Experimental Study on Punching Shear Behavior of Ultra-High-Performance Concrete (UHPC) Slabs

Abstract

1. Introduction

2. Experimental Program

2.1. Specimen Characterizations

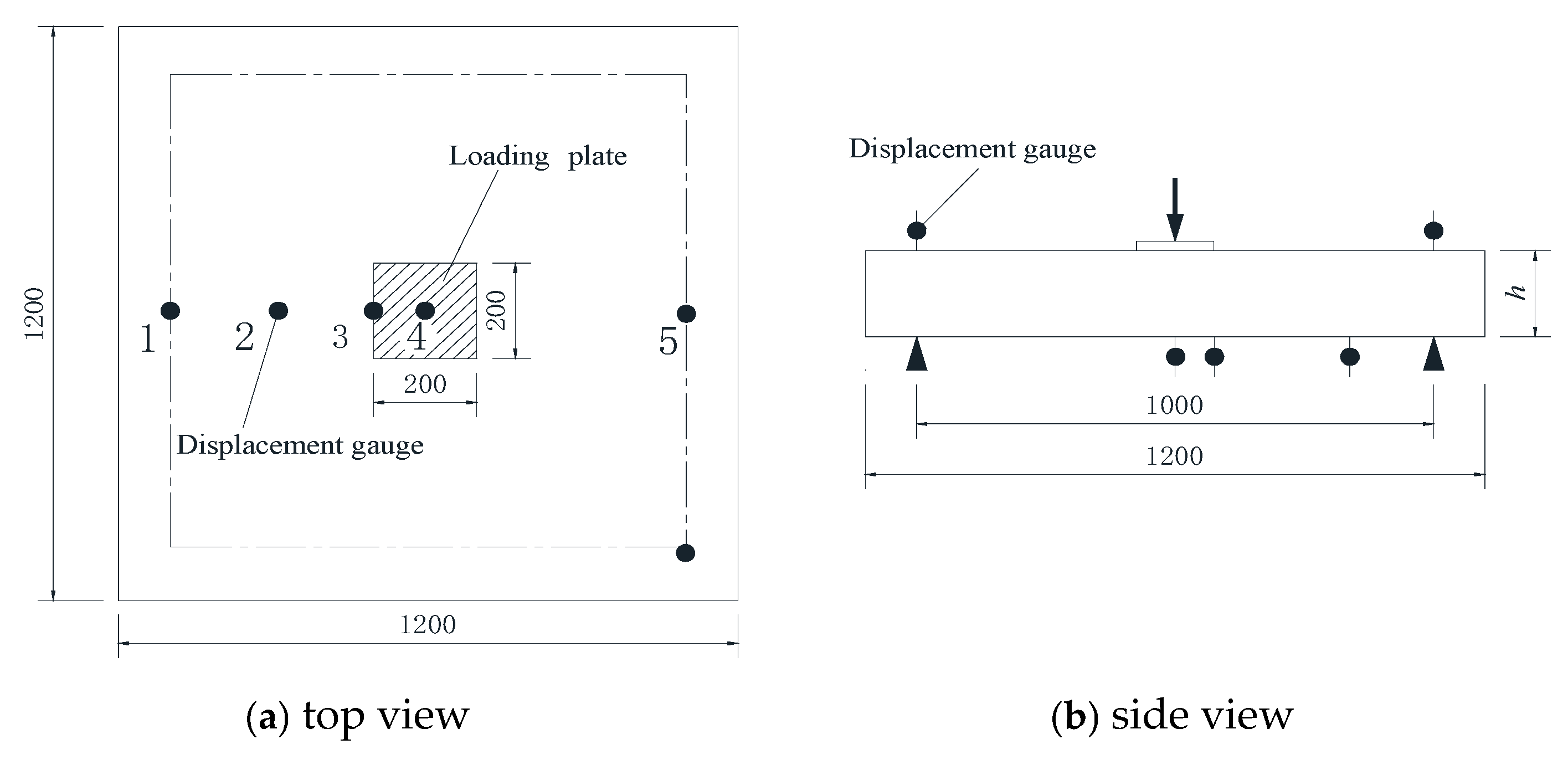

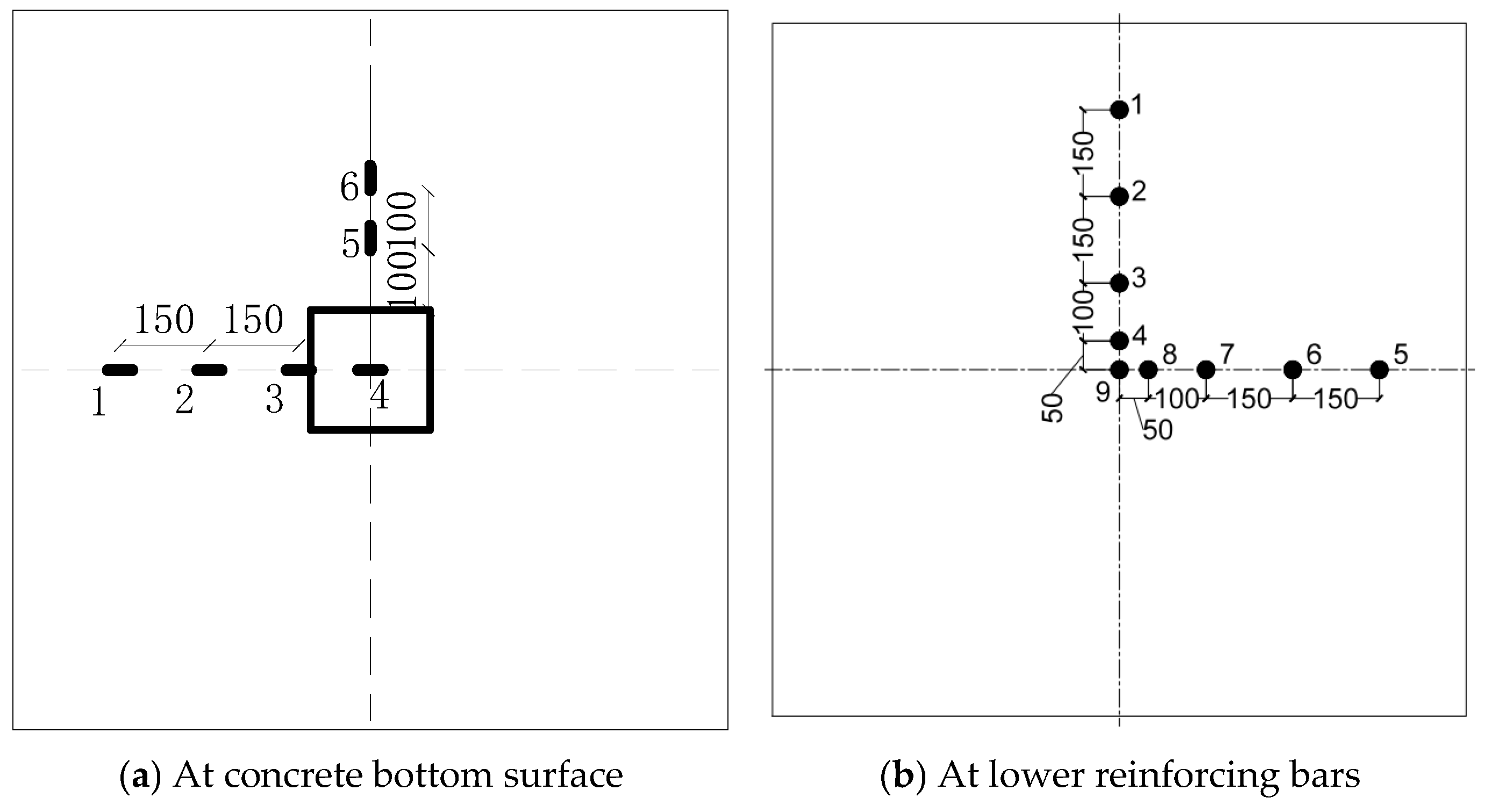

2.2. Loading and Instrumentation

2.3. Test Results and Discussion for Slabs of PHASE I

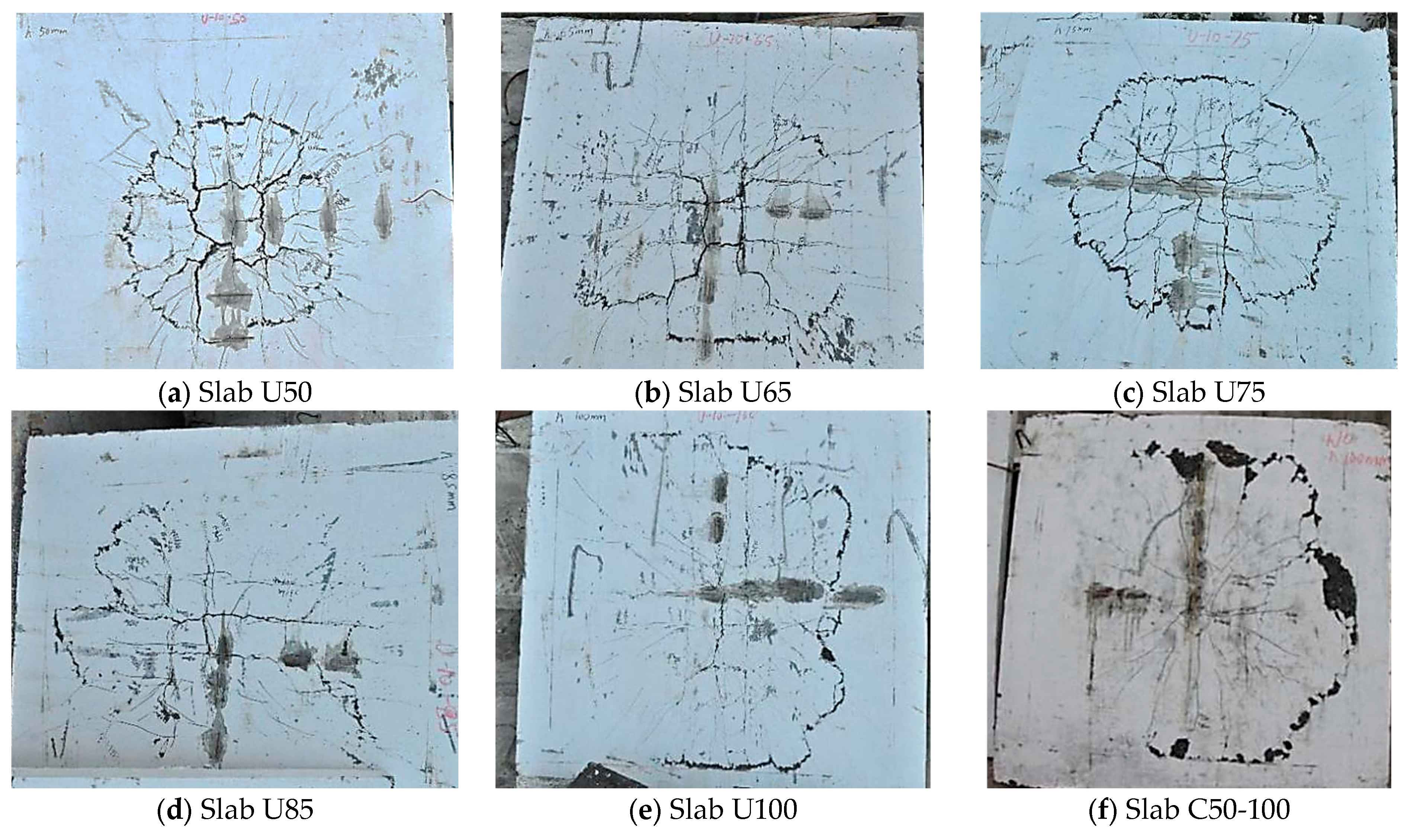

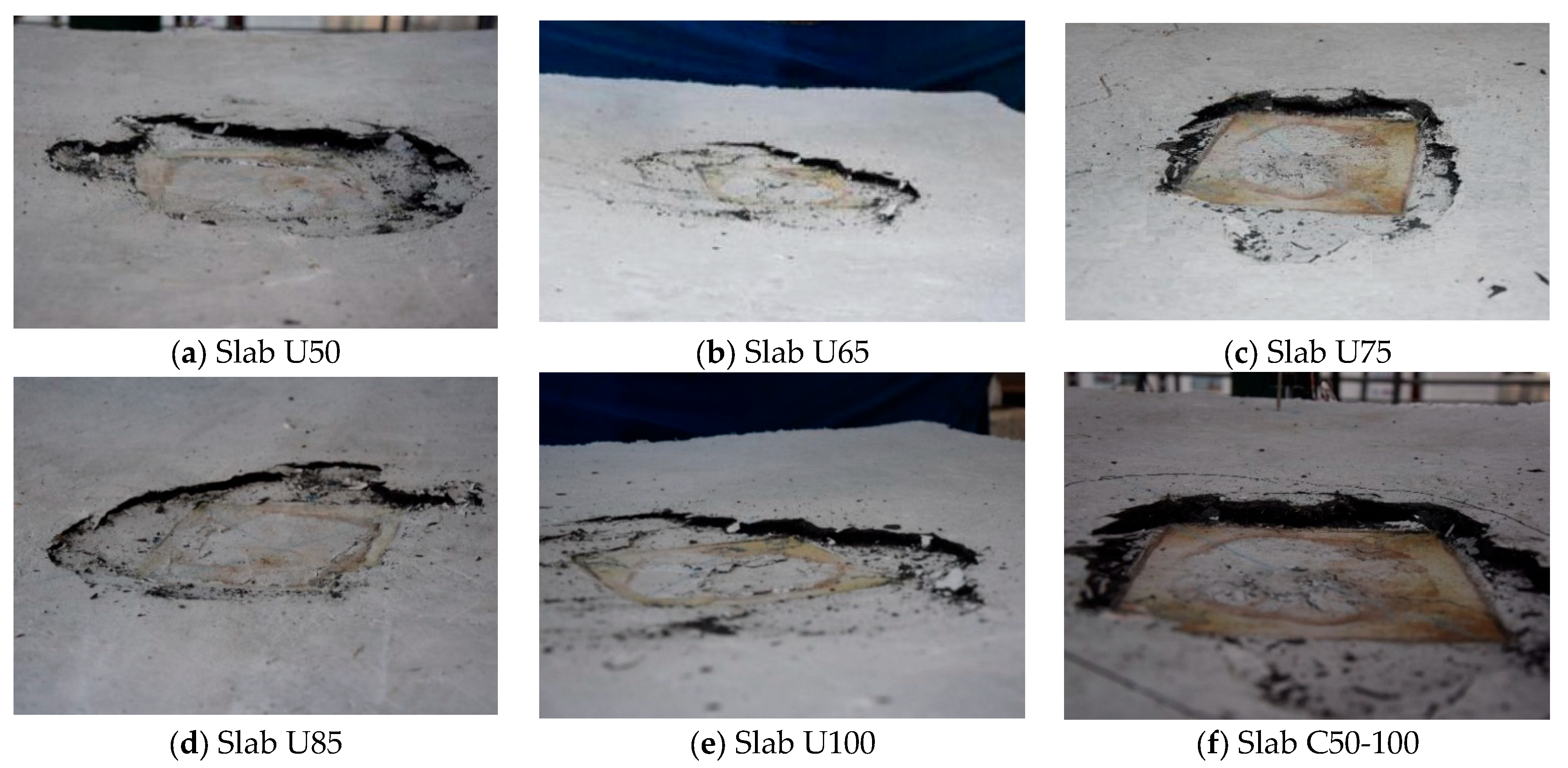

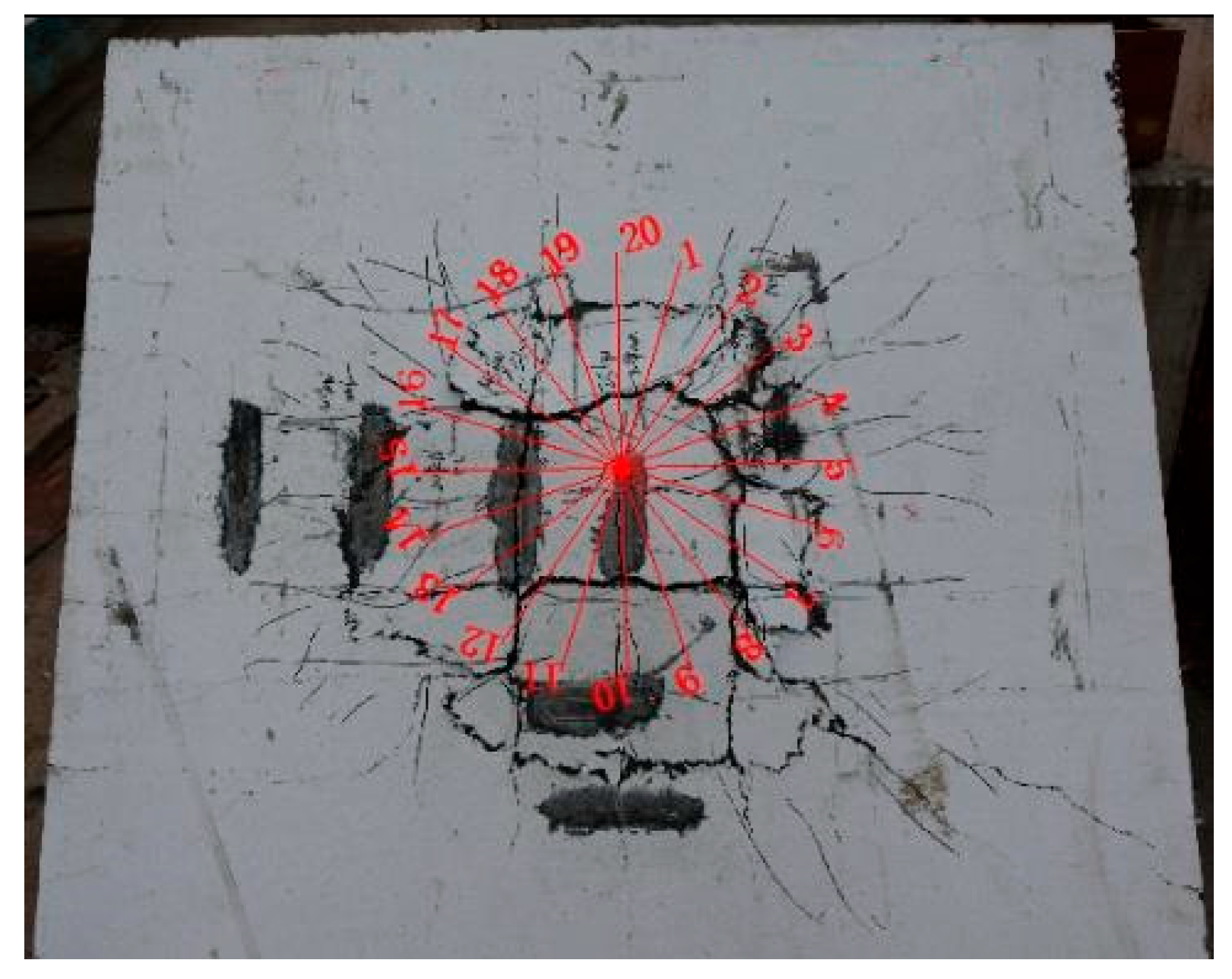

2.3.1. Failure Mode

2.3.2. Load–Deflection Relationship

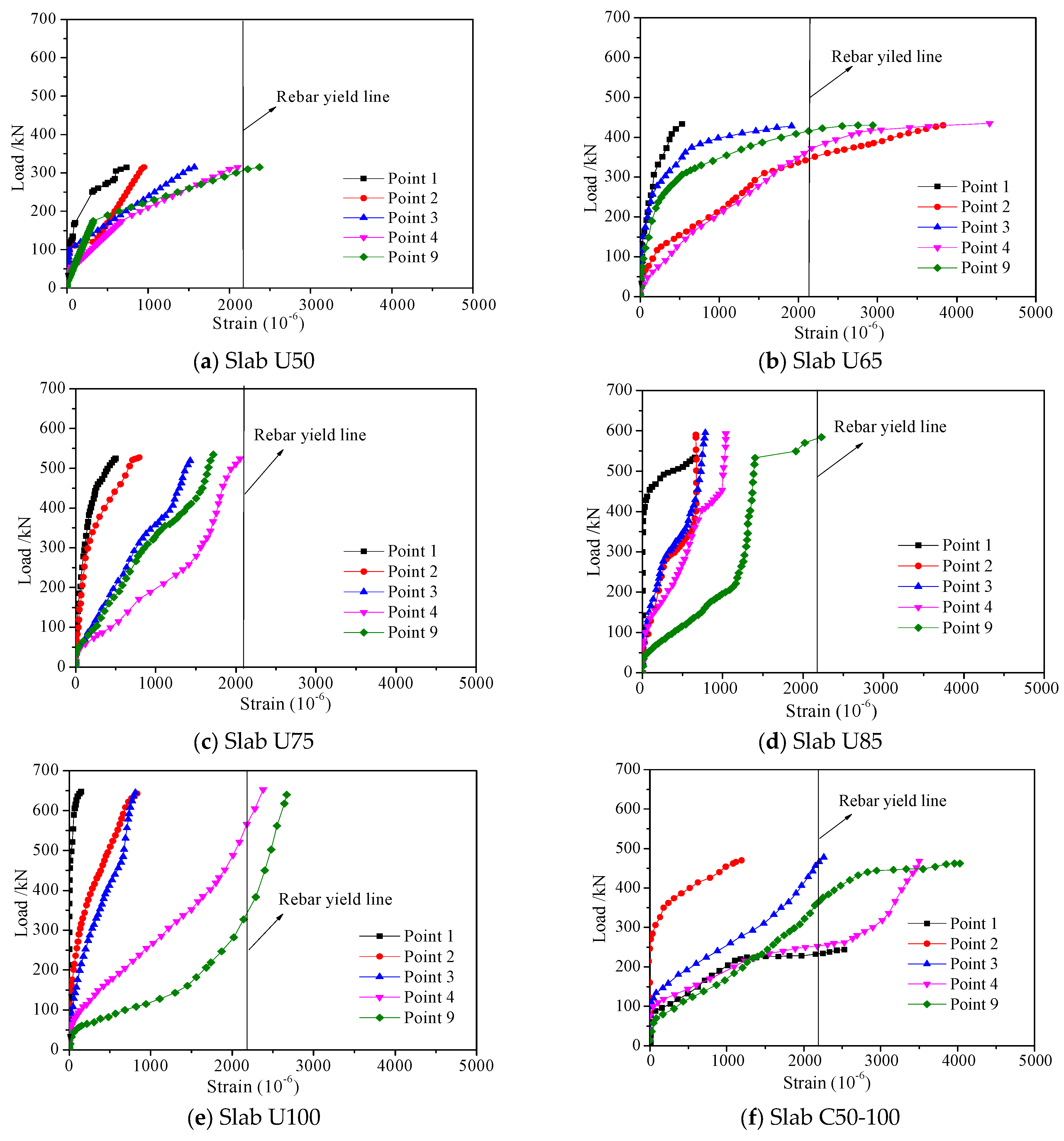

2.3.3. Load–Reinforcing Steel Bar Strains Relationships

2.4. Analysis of Flexural Capacity and Critical Thickness

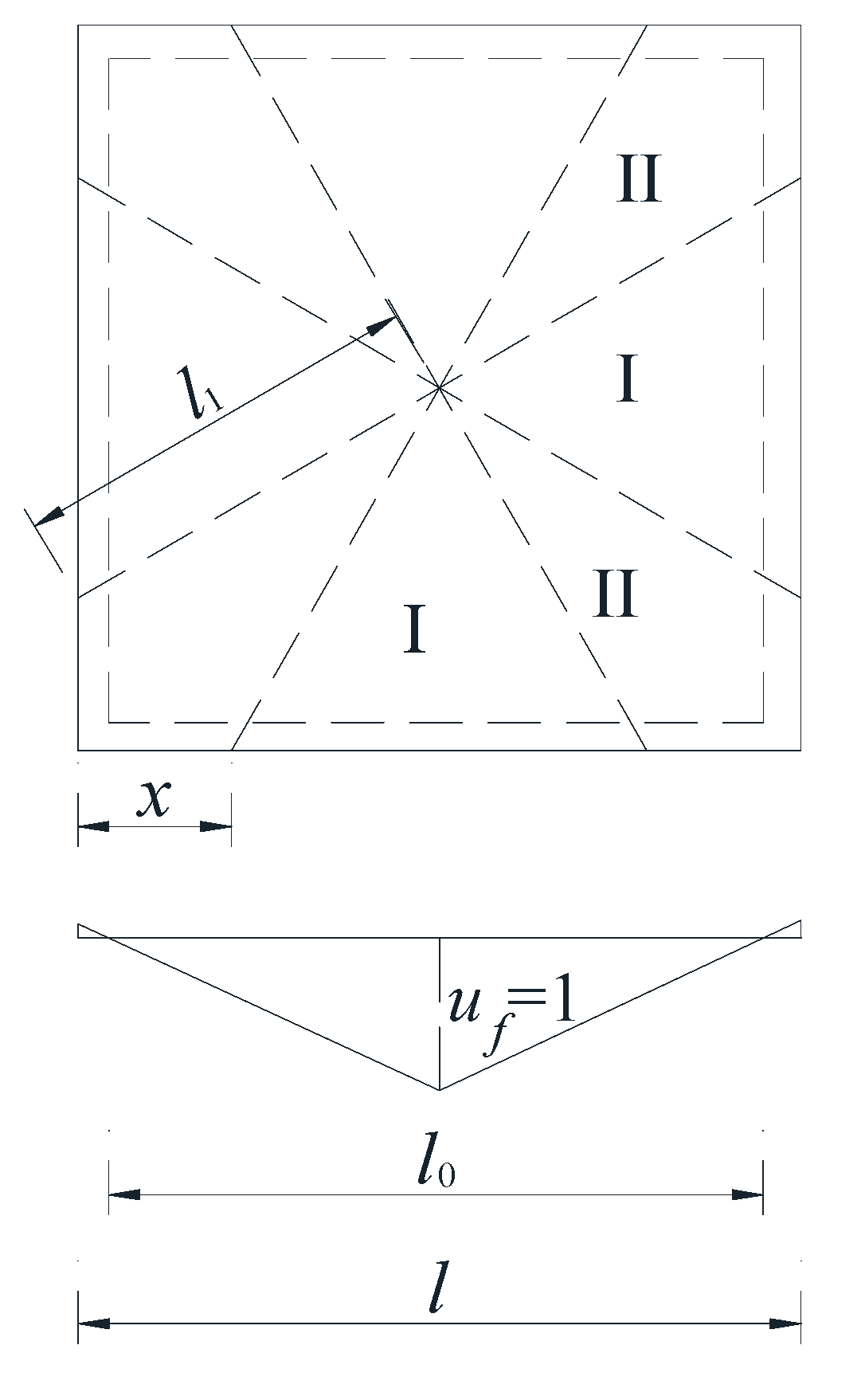

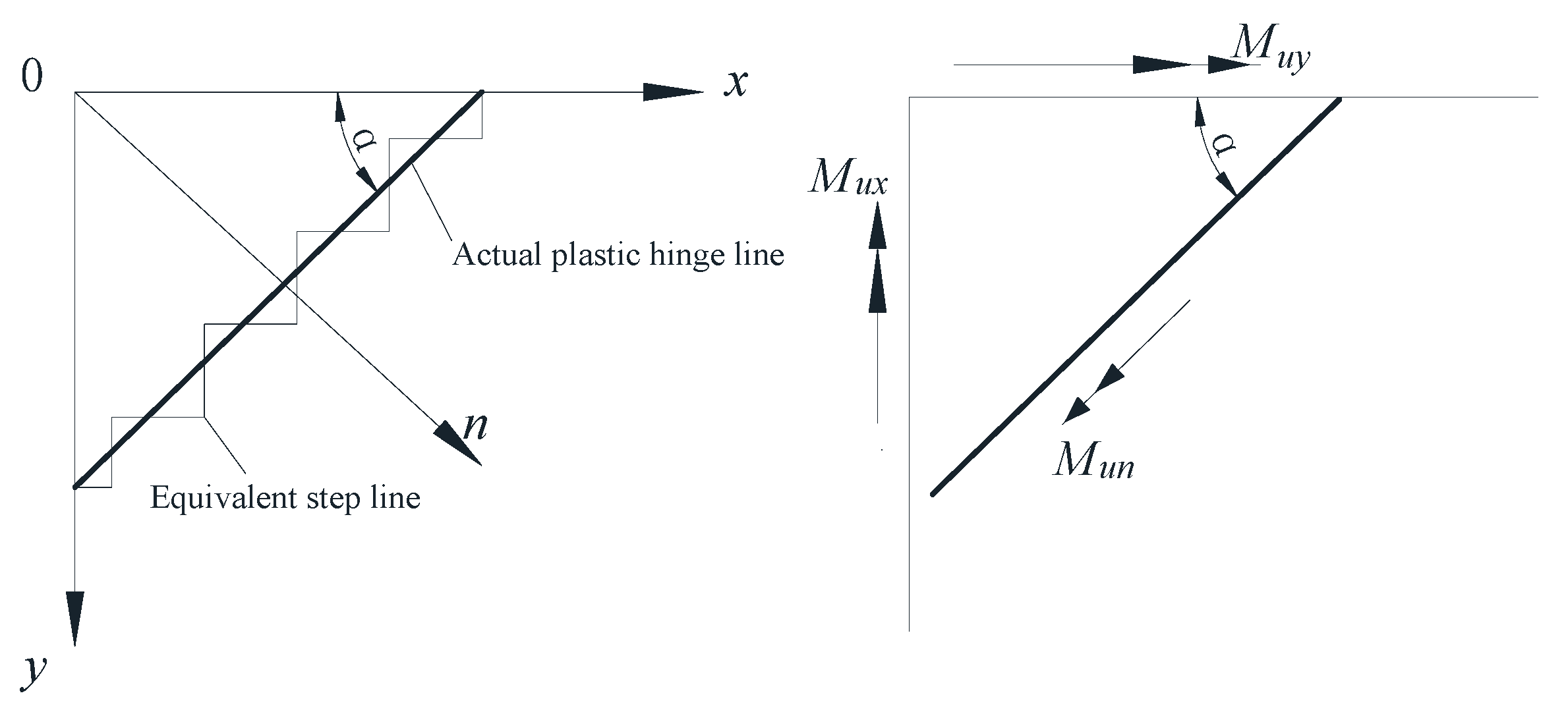

2.4.1. Calculation of Flexural Capacity

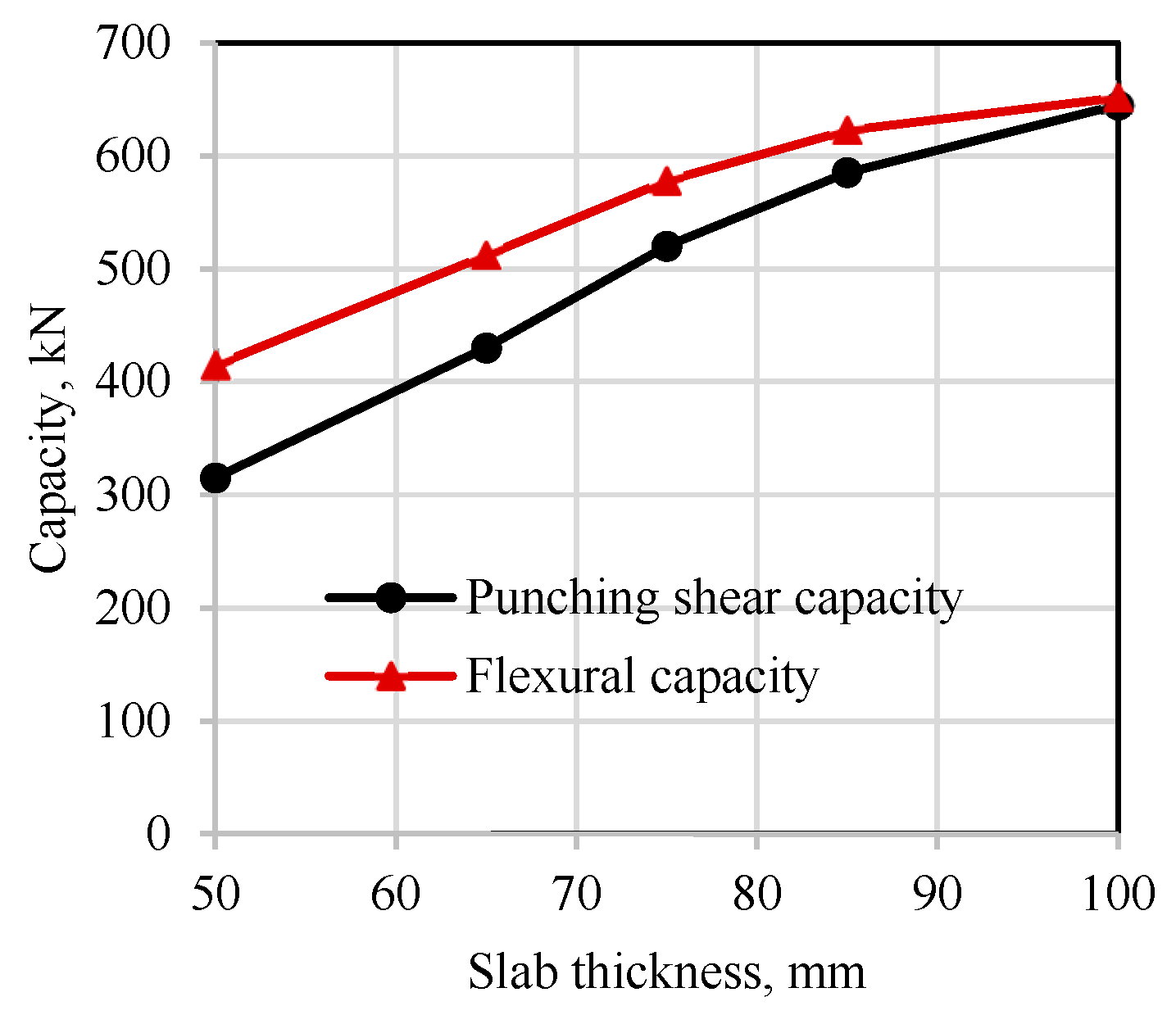

2.4.2. Analysis of Critical Thickness

3. The Effect of Governing Parameters on Punching Shear Behavior of UHPC Slabs (Phase II)

3.1. Specimen Design and Test Results

3.2. Analysis of the Effect of Key Parameters on Punching Shear Strength

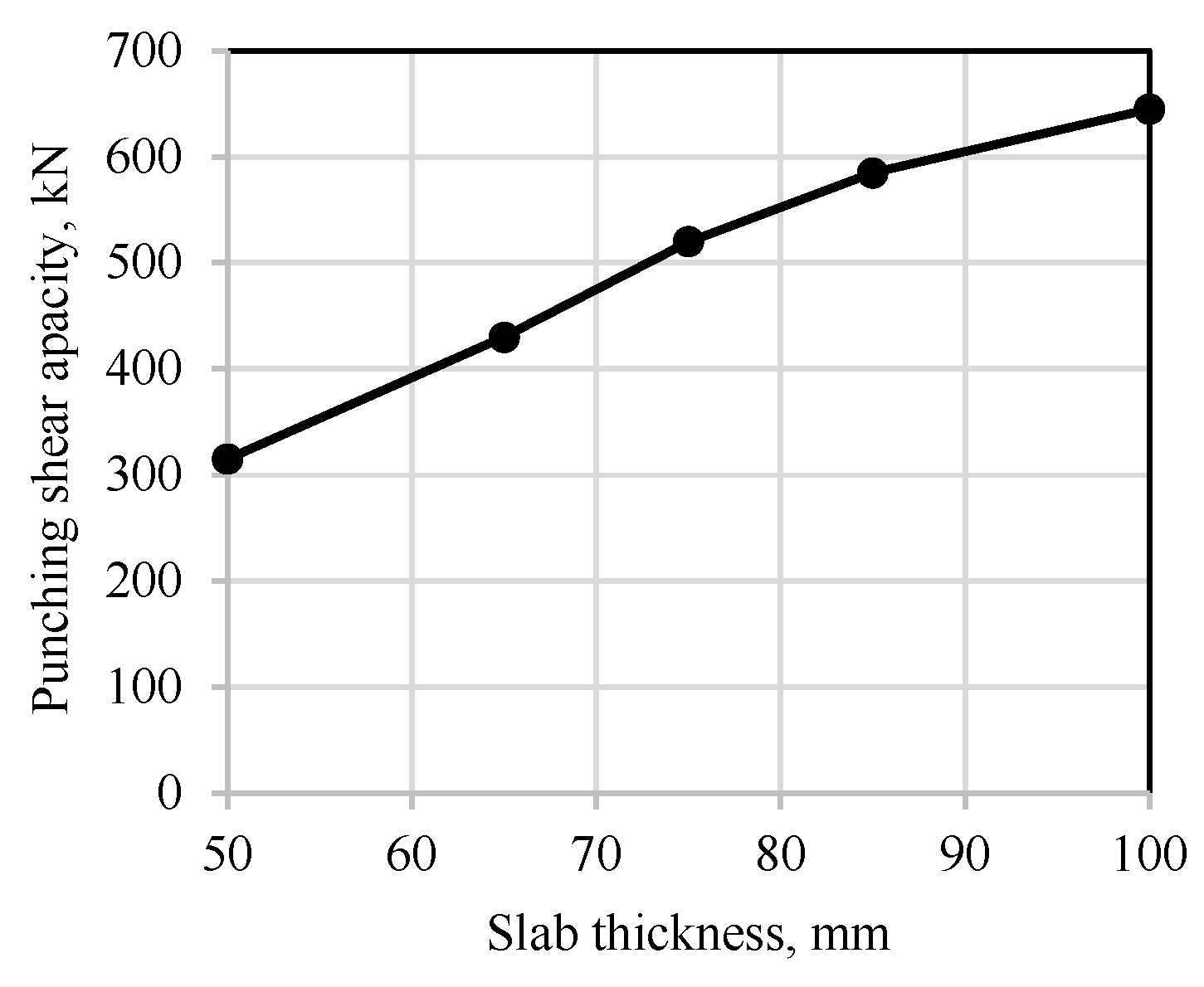

3.2.1. Effect of Slab Thickness (Phase I)

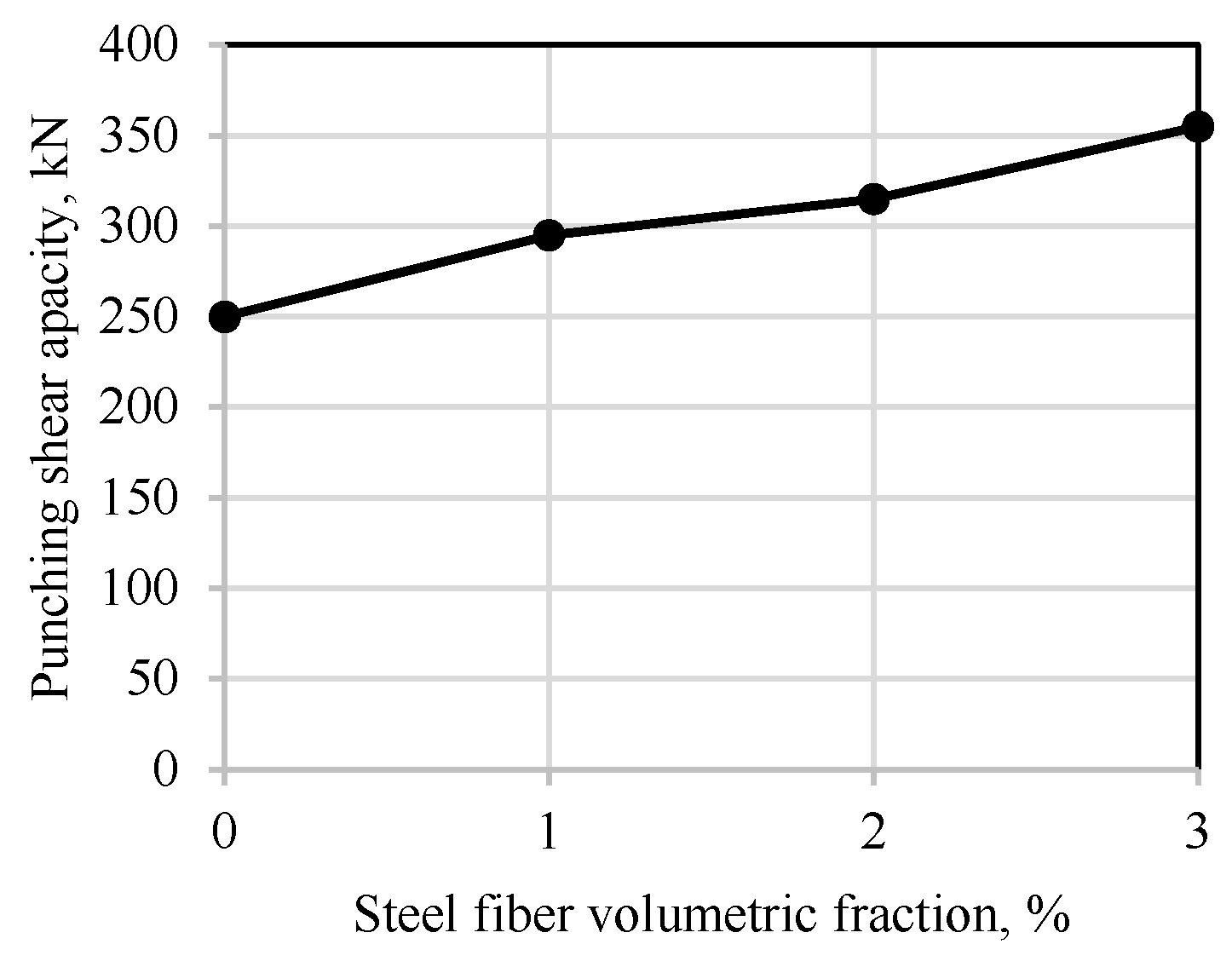

3.2.2. Effect of Steel Fiber Content (Phase II)

3.2.3. Effect of Reinforcement Ratio (Phase II)

3.2.4. Effect of Granite Powder Instead of Silica Fume (Phase II)

4. Calculation Method of Punching Shear Capacity

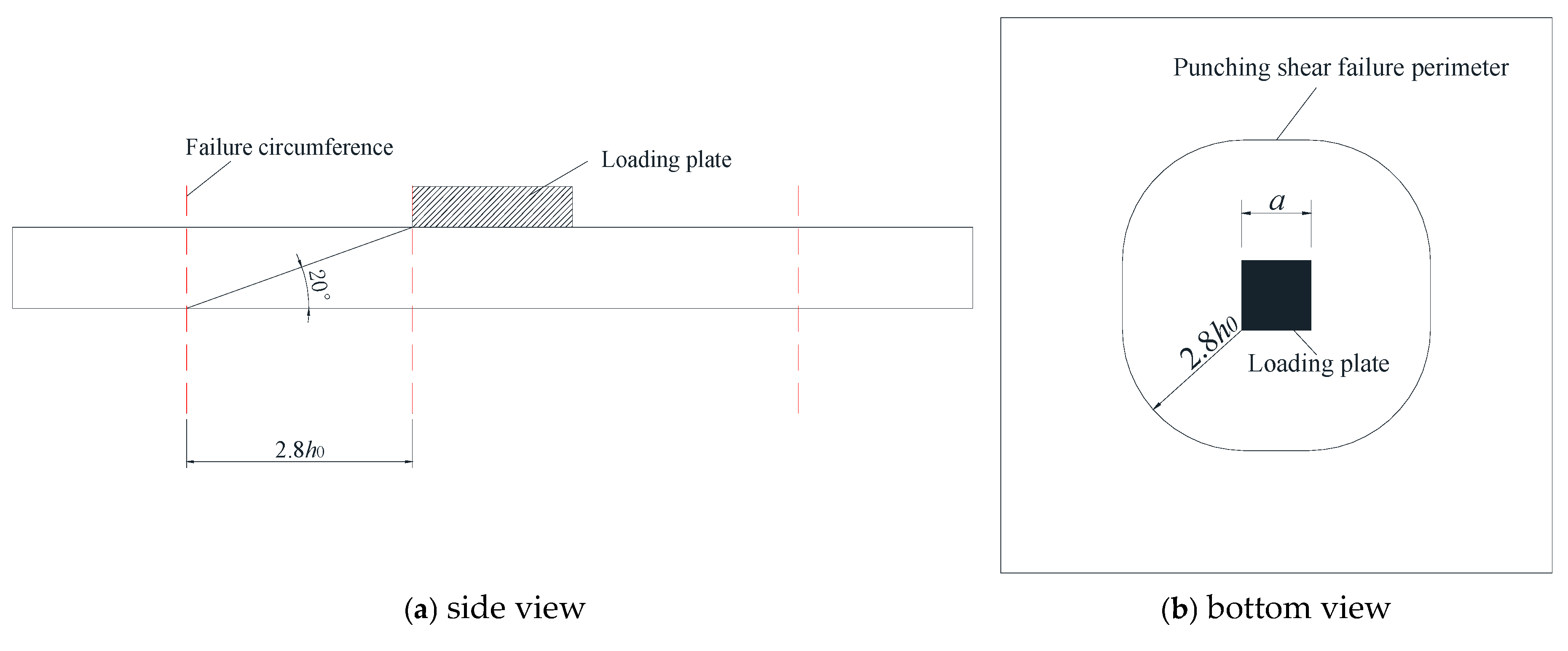

4.1. Determination of Punching Shear Angle and Failure Perimeter

4.2. Comparison of Punching Shear Capacity

- Material Properties: UHPC exhibits unique mechanical properties, including higher compressive strength and ductility compared to conventional concrete. If the models do not adequately account for these enhanced material characteristics, particularly in terms of tensile strength and strain capacity, this can lead to an underestimation of the punching shear strength.

- Geometric Considerations: The geometry of the slab, including thickness, reinforcement layout, and support conditions, can significantly influence shear behavior. Models that simplify these geometric parameters may fail to capture critical stress distribution effects that are present in actual slab scenarios.

- Loading Conditions: The nature of loading, whether it is static or dynamic, can affect the performance of UHPC slabs. Models that do not incorporate factors such as load duration or impact effects may not accurately reflect the true behavior under real-world conditions.

- Crack Propagation and Ductility: The ability of UHPC to sustain loads post-cracking is a vital aspect that many models may overlook. Discrepancies often arise when models assume brittle failure modes instead of recognizing the progressive failure characteristics inherent in UHPC.

- Experimental Variability: Variations in experimental setup, including differences in specimen preparation and testing protocols, can lead to inconsistencies between calculated and observed results. It is crucial to ensure that experimental conditions closely mimic those assumed in theoretical models.

- Model Calibration: Many calculation models rely on empirical coefficients or calibration against specific datasets. If these coefficients are derived from a limited range of tests or do not encompass the full spectrum of UHPC behaviors, they may lead to conservative estimates of punching shear capacity. In conclusion, a thorough investigation into these factors is necessary to reconcile differences between calculated and experimental data for punching shear in UHPC slabs. By addressing these discrepancies through refined modeling techniques and comprehensive experimental validation, we can enhance the reliability of predictive models for structural applications.

| Slab No. | VExp (kN) (2) | Theoretical Punching Capacity (kN) | Experimental Strength/Theoretical Strength | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Al-Quraishi [65] (3) | Fang et al. [66] (4) | AFGC [67] (5) | JSCE [68] (6) | Harris and Wollmann [69] (7) | (2)/(3) | (2)/(4) | (2)/(5) | (2)/(6) | (2)/(7) | ||

| U50 | 315 | 153.39 | 134.37 | 122.18 | 185.32 | 259.96 | 2.05 | 2.34 | 2.58 | 1.70 | 1.21 |

| U65 | 430 | 185.69 | 196.56 | 183.59 | 268.57 | 305.89 | 2.32 | 2.19 | 2.34 | 1.60 | 1.41 |

| U75 | 520 | 207.34 | 251.51 | 227.54 | 327.14 | 338.44 | 2.51 | 2.07 | 2.29 | 1.59 | 1.54 |

| U85 | 585 | 229.12 | 344.32 | 273.91 | 388.37 | 372.16 | 2.55 | 1.70 | 2.14 | 1.51 | 1.57 |

| U100 | 645 | 262.02 | 510.89 | 347.97 | 484.98 | 424.62 | 2.46 | 1.26 | 1.85 | 1.33 | 1.52 |

| U0R35 | 250 | 152.89 | 109.69 | 107.49 | 182.99 | 228.71 | 1.64 | 2.28 | 2.33 | 1.37 | 1.09 |

| U1R35 | 295 | 153.61 | 101.46 | 128.79 | 186.31 | 274.02 | 1.92 | 2.91 | 2.29 | 1.58 | 1.08 |

| U2R0 | 180 | 119.58 | 115.05 | 135.75 | 104.15 | 288.83 | 1.51 | 1.56 | 1.33 | 1.73 | 0.62 |

| U2R13 | 240 | 147.16 | 110.89 | 122.18 | 163.09 | 259.96 | 1.63 | 2.16 | 1.96 | 1.47 | 0.92 |

| U3R35 | 355 | 153.39 | 167.28 | 122.18 | 185.32 | 259.96 | 2.31 | 2.12 | 2.91 | 1.92 | 1.37 |

| Average | 2.090 | 2.059 | 2.202 | 1.580 | 1.233 | ||||||

| Standard deviation | 0.395 | 0.459 | 0.427 | 0.175 | 0.309 | ||||||

| Coefficient of variation, COV | 0.189 | 0.223 | 0.194 | 0.111 | 0.250 | ||||||

| Method | Size Effect | UHPC | Fibers | Punching Parameters | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| fto | lf | df | Vf | Type | a/d | Critical Shear Perimeter from the Face of the Column | |||||

| Al-Quraishi [65] | √ | √ | √ | √ | √ | √ | √ | Straight steel | √ | 1.25d | |

| Fang et al. [66] | √ | √ | √ | √ | √ | Straight steel | √ | 1.73d | |||

| AFGC [67] | √ | √ | 0.5d | ||||||||

| JSCE [68] | √ | √ | √ | √ | √ | √ | √ | Various | √ | 0.5d | |

| Harris and Wollmann [69] | √ | 1.5d | |||||||||

5. Conclusions

- (1)

- The failure mode of Ultra-High-Performance Concrete (UHPC) slabs looks like that of traditional concrete slabs, characterized by a jagged conical indentation on the top surface and nearly circular closed cracks on the bottom surface. Thanks to the reinforcing properties of steel fibers, UHPC slabs exhibit superior punching shear performance compared to conventional concrete slabs, particularly in failure mode, crack propagation, and ultimate load-carrying capacity.

- (2)

- The punching shear capacity increases linearly with the thickness of the slab, and this increase occurs at a rate that surpasses that of flexural capacity. A critical thickness that delineates punching shear failure from flexural failure is advised to be no less than 100 mm. Furthermore, an increase in thickness significantly enhances the load at which the first crack occurs.

- (3)

- The punching shear capacity increases with the increase of steel fiber volume fraction, with a more pronounced rise in the first cracking load.

- (4)

- The punching shear capacity significantly improves with a higher reinforcement ratio; however, the increase in the load at which the first crack occurs is minimal.

- (5)

- The punching shear capacity of UHPC slabs experiences a mere reduction of 1.87% when granite powder is utilized to replace 10% of the mass of silica fume.

- (6)

- A method for calculating the failure perimeter at the bottom surface has been proposed. This information can be a valuable reference for future research and engineering applications.

- (7)

- The test did not exhibit any flexural failure mode; therefore, the critical thickness value proposed in this paper requires validation through additional tests involving greater thickness. It is also recommended that further investigations be conducted into the interaction between punching shear and bending, as well as the effects of dynamic loading.

- (8)

- Among the available prediction models, the JSCE approach provided the most balanced and conservatively accurate estimation of punching shear capacity, effectively incorporating the combined effects of slab thickness, reinforcement ratio, and fiber content, thus highlighting its potential as a reliable reference for future design recommendations.

- (9)

- Although serviceability was not the primary focus of this study, a serviceability limit of Span/800 may be adopted for UHPC bridge deck slabs under general vehicular loading. This serviceability limit is specified in the 2020 AASHTO LRFD Bridge Design Specifications for concrete bridge deck slabs. These limits are intended to ensure user comfort, durability of wearing surfaces, and protection of structural and non-structural components from excessive deformation. Excessive deflections can cause surface cracking, loss of bond, and premature deterioration of overlays.

- (10)

- Although mechanical test results indicated minimal performance reduction when substituting 10% of silica fume with granite powder, no SEM (Scanning Electron Microscopy) analysis was conducted in this study to investigate potential changes in the microstructure. Future research should include SEM and related microstructural analyses to better understand the interaction between granite powder and the cementitious matrix, and to validate its long-term implications for durability and performance.

- (11)

- Although each configuration was tested using a single specimen, experimental repeatability was supported by strict standardization of material preparation, curing, instrumentation, and loading protocols. This approach is common in UHPC and structural slab research, where cost and scale limit extensive repetition. Nonetheless, for increased statistical robustness and validation of variability, future work should include multiple specimens per test configuration.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wight, J.K.; American Concrete Institute (Eds.) Building Code Requirements for Structural Concrete (ACI 318-19) and Commentary (ACI 318R-19): An ACI Standard; ACI: Farmington Hills, MI, USA, 2019. [Google Scholar]

- BS 8110-1; Structural Use of Concrete, Part 1: Code of Practice for Design and Construction. British Standards Institution: London, UK, 2002.

- Standard CANA23.3-24; Design of Concrete Structures for Buildings. Canadian Standards Association (CSA): Rexdale, ON, Canada, 2004.

- CCES01-2004; Chinese Civil Engineering Society. Guide to Durability Design and Construction of Concrete Structures, 2005 ed. Chinese Building Industrial Publishing: Beijing, China, 2005.

- EC 2-1-1; Eurocode 2: Design of Concrete Structures—Part 1: General Rules and Rules for Buildings, The European Standard. European Committee for Standardization (CEN): Brussels, Belgium, 2004.

- ECP 203-2018; Egyptian Code for Design and Construction of Reinforced Concrete Structures. Housing and Building National Research Center: Cairo, Egypt, 2018.

- Subramanian, N. Evaluation and enhancing the punching shear resistance of flat slabs using HSC. Ind. Concr. J. 2005, 79, 31–37. [Google Scholar]

- Elsanadedy, H.M.; Al-Salloum, Y.A.; Alsayed, S.H. Prediction of punching shear strength of HSC interior slab-column connections. KSCE J. Civ. Eng. 2013, 17, 473–485. [Google Scholar] [CrossRef]

- Marzouk, H.; Hussein, A. Experimental investigation on the behavior of high-strength concrete slabs. ACI Struct. J. 1992, 88, 701–713. [Google Scholar]

- Hassanli, R.; Youssf, O.; El-Naqeeb, M.H.; Yekrangnia, M.; Elchalakani, M.; Ghanbari-Ghazijahani, T.; Bazli, M. Investigation of punching shear performance in concrete slabs reinforced with GFRP and synthetic fibers: An experimental study. Eng. Struct. 2024, 311, 118215. [Google Scholar] [CrossRef]

- Afefy, H.M.; El-Tony, E.M. Punching shear resistance of strengthened reinforced concrete interior slab-column connections using ultra-high-performance strain-hardening cementitious composite material. Adv. Struct. Eng. 2019, 22, 1799–1816. [Google Scholar] [CrossRef]

- Afefy, H.M.; El-Tony, E.M. Retrofitting of Interior Slab-to-Column Connections for Punching Shear Using Different Techniques. ASCE J. Perform. Const. Facil. 2019, 33, 04018088. [Google Scholar] [CrossRef]

- Bartolac, M.; Damjanovic, D.; Duvnjak, I. Punching strength of flat slabs with and without shear reinforcement. Građevinar 2015, 67, 771–786. [Google Scholar]

- Hamoda, A.; Sennah, K.; Abadel, A.; Emara, M. Strengthening of Interior Circular Column-slab Region Incorporating Combinations of Bonded UHPECC Layer, CFRP Sheets, and Threaded Steel Bolts. Structures 2024, 69, 107545. [Google Scholar] [CrossRef]

- Elbakry, H.M.; Allam, S.M. Punching strengthening of two-way slabs using external steel plates. Alex. Eng. J. 2015, 54, 1207–1218. [Google Scholar] [CrossRef]

- Najmi, A.S.; Marahlah, R.H. Swimmer bars as shear reinforcement in reinforced concrete flat slabs. Int. J. Eng. Adv. Technol. (IJEAT) 2015, 4, 113–117. [Google Scholar]

- Faria, D.M.; Einpaul, J.; Ramos, A.M.; Ruiz, M.F.; Muttoni, A. On the efficiency of flat slabs strengthening against punching using externally bonded fiber reinforced polymers. Constr. Build. Mater. 2014, 73, 366–377. [Google Scholar] [CrossRef]

- Ferreira, M.P.; Melo, G.S.; Regan, P.E.; Vollum, R.L. Punching of reinforced concrete flat slabs with double-headed shear reinforcement. ACI Struct. J. 2014, 111, 363–374. [Google Scholar]

- AL-Nasra, M.; Duweib, I.; Najmi, A. The use of pyramid swimmer bars as punching shear reinforcement in reinforced concrete flat slabs. J. Civil. Eng. Res. 2013, 3, 75–80. [Google Scholar]

- Khaleel, G.I.; Shaaban, I.G.; Elsayed, K.M.; Makhlouf, M.H. Strengthening of reinforced concrete slab-column connection subjected to punching shear with FRP systems. IACSIT Int. J. Eng. Technol. 2013, 5, 657–661. [Google Scholar] [CrossRef]

- Meisami, M.H.; Mostofinejad, D.; Nakamura, H. Punching shear strengthening of two-way flat slabs using CFRP rods. Compos. Struct. 2013, 99, 112–122. [Google Scholar] [CrossRef]

- Park, H.G.; Kim, Y.N.; Song, J.G. Lattice shear reinforcement for enhancement of slab-column connections. J. Struct. Eng. 2012, 137, 425–437. [Google Scholar] [CrossRef]

- Soudki, K.; El-Sayed, A.K.; Vanzwol, T. Strengthening of concrete slab-column connections using CFRP strips. J. KSU—Eng. Sci. 2012, 24, 25–33. [Google Scholar] [CrossRef]

- Tassinari, L.; Lips, S.; Muttoni, A.; Ruiz, M.F. Applications of Bent-up Bars as Shear and Integrity Reinforcement in R/C Slabs. In Proceedings of the Fib Symposium Prague 2011, Session 2B-5: Construction Technology, 2011, Prague, Czech Republic, 8–10 June 2011; 2011; pp. 631–634. Available online: https://infoscience.epfl.ch/server/api/core/bitstreams/8b6e811c-f1dc-4e19-856f-1dba636dd7f9/content (accessed on 21 April 2025).

- Ruiz, M.F.; Muttoni, A.; Kunz, J. Strengthening of flat slabs against punching shear using post-installed shear reinforcement. ACI Struct. J. 2010, 107, 434–442. [Google Scholar]

- Esfahani, M.R.; Kianoush, M.R.; Moradi, A.R. Punching shear strength of interior slab-column connections strengthened with carbon fiber reinforced polymer sheets. Eng. Struct. 2009, 31, 1535–1542. [Google Scholar] [CrossRef]

- Sissakis, K.; Sheikh, S. Strengthening concrete slabs for punching shear with carbon fiber-reinforced polymer laminates. ACI Struct. J. 2007, 104, 49–59. [Google Scholar]

- Binici, B.; Bayrak, O. Upgrading of slab-column connections using fiber reinforced polymers. Eng. Struct. 2005, 27, 97–107. [Google Scholar] [CrossRef]

- Chen, C.; Li, C. Punching shear strength of reinforced concrete slabs strengthened with glass fiber-reinforced polymer laminates. ACI Strut. J. 2005, 102, 535–542. [Google Scholar]

- Cheng, M.Y.; Parra-Montesinos, G.J. Evaluation of steel fiber reinforcement for punching shear resistance in slab–column connections-part I: Monotonically increased load. ACI Struct. J. 2010, 107, 101–109. [Google Scholar]

- Harajli, M.H.; Soudki, K.A. Shear strengthening of interior slab-column connections using carbon fiber-reinforced polymer sheets. J. Comp. Const. 2003, 7, 145–153. [Google Scholar] [CrossRef]

- Oliveira, D.R.; Melo, G.S.; Regan, P.E. Punching strengths of flat plates with vertical or inclined stirrups. ACI Struct. J. 2000, 97, 485–491. [Google Scholar]

- Wu, X.; Yu, S.; Xue, S.; Kang, T.H.-K.; Hwang, H.-J. Punching shear strength of UHPFRC-RC composite flat plates. Eng. Struct. 2019, 184, 278–286. [Google Scholar] [CrossRef]

- Bastien-Masse, M.; Brühwiler, E. Experimental investigation on punching resistance of R-UHPFRC–RC composite slabs. Mater. Struct. 2016, 49, 1573–1590. [Google Scholar] [CrossRef]

- Al-Obaidi, S.; Davolio, M.; Dicembre, S.; Galdo, M.D.; Monte, F.L.; Ferrara, L. Flexural performance of pre-cracked UHPC slabs exposed to aggressive environments. Constr. Build. Mater. 2025, 466, 140315. [Google Scholar] [CrossRef]

- Moreillon, L. Shear Strength of Structural Elements in High-Performance Fiber Reinforced Concrete (HPFRC). Ph.D Thesis, School of Engineering and Architecture, Fribourg, Switzerland, 2013; p. 480. [Google Scholar]

- Zohrevand, P.; Yang, X.; Jiao, X.; Mirmiran, A. Punching Shear Enhancement of Flat Slabs with Partial Use of Ultrahigh-Performance Concrete. J. Mater. Civ. Eng. 2015, 27, 04014255. [Google Scholar] [CrossRef]

- De Sousa, A.M.D.; Lantsoght, E.O.L.; Genikomsou, A.S.; Krahl, P.A.; El Debs, M.K. Behavior and punching capacity of flat slabs with the rational use of UHPFRC: NLFEA and analytical predictions. Eng. Struct. 2021, 244, 112774. [Google Scholar] [CrossRef]

- Cakmak, F.; Menkulasi, F.; Dogu, M. Punching shear capacity of non-prestressed UHPFRC flat Plates: Evaluation of existing methods. Eng. Struct. 2023, 280, 115662. [Google Scholar] [CrossRef]

- Richard, P.; Cheyrezy, M. Composition of reactive powder concretes. Cem. Concr. Res. 1995, 25, 15011511. [Google Scholar] [CrossRef]

- Nguyen, T.N.; Nguyen, T.T.; Pansuk, W. Experimental study of the punching shear behavior of high-performance steel fiber reinforced concrete slabs considering casting directions. Eng. Struct. 2017, 131, 564–573. [Google Scholar] [CrossRef]

- Nguyen-Minh, L.; Rovnak, M.; Tran-Quoc, T. Punching shear capacity of interior SFRC slab-column connections. J. Struct. Eng. 2012, 138, 613–624. [Google Scholar] [CrossRef]

- Zhou, Y.; Shou, H.; Li, C.; Jiang, Y.; Tian, X. Punching shear behavior of ultra-high-performance fiber-reinforced concrete and normal strength concrete composite flat slabs. Eng. Struct. 2025, 322, 119123. [Google Scholar] [CrossRef]

- Gouveia, N.D.; Lapi, M.; Orlando, M.; Faria, D.M.V.; Ramos, A.M.P. Experimental and theoretical evaluation of punching strength of steel fiber reinforced concrete slabs. Struct. Concr. 2018, 19, 217–229. [Google Scholar] [CrossRef]

- Sine, A.; Pimentel, M.; Nunes, S. Experimental investigation on punching shear behaviour of RC-(R) UHPFRC composite flat slabs without transverse reinforcement. Eng. Struct. 2022, 255, 113951. [Google Scholar] [CrossRef]

- Chen, J.; Fang, Z.; Fang, C.; Tan, X. Flexural performance of UHPC two-way slab reinforced with FRP bars. Eng. Struct. 2025, 322, 119158. [Google Scholar] [CrossRef]

- Ahmed, M.S.; Sennah, K.; Afefy, H.M. Structural Behavior of Full-Depth Deck Panels Having Developed Closure Strips Reinforced with GFRP Bars and Filled with UHPFRC. J. Comp. Sci. 2024, 8, 468. [Google Scholar]

- Ahmed, M.S.; Sennah, K.; Afefy, H.M. Fatigue and Ultimate Strength Evaluation of GFRP-Reinforced, Laterally Restrained, Full-Depth Precast Deck Panels with Developed UHPFRC Filled Transverse Closure Strips. Appl. Sci. 2024, 14, 19. [Google Scholar]

- Semendary, A.A.; Walsh, K.K.; Steinberg, E.P. Early-age behaviour of an adjacent prestressed concrete box-beam bridge containing UHPC shear keys with transverse dowels. J. Bridge. Eng. 2017, 22, 04017007. [Google Scholar] [CrossRef]

- Haber, Z.B.; Graybeal, B.A. Lap-spliced rebar connections with UHPC closures. J. Bridge Eng. 2018, 23, 04018028. [Google Scholar] [CrossRef]

- Honarvar, E.; Sritharan, S.; Matthews Rouse, J.; Aaleti, S. Bridge decks with precast UHPC waffle panels: A field evaluation and design optimization. J. Bridge Eng. 2016, 21, 04015030. [Google Scholar] [CrossRef]

- Youm, H.S.; Hong, S.G. Evaluation for Punching Shear Strength of Slab-Column Connections with Ultra High Performance Fibre-Reinforced Concrete Overlay. Int. J. Struct. Construct. Eng. 2018, 12, 56–61. [Google Scholar]

- Federal Highway Administration. Highway Statistics 2019. 2020. Available online: https://www.fhwa.dot.gov/policyinformation/statistics/2019/ (accessed on 1 May 2025).

- Lampropoulos, A.; Tsioulou, O.; Mina, A.; Nicolaides, D.; Petrou, M.F. Punching shear and flexural performance of ultra-high performance fiber reinforced concrete (UHPFRC) slabs. Eng. Struct. 2023, 281, 115808. [Google Scholar] [CrossRef]

- Saleem, M.A.; Mirmiran, A.; Mackie, K. Ultra-High-Performance Concrete Bridge Deck Reinforced with High Strength Steel. ACI Struct. J. 2011, 108, 601–609. [Google Scholar]

- Joh, C.; Hwang, H.; Kim, B. Punching shear and flexural strengths of ultra-high-performance concrete slabs. High Perform. Struct. Mater. IV 2008, 97, 97–106. [Google Scholar]

- Ricker, M.; Häusler, F.; Randl, N. Punching strength of flat plates reinforced with UHPC and double-headed studs. Eng. Struct. 2017, 136, 345–354. [Google Scholar] [CrossRef]

- Yanhai, W.; Yanbin, H.; Youhua, Y. Investigation on RPC200 mechanical performance. J. Fuzhou Univ. (Nat. Sci.) 2003, 31, 598–602. [Google Scholar]

- Graybeal, B.A. Material Property Characterization of Ultra-High Performance Concrete; FHWA-HRT-06-103; Federal Highway Administration: McLean, VA, USA, 2006. [Google Scholar]

- Peng, G.; Wu, J.; Shi, C.; Hu, X. Effect of thermal curing regimes on the mechanical properties and durability of UHPC: A state-of-the-art review. Structures 2025, 74, 108667. [Google Scholar] [CrossRef]

- Muttoni, A. Punching shear strength of reinforced concrete slabs without transverse reinforcement. ACI Struct. J. 2008, 105, 440–450. [Google Scholar]

- fib Bulletin No. 81. Punching Shear of Structural Concrete Slabs. International Federation for Structural Concrete (Fib). 2017. Available online: https://www.fib-international.org/publications/fib-bulletins/punching-shear-of-structural-concrete-slabs-400-detail.html (accessed on 21 April 2025).

- AASHTO. AASHTO LRFD Bridge Design Specifications; American Association of State Highway and Transportation Officials AASHTO: Washington, DC, USA, 2020. [Google Scholar]

- Xujian, L. Research on the Mechanical Behavior of Steel Fiber Reinforced High-Strength Concrete Slabs Subjected to Punching Shear; Zhejiang University: Hangzhou, China, 1999. [Google Scholar]

- Al-Quraishi, A. Punching Shear Behavior of UHPC Flat Slabs. Doctoral Thesis, University of Kassel, Kassel, Germany, 2014. Available online: https://kobra.uni-kassel.de/handle/123456789/2014092546088 (accessed on 21 April 2025).

- Fang, Z.; Chen, J.; Cao, Q. Experimental study on punching shear behavior of UHPFRC two-way slabs. China J. Highway Transport. 2021, 34, 91. (In Chinese) [Google Scholar]

- AFGC. Ultra-High-Performance Fiber-Reinforced Concrete Recommendations; Association Francaise de Genie Civil: Paris, France, 2013. [Google Scholar]

- JSCE. JSCE82: Recommendations for Design and Construction of High-Performance Fiber Reinforced Cement Composites with Multiple Fine Cracks (HPFRCC); Japan Society of Civil Engineers: Tokyo, Japan, 2008. [Google Scholar]

- Harris, D.; Roberts-Wollmann, C. Characterization of Punching Shear Capacity of Thin Ultra-high-Performance Concrete Slabs. Virginia Tech. 2005. Available online: https://vtechworks.lib.vt.edu/items/9e8ff6a2-8475-4a97-bcad-7ea25f386bc3 (accessed on 21 April 2025).

| Phase No. | Slab No. | Concrete Type | Slab Thickness (mm) | Reinforcements Ratio (%) | Substitution Rate of Granite Powder (%) | Steel Fiber Volumetric Fraction (%) |

|---|---|---|---|---|---|---|

| Phase I | U50 | UHPC | 50 | 3.50 | 0 | 2 |

| U65 | UHPC | 65 | 2.45 | 0 | 2 | |

| U75 | UHPC | 75 | 2.04 | 0 | 2 | |

| U85 | UHPC | 85 | 1.75 | 0 | 2 | |

| U100 | UHPC | 100 | 1.44 | 0 | 2 | |

| C50-100 | NSC | 100 | 1.44 | 0 | 2 | |

| Phase II | U0R35 | UHPC | 50 | 3.50 | 10 | 0 |

| U1R35 | UHPC | 50 | 3.50 | 10 | 1 | |

| U2R0 | UHPC | 50 | 0 | 10 | 2 | |

| U2R13 | UHPC | 50 | 1.34 | 10 | 2 | |

| U3R35 | UHPC | 50 | 3.50 | 10 | 3 |

| Materials | Cement | Silica Fume | Granite Powder | Fine Sand | Water Reducer | Water | Steel Fiber Content |

|---|---|---|---|---|---|---|---|

| Mixing proportion | 1 | 0.27 | 0.03 | 1.2 | 0.025 | 0.18 | 2% * |

| Slab No. | The First Crack Load Pcr (kN) | Mid-Span Deflection Corresponding to Pcr (mm) | Ultimate Load Pu (kN) | Mid-Span Deflection Corresponding to Pu (mm) | Pcr/Pu |

|---|---|---|---|---|---|

| U50 | 30 | 1.75 | 315 | 33.31 | 0.10 |

| U65 | 40 | 1.63 | 430 | 41.68 | 0.10 |

| U75 | 75 | 2.59 | 520 | 33.5 | 0.14 |

| U85 | 80 | 2.33 | 585 | 29.67 | 0.14 |

| U100 | 155 | 1.63 | 645 | 25.45 | 0.24 |

| C50-100 | 120 | 1.51 | 465 | 14.45 | 0.26 |

| Slab No. | Mfu (kN.m) | Ff (kN) | Fu (kN) | Fu/Ff |

|---|---|---|---|---|

| U50 | 52.63 | 414.47 | 315 | 0.76 |

| U65 | 65.00 | 511.90 | 430 | 0.84 |

| U75 | 73.37 | 577.78 | 520 | 0.90 |

| U85 | 79.02 | 622.34 | 585 | 0.94 |

| U100 | 82.73 | 651.52 | 645 | 0.99 |

| C50-100 | 68.66 | 540.70 | 465 | 0.86 |

| Specimen No. | Reinforcement Ratio (%) | Substitution Rate of Granite Powder (%) | Steel Fiber Volumetric Fraction (%) | Cubic Compressive Strength (MPa) | Elastic Modulus (MPa) | Bending Strength (MPa) | The first Crack Load (kN) | Ultimate Load (kN) |

|---|---|---|---|---|---|---|---|---|

| U50 | 3.50 | 0 | 2 | 103.56 | 35.31 | 16.10 | 35 | 315 |

| U0R35 | 3.50 | 10 | 0 | 110.27 | 36.47 | 18.22 | 15 | 250 |

| U1R35 | 3.50 | 10 | 1 | 124.77 | 38.37 | 21.83 | 25 | 295 |

| U2R0 | 0 | 10 | 2 | 127.45 | 39.86 | 23.01 | 22 | 180 |

| U2R134 | 1.34 | 10 | 2 | 120.34 | 38.33 | 20.71 | 25 | 240 |

| U3R35 | 3.50 | 10 | 3 | - | - | - | 40 | 355 |

| Specimen No. | Punching Shear Failure Radius (mm) | Slab Thickness (mm) | Punching Shear Angle (°) |

|---|---|---|---|

| U50 | 153.9 | 50 | 18 |

| U0R35 | 137.4 | 50 | 20 |

| U1R35 | 123.8 | 50 | 22 |

| U2R0 | 186.6 | 50 | 15 |

| U2R134 | 107.2 | 50 | 25 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Chen, B.; Afefy, H.M.; Sennah, K. Experimental Study on Punching Shear Behavior of Ultra-High-Performance Concrete (UHPC) Slabs. Buildings 2025, 15, 1656. https://doi.org/10.3390/buildings15101656

Liu J, Chen B, Afefy HM, Sennah K. Experimental Study on Punching Shear Behavior of Ultra-High-Performance Concrete (UHPC) Slabs. Buildings. 2025; 15(10):1656. https://doi.org/10.3390/buildings15101656

Chicago/Turabian StyleLiu, Junping, Baochun Chen, Hamdy M. Afefy, and Khaled Sennah. 2025. "Experimental Study on Punching Shear Behavior of Ultra-High-Performance Concrete (UHPC) Slabs" Buildings 15, no. 10: 1656. https://doi.org/10.3390/buildings15101656

APA StyleLiu, J., Chen, B., Afefy, H. M., & Sennah, K. (2025). Experimental Study on Punching Shear Behavior of Ultra-High-Performance Concrete (UHPC) Slabs. Buildings, 15(10), 1656. https://doi.org/10.3390/buildings15101656