1. Introduction

In the past couple of decades, research in the field of masonry in Europe has been focused on improving the thermal properties of masonry. Consequently, new materials and techniques have been developed, one of which is the use of hollow clay blocks with enlarged cavities, which are specifically designed to enhance thermal insulation and reduce energy consumption for heating and cooling. When such units are used in combination with a new adhesive (i.e., polyurethane (PU) glue) instead of traditional thin-bed mortar, they have near-zero-thickness joints, which minimize thermal losses and allow for faster construction.

A confined masonry (CM) system, which consists of load-bearing masonry walls enclosed on all four sides by cast-in-place reinforced concrete (RC) tie-columns and tie-beams, offers an effective solution for enhancing the structural performance of masonry buildings, particularly in seismic-prone areas across the world. Although the basic concept of CM is the same everywhere, there are important differences between regions. For example, the typical thickness of CM walls in Mexico, as tested by, e.g., Perez Gavilan et al. [

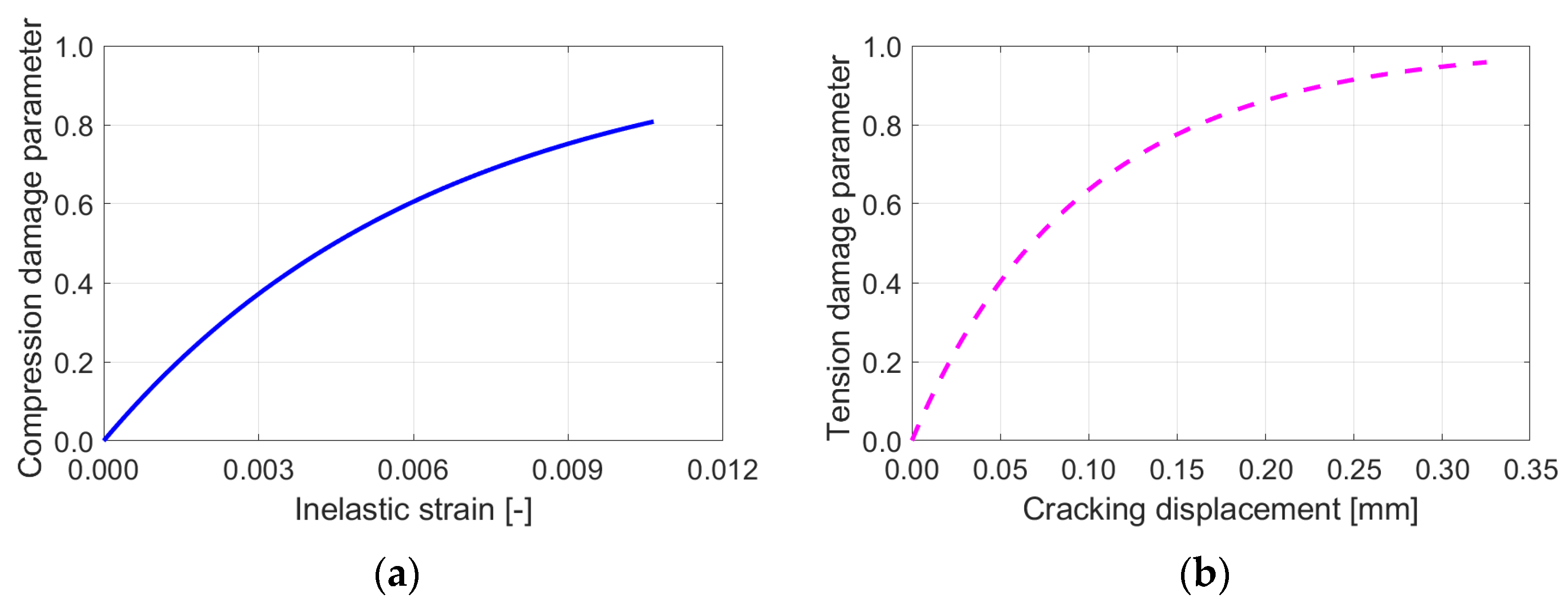

1], is only 12 cm, while in Chile, the typical wall thickness is 15 cm [

2]. Eurocode 8 [

3] specifies a minimum masonry wall thickness of 24 cm, whereas the blocks examined in this study have a thickness of 38 cm. European blocks also have a much larger share of holes compared to other regions. The differences in wall thickness between different regions are significant, and when walls are thick, confining is trickier. From the perspective of structural strength, confinement is most effective when tie-columns cover the entire thickness of the wall. However, this may not always be practical.

In Europe, tie-columns should have a minimum dimension of 15 cm (Eurocode 8 [

3]), which is much less than the required 24 cm thickness of walls, which indicates that different widths of tie-columns and walls are normal. In other countries too, the smallest tie-column cross-section ranges from 10 to 20 cm (Marques and Lourenço [

4]), which is often less than the required width of the wall. This is allowed because tie-columns can provide sufficient confinement even if they are smaller. Moreover, the disparity between the thickness of tie-columns and walls enables thicker thermal insulation of tie-columns, which present thermal bridges. In addition, by decreasing the dimensions of tie-columns, concrete consumption can be significantly minimized, especially since there can be quite a lot of tie-columns in a structure.

The considered masonry has tie-columns with dimensions of 25 × 25 cm, which is 13 cm less than the thickness of the wall (38 cm). The tie-columns are placed so that one surface is flush with the masonry, while the other is depressed by 13 cm. The masonry blocks in contact with the depressed side of the tie-columns are therefore locally stressed, and recent tests on two CM walls [

5] have revealed that a specific type of damage develops at the point of contact with the tie-column.

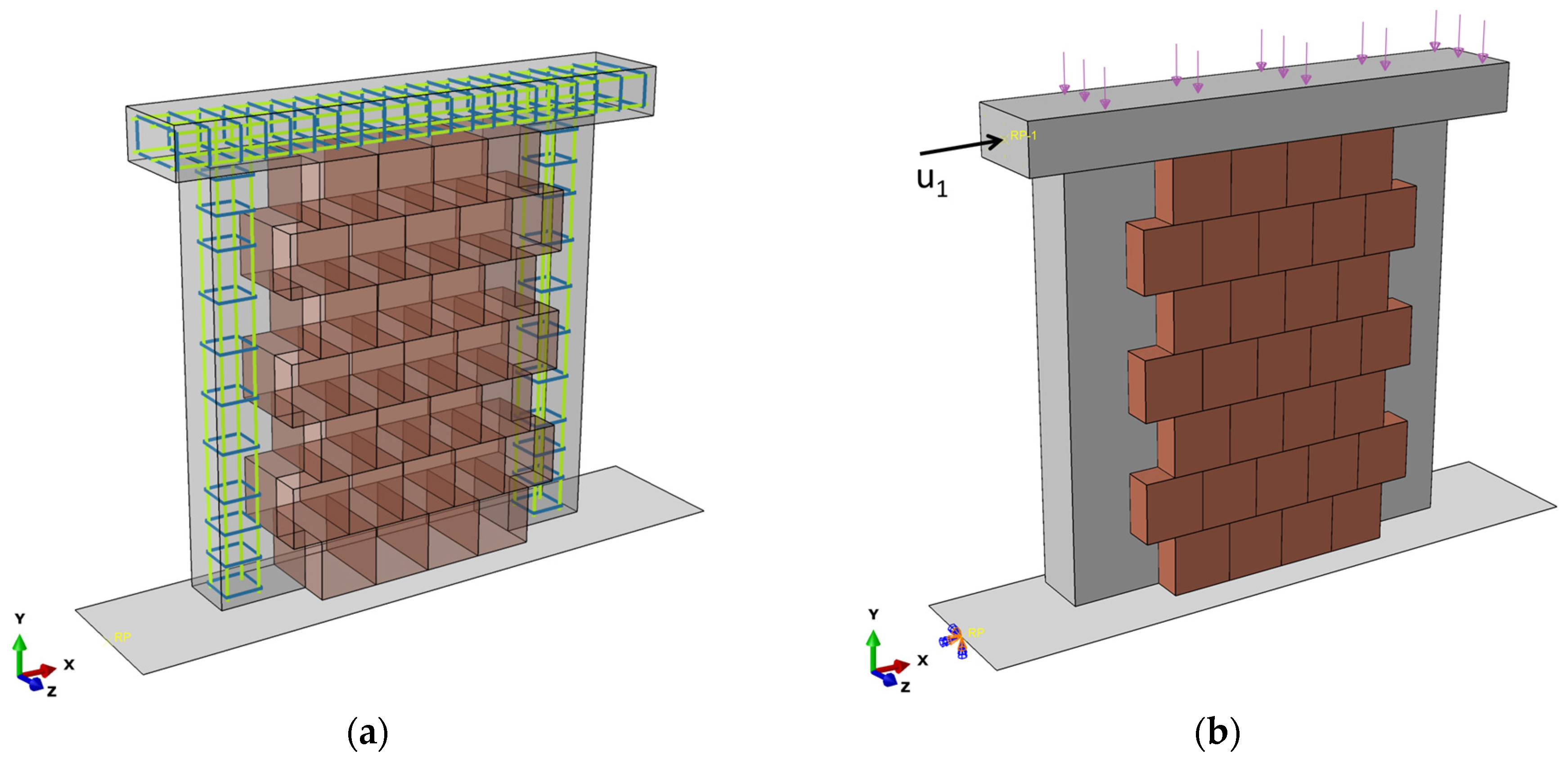

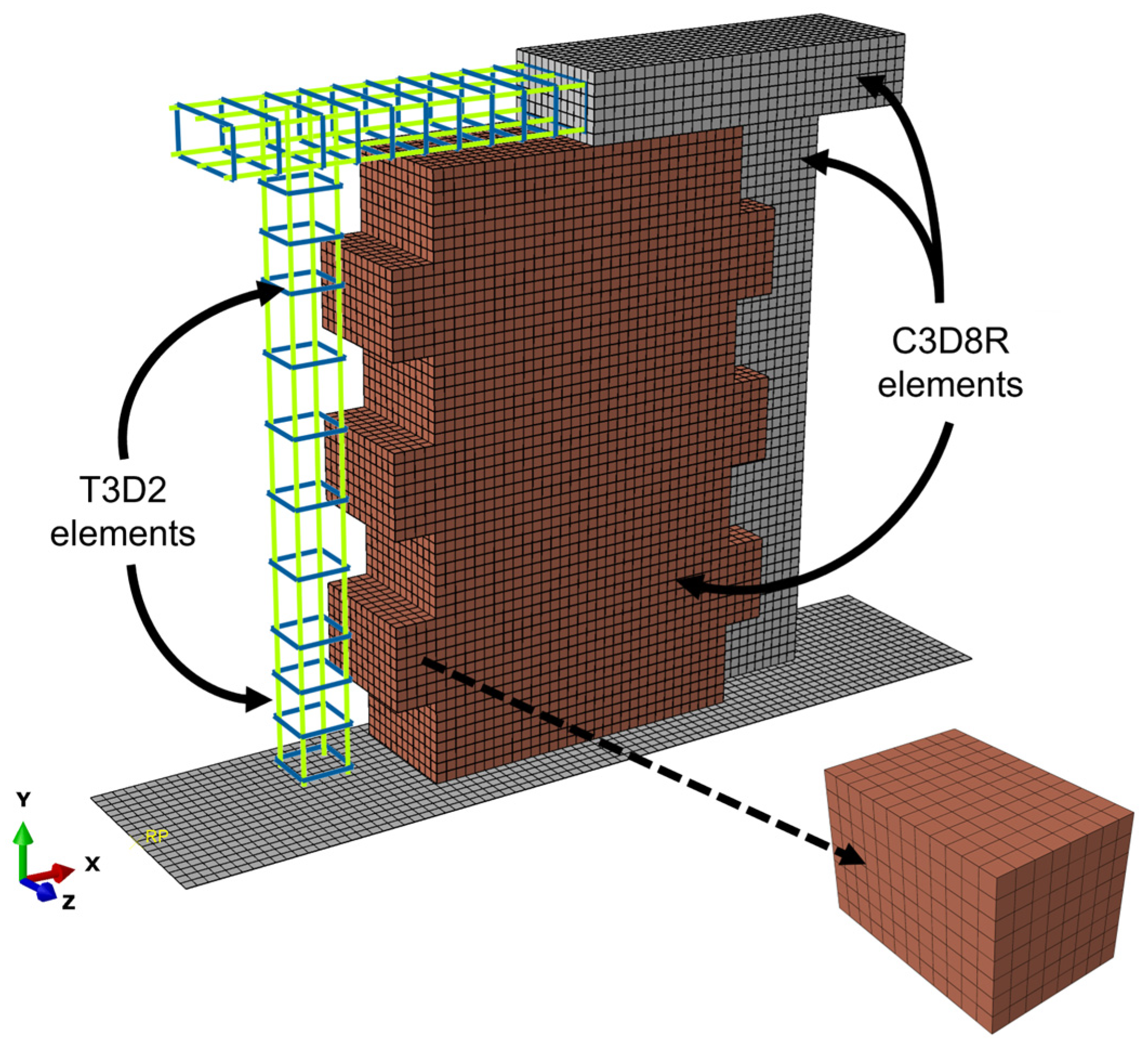

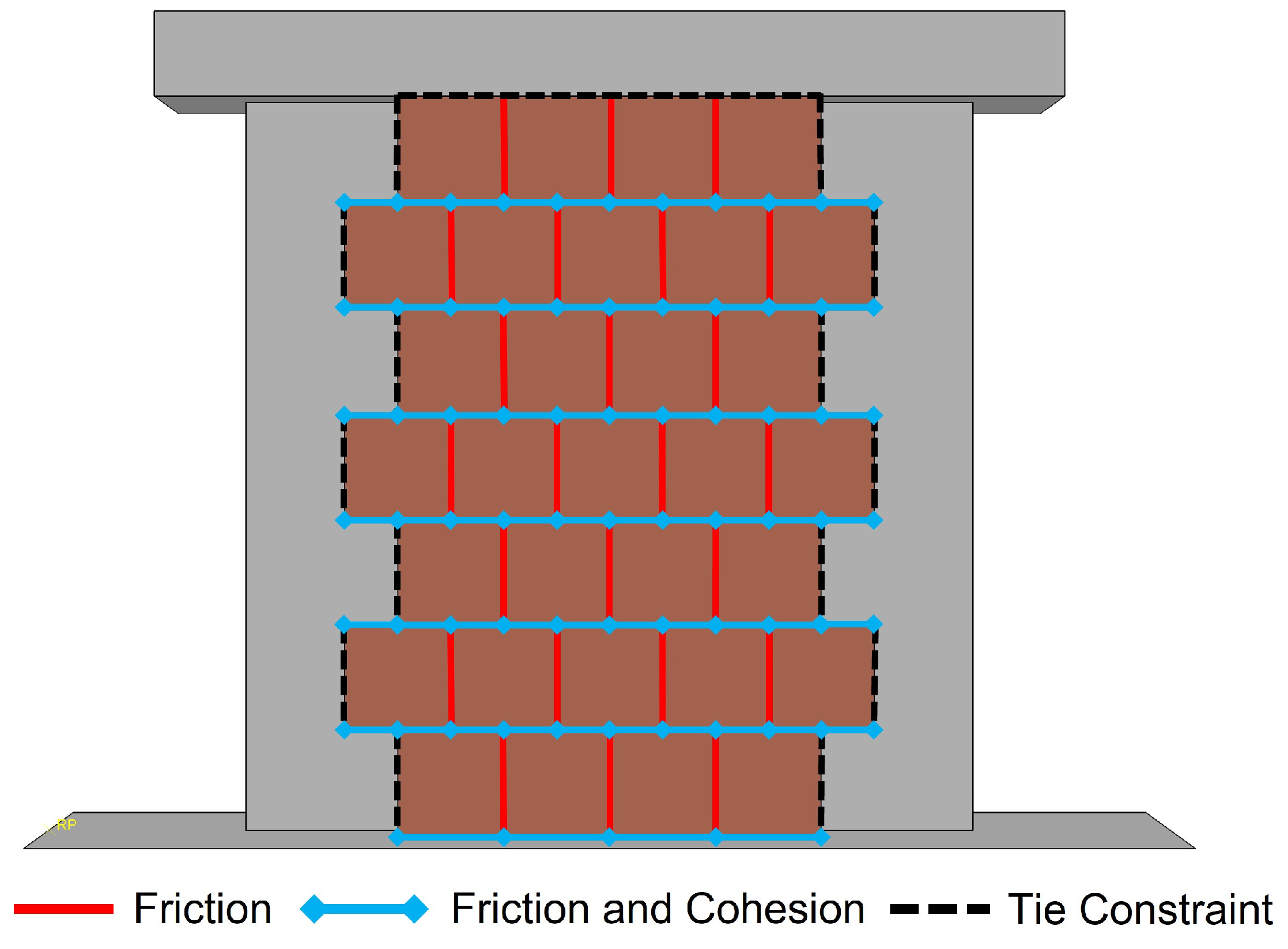

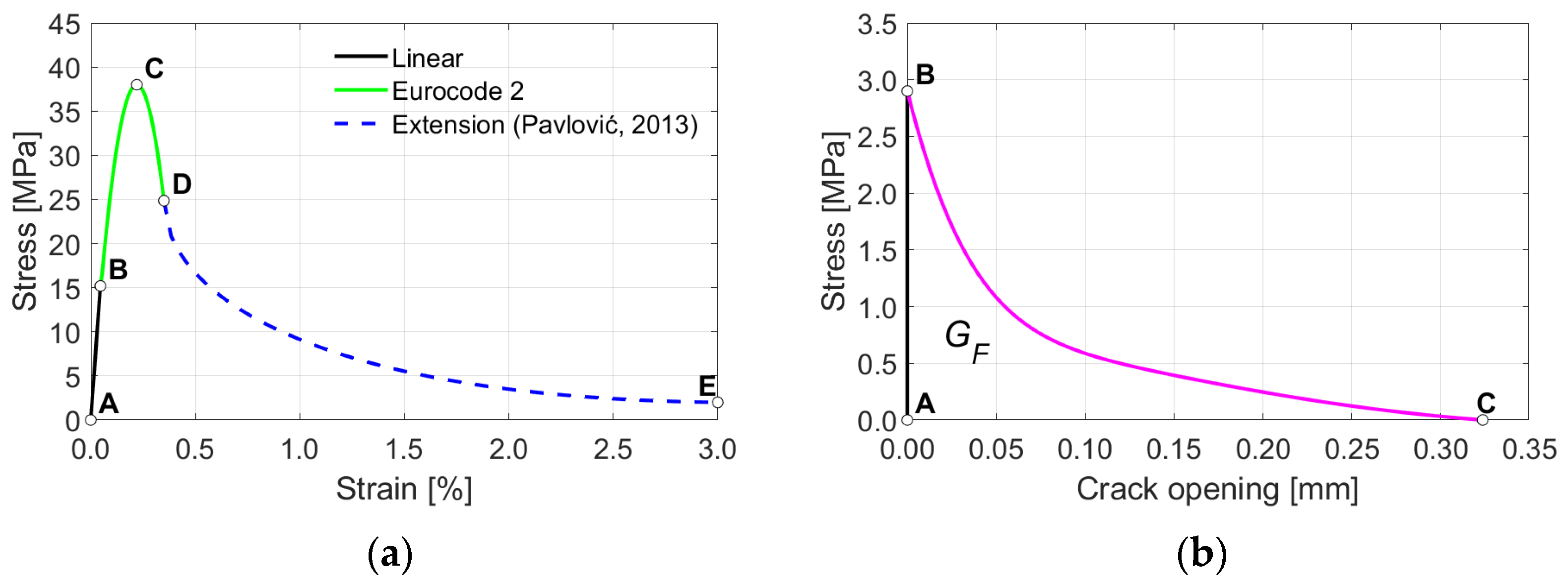

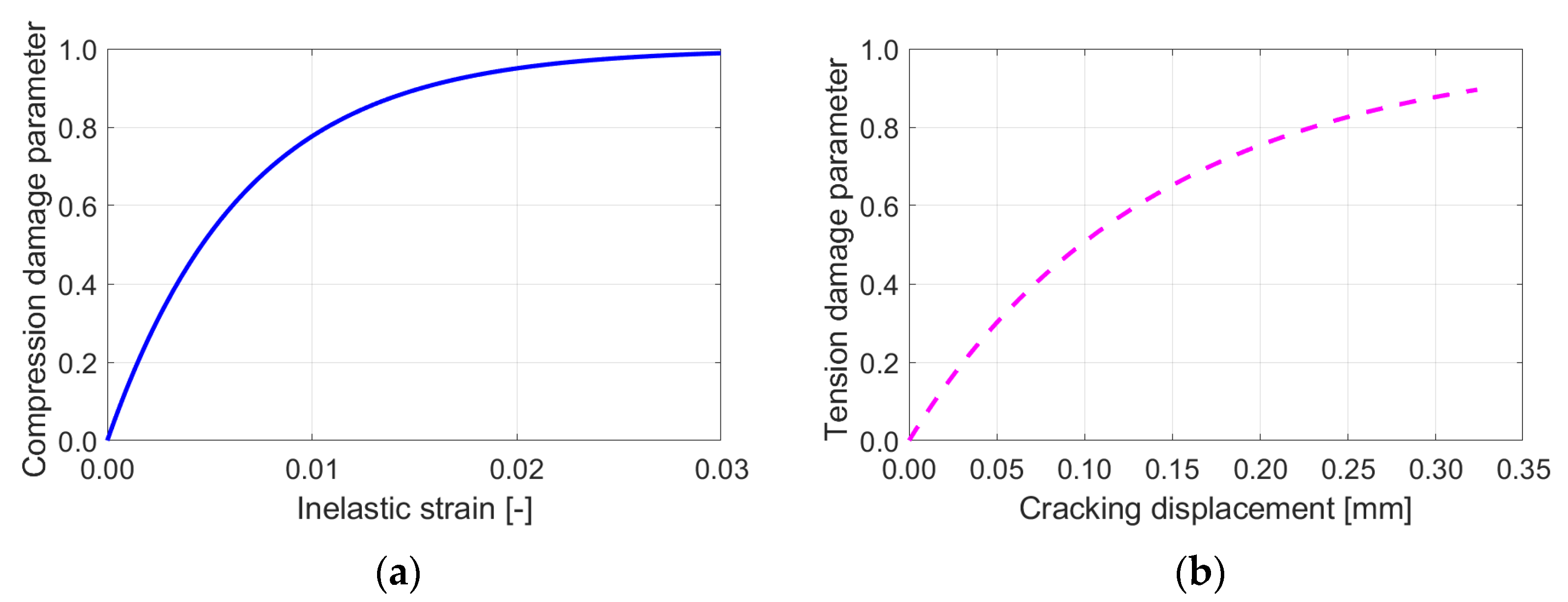

There are different numerical modelling strategies for the seismic analysis of CM structures, as recently presented in Marques et al. [

6] and Borah et al. [

7]. Most typically, the Finite Element Method (FEM) is used for modelling, but the approaches based on FEM (micro, simplified micro, or macro approach) vary in terms of their refinement and capability to capture failure modes and seismic response. Recent publications have shown that the most commonly used FE softwares for the analysis of CM are DIANA [

8] and Abaqus [

9]. Additionally, ANSYS software has been widely used for the modelling and analysis of unreinforced masonry (URM) [

10]. Typically, 2D models are preferred, as they can accurately simulate in-plane responses and are usually sufficient to capture the key phenomena in CM walls, specifically in RC ties and along the interface between the tie-column and masonry. However, 3D models are employed when specific structural effects need to be considered, as demonstrated in studies such as that by Chourasia et al. [

11]. Given the unique nature of the shear damage observed at the interface of the tie-column and masonry in this study, the use of a 3D FE model was necessary. In addition to the necessity of using a full 3D FE model, detailed material models require a significant amount of input data for the materials and different types of contacts. Due to the inherent brittleness of both concrete and masonry [

12], considerable effort was made to gather and record the necessary material and contact properties. These parameters were primarily derived from dedicated tests conducted on the structural elements, materials, and joints [

5,

13]. Additionally, the FE model was validated by comparing it against two experimental tests that evaluated the pushover response and damage patterns, following a methodology similar to that used by Marques et al. [

6] in DIANA software and Tripathy and Singhal [

14] in Abaqus software.

In addition to FEM, the Applied Element Method (AEM) is an alternative for structural analysis, which is particularly useful in simulating the collapse behaviour of masonry structures. Some decades ago, AEM was introduced as a discrete modelling technique [

15], whereby structures are divided into small elements connected by normal and shear springs. These springs simulate stresses and deformations due to loading, allowing the model to capture failure mechanisms as the structure progresses from cracking to complete separation. While FEM remains the predominant method in seismic analysis, AEM offers advantages, especially in modelling collapse scenarios and debris generation, as demonstrated in a study by Domaneschi [

16].

This parametric study systematically investigates the seismic response of CM walls with openings, focusing on the influence of wall geometry (aspect ratio-AR), opening size, position, and shape (solid, window, or door), as well as the presence and size of tie-columns around these openings. The lack of such confining elements around large openings has been linked to significant damage in CM walls during past earthquakes [

17,

18]. Furthermore, this study examines two different approaches for the placement of RC confining elements around openings. The first is based on recommendations by Brzev and Mitra [

19] and international guidelines [

17], which suggest that vertical tie-columns should be positioned on both sides of any opening exceeding 10% of the CM wall’s surface area; otherwise, the wall cannot be considered as a CM wall for seismic design. In contrast, the second approach, as outlined in Eurocode 8 [

3], stipulates that vertical confining elements should be placed on both sides of any opening with an area greater than 1.5 m

2. By comparing these two approaches, this study aims to assess their effectiveness in enhancing the seismic performance of CM walls with various opening configurations.

There is a clear need for further research to address gaps in understanding of how openings affect the seismic performance of CM walls. While it is well known that openings reduce the strength and deformation capacity of these walls, few studies have examined the influence of different opening configurations and the presence of confining elements around them. Following the conclusions of Perez Gavilan et al. [

20], future research should focus on the in-plane behaviour of CM walls with openings, considering different sizes and locations of openings, with an emphasis on verifying the effect of the size of RC confining elements. Comprehensive numerical investigations are crucial to assess these factors, with the primary aim being the development of reliable and accurate FE models, as full-scale experiments are often costly and challenging to conduct.

In recent decades, several experimental studies have been conducted to investigate the seismic behaviour of CM walls with openings. Experimental research by Yanez et al. [

21] revealed that larger openings (over 25% of the CM wall area) led to a 40–50% reduction in strength compared to the corresponding solid specimens, while smaller openings (up to 11% of the CM wall area) had no significant effect on stiffness. Similarly, Kuroki et al. [

22] found that unconfined openings caused a 15–40% reduction in shear resistance, with centrally located openings being less affected than eccentric ones. The results also stated that CM walls with both vertical and horizontal confining elements exhibited improved strength, but experienced a reduction in ductility, compared to CM walls with openings confined only by vertical RC tie-columns.

Recently, an experimental study by Gupta and Singhal [

23] evaluated the effects of openings in CM walls and the role of confining elements around these openings. The study found that walls with unconfined openings experienced strength reductions of 31% to 49%, while the addition of RC confining elements improved in-plane capacity by 36% to 130%. Additionally, a confinement factor was introduced to quantify the contribution of these confining elements, allowing for more accurate strength estimations for CM walls with confinement around the openings.

Okail et al. [

24] conducted a comprehensive experimental and numerical investigation on CM walls, examining the effects of various parameters, such as opening size, position, aspect ratio, axial load, and longitudinal reinforcement in tie-columns, on the lateral load response. Their findings highlighted that larger openings significantly reduced the lateral load capacity of the walls. However, confining elements, particularly tie-columns around openings, were shown to effectively restore this lost capacity and enhance ductility. These results emphasize the importance of incorporating confining elements to maintain strength and improve the deformation capacity of walls with openings under seismic loading.

In addition to these experimental insights, several studies have focused on the numerical investigation of CM walls with openings. Maheri et al. [

25] conducted 18 numerical analyses of CM walls with door openings, considering aspect ratios of 0.5, 1.0, and 2.0, as well as two different masonry compressive strengths (2.0 MPa and 5.0 MPa). Their findings revealed that the size of the opening, particularly the ratio of opening length to wall length (OL/WL), significantly influenced the shear and flexural responses of the walls. As the opening size increased, especially in walls with higher aspect ratios, a notable reduction in shear capacity was observed.

Shandilya et al. [

26] highlighted the significant influence of the window opening size and the shape of openings on the seismic performance of CM walls with rectangular (AR = 0.75) and square (AR = 1) configurations. Increasing the opening size (from 10% to 60%) resulted in a considerable reduction in both ultimate strength and stiffness. For a CM wall with AR = 0.75, the ultimate strength decreased by approximately 30% to 80%, while stiffness was reduced by 55% to 95%. In contrast, for a CM wall with AR = 1.0, strength reductions ranged from 33% to 89%, and stiffness decreased by between 30% and 96%. The study found that both the shape and size of openings significantly affect the strength and energy dissipation capacity of these walls, with larger openings reducing their ability to withstand seismic forces.

Section 2 describes the materials and the results of shear compression tests from the literature.

Section 3 focuses on the description of the numerical model developed in Abaqus software, and the validation of the model with experiments. In

Section 4, the results of the comprehensive parametric study are presented, followed by a brief conclusion.

2. Brief Overview of Past Experimental Study

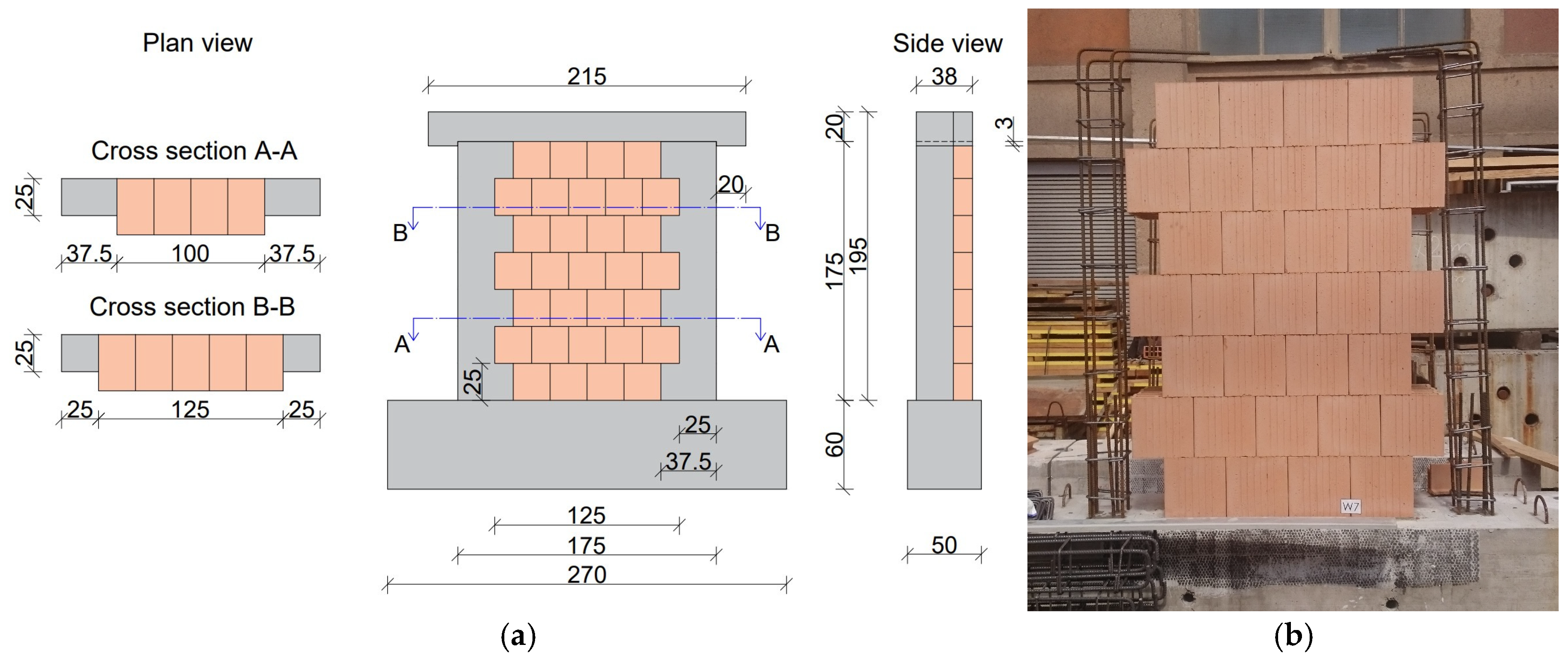

The masonry blocks used in the previous experimental study [

5] were vertically perforated, commercially available units, designed for constructing thermally efficient 38 cm thick walls. Their nominal dimensions were 250 mm in length, 249 mm in height, and 380 mm in thickness, as shown in

Figure 1a. The blocks and their mechanical properties have been extensively tested and thoroughly evaluated in a prior study by Gams et al. [

5].

The mean compressive strength of the blocks

was measured to be 11.4 MPa, while the normalized mean strength

was 13.1 MPa. The results from material characterization tests indicated that the masonry compressive strength

aligned with the strength predicted by Eurocode 6 [

27] for masonry hollow clay blocks with traditional thin-bed mortar, confirming the material’s expected performance. To enhance damage observation during testing, the thermal insulation filling the large cavities of the units (

Figure 1a) was removed, as shown in

Figure 1b. Given its negligible stiffness and strength, its removal did not influence the mechanical behaviour of the masonry wall, as noted in [

5].

For the masonry wall construction, a new adhesive PU glue was applied on blocks without mineral wool in four strips along the width of the units (

Figure 1b). This adhesive was specifically chosen to enhance the thermal efficiency of the masonry wall by minimizing the thickness of the bed-joints. The masonry compressive strength

was determined on three URM wall test samples, amounting to an average value of 3.79 MPa. The modulus of elasticity was calculated from compressive strength tests at one-third and two-thirds of the peak force, and it was 2200 MPa.

Two identical CM wall specimens, labelled W7 and W8, which were 175 cm long, 195 cm tall, and 38 cm thick (

Figure 2a), were tested in the laboratory by Gams et al. [

5]. The walls were built on an RC foundation beam to facilitate transport and fixation to the strong floor during the test. The tie-columns measured 25 × 25 cm (

Figure 2a), and were reinforced with 4 Ø 14 mm ribbed bars, resulting in a longitudinal reinforcement ratio of 1%, as required by Eurocode 8 [

3]. Transverse reinforcement consisted of Ø 8 mm stirrups spaced at about 20 cm (see

Figure 2b). The tie-columns were flush with one side of the wall, while on the opposite side, they were depressed 13 cm from the surface, with the gap filled with thermal insulation. Finally, a spreader RC bond beam was cast together with the tie-columns.

The walls were tested under in-plane shear compression conditions at a constant vertical stress of 0.63 MPa. Rotations were prevented by using double-fixed boundary conditions. Horizontal displacements were cyclically applied at the level of the bond beam, with three repetitions per displacement amplitude in both directions, simulating seismic loading in a standard manner [

28]. Detailed information regarding the test setup, instrumentation, loading protocol, and comprehensive test results can be found in the study by Gams et al. [

5].

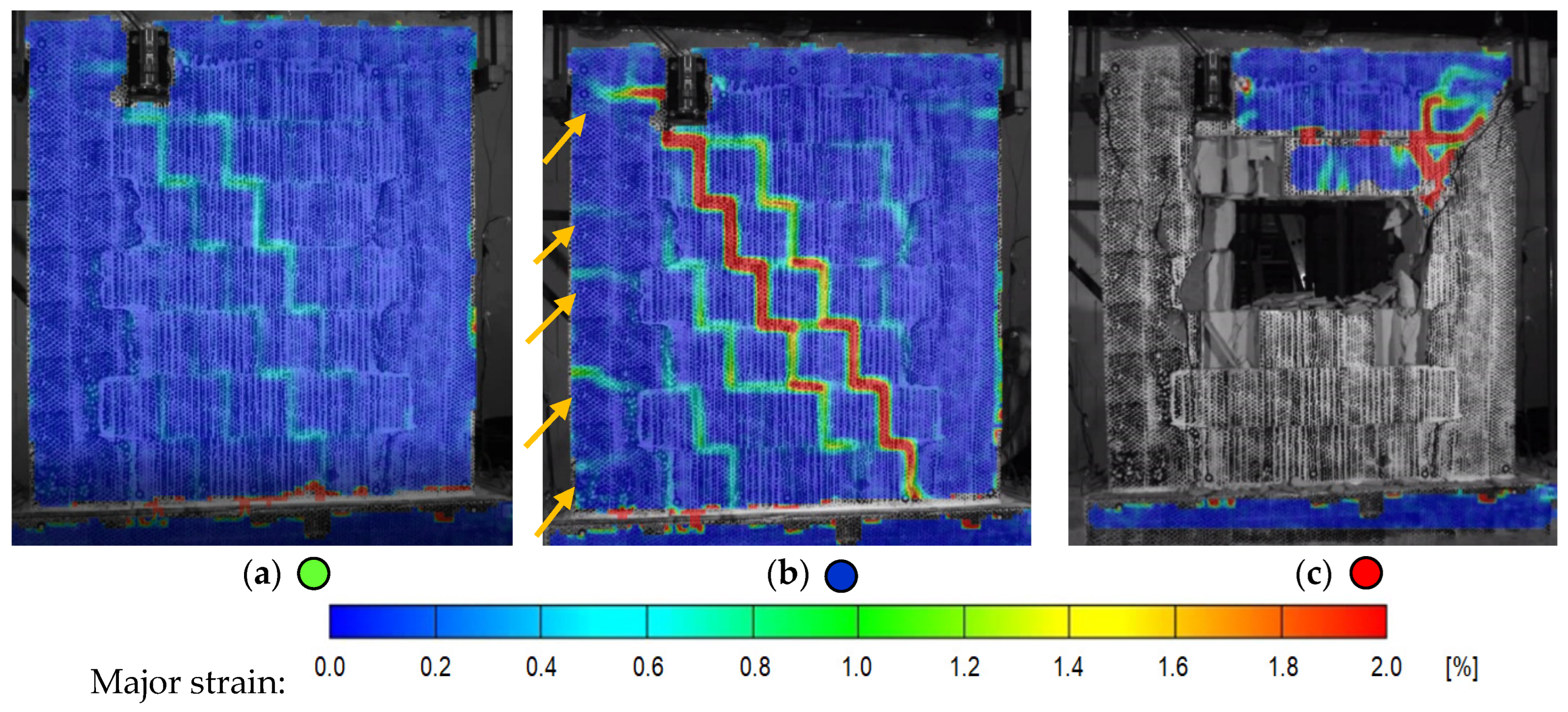

A digital image correlation (DIC) system was used to measure the displacement and strain fields on the wall surface.

Figure 3 shows the damage progression at different limit states (LSs).

During the initial phase of testing, the CM walls showed linear behaviour up to a drift of around 0.1%. The first visible cracks appeared along the bed and head joints, gradually expanding as displacement amplitudes increased (

Figure 3a). At approximately 0.35% drift, horizontal cracks developed in the tie-columns (marked with orange arrows in

Figure 3b), and the protruding part of the masonry began to shear off. By 1.0% drift, damage in the left tie-column changed from evenly spread horizontal tensile cracks to concentrated shear damage at the upper corner of the wall. As the test progressed, the centre of the wall crumbled and disintegrated (

Figure 3c), resulting in the near-collapse limit state. In the end, the tie-columns carried the entire vertical load, preventing the wall from losing its integrity.

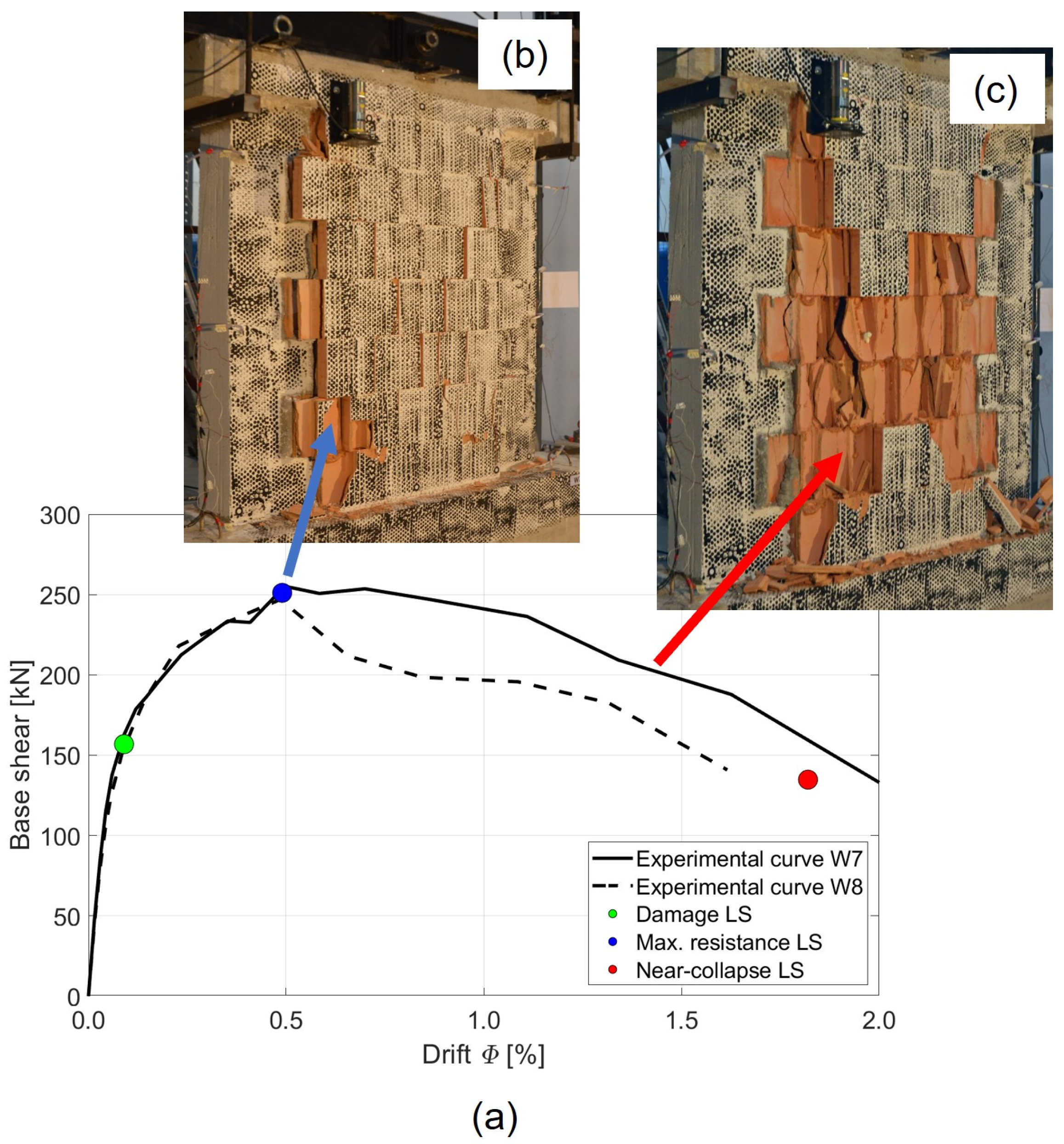

Averaged experimentally obtained envelope curves for both tested CM walls (in the push and pull directions) are presented in

Figure 4a. LSs are denoted by differently coloured circles: green for damage LS, blue for maximum resistance LS, and red for near-collapse LS. At a drift of 0.5%, significant damage occurred, due to the shear-off effect at the interface between the tie-columns and the protruding masonry, causing pieces of masonry blocks to break off (

Figure 4b). This damage contributed to reaching the maximum resistance LS. As shown in

Figure 4c, the protruding masonry parts completely sheared off and fell to the floor at a drift of 1.3%.

4. Parametric Study

The aim of the parametric study was to investigate the effect of aspect ratio (AR), opening configurations, and RC tie-columns on the seismic performance. A total of 20 different models were analyzed, with different opening sizes, shapes, and positions, and different tie-column positions and sizes. An overview of the models is shown in

Table 4, where each model is identified by its name, representing a different combination of aspect ratio and opening shape/position, as well as the presence of tie-columns around openings and, if applicable, their size. In the naming, SW stands for solid wall, C/L/R indicates the position of the opening (central/left/right), ‘Wop/Dop’ stand for window or door opening, 1 or 2 are aspect ratios (1 stands for AR = 0.5 and 2 for AR = 0.71), and EC indicates a window opening larger than 1.5 m

2. ConA and conB designate the size of the internal tie-columns next to the openings. In the case of conA, the size is 25 × 25 cm, and in the case of conB, the size is 15 × 15 cm. All the walls have 25 × 25 cm tie-columns at the sides (see

Figure 13).

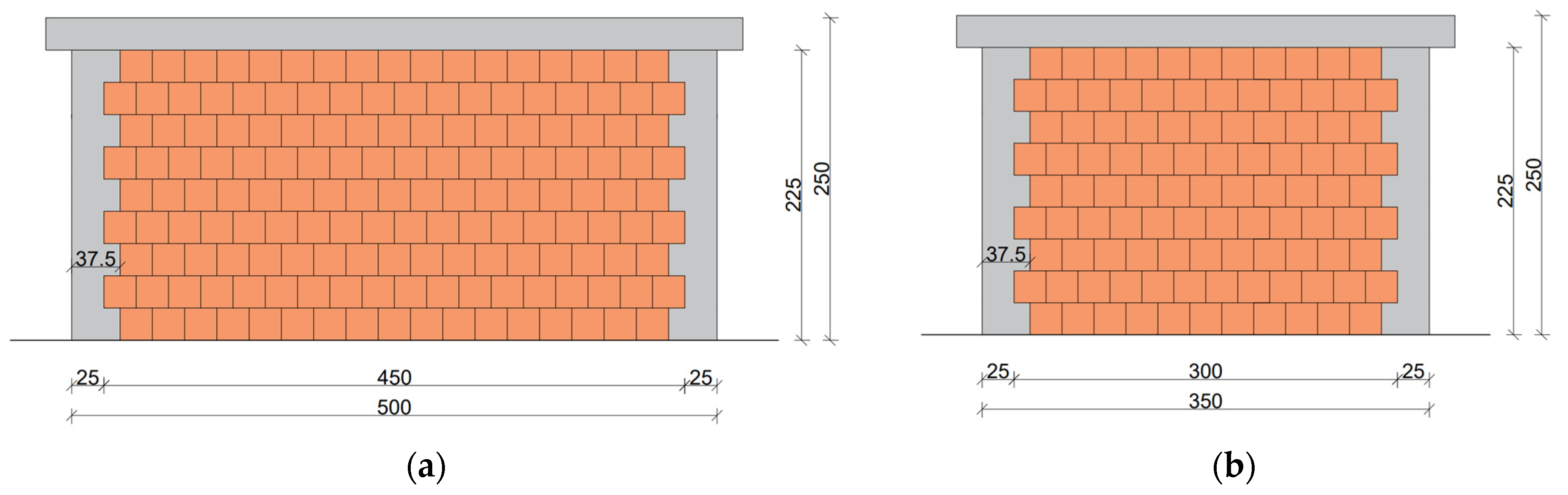

Two different ARs were considered (

and

), with the CM wall height fixed at 2.5 m and CM wall lengths of 5 m and 3.5 m, ensuring compliance with the Eurocode 8 [

3] requirement that the maximum horizontal spacing between vertical confining elements should not exceed 5 m. These geometry configurations ensured that the numerical models represented real CM walls, reflecting the typical dimensions and proportions found in CM structures.

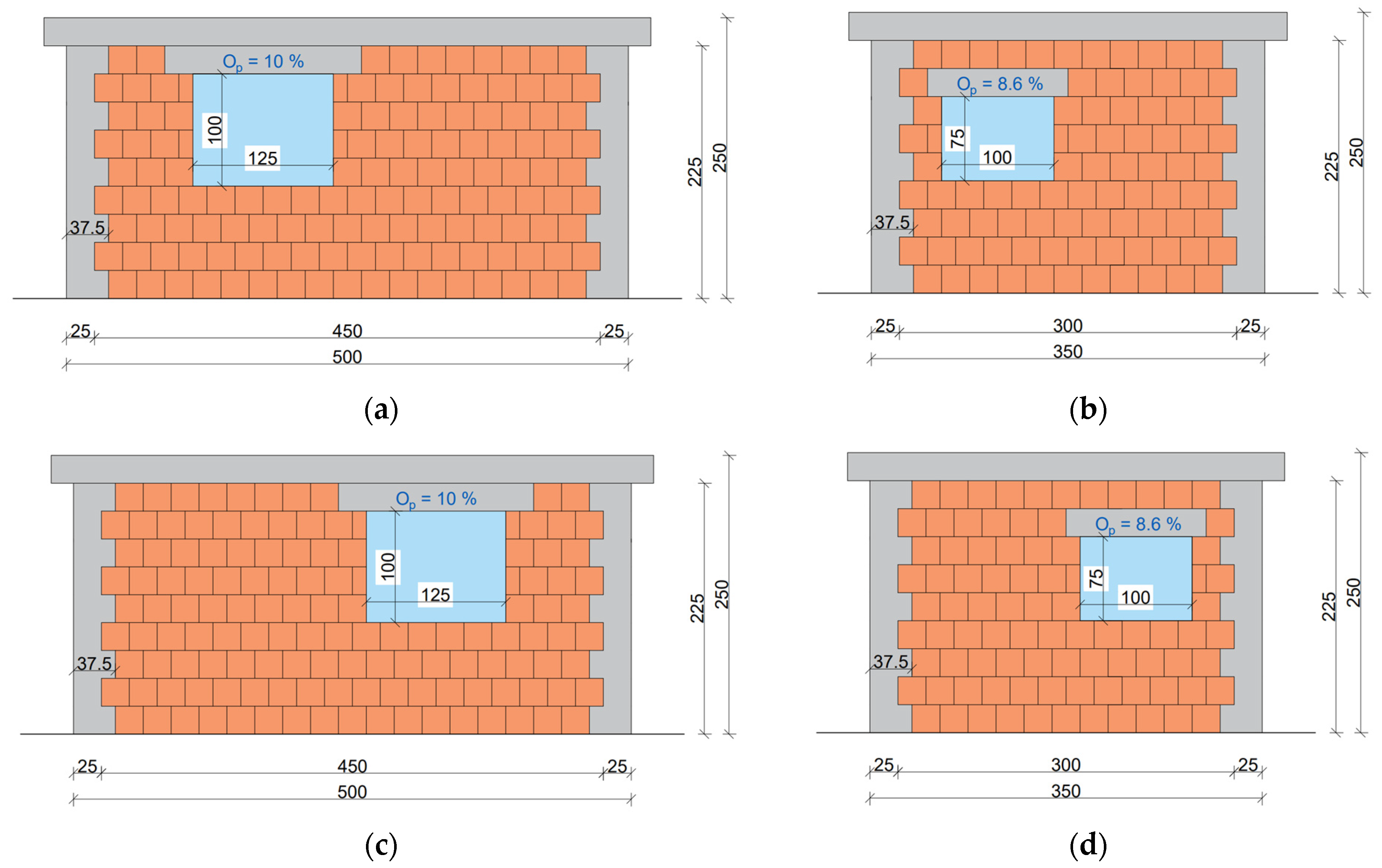

For AR = 0.5, the window dimensions were 1.0 × 1.25 m, and for AR = 0.71, they were 1.0 × 0.75 m. The opening percentages (

s) were 10% and 8.6%, respectively. Because both of these windows are small enough, codes and guidelines do not require tie-columns to be built next to them. The limit for this is 10% of the wall area according to Brzev and Mitra [

19] and Meli et al. [

17], and 1.5 m

2 according to Eurocode 8 [

3]. The windows were considered in central, left, and right positions.

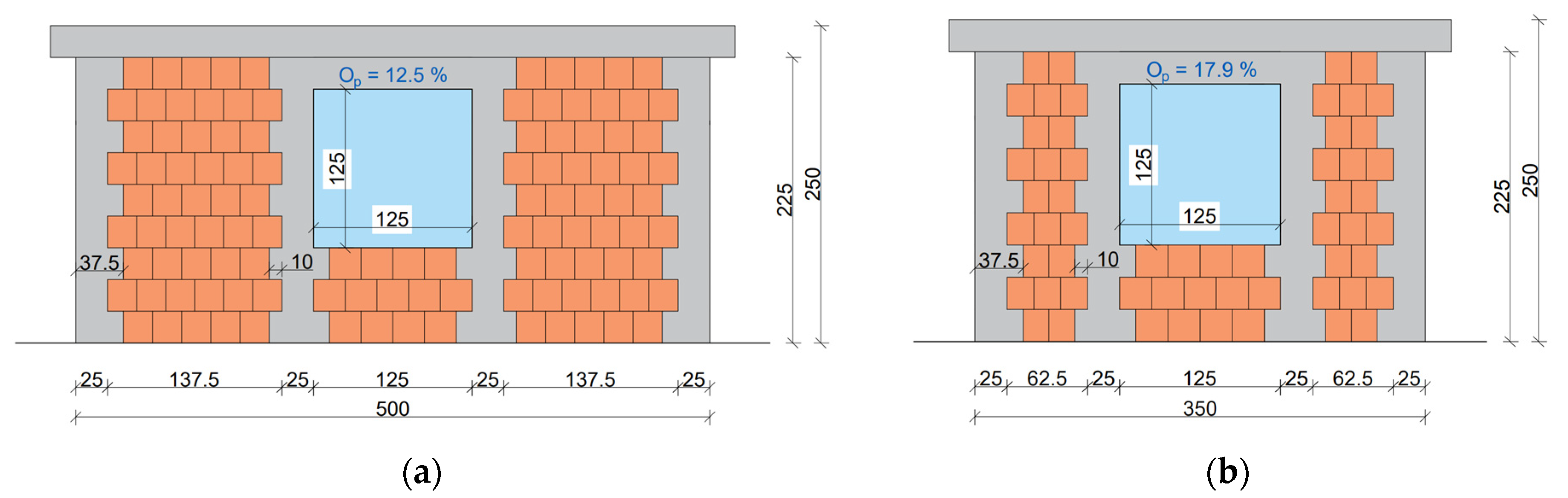

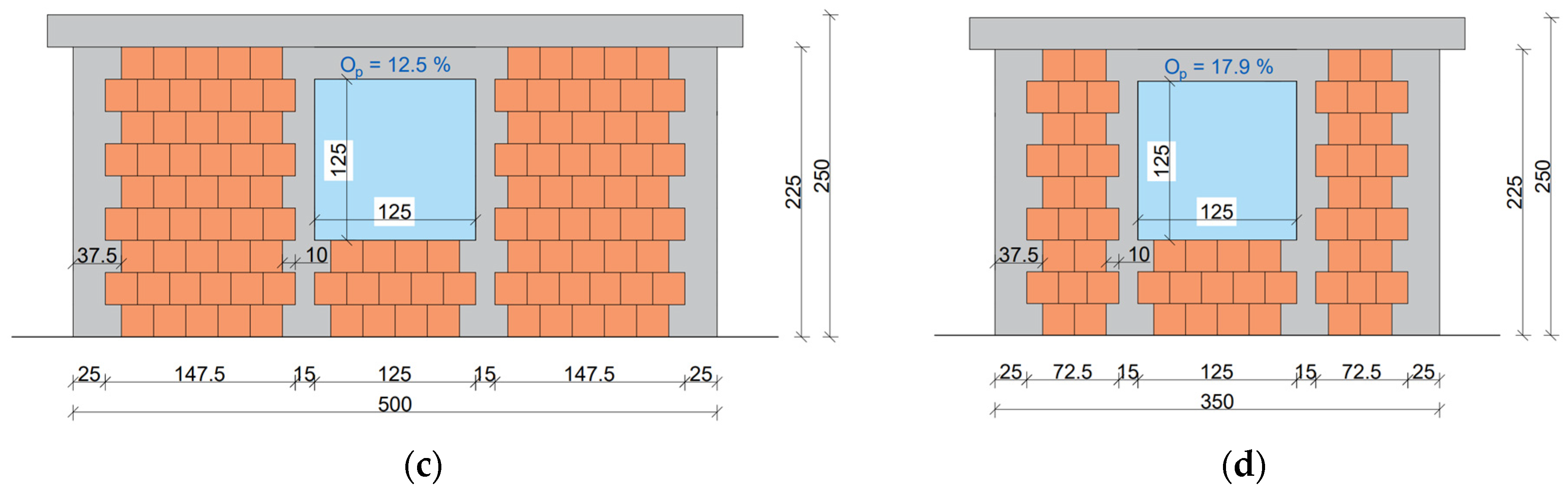

To analyze a case with a large enough window to require tie-columns, one case per AR was considered, with a window sized 1.25 × 1.25 m (area of 1.56 m2). In this case, the opening percentages () were 12.5% and 17.9% for walls with ARs of 0.5 and 0.71, respectively. This window was considered only in the central position, and with 15 × 15 cm and 25 × 25 cm tie-columns.

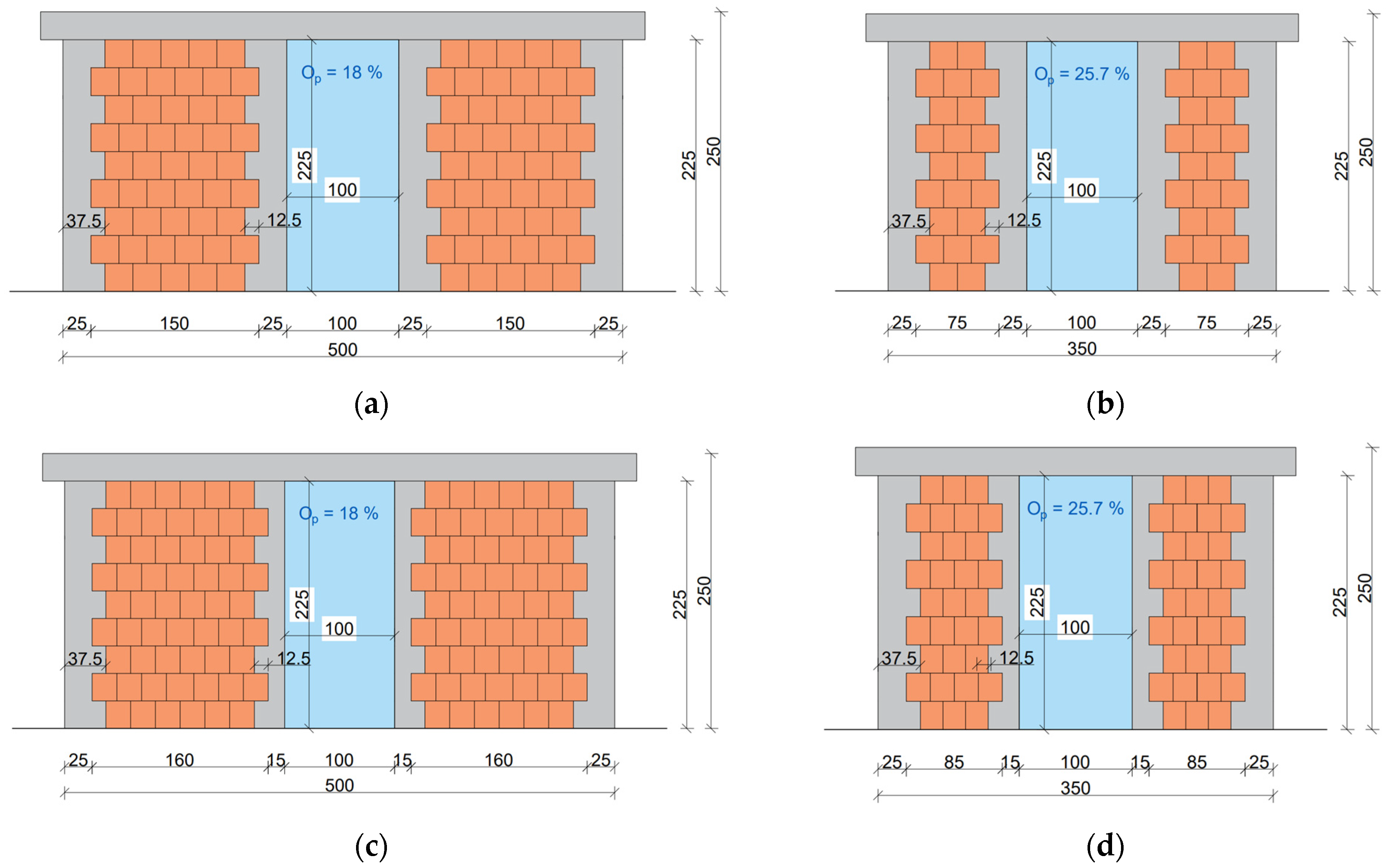

The door opening dimensions were 1.0 × 2.25 m, resulting in s of 18% and 25.7% for walls with AR = 0.5 and AR = 0.71, respectively. The doors, too, were considered only in the central position, and with either 15 × 15 cm or 25 × 25 cm tie-columns.

4.1. Effect of Opening Size and Position on Seismic Response of CM Walls

4.1.1. Effect of Opening Size

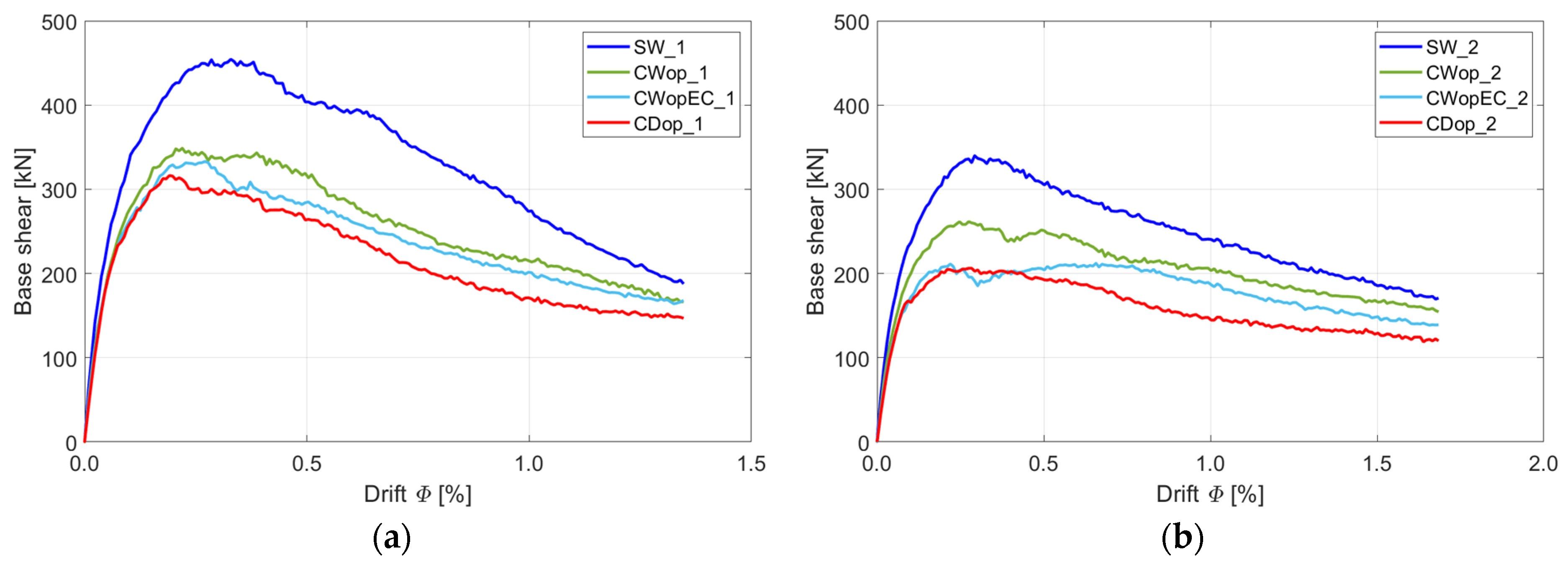

To examine the influence of opening size on the seismic response of CM walls, walls with a central position of the opening and no internal tie-columns were compared with the reference solid walls (shown in

Figure 13). The pushover curves for the analyzed CM walls with varying opening sizes (window or door type) are shown in

Figure 14. It is evident that the presence of openings significantly reduces the strength of the walls compared to the solid ones (SW1, SW2). For example, comparing the solid wall SW_1 with the wall containing a 10% opening (CWop_1), the reduction in strength is 23%. Similarly, for walls with AR = 0.71, the wall CWop_2, which has an opening of 8.6%, exhibits the same 23% reduction in strength compared to the solid wall SW_2. When comparing walls with larger openings, the strength loss becomes even more pronounced. For walls with AR = 0.5, there is an increase in opening size from 10% (CWop_1) to 12.5% (CWopEC_1), leading to a strength reduction of 27% compared to the solid wall SW_1. On the other hand, for walls with AR = 0.71, the effect of larger openings is more severe. For instance, increasing the opening size from 8.6% to 17.9% (CWopEC_2) results in a 38% strength loss compared to the solid wall SW2.

These findings highlight a clear relationship between the size of the openings, the aspect ratio (AR), and the reduction in wall strength. As the opening size increases, the strength reduction becomes more significant, with walls having AR = 0.71 experiencing a more substantial loss in load-bearing capacity, due to the amplified effect of larger openings.

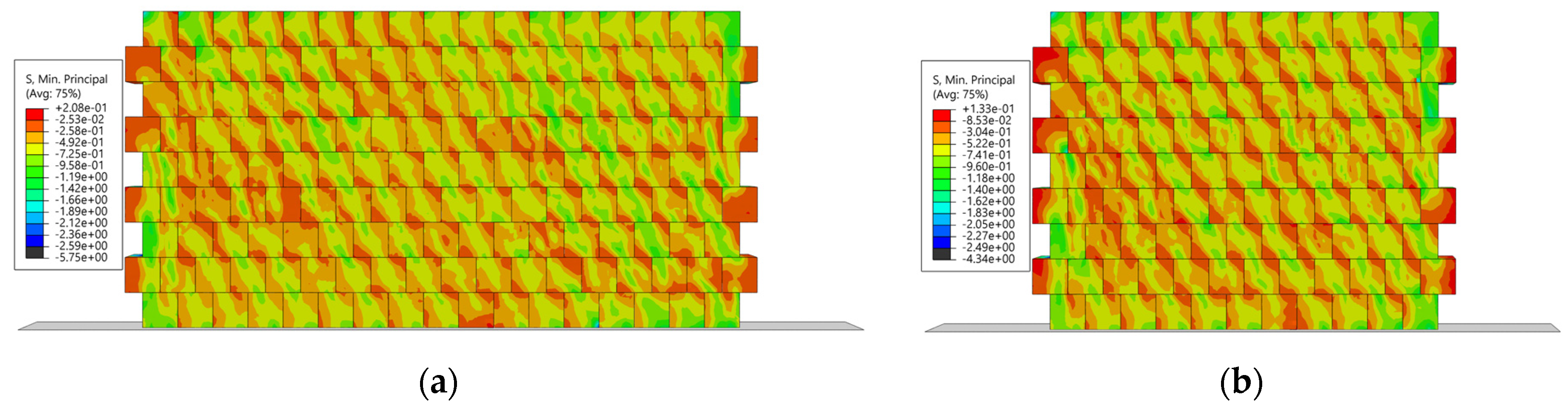

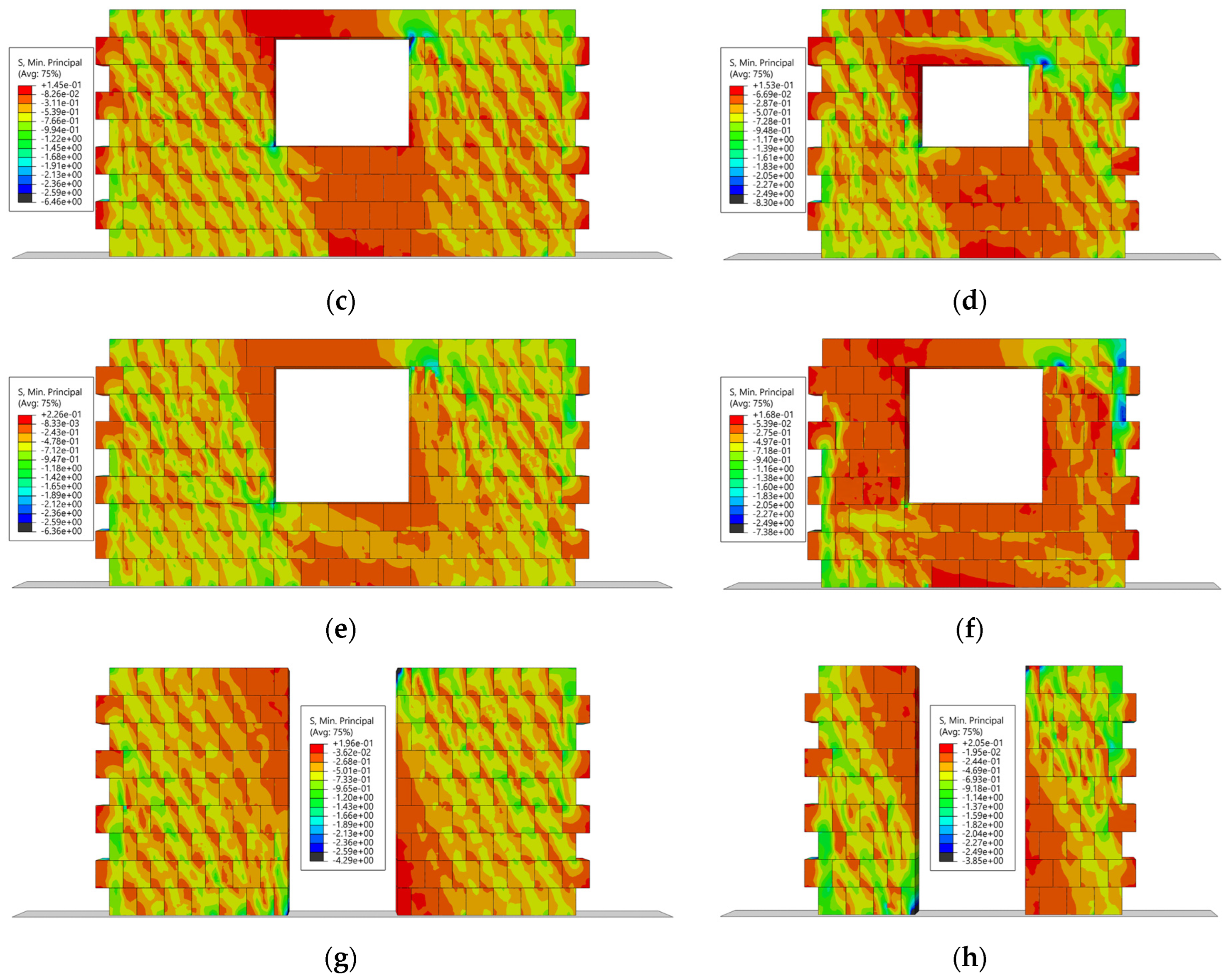

Figure 15 illustrates the distribution of minimum principal stresses at the maximum resistance for each of the considered CM wall configurations. The diagonal struts are clearly visible in the solid walls (SW_1 and SW_2), indicating an efficient transfer of forces through the masonry. Interestingly, the inclination and width of the struts are not affected by the aspect ratio, and appear to be only a function of the unit overlap between rows.

In CM walls with small openings, such as CWop_1 and CWop_2 (

Figure 15c,d), the stress flow is interrupted around the openings. Diagonal struts are observed to the left and right of the central window, but no stress bands form directly around the opening. Instead, stress concentrations occur at the corners of the window, particularly near the top and bottom edges. A similar pattern is evident in CM walls with larger openings (A

p = 1.56 m

2), such as CWopEC_1 and CWopEC_2 (

Figure 15e,f). For CWopEC_2, with an AR of 0.71 (

Figure 15f), the diagonal struts are no longer clearly visible.

For walls with door openings, such as CDop_1 and CDop_2, stress concentrations become evident around the lower-right and upper-left edges of the door openings, as seen in

Figure 15g,h. These zones act as critical areas for stress accumulation, disrupting the continuity of the stress flow and significantly reducing the overall efficiency of force transfer through the wall.

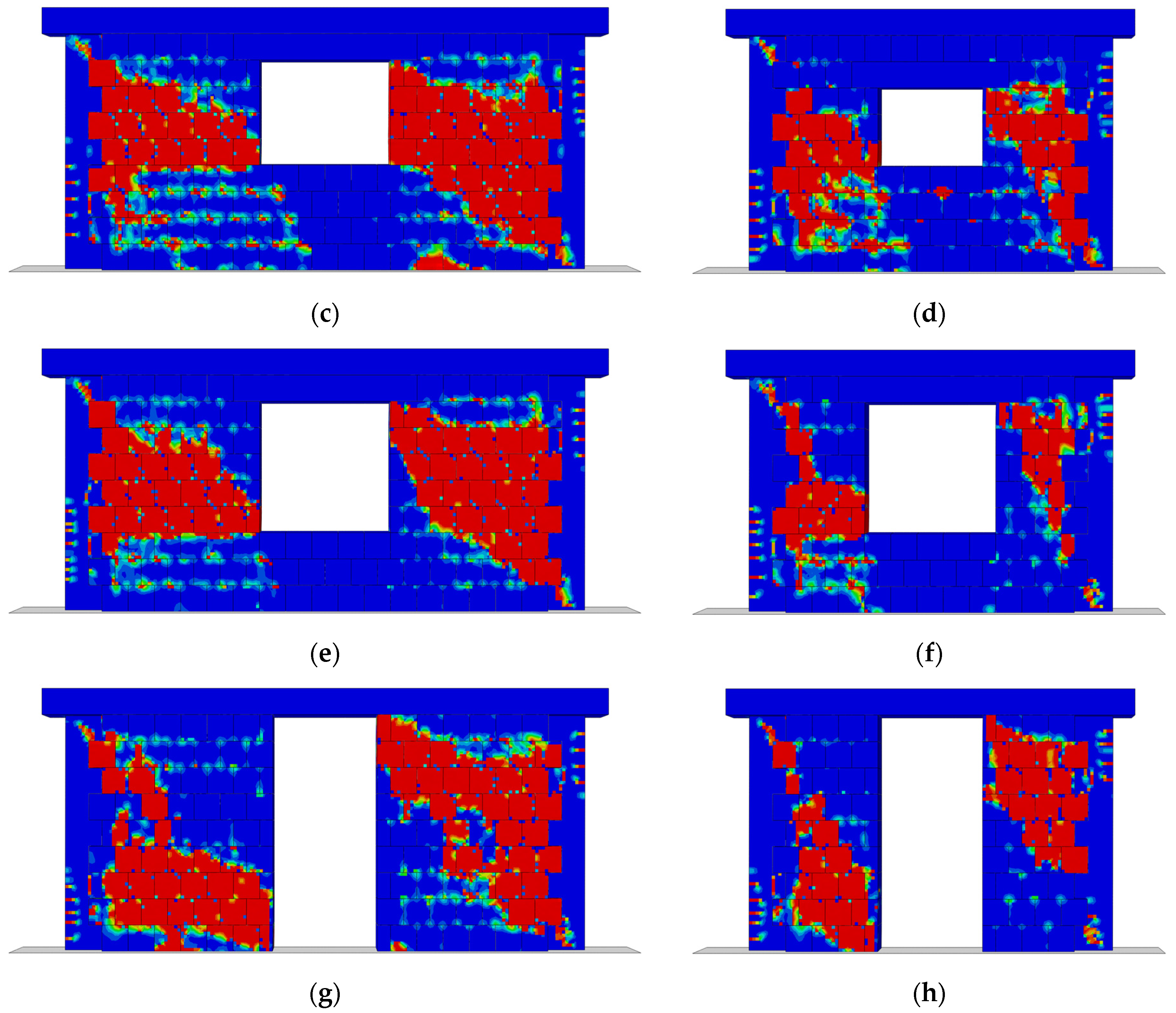

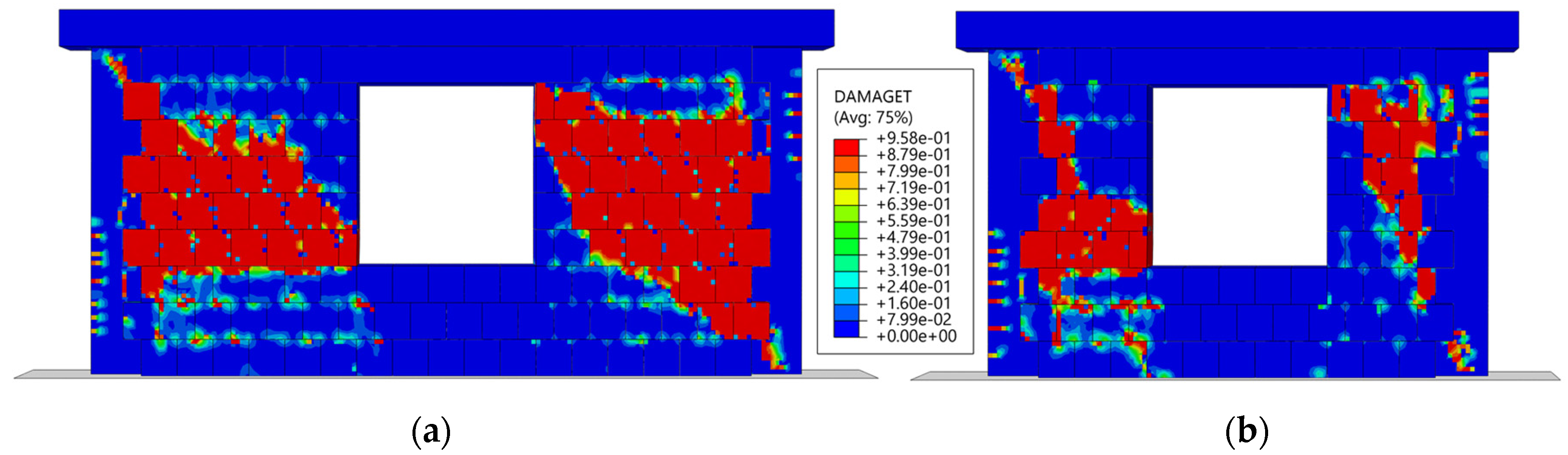

The damage patterns for the eight considered walls at 1.0% drift, illustrated in

Figure 16, align closely with the stress distribution results. Solid CM walls (SW1,

Figure 16a, and SW2,

Figure 16b) exhibit distributed diagonal cracking, while walls with smaller openings, i.e., CWop_1 and CWop_2 (

Figure 16c,d, respectively), show concentrated damage around the openings. The damage occurs primarily at the corners of the openings, with diagonal cracks extending toward the RC confining elements. Walls with door openings (CDop_1, CDop_2) show asymmetric damage through the wall.

The damage patterns in the tie-columns are consistent across all the considered configurations, showing bending damage concentrated at the lower part of the tie-columns. Additionally, a diagonal crack develops from the masonry into the upper corners of the RC tie-columns, eventually leading to shear failure within the tie-columns. This shear failure of tie-columns, however, does not appear to affect the pushover curves, which show no sudden drops.

4.1.2. Position of Window Opening

To further investigate the influence of window opening position on the seismic response of CM walls, four more configurations were analyzed by shifting the window opening left and right while keeping the opening size constant (

for AR = 0.5, and

for AR = 0.71), as shown in

Figure 17. These configurations enabled the assessment of how shifting the window opening influenced the overall reduction in strength and damage patterns.

The pushover curves for the CM walls with varying window opening positions are presented in

Figure 18. The results indicate that shifting the window opening affects both the peak base shear and the overall seismic response, but not by much. For walls with AR = 0.5 (

Figure 18a), the left LWop_1 and right RWop_1 exhibit slightly higher strength compared to the centrally positioned window (CWop_1). A similar trend is observed for walls with AR = 0.71 (

Figure 18b), where LWop_2 and RWop_2 demonstrate better performance compared to the CWop_2 wall configuration in terms of peak strength.

Interestingly, walls with a window opening on the right side (RWop_1 and RWop_2) exhibit a notable drop in capacity at larger drift levels. Specifically, for both aspect ratios, the pushover curves for the RWop configurations fall below those for the CWop and LWop configurations at approximately 0.8% drift. In case of an earthquake, the load acts in the push and pull directions, which means that the worst performing response indicates the expected result. In addition, the post-peak response of walls with offset openings is clearly worse than of those with cantered openings.

The observed differences in capacity can be partially attributed to the distribution of damage and the available wall area for diagonal strut formation. Damage patterns for these configurations at 1.0% drift are shown in

Figure 19. For walls with a central opening, i.e., CWop_1 and CWop_2 (see

Figure 16c,d, respectively), the reduced wall area around the opening limits the development of diagonal struts, leading to a lower base shear capacity compared to configurations with shifted openings. In contrast, when the window opening is shifted to the left or right, a larger portion of the wall becomes active in resisting the lateral (seismic) loads, resulting in slightly higher strengths for the LWop and RWop configurations.

4.1.3. Strength Reduction Factor for CM Walls Without Internal Tie-Columns

The strength reduction factor (

) is defined as the ratio of the strength of a wall with openings to that of a solid wall, and is one of the most important parameters for design. The obtained strength reduction values, according to the FEM model used in this study, were compared to the predictions of the model of Al-Chaar et al. [

42] and the model of Basha et al. [

43], as shown in

Table 5. Both models are explicit functions of the ratio of opening area to the area of the CM wall panel

. The model of Al-Chaar et al. [

42] is given as follows:

whereas the model of Basha et al. [

43] is given as follows:

The performance of both models is compared in

Figure 20, which indicates that the model of Basha et al. [

43] aligns better with the results of the FEM analyses.

4.2. Effect of Internal Tie-Columns

4.2.1. Walls with Windows

The considered wall configurations with two sizes of internal tie-columns (15 × 15 cm and 25 × 25 cm) are illustrated in

Figure 21.

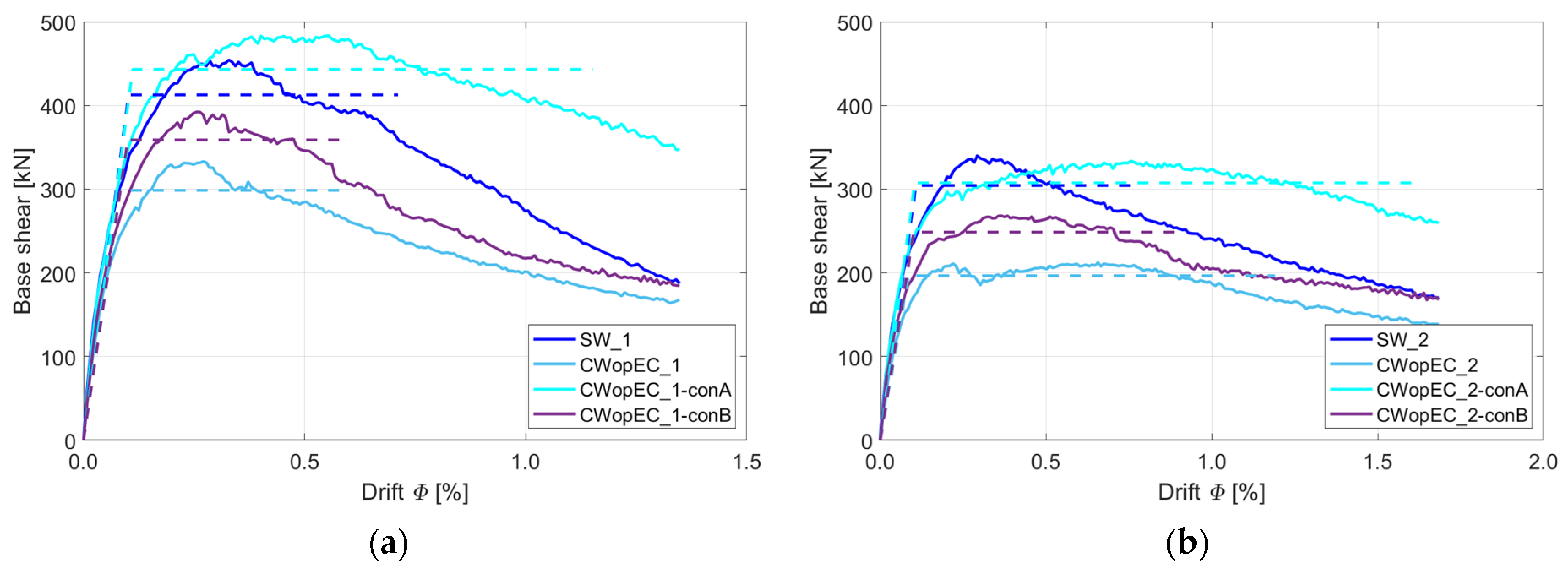

The pushover curves shown in

Figure 22 show how much RC tie-columns around window openings improve peak strength and drift at peak strength, with larger tie-columns providing substantially larger improvements, as well as better post-peak behaviour.

For walls with AR = 0.5, the model with 25 × 25 cm tie-columns (cyan solid curve in

Figure 22a) demonstrates an increase in peak strength of 45% relative to the model without tie-columns (light blue curve,

Figure 22a). The drift at maximum strength is increased by 212%, from 0.26% for the model CWopEC_1 to 0.55% for the model CWopEC_1-conA. In contrast, the model with smaller 15 × 15 cm tie-columns demonstrates a more modest improvement, with an 18% improvement in strength and no change in drift at peak strength.

Similarly, for walls with AR = 0.71, the model with 25 × 25 cm tie-columns shows a 57% increase in peak strength (cyan and blue light solid curve in

Figure 22b) and a 330% increase in drift at maximum strength. This notable increase in drift also highlights the enhanced ductility of the CM wall. On the other hand, the model with 15 × 15 cm tie-columns demonstrates a more limited improvement, with a 26% increase in peak strength and a 61% increase in drift, from 0.23% to 0.37%.

It is interesting to note that the addition of 25 × 25 cm tie-columns around window openings improves the seismic performance of the walls even compared to the solid wall. For walls with AR = 0.5, the strength increases by 7% compared to SW_1. For walls with AR = 0.71, 25 × 25 cm tie-columns give almost identical strength compared to the solid wall (SW_2).

To estimate the effect of tie-column sizes on the ductility of the considered walls with window openings, the response curves were idealized into bilinear curves, as shown in

Figure 22. The idealization was performed by assuming stiffness at 60% of the peak strength, and the ultimate displacement at the point where the strength drops to 80% of its peak value. The idealized curve has equal energy to the original one (areas under both curves are the same). These results of the idealization are presented in

Table 6, and show that 25 × 25 cm tie-columns substantially improve ductility, whereas the effect is much less significant for walls with 15 × 15 cm tie-columns. Higher ductility indicates a much more gradual post-peak degradation and a higher capacity for energy dissipation.

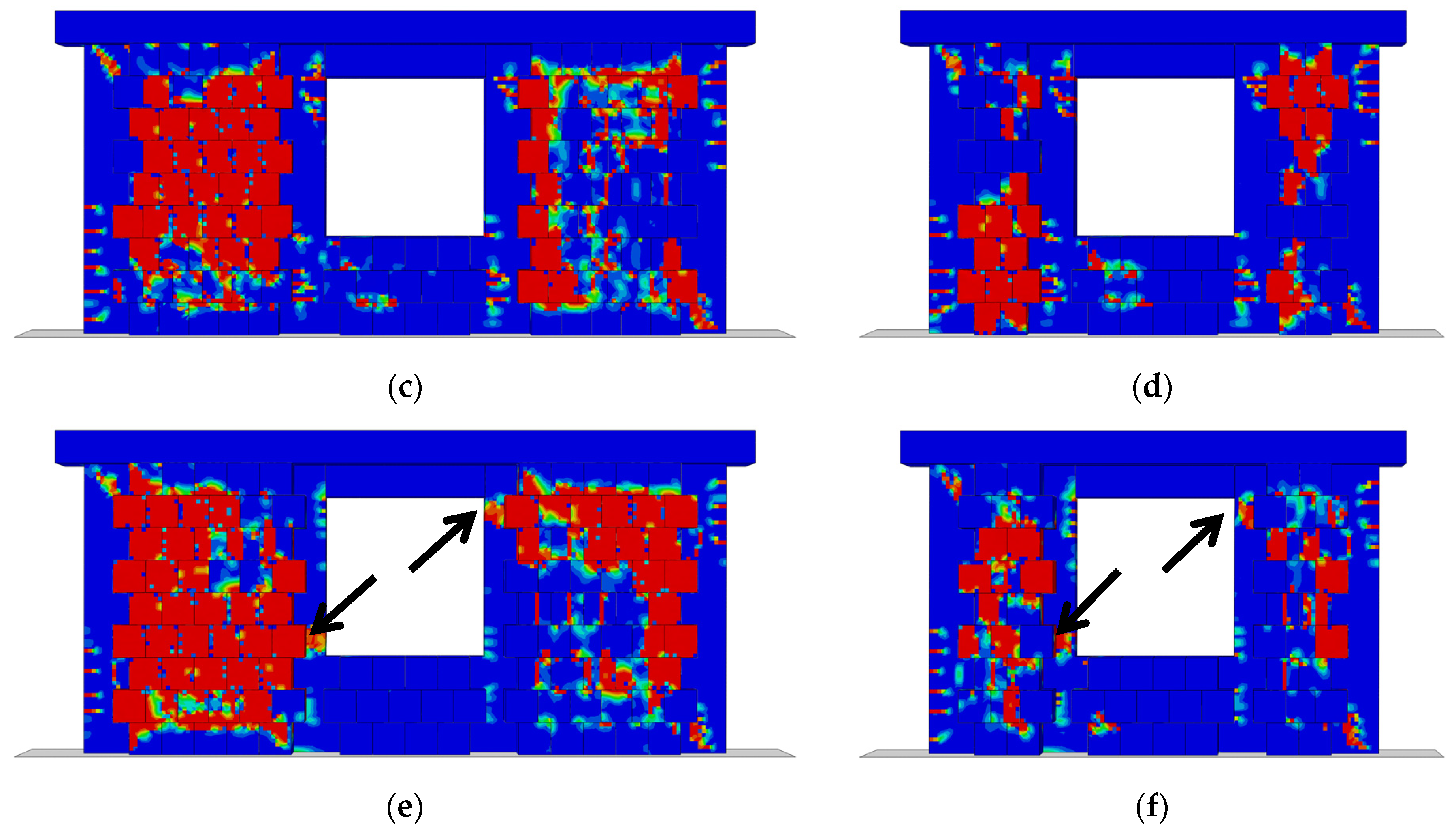

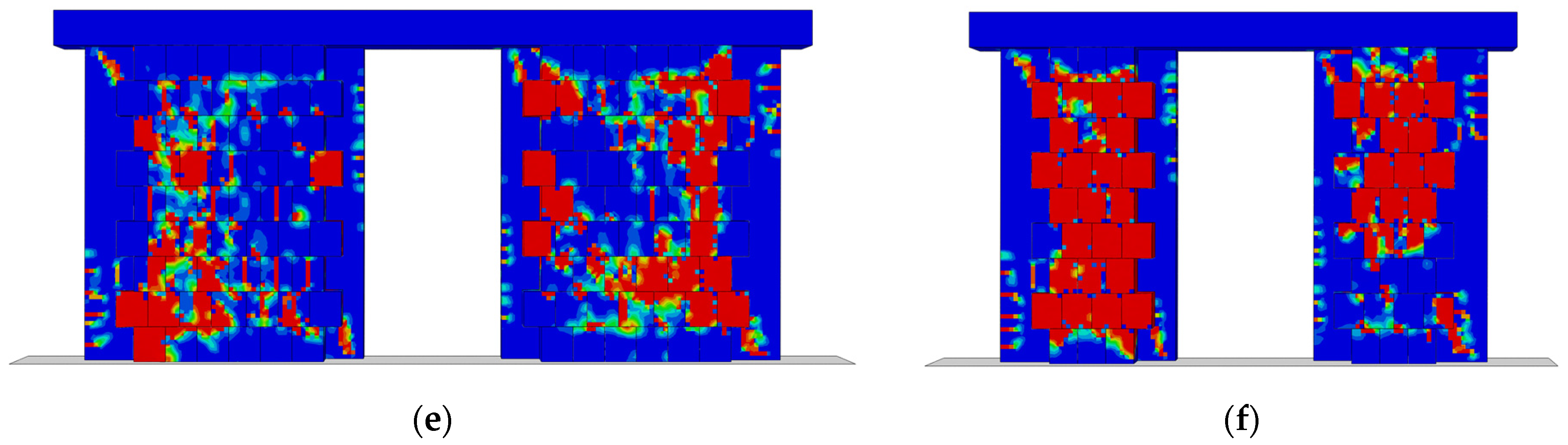

The damage patterns shown in

Figure 23 highlight the key role of RC tie-columns in reducing and localizing damage around window openings. In models with tie-columns of 25 × 25 cm (

Figure 23c,d), these confining elements effectively mitigated stress concentrations and prevented damage at the lower-left and upper-right corners of the window openings observed in the reference models (

Figure 23a,b). In contrast, models with 15 × 15 cm tie-columns (

Figure 23e,f) exhibited vast shear cracks at the lower-left and upper-right corners of the window for both ARs, as indicated by black arrows. Horizontal cracks were also observed at the lower end of the left tie-column and the upper end of the right tie-column, reflecting mixed-mode behaviour that combined flexural and shear damage in these elements.

Overall, the inclusion of larger tie-columns (25 × 25 cm) significantly improved the seismic performance of the walls by reducing damage concentrations, better distributing stress, and limiting crack propagation, compared to smaller tie-columns (15 × 15 cm) or reference models with unconfined window openings.

4.2.2. Walls with Doors

The configurations considered in this section are presented in

Figure 24. RC tie-columns with dimensions of 25 × 25 cm and 15 × 15 cm were considered.

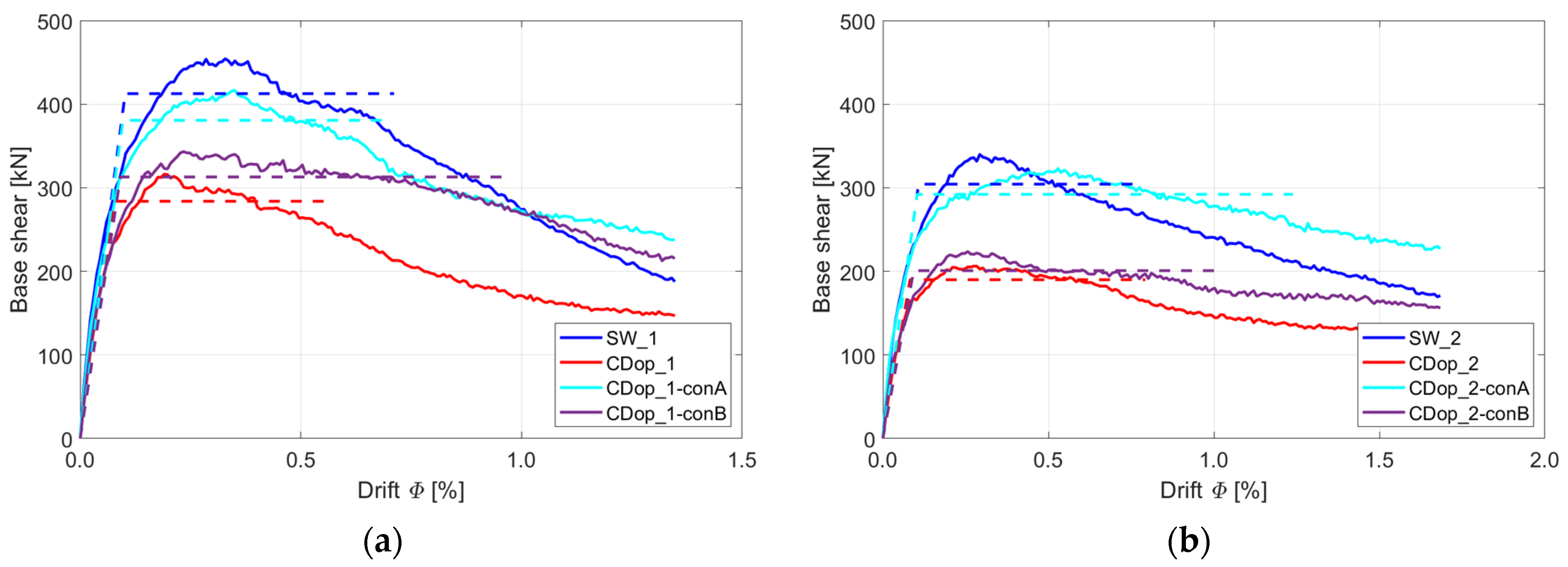

The pushover curves in

Figure 25 highlight the crucial role of RC confining elements around door openings for preventing the degradation of the seismic performance of such walls. The models with larger tie-columns (25 × 25 cm) generally show superior performance compared to the model with 15 × 15 cm tie-columns. The difference in the post-peak region between models with 25 × 25 cm and 15 × 15 cm tie-columns is almost identical for walls with door openings (AR = 0.5). In contrast, for walls with the same AR but with window openings, the difference in post-peak behaviour is much more pronounced. However, it should be noted that the model with 25 × 25 cm tie-columns (AR = 0.71) shows greater ductility and improved post-peak behaviour.

The addition of 25 × 25 cm tie-columns in the wall with AR = 0.5 (cyan solid curve in

Figure 25a) has increased peak strength by 32% compared to the base model (red curve in

Figure 25a). Additionally, the drift at peak strength increases by 84%, rising from 0.19% in the reference model to 0.35% in the wall with 25 × 25 cm internal tie columns. In contrast, the smaller 15 × 15 cm tie-columns provide more modest improvements, with a 9% increase in strength and a 20% increase in drift level.

For walls with AR = 0.71, the model with 25 × 25 cm tie-columns shows a significant 57% increase in peak strength compared to the model without confinement around the opening (cyan and red solid curves in

Figure 25b). In addition, the drift at peak strength rises by 204%, from 0.26% in the reference model to 0.53% in the model with internal tie-columns. The inclusion of 15 × 15 cm tie-columns leads to a slight improvement of 8% for both strength and drift at peak strength.

In contrast to the CM walls with window openings, where the addition of 25 × 25 cm tie-columns significantly enhances seismic performance (even exceeding that of the solid wall), the effect of this on walls with door openings is somewhat less pronounced. The models with 25 × 25 cm tie-columns in walls with AR = 0.5 and AR = 0.71 have ratios of peak strength compared to those of the reference walls of 0.92 and 0.95, respectively.

To analyze the effect of tie-columns sizes on ductility, the response curves were again idealized into bilinear curves, as depicted in

Figure 25, with dashed lines in the same colours, to facilitate comparison. The corresponding values are summarized in

Table 7. In this case, the small tie-columns improved ductility for both ARs. The large tie-columns, on the other hand, were effective only for the wall with AR = 0.71.

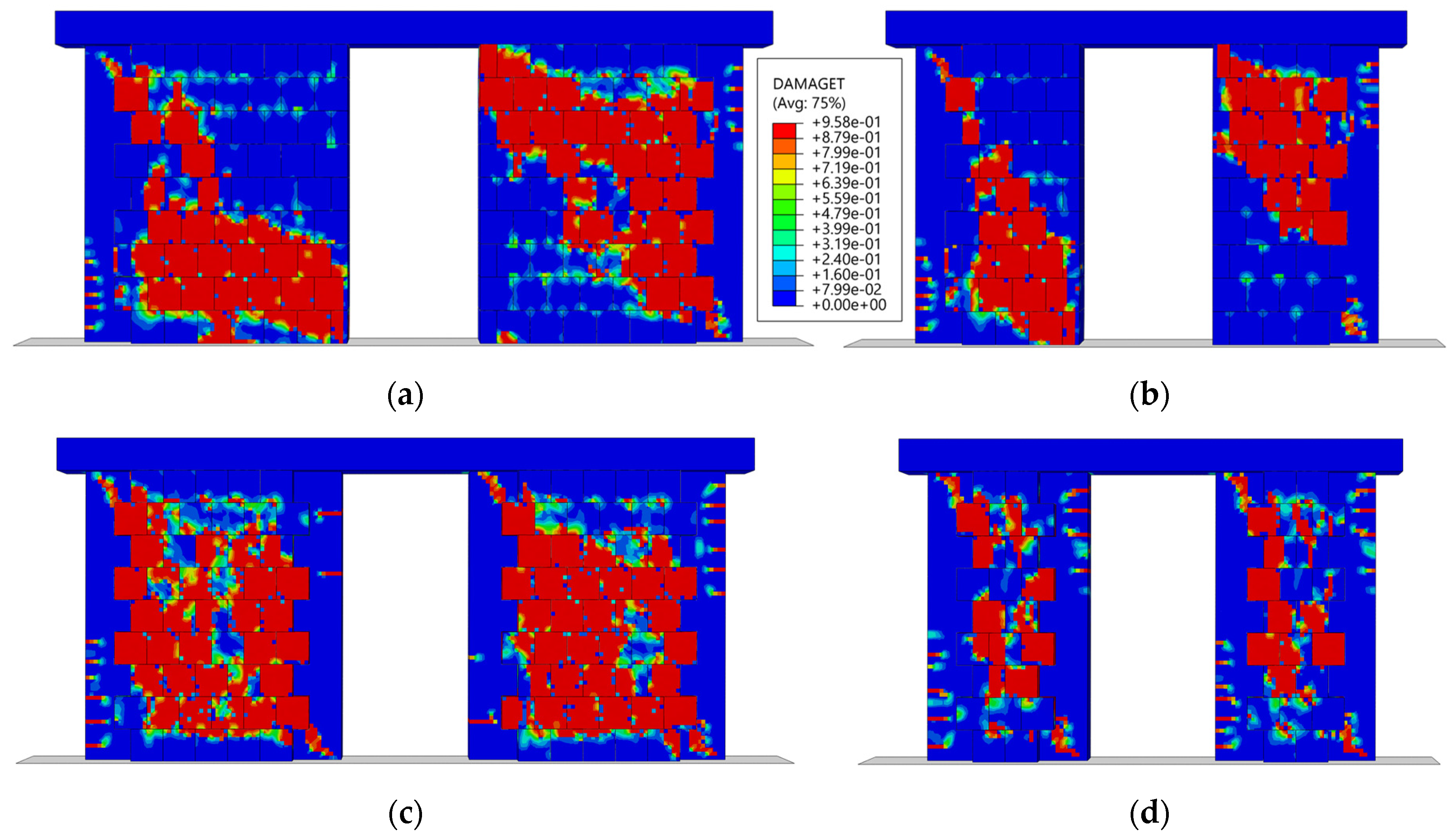

The damage distribution patterns, illustrated in

Figure 26, reveal the role of RC tie-columns in managing stress concentration and localizing damage near door openings. Based on the results, similar observations can be made as for the CM walls with windows. For the model with AR = 0.5, which has 25 × 25 cm tie-columns (

Figure 26c), more extensive damage is observed along the left and right piers, compared to the model with 15 × 15 cm tie-columns (

Figure 26e). This includes shear cracks that extend from the masonry piers into the surrounding tie-columns, both externally and internally. Conversely, for the model with AR = 0.71 and 15 × 15 cm tie-columns, the damage is more widespread compared to the model with 25 × 25 cm tie-columns. Additionally, in the model with AR = 0.71 and 25 × 25 cm tie-columns, the internal tie-columns exhibit significantly more activity, with horizontal cracks observed at the upper part of the interior left column and the lower part of the interior right column, as seen in

Figure 26c,d. It is believed that the damage patterns observed for these models with AR = 0.5 (25 × 25 and 15 × 15 cm tie-columns) are consistent with the behaviour seen in the post-peak region of the pushover curves, where nearly identical performance is noted for both models (cyan and purple solid curves in

Figure 25a).

5. Conclusions

The paper studies the effects of openings and tie-columns on the response of CM walls using a validated micro-FEM model. The type of masonry considered in this study is novel, and has not been analyzed in this manner before.

The results indicate that openings have a very detrimental effect on the seismic performance of CM walls, regardless of their size. Even in cases when the area of the opening was less than 10% of the CM wall area, the resistance decreased by more than 15%. The post-peak response and ductility were affected as well. Additionally, the results show that adding tie-columns next to windows proves to be an effective measure for reducing the detrimental effect of openings. However, because the thickness of the considered masonry is 38 cm, the size of additional the tie-columns should be at least 25 × 25 cm. When smaller tie-columns were used (e.g., 15 × 15 cm), they were much less effective.

For walls with AR = 0.5, the model with 25 × 25 cm internal tie-columns showed an increase in peak strength of 45% relative to the model without tie-columns. The drift at maximum strength increased by 212%, from 0.26% for the model CWopEC_1 to 0.55% for the model CWopEC_1-conA. In contrast, the model with smaller 15 × 15 cm internal tie-columns demonstrated a more modest improvement, with an 18% improvement in strength and no change in drift at peak strength.

Similarly, for walls with AR = 0.71, the model with 25 × 25 cm internal tie-columns showed a 57% increase in peak strength and a 330% increase in drift at maximum strength. This notable increase in drift also highlights the enhanced ductility of this CM wall. On the other hand, the model with 15 × 15 cm internal tie-columns demonstrated a more limited improvement, with a 26% increase in peak strength and a 61% increase in drift, from 0.23% to 0.37%.

It has been shown in this paper that the strength reduction factor due to openings, as obtained from the present analysis, aligns quite well with the predictions of the model of Basha et al. [

43], which confirms the suitability of this model for the considered type of masonry.

The position of the window opening in CM walls was also analyzed. It was determined that an offset position resulted in slightly greater strength due to clearer transfer of stresses in the masonry, but that this position resulted in worse post-peak behaviour due to the tie-columns being more stressed.

It should be noted that all of the conclusions presented here are relevant only for the considered type of masonry, and are solely based on numerical simulations. Further experimental tests should be conducted to fully validate these conclusions.