Bearing Behaviors of Grouted Sleeve Connections After High Temperature Followed by Water Cooling Under Cyclic Loading

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Design and Fabrication of Specimens

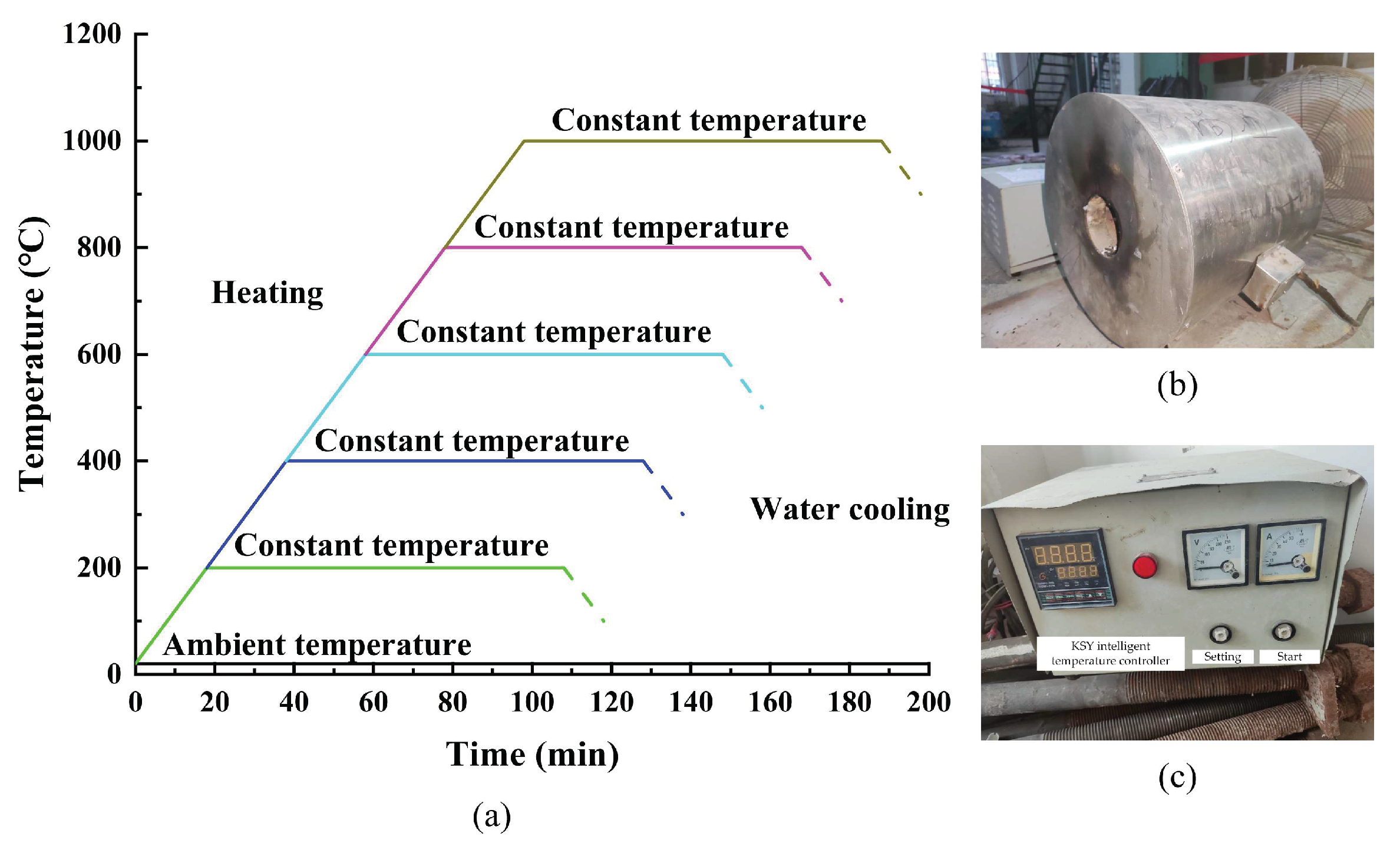

2.3. Heating and Cooling Program

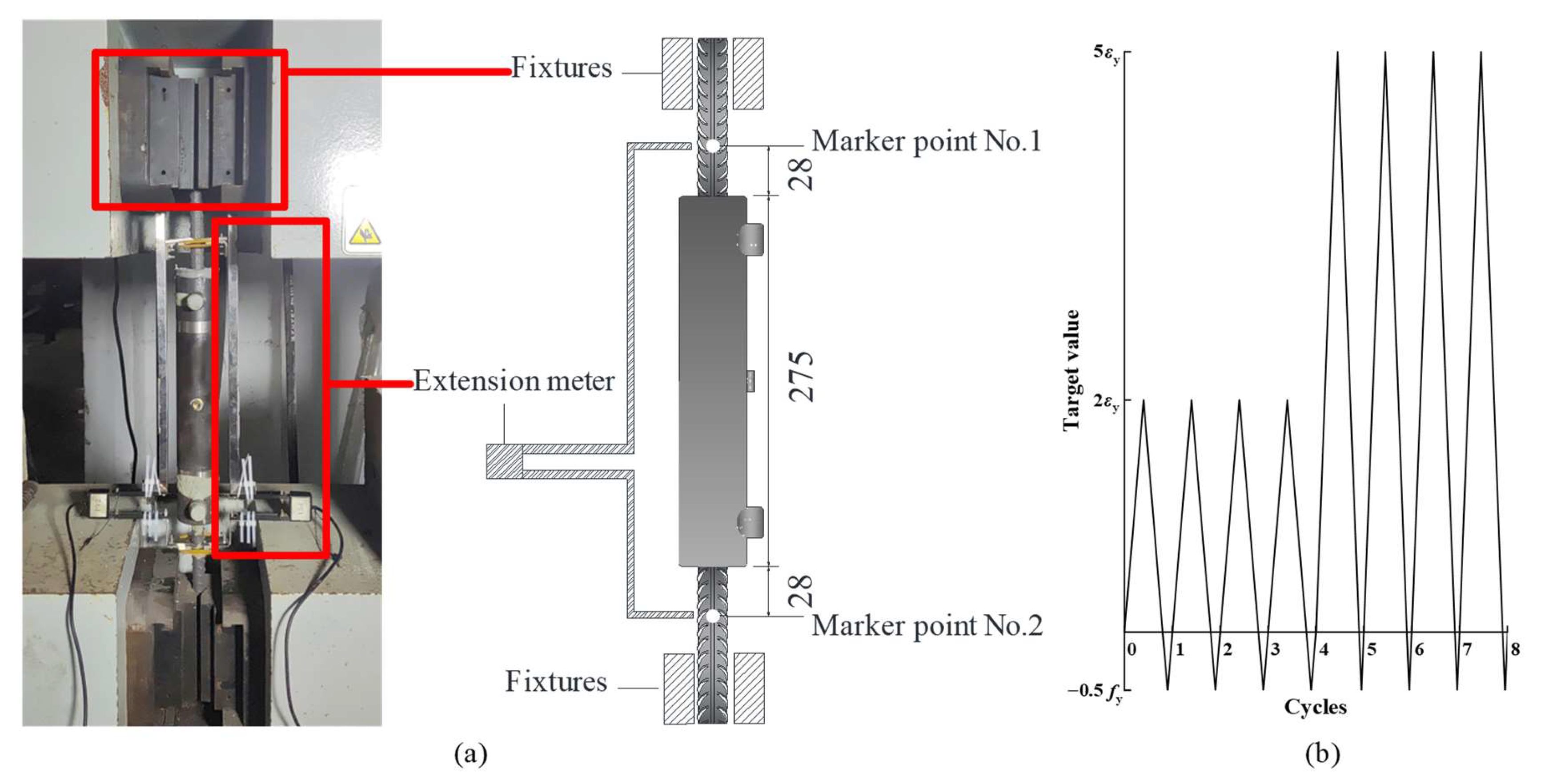

2.4. Test Setup and Loading Scheme

2.5. Data Measurement

3. Results

3.1. Appearance of GSCs After High Temparature and Water Cooling

3.2. Cyclic Loading Results

3.3. Failure Modes

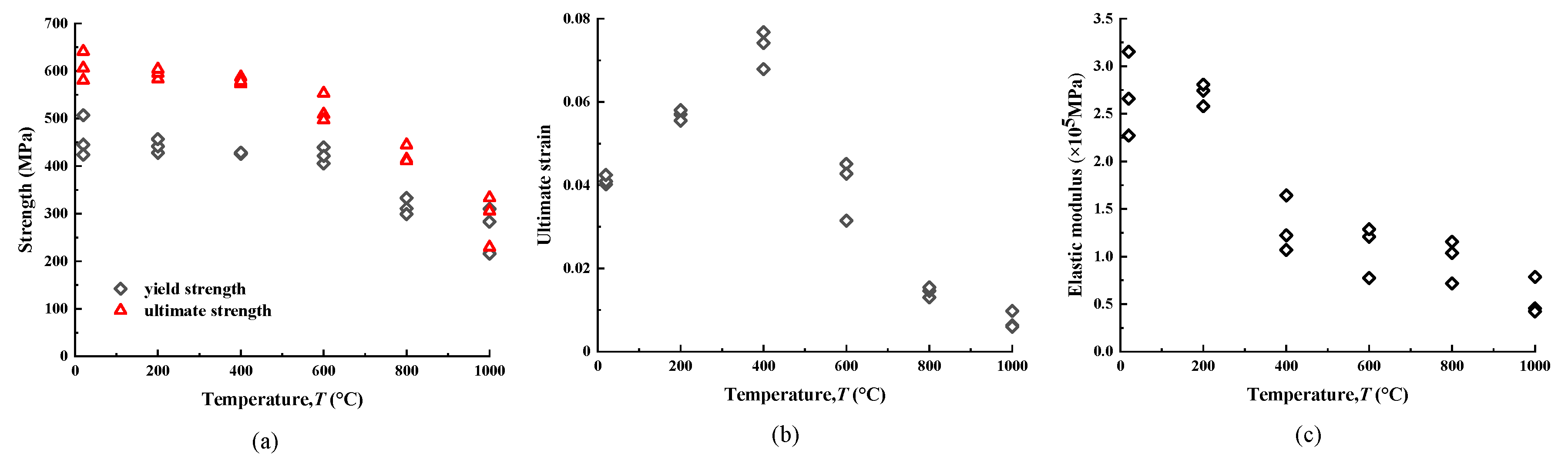

3.4. Strength, Strain, and Elastic Modulus

3.5. Hysteresis Curve

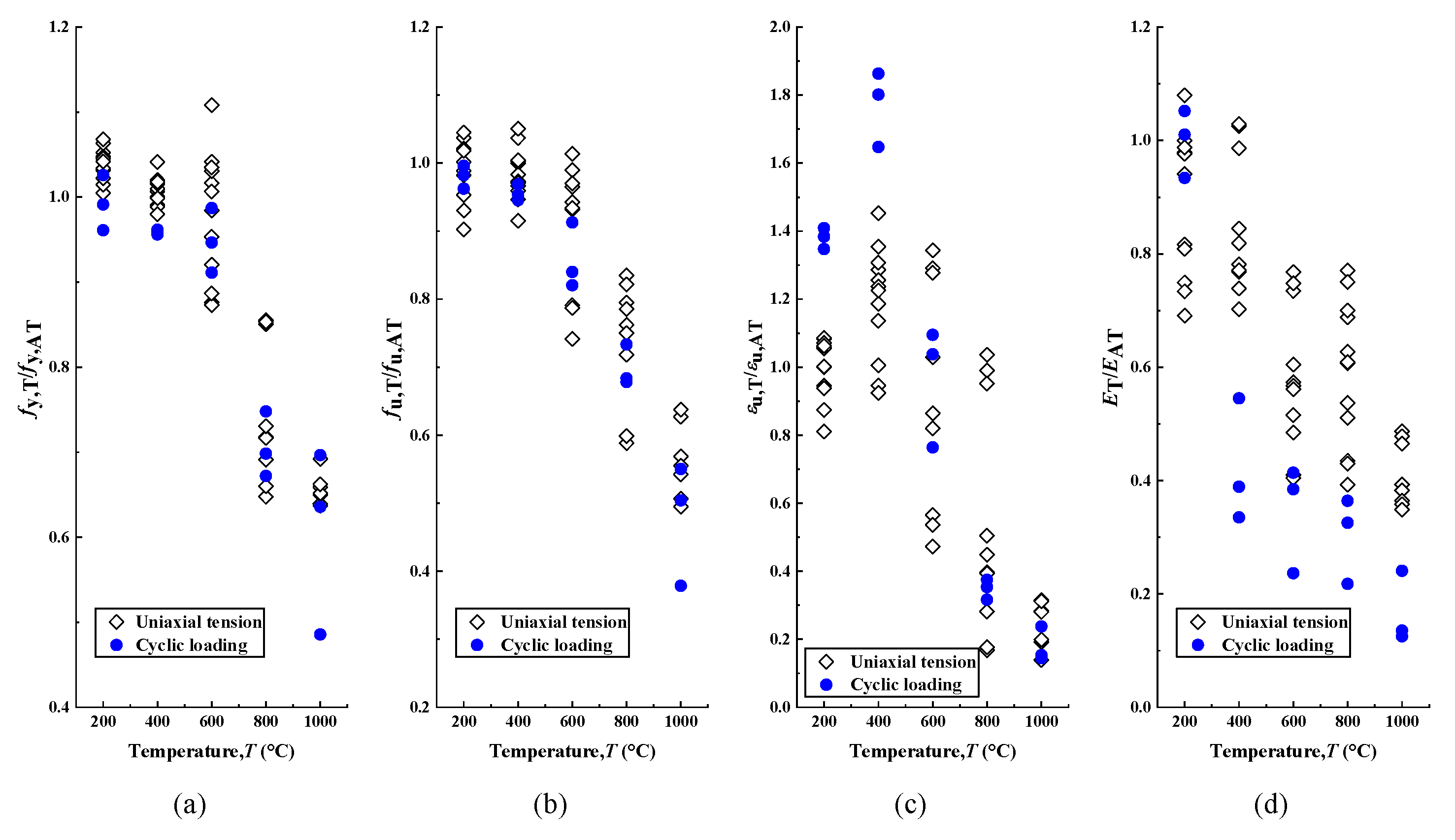

3.6. Evaluation of Connection Performance

4. A Predictive Model for the GSCs’ Performance After Heating and Water Cooling

4.1. Data Collection

4.2. Normal Analysis

4.3. Predictive Model

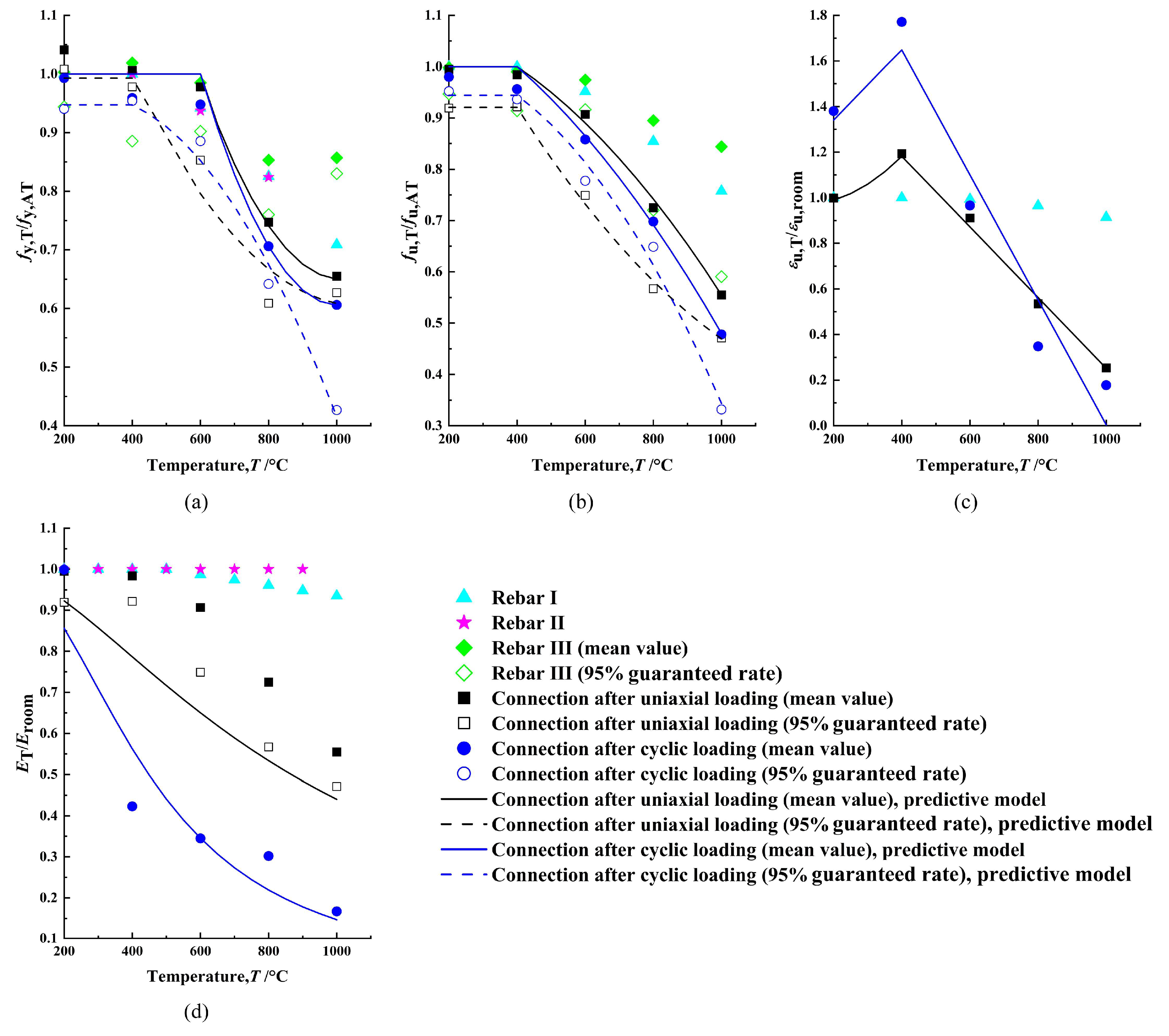

4.3.1. Strength

4.3.2. Ultimate Strain

4.3.3. Elastic Modulus

4.3.4. Repercussions of Loading Scheme on Connection Performance After Heating and Water Cooling

5. Conclusions

- (1)

- Two types of failure modes (rebar fracture and rebar pullout) occurred during the experiment. The two different failure types occur at 400 °C, the crucial heating temperature.

- (2)

- For GSCs after high temperatures followed by water cooling under cyclic loading, the yield strength and ultimate strength remain relatively constant at low temperatures. However, strength decreases as temperature rises. Additionally, the elastic modulus in the given region drops with temperature, while the ultimate strain rises and then falls.

- (3)

- When assessing connection performance at extreme temperatures, cyclic loading demonstrates a more dramatic degradation than uniaxial loading. Cyclic loading at high temperatures causes greater rebar pullout failure than unidirectional tensile loading.

- (4)

- The quantitative models with a 95% guaranteed rate for connections’ yield strength and ultimate strength, as well as models with a 50% guaranteed rate for yield strength, ultimate strength, ultimate strain, and elastic modulus, are established.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, J.; Wang, Y.; Lu, Z.; Li, J. Experimental study and numerical simulation of a laminated reinforced concrete shear wall with a vertical seam. Appl. Sci. 2017, 7, 629. [Google Scholar] [CrossRef]

- Qingbo, J.; Bin, S.; Jinfeng, Z.; Wenzheng, W.; Yang, Z. Experimental study on fire resistance of grouting material for sleeve of rebar splicing. Build. Struct. 2020, 50, 62–66. [Google Scholar]

- Zhang, W.; He, C.; Zhang, J.; Yi, W.; Deng, X. Mechanical behavior of post-fire half-grouted sleeve connection covered by concrete. Constr. Build. Mater. 2019, 201, 218–231. [Google Scholar]

- Zhu, J.; Ma, J.; Guo, D.; Wu, Y.; Ma, J. Study on tensile properties of semi grouted sleeve connectors after high temperature. Constr. Build. Mater. 2021, 302, 124088. [Google Scholar]

- Wang, W.; Li, J.-H.; Guo, F.; Chen, P. Comparison of tensile mechanical properties of half grouted sleeve connection at elevated and post-elevated temperature: An experimental study. Constr. Build. Mater. 2024, 433, 136723. [Google Scholar]

- Wang, Y.; Wang, G. Numerical simulation method for quantitative assessment of fully-grouted sleeve connection damage state and performance under thermal coupling. Int. J. Therm. Sci. 2024, 197, 108789. [Google Scholar]

- Liu, Y.; Zeng, Q.; Liu, H.; Wang, S. Experimental study on post fire tensile properties of reinforcing rebars connected by grout-filled splice sleeves. Key Eng. Mater. 2018, 773, 305–310. [Google Scholar]

- Liu, L.; Ouyang, L.; Ouyang, X.; Li, W.; Xiao, J. Postfire Mechanical Behaviors of Grouted Sleeve Connections Under Strong Earthquakes. Fire Technol. 2023, 59, 2829–2852. [Google Scholar]

- Jin, Q.; Sun, B.; Cui, D.; Mao, S.; Zhang, J. Experimental study on mechanical properties of reinforced sleeve grouting joint after high temperature. Build. Struct. 2018, 48, 38–42. [Google Scholar]

- Hu, S.; Jiang, S.; Chen, D.; Li, H.; Xu, T. Post-Fire Mechanical Properties of Half-Grouted Sleeve Connectors with Grouting Defects. Buildings 2024, 14, 1434. [Google Scholar] [CrossRef]

- Chen, D.; Peng, S.; Hui, Y.; Tam, V.W.; Wang, W.; Li, L.; Cheng, B. Post-fire mechanical properties of full-grouted sleeve connection with different grouting defects. Case Stud. Constr. Mater. 2024, 21, e03616. [Google Scholar]

- Wang, Y.; Fu, C.; Kuang, H.; Qin, H.; Xu, T.; Meng, W. Experimental study on the mechanical properties of cement-based grouting materials after exposed to high temperatures. Case Stud. Constr. Mater. 2024, 20, e03068. [Google Scholar]

- Paramathmeka, S.; Rajeswari, M. Experimental and Numerical Study on the Behaviour of Grouted Sleeve Coupler Joint Used in Precast Member Connection; Springer Nature Singapore: Singapore, 2023; pp. 241–261. [Google Scholar]

- Ghayeb, H.H.; Razak, H.A.; Sulong, N.H.R.; Mo, K.H.; Abutaha, F.; Gordan, M. Performance of mechanical steel bar splices using grouted couplers under uniaxial tension. J. Build. Eng. 2021, 34, 101892. [Google Scholar]

- Al-Jelawy, H.M. Experimental and numerical investigations on monotonic tensile behavior of grouted sleeve couplers with different splicing configurations. Eng. Struct. 2022, 265, 114434. [Google Scholar]

- Borgelt, J.; Possekel, J.; Schaumann, P.; Ghafoori, E. Mechanisms of fatigue degradation process in axially loaded grouted connections under submerged conditions. Int. J. Fatigue 2024, 189, 108576. [Google Scholar]

- Dahal, P.K.; Tazarv, M. Mechanical bar splices for incorporation in plastic hinge regions of RC members. Constr. Build. Mater. 2020, 258, 120308. [Google Scholar]

- Wang, Z.; Chen, J.; Ju, S.; Liu, Z. Experimental study on effect of loading mode and anchorage length on connection behaviour of grouted sleeve for rebars splicing. Ind. Constr. 2021, 51, 118–125. [Google Scholar]

- Lin, F.; Wu, X. Mechanical Performance and Stress–Strain Relationships for Grouted Splices Under Tensile and Cyclic Loadings. Int. J. Concr. Struct. Mater. 2016, 10, 435–450. [Google Scholar]

- Wu, C.; Xiao, X.; Ma, S.; Yang, C. Mechanical performance and failure mode judgment criteria of grouted sleeve connectors considering large deformation and grouting compactness. Case Stud. Constr. Mater. 2024, 21, e03997. [Google Scholar]

- Xu, C.; Liu, H.; Du, X. Experimental study on connection performance of grouted sleeve splicing for rebars under high stress repeated tension-compression loading. Jianzhu Jiegou Xuebao/J. Build. Struct. 2018, 39, 178–184. [Google Scholar]

- Wang, Z.; Zhang, J.; Lv, H.; Yan, X.; Li, T.; Qu, H. Seismic performance of short precast bridge columns with grouted splice sleeve (GSS) connectors for shear study: Quasi-static cyclic test and analytical estimation. Soil Dyn. Earthq. Eng. 2023, 165, 107659. [Google Scholar]

- Guo, H.; Zhang, J.; Wang, C. Experimental Study on Influence of Connection Defects on Joint Strength of Half-Grouted Sleeve Splicing of Rebar. Adv. Civ. Eng. 2020, 2020, 5389861. [Google Scholar]

- Zhao, Y.; Zhang, H.; Pan, Z.; Li, G. Mechanical behavior of grouted sleeve connection for rebars in precast concrete structures and reliability analysis considering the ratio of anchorage length to rebar diameter. Case Stud. Constr. Mater. 2024, 20, e02883. [Google Scholar]

- Kahama, E.; Xie, F.; Lu, C.; Offei, I. Experimental and numerical assessment of the location-based impact of grouting defects on the tensile performance of the fully grouted sleeve connection. Fract. Struct. Integr. 2022, 16, 437–460. [Google Scholar]

- Liu, L.; Xiao, J.; Ding, T.; Zhang, L. Mechanical behaviours of heat-damaged grouted sleeve connections. Fire Saf. J. 2021, 122, 103345. [Google Scholar]

- Li, Y.; Cheng, L.; Lei, W.; Su, Y.; Huang, T.; Zhu, Y.; Mei, C.; He, X. Microstructures and mechanical property of post-fire grouting sleeve connections considering concrete cover. Constr. Build. Mater. 2023, 403, 132578. [Google Scholar]

- GB/T 228.1-2021; Metallic Materials—Tensile Tests—Part 1: Test Method at Room Temperature. National Steel Standardization Technical Committee: Beijing, China, 2021.

- ISO 6892-1:2009; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. International Organization for Standardization (ISO): Geneva, Switzerland, 2009.

- GB 50010-2010; Code for Design of Concrete Structures. Ministry of Housing and Urban-Rural Development of China: Beijing, China, 2010.

- JG/T 408-2019; Cementitious Grout for Coupler of Rebar Splicing. Ministry of Housing and Urban-Rural Development of China: Beijing, China, 2019.

- GB/T 17671-2021; Method of Testing Cements-Determination of Strength. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2021.

- ISO 679:2009; Methods of Testing Cements-Determination of Strength. International Organization for Standardization (ISO): Geneva, Switzerland, 2007.

- JG/T 398-2019; The Grouting Coupler for Rebars Splicing. Ministry of Housing and Urban-Rural Development of China: Beijing, China, 2019.

- JGJ 355-2015; Technical Specification for Grout Sleeve Splicing of Rebars. Ministry of Housing and Urban-Rural Development of China: Beijing, China, 2015.

- JGJ 107-2016; Technical Specification for Mechanical Splicing of Steel Reinforcing Bars. Ministry of Housing and Urban-Rural Development of China: Beijing, China, 2016.

- Zheng, Y.; Shi, C.; Yang, Y.; Huang, W.; Du, j. Research on dynamically mechanical properties of semi-grouting and full-grouted sleeve connection. Ind. Constr. 2021, 51, 121–126. [Google Scholar]

- Wang, T.; Yu, M.; Li, X.; Yan, Z.; Saafi, M.; Ye, J. Experimental investigation on the post-fire cyclic behavior of grouted sleeve connections. Constr. Build. Mater. 2021, 279, 122394. [Google Scholar]

- Liu, Y.; Peng, T.; Miao, J.; Liu, C.; Ba, G.; Zhao, Y.; Xiao, J.; Hou, D.; Liu, Y. Uniaxial tensile behavior of half-grouted sleeve connections with concrete cover after exposure to elevated temperatures. J. Build. Eng. 2024, 87, 109066. [Google Scholar]

- Zhang, W.; Deng, J.; He, C.; Zhang, J.; Yi, W. Experiment and analysis on mechanical properties of Fully-Grouted sleeve connection at elevated temperatures. Constr. Build. Mater. 2020, 244, 118314. [Google Scholar]

- Wang, T.; Zhou, Z.; Yuan, K.; Jiang, R.; Ma, X.; Li, L. Evaluation of common defects of grouted sleeve connectors. Case Stud. Constr. Mater. 2022, 17, e01605. [Google Scholar]

- Ling, J.H.; Baharuddin Abd. Rahman, A.; Ibrahim, I.S. Feasibility study of grouted splice connector under tensile load. Constr. Build. Mater. 2014, 50, 530–539. [Google Scholar]

- ACI 318-19; Building Code Requirements for Structural Concrete. American Concrete Institute Committee: Farmington Hills, MI, USA, 2019.

- Zhang, W.; Lv, W.; Zhang, J.; He, C.; Deng, X.; Yi, W. Post-fire tensile properties of half-grouted sleeve connection under different cooling paths. Fire Saf. J. 2019, 109, 102848. [Google Scholar]

- Zhang, W.; Deng, X.; Zhang, J.; Yi, W. Tensile behavior of half grouted sleeve connection at elevated temperatures. Constr. Build. Mater. 2018, 176, 259–270. [Google Scholar]

- GB 50068-2018; Unified Standard for Reliability Design of Building Structures. Ministry of Construction of the People’s Republic of China: Beijing, China, 2018.

- T/CECS 252-2019; Standard for Identification of Engineering Structures After Fire. China Association for Engineering Construction Standardization: Beijing, China, 2019.

- GB 4882-2001; Statistical Processing and Interpretation of Data: Normality Test. National Bureau of Standards of the People’s Republic of China: Beijing, China, 2001.

- Yap, B.W.; Sim, C.H. Comparisons of various types of normality tests. J. Stat. Comput. Simul. 2011, 81, 2141–2155. [Google Scholar]

- Tao, Z.; Wang, X.; Uy, B. Stress-strain curves of structural and reinforcing steels after exposure to elevated temperatures. J. Mater. Civ. Eng. 2013, 25, 1306–1316. [Google Scholar]

- Yang, H.; Han, L.; Wang, Y. Effects of heating and loading histories on post-fire cooling behaviour of concrete-filled steel tubular columns. J. Constr. Steel Res. 2008, 64, 556–570. [Google Scholar]

- Liang, Y. Statistical analysis and application of high temperature mechanical properties of steel and concrete. Master’s Thesis, South China University of Technology, Guangzhou, China, 2008. [Google Scholar]

| Material | Diameter (mm) | Yield Strength (N/mm2) | Ultimate Strength (N/mm2) |

|---|---|---|---|

| HRB400 [30] | 14 | 474.2 | 612.0 |

| Material | Compression Strength After Different Temperatures (N/mm2/°C) |

|---|---|

| Cementitious grout | 93.1/AT; 83.2/200; 78.3/400; 55.5/600; 39.5/800; 14.6/1000 |

| Material | Outer Diameter (mm) | Inner Diameter (mm) | Di (mm) | Do (mm) | Tensile Strength (N/mm2) |

|---|---|---|---|---|---|

| Carbon structural steel | 46 | 34 | 30 | 26 | 610 |

| Specimen No. | Yield Load, Fy (kN) | Yield Displacement, Δu (mm) | Ultimate Load, Fu (kN) | Ultimate Displacement, Δu (mm) | Failure Modes |

|---|---|---|---|---|---|

| CL-AT-1 | 68.53 | 0.55 | 93.30 | 13.30 | I |

| CL-AT-2 | 78.02 | 0.74 | 98.71 | 13.55 | I |

| CL-AT-3 | 65.29 | 0.45 | 89.37 | 14.05 | I |

| CL-200-1 | 65.86 | 0.52 | 89.79 | 18.87 | I |

| CL-200-2 | 67.94 | 0.52 | 91.66 | 19.21 | I |

| CL-200-3 | 70.31 | 0.59 | 92.93 | 18.37 | I |

| CL-400-1 | 65.75 | 0.86 | 90.41 | 25.40 | I |

| CL-400-2 | 65.52 | 1.32 | 88.22 | 22.46 | II |

| CL-400-3 | 65.91 | 1.16 | 88.98 | 24.56 | II |

| CL-600-1 | 67.66 | 1.88 | 85.17 | 14.93 | II |

| CL-600-2 | 62.44 | 1.11 | 78.37 | 14.15 | II |

| CL-600-3 | 64.87 | 1.08 | 76.56 | 10.42 | II |

| CL-800-1 | 47.86 | 0.99 | 63.78 | 4.31 | II |

| CL-800-2 | 46.06 | 0.86 | 63.28 | 4.82 | II |

| CL-800-3 | 51.26 | 1.54 | 68.43 | 5.11 | II |

| CL-1000-1 | 43.57 | 1.19 | 47.04 | 2.09 | II |

| CL-1000-2 | 33.28 | 1.57 | 35.33 | 1.97 | II |

| CL-1000-3 | 47.74 | 2.43 | 51.34 | 3.24 | II |

| Evaluation Indicators | Computational Formula | Criteria |

|---|---|---|

| Yield strength ratio | ||

| Strength ratio | ||

| Ultimate strength ratio | Rebar fracture

Rebar pullout | |

| Ductility ratio |

| Specimen No. | Ry | Rs | Ru | Rd | Failure Mode | Acceptability |

|---|---|---|---|---|---|---|

| CL-AT-1 | 1.11 | 1.52 | 1.12 | 24.00 | I | Acceptable |

| CL-AT-2 | 1.27 | 1.60 | 1.19 | 18.35 | I | Acceptable |

| CL-AT-3 | 1.06 | 1.45 | 1.08 | 31.57 | I | Acceptable |

| CL-200-1 | 1.07 | 1.46 | 1.08 | 36.55 | I | Acceptable |

| CL-200-2 | 1.10 | 1.49 | 1.10 | 36.90 | I | Acceptable |

| CL-200-3 | 1.14 | 1.51 | 1.12 | 31.36 | I | Acceptable |

| CL-400-1 | 1.07 | 1.47 | 1.09 | 29.51 | I | Acceptable |

| CL-400-2 | 1.06 | 1.43 | 1.06 | 17.04 | II | Unacceptable |

| CL-400-3 | 1.07 | 1.45 | 1.07 | 21.19 | II | Unacceptable |

| CL-600-1 | 1.10 | 1.38 | 1.02 | 7.94 | II | Unacceptable |

| CL-600-2 | 1.01 | 1.27 | 0.94 | 12.71 | II | Unacceptable |

| CL-600-3 | 1.05 | 1.24 | 0.92 | 9.62 | II | Unacceptable |

| CL-800-1 | 0.78 | 1.04 | 0.77 | 4.34 | II | Unacceptable |

| CL-800-2 | 0.75 | 1.03 | 0.76 | 5.62 | II | Unacceptable |

| CL-800-3 | 0.83 | 1.11 | 0.82 | 3.33 | II | Unacceptable |

| CL-1000-1 | 0.71 | 0.76 | 0.57 | 1.75 | II | Unacceptable |

| CL-1000-2 | 0.54 | 0.57 | 0.42 | 1.25 | II | Unacceptable |

| CL-1000-3 | 0.78 | 0.83 | 0.62 | 1.33 | II | Unacceptable |

| Loading Scheme | Strength of Grouting Material (MPa) | Influence Coefficient | Temperature T/°C | ||||

|---|---|---|---|---|---|---|---|

| 200 | 400 | 600 | 800 | 1000 | |||

| Uniaxial loading | 85–95 | fy,T/fy,AT | 0.78 | 0.91 | 0.42 | 0.06 | 0.12 |

| fu,T/fu,AT | 0.18 | 0.97 | 0.05 | 0.07 | 0.26 | ||

| ET/EAT | 0.15 | 0.07 | 0.18 | 0.57 | 0.09 | ||

| εu,T/εu,AT | 0.07 | 0.54 | 0.23 | 0.06 | 0.08 | ||

| Cyclic loading | fy,T/fy,AT | 0.93 | 0.81 | 0.93 | 0.67 | 0.54 | |

| fu,T/fu,AT | 0.79 | 0.67 | 0.39 | 0.17 | 0.50 | ||

| ET/EAT | 0.68 | 0.48 | 0.30 | 0.49 | 0.15 | ||

| εu,T/εu,AT | 0.79 | 0.54 | 0.31 | 0.70 | 0.16 | ||

| Source | Computational Model | Scope of Application | |||

|---|---|---|---|---|---|

| [50] (I) | |||||

| [51] (II) | |||||

| [52] (III) | (Mean value) | (95% guaranteed rate) | (Mean value) | (95% guaranteed rate) | |

| 1.00 | 0.94 | 1.00 | 0.95 | 200 °C | |

| 1.02 | 0.89 | 0.99 | 0.91 | 400 °C | |

| 0.99 | 0.90 | 0.97 | 0.92 | 600 °C | |

| 0.85 | 0.76 | 0.90 | 0.72 | 800 °C | |

| 0.86 | 0.83 | 0.84 | 0.59 | 1000 °C | |

| Coefficients | Loading Scheme | Guaranteed Rate (%) | A | B | C | D | T1 | T2 | T3 | R1 |

|---|---|---|---|---|---|---|---|---|---|---|

| fy,T/fy,AT | Uniaxial loading | 50 | 1.000 | 1.922 × 10−6 | −0.004 | 2.698 | 200 | 600 | 1000 | 0.99879 |

| 95 | 0.993 | 8.701 × 10−7 | −0.002 | 1.598 | 200 | 400 | 1000 | 0.98790 | ||

| fu,T/fu,AT | 50 | 1.000 | −4.813 × 10−7 | −73.100 | 1.104 | 200 | 400 | 1000 | 0.99997 | |

| 95 | 0.920 | 4.710 × 10−7 | −0.001 | 1.408 | 200 | 400 | 1000 | 0.99997 | ||

| fy,T/fy,AT | Cyclic loading | 50 | 1.000 | 2.422 × 10−6 | −0.005 | 3.044 | 200 | 600 | 1000 | 0.98182 |

| 95 | 0.947 | −1.027 × 10−6 | 5.522 × 10−4 | 0.891 | 200 | 400 | 1000 | 0.99676 | ||

| fu,T/fu,AT | 50 | 1.000 | −4.765 × 10−7 | −1.995 × 10−4 | 1.156 | 200 | 400 | 1000 | 0.98784 | |

| 95 | 0.944 | −8.657 × 10−7 | 2.111 × 10−4 | 0.998 | 200 | 400 | 1000 | 0.99719 |

| Loading Scheme | A | B | C | D | E | T1 | T2 | T3 | R1 |

|---|---|---|---|---|---|---|---|---|---|

| Uniaxial loading | 2.542 × 10−6 | −5.646 × 10−4 | 1.000 | −0.002 | 1.802 | 200 | 400 | 1000 | 0.99913 |

| Cyclic loading | 0 | 0.002 | 1.031 | −0.003 | 2.744 | 200 | 400 | 1000 | 0.98305 |

| Loading Scheme | A | B | C | |||

|---|---|---|---|---|---|---|

| Uniaxial loading | 0.998 | 1.276 | 1.683 | 200 | 1000 | 0.99042 |

| Cyclic loading | 0.997 | 5.831 | 2.191 | 200 | 1000 | 0.97992 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, W.; Wang, J.; Zhou, Y.; Wang, J.; Yi, W. Bearing Behaviors of Grouted Sleeve Connections After High Temperature Followed by Water Cooling Under Cyclic Loading. Buildings 2025, 15, 1014. https://doi.org/10.3390/buildings15071014

Zhang W, Wang J, Zhou Y, Wang J, Yi W. Bearing Behaviors of Grouted Sleeve Connections After High Temperature Followed by Water Cooling Under Cyclic Loading. Buildings. 2025; 15(7):1014. https://doi.org/10.3390/buildings15071014

Chicago/Turabian StyleZhang, Wangxi, Jialu Wang, Yibo Zhou, Jia Wang, and Weijian Yi. 2025. "Bearing Behaviors of Grouted Sleeve Connections After High Temperature Followed by Water Cooling Under Cyclic Loading" Buildings 15, no. 7: 1014. https://doi.org/10.3390/buildings15071014

APA StyleZhang, W., Wang, J., Zhou, Y., Wang, J., & Yi, W. (2025). Bearing Behaviors of Grouted Sleeve Connections After High Temperature Followed by Water Cooling Under Cyclic Loading. Buildings, 15(7), 1014. https://doi.org/10.3390/buildings15071014