Investigation on Mix Proportions of Ultra-High Performance Concrete with Recycled Powder and Recycled Sand

Abstract

1. Introduction

2. Experimental Materials

2.1. Cementitious Materials

2.1.1. Cement

2.1.2. Silica Fume

2.1.3. Recycled Powder

2.2. Fine Aggregate

2.2.1. Natural Sand

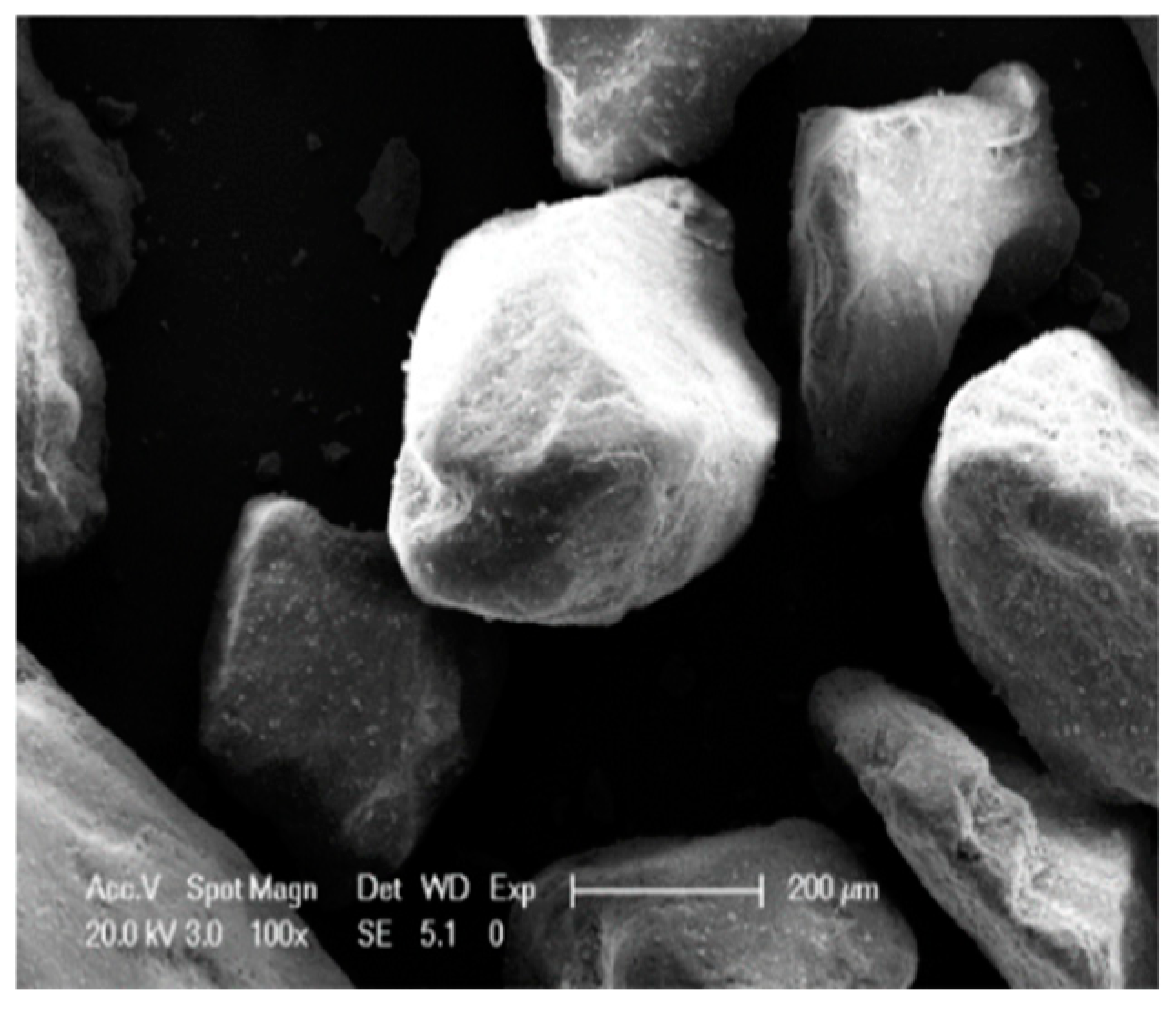

2.2.2. Recycled Sand

2.3. Steel Fiber

2.4. Superplasticizer

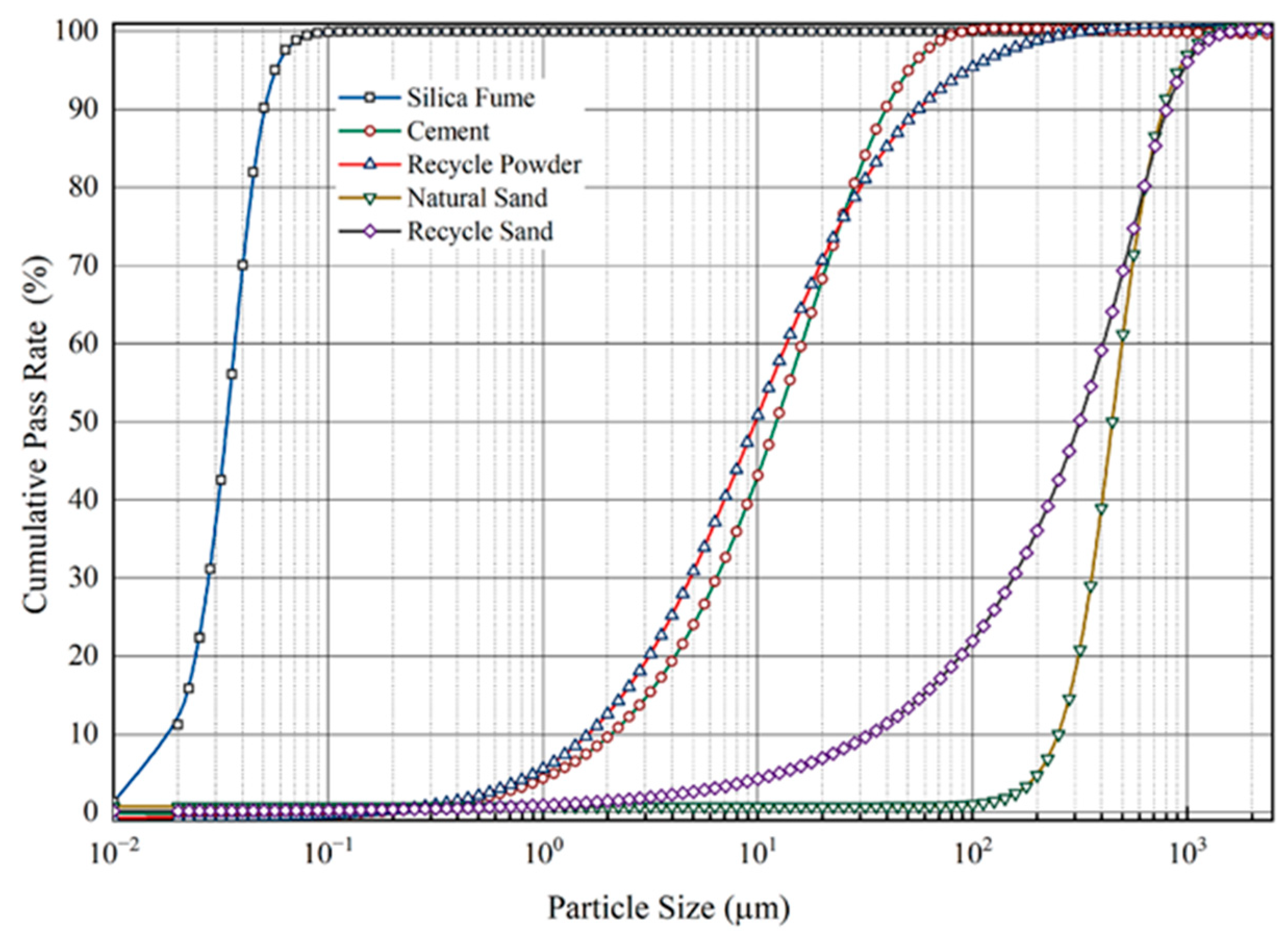

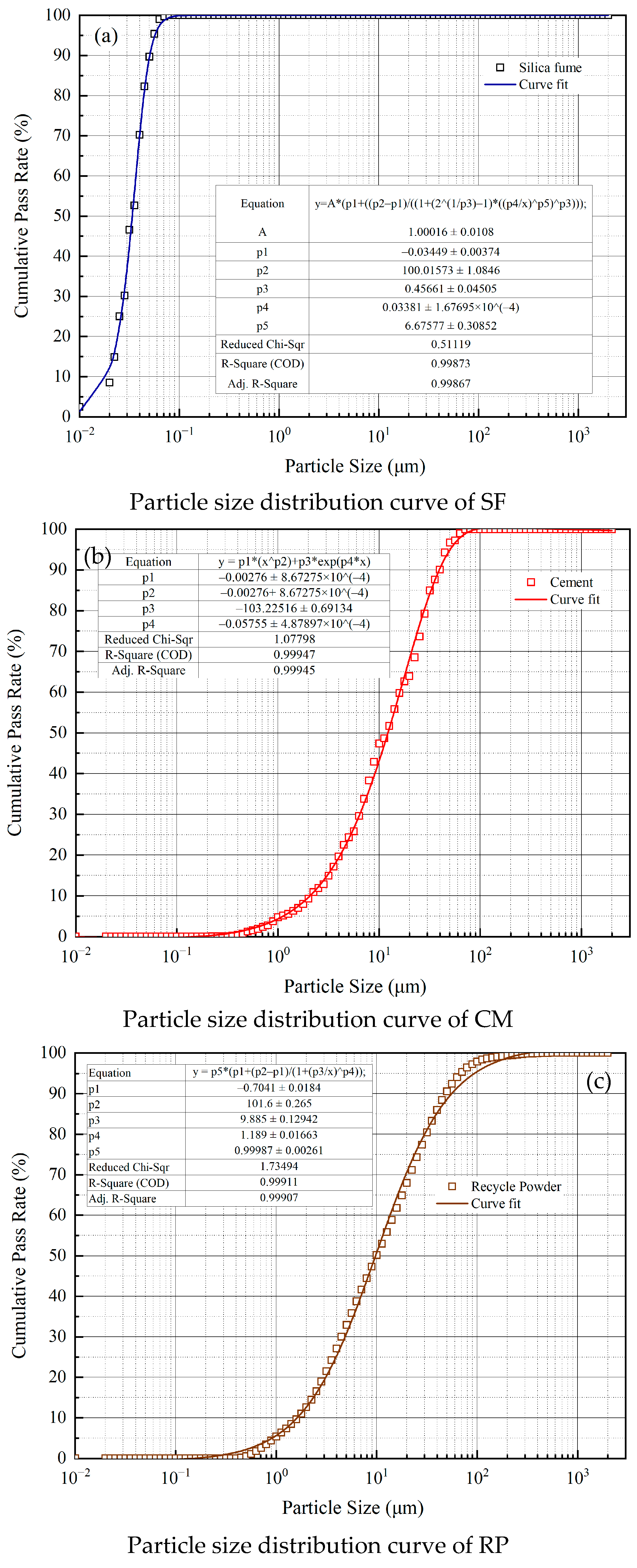

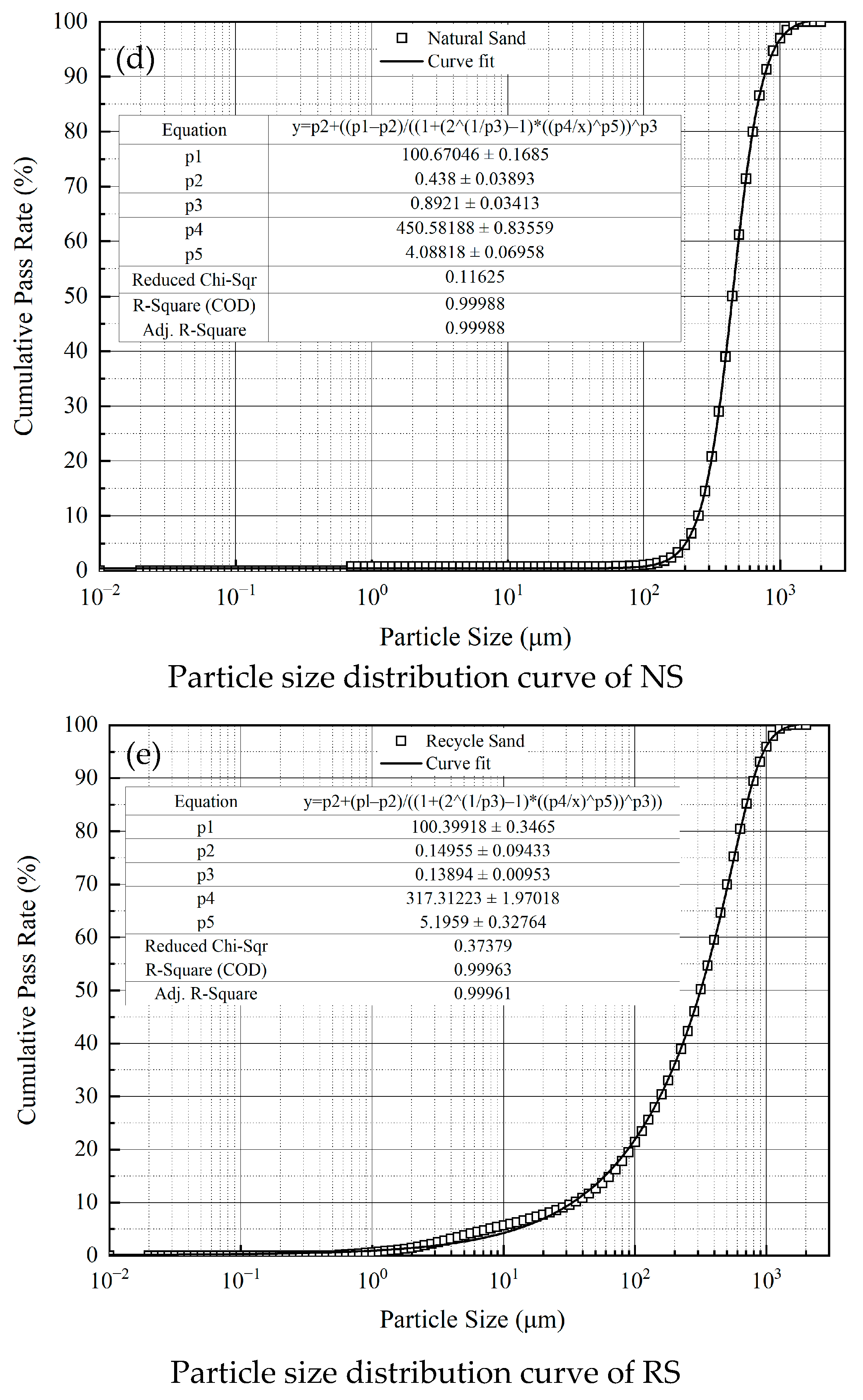

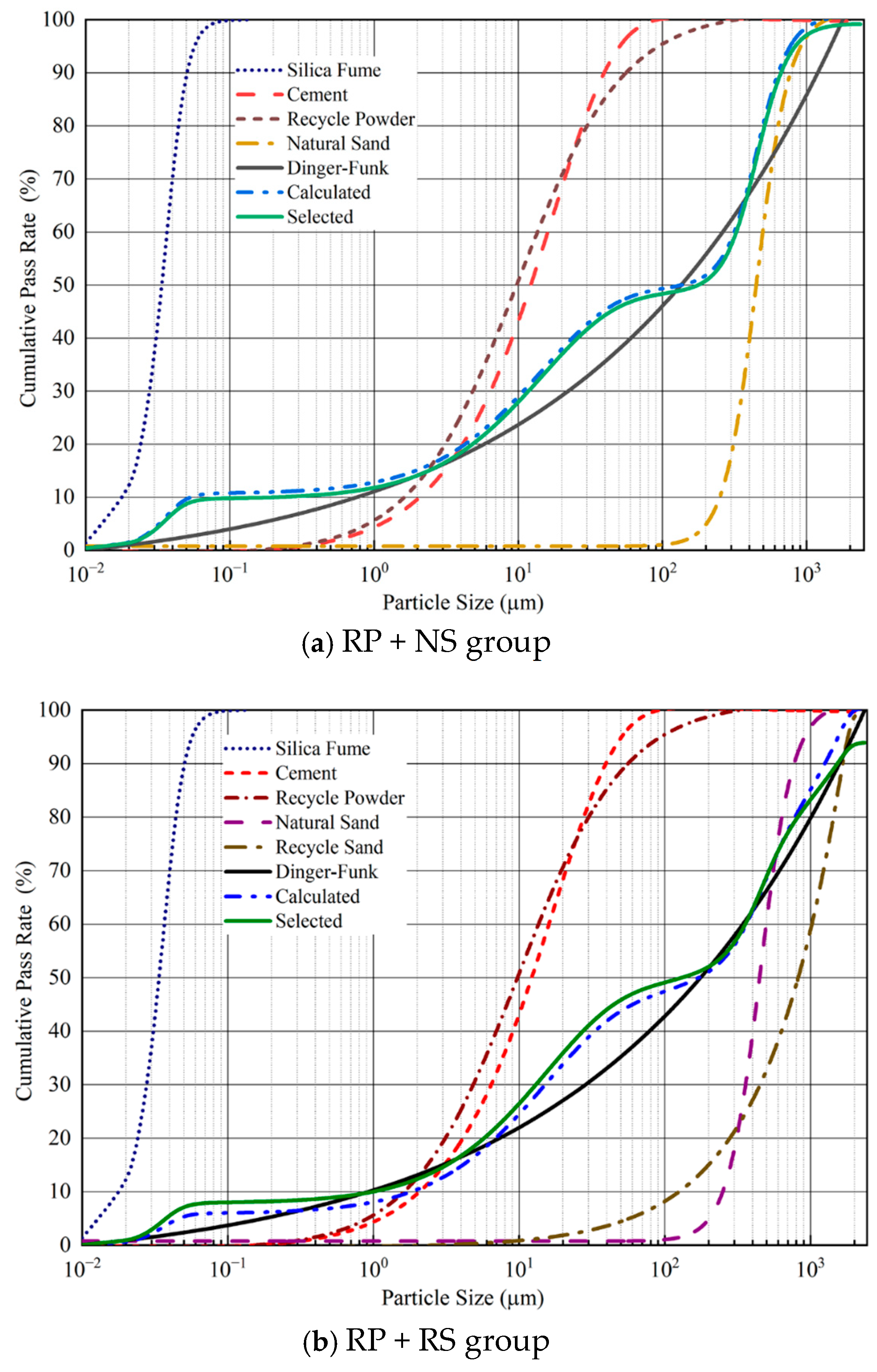

2.5. Size Distribution

3. Optimization Design of UHPC Mix Proportions Based on Dinger–Funk Model

3.1. Dinger–Funk Model

- —The volume fraction of particles with a particle size smaller than ;

- —Particle size or screen size;

- ,—The Maximum and minimum particle size in the system;

- —Distribution index.

3.2. Mix Proportion Optimization Design

4. Specimen Fabrication and Test Methods

5. Experimental Program

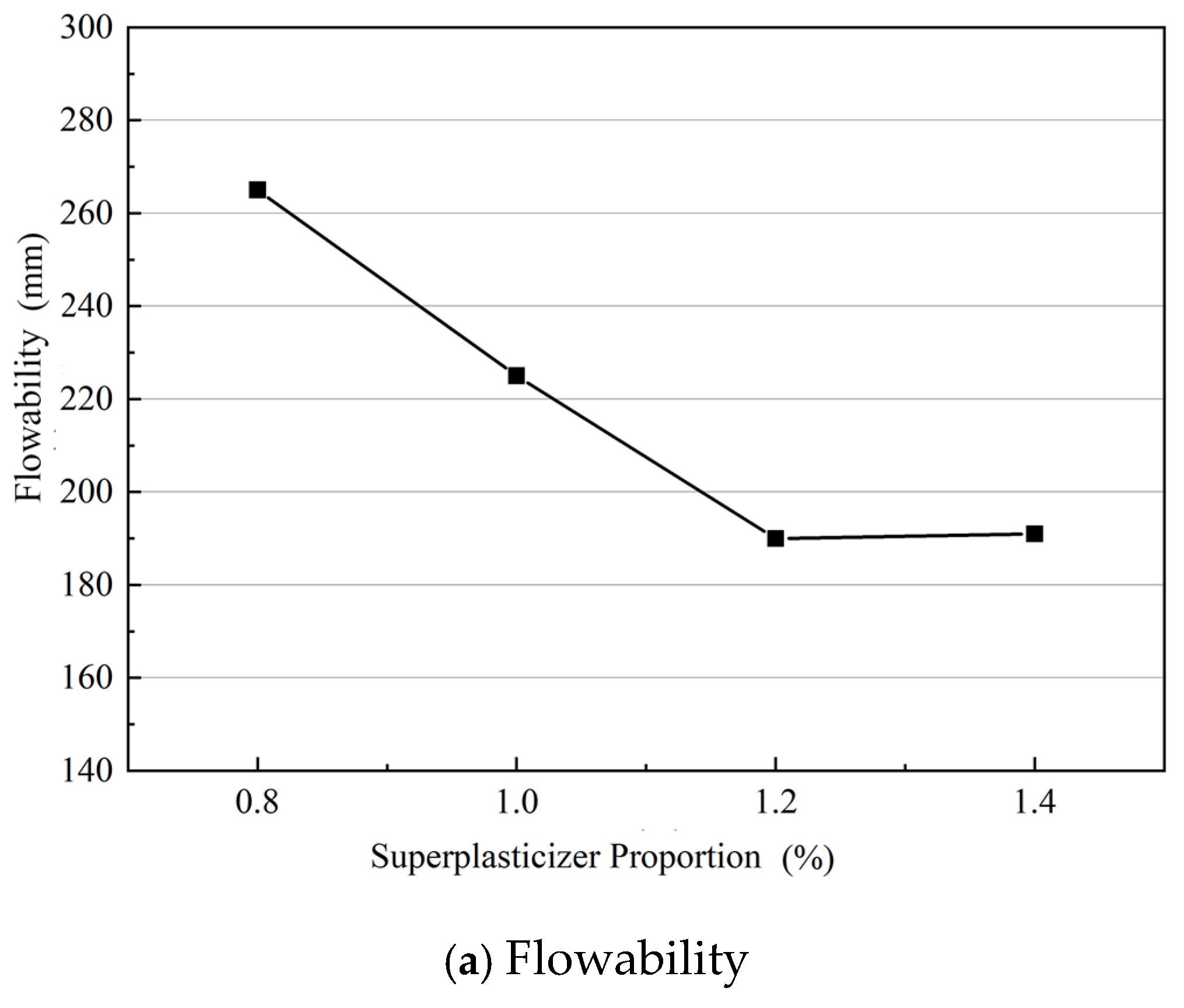

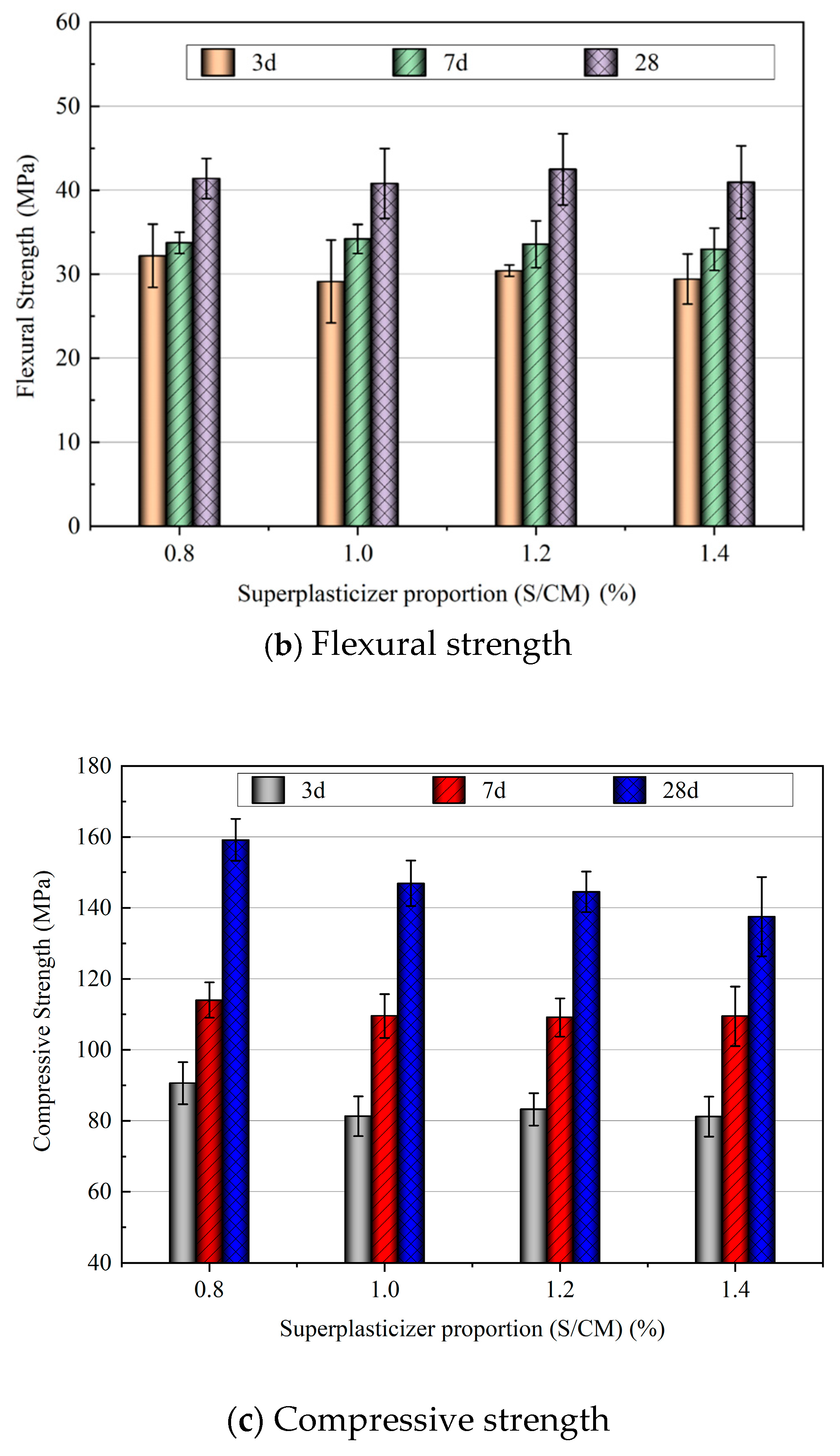

5.1. Superplasticizer Proportion

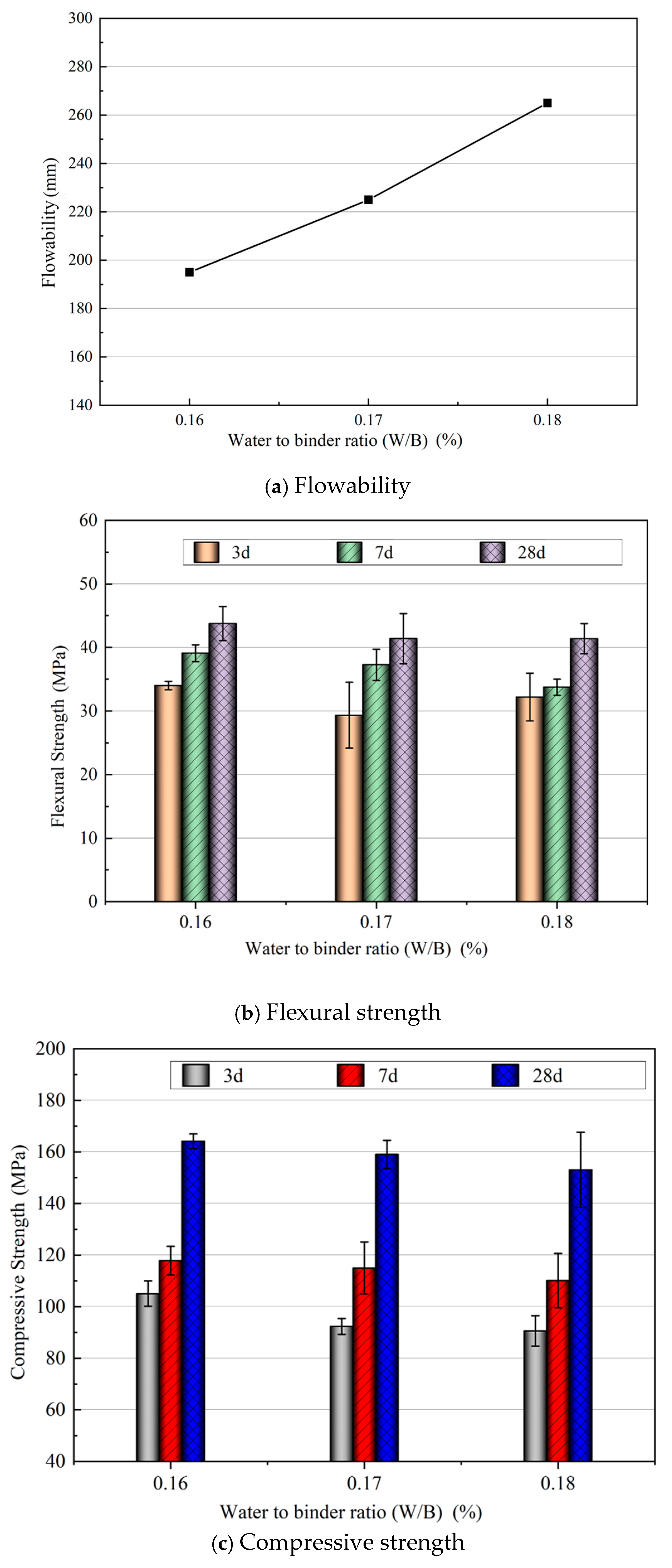

5.2. Water–Binder Ratio

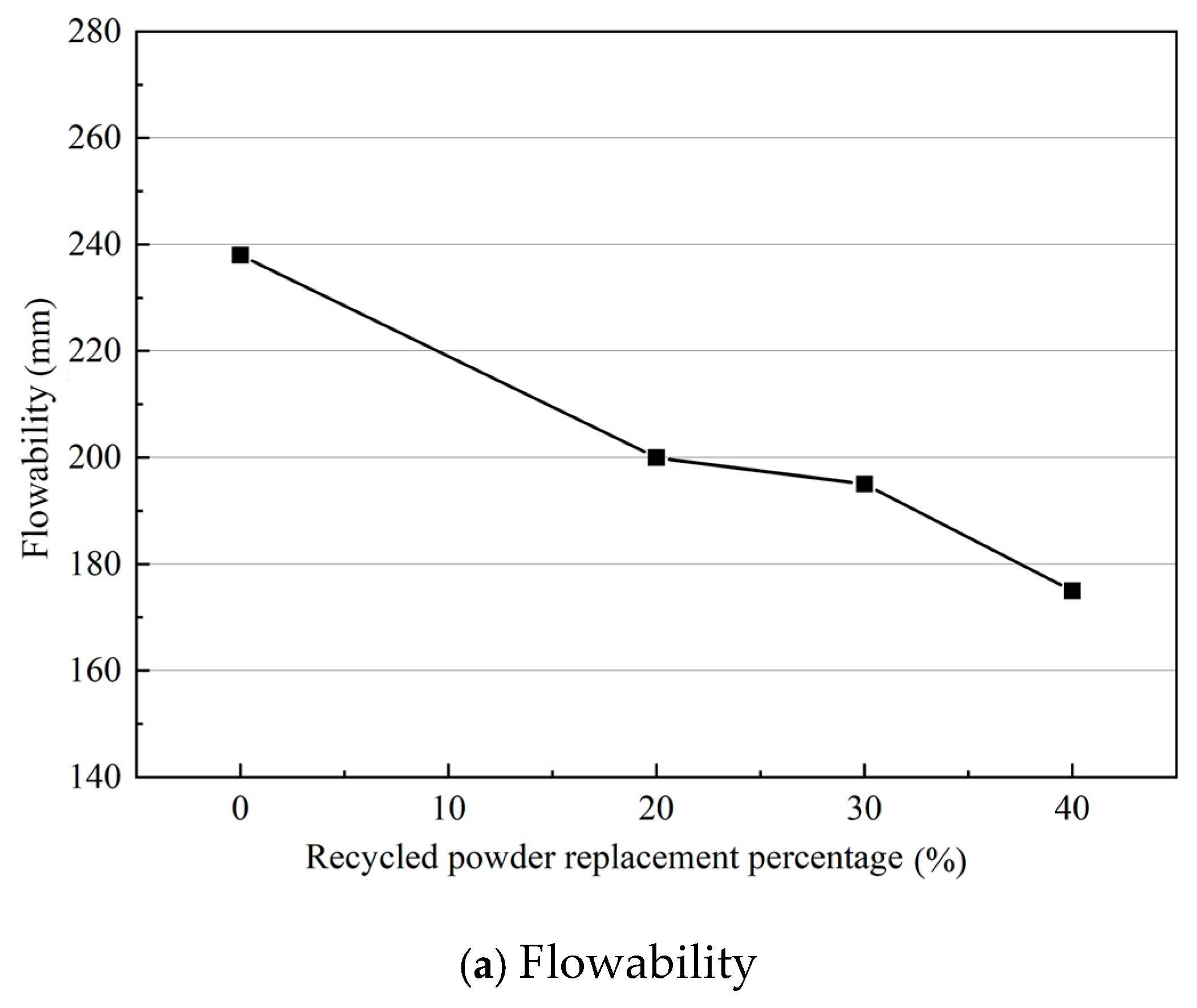

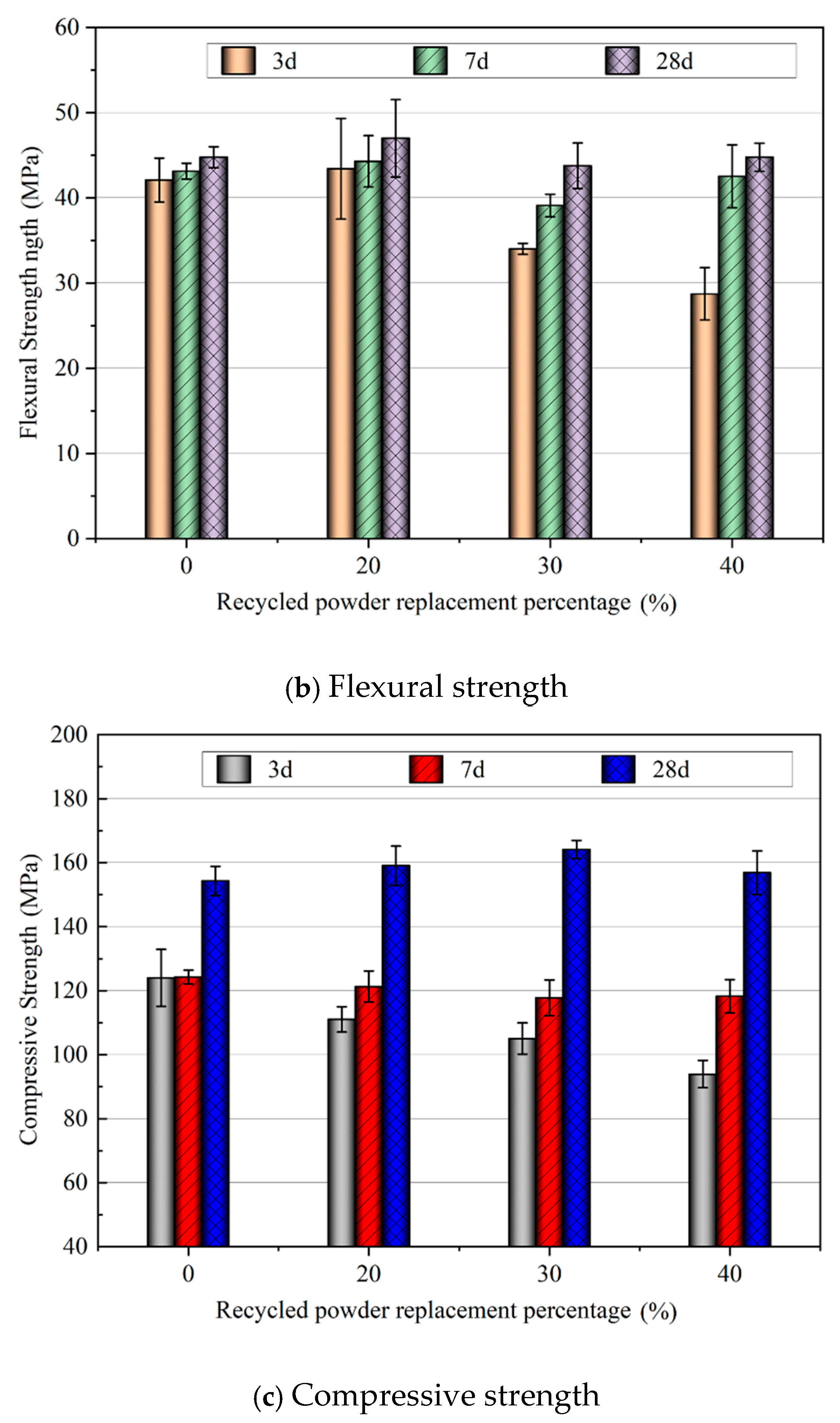

5.3. Substitution Rate of Recycled Powder

- —Compressive strength of concrete, MPa;

- m—Mass percentage of CM in the total mass of RP and CM, %.

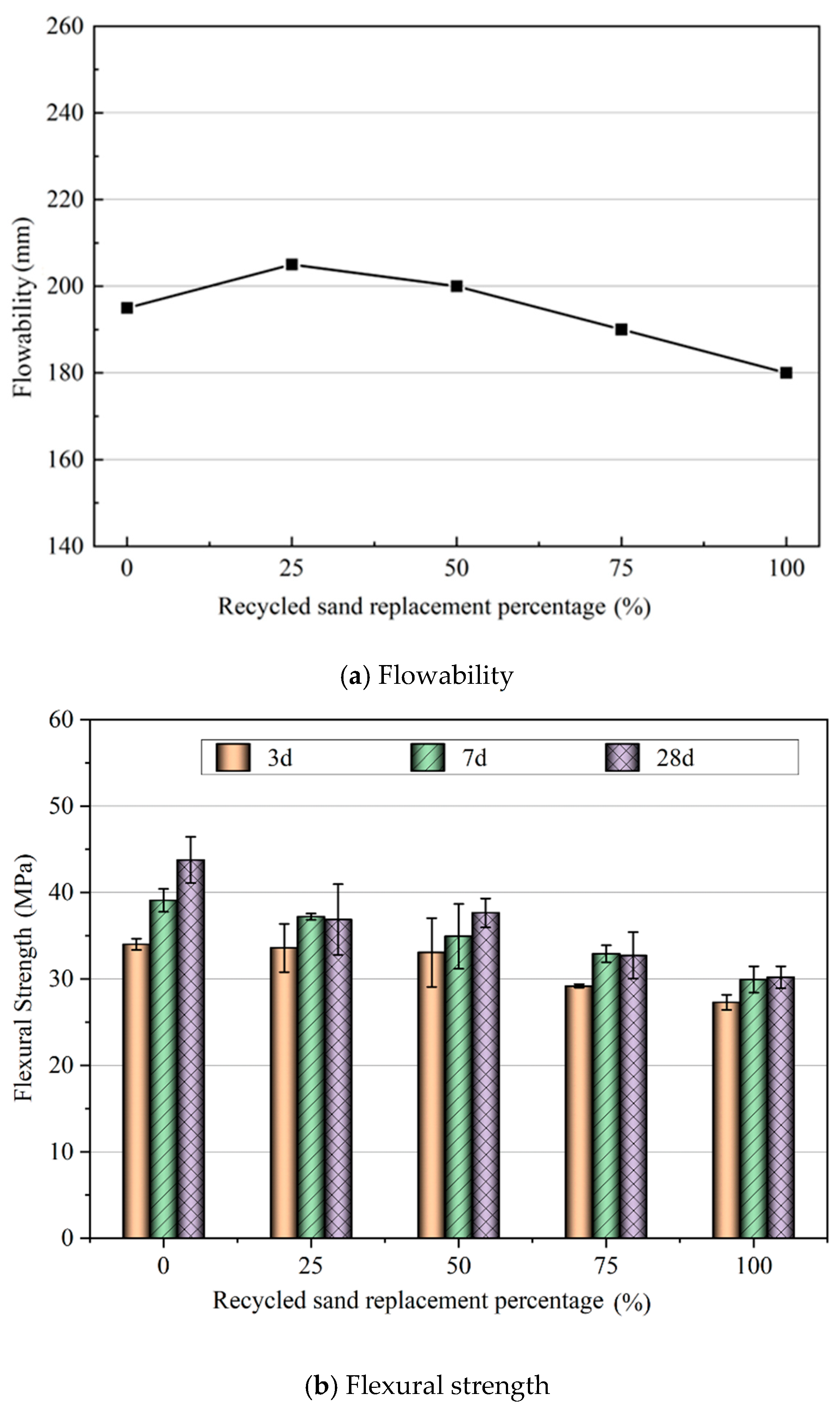

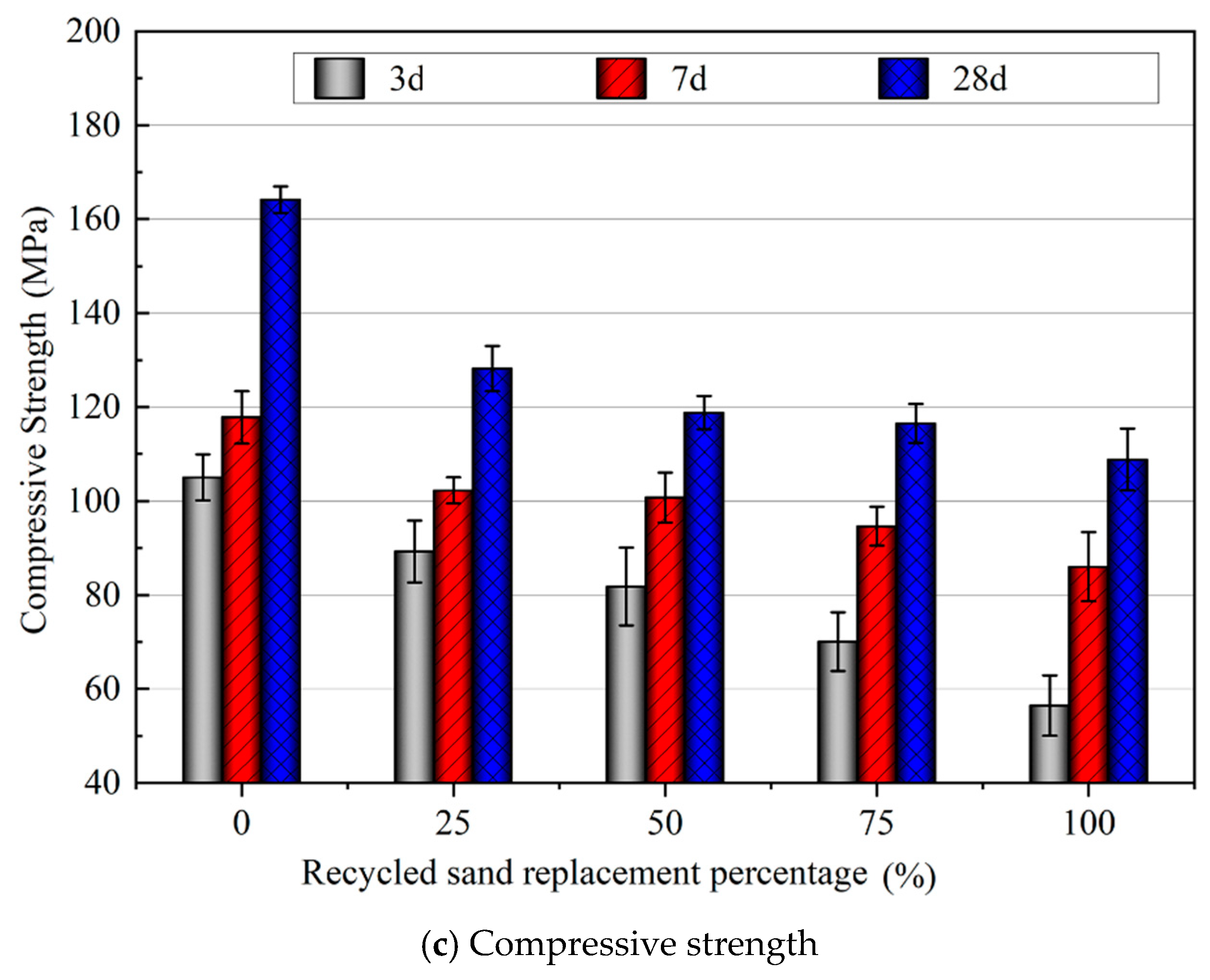

5.4. Substitution Rate of RS

6. Conclusions

- (1)

- When SP/CM was 0.8%, the flowability and the 28 d compressive strength of the GUHPC mixture were the largest, and thus, the SP/CM of 0.8% was selected. With increases in the water–binder ratio, the flowability of the GUHPC increased and the flexural and compressive strength decreased. For a water–binder ratio of 0.16, 0.17 and 0.18, the flowability was higher than 180 mm. Thus, the water–binder ratio of 0.16 was selected.

- (2)

- With increases in RP, the flowability of the GUHPC decreased, the 3 d and 7 d flexural strength increased first and then decreased, the 28 d flexural strength changed little, the 3 d and 7 d compressive strength decreased, and the 28 d compressive strength increased first and then decreased. The 28 d compressive strength of the GUHPC with an RP replacement rate of 30% was the highest.

- (3)

- With increases in the RP, the relative strength at each age increased, indicating that RP can enhance the contribution of cement to the strength of GUHPC. With increases in age, the relative strength of the different RP substitutes increased, indicating that the enhancement effect of RP increased with increases in age. The comprehensive contribution rate of the RP gradually increased with increases in RP and age. Based on the comprehensive analysis and also the performance of the concrete, an RP replacement rate of 30% is selected.

- (4)

- With increases in RS, the flowability of the GUHPC first increased and then decreased, and the flexural strength and compressive strength at each age decreased. With increases in RS, the f:c at 3 d of age increased, the f:c at 7 d of age had no significant change, and the f:c at 28 d of age first increased and then decreased. Considering the flowability, strength and toughness of GUHPC, the RS replacement rate of 50% was selected.

- (5)

- GUHPC can be produced by using RP and RS simultaneously with standard curing instead of steam curing. The optimal mix proportion was determined considering the flowability, mechanical properties and substitution rate of RP and RS. Furthermore, the proportion design method for GUHPC with RP and RS based on the revised Dinger–Funk model was also verified.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhu, P.; Mao, X.Q.; Qu, W.J.; Li, Z.Y.; Ma, Z.J. Investigation of using recycled powder from waste of clay bricks and cement solids in reactive powder concrete. Constr. Build. Mater. 2016, 30, 246–254. [Google Scholar]

- Xue, C.; Shen, A.; Guo, Y. Utilization of construction waste composite powder materials as cementitious materials in small-scale prefabricated concrete. Adv. Mater. Sci. Eng. 2016, 2016, 8947935. [Google Scholar] [CrossRef]

- Janotka, I.; Martauz, P.; Bačuvčík, M. Design of concrete made with recycled brick waste and its environmental performance. Minerals 2021, 11, 463. [Google Scholar] [CrossRef]

- Zhu, P.; Mao, X.Q.; Qu, W.J. Investigation of recycled powder as supplementary cementitious material. Mag. Concr. Res. 2019, 71, 1312–1324. [Google Scholar]

- Mao, X.Q.; Qu, W.J.; Zhu, P. Mixture optimization of green reactive powder concrete with recycled powder. J. Mater. Civ. Eng. 2019, 31, 1–11. [Google Scholar] [CrossRef]

- Mao, X.Q.; Qu, W.J.; Zhu, P.; Xiao, J.Z. Influence of recycled powder on chloride penetration resistance of green reactive powder concrete. Constr. Build. Mater. 2020, 251, 119049. [Google Scholar] [CrossRef]

- Cantero, B.; Bravo, M.; De Brito, J. Thermal performance of concrete with recycled concrete powder as partial cement replacement and recycled CDW aggregate. Appl. Sci. 2020, 10, 4540. [Google Scholar] [CrossRef]

- Mohamed, A.; Ibrahim, Y.H.; Abdullah, M.Z.; Bassam, A.T.; Ahmed, M.M.; Ibrahim, S.A. Influence of recycled aggregates and carbon nanofibres onproperties of ultra-high-performance concrete under elevated temperatures. Case Stud. Constr. Mater. 2022, 16, e01063. [Google Scholar]

- Zhou, Y.W.; Guo, D.C. Multiscale mechanical characteristics of ultra-high-performance concrete incorporating different particle size ranges of recycled fine aggregate. Constr. Build. Mater. 2021, 30, 246–254. [Google Scholar]

- Ma, Z.; Liu, X.; Hu, R. Using recycled aggregate and powder from high-strength mortar waste for durable cement-based materials: Microstructure and chloride transport. J. Clean. Prod. 2023, 417, 137998. [Google Scholar]

- Salahuddin, H.; Qureshi, L.A.; Nawaz, A. Elevated temperature performance of reactive powder concrete containing recycled fine aggregates. Materials 2020, 13, 3748. [Google Scholar] [CrossRef] [PubMed]

- Yu, L.; Wu, R. Using graphene oxide to improve the properties of ultra-high-performance concrete with fine recycled aggregate. Constr. Build. Mater. 2020, 259, 120657. [Google Scholar] [CrossRef]

- Chu, H.; Zhang, Y.; Wang, F. Effect of graphene oxide on mechanical properties and durability of ultra-high-performance concrete prepared from recycled sand. Nanomaterials 2020, 10, 1718. [Google Scholar] [CrossRef] [PubMed]

- Mao, X.Q. Study on Green Reactive Powder Concrete (GRPC). Ph.D. Thesis, Tongji University, Shanghai, China, 2019. [Google Scholar]

- Dinger, D.R.; Funk, J.E. Particle-packing phenomena and their application in materials processing. MRS Bull. 1997, 22, 19–23. [Google Scholar] [CrossRef]

- Funk, J.E.; Dinger, D.R. Predictive Process Control of Crowded Particulate Suspensions: Applied to Ceramic Manufacturing; Springer: Boston, MA, USA, 2013. [Google Scholar]

- Martin, H. An integral Design Concept for Ecological Self-Compacting Concrete. Ph.D. Thesis, Technische Universiteit Eindhoven, Eindhoven, The Netherlands, 2010. [Google Scholar]

- Yu, Q.L.; Spiesz, P.; Brouwers, H.J.H. Development of cement-based lightweight composites—Part 1: Mix design methodology and hardened properties. Cem. Concr. Compos. 2013, 44, 17–29. [Google Scholar] [CrossRef]

- Yu, R.; Spiesz, P.; Brouwers, H.J.H. Mix design and properties assessment of ultra-high performance fibre reinforced concrete (UHPFRC). Cem. Concr. Res. 2014, 56, 29–39. [Google Scholar] [CrossRef]

- GB 175-2007; PRC National Standard. General Purpose Portland Cement. Standards Press of China: Beijing, China, 2008.

- Wang, X.; Yu, R.; Shui, Z. Optimized treatment of recycled construction and demolition waste in developing sustainable ultra-high-performance concrete. J. Clean. Prod. 2019, 221, 805–816. [Google Scholar]

- Ahmet, F.Ş.; Cenk, K. High-strength self-compacting concrete produced with recycled clay brick powders: Rheological, mechanical and microstructural properties. J. Build. Eng. 2024, 88, 109175. [Google Scholar]

- Heikal, M.; Zohdy, K.M.; Abdelkreem, M. Mechanical, microstructure and theological characteristics of high performance self-compacting cement pastes and concrete containing ground clay bricks. Constr. Build. Mater. 2013, 38, 101–109. [Google Scholar]

- Pu, X.C. Ultra-High-Performance Concrete; Chongqing University Press: Chongqing, China, 2004. [Google Scholar]

- Salahuddin, H.; Qureshi, L.A.; Nawaz, A. Effect of recycled fine aggregates on performance of Reactive Powder Concrete. Constr. Build. Mater. 2020, 243, 118223. [Google Scholar] [CrossRef]

| Component | SiO2 (%) | Al2O3 (%) | Fe2O3 (%) | CaO (%) | Mg (%) | Na2O (%) | K2O (%) | SO3 (%) |

|---|---|---|---|---|---|---|---|---|

| CM | 15.40 | 6.05 | 4.32 | 64.47 | 1.25 | 0.11 | 1.22 | 2.01 |

| RP | 59.74 | 16.90 | 6.93 | 8.47 | 1.82 | 1.29 | 2.21 | 1.37 |

| SF | 92.40 | 0.87 | 0.10 | 0.43 | 1.56 | 0.08 | 0.33 | - |

| Density (kg/m3) | LOI (%) | Fineness (%) | Specific Surface Area (m2/kg) | Initial Setting Time | Final Setting Time | Flexural Strength (MPa) | Compressive Strength (MPa) | ||

|---|---|---|---|---|---|---|---|---|---|

| (min) | (min) | 3d | 28d | 3d | 28d | ||||

| 3180 | 3.02 | 6.18 | 357 | 203 | 250 | 5.9 | 7.7 | 27.4 | 45.0 |

| Density (kg/m3) | LOI (%) | Fineness (%) | Specific Surface Area (m2/kg) | Water Content (%) | Water Demand Ratio (%) | Activity Index(%) |

|---|---|---|---|---|---|---|

| 2200 | 3.12 | 2.34 | 18,900 | 0.67 | 114 | 121 |

| Raw Material | Milling Time (min) | Power Consumption (kwh/kg) | Fineness (%) | Density (g/cm3) |

|---|---|---|---|---|

| CM | - | - | 6.18 | 3.18 |

| BP | 30 | 0.15 | 14.91 | - |

| BP | 60 | 0.30 | 6.67 | 2.58 |

| CP | 90 | 0.45 | 22.54 | 2.51 |

| RP (BP:CP = 7:3) | 90 | 0.45 | 6.84 | 2.56 |

| RP (BP:CP = 7:3) [14] | - | - | 6.77 | 2.60 |

| Screen Size (mm) | Cumulative Screening Margin (%) | |

|---|---|---|

| RS | NS | |

| 9.50 | 0.0 | 0.0 |

| 4.75 | 0.0 | 0.0 |

| 2.36 | 0.0 | 0.0 |

| 1.18 | 40.7 | 1.7 |

| 0.60 | 58.5 | 42.3 |

| 0.30 | 83.9 | 93.2 |

| 0.15 | 92.0 | 99.0 |

| Fine Aggregate | NS | RS |

|---|---|---|

| Grain size (mm) | 0.08–1.18 | 0.08–2.36 |

| Apparent density (kg/m3) | 2550 | 2528 |

| Bulk density (kg/m3) | 1582 | 1250 |

| Loose density (kg/m3) | 1353 | 1105 |

| Fineness modulus | 2.36 | 2.75 |

| Porosity (%) | 40 | 50 |

| Water absorption (%) | 0.8 | 11.8 |

| Length (mm) | Diameter (mm) | Length Diameter Ratio | Tensile Strength (MPa) | Quantity of Fiber per Gram |

|---|---|---|---|---|

| 14 | 0.22 | 65 | ≥2000 | 230 |

| Performance Index | Value |

|---|---|

| Solid content (%) | 50.26 |

| pH value | 6.5 ± 1.0 |

| Density (g/cm3, 22 °C) | 1.10 ± 0.05 |

| Viscosity (cP, 22 °C) | <2000 |

| Water-reducing rate (%) | 30.0 |

| Flowability (mm) | 290 |

| Chlorine ion content (%) | 0.05 |

| Total alkali content (%) | 2.0 |

| Composition | SF | CM | RP | NS |

|---|---|---|---|---|

| Volume fraction | 0.095 | 0.230 | 0.160 | 0.500 |

| Density (kg/m3) | 2200 | 3180 | 2565 | 2550 |

| Theoretical mass proportion | 0.18 | 0.64 | 0.36 | 1.12 |

| Selected mass proportion | 0.15 | 0.70 | 0.30 | 1.00 |

| Composition | SF | CM | RP | NS | RS |

|---|---|---|---|---|---|

| Volume fraction | 0.061 | 0.239 | 0.150 | 0.250 | 0.300 |

| Density (kg/m3) | 2200 | 3180 | 2565 | 2550 | 2528 |

| Theoretical mass proportion | 0.12 | 0.66 | 0.34 | 0.56 | 0.66 |

| Selected mass proportion | 0.15 | 0.70 | 0.30 | 0.50 | 0.50 |

| Mix ID | W/B | Water kg/m3 | SF kg/m3 | CM kg/m3 | RP kg/m3 | NS kg/m3 | RS kg/m3 | STF kg/m3 |

|---|---|---|---|---|---|---|---|---|

| RP30 + NS | 0.18 | 198 | 150 | 700 | 300 | 1000 | 0 | 157 |

| RP30 + RS50 | 0.18 | 198 | 150 | 700 | 300 | 500 | 500 | 157 |

| ID | SP0.8 | SP1.0 | SP1.2 | SP1.4 | |

|---|---|---|---|---|---|

| W/B | 0.18 | 0.18 | 0.18 | 0.18 | |

| Water | (kg/m3) | 193 | 193 | 193 | 193 |

| SP/CM | (%) | 0.8 | 1.0 | 1.2 | 1.4 |

| SP | (kg/m3) | 18 | 24 | 29 | 35 |

| CM | (kg/m3) | 700 | 700 | 700 | 700 |

| RP | (kg/m3) | 300 | 300 | 300 | 300 |

| SF | (kg/m3) | 150 | 150 | 150 | 150 |

| NS | (kg/m3) | 1000 | 1000 | 1000 | 1000 |

| STF | (kg/m3) | 157 | 157 | 157 | 157 |

| Mix ID | W16 | W17 | W18 | |

|---|---|---|---|---|

| W/B | 0.16 | 0.17 | 0.18 | |

| Water | (kg/m3) | 175 | 190 | 198 |

| SP/CM | (%) | 0.8 | 0.8 | 0.8 |

| SP | (kg/m3) | 18 | 18 | 18 |

| Cement | (kg/m3) | 700 | 700 | 700 |

| RP | (kg/m3) | 300 | 300 | 300 |

| SF | (kg/m3) | 150 | 150 | 150 |

| NS | (kg/m3) | 1000 | 1000 | 1000 |

| STF | (kg/m3) | 157 | 157 | 157 |

| Mix (ID) | RP0 + NS | RP20 + NS | RP30 + NS | RP40 + NS | |

|---|---|---|---|---|---|

| W/B | 0.16 | 0.16 | 0.16 | 0.16 | |

| Water | (kg/m3) | 175 | 175 | 175 | 175 |

| SP/CM | (%) | 0.8 | 0.8 | 0.8 | 0.8 |

| SP | (kg/m3) | 18 | 18 | 18 | 18 |

| CM | (kg/m3) | 1000 | 800 | 700 | 600 |

| RP | (kg/m3) | 0 | 200 | 300 | 400 |

| SF | (kg/m3) | 150 | 150 | 150 | 150 |

| NS | (kg/m3) | 1000 | 1000 | 1000 | 1000 |

| STF | (kg/m3) | 157 | 157 | 157 | 157 |

| Mix (ID) | RP30 + RS25 | RP30 + RS50 | RP30 + RS75 | RP30 + RS100 | |

|---|---|---|---|---|---|

| Water | (kg/m3) | 175 | 175 | 175 | 175 |

| Additional water | (kg/m3) | 19 | 43 | 58 | 77 |

| SP/CM | (%) | 1.2 | 1.2 | 1.4 | 1.4 |

| SP | (kg/m3) | 28 | 28 | 32 | 32 |

| CM | (kg/m3) | 700 | 700 | 700 | 700 |

| RP | (kg/m3) | 300 | 300 | 300 | 300 |

| SF | (kg/m3) | 150 | 150 | 150 | 150 |

| NS | (kg/m3) | 750 | 500 | 250 | 0 |

| RS | (kg/m3) | 250 | 500 | 750 | 1000 |

| STF | (kg/m3) | 157 | 157 | 157 | 157 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, P.; Du, S.; Heng, P.; Zhang, L.; Zhang, S.; Wu, Y. Investigation on Mix Proportions of Ultra-High Performance Concrete with Recycled Powder and Recycled Sand. Buildings 2025, 15, 1048. https://doi.org/10.3390/buildings15071048

Zhu P, Du S, Heng P, Zhang L, Zhang S, Wu Y. Investigation on Mix Proportions of Ultra-High Performance Concrete with Recycled Powder and Recycled Sand. Buildings. 2025; 15(7):1048. https://doi.org/10.3390/buildings15071048

Chicago/Turabian StyleZhu, Peng, Shijie Du, Phirun Heng, Lianzhen Zhang, Shengdong Zhang, and Yuching Wu. 2025. "Investigation on Mix Proportions of Ultra-High Performance Concrete with Recycled Powder and Recycled Sand" Buildings 15, no. 7: 1048. https://doi.org/10.3390/buildings15071048

APA StyleZhu, P., Du, S., Heng, P., Zhang, L., Zhang, S., & Wu, Y. (2025). Investigation on Mix Proportions of Ultra-High Performance Concrete with Recycled Powder and Recycled Sand. Buildings, 15(7), 1048. https://doi.org/10.3390/buildings15071048