Deformation Evaluation in Welded Rebar Parts for Pylons and Its Application in Changtai Yangtze River Bridge

Abstract

1. Introduction

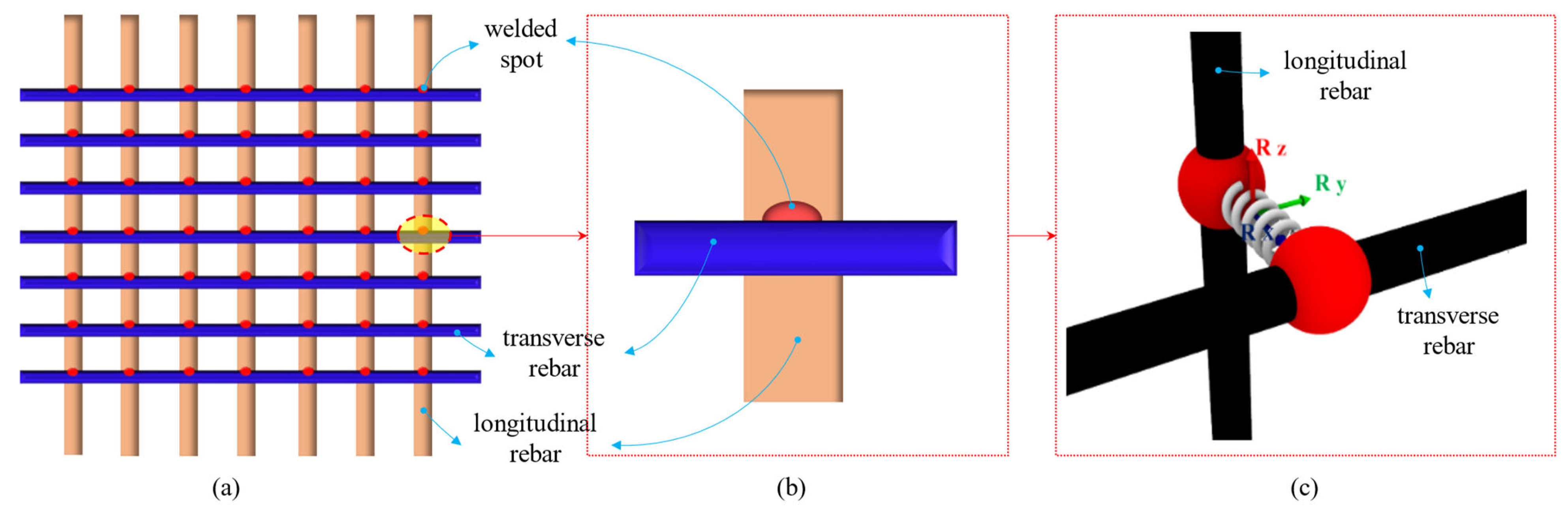

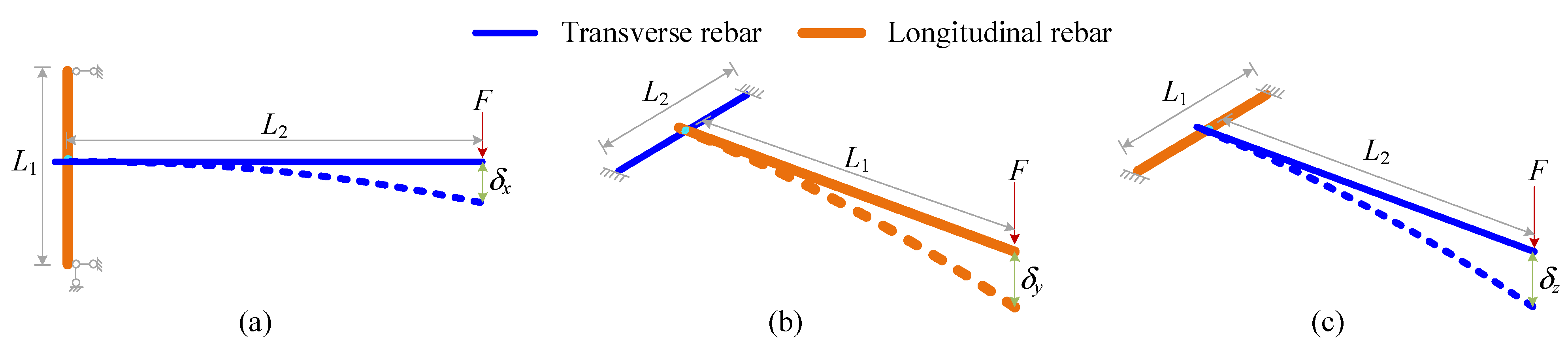

2. Theoretical Analysis of the Overall Stiffness of Welded Rebar Parts

3. Rotational Stiffness Experiment of Welded Spot

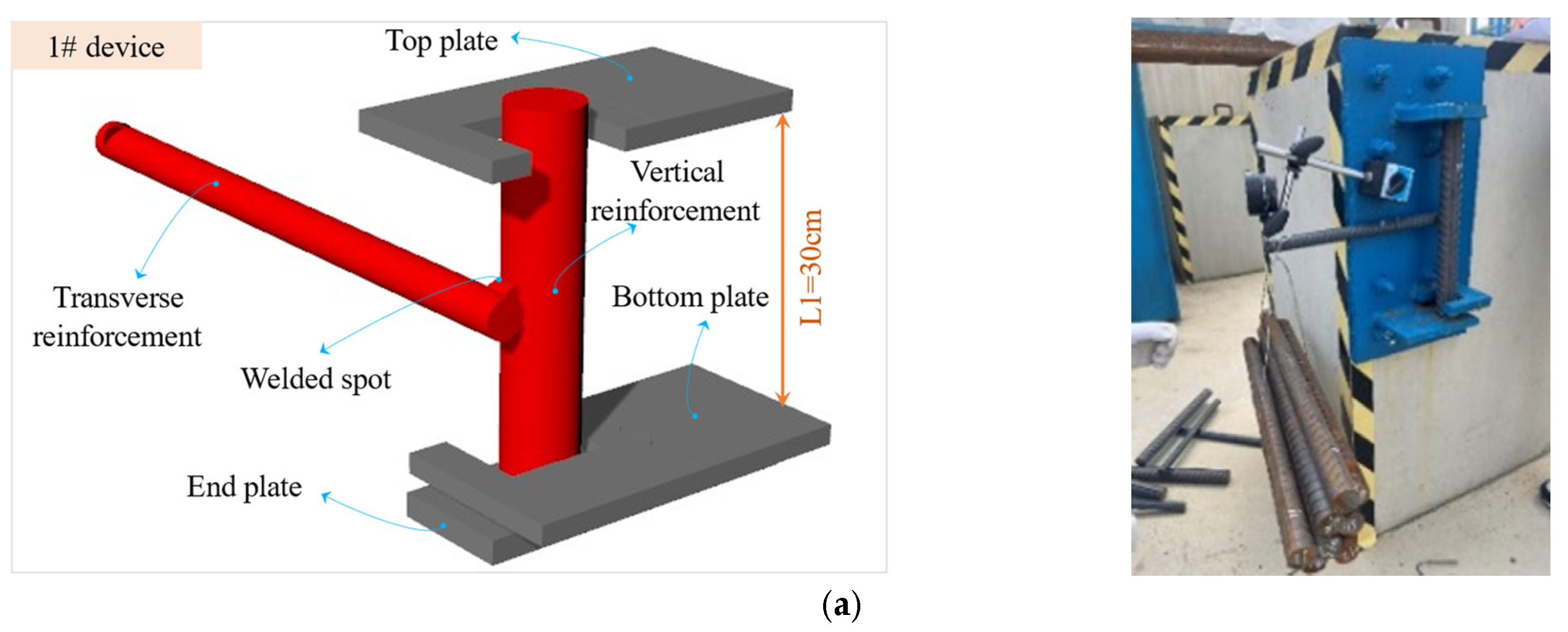

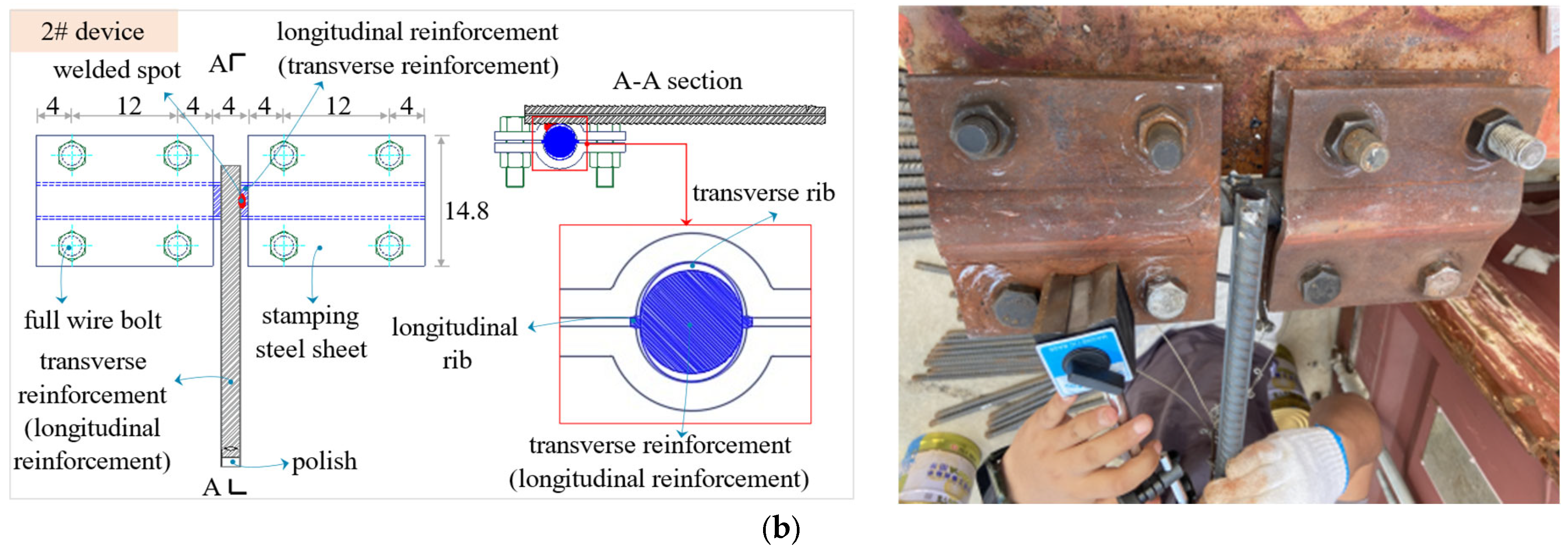

3.1. Experimental Design

3.2. Loading Device Design

3.3. Results and Discussion

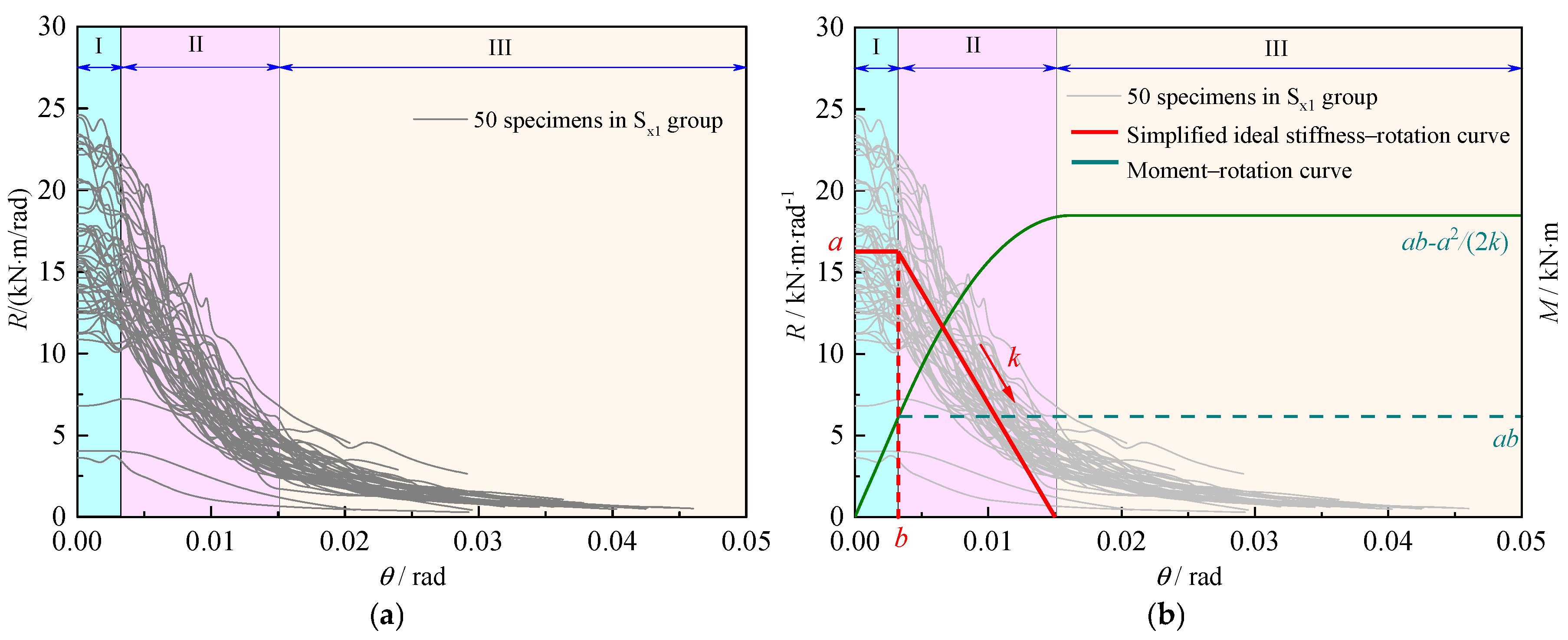

4. Establishment of Moment–Rotation Constitutive Model of Welded Spots

4.1. Moment–Rotation Constitutive Model

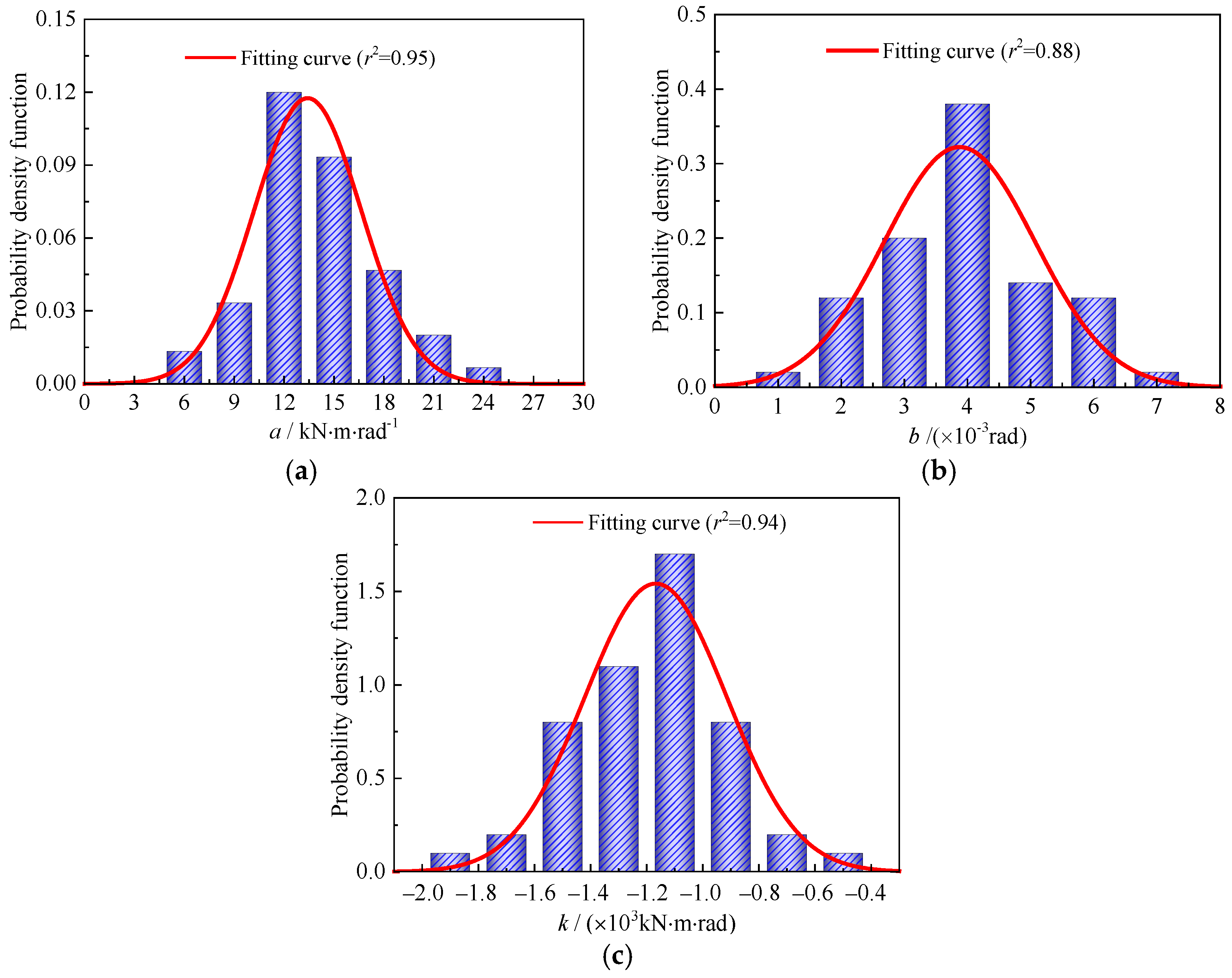

4.2. Parameter Analysis

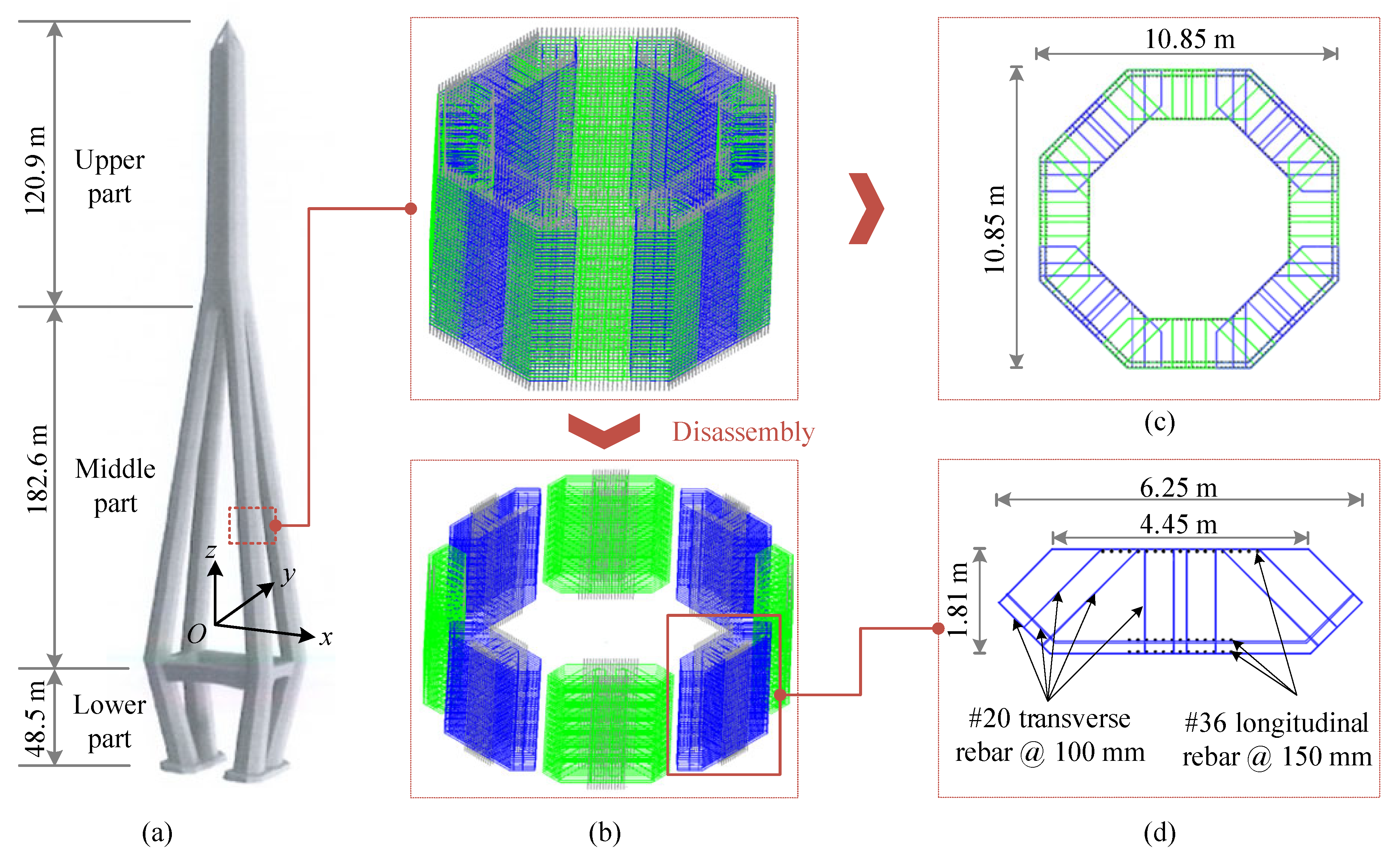

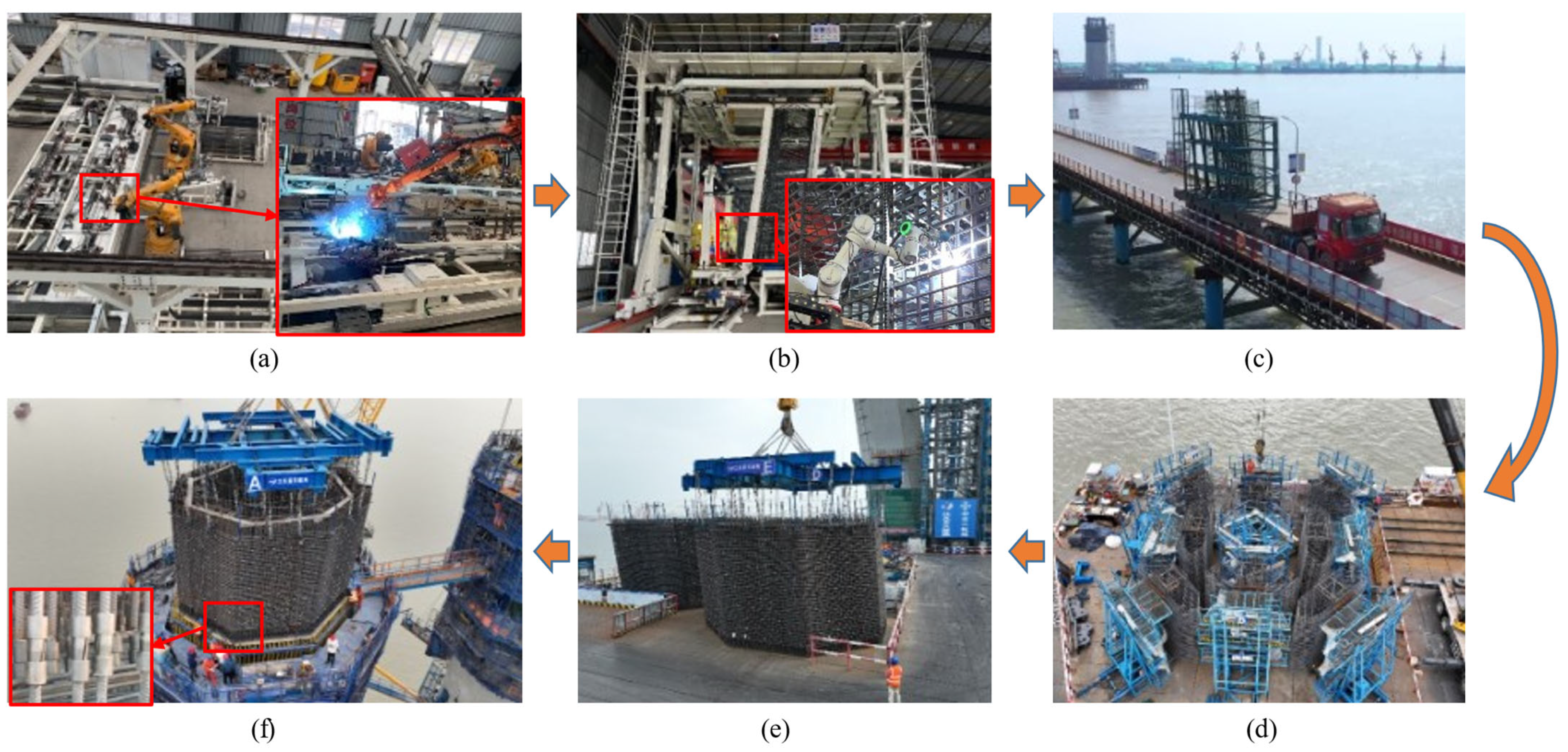

5. Application of Welded Rebar Parts in Changtai Yangtze River Bridge

5.1. Overview of Pylon

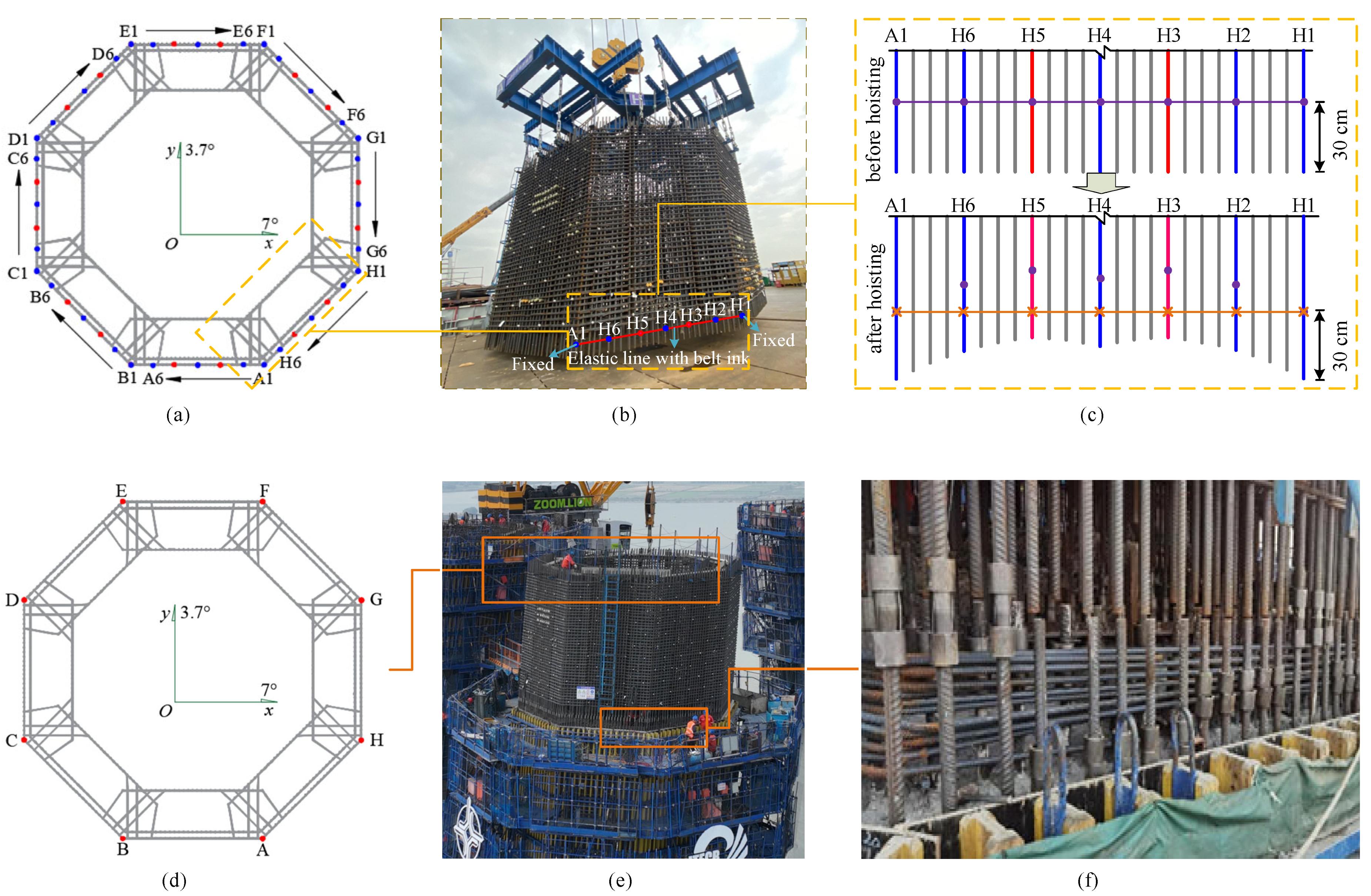

5.2. Scheme of Field Test

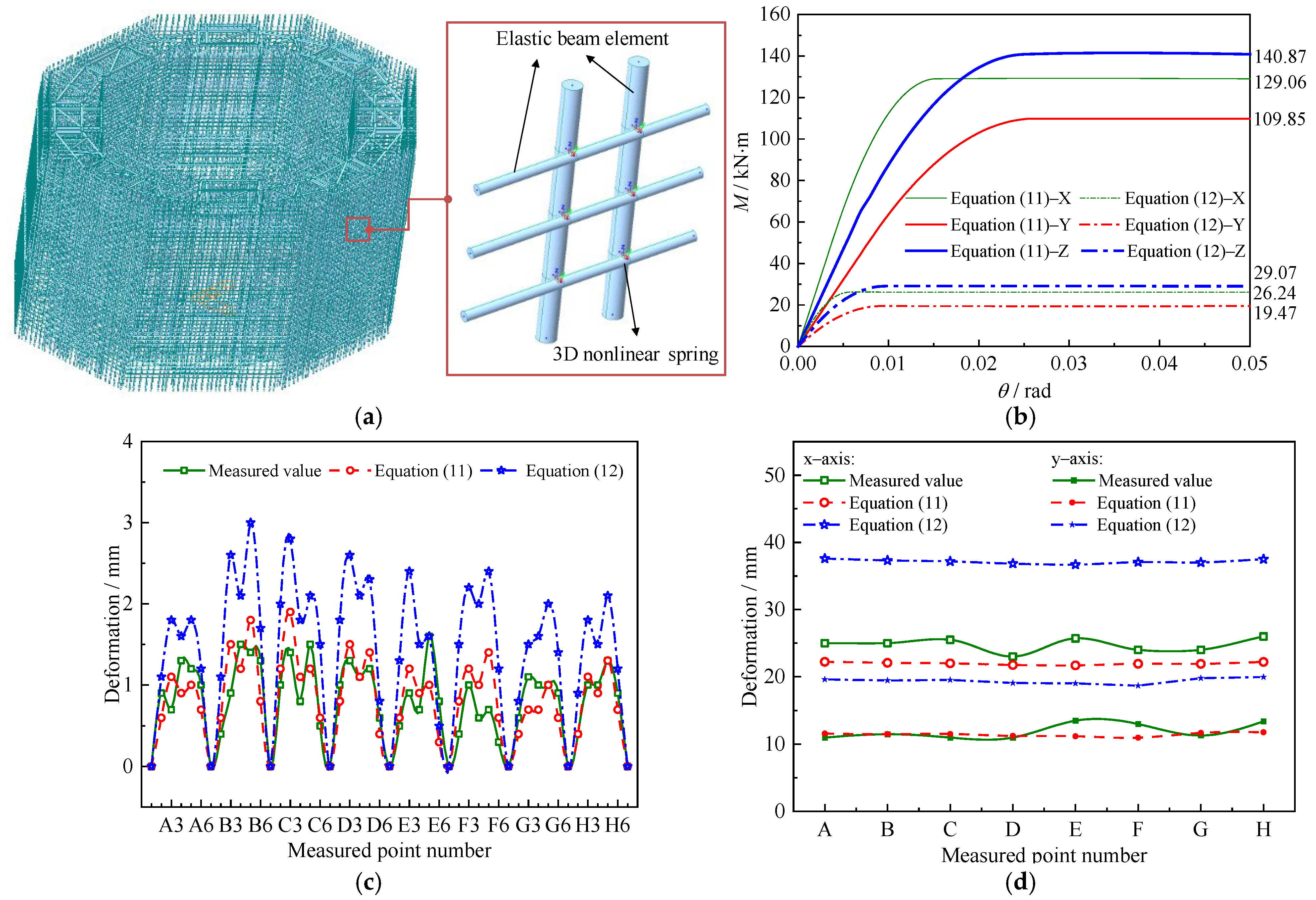

5.3. Finite Element Simulation

5.4. Discussion of Results

6. Conclusions

- The moment–rotation constitutive model of welded spots proposed in this paper is only driven by three parameters: the initial stiffness, elastic rotation angle, and stiffness degradation rate. It not only has reliable calculation accuracy but is also very suitable for practical engineering applications.

- Model parameters such as initial stiffness, elastic rotation angle, and stiffness degradation rate all conform to the Gaussian distribution, but the standard deviation is relatively large. It is advisable to promote the use of automatic welding robots and establish standardized welding parameters.

- The initial stiffness is greatly affected by the rebar diameter and decreases with the decrease in the rebar diameter. The elastic rotation angle and stiffness degradation rate are basically not affected by the rebar diameter.

- The deformation evaluation of rebar parts can guide the design of the rigid skeleton to make the rebar connecting feasible by means of a taper sleeve or straight thread sleeve and can also be used to calculate the pre-offset of the rebar parts so that the thickness of the concrete cover and the overall alignment meet the requirements of the specification.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tuesta, R.; Vicuña, M.; Del Savio, A.A.; Palpan, A.; Valle, E.; Quiroz, F. Prefabricated reinforcement in construction using VDC: Case study Ovalo Monitor Bridge. In Proceedings of the 30th Annual Conference of the International Group for Lean Construction (IGLC), Edmonton, AB, Canada, 25–31 July 2022; pp. 27–29. [Google Scholar]

- Qi, B.; Razkenari, M.; Costin, A.; Kibert, C.; Fu, M. A systematic review of emerging technologies in industrialized construction. J. Build. Eng. 2021, 39, 102265. [Google Scholar] [CrossRef]

- Zhou, X.; Zhang, X. Thoughts on the development of bridge technology in China. Engineering 2019, 5, 1120–1130. [Google Scholar] [CrossRef]

- He, X.; Wu, T.; Zou, Y.; Chen, Y.F.; Guo, H.; Yu, Z. Recent developments of high-speed railway bridges in China. Struct. Infrastruct. Eng. 2017, 13, 1584–1595. [Google Scholar] [CrossRef]

- Harryson, P. Industrial Bridge Engineering-Structural Developments for More Efficient Bridge Construction. Ph.D. Thesis, Chalmers Tekniska Hogskola, Gothenburg, Sweden, 2008. [Google Scholar]

- Park, B.S.; Park, S.H.; Cho, J.Y. A pre-assembly method of steel reinforcement to improve the constructability of pier coping. Eng. Struct. 2013, 48, 166–175. [Google Scholar] [CrossRef]

- Palpan, A.; Vega, S.; Quiroz, F.Q.; Vicuña, M.; Tuesta, R.; del Savio, A.A. VDC management in the industrialization process using prefabricated reinforcement cages. Case Study: Ovalo Monitor Bridge. In Proceedings of the Modular and Offsite Construction (MOC) Summit Proceedings, Edmonton, AB, Canada, 27–29 July 2022; pp. 217–224. [Google Scholar]

- Vahedi, M.; Ebrahimian, H.; Itani, A.M. Experimental investigation of U-bolt connectors for application in rebar cages. J. Struct. Eng. 2023, 149, 04022216. [Google Scholar] [CrossRef]

- Lee, K.M.; Lee, Y.B.; Shim, C.S.; Park, K.L. Bridge information models for construction of a concrete box-girder bridge. Struct. Infrastruct. Eng. 2012, 8, 687–703. [Google Scholar] [CrossRef]

- Simonsson, P.; Emborg, M. Industrialization in Swedish Bridge Engineering: A Case Study of Lean Construction. In Proceedings of the Annual Conference of the International Group for Lean Construction, East Lansing, MI, USA, 18–20 July 2007; Michigan State University Press: East Lansing, MI, USA, 2007; pp. 244–253. [Google Scholar]

- Pacheco, P.; Coelho, H.; Borges, P.; Resende, A.; Carvalho, D. New frontiers in multi-span prestressed concrete deck construction: A case study. Struct. Eng. Int. 2021, 31, 106–117. [Google Scholar] [CrossRef]

- Young, Y.J.; Han, C.S. Development of pier coping pre-assembly method. Mag. Korea Concr. Inst. 2004, 16, 91–95. [Google Scholar]

- Kim, Y.J.; Choi, H.S.; Shin, W.S. Ground fabrication of coping rebar of rectangular pier. Mag. Korea Concr. Inst. 2006, 18, 52–55. [Google Scholar]

- Devine, R.D.; Barbachyn, S.M.; Thrall, A.P.; Kurama, Y.C. Effect of tripping prefabricated rebar assemblies on bar spacing. J. Constr. Eng. Manag. 2018, 144, 04018099. [Google Scholar] [CrossRef]

- Chen, H.; Chen, S. Key information perception and control strategy of intellignet welding under complex scene. Acta Met. Sin 2022, 58, 541–550. [Google Scholar] [CrossRef]

- Wang, B.; Hu, S.J.; Sun, L.; Freiheit, T. Intelligent welding system technologies: State-of-the-art review and perspectives. J. Manuf. Syst. 2020, 56, 373–391. [Google Scholar] [CrossRef]

- Wahba, M.; Mizutani, M.; Katayama, S. Hybrid welding with fiber laser and CO2 gas shielded arc. J. Mater. Process. Technol. 2015, 221, 146–153. [Google Scholar] [CrossRef]

- Li, J.; Shang, X.; Yuan, M. Research on reliability of straight thread connection of reinforcement cage of bridge foundation. E3S Web Conf. 2021, 238, 03064. [Google Scholar] [CrossRef]

- Dabiri, H.; Kheyroddin, A.; Dall’Asta, A. Splice methods used for reinforcement steel bars: A state-of-the-art review. Constr. Build. Mater. 2022, 320, 126198. [Google Scholar] [CrossRef]

- Zhao, E.; Song, C.; Zhang, X.; Zhou, Q.; Yan, K. Experimental study on monotonic, cyclic mechanics and fatigue performance of pressed cone sleeve splices. In Structures; Elsevier: Amsterdam, The Netherlands, 2022; pp. 482–495. [Google Scholar] [CrossRef]

- Del-Giudice, L.; Wróbel, R.; Katsamakas, A.A.; Leinenbach, C.; Vassiliou, M.F. Physical modelling of reinforced concrete at a 1: 40 scale using additively manufactured reinforcement cages. Earthq. Eng. Struct. Dyn. 2022, 51, 537–551. [Google Scholar] [CrossRef]

- Yuan, X.; Smith, A.; Moreu, F.; Sarlo, R.; Lippitt, C.D.; Hojati, M.; Alampalli, S.; Zhang, S. Automatic evaluation of rebar spacing and quality using LiDAR data: Field application for bridge structural assessment. Autom. Constr. 2023, 146, 104708. [Google Scholar] [CrossRef]

- Rabi, M.; Shamass, R.; Cashell, K.A. Structural performance of stainless steel reinforced concrete members: A review. Constr. Build. Mater. 2022, 325, 126673. [Google Scholar] [CrossRef]

- Rabi, M.; Shamass, R.; Cashell, K.A. Experimental investigation on the flexural behaviour of stainless steel reinforced concrete beams. Struct. Infrastruct. Eng. 2023, 19, 1847–1859. [Google Scholar] [CrossRef]

- Rabi, M.; Cashell, K.A.; Shamass, R. Analysis of concrete beams reinforced with stainless steel. In Proceedings of the fib Symposium 2019: Concrete-Innovations in Materials, Design and Structures 2019, Krakow, Poland, 27–29 May 2019; pp. 690–697. [Google Scholar]

- Rabi, M. Bond prediction of stainless-steel reinforcement using artificial neural networks. Proc. Inst. Civ. Eng. Constr. Mater. 2023, 177, 87–97. [Google Scholar] [CrossRef]

- Rabi, M.; Cashell, K.A.; Shamass, R. Ultimate behaviour and serviceability analysis of stainless steel reinforced concrete beams. Eng. Struct. 2021, 248, 113259. [Google Scholar] [CrossRef]

- Rabi, M.; Cashell, K.A.; Shamass, R.; Desnerck, P. Bond behaviour of austenitic stainless steel reinforced concrete. Eng. Struct. 2020, 221, 111027. [Google Scholar] [CrossRef]

- Rabi, M.; Cashell, K.A.; Shamass RJ, E.S. Flexural analysis and design of stainless steel reinforced concrete beams. Eng. Struct. 2019, 198, 109432. [Google Scholar] [CrossRef]

- Kim, J.H.; Cho, Y.; Jang, Y.H. Estimation of the weldability of single-sided resistance spot welding. J. Manuf. Syst. 2013, 32, 505–512. [Google Scholar] [CrossRef]

- Nishibata, H.; Fukumoto, M.; Uchihara, M. Influence of welding conditions on nugget formation in single-sided resistance spot welding process. Weld. World 2009, 53, 15–22. [Google Scholar] [CrossRef]

- Rabi, M.; Shamass, R.; Cashell, K.A. Description of the constitutive behaviour of stainless steel reinforcement. Case Stud. Constr. Mater. 2024, 20, e03013. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, W.; Tian, G.; Liu, Z. Joint values determination of wind and temperature actions on long-span bridges: Copula-based analysis using long-term meteorological data. Eng. Struct. 2020, 219, 110866. [Google Scholar] [CrossRef]

- Ge, P.Y.; Xu, P.D.; Sun, P.L.; Sun, P.Z. Introduction: Recent structures and research in China. Struct. Eng. Int. 2022, 32, 133. [Google Scholar] [CrossRef]

- Garg, A.; Kamat, V.R. Virtual prototyping for robotic fabrication of rebar cages in manufactured concrete construction. J. Archit. Eng. 2014, 20, 06013002. [Google Scholar] [CrossRef]

- Karadeniz, E.; Ozsarac, U.; Yildiz, C. The effect of process parameters on penetration in gas metal arc welding processes. Mater. Des. 2007, 28, 649–656. [Google Scholar] [CrossRef]

- Gao, M.; Zeng, X.; Hu, Q. Effects of gas shielding parameters on weld penetration of CO2 laser-TIG hybrid welding. J. Mater. Process. Technol. 2007, 184, 177–183. [Google Scholar] [CrossRef]

- Rabi, M.; Abarkan, I.; Shamass, R. Buckling resistance of hot-finished CHS beam-columns using FE modelling and machine learning. Steel Constr. 2024, 17, 93–103. [Google Scholar] [CrossRef]

- Rabi, M.; Jweihan, Y.S.; Abarkan, I.; Ferreira FP, V.; Shamass, R.; Limbachiya, V.; Tsavdaridis, K.D.; Santos LF, P. Machine learning-driven web-post buckling resistance prediction for high-strength steel beams with elliptically-based web openings. Results Eng. 2024, 21, 101749. [Google Scholar] [CrossRef]

- Jweihan, Y.S.; Al-Kheetan, M.J.; Rabi, M. Empirical model for the retained stability index of asphalt mixtures using hybrid machine learning approach. Appl. Syst. Innov. 2023, 6, 93. [Google Scholar] [CrossRef]

| Group of Specimens | Longitudinal Rebar (mm) | Transverse Rebar (mm) | Type | Number | ||

|---|---|---|---|---|---|---|

| Diameter | Length | Diameter | Length | |||

| Sx1 | 36 | 350 | 20 | 350 | HRB400 | 50 |

| Sx2 | 32 | 350 | 20 | 350 | HRB400 | 5 |

| Sx3 | 32 | 350 | 16 | 350 | HRB400 | 5 |

| Sx4 | 28 | 350 | 16 | 350 | HRB400 | 5 |

| Sy1 | 36 | 350 | 20 | 400 | HRB400 | 5 |

| Sy2 | 32 | 350 | 20 | 400 | HRB400 | 5 |

| Sy3 | 32 | 350 | 16 | 400 | HRB400 | 5 |

| Sy4 | 28 | 350 | 16 | 400 | HRB400 | 5 |

| Sz1 | 36 | 400 | 20 | 350 | HRB400 | 5 |

| Sz2 | 32 | 400 | 20 | 350 | HRB400 | 5 |

| Sz3 | 32 | 400 | 16 | 350 | HRB400 | 5 |

| Sz4 | 28 | 400 | 16 | 350 | HRB400 | 5 |

| Group of Specimens | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| a | b | k | a | b | k | a | b | k | |

| Sx1 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| Sx2 | 0.95 | 0.97 | 1.04 | 1.06 | 1.03 | 1.15 | 1.12 | 1.06 | 1.11 |

| Sx3 | 0.85 | 1.12 | 0.96 | 0.82 | 0.94 | 0.84 | 0.96 | 0.84 | 0.88 |

| Sx4 | 0.79 | 1.01 | 1.07 | 0.70 | 0.99 | 1.00 | 0.89 | 0.98 | 0.93 |

| Sy1 | 0.48 | 2.03 | 0.30 | 0.51 | 2.09 | 0.27 | 1.06 | 1.03 | 0.90 |

| Sy2 | 0.43 | 2.18 | 0.38 | 0.40 | 2.27 | 0.41 | 0.93 | 1.04 | 1.08 |

| Sy3 | 0.35 | 2.25 | 0.31 | 0.30 | 1.96 | 0.34 | 0.86 | 0.87 | 1.10 |

| Sy4 | 0.32 | 2.17 | 0.28 | 0.28 | 2.15 | 0.24 | 0.88 | 0.99 | 0.86 |

| Sz1 | 0.70 | 1.21 | 0.39 | 0.76 | 1.09 | 0.43 | 1.09 | 0.90 | 1.10 |

| Sz2 | 0.67 | 1.35 | 0.45 | 0.58 | 1.53 | 0.48 | 0.87 | 1.13 | 1.07 |

| Sz3 | 0.62 | 1.29 | 0.40 | 0.63 | 1.30 | 0.39 | 1.02 | 1.01 | 0.98 |

| Sz4 | 0.59 | 1.41 | 0.49 | 0.54 | 1.44 | 0.43 | 0.92 | 1.02 | 0.88 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, H.; Shen, H.; Liu, Z.; Xi, Z. Deformation Evaluation in Welded Rebar Parts for Pylons and Its Application in Changtai Yangtze River Bridge. Buildings 2025, 15, 976. https://doi.org/10.3390/buildings15060976

Zheng H, Shen H, Liu Z, Xi Z. Deformation Evaluation in Welded Rebar Parts for Pylons and Its Application in Changtai Yangtze River Bridge. Buildings. 2025; 15(6):976. https://doi.org/10.3390/buildings15060976

Chicago/Turabian StyleZheng, Hehui, Huijun Shen, Zhao Liu, and Zhuo Xi. 2025. "Deformation Evaluation in Welded Rebar Parts for Pylons and Its Application in Changtai Yangtze River Bridge" Buildings 15, no. 6: 976. https://doi.org/10.3390/buildings15060976

APA StyleZheng, H., Shen, H., Liu, Z., & Xi, Z. (2025). Deformation Evaluation in Welded Rebar Parts for Pylons and Its Application in Changtai Yangtze River Bridge. Buildings, 15(6), 976. https://doi.org/10.3390/buildings15060976