Lean-Enhanced Virtual Reality Training for Productivity and Ergonomic Safety Improvements

Abstract

1. Introduction

2. Literature Review

2.1. VR/AR in Construction Training

2.2. Lean, Productivity, and Safety

3. Research Method

3.1. Training Platform

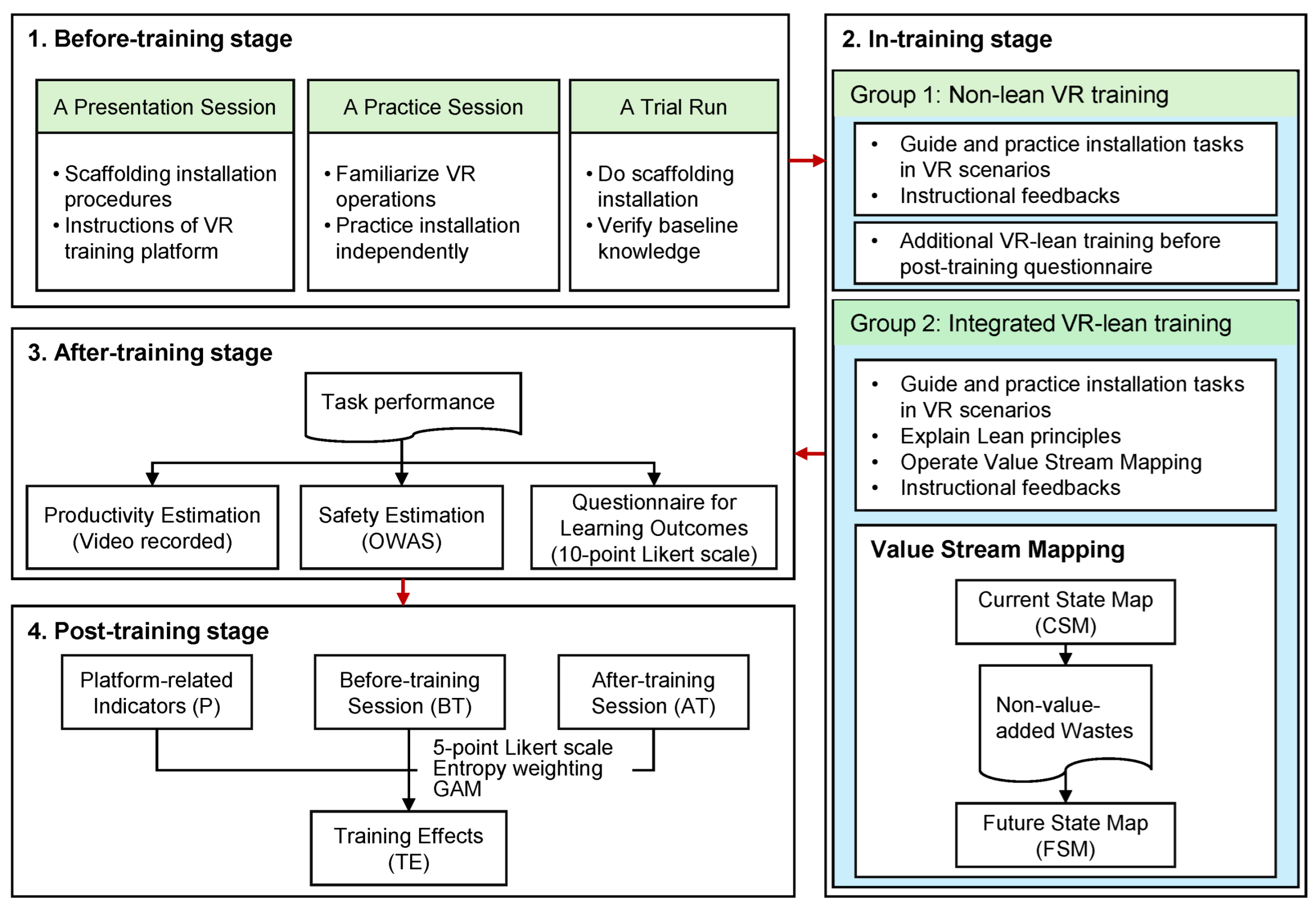

3.2. Training Design

- Group 1 received non-lean VR training, which simulated installation activities using the video-assisted feedback method [45]. No lean principles, waste identification, or optimization strategies were introduced. Trainers provided instructional feedback based on their observations of trainees’ task performance, with particular attention to error correction and basic guidance during installation.

- Group 2 received integrated VR and lean training. In addition to the basic VR training provided to Group 1, this approach embedded value stream mapping (VSM), a key lean construction tool, into the VR scenarios to serve as a structured guidance mechanism during task execution. Individual participants developed a current state map (CSM) using VSM to identify waste in each installation activity, such as rework, unnecessary travelling, idling, and poor planning. Based on this analysis, a future state map (FSM) was introduced to illustrate an optimized workflow with reduced waste.

3.3. Participants

3.4. Presentation and Practice

3.5. Training Evaluation

3.6. Integrated VR-Lean Training Framework

4. Results

4.1. Training Performance on Productivity

4.2. Training Performance on Ergonomic Safety

4.3. Evaluation of Learning Outcomes

4.4. Factors Affecting Training Effects

5. Discussions

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hasan, A.; Baroudi, B.; Elmualim, A.; Rameezdeen, R. Factors affecting construction productivity: A 30 year systematic review. Eng. Constr. Archit. Manag. 2018, 25, 916–937. [Google Scholar] [CrossRef]

- Wilson, M.; Brooks, J. Size Matters: Why Construction Productivity Is So Weak; Centre for Economic Development Australia: Melbourne, Australia, 2025. [Google Scholar]

- Rathnayake, A.; Middleton, C. Systematic review of the literature on construction productivity. J. Constr. Eng. Manag. 2023, 149, 03123005. [Google Scholar] [CrossRef]

- Department of Labor. Commonly Used Statistics; Department of Labor: Washington, DC, USA, 2022.

- Liao, L.; Liao, K.; Wei, N.; Ye, Y.; Li, L.; Wu, Z. A holistic evaluation of ergonomics application in health, safety, and environment management research for construction workers. Saf. Sci. 2023, 165, 106198. [Google Scholar] [CrossRef]

- Li, X.; Yi, W.; Chi, H.L.; Wang, X.; Chan, A.P. A critical review of virtual and augmented reality (VR/AR) applications in construction safety. Autom. Constr. 2018, 86, 150–162. [Google Scholar] [CrossRef]

- Zhang, S.; Teizer, J.; Lee, J.K.; Eastman, C.M.; Venugopal, M. Building information modeling (BIM) and safety: Automatic safety checking of construction models and schedules. Autom. Constr. 2013, 29, 183–195. [Google Scholar] [CrossRef]

- Dhalmahapatra, K.; Maiti, J.; Krishna, O. Assessment of virtual reality based safety training simulator for electric overhead crane operations. Saf. Sci. 2021, 139, 105241. [Google Scholar] [CrossRef]

- Lampropoulos, G.; Fernández-Arias, P.; Antón-Sancho, Á.; Vergara, D. Examining the role of augmented reality and virtual reality in safety training. Electronics 2024, 13, 3952. [Google Scholar] [CrossRef]

- Bigwanto, A.; Widayati, N.; Wibowo, M.A.; Sari, E.M. Lean Construction: A Sustainability Operation for Government Projects. Sustainability 2024, 16, 3386. [Google Scholar] [CrossRef]

- Wang, P.; Wu, P.; Chi, H.L.; Li, X. Adopting lean thinking in virtual reality-based personalized operation training using value stream mapping. Autom. Constr. 2020, 119, 103355. [Google Scholar] [CrossRef]

- Pedro, A.; Le, Q.T.; Park, C.S. Framework for integrating safety into construction methods education through interactive virtual reality. J. Prof. Issues Eng. Educ. Pract. 2016, 142, 04015011. [Google Scholar] [CrossRef]

- Teizer, J.; Cheng, T.; Fang, Y. Location tracking and data visualization technology to advance construction ironworkers’ education and training in safety and productivity. Autom. Constr. 2013, 35, 53–68. [Google Scholar] [CrossRef]

- Zhou, W.; Whyte, J.; Sacks, R. Construction safety and digital design: A review. Autom. Constr. 2012, 22, 102–111. [Google Scholar] [CrossRef]

- Nahmens, I.; Ikuma, L.H. An Empirical Examination of the Relationship between Lean Construction and Safety in the Industrialized Housing Industry. Lean Constr. J. 2009, 1–12. [Google Scholar] [CrossRef]

- Gambatese, J.A.; Pestana, C.; Lee, H.W. Alignment between lean principles and practices and worker safety behavior. J. Constr. Eng. Manag. 2017, 143, 04016083. [Google Scholar] [CrossRef]

- Wang, P.; Wu, P.; Wang, X.; Chen, X.; Zhou, T. Developing optimal scaffolding erection through the integration of lean and work posture analysis. Eng. Constr. Archit. Manag. 2020, 27, 2109–2133. [Google Scholar] [CrossRef]

- Robson, L.S.; Clarke, J.A.; Cullen, K.; Bielecky, A.; Severin, C.; Bigelow, P.L.; Irvin, E.; Culyer, A.; Mahood, Q. The effectiveness of occupational health and safety management system interventions: A systematic review. Saf. Sci. 2007, 45, 329–353. [Google Scholar] [CrossRef]

- Hale, A.; Borys, D.; Else, D. Management of Safety Rules and Procedure. A Review of the Literature; IOSH Research Committee: Washington, DC, USA, 2012. [Google Scholar]

- Occupational Safety and Health Administration. Scaffolding; Occupational Safety and Health Administration: Washington, DC, USA, 2022.

- Jeelani, I.; Han, K.; Albert, A. Development of virtual reality and stereo-panoramic environments for construction safety training. Eng. Constr. Archit. Manag. 2020, 27, 1853–1876. [Google Scholar] [CrossRef]

- Wang, P.; Wu, P.; Wang, J.; Chi, H.L.; Wang, X. A critical review of the use of virtual reality in construction engineering education and training. Int. J. Environ. Res. Public Health 2018, 15, 1204. [Google Scholar] [CrossRef] [PubMed]

- Kim, B.; Kim, C.; Kim, H. Interactive modeler for construction equipment operation using augmented reality. J. Comput. Civ. Eng. 2012, 26, 331–341. [Google Scholar] [CrossRef]

- Juang, J.R.; Hung, W.H.; Kang, S.C. SimCrane 3D+: A crane simulator with kinesthetic and stereoscopic vision. Adv. Eng. Inform. 2013, 27, 506–518. [Google Scholar] [CrossRef]

- da Silva, A.G.; Winkler, I.; Gomes, M.M.; Pinto, U.D.M. Ergonomic analysis supported by virtual reality: A systematic literature review. In Proceedings of the 2020 22nd Symposium on Virtual and Augmented Reality (SVR), Porto de Galinhas, Brazil, 7–10 November 2020; pp. 463–468. [Google Scholar]

- Sacks, R.; Perlman, A.; Barak, R. Construction safety training using immersive virtual reality. Constr. Manag. Econ. 2013, 31, 1005–1017. [Google Scholar] [CrossRef]

- Le, Q.T.; Pedro, A.; Park, C.S. A social virtual reality based construction safety education system for experiential learning. J. Intell. Robot. Syst. 2015, 79, 487–506. [Google Scholar] [CrossRef]

- Dang, H.; Serne, J.; Tafazzoli, M. Virtual reality safety training assessment in construction management and safety and health management programs. In Proceedings of the Computing in Civil Engineering 2023, Corvallis, OR, USA, 25–28 June 2023; pp. 28–35. [Google Scholar]

- Scorgie, D.; Feng, Z.; Paes, D.; Parisi, F.; Yiu, T.; Lovreglio, R. Virtual reality for safety training: A systematic literature review and meta-analysis. Saf. Sci. 2024, 171, 106372. [Google Scholar] [CrossRef]

- Stork, S.; Schubö, A. Human cognition in manual assembly: Theories and applications. Adv. Eng. Inform. 2010, 24, 320–328. [Google Scholar] [CrossRef]

- Hines, P.; Holweg, M.; Rich, N. Learning to evolve: A review of contemporary lean thinking. Int. J. Oper. Prod. Manag. 2004, 24, 994–1011. [Google Scholar] [CrossRef]

- Ohno, T. Toyota Production System: Beyond Large-Scale Production; Productivity Press: Boca Raton, FL, USA, 2019. [Google Scholar]

- Filip, F.; Marascu-Klein, V. The 5S lean method as a tool of industrial management performances. In Proceedings of the IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2015; Volume 95, p. 012127. [Google Scholar] [CrossRef]

- Ansah, R.H.; Sorooshian, S. Effect of lean tools to control external environment risks of construction projects. Sustain. Cities Soc. 2017, 32, 348–356. [Google Scholar] [CrossRef]

- Dudek-Burlikowska, M.; Szewieczek, D. The Poka-Yoke method as an improving quality tool of operations in the process. J. Achiev. Mater. Manuf. Eng. 2009, 36, 95–102. [Google Scholar]

- Bajjou, M.S.; Chafi, A.; En-Nadi, A. The potential effectiveness of lean construction tools in promoting safety on construction sites. Int. J. Eng. Res. Afr. 2017, 33, 179–193. [Google Scholar] [CrossRef]

- Longoni, A.; Pagell, M.; Johnston, D.; Veltri, A. When does lean hurt?—An exploration of lean practices and worker health and safety outcomes. Int. J. Prod. Res. 2013, 51, 3300–3320. [Google Scholar] [CrossRef]

- Xing, W.; Hao, J.L.; Qian, L.; Tam, V.W.; Sikora, K.S. Implementing lean construction techniques and management methods in Chinese projects: A case study in Suzhou, China. J. Clean. Prod. 2021, 286, 124944. [Google Scholar] [CrossRef]

- Brito, M.F.; Ramos, A.L.; Carneiro, P.; Gonçalves, M.A. A continuous improvement assessment tool, considering lean, safety and ergonomics. Int. J. Lean Six Sigma 2020, 11, 879–902. [Google Scholar] [CrossRef]

- Wu, X.; Yuan, H.; Wang, G.; Li, S.; Wu, G. Impacts of lean construction on safety systems: A system dynamics approach. Int. J. Environ. Res. Public Health 2019, 16, 221. [Google Scholar] [CrossRef]

- Simukonda, W.; Emuze, F. A Perception Survey of Lean Management Practices for Safer Off-Site Construction. Buildings 2024, 14, 2860. [Google Scholar] [CrossRef]

- Gao, M.; Wu, X.; Wang, Y.h.; Yin, Y. Study on the mechanism of a lean construction safety planning and control system: An empirical analysis in China. Ain Shams Eng. J. 2023, 14, 101856. [Google Scholar] [CrossRef]

- Chen, J.; Man, F.; Han, S.; Kim, M.; Du, Q.; Chi, H.L. Integrating lean thinking into crane operator training with a digital coach to enhance safety and productivity in virtual environments. Autom. Constr. 2025, 178, 106430. [Google Scholar] [CrossRef]

- Kim, J.; Kim, D.; Oh, S.H.; Kwon, H. Virtual reality for preoperative patient education: Impact on satisfaction, usability, and burnout from the perspective of new nurses. World J. Clin. Cases 2024, 12, 6204. [Google Scholar] [CrossRef] [PubMed]

- Oseni, Z.; Than, H.H.; Kolakowska, E.; Chalmers, L.; Hanboonkunupakarn, B.; McGready, R. Video-based feedback as a method for training rural healthcare workers to manage medical emergencies: A pilot study. BMC Med. Educ. 2017, 17, 149. [Google Scholar] [CrossRef] [PubMed]

- Daniel, J. Sampling Essentials: Practical Guidelines for Making Sampling Choices; Sage Publications: Thousand Oaks, CA, USA, 2011. [Google Scholar]

- VanVoorhis, C.W.; Morgan, B.L. Understanding power and rules of thumb for determining sample sizes. Tutorials Quant. Methods Psychol. 2007, 3, 43–50. [Google Scholar] [CrossRef]

- Kim, T.K.; Park, J.H. More about the basic assumptions of t-test: Normality and sample size. Korean J. Anesthesiol. 2019, 72, 331–335. [Google Scholar] [CrossRef]

- Saurin, T.A.; de Macedo Guimarães, L.B. Ergonomic assessment of suspended scaffolds. Int. J. Ind. Ergon. 2006, 36, 229–237. [Google Scholar] [CrossRef]

- Dewangan, C.P.; Singh, A.K. Ergonomic study and design of the pulpit of a wire rod mill at an integrated steel plant. J. Ind. Eng. 2015, 2015, 412921. [Google Scholar] [CrossRef]

- Yuan, L.; Buvens, M. Ergonomic evaluation of scaffold building. Procedia Manuf. 2015, 3, 4338–4341. [Google Scholar] [CrossRef]

- Kivi, P.; Mattila, M. Analysis and improvement of work postures in the building industry: Application of the computerised OWAS method. Appl. Ergon. 1991, 22, 43–48. [Google Scholar] [CrossRef] [PubMed]

- Hastie, T.J. Generalized additive models. In Statistical Models in S; Routledge: Oxfordshire, UK, 2017; pp. 249–307. [Google Scholar]

- Wood, S.N. mgcv: GAMs and generalized ridge regression for R. R News 2001, 1, 20–25. [Google Scholar]

- Akoglu, H. User’s guide to correlation coefficients. Turk. J. Emerg. Med. 2018, 18, 91–93. [Google Scholar] [CrossRef] [PubMed]

- Singh, J.; Singh, H.; Singh, G. Productivity improvement using lean manufacturing in manufacturing industry of Northern India: A case study. Int. J. Product. Perform. Manag. 2018, 67, 1394–1415. [Google Scholar] [CrossRef]

- Shou, W.; Wang, J.; Wu, P.; Wang, X. Value adding and non-value adding activities in turnaround maintenance process: Classification, validation, and benefits. Prod. Plan. Control 2022, 31, 60–77. [Google Scholar] [CrossRef]

- Abu Aisheh, Y.I.; Tayeh, B.A.; Alaloul, W.S.; Almalki, A. Health and safety improvement in construction projects: A lean construction approach. Int. J. Occup. Saf. Ergon. 2022, 28, 1981–1993. [Google Scholar] [CrossRef]

| Categories | Indicators | Descriptions | Collection or Analysis Methods |

|---|---|---|---|

| Productivity | Processing time | Total time to complete the entire scaffolding installation cycle. | Video recorded |

| Value-adding time | Time spent on activities identified as value-adding in the VSM (tasks that directly transform components toward the completed scaffold). | Video recorded | |

| Waste time | Time spent on activities identified as non-value-adding in the VSM (e.g., rework, unnecessary walking). | Video recorded | |

| Productivity index | Productivity of the installation cycle. | [11] | |

| Number of errors | Instances of incorrect installation, e.g., using scaffolding components that do not meet the dimensional requirements. | Video recorded | |

| Ergonomic safety | Safety risk category | Each activity is assigned a safety risk category based on working postures influencing occupational risk. | OWAS |

| Overall risk index | Overall risk index of the installation cycle is calculated based on the safety risk of each activity. | [17] |

| Categories | Factors |

|---|---|

| Platform-related indicators (P) | P1: the reliability and stability of the platform will influence my learning experience |

| P2: a user-friendly and easy-to-navigate interface will influence my learning experience | |

| P3: an easy-to-navigate case project in VR will influence my learning experience | |

| Before-training session (BT) | BT1: a preparatory VR training session will influence my learning experience |

| BT2: a detailed explanation and demonstration of the waste concept will influence my learning experience | |

| After-training session (AT) | AT1: a comprehensive post-training feedback session will influence my learning experience |

| AT2: clear and easy-to-follow performance indicators will influence my learning experience | |

| Training effects (TE) | TE1: I am satisfied with the integrated VR training platform |

| TE2: the integrated VR training platform can reduce unsafe behavior | |

| TE3: the integrated VR training platform can improve productivity |

| Productivity Indicators | Sig. |

|---|---|

| Processing time | 0.000 * |

| Value-adding time | 0.000 * |

| Waste time | 0.000 * |

| Productivity index | 0.000 * |

| Number of errors | 0.000 * |

| Productivity Indicators (Mean Value) | Non-Lean VR (Group 1) | Integrated VR-Lean (Group 2) | Asymp. Sig. (2-Tailed) |

|---|---|---|---|

| Processing time (mins) | 23.25 | 20.40 | 0.009 * |

| Value-adding time (mins) | 11.90 | 11.51 | 0.340 |

| Waste time (mins) | 11.35 | 8.90 | 0.001 * |

| Productivity index | 4.13 | 4.99 | 0.004 * |

| Number of errors | 22.66 | 18.50 | 0.002 * |

| Safety Indicators | Sig. |

|---|---|

| Safety risk category: C1 | 0.000 * |

| Safety risk category: C2 | 0.000 * |

| Safety risk category: C3 | 0.000 * |

| Safety risk category: C4 | 0.000 * |

| Overall risk index | 0.000 * |

| Safety Indicators | Non-Lean VR (Group 1) | Integrated VR-Lean (Group 2) | Asymp. Sig. (2-Tailed) |

|---|---|---|---|

| Safety risk category: C1 | 100 | 116 | 0.015 * |

| Safety risk category: C2 | 90 | 91 | 0.922 |

| Safety risk category: C3 | 26 | 16 | 0.037 * |

| Safety risk category: C4 | 8 | 4 | 0.207 |

| Overall risk index | 174.11 | 161.61 | 0.030 * |

| Response Indicator | Explanatory Indicator | Sig. | Deviance Explained | |

|---|---|---|---|---|

| TE | P | 0.310 | 0.000 | 32.3% |

| TE | BT | 0.262 | 0.001 | 31.4% |

| TE | AT | 0.046 | 0.048 | 6.2% |

| Indicators | R | Sig. | Indicators | R | Sig. | Indicators | R | Sig. | |||

|---|---|---|---|---|---|---|---|---|---|---|---|

| TE1 | P1 | 0.470 | 0.000 | TE2 | P1 | 0.390 | 0.002 | TE3 | P1 | 0.450 | 0.000 |

| TE1 | P2 | 0.430 | 0.000 | TE2 | P2 | 0.320 | 0.011 | TE3 | P2 | 0.290 | 0.020 |

| TE1 | P3 | 0.380 | 0.002 | TE2 | P3 | 0.230 | 0.071 | TE3 | P3 | 0.310 | 0.013 |

| TE1 | BT1 | −0.091 | 0.476 | TE2 | BT1 | −0.019 | 0.882 | TE3 | BT1 | 0.060 | 0.637 |

| TE1 | BT2 | 0.380 | 0.002 | TE2 | BT2 | 0.340 | 0.006 | TE3 | BT2 | 0.370 | 0.003 |

| TE1 | AT1 | 0.280 | 0.023 | TE2 | AT1 | 0.490 | 0.000 | TE3 | AT1 | 0.390 | 0.002 |

| TE1 | AT2 | 0.073 | 0.566 | TE2 | AT2 | 0.048 | 0.704 | TE3 | AT2 | −0.057 | 0.656 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, R.; Wang, P.; Chen, C. Lean-Enhanced Virtual Reality Training for Productivity and Ergonomic Safety Improvements. Buildings 2025, 15, 4534. https://doi.org/10.3390/buildings15244534

Liu R, Wang P, Chen C. Lean-Enhanced Virtual Reality Training for Productivity and Ergonomic Safety Improvements. Buildings. 2025; 15(24):4534. https://doi.org/10.3390/buildings15244534

Chicago/Turabian StyleLiu, Rongzhen, Peng Wang, and Chunjiang Chen. 2025. "Lean-Enhanced Virtual Reality Training for Productivity and Ergonomic Safety Improvements" Buildings 15, no. 24: 4534. https://doi.org/10.3390/buildings15244534

APA StyleLiu, R., Wang, P., & Chen, C. (2025). Lean-Enhanced Virtual Reality Training for Productivity and Ergonomic Safety Improvements. Buildings, 15(24), 4534. https://doi.org/10.3390/buildings15244534