Abstract

This paper provides a research review regarding the creep of ultra-high-performance concrete with or without the addition of fibers. Unlike other similar studies that mainly considered influential factors and their effects on the creep behavior, this research focuses more attention on the analysis of UHPC creep models. For the creep strain assessments of these concretes, the creep models given in the latest standards cannot be used, but it is necessary to modify them to give reliable results, given the rather complex composition of UHPC. Several proposed creep models for UHPC are presented with comparative analysis. The observation is that by varying key parameters such as compressive strength, relative humidity, cross-sectional dimensions, and temperature, there may be major discrepancies between models, so additional experimental investigations are necessary to perform their calibration. In this paper, the parameters α1, α2, and γ of FIB Model Code 2010 have been modified in order to obtain a match with other proposed models in terms of the final value of the creep coefficient and the creep curve. The creep coefficient of the UHPC decreases when steel fiber content increases, but it is important to consider the excessive fiber addition because very often it causes an increase in creep strain. The application of thermal treatment at a temperature of 90 °C for 48 h significantly improves the time-dependent properties of UHPC. An analysis of the impact of the steel fiber content, fiber type, thermal treatment, and the age of the concrete under load on strains of UHPC specimens and beams under long-term loads is performed.

1. Introduction

Ultra-high-performance concrete (UHPC) represents a relatively new generation of cementitious materials characterized by very high strength, ductility, and durability [1]. Most often, ultra-high-performance concretes are fiber-reinforced, and thus, UHPC can be treated as a combination of three concrete technologies: self-compacting concrete (SCC), fiber-reinforced concrete (FRC), and high-performance concrete (HPC) [2].

UHPC have an increased binder content (cement and silica fume), and due to the presence of very fine quartz sand and low water/binder ratio, these concretes are more like mortars in terms of consistency [3]. The value of the water/binder ratio usually ranges from 0.16 to 0.22. Concretes of this type are compact and homogeneous, with very dense structures, and are characterized by high compressive strength after 28 days (greater than 150 MPa) and high tensile strength (greater than 7 MPa in the case of concrete without the addition of steel fibers) [4].

UHPC is often reinforced with steel fibers, which significantly increases its ductility. In this way, a new material with pronounced mechanical characteristics is formed and called ultra-high-performance fiber-reinforced concrete, which belongs to the group of cement composites that exhibit strain-hardening under uniaxial tension [5]. Compared to high-performance concrete (HPC), UHPC exhibits better compressive and tension behavior as well as greater durability [6]. This property of exceptional durability reduces the cost of structure maintenance and potentially reduces the protective layer of concrete needed to ensure weather resistance compared to normal concrete.

Improvement of the mixture homogeneity is achieved by removing the coarse aggregate.

It is necessary to optimize the grain size distribution of cement, silica fume, and sand to achieve a dense matrix structure with very low permeability. The participation ranges of the individual constituents in the UHPC mix are shown in Table 1.

Table 1.

Constituent participation ranges in the UHPC mixture [7,8].

Steel fibers, a large amount of cement, the elimination of coarse aggregate, and the use of special materials are factors that raise the cost of UHPC. The relatively high starting price of UHPC limits its wider application in the construction industry. The initial cost of UHPC exceeds the price of conventional concretes by far, so constant research is currently being carried out in the world to minimize material costs while maintaining the beneficial properties of these concretes [9]. New recipes for UHPC are being developed in the world by various researchers, and in this regard, mineral additives such as fly ash, silica fume, ground granular blast furnace slag, and rice husk ash are being used to replace part of the cement to produce sustainable UHPC and reduce the use of cement. Silica fume is a secondary cementitious material that represents a critical component in the UHPC concrete production process. It has a significant role and impact on the overall properties of concrete due to the high content of amorphous silicon dioxide SiO2 and the ability to increase the packing density of the matrix. It is important to define the optimal dose of silica fume since larger quantities may cause a harmful alkali–silica reaction in concretes. Previous investigations have indicated the typical silica fume content used in UHPC mixture is approximately 20–30% by mass of cementitious materials [10,11].

UHPC is quite effective in terms of radiation shielding due to its high density and dense microstructure [12]. The best protection against γ-rays can be ensured in high-strength concrete with the participation of nano-lead monoxide and nano granodiorite powder in the concrete mix. These nanomaterials have revolutionized the field of radiation-shielding concrete, offering a promising approach to develop safer and more efficient construction materials for nuclear power plants, medical facilities, and other radiation-exposed environments [13].

The total costs related to the structure of the building are directly related to the dimensions of the cross-sections of the structural elements. Due to the enhanced mechanical properties and ultra-high-strength of this material, structural elements made using UHPC may have reduced cross-sectional dimensions, and hence, lighter weight [14]. The high-strength properties of UHPC allow the design of slender structures, leading to a reduction in the self-weight of the structure due to less use of materials [9]. This is important in terms of time-dependent deformations, since it is known that the cross-sectional dimensions affect the final value of the creep coefficient. In general, elements with smaller dimensions will exhibit higher creep compared to elements with larger cross-sectional dimensions.

The use of UHPC is still quite limited in the world, and most of the projects completed so far have been motivated by state agencies to encourage the use of this innovative material as much as possible. What certainly prevents wider application is the lack of design regulations, limited knowledge in terms of material behavior and production technology, as well as the high price.

This review focuses more attention on the analysis of UHPC creep models, while other similar studies such as [15,16] mainly considered influential factors and their effects on the creep behavior. The behavior of UHPC under long-term loads has not yet been sufficiently investigated, and this is supported by the fact that there is no unified creep model for these concretes. This review aims to identify the main advantages and disadvantages of the proposed creep models with the aim that the authors can come up with their own improved model in the future by using the datasets of further experimental studies on the creep behavior of UHPC. In addition, the goal is to modify certain parameters in the FIB Model Code 2010 so that it can be applied in the analysis of creep deformations of this type of concrete. On the other hand, a large number of parameters that affect the creep of UHPC have been considered in order to propose improvements to the existing creep models.

The following important influential parameters for creep were analyzed: the content of steel fibers, type of fibers, water/binder ratio, compressive strength of concrete, modulus of elasticity of concrete and fibers, level of load at which specimens are tested, heat treatment, and age of concrete at load. Given the limited number of studies on the creep of UHPC, this paper will present an overview of previous research to calibrate the existing models of creep of these concretes. Additional experimental tests will contribute to the calibration of the existing creep models.

2. Overview of UHPC Creep Research

Concrete creep is defined as the time-dependent component of strains due to long-term load. Currently, there are several theories to explain the phenomenon of concrete creep: viscoelasticity theory, seepage theory, viscous flow theory, plastic flow theory, micro-fractures theory, and internal force balance theory [17]. Concrete creep strains occur under long-term loads due to displacement of chemically unbound water in cement stone. These strains significantly affect the building structure’s lifetime. This primarily refers to the negative effects of creep such as excessive beam deflections, the occurrence of cracks in concrete, and the loss of prestressing force in prestressed concrete elements.

The creep phenomenon can be divided into two components, namely the basic creep and the drying creep. The former occurs in the element with a homogeneous arrangement of humidity without the exchange of humidity with the environment, while the latter is the result of the exchange of humidity with the environment. To achieve superior mechanical and rheological properties, UHPC is usually fabricated by applying a large amount of cement, a low water/binder ratio, ultra-fine steel fibers, and superplasticizers as concrete additives. These characteristics make the creep performance of UHPC different from traditional concrete [18]. For example, creep strains are reduced with lower values of the water/binder ratio. The development of the creep function depends on the age of the material at the moment of applying load. For example, for UHPC named Ductal (manufactured by Lafarge, France), a creep coefficient of 0.2–0.8 is suggested, with the lower values corresponding to thermally treated material and the higher to non-treated material. Therefore, the thermal treatment of UHPC significantly reduces their creep [19]. In normal concrete, the creep coefficient can reach the value of three to four. Low creep values are of particular interest for the application of prestressing (reduction in prestress losses) [20,21].

To improve the development of UHPC and establish standards for the calculation of structures made of this material, it is necessary to perform investigations of creep properties to ultimately obtain a creep model that is applicable for UHPC. In doing so, the basic and drying creep should be separated in experiments to better understand the fundamental mechanisms of the behavior of UHPC under long-term loads. One such study was conducted in [22,23].

Rossi et al. [24] proposed a microcrack theory that treats the basic creep of concrete as additional shrinkage under stress. This theory links concrete shrinkage and creep, and it gives a viable explanation as to why concrete tensile creep is normally smaller than compressive creep. It should be emphasized that UHPC dominates the basic creep component and that the effects of drying are very small. On the other hand, unlike conventional concretes that have little autogenous shrinkage and where drying shrinkage strains predominate in total shrinkage strains, UHPC has much greater autogenous shrinkage and smaller drying shrinkage. This is because UHPC possesses a fine pore structure and low water content, resulting in great capillary stress. These observations were based on previous experimental works, where the exchange of humidity within the environment was prevented (for the case of basic creep) by sealing UHPC samples with aluminum adhesive tape.

In the last ten years, some experimental investigations of UHPC creep have been conducted, as listed in Table 2.

Table 2.

Experimental investigations of UHPC creep.

In the listed experiments, the duration of loading was 28, 90, 159, 180, 360, and 386 days. During testing, a load of 20, 30, 40, and 50% of the measured compressive strength fc was applied to the specimens, using a creep apparatus. Concrete specimens are often loaded up to 50% of the measured value fc, as this ensures that the concrete remains in a linearly elastic behavioral area. For elements to which stresses below 0.5·fc are applied, certain simplifications in the calculation (linear creep of concrete) are allowed. Most standards for predicting creep deformations of concrete allow the application of these simplifications.

Various standards currently used in the world, such as FIB Model Code 2010 [38], ACI 209-08 [39], GB 50010-2010 [40], and AS 3600:2018 [41] provide models for the estimation of creep strains for traditional concrete. In addition, the B4 model is often used [42], which is in line with a large number of experimental results and measurements on actual structures and bridges and has been proposed by RILEM (Réunion Internationale des Laboratoires et Experts des Matériaux) [43]. Compared to previous models, these latest models have been developed to be as suitable as possible for modern high-strength concrete, while on the other hand, they are not fully applicable for the creep assessment of UHPC characterized by ultra-high compressive strength and a very low water/binder ratio.

Mohebbi A. et al. [27] focused their research on the defining of equations for the assessment of creep and shrinkage of UHPC derived from the existing models for conventional concretes given in AASHTO 2020 [44]. Considering the available experimental data, it was concluded that the current AASHTO equations cannot accurately estimate the coefficient of creep and strain of the UHPC shrinkage, and therefore a recalibration of individual parameters is necessary.

The parameters analyzed in this research are compressive strength, loading age of concrete, and relative humidity of the environment. This research has made additional efforts to develop models of prestressing loss and to define guidelines for the design of prestressed UHPC girders.

The B4 creep model accounts for ingredient proportions and heat treatment effects, making it more applicable to modern concrete types. However, this model also has certain limitations and needs to be adapted to a material such as UHPC. Pribramsky [43] identified the most important limitations of the B4 model and based on the available experimental data by other authors, performed its adaptation to make it fully applicable to UHPC. The adaptive and calibrated B4 model showed good concordance with experimental results taken from [29,45], especially those conducted in the USA [29]. The concurrence of concrete creep strains is confirmed both in terms of their final value and in terms of the temporal development (increase) of the strains.

Mazloom M. [46] proposed equations that can assess long-term strains of creep and shrinkage of high-strength concrete based on their experimental results. Pan Z. et al. [47] evaluated the CEB-FIP 90 [48] model in terms of its application for the determination of creep and shrinkage of normal and high-strength concrete, comparing it with an extensive database available in the literature. Based on the statistical regression analysis of the collected data during creep and shrinkage tests, the CEB-FIP 90 model was revised by modifying the influencing coefficients concerning the compressive strength of concrete and the functions of the time development of creep and shrinkage. The proposed modified model showed better results than the CEB-FIP 90 model, especially for high-strength concretes.

According to [18,22,25], the model given in the FIB Model Code 2010 provides the closest prediction of UHPC creep strains, but to be fully applicable, it needs to be modified to some extent.

3. Creep Models

3.1. Creep Model Aligning to FIB Model Code 2010

The Model Code 2010 brings certain changes in terms of creep compared to previous CEB-FIP models. This creep model has been calibrated based on existing experimental data and new laboratory tests considering a load duration of 30 years [49]. The model was estimated to provide a relatively good approximation of creep values for concrete ages up to 50 years, under certain conditions. For longer periods of load life, from 50 to 150 years, the equations for calculating the creep coefficient give an increase of about 10%. However, practical observations show higher values of creep strains after a load life of 30 to 50 years [50].

The creep equations that will be shown below apply to ordinary structural concretes (20 MPa ≤ fcm ≤ 130 MPa) subjected to compressive stresses |σc| ≤ 0.4žfcm(t0) at the time of load application t0, located in the environment of relative humidity ranging from 40% to 100%, where the mean temperature ranges from 5 °C to 30 °C. The age of concrete at loading should be at least one day [38].

In linear creep, concrete creep strains εcc (t,t0) can be calculated as follows:

where φ(t,t0) is the creep coefficient and Eci is the elastic modulus at the concrete age of 28 days.

The creep coefficient is defined as the ratio of creep strain and elastic strain of concrete aged 28 days at the same stress. It is determined according to the following equation:

where φbc(t,t0) is the basic creep coefficient, φdc(t,t0) is the drying creep coefficient, t is the age of concrete in days up to the considered moment, and t0 is the age of concrete in days at the moment of the applied load. The calculation equations of the creep coefficient are empirical and have been calibrated based on laboratory tests (compressive creep) performed on structural concretes.

The basic creep coefficient φbc(t,t0) can be obtained from the equation:

where the effect of the 28-day mean compressive strength fcm is encompassed by a factor of

where α1 = 0.7 for normal-strength concrete, while the creep time development function:

t0,adj represents the modified concrete age at load application in days, while the coefficient γ has a value of 0.035. The drying creep coefficient φdc(t,t0) can be obtained from the equation:

where

where α2 = 1.4 for normal strength concretes. The temporal development of drying creep is described by the following equation:

where

In the above equations, RH represents the relative humidity of the environment in %, while h = 2∙Ac/u is the nominal dimension of the element in mm which measures speed and intensity of the drying process.

So far, it is not known whether the creep strains reach their final value or not. However, in this fundamental approach, the development of basic creep is predicted by a logarithmic function that has no final value, while a hyperbolic function approaching the asymptotic value for t → ∞ is selected for the drying creep.

3.2. Modification of the Creep Model for Application in UHPC

3.2.1. Creep Model According to Xu Y. et al. [18]

In general, in basic concretes, the increase in compressive strength leads to a decrease in the creep coefficient due to the lower value of the water/binder ratio. However, UHPC as a material has a rather complex composition and there are also different recipes for concrete mixtures.

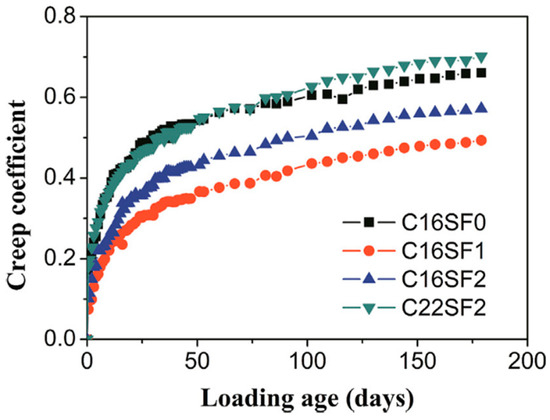

Xu Y. et al. [18] performed experimental investigations on four groups of specimens under the names C16SF0, C16SF1, C16SF2, and C22SF2, where 16 and 22 denote the water/binder ratio used in amounts 0.16 and 0.22, while SF0, SF1, and SF2 represent the steel fiber content of 0, 1, and 2%, respectively. For these specimens the creep coefficients are shown in Figure 1. After 180 days from the initial load application, the C22SF2 has a 42.2% higher creep coefficient than the C16SF1.

Figure 1.

UHPC creep coefficients [18].

Concerning the compressive strengths of these two specimens with the largest difference in creep coefficient, C16SF1 is 152.5 MPa, while the C22SF2 value is 150.6 MPa. Therefore, it can be concluded that the strains of UHPC under long-term load do not depend only on its strength, but it is necessary to include several influencing factors including the composition of the mix to perform the creep analysis as accurately as possible. In this paper, the authors concluded that the elastic modulus significantly influences the creep strains of UHPC.

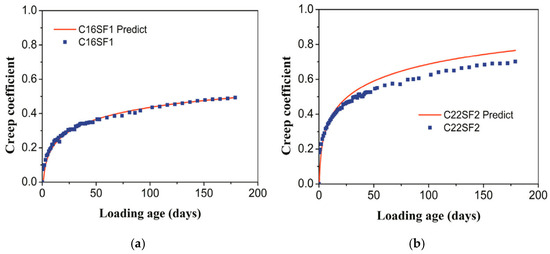

Thus, the interaction influence of the compressive strength and elastic modulus of concrete on the creep of UHPC must be considered. In the result’s analysis, considerable deviations in experimental data were observed concerning the calculated values of the creep coefficients according to various standards. However, the shape of the creep curve obtained according to the FIB Model Code 2010 most closely matches the experimental results. Therefore, a modification of the creep model given in the FIB Model Code 2010 was made to apply it to UHPC, and the equation for the creep coefficient now reads [18]:

A comparison of the results of the proposed creep model with the experimental data for two specimens C16SF1 and C22SF2 is shown in Figure 2.

Figure 2.

Results comparison of the modified model with experimental data: (a) C16SF1 and (b) C22SF2.

The proposed model provides a major improvement in the assessment of creep strains of UHPC.

3.2.2. Creep Model According to Sun M. et al. [22]

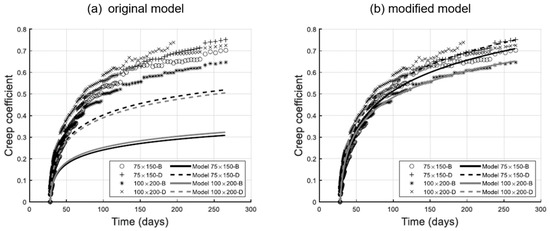

The study [22] separately considered the basic creep and drying creep of the UHPC specimens strained at two different load levels with a total duration of one year, using two different specimen sizes. The specimens needed to determine the basic creep were sealed using an aluminum strip and thus the exchange of humidity within the environment was prevented. During cylindrical specimens testing of dimensions ϕ75 × 150 mm and ϕ100 × 200 mm, loads in the amount of 20% and 40% of the measured compressive strength of concrete were applied after 28 days. The impact of the load level and specimen size on creep strains was analyzed, separating the basic from the drying creep.

For the creep model given in FIB MC 2010 to be suitable for use in UHPC, the value of the basic creep coefficient should be increased, while the drying creep coefficient should be reduced since this standard underestimates the values of the basic creep and overestimates the drying creep of UHPC. The difference in the magnitude of strains between basic creep and drying creep is very small in UHPC, which indicates that the impact of drying on UHPC creep is negligible. Therefore, in Equations (4) and (7), the value of the coefficients α1 and α2 related to the compressive strength of concrete was modified, while in Equation (5), the coefficient γ also took on new values to ensure the correct shape of the time curve. The values of the calibrated parameters are shown in Table 3.

Table 3.

Modified parameters in FIB MC 2010 according to Sun M. [23].

Data from the experimental part of this study (creep coefficient) are drawn in Figure 3a, together with the curves obtained according to FIB MC 2010 using the original values of coefficients related to concretes of normal strength. Creep coefficients can be obtained by dividing the measured creep strains by elastic strains.

Figure 3.

Comparison of experimental results with results obtained according to standard: (a) original FIB MC 2010, and (b) modified FIB MC 2010 (B—basic, D—drying).

Approximation to experimental results was achieved by calibration of parameters α1, α2, and γ, which is also shown by the curves in Figure 3b. For this model to find applications in a wider range of strengths, more data on the creep of high-strength concrete is needed.

3.2.3. Creep Model According to Zhu L. et al. [25]

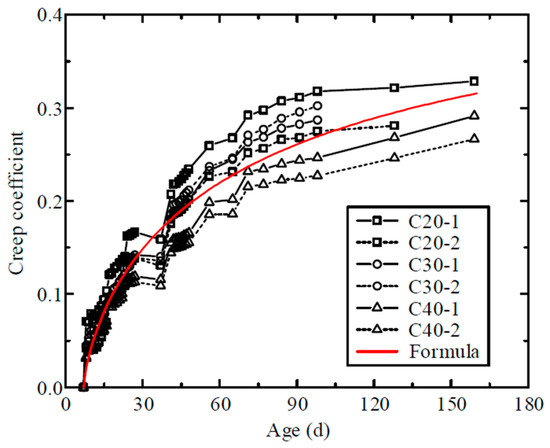

Zhu L. et al. [25] performed their compressive creep tests on six 70 × 70 × 240 mm prismatic specimens, using steel fibers in the concrete mix with a 2% participation by volume. Three load levels of 20%, 30%, and 40% of the measured compressive strength of concrete were considered, and the total duration of the load was 160 days. Creep strains were measured using strain gauges placed on both sides of the specimens.

Since the existing standards for concrete structures do not provide a formula for calculating the creep coefficient of UHPC, a simplified equation was developed in this research and obtained by non-linear adjustment of the test results. The proposed simplified formula for calculating the creep coefficient of UHPC is as follows:

where t ≥ t0. Equation (15) can be further simplified by presenting it as a product of the final creep coefficient φ∞ and the factor βc (t,t0) which takes into account the time development of creep:

where the final value of the creep coefficient is φ∞ = 0.46, while the second term (root) is the factor βc (t,t0).

While comparing the results obtained using Equations (15) and (16) in Figure 4, it was concluded that the model provides sufficient accuracy in the creep coefficient estimate. The test results showed that creep develops rapidly between the 5th and 30th day after concrete casting, while the increase in creep coefficient is slight after 90 days.

Figure 4.

Demonstration of the UHPC creep development according to the test results and proposed simplified formula [25].

The final value of the creep coefficient in this study ranges from 0.26 to 0.30, emphasizing that the specimens were solidified at high temperatures of 75 °C in the steam cure box. For comparison, the values of the creep coefficient ranging from 0.49 to 0.70 were obtained experimentally in the paper [18], where the specimens were solidified in a room with a temperature of 20 °C. It can be concluded that various thermal treatments of concrete can significantly affect the values of the final creep coefficient.

3.2.4. Comparison of Modified Creep Models

Here, a comparative analysis of the three modified creep models will be performed in terms of the time development of the creep and the final value of the creep coefficient. As an example, a UHPC specimen of 100 × 100 × 300 mm with a compressive strength of 125 MPa was taken. The load is applied at the concrete age of t0 = 28 days, and during this period of maturation, the concrete specimen is in a room with a temperature of 20 °C. For relative humidity, the value of RH = 50% was adopted, and the nominal size of the element is h = 50 mm, while cement class n was used for the preparation of concrete. A ten year (3650 days) creep load development was analyzed. The values of creep coefficients for all three proposed UHPC creep models and values φ obtained using the original FIB MC 2010 are shown in Table 4. It is clear that creep strains also depend on other parameters that take into account the composition of the UHPC mix (e.g., fiber types, water/binder ratio, or silica fume content), but these influential parameters are not included in the proposed models. In general, with the reduction of water/binder ratio, the creep development of UHPC decreases. Also, research [51] showed that the basic creep of high-strength concrete decreased at higher silica fume dosage levels, while the drying creep of specimens was negligible in this investigation.

Table 4.

Values of creep coefficients according to the proposed UHPC creep models.

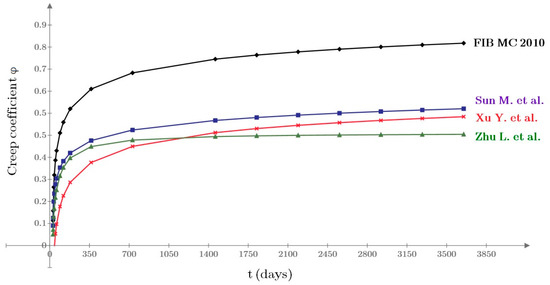

The creep coefficient development at time t for the considered specimen according to three modified creep models and according to the model given in FIB MC 2010 is shown in Figure 5. Concerning FIB MC 2010, the creep diagrams obtained according to [18,22,25] describe the behavior of UHPC under long-term load well and the ordinates are considerably smaller. By considering the values of the creep coefficient after ten years, according to the FIB MC 2010, its value is 0.826, while according to the model given in [25], it is 0.454, which represents an increase of 82%.

Figure 5.

Diagrams φ–t for all UHPC creep models.

The model given in [25] is the simplest of all and is based on only two variables (t and t0). The model proposed in [22] has a good match with the other two modified models if the following parameters are adopted: α1 = 0.75, α2 = 1.6, and γ = 0.53. In the model given in [18], there is a certain difference in curve form compared to other models, but in terms of the final value of the creep coefficient, the differences are very small.

However, by varying parameters such as mean compressive strength (fcm), relative humidity of the environment (RH), dimensions of the element (h), and temperature (T), differences between models can become more significant, which means that they need to be improved in a certain way. For these models to apply to the wider ranges of values of mentioned parameters, additional experimental research is needed to perform their calibration. The goal is to come up with a unique creep model for UHPC in the future that would be listed in the structure design regulations. In this way, it would certainly encourage the application of this modern material even more.

4. Analysis of Individual Parameters of Importance for the Creep of UHPC

4.1. Impact of the Steel Fiber Content

Typical steel fibers commonly used in UHPC mixtures are flat fibers with lengths of 10 to 13 mm, diameters of approximately 0.2 mm, and tensile strengths greater than 2070 MPa, and steel fibers with hooks at the ends with lengths of 25 to 30 mm, diameters of approximately 0.5 mm, and tensile strengths greater than 1030 MPa. The size and shape of the fibers have a slight impact on the compressive strength of concrete, while their impact on the tensile properties of UHPC is significant. The UHPC specimen’s test results for bending and centric tension showed a very pronounced influence of steel fiber dimensions and shapes [52].

In previous studies, it has been observed that the addition of steel fibers changes the type of cracking on UHPC specimens, from total damage or sudden cracking to a somewhat ductile behavior where the specimens can remain intact without crushing and separating [53]. In addition, it is known that compressive strength is not affected by the addition of large amounts of steel fibers [54]. However, in the work of El-Din H.K. et al. [55], the test results showed that the increase in the volume fraction of the steel fiber from 0% to 3% for UHPC causes a maximal increase in compressive strength by 18.2%, flexural strength by 40%, and tensile strength by 66.1%. A detailed analysis of the influence of the content, type, and combination of different fiber types on the compressive and tensile strength of UHPC is given in [56].

When it comes to the elastic modulus of UHPC, it has been observed that the addition of fibers does not significantly affect its value. For example, with an additional 2% steel fibers in the mix volume, an increase in the elastic modulus of only 7% is obtained, compared to the control UHPC specimen without fibers [57].

In general, to achieve the strain-hardening effect in a material such as UHPC, a large amount (from 4% to 6%) of short smooth steel fibers is required because the bond strength of these fibers is relatively low. Large quantities of fibers significantly increase the cost of UHPC; therefore, the fiber content should be minimized for the practical application of these concretes [58].

Chern and Young [59] investigated the influence of steel fibers on the creep and shrinkage of concrete specimens, whereby specimens were loaded at different ages during creep tests. The results showed that steel fiber reinforcement leads to a significant reduction in concrete creep, i.e., creep is gradually reduced with a fiber content increase. In addition, it was observed that the reduction in creep strains is greater at an increase in the volume percentage of fibers from 0% to 1% than at an increase of 1% to 2%. The results also showed that steel fibers become even more effective in creep containment as the load duration increases.

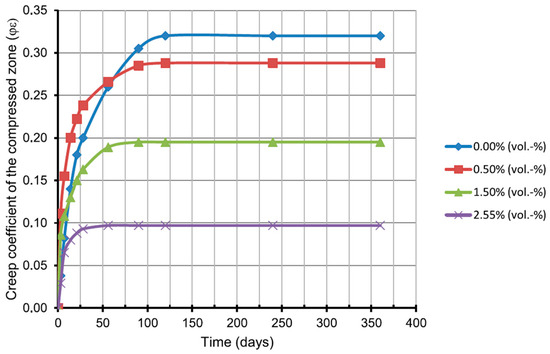

Barbos G. [26] investigated the behavior of bent UHPC beams under a long-term load. Four RC I–section beams with a total length of 3200 mm were used. The duration of the load was 360 days. Among the four beams, one was without steel-fiber addition, while the others contained a 0.5%, 1.5%, and 2.55% (vol. %) addition of steel fibers. Thus, the behavior of the beams with different fiber contents was analyzed in terms of the time increase in strains and deflections. After 360 days of monitoring, it was observed that the total strains of the compressed zone decreased by increasing the steel-fiber percentage, which is shown in Table 5.

Table 5.

Specific strains of the compressed zone [26].

The maximum value of the creep coefficient from the compressed zone, at 360 days, was 0.32 for the beam without steel-fiber additions, while in the case of the beam with 2.55% (vol.-%), steel-fiber addition was 0.097, which means a decrease of 70% (Figure 6). The differences between beams with percentages of 0.50%, 1.50%, and 2.55% (vol.-%) steel-fibers were about 30%. This can be related to the moment of inertia of the cross-section, which increases with the increase in the steel-fiber addition from 0.50% (vol.-%) to 2.55% (vol.-%). This fact directly influenced the instant and long-term deflection because of the increasing stiffness.

Figure 6.

Creep coefficients of the compressed zone of the tested beams.

In general, it is recommended to use a volume percentage of 0.5% steel fibers for practical application in UHPC structures [26]. Thus, steel fibers affect the reduction in concrete creep, but excessive addition of fibers (from 2% to 3%) can sometimes cause an increase in creep strain. This was confirmed in research [60], where the authors concluded that the interface layer between fiber and concrete matrix can increase the creep of the concrete. The effect of interface layer on the creep increases at an excessive dosage of steel fibers.

Therefore, the higher content of ultra-fine steel fiber decreases the flowability of the fresh concrete when the water/binder ratio of UHPC is ultra-low, resulting in a relatively weak interfacial transition zone (ITZ) between the steel fiber and the matrix, causing more internal defects in the concrete [18].

Chen P. et al. [61] analyzed the shrinkage and creep of reactive powder concrete (RPC) with different steel fiber contents (0%, 1%, and 2% by volume). In this article, the effect of steel fiber on shrinkage and creep and the influence of the axial stress ratio on creep were discussed. The obtained results showed that creep of reactive powder concrete decreases with increasing steel fiber content, which is obvious during the later period after loading, as steel fiber can prevent the development of microcracks. Also, the experimental results revealed that the elastic modulus and compressive strength increase with increasing steel fiber content.

4.2. Effect of UHPC Layer Height in Hybrid Systems

A very important area of UHPC applications is hybrid systems. Several research papers on this topic have been published in recent years. Significant efforts have been made to develop new hybrid systems that will include UHPC such as hybrid steel-UHPC, wood-UHPC, and standard (normal concrete—NC) NC-UHPC construction elements. The hybrid beam in combination with a NC-UHPC is a two-layer composite beam where the upper part, including the compression zone, is made of normal concrete, while the thin UHPC layer is in the lower part of the beam, i.e., in the tensile zone. The UHPC layer replaces the steel reinforcement required in standard RC beams to cater to tensile stresses that occur on the underside of the bent beam.

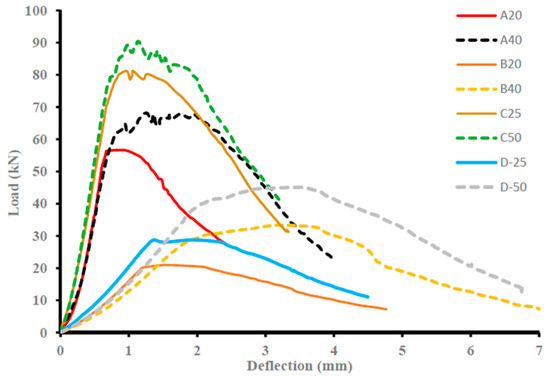

Hakeem I. et al. [62] researched 24 simply supported hybrid NC-UHPC beams (UHPC bottom layer without steel reinforcement), where flexural strength, cracking, and failure modes of hybrid beams were investigated. The research aimed to find alternative shapes of beams or slabs in structures that would eliminate the use of conventional steel reinforcement. The use of concrete beams and slabs without steel reinforcement could eliminate the problems of the durability of the structure associated with corrosion. The beams were made without shear reinforcement and designed to fail in flexure, precluding shear failure. The specimens were cast in the four different thicknesses of UHPC layers, 20, 40, 25, and 50 mm, and different testing spans, 630 mm, 750 mm, 900 mm, and 1100 mm, with two different cross-sections, 150 mm × 150 mm and 150 mm × 200 mm.

The test results showed that for each of the four ranges of hybrid beams, an increase in failure load is obtained when the thickness of the UHPC layer doubles (Figure 7). Nevertheless, UHPC layer thickness is preferably kept within a certain beam depth, since a greater layer thickness is not excessively effective from the load-bearing point of view. In most hybrid beams, cracking can be characterized by one vertical crack that extends through the UHPC layer and part of the NC layer, reaching almost to the top of the beam. It has been shown that the UHPC layer in the tension zone imparts a high ductility to the beam and significantly enhances the cracking resistance and moment capacity due to the presence of steel fiber. The load–deflection response of all eight hybrid beams with two different depths, 150 mm and 200 mm, and four different thicknesses of UHPC layers (20, 40, 25, and 50 mm) is shown in Figure 7.

Figure 7.

Load–deflection curves for all eight tested hybrid beams [62].

Thus, it has been demonstrated that the moment capacity increases as the shear span/height ratio of the beam decreases. The thickness of the UHPC layer enhances the ductility of the hybrid beams.

Kadhim M. A. et al. [63] focused on the development and behavior of hybrid UHPC-NC beams that strategically incorporate UHPC to leverage its superior compressive strength and sustained post-cracking tensile strength. The goal with these hybrid beams is to achieve a flexural capacity close to the capacity of a beam made entirely of UHPC. The results showed that the hybrid UHPC-NC beam with UHPC located at the beam’s midspan and NC at the end portions achieves similar strengths as the beam made entirely of UHPC when the UHPC length is 50% (Lu/L ≥ 0.5). The ductility of these hybrid beams is 16% less than the fully UHPC beams. With this method, significant cost savings can be achieved considering the high unit cost of UHPC. In the work of Lin P. et al. [64], the strength and cracking moment of prestressed NC-UHPC composite beams with different NC layer heights were analyzed. In accordance with the current railway bridge design code, the calculation formulas for the cracking moment and the normal section strength of NC-UHPC composite beam were established. In addition, the experimental results for flexural performance of six NC-UHPC composite beams showed that flexural damage to the NC-UHPC composite beams exhibited four different stages: an elastic stage, a uniform cracking stage, a crack development stage, and a yielding stage. The structural behaviors of UHPC-NC composite beams were also experimentally investigated in [65]. Their different failure patterns signified the role of bond strength, including typical flexural failure, the hybrid of debonding and NC overlay’s flexural failure, and the hybrid of debonding and NC overlay’s shear failure.

To reduce the cost of UHPC element production, instead of full, it is possible to distribute the fibers in partial depths of the specimen’s cross-sections. In this case, all the advantages provided by steel fibers are optimally exploited. Hybrid concrete elements are obtained and cast in two layers; the top layer is UHPC without steel fibers while the bottom layer is UHPC with steel fibers.

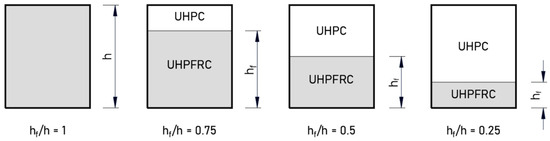

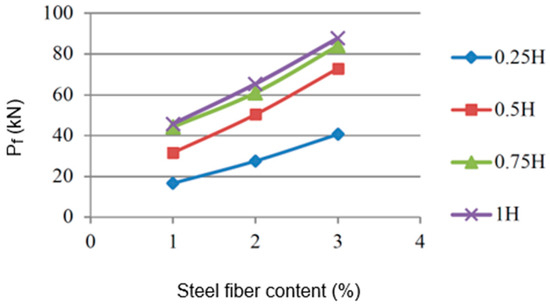

Danha L. et al. [66] researched this topic on 26 specimens measuring 100 × 100 × 500 mm with the following variables: the volumetric ratio of the steel fiber used (0, 1, 2, and 3%) and the fraction of depth (hf/h ratio) where the steel fibers were distributed (0.25, 0.5, 0.75, and 1). The flexural behavior of specimens under third-point loading was analyzed. Cross-sections of the hybrid specimens are shown in Figure 8.

Figure 8.

Cross-sections of the hybrid specimens.

The investigation confirmed that for each volumetric ratio of the steel fiber used, the failure load Pf increases with the increase in the fraction of depth, i.e., hf/h ratio. This increase was more significant as the fraction of depth increases from 0.25 to 0.5 and from 0.5 to 0.75. By reaching the value hf/h = 0.75, the increase is no longer expressed and that is why the failure load is almost similar to that obtained for hf/h = 1 (Figure 9). Therefore, it was concluded that the maximum effective fraction of depth would be 0.75, which gave almost the same results as distributing the steel fibers within the full depth of the specimen.

Figure 9.

Effect of a fraction of depth (h) of steel fibers on the failure load [66].

It was noted that the different distribution of the same amount of steel fibers within the depth of the section greatly affects the specimen load capacity and using the steel fibers in the tension zone effectively enhances the flexural performance of UHPC. What is currently unknown are the hybrid beam strains under long-term loads, so some future research should certainly be focused on this topic.

4.3. Influence of the Fiber Type

Fibers are natural or synthetic threads of a material that have an incomparably greater length than width, i.e., cross-section. Depending on the material from which they are made, fibers can be divided into four large groups: steel, glass, polymer, and natural fibers [67]. In addition to differing in their mechanical properties, these fibers provide different effects in terms of creep of both normal and ultra-high performance concrete.

Research [56,68,69] has shown that the orientation and distribution of fibers within the UHPC can have a significant impact on concrete mechanical properties. This effect must be considered in practical applications as the difference in fiber distribution within larger cross-sections can lead to significant variations in the mechanical behavior of concrete. The casting direction of fresh UHPC can affect the fiber’s orientation, and when the concrete workability is very high or if there is more vibration on the specimens during casting, fiber subsidence can occur which leads to disrupted orientation and dispersion of fibers.

Non-destructive testing (NDT) techniques are often used to evaluate fiber orientation and distribution. X-ray computed tomography (CT) is one of the most popular NDT methods for measuring the spatial distribution and directional orientation of fibers in concrete. When used for analysis of steel fiber reinforced concrete, this method typically relies on the fact that the fibers have significantly higher X-ray attenuations than the surrounding concrete material [70]. NDT methods can also be applied for repair validation and could also be applied for initial damage state assessment of concrete structures [71]. Ultrasonic pulse velocity measurements provide insights into concrete’s elastic properties and internal conditions, allowing correlations to be drawn with its strength and overall integrity. The analysis of acoustic emission indices can yield valuable information about the damage content and strength characteristics, as well as help identify the dominant modes of fracture occurring within the concrete [72].

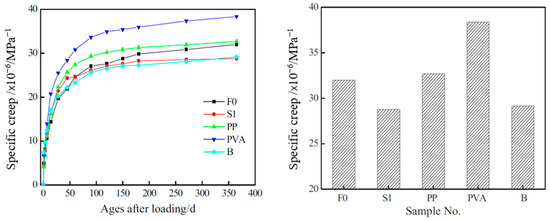

Zhao Q. et al. [73] investigated the long-term strain of concrete creep with four different types of fibers. The total load duration was 365 days and the fiber’s influence mechanism on concrete creep was analyzed. Steel (S), polypropylene (PP), polyvinyl alcohol (PVA), and basalt (B) fibers were used. The physical and mechanical characteristics of the applied fibers are given in Table 6. Volumetric percentages of steel fibers were 1, 2, and 3%, while polypropylene and polyvinyl alcohol fibers were applied in the amount of 0.9 kg/m3. The content of basalt fibers was 1.5 kg/m3. For the analysis of creep, specimens of 100 × 100 × 400 mm were used, loaded at 28 days of concrete age.

Table 6.

Physical and mechanical properties of fibers.

Diagrams of specific creep of concrete reinforced with different fibers are shown in Figure 10. The specific creep Ct at the time t from the load application is determined as follows:

where εct is the measured creep strain, εt is the concrete shrinkage strain, and σ is the compressive stress.

Figure 10.

Specific creep of normal concrete (F0) and concrete with the addition of different fibers [73].

The effect of the addition of different fibers on the ability to concrete creep varies. After one year of constant load duration, compared to the specific creep of normal concrete (without fibers addition), the creep of concrete with PP fibers is slightly higher, while the concrete with the addition of PVA fibers shows an increase of 19.9%. Compared to F0, the specific creep of concrete with basalt (B) fibers is 8.8% lower and a reduction of 10.1% is obtained when 1% of steel fibers are used.

It can be observed that when the elastic modulus of the fibers Ef is much higher than the elastic modulus of normal concrete (F0), the specific creep of concrete with these fibers is smaller than that with ordinary ones, and the ability to resist long-term strain increases. On the other hand, when the elastic modulus of the fibers Ef is less than or equal to the elastic modulus of normal concrete, the addition of fibers diminishes the ability of the concrete to resist creep. In this sense, according to Table 6, we see that the fibers that have a higher elastic modulus than normal concrete are steel and basalt, while PP and PVA fibers have a lower elastic modulus.

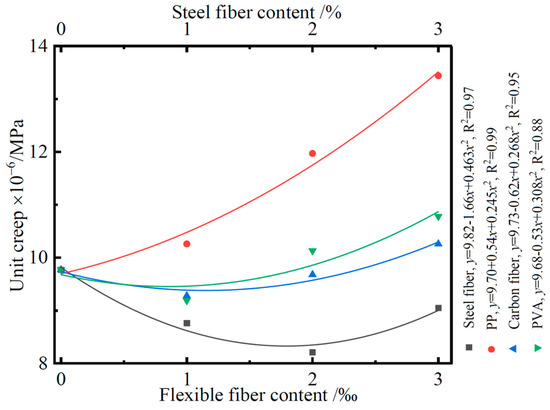

Chen Y. et al. [36] analyzed the effects of the type and content of fibers, water/binder ratio, and content of cementitious materials on the shrinkage and creep of UHPC. In their experimental part, they used carbon, PVA, PP, and steel fibers when making specimens. Figure 11 shows how the type and content of fibers can have a different effect on the creep of UHPC. The results showed that the specific creep decreases gradually when the steel fiber content is not more than 2%. In short, steel fibers prevent the development of creep strain in UHPC. Carbon fibers have an excellent effect in terms of reducing specific creep when their volume percentage is 0.1%. However, the increases in UHPC creep occurred when the carbon fiber content increased to 0.3%. The amount of PVA fibers had very little impact on the size of creep, and with the 0.3% fiber content, there was an increase in specific creep. On the other hand, the addition of PP fibers to the mixture significantly increases the specific creep and the rate of change in the specific creep becomes more pronounced as the percentage content of these fibers increases.

Figure 11.

Specific creep curves of UHPC specimens reinforced with different types of fibers [36].

This may be due to differences in fiber characteristics, such as slenderness, roughness, shape, and elasticity modulus. Shen D. et al. [74] produced UHPC with PP fibers, and their UHPC’s basic and specific tensile creep both increased when the PP fibers volume changed from 0% to 1%, and to 2%, but reduced when the PP fibers portion changed from 2% to 3%. The influence of PVA fiber volume fraction and fly ash content on the specific creep of high-ductility cementitious composites under compression was investigated in [75]. High-ductility cementitious composites are based on the theory of micromechanics and fracture mechanics and are primarily expected to exhibit high ductility under tensile and shear loads. The results of the experiment showed that the specific creep of prismatic specimens increases with the increase in PVA fiber content and fly ash content. On the other hand, it was observed that the amount of PVA fibers plays a significant role in the specific creep of these composite materials under the action of a short-term load, while the fly ash content plays a key role in the case of long-term loads.

4.4. Effect of Thermal Treatment and Concrete Age at Loading

Studies to date have confirmed that the application of thermal treatment at a temperature of 90 °C for 48 h significantly improves almost all UHPC properties [19]. Furthermore, some studies have shown that the application of the thermal treatment on concrete, and in particular on UHPC, can activate silica fume (and possibly other materials), resulting in a pore size reduction, which improves the structure and properties of the cement matrix [76].

Garas V. et al. [31] investigated the tensile creep strains of UHPC under short-term loads to assess the effects of the load level (stress/strength ratio), steel fiber reinforcement, and thermal treatment. The 48 h UHPC chamber thermal treatment at 90 °C, after 7 days of loading, resulted in a 73% tensile creep coefficient decrease and 77% specific creep decrease, compared to concrete that was not subjected to thermal treatment (room temperature 23 °C). In addition, by increasing the tensile stress/strength ratio from 40% to 60%, an increase of 44% and 11% is obtained in the values of tensile creep coefficient and specific tensile creep after 14 days of loading.

Another similar research was conducted in [32], where the effects of three different thermal treatment regimes on tensile and compressive creep of UHPC were considered. The first regime refers to thermal treatment at a temperature of 90 °C starting at the 48 h specimen and the 48 h heating process duration. In the second regime, the temperature of 60 °C was applied to a 48 h specimen with a total duration of 72 h of the heating process, while the third regime represented concrete hardening at ambient temperature. Experimental results showed that the tensile creep of UHPC is more sensitive to the effects of thermal treatment compared to tensile strength. Studies have also shown that thermal treatment at 90 °C for 48 h and at 60 °C for 72 h before specimen loading reduces specific tensile creep by about 63% and 57%, respectively, compared to UHPC not subjected to thermal treatment. In the case of compression creep, the application of thermal treatment at 90 °C resulted in a reduction of 60% in the specific compression creep values after one year of loading, compared to specimens that were not thermally treated. The results of these studies suggest that the phenomenon of tensile creep in UHPC occurs differently from compressive creep in UHPC.

Flietstra [34] conducted compression creep and shrinkage research of early-age UHPC concrete under multiple thermal treatment (curing) regimes to simulate current processes within U.S. manufacturing precast plants. The research results showed that the thermal treatment delay for UHPC specimens under the compressive load has no significant effect on the final creep coefficient.

Materials such as UHPC have large instantaneous and time-dependent strain under compressive and tensile loads when loaded at an early age. This behavior can be attributed to the relatively low material stiffness at an early age as well as to the material components (high silica fume content and large paste volume). Kamen A. et al. [77,78] concluded that creep strain mainly occurs in cement paste, and, therefore, a large volume of paste in a material such as UHPC causes an increase in creep during an early age. In experiments conducted by Mohebbi A. et al. [27], it was demonstrated that UHPC specimens loaded at the mature age showed nearly half the ultimate creep of those loaded at the early age. Results demonstrated that 50% of ultimate creep in the specimens loaded at an early age in the 50% ambient humidity had been attained between 1 and 7 days after loading, and 90% of ultimate creep had been attained between 27 and 156 days. This finding indicates that delaying the application of sustained compressive strength to UHPC until it approaches its final mechanical properties can significantly reduce the effects of creep on our concrete elements.

5. Conclusions

The creep of UHPC differs from the creep of ordinary concrete because it uses an extremely large amount of cement, which significantly reduces the water/binder ratio, and is very often reinforced with fibers that can be made of different materials. Basic creep is the dominant component of UHPC creep, while drying creep values are considerably smaller. Experimental tests of specimens under long-term loads have shown that creep strain is the closest match to the calculated values according to the model given in the FIB MC 2010, but for this model to be fully applicable for UHPC, it is necessary to modify it to a certain extent. Several such modified models for creep estimation are shown in this review. A comparative analysis of these proposed models was performed, and it was observed how well they describe UHPC behavior under long-term loads. However, by varying certain parameters such as compressive strength, relative humidity, cross-sectional dimensions, and temperature, it may lead to a greater discrepancy between models and uncertainties in results. Therefore, it is necessary to expand the existing experimental database regarding the long-term strains of the UHPC to perform the calibration of these models. In order to obtain reliable values of the creep coefficient as well as an adequate creep curve, the parameters α1, α2, and γ were modified within the FIB MC 2010. This review systematically collected most of the data on parameters that are important for creep, and it can serve as a basis for future experimental work on this topic, both for us and for other researchers. New experimental research can lead to improvements in existing creep models, and the ultimate goal is to obtain a unified creep model that would be an integral part of the regulations for the design of concrete structures.

In the case of concrete with such complicated components, besides compressive strength, the concrete elastic modulus also greatly influences creep. Generally, the creep coefficient (creep strain) of the UHPC decreases with an increase in steel fiber content, but it is important to consider that excessive fiber addition (from 2 to 3%) very often causes an increase in creep strain. It was observed that the reduction in creep strains is greater with the increase in the volume percentage of fibers from 0% to 1% than at the increase of 1% to 2%. During the effect analysis of different types of fibers on the creep of concrete, the fibers elastic modulus proved to be a key parameter. In the case of a higher elastic modulus of fibers compared with the elastic modulus of concrete (e.g., steel and basalt), long-term creep strain is ultimately smaller, while on the other hand, a lower elastic modulus of fibers compared with elastic modulus of concrete (PP and PVA fibers) creates a counter-effect because creep strains increase further. With PP fiber content increasing within the concrete mix, specific creep is significantly increased and this can be attributed to differences in the characteristics of the fibers themselves such as slenderness, roughness, shape, and elastic modulus. In the case of carbon fiber applications, they have been shown to reduce specific creep when their volume percentage is 0.1%.

Hybrid systems in combination NC-UHPC were also analyzed, whereby a thin UHPC layer is installed within the tensile zone and a layer of normal concrete within the compression zone of the beam. Studies have shown that a layer of UHPC in the tensile zone of the beam increases ductility, load-bearing capacity, and resistance to the occurrence of cracks. The thermal treatment of UHPC elements significantly influences the reduction in both tensile and compressive creep. UHPC has very pronounced creep strains when the specimen is loaded at an early age, so it is concluded that by delaying the application of compressive load, the effects of creep on the girders can be significantly reduced.

By reviewing the literature, it was observed that hybrid NC-UHPC girders were tested only to determine their mechanical properties (flexural performance, cracking, failure modes, and bond strength), while time-dependent deformations were not considered. Therefore, for future research directions, a study of the behavior of hybrid NC-UHPC girders under long-term loads is recommended.

An updated model that takes into account more parameters, and calibrates with valuable experimental datasets, would be most welcome for future studies to describe the creep of UHPC more adequately.

Author Contributions

Conceptualization, N.R. and G.B.; methodology, N.R.; investigation, N.R. and N.G.; resources, N.G.; data curation, G.B.; writing—original draft preparation, N.R.; writing—review and editing, N.G. and G.B.; visualization, G.B.; supervision, N.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data sharing is not applicable.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Richard, P.; Cheyrezy, M. Composition of Reactive Powder Concretes. Cem. Concr. Res. 1995, 25, 1501–1511. [Google Scholar] [CrossRef]

- Azmee, N.M.; Shafiq, N. Ultra-High Performance Concrete: From Fundamental to Applications. Case Stud. Constr. Mater. 2018, 9, e00197. [Google Scholar] [CrossRef]

- Shaheen, E.; Shrive, N.J. Optimization of Mechanical Properties and Durability of Reactive Powder Concrete. ACI Mater. J. 2006, 103, 444–451. [Google Scholar]

- Shah, S.P.; Weiss, W.J. Ultra high performance concrete: A look to the future. Int. J. Civ. Struct. Eng. 1998. [Google Scholar]

- Habel, K. Structural Behaviour of Elements Combining Ultra-High Performance Fibre Reinforced Concretes (UHPFRC) and Reinforced Concrete. Ph.D. Thesis, Federal Institute of Technology, Lausanne, Switzerland, 2004. [Google Scholar] [CrossRef]

- Parra-Montesinos, G.J.; Peterfreund, S.W.; Chao, S.H. Highly damage-tolerant beam-column joints through use of high-performance fiber-reinforced cement composites. ACI Struct. J. 2005, 102, 487–495. [Google Scholar]

- Bassam, A.T.; Ayad, S.A.; Nahla, N.H.; Abu Bakar, B.H.; Al-Tayeb, M.M.; Mansour, W.N. Properties of Ultra-High-Performance Fiber-Reinforced Concrete (UHPFRC)—A Review Paper. AIP Conf. Proc. 2019, 2157, 020040. [Google Scholar] [CrossRef]

- Graybeal, B.A. Compressive behavior of ultra-high-performance fiber-reinforced concrete. ACI Mater. J. 2007, 104, 146–152. [Google Scholar]

- Abbas, S.; Nehdi, M.L.; Saleem, M.A. Ultra-High Performance Concrete: Mechanical Performance, Durability, Sustainability and Implementation Challenges. Int. J. Concr. Struct. Mater. 2016, 10, 271–295. [Google Scholar] [CrossRef]

- Ullah, R.; Qiang, Y.; Ahmad, J.; Vatin, N.I.; El-Shorbagy, M.A. Ultra-High-Performance Concrete (UHPC): A State-of-the-Art Review. Materials 2022, 15, 4131. [Google Scholar] [CrossRef]

- Zhang, D.; Dasari, A.; Tan, K.H. On the mechanism of prevention of explosive spalling in ultra-high performance concrete with polymer fibers. Cem. Concr. Res. 2018, 113, 169–177. [Google Scholar] [CrossRef]

- Fathy, I.N.; El-Sayed, A.A.; Elfakharany, M.E.; Mahmoud, A.A.; Abouelnour, M.A.; Mahmoud, A.S.; Nabil, I.M. Enhancing mechanical properties and radiation shielding of high-strength concrete with bulk lead oxide and granodiorite. Nucl. Eng. Des. 2024, 429, 113626. [Google Scholar] [CrossRef]

- Fathy, I.N.; El-Sayed, A.A.; Elfakharany, M.E.; Mahmoud, A.A.; Abouelnour, M.A.; Mahmoud, A.S.; Mahmoud, K.A.; Hanafy, T.A.; Sayyed, M.I.; Nabil, I.M. Upgrading the compressive strength and radiation shielding properties of high strength concrete supported with nano additives of lead monoxide and granodiorite. Prog. Nucl. Energy 2025, 180, 105562. [Google Scholar] [CrossRef]

- Hajek, P.; Fiala, C. Environmentally optimized floor slabs using UHPC-contribution to sustainable building. In Proceedings of the 2nd International Symposium on Ultra-High Performance Concrete, Kassel, Germany, 5–7 March 2008; pp. 879–886. [Google Scholar]

- Liu, Y.; Wang, L.; Wei, Y.; Sun, C.; Xu, Y.; Sun, C.; Xu, Y. Current research status of UHPC creep properties and the corresponding applications—A review. Constr. Build. Mater. 2024, 416, 135120. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, J.; Wei, Q.; Shang, H.; Liu, X. Creep behaviour of ultra-high-performance concrete (UHPC): A review. J. Build. Eng. 2023, 69, 106187. [Google Scholar] [CrossRef]

- Liu, G.J. Research on mechanism of concrete creep. Appl. Mech. Mater. 2014, 670–671, 441–444. [Google Scholar] [CrossRef]

- Xu, Y.; Liu, J.; Liu, J.; Zhang, P.; Zhang, Q.; Jiang, L. Experimental studies and modeling of creep of UHPC. Constr. Build. Mater. 2018, 175, 643–652. [Google Scholar] [CrossRef]

- Graybeal, B. Characterization of the Behaviour of Ultra–High Performance Concrete. Ph.D. Thesis, Faculty of the Graduate School of the University of Maryland, College Park, MD, USA, 2008. [Google Scholar]

- Acker, P.; Behloul, M. Ductal Technology: A Large Spectrum of Properties, a Wide Range of Applications. In Proceedings of the International Symposium on Ultra-High Performance Concrete, Kassel, Germany, 5–7 March 2008; pp. 11–23. [Google Scholar]

- Spasojević, A. Structural Implications of Ultra-High Performance Fibre-Reinforced Concrete in Bridge Design. Ph.D. Thesis, Ecole Polytechnique Fédérale de Lausanne (EPFL), Lausanne, Switzerland, 2008. [Google Scholar] [CrossRef]

- Sun, M.; Visintin, P.; Bennett, T. Basic and drying creep of Ultra-high performance concrete. Aust. J. Civ. Eng. 2023, 1–11. [Google Scholar] [CrossRef]

- Sun, M. Time-Dependent Deformation of Ultra-High Performance Concrete. Ph.D. Thesis, University of Adelaide, Adelaide, Australia, 2022. [Google Scholar]

- Rossi, P.; Tailhan, J.L.; Le Maou, F.; Gaillet, L.; Martin, E. Basic creep behavior of concretes investigation of the physical mechanisms by using acoustic emission. Cem. Concr. Res. 2012, 42, 61–73. [Google Scholar] [CrossRef]

- Zhu, L.; Wang, J.J.; Li, X.; Zhao, G.Y.; Huo, X.J. Experimental and numerical study on creep and shrinkage effects of ultra high performance concrete beam. Compos. B 2020, 184, 107713. [Google Scholar] [CrossRef]

- Barbos, G.A. Long-term behavior of ultra–high performance concrete (UHPC) bended beams. Proc. Technol. 2016, 22, 203–210. [Google Scholar] [CrossRef]

- Mohebbi, A.; Graybeal, B.A.; Haber, Z.B. Time-dependent properties of ultrahigh-performance concrete: Compressive creep and shrinkage. J. Mater. Civ. Eng. 2022, 34, 04022096. [Google Scholar] [CrossRef]

- Rossi, P.; Charron, J.P.; Bastien-Masse, M.; Tailhan, J.L.; Le Maou, F.; Ramanich, S. Tensile basic creep versus compressive basic creep at early ages: Comparison between normal strength concrete and a very high strength fibre reinforced concrete. Mater. Struct. 2014, 47, 1773–1785. [Google Scholar] [CrossRef]

- Graybeal, B.A. Material Property Characterization of Ultra-High Performance Concrete; Report Number FHWA-HRT-06-103; Federal Highway Administration: Washington, DC, USA, 2006. [Google Scholar]

- Haber, Z.B.; De la Varga, I.; Graybeal, B.A.; Nakashoji, B.; El-Helou, R. Properties and Behavior Of UHPC-Class Materials; Report Number FHWA-HRT-18-036; Federal Highway Administration: Washington, DC, USA, 2018. [Google Scholar]

- Garas, V.Y.; Kahn, L.F.; Kurtis, K.E. Short-term tensile creep and shrinkage of ultra-high performance concrete. Cem. Concr. Compos. 2009, 31, 147–152. [Google Scholar] [CrossRef]

- Garas, V.Y.; Kurtis, K.E.; Kahn, L.F. Creep of UHPC in tension and compression: Effect of thermal treatment. Cem. Concr. Compos. 2012, 34, 493–502. [Google Scholar] [CrossRef]

- Mertol, H.C.; Rizkalla, S.; Zia, P.; Mirmiran, A. Creep and shrinkage behavior of high-strength concrete and minimum reinforcement ratio for bridge columns. PCI J. 2010, 55, 138–154. [Google Scholar] [CrossRef]

- Flietstra, J.C. Creep and Shrinkage Behaviour of Ultra-High-Performance Concrete Under Compressive Loading with Varying Curing Regimes. Master’s Thesis, Michigan Technological University, Houghton, MI, USA, 2011. [Google Scholar] [CrossRef]

- Ul Islam, M.M. Investigation of tensile creep for Ultra-High-Performance Fiber Reinforced Concrete (UHPFRC) for the long-term. Constr. Build. Mater. 2021, 305, 124752. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, P.; Sha, F.; Yu, Z.; He, S.; Xu, W.; Lv, M. Effects of type and content of fibers, water-to-cement Ratio and cementitious materials on the shrinkage and creep of ultra-high performance concrete. Polymers 2022, 14, 1956. [Google Scholar] [CrossRef]

- Rogowski, R. Time Dependent Creep Response of Ultra-High Performance Concrete Without Fiber Reinforcing. Master’s Thesis, Kansas State University, Manhattan, KS, USA, 2022. [Google Scholar]

- Fib Model Code for Concrete Structures 2010; Fédération International du Béton; Ernst & Sohn: Berlin, Germany, 2013.

- ACI Committee 209; Guide for Modeling and Calculating Shrinkage and Creep in Hardened Concrete. American Concrete Institute: Farmington Hills, MI, USA, 2008.

- GB 50010-2010; The National Standard of the People’s Republic of China, Code for Design of Concrete Structures. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2010.

- AS 3600:2018; Concrete Structures. Standards Australia: Sydney, Australia, 2018.

- Bažant, Z.P.; Jirasek, M.I.; Hubler, M.H.; Carol, I. RILEM draft recommendation: TC-242-MDC multi-decade creep and shrinkage of concrete: Material model and structural analysis. Mater. Struct. 2015, 48, 753–770. [Google Scholar] [CrossRef]

- Pribramsky, V. B4 model adaptation for prediction of UHPC strains from creep and shrinkage. Solid State Phenom. 2019, 292, 210–216. [Google Scholar] [CrossRef]

- LRFD Bridge Design Specification, 9th ed.; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2020.

- Flietstra, J.C.; Ahlborn, T.M.; Harris, D.K.; De Melo e Silva, H. Creep behaviour of UHPC under compressive loading with varying curing regimes. In Proceedings of the 3rd International Symposium on UHPC, Kassel, Germany, 7–9 March 2012; pp. 333–340. [Google Scholar]

- Mazloom, M. Estimating long-term creep and shrinkage of high-strength concrete. Cem. Concr. Compos. 2008, 30, 316–326. [Google Scholar] [CrossRef]

- Pan, Z.; Li, B.; Lu, Z. Re-evaluation of CEB-FIP 90 prediction models for creep and shrinkage with experimental database. Constr. Build. Mater. 2013, 38, 1022–1030. [Google Scholar] [CrossRef]

- CEB-FIP Model Code for Concrete Structures; Comité Euro-International du Béton (CEB): Lausanne, Switzerland, 1990.

- Code-Type Models for Concrete Behaviour; Background of MC2012, Bulletin Number 70; Fédération International du Béton (FIB): Lausanne, Switzerland, 2013.

- Holowaty, J. New formula for creep of concrete in fib Model Code 2010. Am. J. Mater. Sci. 2015, 3, 59–66. [Google Scholar]

- Mazloom, M.; Ramezanianpour, A.A.; Brooks, J.J. Effect of silica fume on mechanical properties of high-strength concrete. Cem. Concr. Compos. 2004, 26, 347–357. [Google Scholar] [CrossRef]

- Rezakhani, R.; Scott, D.A.; Bousikhane, F.; Pathirage, M.; Moser, R.D.; Green, B.H.; Cusatis, G. Influence of steel fiber size, shape, and strength on the quasi-static properties of ultra-high performance concrete: Experimental investigation and numerical modeling. Constr. Build. Mater. 2021, 296, 123532. [Google Scholar] [CrossRef]

- El-Dieb, A. Mechanical, durability and microstructural characteristics of ultra-high-strength self-compacting concrete incorporating steel fibers. Mater. Des. 2009, 30, 4286–4292. [Google Scholar] [CrossRef]

- Schmidt, M.; Fehling, E.; Teichmann, T.; Bunje, K.; Bornemann, R. Ultra-high performance concrete: Perspective for the precast concrete industry. Concr. Precast. Plant Technol. 2003, 69, 16–29. [Google Scholar]

- Shehab El-Din, H.K.; Mohamed, H.A.; Khater, M.; Ahmed, S. Effect of Steel Fibers on Behavior of Ultra High Performance Concrete. In Proceedings of the International Interactive Symposium on Ultra-High Performance Concrete, Des Moines, IA, USA, 18–20 July 2016; Iowa State University Digital Press: Ames, IA, USA, 2016. [Google Scholar] [CrossRef]

- Larsen, I.L.; Thorstensen, R.T. The influence of steel fibres on compressive and tensile strength of ultra high performance concrete: A review. Constr. Build. Mater. 2020, 256, 119459. [Google Scholar] [CrossRef]

- Bonneau, O.; Poulin, C.; Dugat, J.; Richard, P.; Aitcin, P. Reactive Powder Concretes: From Theory to Practice. Concr. Int. 1996, 18, 47–49. [Google Scholar]

- Park, S.H.; Kim, D.J.; Ryu, G.S.; Koh, K.T. Tensile behavior of ultra high performance hybrid fiber reinforced concrete. Cem. Concr. Compos. 2012, 34, 172–184. [Google Scholar] [CrossRef]

- Chern, J.C.; Young, C.H. Compressive creep and shrinkage of steel fibre reinforced concrete. Int. J. Cem. Compos. Lightweight Concr. 1989, 11, 205–214. [Google Scholar] [CrossRef]

- Yu, J.; Zhao, Q. Effect of Steel Fiber on Creep Behavior of Concrete. J. Chin. Ceram. Soc. 2013, 41, 1087–1093. [Google Scholar] [CrossRef]

- Chen, P.; Zheng, W.; Wang, Y.; Chang, W. Analysis and Modelling of Shrinkage and Creep of Reactive Powder Concrete. Appl. Sci. 2018, 8, 732. [Google Scholar] [CrossRef]

- Hakeem, I.Y.; Rahman, M.K.; Althoey, F. Experimental investigation of hybrid beams utilizing Ultra-High Performance Concrete (UHPC) as tension reinforcement. Materials 2022, 15, 5619. [Google Scholar] [CrossRef] [PubMed]

- Kadhim, M.M.A.; Jawdhari, A.; Peiris, A. Development of hybrid UHPC-NC beams: A numerical study. Eng. Struct. 2021, 233, 111893. [Google Scholar] [CrossRef]

- Lin, P.; Yan, W.; Zhao, H.; Ma, J. Theoretical and Experimental Investigation on the Flexural Behaviour of Prestressed NC-UHPC Composite Beams. Materials 2023, 16, 879. [Google Scholar] [CrossRef]

- Tong, T.; Yuan, S.; Wang, J.; Liu, Z. The role of bond strength in structural behaviors of UHPC-NC composite beams: Experimental investigation and finite element modeling. Compos. Struct. 2021, 255, 112914. [Google Scholar] [CrossRef]

- Danha, L.S.; Abdul-Hussien, Z.A.; Abduljabbar, M.S.; Yassin, L.A.G. Flexural behavior of hybrid ultra-high-performance concrete. IOP Conf. Ser. Mater. Sci. Eng. 2020, 737, 012008. [Google Scholar] [CrossRef]

- Wight, J.K.; MacGregor, J.G. Reinforced Concrete-Mechanics and Design, 6th ed.; Prentice Hall: Saddle River, NJ, USA, 2011. [Google Scholar]

- Nezhentseva, A.; Sørensen, E.V.; Andersen, L.V.; Schuler, F. Distribution and Orientation of Steel Fibers in UHPFRC; DCE Technical Report Number 151; Aalborg University: Aalborg Øst, Denmark, 2013. [Google Scholar]

- Barnett, S.J.; Lataste, J.F.; Parry, T.; Millard, S.G.; Soutsos, M.N. Assessment of fiber orientation in ultra-high performance fibre reinforced concrete and its effect on flexural strength. Mater. Struct. 2010, 43, 1009–1023. [Google Scholar] [CrossRef]

- Kruschwitz, S.; Oesch, T.; Mielentz, F.; Meinel, D.; Spyridis, P. Non-Destructive Multi-Method Assessment of Steel Fiber Orientation in Concrete. Appl. Sci. 2022, 12, 697. [Google Scholar] [CrossRef]

- Shiotani, T.; Ogura, N.; Okude, N.; Watabe, K.; Van Steen, C.; Tsangouri, E.; Lacidogna, G.; Czarnecki, S.; Chai, H.K.; Yang, Y.; et al. Non-destructive inspection technologies for repair assessment in materials and structures. Dev. Built Environ. 2024, 18, 100443. [Google Scholar] [CrossRef]

- Mpalaskas, A.C.; Kytinou, V.K.; Zapris, A.G.; Matikas, T.E. Optimizing Building Rehabilitation through Nondestructive Evalua-tion of Fire-Damaged Steel-Fiber-Reinforced Concrete. Sensors 2024, 24, 5668. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Q.; Yu, J.; Geng, G.; Jiang, J.; Liu, X. Effect of fiber types on creep behavior of concrete. Constr. Build. Mater. 2016, 105, 416–422. [Google Scholar] [CrossRef]

- Shen, D.; Liu, C.; Luo, Y.; Shao, H.; Zhou, X.; Bai, S. Early-age autogenous shrinkage, tensile creep, and restrained cracking behavior of ultra-high-performance concrete incorporating polypropylene fibers. Cem. Concr. Compos. 2023, 138, 104948. [Google Scholar] [CrossRef]

- Chen, B.; Guo, L.; Zhang, L.; Zhang, W.; Bai, Y.; Wang, X. Influence of polyvinyl alcohol fiber and fly ash content on compressive creep properties of high ductility cementitious composites. E3S Web Conf. 2021, 272, 02014. [Google Scholar] [CrossRef]

- Richard, P.; Cheyrezy, M.H. Reactive powder concretes with high ductility and 200-800 MPa compressive strength. Am. Concr. Inst. SP 1994, 144, 507–518. [Google Scholar] [CrossRef]

- Kamen, A.; Denarié, E.; Brühwiler, E. Viscoelastic behavior of a strain hardening Ultra-High Performance Fiber Reinforced Concrete. In Advances in Construction Materials; Springer: Berlin/Heidelberg, Germany, 2007; pp. 157–164. [Google Scholar] [CrossRef]

- Kamen, A.; Denarié, E.; Sadouki, H.; Brühwiler, E. UHPFRC tensile creep at early age. Mater. Struct. 2009, 42, 113–122. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).