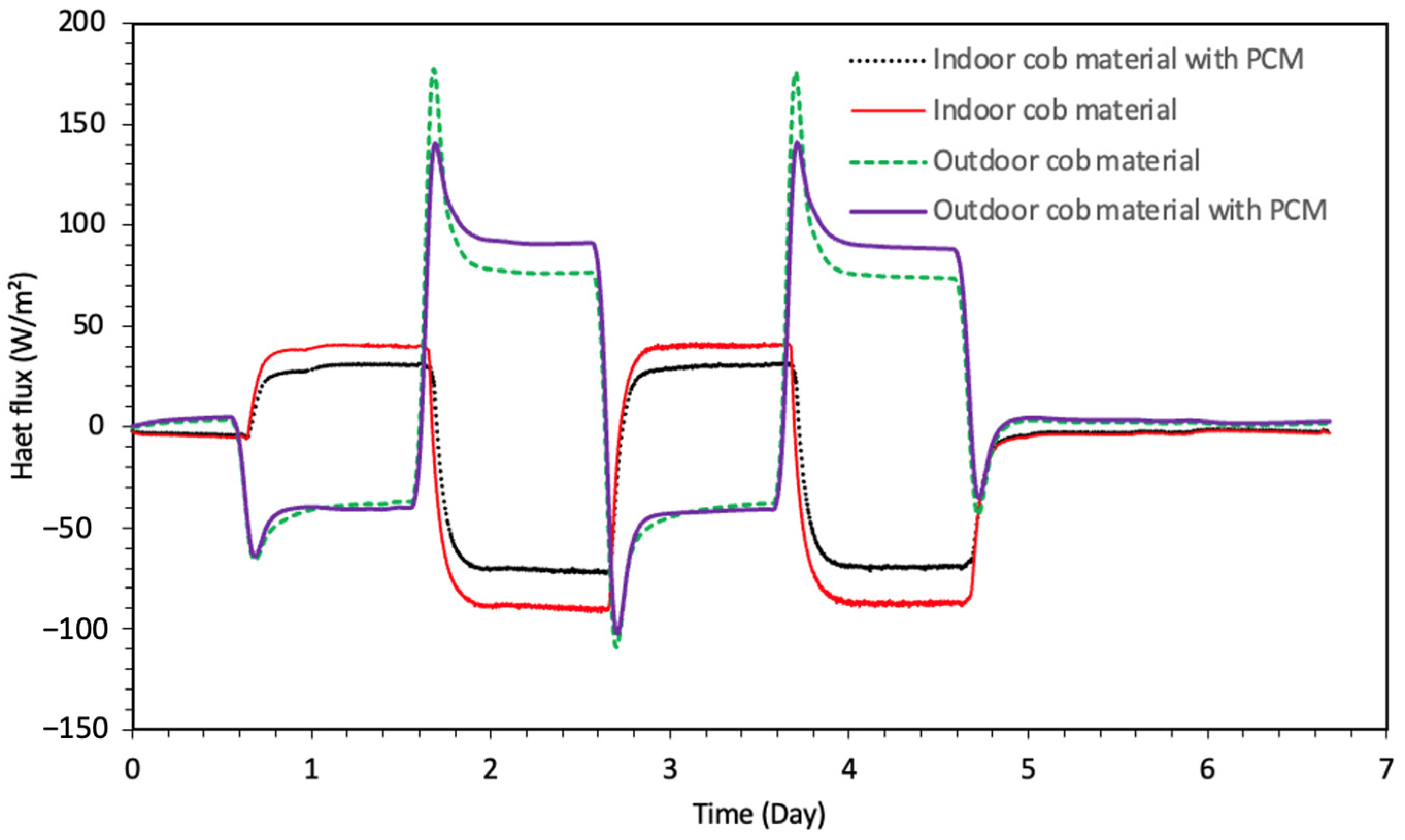

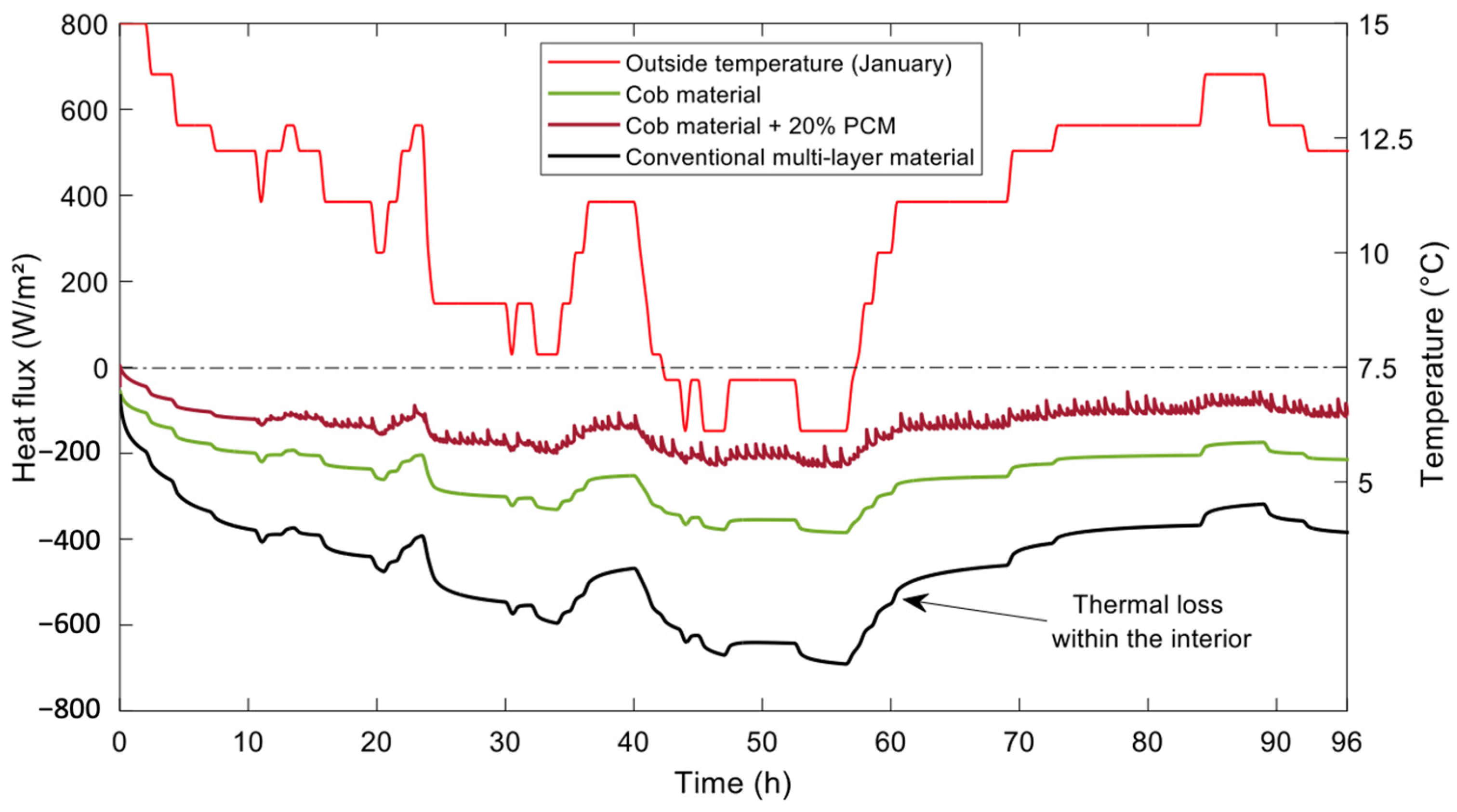

Figure 20 compares the thermal performance of walls made from different materials under fluctuating outside temperatures in January, ranging from approximately 6 °C to 15 °C, with an indoor temperature maintained at 20 °C. Walls built with conventional multi-layer materials exhibit significant heat losses, reaching up to −600 W/m

2 during colder periods. Walls constructed with biobased structural materials reduce these losses to approximately −200 W/m

2. Incorporating 20% PCM into the biobased structural material further enhances thermal stability, limiting heat losses to around −100 W/m

2. The walls made with biobased materials, with or without PCM, outperform walls made with conventional materials. This improvement is due to the lower thermal conductivity and optimized thickness of biobased walls, which enhance their insulating capacity. Adding PCM to biobased walls significantly improves the thermal performance by considering the latent heat storage capacity. When the outside temperature drops sharply, the PCM within the wall releases heat during its phase change, effectively stabilizing the wall’s interior temperature, compared to biobased walls alone. PCM-enhanced walls act as thermal reservoirs.

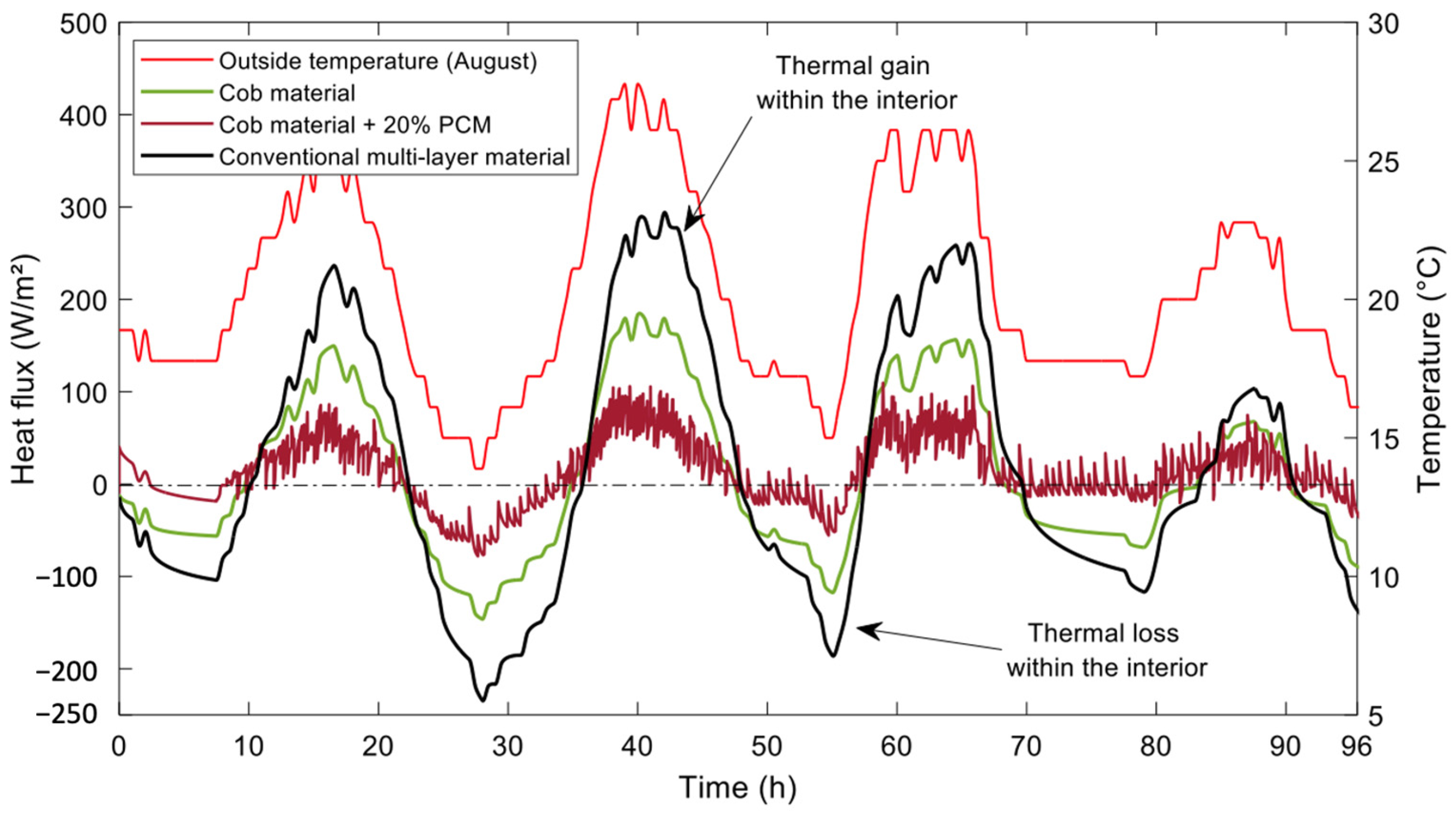

Figure 21 shows the thermal performances under fluctuating outside temperatures in August (15 °C to 28 °C), heat flux is positive when the exterior temperature exceeds 20 °C, indicating inward heat flux (thermal gain), and negative when below 20 °C, showing outward heat flux (thermal loss). PCM-biobased walls significantly outperform conventional and biobased walls in reducing heat flux. The conventional multi-layer wall exhibits the highest heat flux peaks, exceeding +200 W/m

2 during thermal gain and −200 W/m

2 during thermal loss, indicating rapid heat transfer. Biobased walls reduce heat flux to below −120 W/m

2 and 150 W/m

2, leveraging higher thermal inertia. However, PCM-biobased walls show the best performance, with heat flux dampened to around −35 W/m

2 and 50 W/m

2. This is due to the PCM storing thermal energy (enthalpy) during high external temperatures, preventing heat from entering the interior and releasing it during cooling periods. This highlights the PCM’s ability to regulate heat transfer, improve energy efficiency, and maintain stable indoor conditions. Oscillations and noise in the PCM-biobased curve arise from the dynamic phase-change process, as the material absorbs and releases heat intermittently, causing small fluctuations in heat flux due to localized thermal gradients.

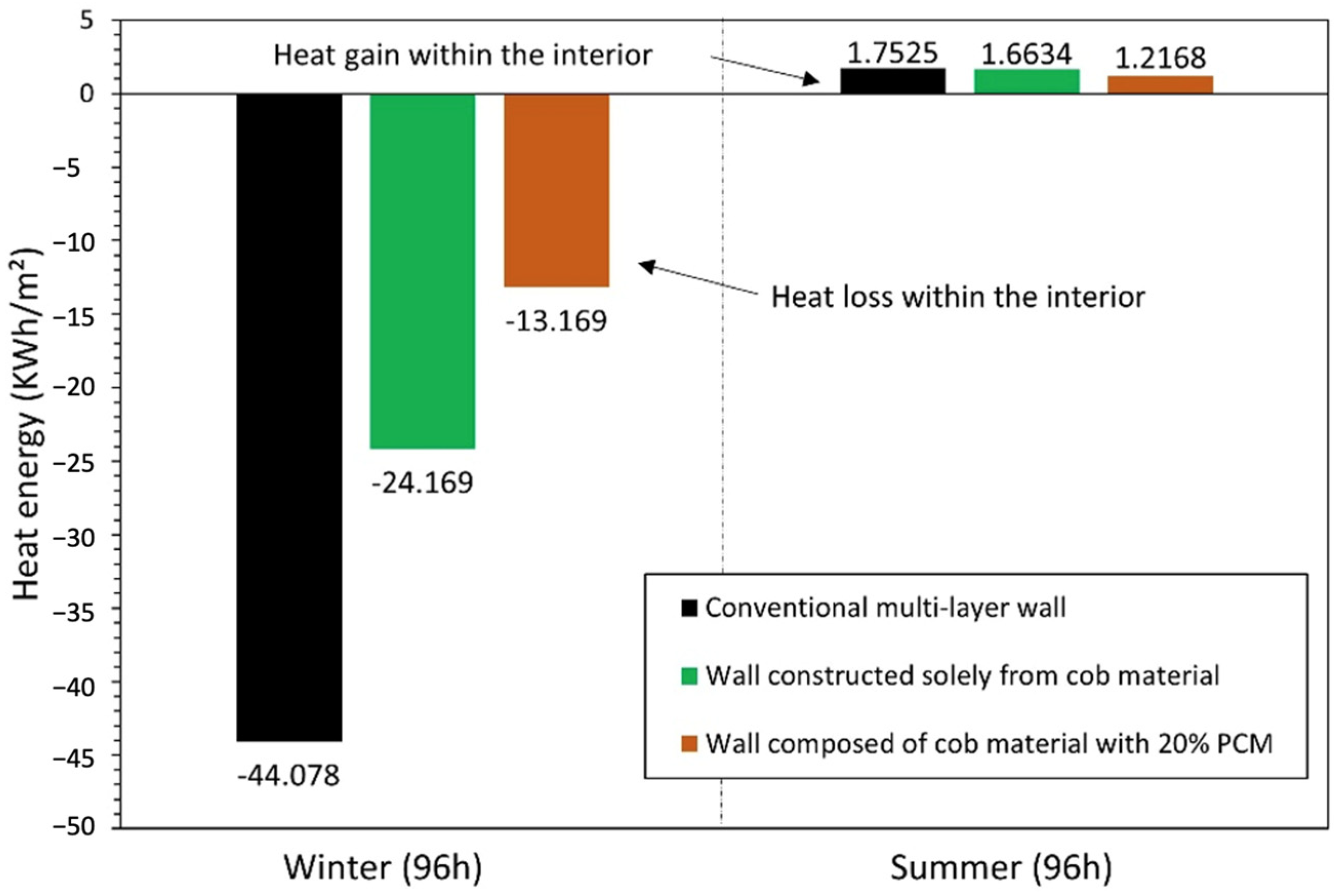

Figure 22 illustrates heat energy within walls over 96 h in winter and summer, comparing three wall materials. In winter, the conventional multi-layer wall loses the most energy at −44.078 kWh/m

2, highlighting poor insulation, while the biobased wall reduces losses to −24.169 kWh/m

2 due to better thermal properties. The biobased wall with 20% PCM performs best, limiting losses to −13.169 kWh/m

2 by storing heat as latent energy and reducing thermal flux. In summer, all walls show net heat gain, as exterior temperatures consistently exceed the interior’s 20 °C. Gains are low due to averaging between variations of thermal gain and loss, with the conventional wall gaining 1.7525 kWh/m

2, the biobased wall gaining 1.6634 kWh/m

2, and the PCM wall gaining only 1.2168 kWh/m

2. PCM effectively buffers temperature fluctuations and outperforms the other materials in both seasons.

5. Conclusions

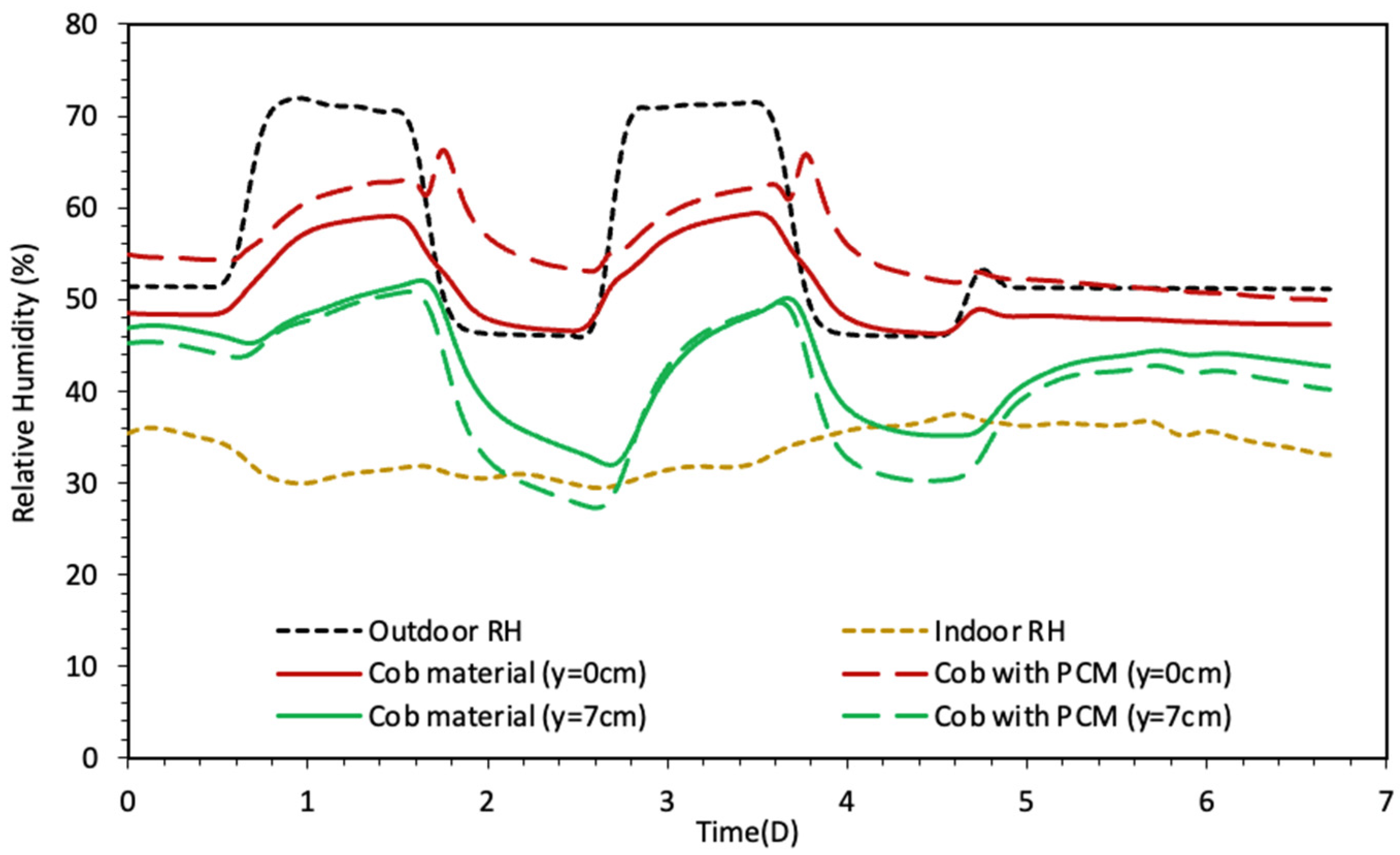

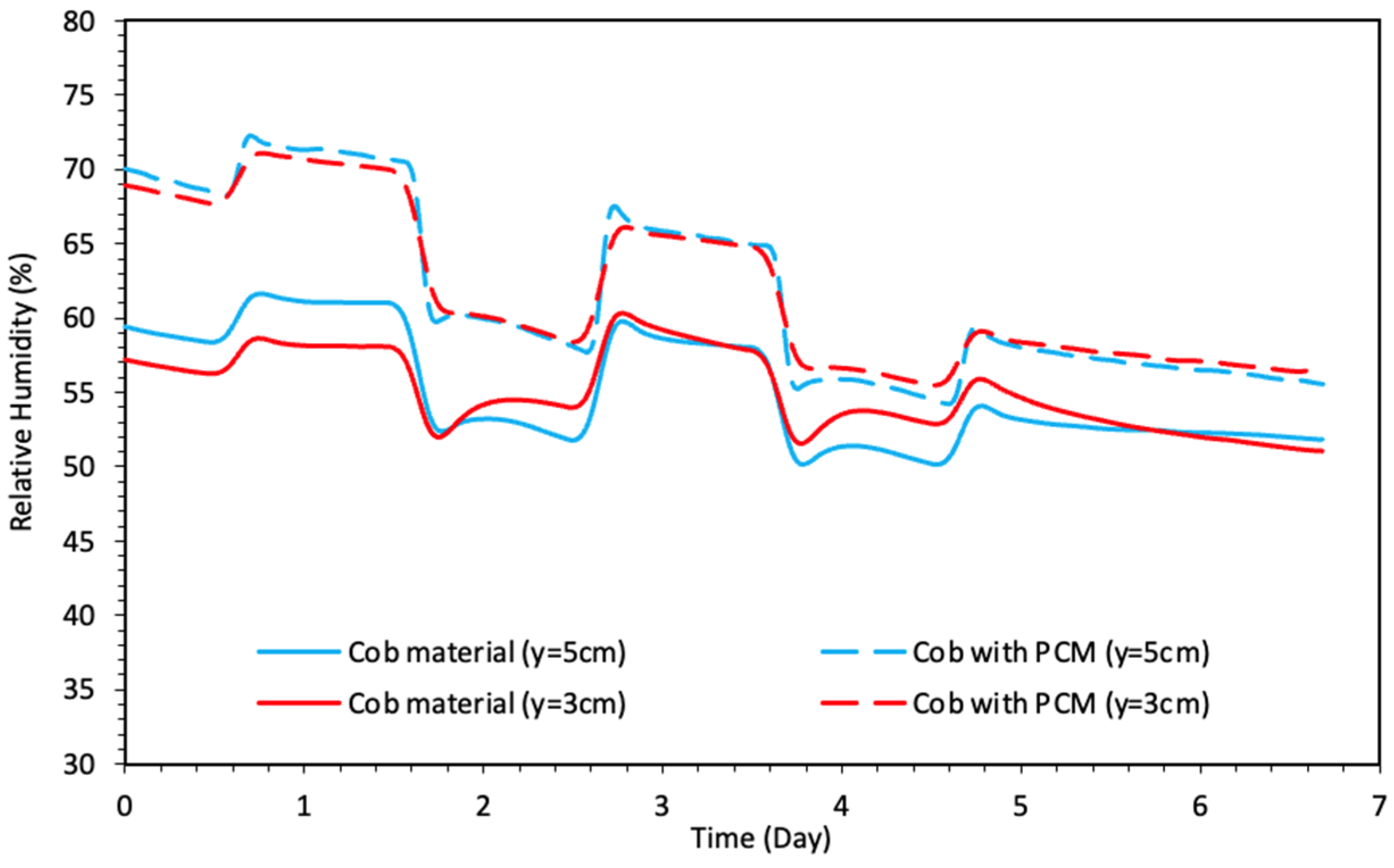

This paper explores the effects of integrating microencapsulated phase-change materials into cob materials to improve their thermal and hygroscopic performance. An experimental setup simulated realistic environmental conditions, with one side exposed to a climate chamber and the other maintained under stable indoor conditions. The results show a homogeneous thermal and hygroscopic distribution, with minimal temperature variations (≈0.02 °C) and a uniform distribution of relative humidity, confirming the one-dimensional profiles essential for stable performance.

Samples containing PCM demonstrated improved thermal and hygroscopic regulation. These materials absorb and release heat in a controlled manner, providing improved thermal insulation and attenuating temperature variations. In terms of humidity, PCM enables better management by absorbing and releasing moisture according to ambient conditions.

In addition, the integration of PCM reduces the thermal conductivity of the cob and increases its thermal capacity by up to 2.6 times that of conventional cob at phase transition, improving energy storage and thermal regulation. These results highlight the potential of PCM to optimize building materials from a sustainable bioclimatic perspective.

Finally, a simulation was carried out to study the impact of wall materials on thermal performance, taking into account the transient thermal equation. This study compared three scenarios: a 70 cm wall made entirely of cob, a 70 cm wall with 20% phase-change material (PCM), and a conventional 30 cm multi-layer wall made of concrete, polystyrene, and gypsum. The results show that cob walls, with or without PCM, reduce heat flux more than conventional walls. The integration of PCMs improves thermal regulation and energy efficiency, offering a sustainable solution for bioclimatic construction while notably reducing the ecological footprint and contributing to comfort.