Abstract

The durability degradation of concrete structures in marine and urban underground environments is largely governed by chloride-induced corrosion. This process becomes significantly more severe under the coupled action of external loading and drying–wetting cycles, which accelerate chloride transport and structural deterioration. However, the existing research often isolates the effects of mechanical loading or environmental exposure, failing to comprehensively capture the synergistic interaction between these factors. This lack of understanding of chloride ingress under simultaneous mechanical and environmental loading limits the development of reliable service life prediction models for concrete structures. In this study, a self-made loading system was employed to simulate this coupled environment, combining external loading with 108 days of drying–wetting cycles. Chloride profiles were obtained to assess the combined effects of stress level, water/binder ratio, and fiber content on chloride penetration in fiber-reinforced cementitious composites (FRCCs). To further extend the analysis, a Crank–Nicolson-based finite difference approach was developed for the numerical assessment of chloride diffusion in concrete structures after repair. This model enables the point-wise treatment of nonlinear chloride concentration profiles and provides space- and time-dependent chloride concentration distributions. The results show that using an FRCC as a repair material significantly enhances the service life of chloride-contaminated concrete structures. The remaining service life of the repaired concrete was extended by 36.82% compared to the unrepaired case, demonstrating the clear practical value of FRCC repairs in aggressive environments.

1. Introduction

With the rapid development of large-scale civil engineering, concrete, as one of the most widely used building materials globally, has an annual consumption exceeding 2 billion tons, making it the second most consumed resource after water [1]. In marine and urban underground environments, chloride ion erosion has become one of the primary factors contributing to the deterioration of concrete structures [2,3]. Under the long-term effects of external loads and complex environmental conditions, the performance of concrete gradually degrades, and the penetration of chloride ions further accelerates this deterioration process [4,5].

Under external loads, microcracks inevitably form within concrete [6]. The propagation of these cracks significantly increases the rate of chloride ion penetration. During chloride-induced steel corrosion, the volumetric expansion of corrosion products generates tensile stress, further reducing the load-bearing capacity and service life of concrete structures [7,8]. Additionally, the interaction between external loads and microcracks complicates the transport behavior of chloride ions [9], especially in marine and urban underground environments, where predicting structural lifespan poses greater challenges [10]. Moreover, under wet–dry cycling conditions, the rate of chloride ion penetration further accelerates [11]. Therefore, when assessing the durability of concrete structures, it is essential to consider their load history and environmental factors [12,13].

To address this issue, numerous studies have focused on the impact of external loads on chloride ion penetration mechanisms and the degradation of concrete durability. For example, American scholar Powers [14] first investigated water in the capillary pores of concrete from a sub-microscopic perspective in 1945, concluding that the expansion pressure generated by the freezing of free water in capillary pores is the primary cause of freeze–thaw damage in concrete, thereby proposing the hydrostatic pressure theory. Bao and Wang [15] found that chloride ion permeability is significantly influenced by the degree of saturation and loading conditions of concrete. Wang et al. [16] experimentally observed that when crack widths exceed 0.07 mm, the diffusion rate of chloride ions increases significantly, whereas the effect is negligible for crack widths below 0.07 mm. Similar studies have also found that the chloride ion diffusion coefficient in concrete under alternating wet–dry conditions is higher than that in fully submerged concrete, and the chloride ion transport rate in tensile regions is significantly higher than in compressive regions [17]. Xu and Chen [18] studied the impact of Friedel’s salt formation on chloride ion erosion and proposed a porosity diffusion equation that considers chemical reactions and corrosion damage. Wang et al. [19] explored the effects of external loads and freeze–thaw cycles on chloride ion diffusion, emphasizing that loading conditions are crucial for predicting the durability of concrete structures. With the deepening of research, related achievements have covered various aspects, including damage mechanisms, experimental methods, and durability evaluation [20].

However, most studies still primarily focus on the influence of load history on the chloride ion penetration behavior of original concrete [21,22], while research on repaired concrete under the combined effects of load, erosive environments, and wet–dry cycles is relatively limited. To extend the service life of concrete structures, surface treatments are widely used to prevent chloride ion ingress. However, current research on the long-term durability of repaired concrete under load is still insufficient, leading to inadequate durability assessments of repaired structures. Additionally, traditional chloride ion transport prediction models are typically based on Fick’s second law [23], but this assumption may no longer hold when part of the original concrete is replaced with new repair materials [24].

In recent years, domestic and international studies have shown that the main materials for repairing concrete can be divided into cement-based materials, resin-based materials, and polymer-modified cement-based composite materials (PMCs) [25,26]. Cement-based materials are widely used in repair engineering due to their good compatibility and ease of construction, but their crack resistance and durability are poor, making it difficult to meet the requirements for high strength, high toughness, and long service life in engineering. Resin-based materials, despite their high strength, are limited in widespread application due to their strong temperature sensitivity, high construction requirements, high cost, and susceptibility to aging. Polymer-modified cement-based composite materials (PMCs) [27] can significantly improve the mechanical properties, impermeability, and construction performance of concrete. However, their high cost and the environmental impact of some polymer materials limit their use in large-scale repair projects.

Fiber-reinforced cementitious composites (FRCCs), also known as fiber-reinforced cement-based composites, are composed of short or long fibers combined with a cementitious matrix [28]. Addressing the issues of brittle failure and insufficient durability in traditional concrete, FRCCs offer an effective solution. The reinforcing fibers in FRCCs mainly include steel fibers, polypropylene fibers, and polyvinyl alcohol (PVA) fibers. Among these, steel fibers have the longest history of application in cement-based composites, spanning a century; polypropylene fibers [29] and PVA fibers [30] are widely used in cement-based composites due to their excellent crack resistance and durability. Research has found that ultra-high toughness cementitious composites (UHTCCs) [31,32] and engineered cementitious composites (ECCs) [33] exhibit exceptional ductility and durability. Compared to ordinary concrete, UHTCCs have a significantly lower permeability coefficient, and their chloride ion penetration capability is much lower than that of traditional cement-based materials, indicating a significant advantage in resisting chloride ion erosion [34,35].

In summary, fiber-reinforced cementitious composites, as a new type of repair material, have made significant progress in improving the mechanical properties, durability, and toughness of concrete structures. However, to further promote their application in engineering, it is necessary to optimize material formulations, reduce production costs, and enhance their adaptability under different environmental conditions. Based on this, this study simulates continuous loading and wet–dry cycling conditions in marine and urban underground environments to analyze the effects of stress levels, water-to-binder ratio, and fiber content on the chloride ion permeability of FRCCs. Additionally, this paper proposes a finite difference numerical solution method based on the Crank–Nicolson method and derives a chloride ion transport model for evaluating the extended service life of structures after the application of repair materials.

2. Experiment Investigation

2.1. Materials

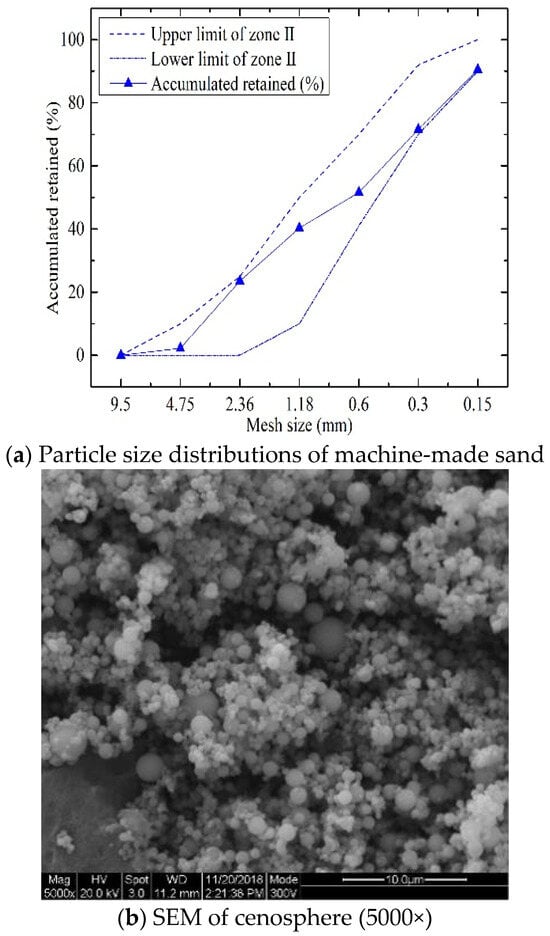

The raw materials used in this study include cement, machine-made sand, cenospheres, polypropylene fibers, and polycarboxylate superplasticizer. The cement is P.O 42.5, and its chemical compositions and physical properties are listed in Table 1 and Table 2, respectively. The machine-made sand was used as the fine aggregate, and its physical properties are shown in Table 3. The particle size distribution curve of the machine-made sand is presented in Figure 1a. Cenospheres were used as lightweight fillers. Their chemical compositions are given in Table 4, and the microscopic morphology of the cenospheres can be seen in the SEM image in Figure 1b. Polypropylene fibers were added to improve the tensile properties and crack resistance of FRCCs. The physical properties of the fibers are shown in Table 5, and their appearance is illustrated in Figure 1c. A polycarboxylate superplasticizer with a solid content of 32% and a water reduction rate of 40% was used to enhance workability.

Table 1.

Material characteristics of OPC.

Table 2.

Chemical compositions of OPC.

Table 3.

Material characteristics of machine-made sand.

Figure 1.

Properties of raw materials.

Table 4.

Chemical compositions of cenosphere.

Table 5.

Material characteristics of polypropylene (PP) fiber.

2.2. Specimen Preparation and Curing

An experimental program was designed to investigate the chloride permeability of FRCC based on external stress level, water/binder ratio, and PP fiber content. For this purpose, four mix proportions of FRCC were prepared. As a reference, a mix proportion of C40 concrete was selected as the control concrete (CC). The proportions of four mixtures and control concrete are rendered in Table 6 and Table 7, respectively.

Table 6.

Mix proportions of FRCC (Unit: kg/m3).

Table 7.

Mix proportions of control concrete (unit: kg/m3).

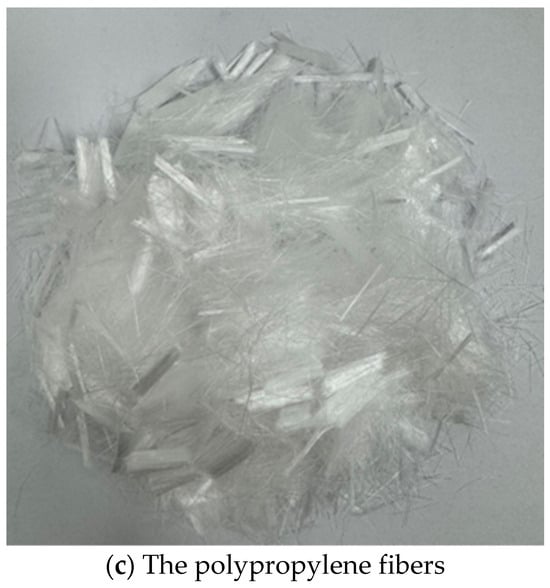

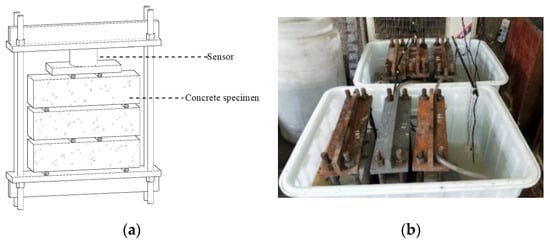

A low water/binder ratio is commonly used in high-strength and durable concrete. To prevent fiber agglomeration in the paste, a specific mixing procedure, as illustrated in Figure 2, was implemented in this study. The durability of fiber-reinforced cementitious composites (FRCC) under the combined effects of external loading and drying–wetting cycles in artificial seawater was evaluated using prismatic specimens, each measuring 100 mm × 100 mm × 400 mm. The FRCC mixture is shown in Figure 3.

Figure 2.

The mixing procedure.

Figure 3.

Fluidity and workability of FRCC repair system.

2.3. Experimental Methods

2.3.1. The Drying-and-Wetting Cycle of Marine and Urban Underground Environments Under External Four-Point Load System

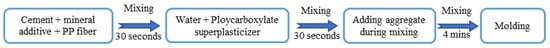

A custom-designed dry–wet cycling machine, as shown in Figure 4, was utilized in this study. The system incorporated a time relay, water level sensor, and pump to enable an automated circulation process between the two containers. During each cycle, the specimens were fully immersed in a seawater solution for 12 h, followed by 12 h of natural drying. As a result, each cycle represented one full day of exposure.

Figure 4.

Sustained external loading system (unit, mm). (a) Schematic diagram of sustaining external flexure loading system; (b) The drying-and-wetting cycle of seawater under external four-point load system.

To examine the effect of stress level on the chloride permeability of prismatic concrete specimens, three different flexural stress levels (ranging from 0% to 50% of the corresponding flexural loading capacity) were selected. The external flexural loading applied to each specimen is detailed in Table 8.

Table 8.

Design of mechanical loading.

To accelerate the corrosion process, a seawater solution with five times the ion concentration of natural seawater was used in this study. The composition of the seawater solution was prepared as shown in Table 9, with specific ions increased by a factor of five to enhance the corrosion effect.

Table 9.

The chemical composition of high-concentration seawater (unit g/L).

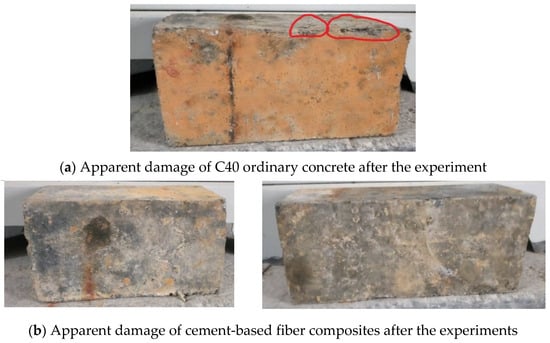

As shown in Figure 5, after 108 dry–wet cycles under the combined effects of loading and the marine environment, the surface of the C40 conventional concrete exhibited slight spalling and peeling. In contrast, the surface, edges, and corners of the fiber-reinforced cementitious composite remained intact, with almost no visible damage.

Figure 5.

Comparison of the surface damage after the test.

2.3.2. Test Method of Chloride Ion Content in Hardened Concrete

The determination of water-soluble chloride ion content in hardened concrete was carried out in accordance with the relevant provisions of JGJ/T 322-2013 “Technical Specification for Test of Chloride Ion Content in Concrete” [36]. The testing procedure involved the following steps: First, concrete powder samples were collected from different depths of the specimens using a drill with a stainless steel bit to prevent contamination. The collected powder was sieved through a 0.63 mm mesh to obtain fine particles suitable for testing. Second, a specified amount of the prepared concrete powder was dissolved in distilled water at a controlled liquid-to-solid ratio. The mixture was then subjected to continuous stirring to ensure thorough extraction of water-soluble chloride ions. The solution was left to settle before filtering to remove solid particles. Then, the chloride ion concentration in the extracted solution was measured using potentiometric titration with silver nitrate (AgNO3), following the standard Mohr method or automatic titration method. The chloride content was then calculated based on the volume of silver nitrate solution consumed during the reaction. Finally, the obtained chloride ion content was expressed as a percentage of the cementitious material’s mass.

3. Experimental Results and Analysis

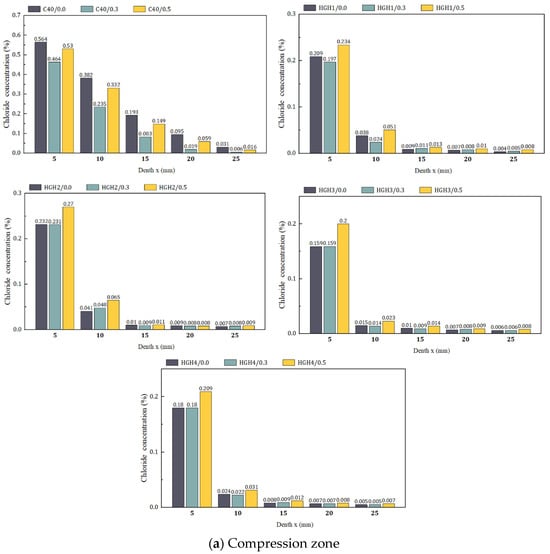

After more than 108 days of exposure to drying–wetting cycles under external loading in both marine and urban underground environments, the chloride concentration profiles at different depths for all test conditions were obtained and are presented in Figure 6 for comparison.

Figure 6.

The profile of chloride concentration along the depth.

As shown in Figure 6, the chloride concentration of all mixtures exhibited a decreasing trend with increasing depth (x). A sharp decline in chloride concentration was observed as the depth increased from 5 mm to 15 mm, eventually stabilizing at a terminal content of 0.0035% of the concrete mass. Notably, the chloride concentration in the FRCC was significantly lower compared to C40 concrete, demonstrating the superior durability of the FRCC in resisting chloride penetration. This enhanced resistance highlights the potential of an FRCC as an effective repair material in aggressive environments.

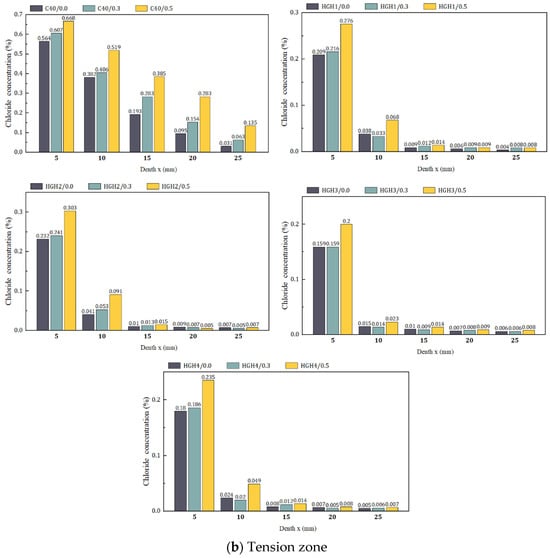

To further examine the influence of stress levels on chloride penetration resistance, the chloride concentration of all mixtures at a depth of 5 mm is summarized in Figure 7.

Figure 7.

The influence of stress level on chloride penetration resistance.

As shown in Figure 7, the chloride concentration in the compression zone exhibited a nonlinear trend, initially decreasing and then increasing with stress levels, reaching its minimum at a stress level of 0.3. In contrast, the tension zone showed a continuous increase in chloride concentration as the stress level increased. At the same stress level, chloride concentration in the tension zone was consistently higher than in the compression zone. This phenomenon can be attributed to tensile-induced damage at the aggregate-paste interface, which accelerates chloride diffusion. Conversely, concrete under 0.3 stress level in the compression zone exhibited reduced porosity, thereby impeding chloride penetration.

The influence of stress level on an FRCC was significantly less pronounced than on C40 concrete. In the FRCC, the chloride concentration remained almost unchanged when the stress level increased from 0 to 0.3. However, at a 0.5 stress level, the chloride concentration increased by approximately 1.12 to 1.16 times compared to that at a stress level of 0, a trend also observed in the tension zone (JGJ/T 322-2013). This can be explained by the high modulus of FRCC, which results in lower strain at a 0.3 stress level, minimizing its effect on porosity. However, under higher stress, microcrack formation and propagation occur, accelerating chloride diffusion [37].

The effect of the water/binder ratio on chloride penetration resistance is prominently illustrated in Figure 6. As the water/binder ratio increased, the chloride concentration also increased. Specifically, the chloride concentration at a 0.2 water/binder ratio was approximately 1.26 to 1.38 times higher than that at a 0.16 water/binder ratio. A lower water/binder ratio reduces the initial porosity of cement paste, effectively refining its microstructure and enhancing chloride penetration resistance.

A similar trend was observed with PP fiber dosage. As the fiber content increased, the chloride concentration also rose. This is likely due to the difficulty in dispersing PP fibers in a paste with lower fluidity when the water/binder ratio decreases from 0.2 to 0.16. The agglomeration of PP fibers can create inherent weak spots in the concrete matrix, leading to increased chloride diffusion and a subsequent decline in chloride penetration resistance [38].

4. Chloride Transport Model for Predicting the Service Life of Concrete with Repaired Under the Coupled Effect of External Flexure Load and Drying-and-Wetting Cycle in Marine and Urban Underground Environments

Chloride-induced corrosion is a fundamental durability issue in concrete structures located in marine and urban underground environments. The corrosion of reinforcement in the drying-and-wetting cycle zone is becoming an increasingly common problem. A careful method to assess the service life and predict the remaining service life after repair is of significant interest. Establishing a transport model of chloride ions into concrete under the coupled effects of external load and drying-and-wetting cycles in marine and urban underground environments is the first step toward predicting the service life of such concrete structures. Fick’s second law has been extensively applied to predict the time to chloride-induced corrosion, as given by Equation (1).

where C = C(x, t) is the chloride concentration at depth x after time t, and D is the diffusion coefficient. The solution of the above equation can be given as (2)

where C0 is the initial chloride concentration (as explained in the previous section, the chloride concentration levels off at a terminal content; this value of chloride content is considered the initial chloride concentration, which is about 0.0035% of concrete mass). In addition, Cs is the surface chloride concentration (in this paper, based on the GB/T 50476-2019 “Standard for design of concrete structure durability” [39], a Cs of the FRCC of 0.65% and a Cs of C40 concrete of 0.8% were adopted), and erf () is the error function, which is given in Equation (3).

In this paper, since the experimental period is far shorter than the service time in a practical environment, the time-varying effect of the chloride diffusion coefficient can be ignored. Therefore, the chloride diffusion coefficient can be described as follows:

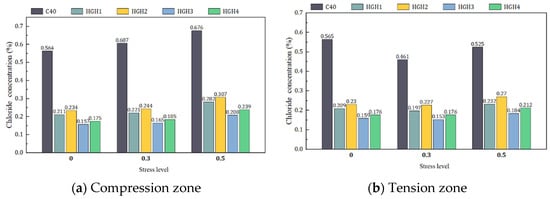

where t is 108 days, the diffusion coefficient can be obtained by inserting C0 and Cs into Equation (4). Based on the chloride concentration profiles shown in Figure 6, the diffusion coefficient D of mixtures can be obtained and summarized in Table 10.

Table 10.

The diffusion coefficient D (10−12 m2/s).

From the inspection of Table 10, it can be seen that the value of chloride diffusion coefficient D of C40 concrete is significantly greater than the value of the FRCC. In C40 concrete, the value of D increases monotonically with the increase in flexural strength. However, a tendency of decreasing first then increasing can be observed in the compression zone, and the value of D in the compression zone is lower than in the tension zone.

The influence of stress level on the diffusion coefficient of the FRCC is far less pronounced than that of C40 concrete. The mixtures of HGH1 and HGH2 show similar values of D in the compression or tension zone when the stress level is lower than 0.3, but decrease at a stress level of 0.5. The value of D at a stress level of 0.5 was about 1.18~1.59 times that of the value at a stress level of 0.

4.1. Description of the Chloride Transport Model of Repaired Concrete

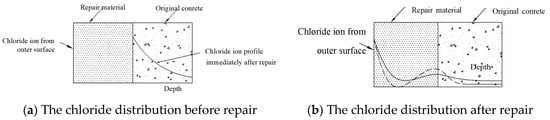

Structural members damaged by corrosion are typically repaired by applying surface treatment [40,41], which involves the removal of the original concrete cover and its replacement with a chloride-free repair material. Concrete is retrofitted using repair coatings, which ideally limit the ingress of chloride and oxygen to the embedded steel. The effectiveness of surface treatment has been demonstrated by extensive studies [42,43,44]. There are two main steps for the prediction of chloride ion profile in repaired concrete as shown in Figure 8 and Figure 9, i.e., penetration from the outer surface through the original concrete and the redistribution after repair.

Figure 8.

Chloride profile after repairing by FRCC.

Figure 9.

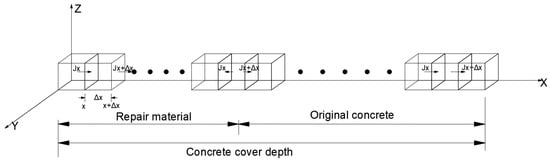

Schematic diagram of the transport of chloride ions in repaired concrete.

There are two sources of initial chloride ions: surface chloride ions in the new repaired concrete cover and remaining chloride ions in the original concrete. In addition, the diffusion coefficient is space-dependent due to the difference in properties between the original concrete and the repair material [45]. This makes analytical solutions to the partial differential equation, i.e., Fick’s second law, unavailable. To address these difficulties, a Crank–Nicolson-based numerical scheme derived from Fick’s first law is introduced for computation. The diffusion in concrete is regarded as a one-dimensional process. In this case, the chloride transport through the repaired concrete is described by Fick’s law:

where the C is the chloride concentration (mol/m3), D (m2/s) is the diffusion coefficient which was determined experimentally, and J (mol/m2) is the ionic flux. In this case, the accumulation of chloride ions diffused in the volume element in the incremental time step Δt can be repressed by follows:

where the is the ionic flux into the volume element and the is the flux outflow the volume element. In addition, is the size of mesh point. A Crank–Nicolson numerical scheme for Equation (1) can be written as

where the and are the chloride concentration at depth x from the surface at time and , respectively. Additionally, , , and are the chloride concentrations at depths , , and from the boundary at time . The numerical computation was performed using the transport model. By adopting the finite difference method, the nonlinear chloride profile can be treated point-wise, allowing the problem involving the nonlinear chloride ion profile in repaired concrete to be solved.

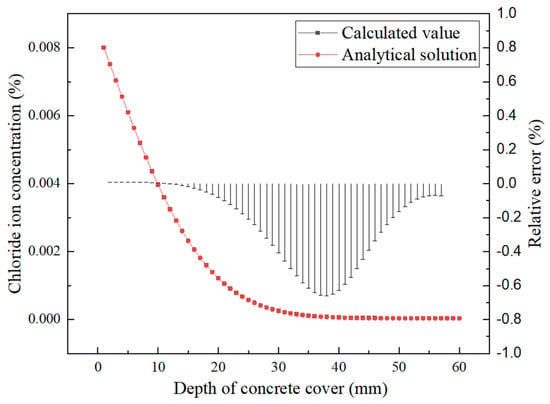

To validate the numerical model mentioned above, chloride concentrations in a no-stress state at different depths were calculated using the space-dependent diffusion coefficient model proposed in this paper and compared with the analytical solution based on Fick’s second law, where C0 = 0.0035%, Cs = 0.8%, and D = 9.26 × 10−12. Figure 10 compares the predicted values from the model with the calculated values based on Fick’s second law after 108 days of exposure.

Figure 10.

Comparison between predicted value and analytical solution.

According to the comparison results in Figure 10, it can be seen that the predicted free chloride concentrations in concrete calculated by the space-dependent prediction model of chloride diffusivity proposed in this paper are in good agreement with the measured concentrations. The calculated relative error for this chloride transport model is at a maximum at a depth of 37 mm. The numerical error of this model is less than 0.659%, indicating that this method can be used for calculating the chloride profile of concrete after repair. This model for all mixtures was implemented using MATLAB R2014b.

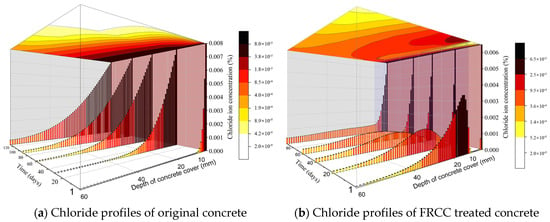

4.2. Application of the Model

Based on the aforementioned chloride ion transport model, the service life of original concrete and original concrete coated with HGH3 exposed to marine and urban underground environments was evaluated. The chloride ion profiles with a 60 mm concrete cover and a 10 mm replacement by HGH3 were predicted, as shown in Figure 11a,b, respectively.

Figure 11.

Chloride profiles of concrete obtained from the developed approach.

As shown in Figure 11a, the chloride concentration at a depth of 60 mm reached the critical chloride concentration, which is 0.04% of the concrete mass, at an exposure age of 129 days. At an exposure age of 60 days, a 10 mm FRCC layer replaced the equivalent thickness of the original concrete cover. The chloride ions penetrating through the surface of the concrete and the remaining chloride ions in the original concrete will both redistribute through the repair material and penetrate further into the original concrete. According to Figure 11b, the chloride concentration of the repaired original concrete at a depth of 60 mm reached the critical chloride concentration at an exposure age of 95 days. As shown in the results, there is a significant increase in performance between the repaired concrete and the original concrete. The residual service life of the original concrete was increased by 36.82% after repair with the FRCC.

4.3. Coulomb Electrical Flux Results and Analysis

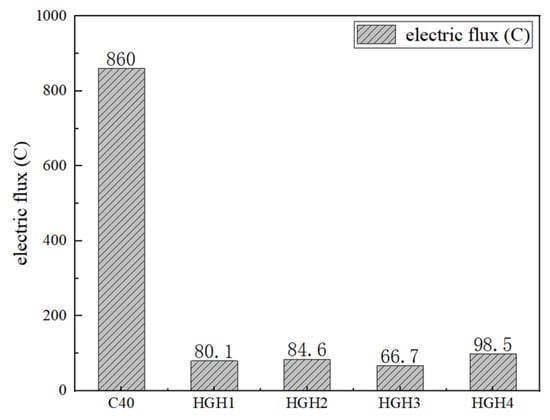

The results of the coulomb electrical flux of the specimens 28d are shown in Figure 12:

Figure 12.

Results of the coulomb electrical flux experiments.

As shown in Figure 12, the coulomb electrical flux of this material is below 100 coulombs, significantly lower than that of C40 ordinary concrete. According to the ASTM classification standard for chloride permeability in concrete, this indicates negligible chloride permeability, demonstrating excellent resistance to chloride penetration. Among the tested mixtures, the water/binder ratio of 0.16 combined with 1% fiber content (HGH 3) exhibited the lowest coulomb electrical flux value, confirming its superior chloride resistance. This aligns with the experimental results obtained from the drying–wetting cycles under load. However, when the fiber content increased to 2%, the chloride permeability resistance declined. This is likely due to excessive fiber content creating a high density of fiber–cement interfaces and fiber entanglement, making dispersion difficult. When the water/binder ratio is particularly low, the concrete’s workability is further reduced, exacerbating this issue. It is also worth noting that in the early testing stages, the coulomb electrical flux readings were unstable. After 56 days of exposure, the flux had further decreased to nearly zero, at which point additional measurements were not conducted. Given this trend, no further conclusions were drawn regarding long-term flux behavior.

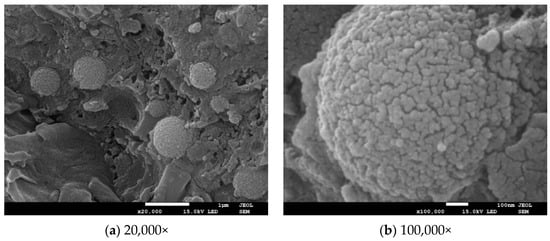

4.4. SEM and EDS Microscopic Analysis

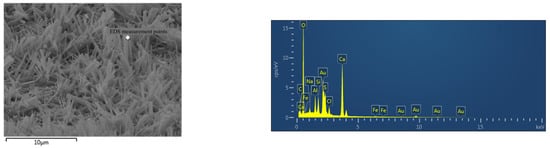

Figure 13 presents the SEM images, EDS spectra, and elemental analysis of the internal air voids in C40 ordinary concrete after 108 days of exposure. As observed in Figure 13, a large number of rod-like calcium crystals measuring approximately 5–10 μm in length were formed within the C40 concrete. These are likely sulfate corrosion products generated due to prolonged exposure to the high-concentration seawater drying–wetting cycles. In contrast, the cement-based fiber composite material exhibits a significant presence of spherical hydration products, with no detectable rod-like ettringite crystals, as shown in Figure 14. Combined with an EDS elemental spectrum analysis, the primary elements identified are calcium, silicon, and oxygen (see Table 11), with a Ca/Si ratio of approximately 1.2. This indicates that the hydration product belongs to C-S-H gel, which was not found in the C40 ordinary concrete and is unrelated to corrosion. The likely explanation for this difference is the high density of the cement-based fiber composite, which restricts the formation of distinctive C-S-H gel morphologies. As a result, the microstructure predominantly consists of spherical particles, aligning with findings from previous research studies.

Figure 13.

SEM plots and EDS plots of C40 ordinary concrete after the experiment.

Figure 14.

SEM plots and EDS plots of the cement-based fiber composites after the experiment.

Table 11.

EDS composition (%).

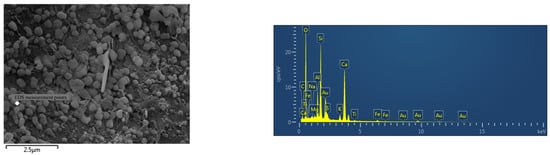

The interfacial transition zone (ITZ) between the aggregate and cement paste in ordinary concrete exhibits a loose grid-like structure with numerous defects, making it the weakest link in the material. In contrast, as shown in Figure 15, the ITZ of the cement-based fiber composite remains remarkably dense even after prolonged exposure to combined external loading and a marine environment. Even under 10,000× magnification, no significant cracks or visible defects are observed in the cement-based fiber composite, indicating a notably enhanced ITZ. This suggests that the incorporation of fibers effectively improves the bonding strength at the slurry–aggregate interface, significantly reinforcing the material’s durability.

Figure 15.

The morphology of the interface transition zone of the cement-based fiber composite after the test.

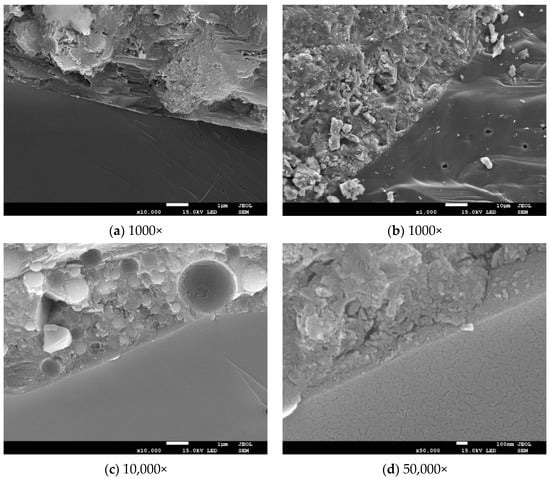

Figure 16 presents the typical micromorphology of the reaction-generated beads. As observed, a significant amount of hydration products have formed around the beads, creating a strong bond with the material matrix. The hydration reaction primarily occurs on the particle surfaces, contributing positively to the strength development of the material.

Figure 16.

Microtopography after the microbead reaction.

5. Discussion

In previous studies, significant progress has been made in understanding the chloride ion penetration resistance of cement-based fiber-reinforced composites. Many studies have primarily focused on the fundamental properties of cement-based composites, such as compressive strength, flexural strength, and durability. Researchers have commonly introduced various fiber materials (such as glass fibers and steel fibers) to enhance the mechanical properties and durability of cement-based materials. Furthermore, chloride ion permeability, as a crucial durability indicator, has received widespread attention in multiple studies. Most previous research has concentrated on improving chloride penetration resistance by modifying the pore structure of cement-based composites, reducing the water-to-cement ratio, or optimizing the fiber content.

However, existing studies mainly focus on performance evaluations under single environmental conditions, lacking systematic assessments of cement-based fiber-reinforced composites under the combined influence of complex environmental factors. While previous research has highlighted the significant role of fiber materials in improving the chloride penetration resistance of concrete, systematic studies on the variation in chloride permeability in cement-based fiber composites under different stress levels remain relatively scarce. In particular, the differential effects of tensile and compressive stresses on chloride penetration under high-stress conditions have not been thoroughly explored.

Building on previous research, this study further expands the understanding of chloride ion penetration resistance in cement-based fiber-reinforced composites, especially under complex environmental conditions. In addition to examining the common factors affecting chloride penetration, such as fiber content and water-to-cement ratio, this study focuses on the combined effects of loading and marine environments on the overall performance of cement-based fiber composites. Through dry–wet cyclic tests under loading conditions, this study investigates the influence of different stress levels—particularly the effects of tensile and compressive stresses under high-stress conditions—on the chloride diffusion coefficient. The results indicate that tensile stress significantly worsens permeability, whereas low-stress levels have minimal impact, providing new insights into the durability and service life prediction of concrete structures.

Additionally, this study explores the corrosion resistance of cement-based fiber composites under the combined action of loading and marine environments through a microstructural analysis. Scanning electron microscopy (SEM) observations reveal that the interfacial transition zone between the cementitious matrix and aggregates is significantly enhanced in fiber-reinforced composites. This microstructural improvement is considered a key factor in enhancing the chloride penetration resistance of the material. Compared with previous studies, this research places greater emphasis on the durability performance and microstructural mechanisms of cement-based fiber-reinforced composites under complex environmental conditions, thereby providing more comprehensive theoretical support for their application.

Experimental results demonstrate that sustained loading significantly affects chloride diffusion. Under tensile stress, microcracks develop and propagate within the concrete, increasing permeability and accelerating chloride ingress. This finding aligns with previous studies [16,17], which indicate that when crack widths exceed 0.07 mm, chloride diffusion is significantly accelerated, whereas cracks smaller than 0.07 mm have negligible effects. In contrast, in compressive regions, the concrete microstructure becomes denser, hindering ion diffusion to some extent. However, prolonged exposure to aggressive environments can still lead to gradual deterioration. Furthermore, the synergistic effect of mechanical loading and chloride penetration complicates the prediction of concrete structure service life. Traditional diffusion models based on Fick’s second law may not accurately capture the interaction between damage evolution and ion diffusion, necessitating more refined models that incorporate mechanical–chemical coupling effects. The study suggests that in chloride-rich environments, selecting appropriate repair materials is critical for extending the service life of concrete structures. For marine and urban underground engineering applications, fiber-reinforced repair materials should be prioritized to enhance structural durability. Additionally, the integration of advanced predictive models will assist engineers in more accurately assessing structural service life, optimizing maintenance planning, and reducing repair costs.

Despite the significant findings of this study, some limitations remain. First, the experiments were conducted under controlled laboratory conditions, which may not fully replicate the complexities of real-world engineering environments. Future research should involve long-term field monitoring to validate the applicability of the experimental results. Second, the proposed chloride ion penetration model requires further optimization to better account for loading effects and dynamic environmental variations over time. Lastly, limited research has been conducted on the comparative performance of different repair strategies under multiple deterioration mechanisms (e.g., freeze–thaw cycles, sulfate attack). Future studies should establish a more comprehensive durability assessment system.

6. Conclusions

This study examined the effects of stress levels, water/binder ratio, and fiber content on the chloride permeability of concrete under the combined influence of external loading and drying–wetting cycles in simulated marine and urban underground environments. A custom-designed testing system was utilized to replicate these coupled environmental and mechanical conditions for both fiber-reinforced cementitious composites (FRCCs) and conventional C40 concrete. Furthermore, a numerical model based on Fick’s law was developed to characterize chloride transport in repaired concrete, enabling the estimation of the remaining service life of repaired concrete structures. The key conclusions drawn from this study are as follows:

- (1)

- In the accelerated coupling test of load and a marine wet–dry cyclic environment, the apparent chloride diffusion coefficient of the cement-based fiber composite material is lower by an order of magnitude compared to that of C40 ordinary concrete, resulting in a significantly longer service life. Stress levels have a significant impact on the chloride apparent diffusion coefficient of ordinary concrete, especially under sustained tensile stress, where the diffusion coefficient increases almost exponentially. For the cement-based fiber composite material, low stress levels have minimal effect on its chloride diffusion coefficient, while high stress levels have a certain degree of impact, with the effect of tensile stress being more significant than that of compressive stress.

- (2)

- The presence of compressive stress has a beneficial effect on the durability of the structure, while under tensile stress, the durability almost decreases linearly, and the presence of tensile stress severely reduces the service life of the structure. However, for the cement-based fiber composite material, low stress levels have almost no noticeable effect on its durability, while high stress levels have a more significant impact, especially under high tensile stress. This indicates that previous experiments without load for predicting the service life of structures may present potential risks. When predicting the service life of structures, the effect of stress levels on the structure’s lifespan should be considered.

- (3)

- The cement-based fiber composite material exhibits excellent resistance to chloride ion penetration, with its coulomb electrical flux value being less than 100 coulombs, about one-tenth that of C40 ordinary concrete. The lowest coulomb electrical flux value and best permeability resistance are observed when the water-to-cement ratio is 0.16 and the fiber content is 1%, which is consistent with the results from the wet–dry cyclic test under load.

- (4)

- From a microscopic perspective, after C40 ordinary concrete undergoes the combined action of load and marine environment, a large amount of corrosion products, such as ettringite, are generated within the internal bubble pores. In contrast, for the cement-based fiber composite material, corrosion products such as ettringite are almost invisible, showing better resistance to chemical corrosion. Even when the paste–aggregate interfacial transition zone is magnified over 10,000 times, no obvious cracks or defects are observed. The interfacial transition zone is significantly enhanced, which is the main reason for the high chloride ion penetration resistance of this cement-based fiber composite material.

- (5)

- This study provides a basis for evaluating the chloride resistance and service life of repaired concrete under coupled loading and environmental actions. Future research should further consider the effects of multi-axial stress states, time-dependent mechanical damage, and multi-factor coupling (such as chloride ingress, sulfate attack, carbonation, and freeze–thaw cycles). Field validation, full-scale tests, and the integration of data-driven methods will also be important directions to enhance the applicability and predictive accuracy of the proposed model in practical engineering.

Author Contributions

Conceptualization, S.-A.C.; methodology, Q.X. and J.-J.Z.; software, J.-J.Z. and J.W.; validation, J.W. and J.-J.Z.; formal analysis, J.W., T.-Y.Z. and W.X.; investigation, Q.X.; resources, S.-A.C.; data curation, Q.X. and T.-Y.Z.; writing—original draft preparation, Q.X. and W.X.; writing—review and editing, Q.X. and T.-Y.Z.; visualization, Q.X. and J.W.; supervision, S.-A.C.; project administration, S.-A.C.; funding acquisition, S.-A.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Science and Technology Projects of Beijing Zhuoyue Electric Power Construction Co., Ltd., grant number ZYKCJS [2024]009 and the International Science and Technology Cooperation Program of Sichuan Province, China, grant number 2023YFH0061.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Conflicts of Interest

Authors Qiang Xue, Tian-Yu Zheng, Jian Wang and Jian-Jun Zhang were employed by the company State Grid Beijing Electric Power Company. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest. The sponsors had no role in the design, execution, interpretation, or writing of the study.

References

- Vaysburd, A.M.; Emmons, P.H. How to Make Today’s Repairs Durable for Tomorrow—Corrosion Protection in Concrete Repair. Constr. Build. Mater. 2000, 14, 189–197. [Google Scholar] [CrossRef]

- Yang, L.; Liu, Y.; Wang, X.; Wei, J.; Xiao, D.; Rao, F. The Preparation of BFS/FA-Based Geopolymers with High Compressive Strength and Anti-Corrosion Property to Chloride. Arab. J. Sci. Eng. 2025, 1–12. [Google Scholar] [CrossRef]

- Ghanooni-Bagha, M. Influence of Chloride Corrosion on Tension Capacity of Rebars. J. Cent. South Univ. 2021, 28, 3018–3028. [Google Scholar] [CrossRef]

- Chen, C.; Chen, Y.; He, J.; Zhu, P.; Liu, R.; Wang, X. Chloride Ion-Induced Deterioration in Concrete under Dry-Wet Cycling Using the Air-Drying Method. Constr. Build. Mater. 2024, 451, 138750. [Google Scholar] [CrossRef]

- Paul, S.C.; van Zijl, G.P.A.G.; Babafemi, A.J.; Tan, M.J. Chloride Ingress in Cracked and Uncracked SHCC under Cyclic Wetting-Drying Exposure. Constr. Build. Mater. 2016, 114, 232–240. [Google Scholar] [CrossRef]

- Russo, N.; Gastaldi, M.; Schiavi, L.; Strini, A.; Lollini, F. Effects of Cracks on Chloride-Induced Corrosion Initiation and Propagation of Carbon and Stainless Steel Rebar. Struct. Concr. 2023, 24, 156–169. [Google Scholar] [CrossRef]

- Smyl, D.; Rashetnia, R.; Seppänen, A.; Pour-Ghaz, M. Can Electrical Resistance Tomography Be Used for Imaging Unsaturated Moisture Flow in Cement-Based Materials with Discrete Cracks? Cem. Concr. Res. 2017, 91, 61–72. [Google Scholar] [CrossRef]

- Yoo, S.-W.; Kwon, S.-J. Effects of Cold Joint and Loading Conditions on Chloride Diffusion in Concrete Containing GGBFS. Constr. Build. Mater. 2016, 115, 247–255. [Google Scholar] [CrossRef]

- Luo, D.; Zhou, M.; Li, F.; Niu, D. Chloride Ion Transport in Coral Aggregate Concrete Subjected to Coupled Erosion by Sulfate and Chloride Salts in Drying-Wetting Cycles. J. Mater. Res. Technol. 2024, 30, 3251–3267. [Google Scholar] [CrossRef]

- Van Steen, C.; Nasser, H.; Verstrynge, E.; Wevers, M. Acoustic Emission Source Characterisation of Chloride-Induced Corrosion Damage in Reinforced Concrete. Struct. Health Monit. 2021, 21, 147592172110133. [Google Scholar] [CrossRef]

- François, R.; Arliguie, G. Effect of Microcracking and Cracking on the Development of Corrosion in Reinforced Concrete Members. Mag. Concr. Res. 1999, 51, 143–150. [Google Scholar] [CrossRef]

- Lee, T.; Kim, D.; Cho, S.; Kim, M.O. Advancements in Surface Coatings and Inspection Technologies for Extending the Service Life of Concrete Structures in Marine Environments: A Critical Review. Buildings 2025, 15, 304. [Google Scholar] [CrossRef]

- Omikrine Metalssi, O.; Quiertant, M.; Jabbour, M.; Baroghel-Bouny, V. New Methods for Assessing External Sulfate Attack on Cement-Based Specimens. Appl. Sci. 2024, 14, 1410. [Google Scholar] [CrossRef]

- Powers, T.C. A Working Hypothesis for Further Studies of Frost Resistance of Concrete. ACI J. Proc. 1945, 41, 245–272. [Google Scholar] [CrossRef]

- Bao, J.; Wang, L. Combined Effect of Water and Sustained Compressive Loading on Chloride Penetration into Concrete. Constr. Build. Mater. 2017, 156, 708–718. [Google Scholar] [CrossRef]

- Wang, H.-L.; Dai, J.-G.; Sun, X.-Y.; Zhang, X.-L. Characteristics of Concrete Cracks and Their Influence on Chloride Penetration. Constr. Build. Mater. 2016, 107, 216–225. [Google Scholar] [CrossRef]

- Fu, C.; Zhou, K.; Ling, Y.; Jin, X.; Fang, D.; Zhou, J. Chloride Transport Behavior in Bending-Shear Section of Reinforced Concrete Beam under Combined Effect of Load and Environment. Constr. Build. Mater. 2020, 257, 119533. [Google Scholar] [CrossRef]

- Xu, H.; Chen, J. Coupling Effect of Corrosion Damage on Chloride Ions Diffusion in Cement Based Materials. Constr. Build. Mater. 2020, 243, 118225. [Google Scholar] [CrossRef]

- Wang, Y.; Cao, Y.; Zhang, P.; Ma, Y.; Zhao, T.; Wang, H.; Zhang, Z. Water Absorption and Chloride Diffusivity of Concrete under the Coupling Effect of Uniaxial Compressive Load and Freeze–Thaw Cycles. Constr. Build. Mater. 2019, 209, 566–576. [Google Scholar] [CrossRef]

- Shi, X.; Xie, N.; Fortune, K.; Gong, J. Durability of Steel Reinforced Concrete in Chloride Environments: An Overview. Constr. Build. Mater. 2012, 30, 125–138. [Google Scholar] [CrossRef]

- Wang, D.; Zhou, X.; Fu, B.; Zhang, L. Chloride Ion Penetration Resistance of Concrete Containing Fly Ash and Silica Fume against Combined Freezing-Thawing and Chloride Attack. Constr. Build. Mater. 2018, 169, 740–747. [Google Scholar] [CrossRef]

- Nielsen, E.P.; Geiker, M.R. Chloride Diffusion in Partially Saturated Cementitious Material. Cem. Concr. Res. 2003, 33, 133–138. [Google Scholar] [CrossRef]

- Chen, D.; Yang, K.; Hu, D.; Shi, J. A Meso-Stochastic Research on the Chloride Transport in Unsaturated Concrete. Constr. Build. Mater. 2021, 273, 121986. [Google Scholar] [CrossRef]

- Zhou, J.; Ye, G.; van Breugel, K. Cement Hydration and Microstructure in Concrete Repairs with Cementitious Repair Materials. Constr. Build. Mater. 2016, 112, 765–772. [Google Scholar] [CrossRef]

- da Porto, F.; Stievanin, E.; Pellegrino, C. Efficiency of RC Square Columns Repaired with Polymer-Modified Cementitious Mortars. Cem. Concr. Compos. 2011, 34, 545–555. [Google Scholar] [CrossRef]

- Tong, L.; Liu, Q.; Xiong, Q.; Meng, Z.; Amiri, O.; Zhang, M. Modeling the Chloride Transport in Concrete from Microstructure Generation to Chloride Diffusivity Prediction. Comput.-Aided Civ. Infrastruct. Eng. 2024. [Google Scholar] [CrossRef]

- Li, S.; Liang, L.; Guan, C. Optimization Design and Evaluation of Polymer-Modified Hybrid Fiber-Reinforced Cement-Based Composites. Constr. Build. Mater. 2025, 462, 139915. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, P.; Guo, J.; Wang, J.; Zhang, T. Durability and Microstructure of Cementitious Composites under the Complex Environment: Synergistic Effects of Nano-SiO2 and Polyvinyl Alcohol Fiber. Constr. Build. Mater. 2023, 400, 132621. [Google Scholar] [CrossRef]

- Kroviakov, S.; Kryzhanovskyi, V.; Hedulian, D. Comparison of the Corrosion Resistance of Fiber-Reinforced Concrete with Steel and Polypropylene Fibers in an Acidic Environment. Constr. Mater. 2025, 5, 6. [Google Scholar] [CrossRef]

- Udebunu, J.; Abdolpour, H.; Sadowski, Ł. Comprehensive Experimental Investigation of the Mechanical Properties and Performance Enhancement of Polyvinyl Alcohol Fiber-Reinforced Cement Mortar. Arch. Civ. Mech. Eng. 2024, 25, 58. [Google Scholar] [CrossRef]

- Li, V.C. Performance Driven Design of Fiber Reinforced Cementitious Composites; CRC Press eBooks: Boca Raton, FL, USA, 1992; pp. 34–52. [Google Scholar] [CrossRef]

- Yang, Y.; Lepech, M.D.; Yang, E.-H.; Li, V.C. Autogenous Healing of Engineered Cementitious Composites under Wet–Dry Cycles. Cem. Concr. Res. 2009, 39, 382–390. [Google Scholar] [CrossRef]

- Li, V.C.; Leung, C.K.Y. Steady-State and Multiple Cracking of Short Random Fiber Composites. J. Eng. Mech. 1992, 118, 2246–2264. [Google Scholar] [CrossRef]

- Sahmaran, M.; Li, V.C.; Andrade, C. Corrosion Resistance Performance of Steel-Reinforced Engineered Cementitious Composite Beams. ACI Mater. J. 2008, 105, 243. [Google Scholar] [CrossRef]

- Şahmaran, M.; Li, V.C. Durability of Mechanically Loaded Engineered Cementitious Composites under Highly Alkaline Environments. Cem. Concr. Compos. 2008, 30, 72–81. [Google Scholar] [CrossRef]

- JGJ/T322-2013; Technical Specification for Test of Chloride Ion Content in Concrete. China Building Industry Press: Beijing, China, 2013.

- Lu, C.; Li, V.C.; Leung, C.K.Y. Flaw characterization and correlation with cracking strength in Engineered Cementitious Composites (ECC). Cem. Concr. Res. 2018, 107, 64–74. [Google Scholar] [CrossRef]

- Boulekbache, B.; Hamrat, M.; Chemrouk, M.; Amziane, S. Flowability of fibre-reinforced concrete and its effect on the mechanical properties of the material. Constr. Build. Mater. 2010, 24, 1664–1671. [Google Scholar] [CrossRef]

- GB/T 50476-2019; Standard for Design of Concrete Structure Durability. China Building Industry Press: Beijing, China, 2019.

- Petcherdchoo, A. Environmental Impacts of Combined Repairs on Marine Concrete Structures. J. Adv. Concr. Technol. 2015, 13, 205–213. [Google Scholar] [CrossRef]

- Beushausen, H.; Burmeister, N. The use of surface coatings to increase the service life of reinforced concrete structures for durability class XC. Mater. Struct. 2013, 48, 1243–1252. [Google Scholar] [CrossRef]

- Petcherdchoo, A. Repairs by fly ash concrete to extend service life of chloride-exposed concrete structures considering environmental impacts. Constr. Build. Mater. 2015, 98, 799–809. [Google Scholar] [CrossRef]

- Herb, H.; Gerdes, A.; Brenner-Weiß, G. Characterization of silane-based hydrophobic admixtures in concrete using TOF-MS. Cem. Concr. Res. 2015, 70, 77–82. [Google Scholar] [CrossRef]

- Petcherdchoo, A. Closed-form solutions for bilinear surface chloride functions applied to concrete exposed to deicing salts. Cem. Concr. Res. 2017, 102, 136–148. [Google Scholar] [CrossRef]

- Petcherdchoo, A.; Chindaprasirt, P. Exponentially aging functions coupled with time-dependent chloride transport model for predicting service life of surface-treated concrete in tidal zone. Cem. Concr. Res. 2019, 120, 1–12. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).