The Effect of Timing Polymer Fiber Addition on the Compressive Strength of Adobe Bricks: Towards an Approach Compatible with Sustainable Architecture

Abstract

1. Introduction

2. Literature Review

2.1. Clay Bricks as an Economical and Sustainable Building Material

2.2. The Effect of Natural and Synthetic Fibers

3. Materials and Methods

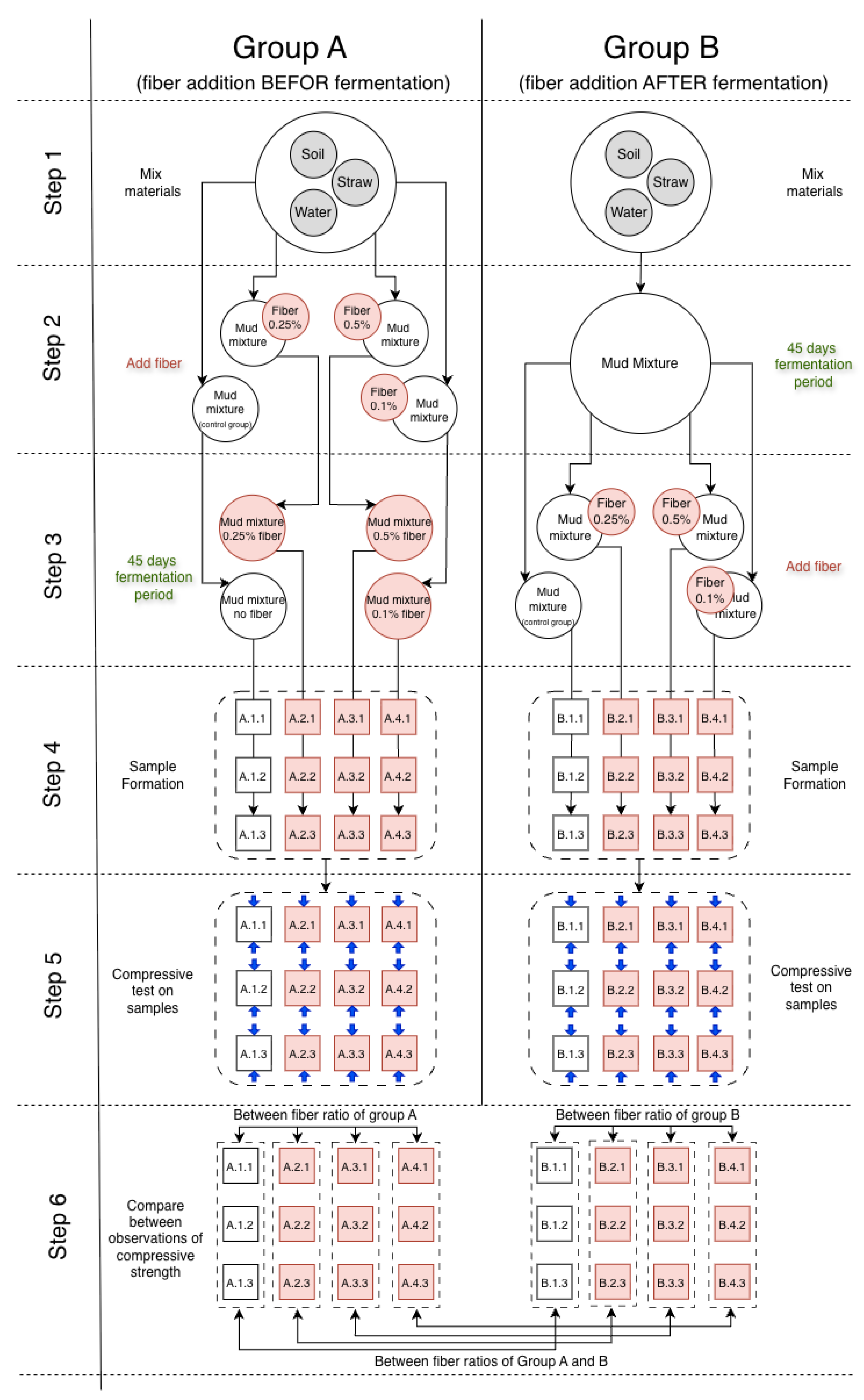

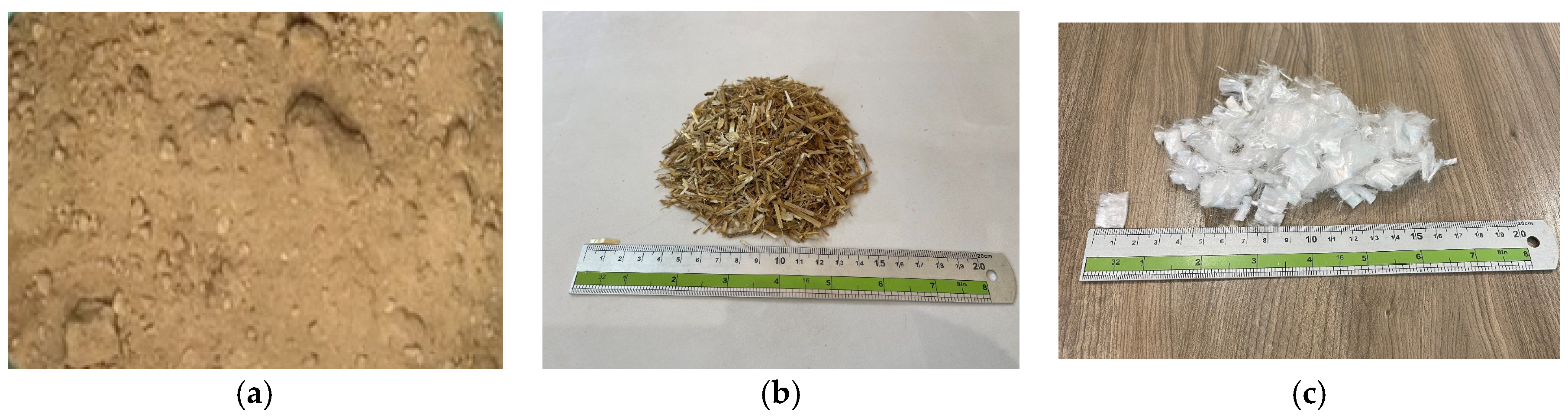

- Material Preparation: The base soil was first processed through a 2 mm sieve to eliminate large aggregates and impurities, while agricultural straw was cut to a uniform length of 15 mm to facilitate homogeneous mixing.

- Mixing: The soil and straw were manually blended with drinking water (approximately 40% by weight) to create a cohesive mud paste. For Group A specimens, PP fibers were gradually integrated during the initial kneading phase.

- Fermentation: The mixture was stored in covered containers for a 45-day fermentation period under ambient outdoor conditions (averaging 37.2 °C and 28% relative humidity), with weekly stirring to maintain moisture equilibrium.

- Post-Fermentation Addition: For Group B, fibers were introduced only after the 45-day fermentation period was complete; they were sprinkled into the fermented mud during the secondary kneading stage.

- Molding and Drying: The processed mixtures were compacted into lubricated 50 mm3 metal molds, leveled, and subsequently air-dried in direct sunlight for 14 days to ensure natural hardening.

- Testing: Finally, the cured specimens were subjected to uniaxial compressive strength tests to quantify mechanical performance.

3.1. Material Used

3.2. Preparation of Materials and Mixtures

3.3. Experimental Groups

- Group A—Pre-fermentation: Soil, straw, water, and fiber were mixed together before beginning fermentation for 45 days.

- Group B—Post-fermentation: Soil, straw, and water were mixed together, then fermented for 45 days, and fibers were then added immediately before forming.

3.4. Fermentation

3.5. Sample Formation and Dimensions

3.6. Compression Resistance Test

3.7. Statistical Analysis Plan

4. Results

4.1. The First Experiment—Adding Polymeric Fibers Before Fermentation (Group A)

4.2. The Second Experiment—Adding Polymeric Fibers After Fermentation (Group B)

4.3. Summary of Results

5. Discussion

5.1. Ineffectiveness of Added Fibers with Straw

- PP fiber is inherently hydrophobic, which limits its adhesion to the surrounding clay particles and leads to the formation of a weak Interfacial Transition Zone (ITZ) around the fibers. This effect becomes more pronounced in the presence of straw, as the hydrophobic PP fibers interfere with the development of the biopolymer network generated during straw fermentation. As a result, the coexistence of straw and PP fibers disrupts matrix continuity and further weakens the ITZ.

- Mechanical Interference with Biopolymer Bonding: Traditional processing relies on the biological decomposition of organic straw: a process which releases natural biopolymers (such as polysaccharides) that act as binding agents for clay particles [10,14,15]. The presence of PP fibers, particularly in Group A, mechanically interrupts this continuous organic network, suggesting that polymeric fibers may interfere with the fermentation process and initiate internal cracking points, consistent with observations from other studies [4]. Unlike straw, which decomposes to chemically enhance cohesion, PP fibers are inert inclusions, potentially creating voids or discontinuities within the matrix where these organic binders fail to bridge the gap.

5.2. Effect of Timing of Addition

5.3. Comparison with the Findings of Previous Studies

- Natural fibers: Studies such as [13] have established that natural fiber reinforcement enhances cohesion and mitigates shrinkage cracking. However, the net efficacy of inclusions is variable, contingent upon the specific fiber type utilized and the methodology of addition.

- Polymer fibers: Studies such as [8] support mechanical benefits of low-dosage polymer addition in standard mixes; they also highlight inconsistencies when these fibers are introduced into organic clay mixtures. The results of the present study corroborate these findings, confirming that the presence of organic matter complicates the reinforcement mechanisms.

- A critical comparison clarifies the mechanism behind these discrepancies. For instance, Ref. [9] reported an 84% increase in strength with 0.23% PP fibers. Their study utilized laterite soil without straw fermentation. In contrast, our results align with [4], which observed reductions in strength of organic-rich soils. This discrepancy underscores the fact that the success of synthetic reinforcement is highly context-dependent: PP fibers work well in inert, mechanically stabilized soils but may be counterproductive in biologically stabilized (fermented) traditional adobe.

5.4. Applied Implications

5.5. Alignment with Sustainable Architecture

6. Conclusions and Recommendations

6.1. Conclusions

6.2. Recommendations

- Based on the findings and the identified limitations of this investigation, the following recommendations are proposed to guide future research and practice.

- Future Research Directions

- Future studies should employ Scanning Electron Microscopy (SEM) to visualize the micro-scale interaction between the hydrophobic PP fibers and the fermented clay–straw matrix. Such imaging would provide clearer insight into how fiber hydrophobicity interrupts the biopolymer bonding produced by straw decomposition.

- To address the incompatibility observed in this study, investigations should test the efficacy of chemically treating PP fibers (e.g., plasma treatment or coating) to increase their hydrophilicity and adhesion capability within a wet, fermented clay matrix.

- Detailed biochemical analysis is required to quantify how the presence of synthetic fibers affects the metabolic activity of microorganisms during straw fermentation. Research should determine if specific fiber materials inhibit the production of stabilizing biopolymers.

- Research should explore biocompatible synthetic fibers or alternative natural fibers that possess the durability of polymers but do not disrupt continuity of fermentation.

- Implications for Practice and Policy

- Practitioners utilizing traditional fermentation methods for Salmani architecture projects should prioritize traditional straw reinforcement. Synthetic fibers should only be introduced if the mix design is not fermented or if specific adhesives are used to ensure bonding.

- Regulatory bodies and code developers should work towards establishing testing standards that differentiate between “inert stabilized earth” (e.g., cement-stabilized) and “biologically stabilized earth” (e.g., fermented adobe), as the reinforcement requirements for each differ significantly.

- For projects requiring the durability of PP fibers, field trials should focus on minimizing fiber length and optimizing mixing protocols to prevent the agglomeration observed in this study, ensuring that the structural integrity of the brick is not compromised by processing defects.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| PP | Polypropylene |

| SA | Saudi Arabia |

| MPa | Megapascal |

| ADR | Advanced Digital Readout |

| ASTM | American Society for Testing and Materials |

| IBC | International Building Code |

References

- Houben, H.; Guillaud, H. Earth Construction: A Comprehensive Guide; Intermediate Technology Publications: Rugby, UK, 1994. [Google Scholar]

- Silveira, D.; Varum, H.; Costa, A.; Martins, T.; Pereira, H.; Almeida, J. Mechanical properties of adobe bricks in ancient constructions. Constr. Build. Mater. 2012, 28, 36–44. [Google Scholar] [CrossRef]

- Minke, G. Earth Construction Handbook: The Building Material Earth in Modern Architecture; WIT Press: Southampton, UK, 2000. [Google Scholar]

- Bertelsen, I.M.G.; Belmonte, L.J.; Fischer, G.; Ottosen, L.M. Influence of synthetic waste fibres on drying shrinkage cracking and mechanical properties of adobe materials. Constr. Build. Mater. 2021, 286, 122738. [Google Scholar] [CrossRef]

- Mostafa, M.; Uddin, N. Experimental analysis of compressed earth block (CEB) with banana fibers resisting flexural and compression forces. Case Stud. Constr. Mater. 2016, 5, 53–63. [Google Scholar] [CrossRef]

- Walker, P.J. Strength and erosion characteristics of earth blocks and earth block masonry. J. Mater. Civ. Eng. 2004, 16, 497–506. [Google Scholar] [CrossRef]

- Guettala, A.; Abibsi, A.; Houari, H. Durability study of stabilized earth concrete under both laboratory and climatic conditions exposure. Constr. Build. Mater. 2006, 20, 119–127. [Google Scholar] [CrossRef]

- Millogo, Y.; Morel, J.-C.; Aubert, J.-E.; Ghavami, K. Experimental analysis of pressed adobe blocks reinforced with Hibiscus cannabinus fibers. Constr. Build. Mater. 2014, 52, 71–78. [Google Scholar] [CrossRef]

- Salaou, N.M.L.; Thuo, J.; Kabubo, C.; Gariy, Z.A. Performance of polypropylene fibre reinforced laterite masonry bricks. Civ. Eng. Archit. 2021, 9, 2178–2186. [Google Scholar] [CrossRef]

- Yazıcı, M.F.; Keskin, N. Zeminlerin doğal ve sentetik lifler ile güçlendirilmesi üzerine bir derleme çalışması. Erzincan Üniv. Fen Bilim Enst. Derg. 2021, 14, 631–663. [Google Scholar]

- ASTM D422-63(2007)e2; Standard Test Method for Particle-Size Analysis of Soils. ASTM International: West Conshohocken, PA, USA, 2007; Reapproved 2016.

- ASTM C67/C67M-24; Standard Test Methods for Sampling and Testing Brick and Structural Clay Tile. ASTM International: West Conshohocken, PA, USA, 2024.

- Laborel-Préneron, A.; Aubert, J.E.; Magniont, C.; Tribout, C.; Bertron, A. Plant aggregates and fibers in earth construction materials: A review. Constr. Build. Mater. 2016, 111, 719–734. [Google Scholar] [CrossRef]

- Labiad, Y.; Meddah, A.; Beddar, M. Performance of sisal fiber-reinforced cement-stabilized compressed-earth blocks incorporating recycled brick waste. Innov. Infrastruct. Solut. 2023, 8, 107. [Google Scholar] [CrossRef]

- Mohajerani, A.; Hui, S.-Q.; Mirzababaei, M.; Arulrajah, A.; Horpibulsuk, S.; Abdul Kadir, A.; Rahman, M.T.; Maghool, F. Amazing types, properties, and applications of fibres in construction materials. Material 2019, 12, 2513. [Google Scholar] [CrossRef] [PubMed]

| Polymeric Fiber % | Compressive Strength (MPa) | SD | |||

|---|---|---|---|---|---|

| 1st Sample | 2nd Sample | 3rd Sample | Mean | ||

| 0.00% 1 | 1.96 | 1.88 | 1.92 | 1.92 | 0.04 |

| 0.25% | 1.65 | 1.64 | 1.68 | 1.66 | 0.02 |

| 0.50% | 1.56 | 1.6 | 1.64 | 1.60 | 0.04 |

| 1.00% | 1.36 | 1.6 | 1.68 | 1.55 | 0.17 |

| Polymeric Fiber % | Compressive Strength (MPa) | SD | |||

|---|---|---|---|---|---|

| 1st Sample | 2nd Sample | 3rd Sample | Mean | ||

| 0.00% 1 | 1.64 | 1.88 | 1.92 | 1.81 | 0.15 |

| 0.25% | 1.6 | 1.6 | 2 | 1.73 | 0.23 |

| 0.50% | 1.68 | 1.56 | 1.72 | 1.65 | 0.08 |

| 1.00% | 1.52 | 1.88 | 1.92 | 1.77 | 0.22 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alnahar, A.Y.; Abolkhair, K.; Albrithen, H.A.; Altassan, A.A. The Effect of Timing Polymer Fiber Addition on the Compressive Strength of Adobe Bricks: Towards an Approach Compatible with Sustainable Architecture. Buildings 2025, 15, 4565. https://doi.org/10.3390/buildings15244565

Alnahar AY, Abolkhair K, Albrithen HA, Altassan AA. The Effect of Timing Polymer Fiber Addition on the Compressive Strength of Adobe Bricks: Towards an Approach Compatible with Sustainable Architecture. Buildings. 2025; 15(24):4565. https://doi.org/10.3390/buildings15244565

Chicago/Turabian StyleAlnahar, Abdullah Y., Khalid Abolkhair, Hamad A. Albrithen, and Abdulrahman A. Altassan. 2025. "The Effect of Timing Polymer Fiber Addition on the Compressive Strength of Adobe Bricks: Towards an Approach Compatible with Sustainable Architecture" Buildings 15, no. 24: 4565. https://doi.org/10.3390/buildings15244565

APA StyleAlnahar, A. Y., Abolkhair, K., Albrithen, H. A., & Altassan, A. A. (2025). The Effect of Timing Polymer Fiber Addition on the Compressive Strength of Adobe Bricks: Towards an Approach Compatible with Sustainable Architecture. Buildings, 15(24), 4565. https://doi.org/10.3390/buildings15244565