Performance Evaluation of Field Concretes: Surface Hardener and Algal Growth Effect of Pyrite

Abstract

1. Introduction

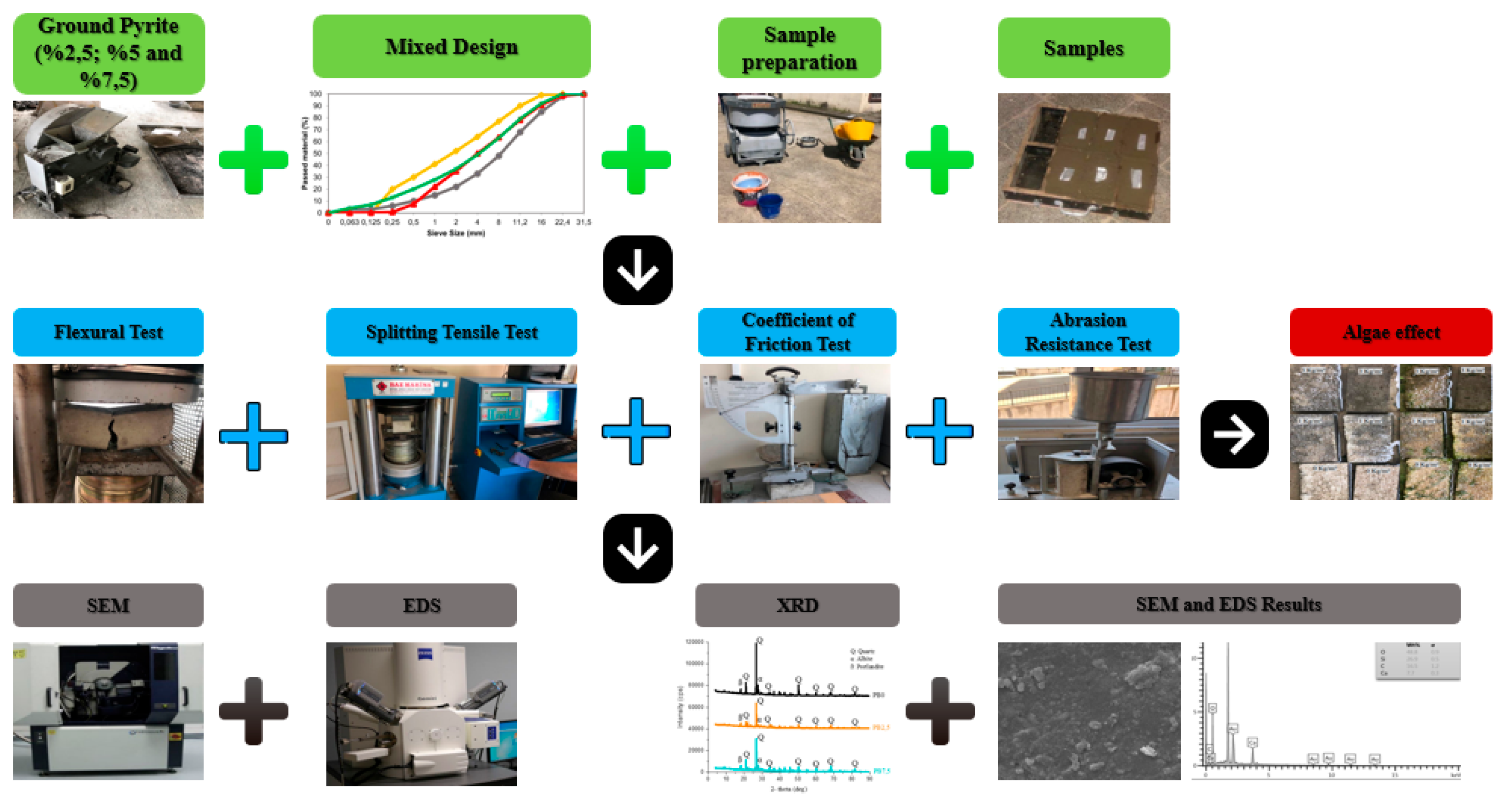

2. Materials and Methods

3. Results and Discussion

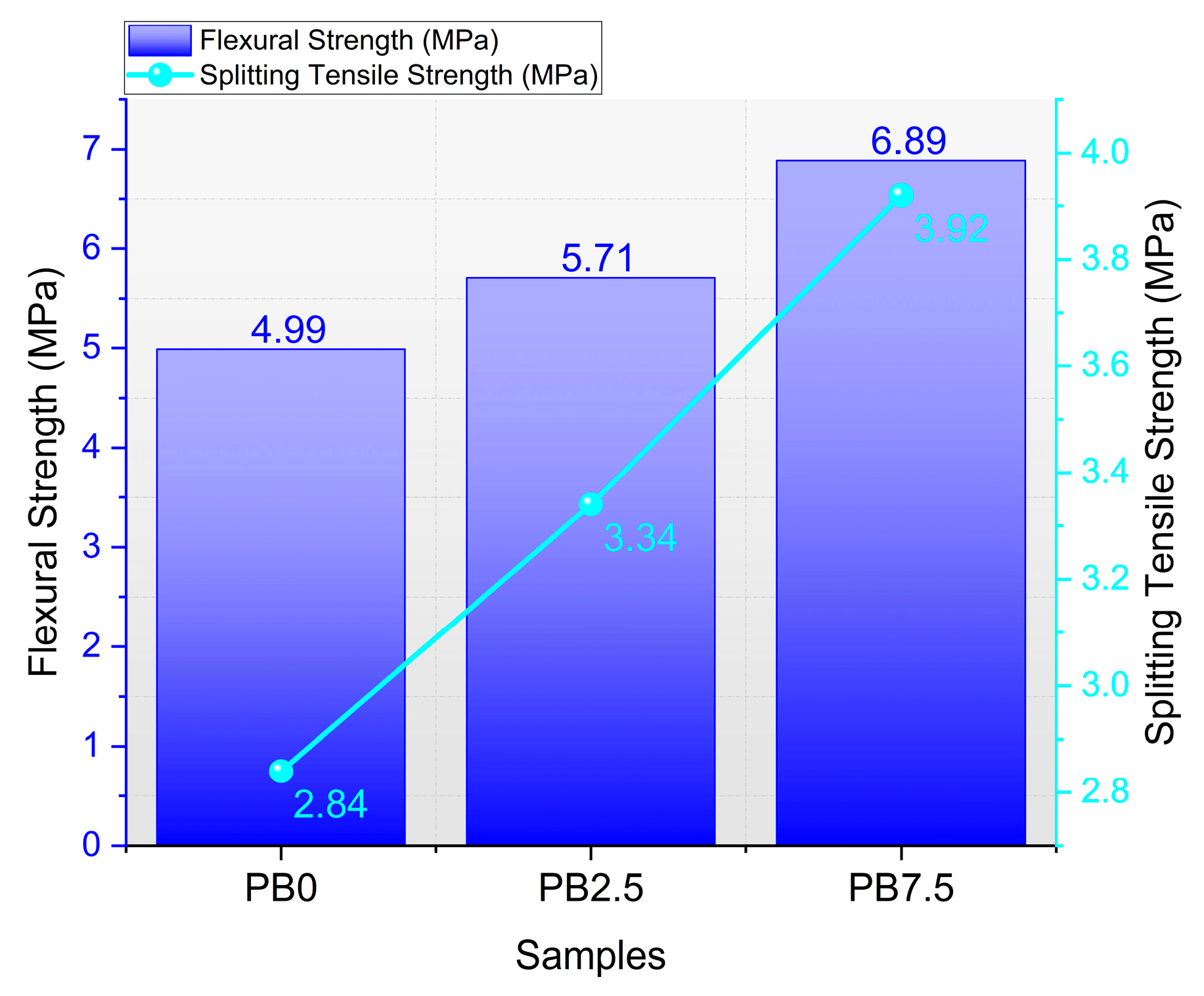

3.1. Mechanical and Physical Properties of Concrete Produced with Pyrite Fine Aggregate

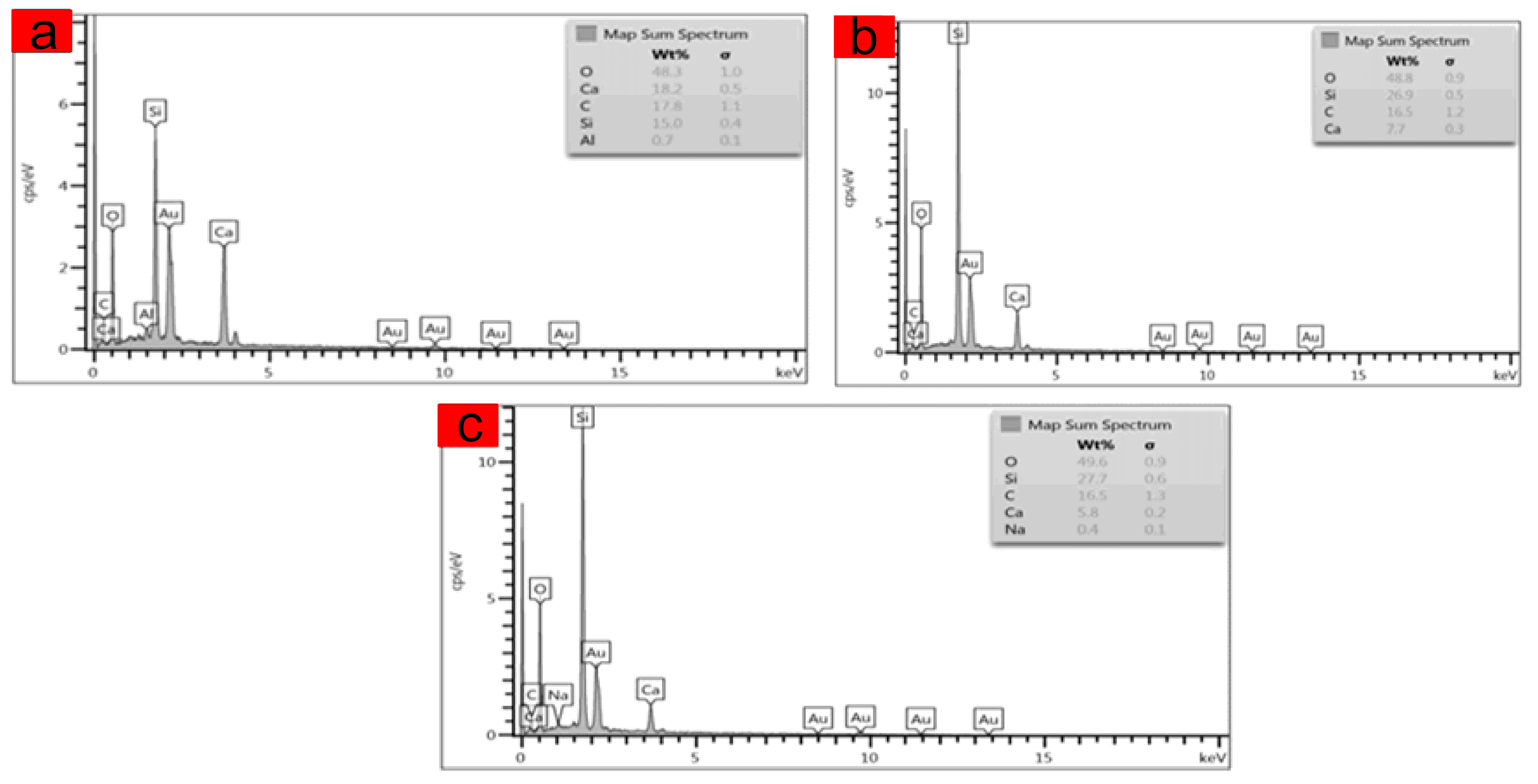

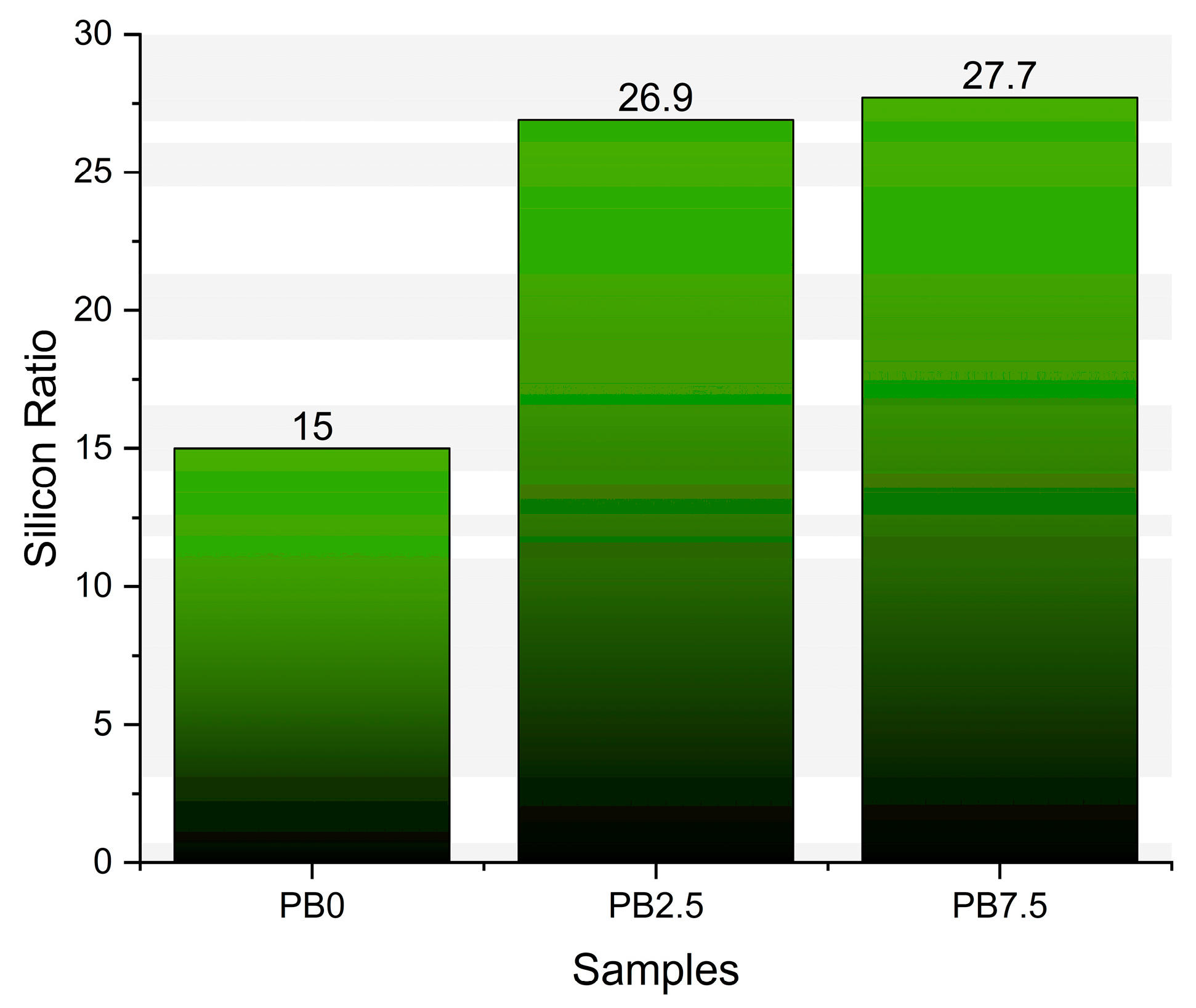

3.2. SEM (Scanning Electron Microscopy) and EDS (Energy-Dispersive Spectroscopy) Analysis

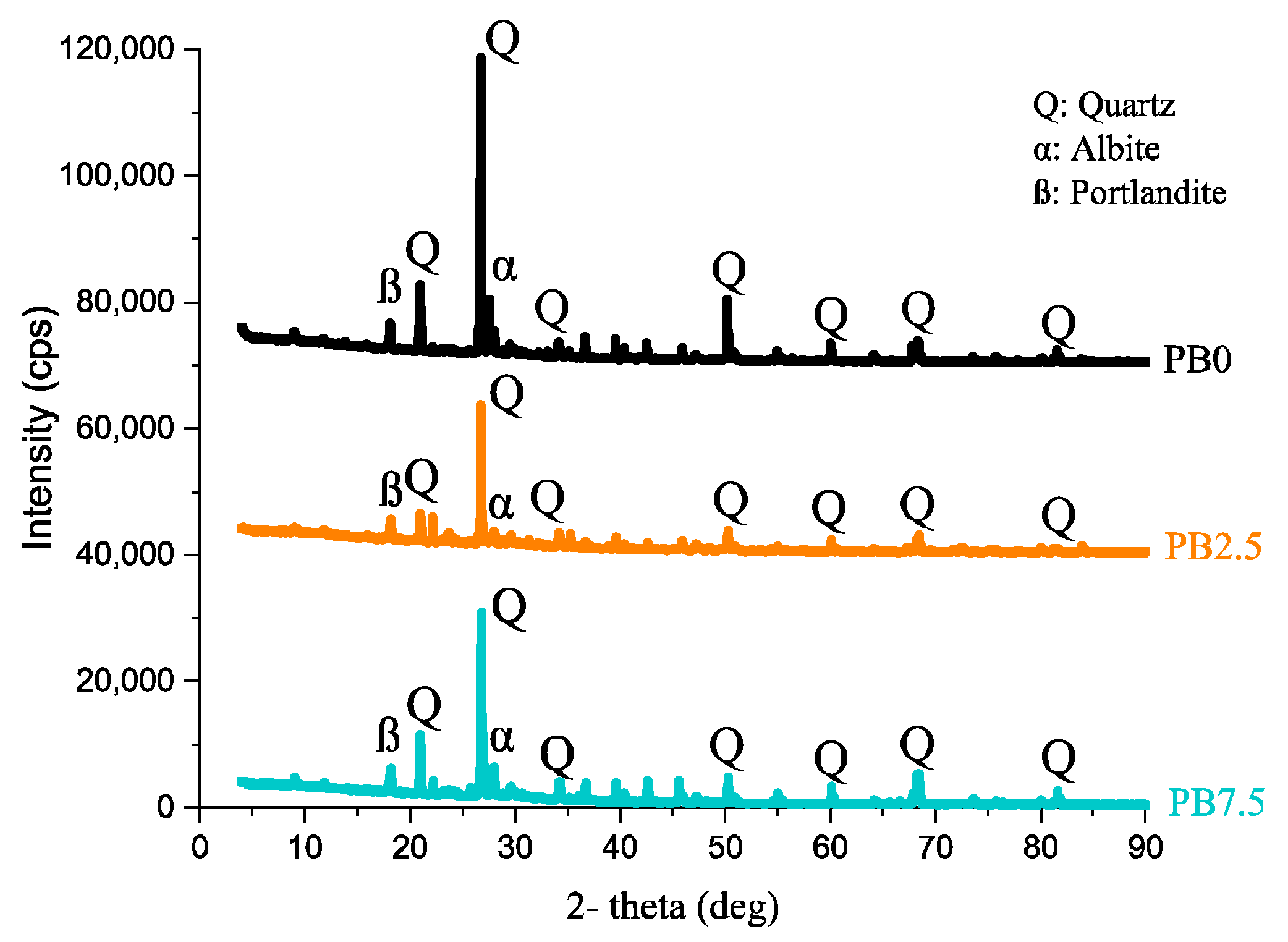

3.3. XRD Analysis

4. Conclusions

- -

- When pyrite was used as fine aggregate in the concrete mix, an increase in flexural strength and tensile strength at splitting was observed with increasing pyrite content.

- -

- The use of pyrite on the concrete surface resulted in an increase in the coefficient of friction and a decrease in wear values.

- -

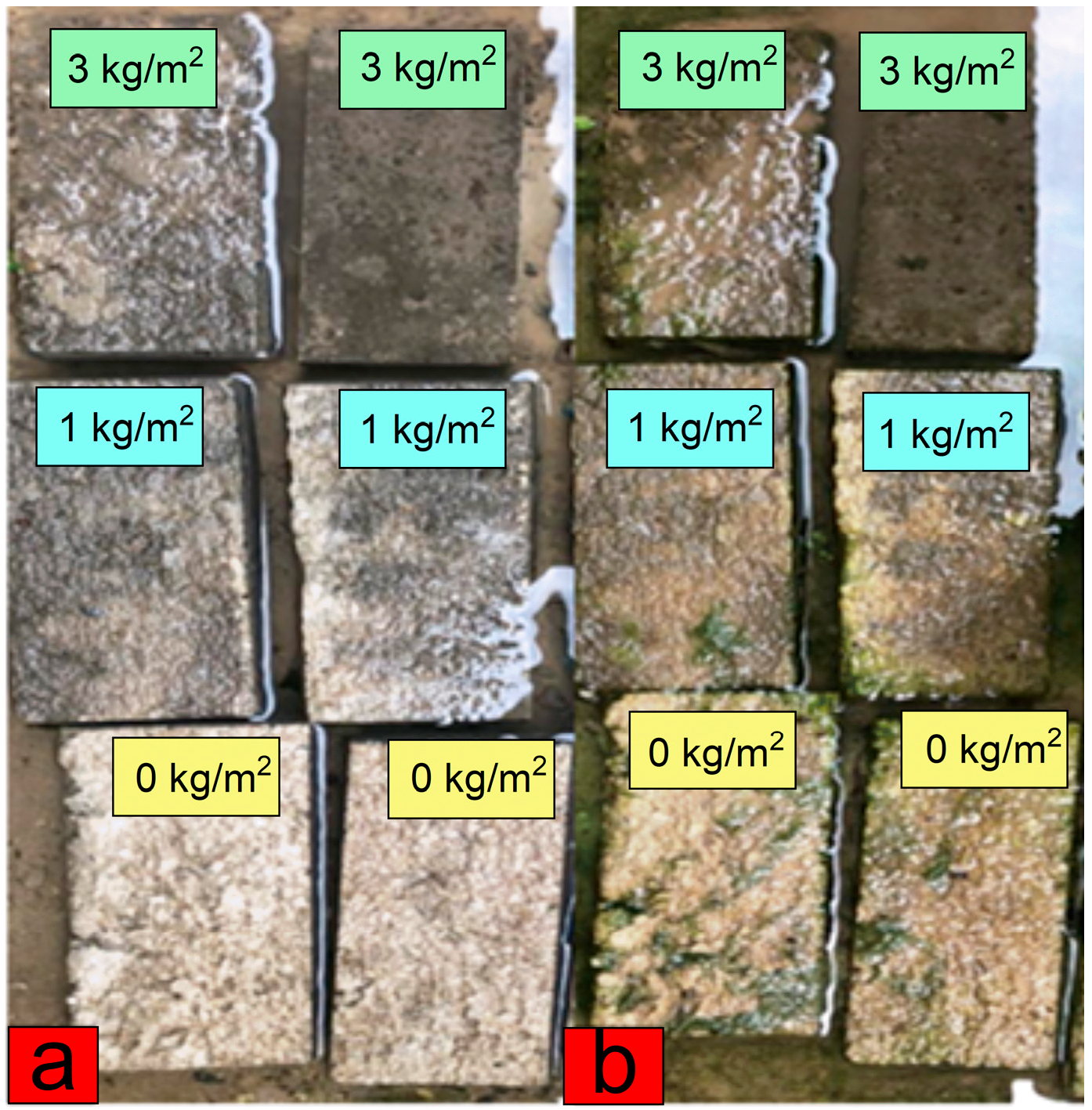

- Under natural water, pyrite inhibited changes in the surface, while when exposed to polluted water, it reduced and delayed the process of algae growth.

- -

- The findings revealed that pyrite aggregate positively contributes to the mechanical and surface properties of concrete.

5. Limitations and Future Recommendations

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Stępczak, M.; Kazimierczak, M.; Roszak, M.; Kurzawa, A.; Jamroziak, K. Microstructural and Impact Resistance Optimization of Concrete Composites with Waste-Based Aggregate Substitutions. Polymers 2025, 17, 2574. [Google Scholar] [CrossRef]

- Fakharian, P.; Bazrgary, R.; Ghorbani, A.; Tavakoli, D.; Nouri, Y. Compressive Strength Prediction of Green Concrete with Recycled Glass-Fiber-Reinforced Polymers Using a Machine Learning Approach. Polymers 2025, 17, 2731. [Google Scholar] [CrossRef]

- Ghorbankhani, A.H.; Nili, M. Experimental and numerical assessment of thermal properties of self-compacting mass concrete at early ages. Eur. J. Environ. Civ. Eng. 2022, 26, 8194–8211. [Google Scholar] [CrossRef]

- Wang, Y.; Shen, Y.; Yi, M.; Li, Q. Research on the expansion properties of concrete with waste granite aggregate during a high temperature process. J. Build. Eng. 2025, 113, 114199. [Google Scholar] [CrossRef]

- Huang, Y.; Yu, R.; Sun, J.; Liu, Y.; Luo, S.; Li, S. Optimization of All-Desert Sand Concrete Aggregate Based on Dinger–Funk Equation. Buildings 2024, 14, 2332. [Google Scholar] [CrossRef]

- Chen, R.; Jiao, Y.; Xiao, M.; Yang, H.; Wang, C. Effect of Composition Characteristics on Mechanical Properties of UHPMC Based on Response Surface Methodology and Acoustic Emission Monitoring. Materials 2024, 17, 2714. [Google Scholar] [CrossRef]

- Yao, D.; Li, J.; Xiao, H.; Yang, W.; Liu, R. Research on the surface abrasion resistance performance of basalt fiber reinforced concrete. J. Build. Eng. 2024, 88, 109125. [Google Scholar] [CrossRef]

- Ting, M.Z.Y.; Wong, K.S.; Rahman, M.E.; Meheron, S.J. Deterioration of marine concrete exposed to wetting-drying action. J. Clean. Prod. 2021, 278, 123383. [Google Scholar] [CrossRef]

- Thaulow, N.; Sahu, S. Mechanism of concrete deterioration due to salt crystallization. Mater. Charact. 2004, 53, 123–127. [Google Scholar] [CrossRef]

- García, A.; Castro-Fresno, D.; Polanco, J.A.; Thomas, C. Abrasive wear evolution in concrete pavements. Road Mater. Pavement Des. 2012, 13, 534–548. [Google Scholar] [CrossRef]

- Khan, U.R.; Ali, A.; Raheem, A.; Naseer, A.; Wright, K.; Bhatti, J. Injury hazard assessment in schools: Findings from a pilot study in Karachi, Pakistan. Injury 2023, 54, 110666. [Google Scholar] [CrossRef]

- Nowicka-Krawczyk, P.; Komar, M.; Gutarowska, B. Towards understanding the link between the deterioration of building materials and the nature of aerophytic green algae. Sci. Total Environ. 2022, 802, 149856. [Google Scholar] [CrossRef]

- Richhariya, V.; Tripathy, A.; Carvalho, O.; Nine, J.; Losic, D.; Silva, F.S. Unravelling the physics and mechanisms behind slips and falls on icy surfaces: A comprehensive review and nature-inspired solutions. Mater. Des. 2023, 234, 112335. [Google Scholar] [CrossRef]

- Eklund, J.A. Biological Growth on Masonry: Identification & Understanding; Historic Scotland: Edinburgh, UK, 2013. [Google Scholar]

- Waluś, K.J.; Łukasz, W.; Wieczorek, B.; Krawiec, P. Slip risk analysis on the surface of floors in public utility buildings. J. Build. Eng. 2022, 54, 104643. [Google Scholar] [CrossRef]

- Marcelino, A.P.; Calixto, J.M.; Gumieri, A.G.; Ferreira, M.C.; Caldeira, C.L.; Silva, M.V.; Costa, A.L. Evaluation of pyrite and pyrrhotite in concretes. Rev. Ibracon Estrut. E Mater. 2016, 9, 484–493. [Google Scholar] [CrossRef]

- Hobbs, D.W.; Taylor, M.G. Nature of the thaumasite sulfate attack mechanism in field concrete. Cem. Concr. Res. 2000, 30, 529–533. [Google Scholar] [CrossRef]

- Chu, I.; Lee, Y.; Amin, M.N.; Jang, B.S.; Kim, J.K. Application of a thermal stress device for the prediction of stresses due to hydration heat in mass concrete structure. Constr. Build. Mater. 2013, 45, 192–198. [Google Scholar] [CrossRef]

- Li, Z.; Hao, G.; Du, H.; Fu, T.; Liu, D.; Huang, Y.; Ji, Y. Composite Fiber Wrapping Techniques for Enhanced Concrete Mechanics. Polymers 2024, 16, 2820. [Google Scholar] [CrossRef] [PubMed]

- Ustabas, I.; Deşik, F. Transition coefficients between compressive strengths of samples with different shape and size in mass concrete and use of weight maturity method in dam construction. Struct. Concr. 2021, 22, E696–E709. [Google Scholar] [CrossRef]

- Li, J.; Yu, Z.; Wu, J.; Ding, Q.; Xu, W.; Huang, S. The application of heat-shrinkable fibers and internal curing aggregates in the field of crack resistance of high-strength marine structural mass concrete: A review and prospects. Polymers 2023, 15, 3884. [Google Scholar] [CrossRef]

- Pang, C.; Mao, Y.; Zhang, C.; Song, X. Effect and mechanism of phase change lightweight aggregate on temperature control and crack resistance in high-strength mass concrete. J. Build. Eng. 2024, 97, 110498. [Google Scholar] [CrossRef]

- Ha, J.; Jung, Y.S.; Cho, Y. Thermal crack control in mass concrete structure using an automated curing system. Autom. Constr. 2014, 45, 16–24. [Google Scholar] [CrossRef]

- Rohini, I.; Padmapriya, R. Properties of bacterial copper slag concrete. Buildings 2023, 13, 290. [Google Scholar] [CrossRef]

- Seo, T.S.; Kim, S.S.; Lim, C.K. Experimental study on hydration heat control of mass concrete by vertical pipe cooling method. J. Asian Archit. Build. Eng. 2015, 14, 657–662. [Google Scholar] [CrossRef]

- Zhang, L.; Ruan, S.; Qian, K.; Gu, X.; Qian, X. Will wind always boost early--age shrinkage of cement paste? J. Am. Ceram. Soc. 2022, 105, 2832–2846. [Google Scholar] [CrossRef]

- Dobrovolski, M.E.; Munhoz, G.S.; Pereira, E.; Medeiros-Junior, R.A. Effect of crystalline admixture and polypropylene microfiber on the internal sulfate attack in Portland cement composites due to pyrite oxidation. Constr. Build. Mater. 2021, 308, 125018. [Google Scholar] [CrossRef]

- Dos Santos, E.C.; de Mendonça Silva, J.C.; Duarte, H.A. Pyrite oxidation mechanism by oxygen in aqueous medium. J. Phys. Chem. C 2016, 120, 2760–2768. [Google Scholar] [CrossRef]

- Ferreira, L.P.; Müller, T.G.; Cargnin, M.; De Oliveira, C.M.; Peterson, M. Valorization of waste from coal mining pyrite beneficiation. J. Environ. Chem. Eng. 2021, 9, 105759. [Google Scholar] [CrossRef]

- Mârșolea, A.C.; Orbeci, C.; Rusen, E.; Stanescu, P.O.; Brincoveanu, O.; Irodia, R.; Pîrvu, C.; Dinescu, A.; Bobirica, C.; Mocanu, A. Design of polyurethane composites obtained from industrial plastic wastes, pyrite and red mud. Constr. Build. Mater. 2023, 405, 133319. [Google Scholar] [CrossRef]

- Alum, A.; Rashid, A.; Mobasher, B.; Abbaszadegan, M. Cement-based biocide coatings for controlling algal growth in water distribution canals. Cem. Concr. Compos. 2008, 30, 839–847. [Google Scholar] [CrossRef]

- Song, P.; Zhou, Y.; Guan, Q.; Wang, J.; Xia, J.; Huang, J.; Zhang, P. Prevention and control of chlorella for C30 concrete surface with coral aggregate, Journal of Wuhan University of Technology-Mater. Sci. Ed. 2022, 37, 628–635. [Google Scholar] [CrossRef]

- Martinez, T.; Bertron, A.; Escadeillas, G.; Ringot, E. Algal growth inhibition on cement mortar: Efficiency of water repellent and photocatalytic treatments under UV/VIS illumination. Int. Biodeterior. Biodegrad. 2014, 89, 115–125. [Google Scholar] [CrossRef]

- Jayakumar, S.; Saravanane, R. Biodeterioration of coastal concrete structures by marine green algae. Int. J. Civ. Eng. 2010, 8, 352–361. [Google Scholar]

- Ustabas, I.; Erdogdu, S.; Akyuz, C.; Kurt, Z.; Cakmak, T. Heavy aggregate and different admixtures effect on pavings: Pyrite, corundum and water-retaining polymer. Rev. La Construcción 2024, 23, 31–46. [Google Scholar] [CrossRef]

- Ustabas, I.; Erdogdu, S.; Ucok, M.; Kurt, Z.; Cakmak, T. Heavy aggregate and different admixtures effect on parquets: Chrome, magnetite, and quartz-based surface hardener. Rev. La Construcción 2024, 23, 230–245. [Google Scholar] [CrossRef]

- Padilha, F.; Lemos, G.V.B.; Silva, C.V.D. Effects of surface hardeners on the performance of concrete floors prepared with different mixture proportions. REM-Int. Eng. J. 2023, 76, 147–158. [Google Scholar] [CrossRef]

- EN, TS, 1097–6; Tests for Mechanical and Physical Properties of Aggregates-Part 6: Determination of Particle Density and Water Absorption. Turkish Standards Institute: Ankara, Turkey, 2022.

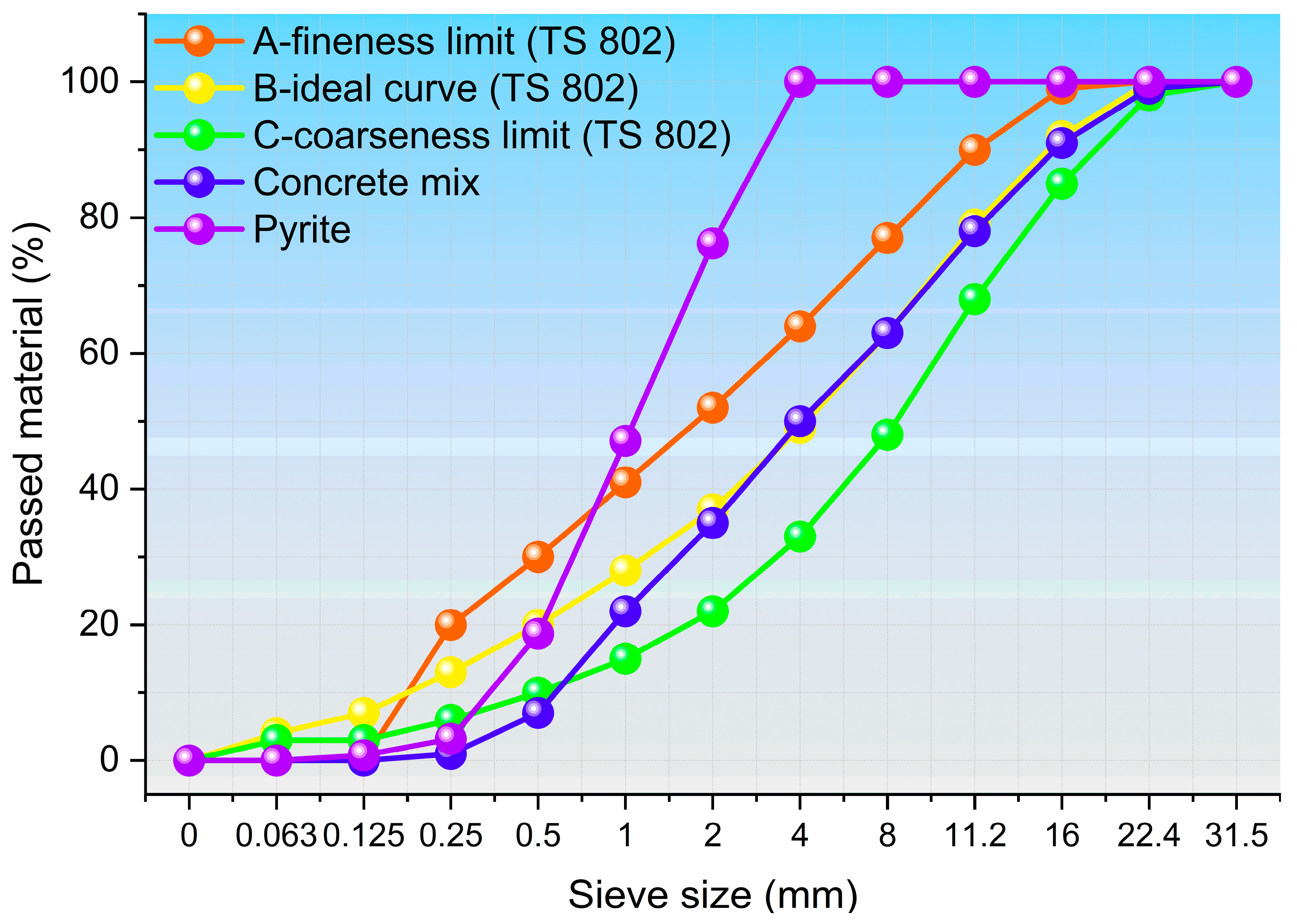

- EN, TS, 802; Design Concrete Mixes. Turkish Standards Institute: Ankara, Turkey, 2016.

- EN, TS, 12390–12392; Testing Hardened Concrete-Part 2: Making and Curing Specimens for Strength Tests. Turkish Standards Institute: Ankara, Turkey, 2019.

- EN, TS, 12390–12395; Testing Hardened Concrete-Part 5: Flexural Strength of Test Specimens. Turkish Standards Institute: Ankara, Turkey, 2019.

- EN, TS, 12390–12396; Testing Hardened Concrete-Part 6: Tensile Splitting Strength for Test Specimens. Turkish Standards Institute: Ankara, Turkey, 2010.

- EN, TS, 1341; Slabs of Natural Stone for External Paving–Requirements and Test Methods. Turkish Standards Institute: Ankara, Turkey, 2014.

- EN, TS, 1342; Setts of Natural Stone for External Paving-Requirements and Test Methods. Turkish Standards Institute: Ankara, Turkey, 2014.

- EN, TS, 1097–1098; Tests for Mechanical and Physical Properties of Aggregates-Part 8: Determination of the Polished Stone Value. Turkish Standards Institute: Ankara, Turkey, 2010.

- EN, TS, 1338; Concrete Paving Blocks-Requirements and Test Methods. Turkish Standards Institute: Ankara, Turkey, 2005.

- TS EN 1008; Mixing Water for Concrete-Spesifications for Sampling, Testing, and Assessing the Suitability of Water, Including Water Recovered from Processes in the Concrete Industry, as Mixing Water for Concrete. Turkish Standards Institution: Ankara, Turkey.

- Espindola-Flores, A.C.; Luna-Jimenez, M.A.; Onofre-Bustamante, E.; Morales-Cepeda, A.B. Study of the Mechanical and Electrochemical Performance of Structural Concrete Incorporating Recycled Polyethylene Terephthalate as a Partial Fine Aggregate Replacement. Recycling 2024, 9, 51. [Google Scholar] [CrossRef]

- Yuan, H.; Ge, Z.; Sun, R.; Xu, X.; Lu, Y.; Ling, Y.; Zhang, H. Drying shrinkage, durability and microstructure of foamed concrete containing high volume lime mud-fly ash. Constr. Build. Mater. 2022, 327, 126990. [Google Scholar] [CrossRef]

- Luo, B.; Su, Y.; Hu, X.; Chen, Z.; Chen, Y.; Ding, X. Strength behavior and microscopic mechanisms of geopolymer-stabilized waste clays considering clay mineralogy. J. Clean. Prod. 2025, 530, 146877. [Google Scholar] [CrossRef]

- Wei, C.; Zhang, Y.; Guo, J.; Han, B.; Yang, X.; Yuan, J. Effects of silica nanoparticles on growth and photosynthetic pigment contents of Scenedesmus obliquus. J. Environ. Sci. 2010, 22, 155–160. [Google Scholar] [CrossRef] [PubMed]

- Yavasi, H. The Determination of the Mechanical and Radiation Absorption Properties of Mortars Supplemented with Granulated Pyrite, Chromium and Magnetic. Master’s Thesis, Recep Tayyip Erdogan University, Rize, Turkey, 2018. [Google Scholar]

- Tuntachon, S.; Kamwilaisak, K.; Somdee, T.; Mongkoltanaruk, W.; Sata, V.; Boonserm, K.; Chindaprasirt, P. Resistance to algae and fungi formation of high calcium fly ash geopolymer paste containing TiO2. J. Build. Eng. 2019, 25, 100817. [Google Scholar] [CrossRef]

- Kang, S.; Cho, S.; Jeong, D.; Kim, U.; Kim, J.; Lee, S.; Jung, Y. The Impact of Calcium Depletion on Proliferation of Chlorella sorokiniana Strain DSCG150. J. Microbiol. Biotechnol. 2024, 34, 1425. [Google Scholar] [CrossRef]

- Altomare, A.; Corriero, N.; Cuocci, C.; Falcicchio, A.; Moliterni, A.; Rizzi, R. QUALX2.0: A qualitative phase analysis software using the freely available database POW_COD. J. Appl. Cryst. 2015, 48, 598–603. [Google Scholar] [CrossRef]

- Zhu, L.; Zheng, M.; Zhang, W.; Jing, H.; Ou, Z. Multicomponent cementitious materials optimization, characteristics investigation and reinforcement mechanism analysis of high-performance concrete with full aeolian sand. J. Build. Eng. 2024, 84, 108562. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, B.; Liu, N.; Jiang, Z. Utilization of waste phosphogypsum in high-strength geopolymer concrete: Performance optimization and mechanistic exploration. J. Build. Eng. 2024, 98, 111253. [Google Scholar] [CrossRef]

| Sample | Cement | Water | Admixture | Sand (0/4) | Crushed Sand (0/4) | Coarse Aggregate (4/16) | Coarse Aggregate (16/32) | Ground Pyrite (0/4) | Sum |

|---|---|---|---|---|---|---|---|---|---|

| 0% Pyrite Concrete PB0 | 380 | 194 | 4 | 364 | 624 | 504 | 222 | 0 | 2292 |

| 2.5% Pyrite Concrete PB2.5 | 380 | 194 | 4 | 354.9 | 608.4 | 504 | 222 | 24.7 | 2292 |

| 7.5% Pyrite Concrete PB7.5 | 380 | 194 | 4 | 336.7 | 577.2 | 504 | 222 | 74.1 | 2292 |

| Sample Code | Flexural Strength (N/mm2) | Splitting Tensile Strength (N/mm2) |

|---|---|---|

| PB0 | 4.99 | 2.84 |

| PB2.5 | 5.71 | 3.34 |

| PB7.5 | 6.89 | 3.92 |

| Sample Code | Friction | Abrasion Measures (mm) | Weight Losses % |

|---|---|---|---|

| PB0 | 0.793 | 25 | 0.04 |

| PB2.5 | 0.976 | 24 | 0.07 |

| PB7.5 | 1.008 | 23 | 0.05 |

| Sample Code | Friction | Abrasion Length (mm) | Weight Losses (%) | Flexural Strength (N/mm2) | Flexural Load (kN) |

|---|---|---|---|---|---|

| 0 kg/m2 | 0.694 | 28 | 0.18 | 0.51 | 8.10 |

| 1 kg/m2 | 0.822 | 25 | 0.11 | 0.57 | 9.25 |

| 3 kg/m2 | 0.929 | 24 | 0.05 | 0.66 | 10.63 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kurt, Z.; Ustabas, I.; Aydin, M.E.; Oksuz, K.M.; Ustabas, C.I. Performance Evaluation of Field Concretes: Surface Hardener and Algal Growth Effect of Pyrite. Buildings 2025, 15, 4494. https://doi.org/10.3390/buildings15244494

Kurt Z, Ustabas I, Aydin ME, Oksuz KM, Ustabas CI. Performance Evaluation of Field Concretes: Surface Hardener and Algal Growth Effect of Pyrite. Buildings. 2025; 15(24):4494. https://doi.org/10.3390/buildings15244494

Chicago/Turabian StyleKurt, Zafer, Ilker Ustabas, Muhammet Emin Aydin, Kenan Mert Oksuz, and Ceren Ilknur Ustabas. 2025. "Performance Evaluation of Field Concretes: Surface Hardener and Algal Growth Effect of Pyrite" Buildings 15, no. 24: 4494. https://doi.org/10.3390/buildings15244494

APA StyleKurt, Z., Ustabas, I., Aydin, M. E., Oksuz, K. M., & Ustabas, C. I. (2025). Performance Evaluation of Field Concretes: Surface Hardener and Algal Growth Effect of Pyrite. Buildings, 15(24), 4494. https://doi.org/10.3390/buildings15244494