Mechanical Properties of Self-Healing Concrete with Dawson Microcapsule

Abstract

1. Introduction

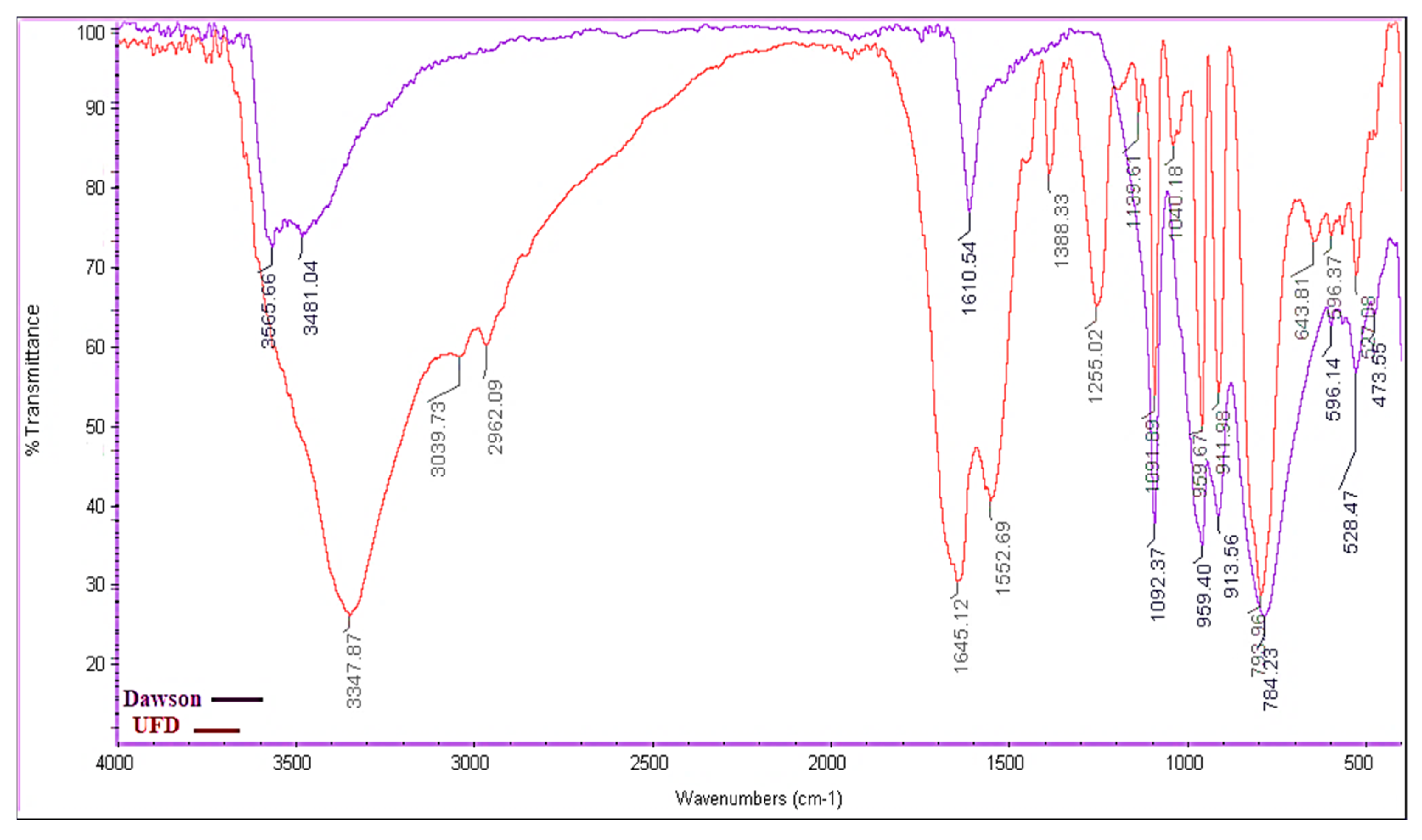

2. Experimental Procedure

2.1. Materials

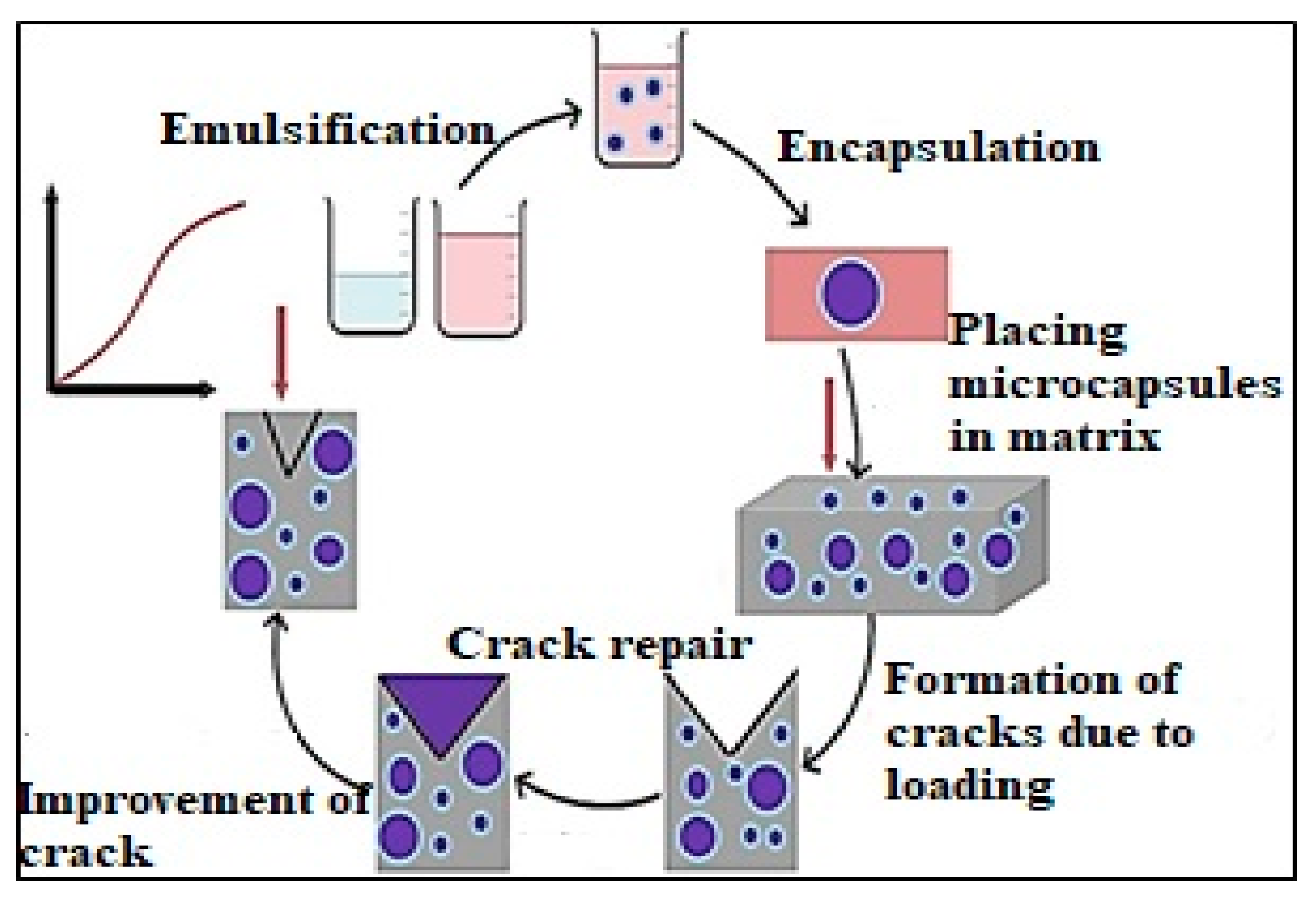

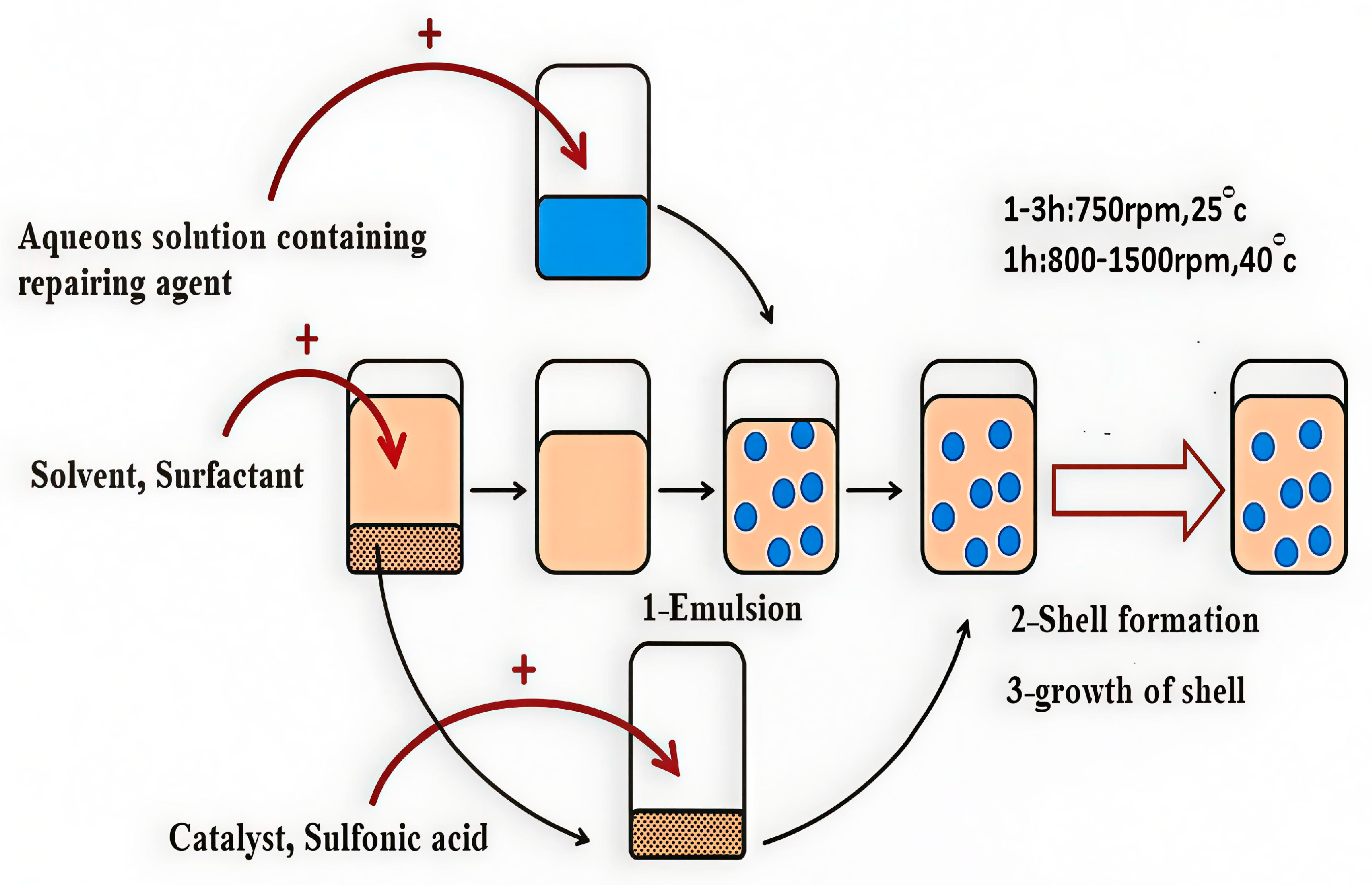

2.2. Microcapsules Preparation

2.3. Concrete Preparation

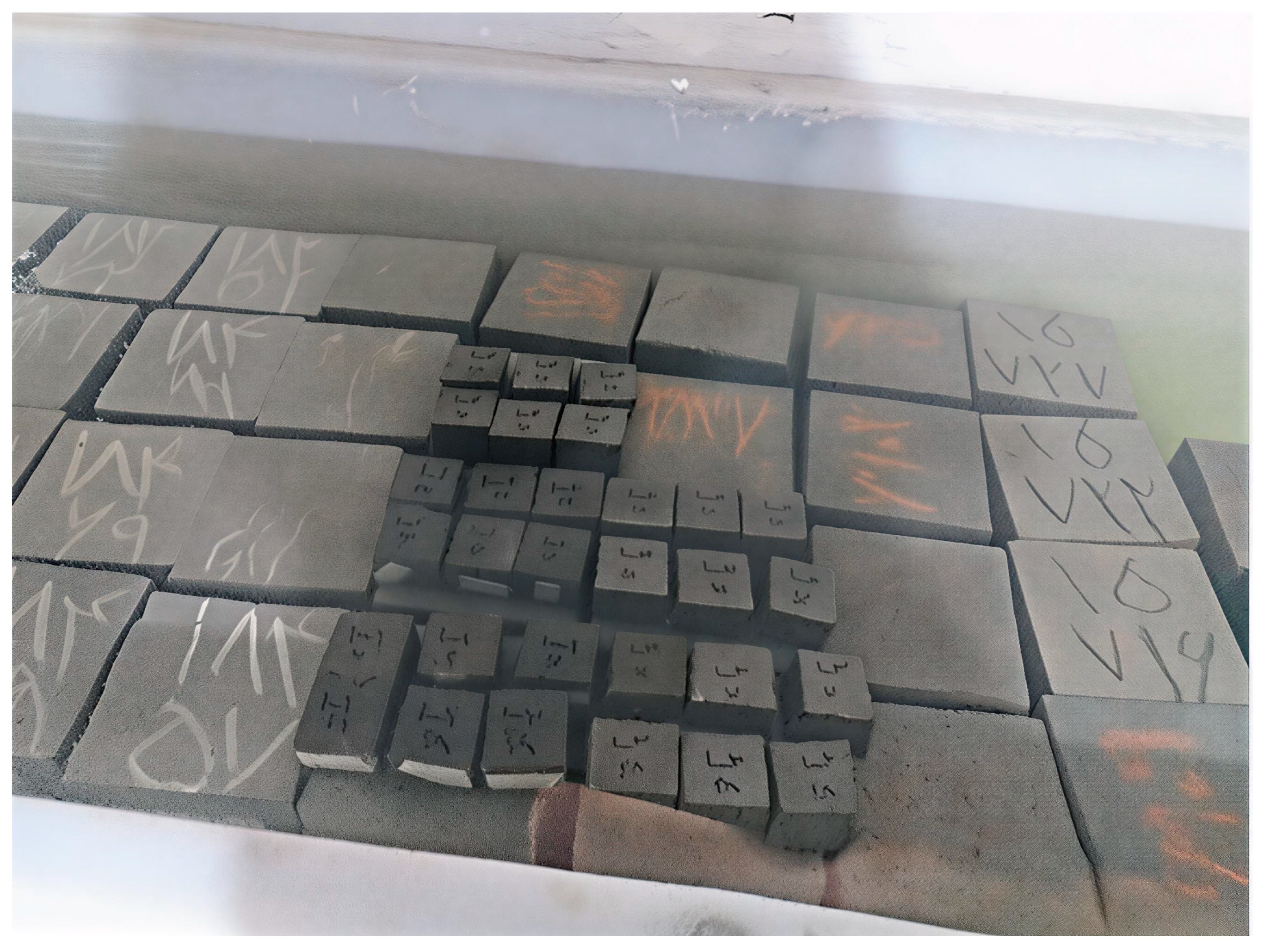

Reactive Powder Concrete Specimens

2.4. Assessment of Mechanical Properties and Post-Damage Strength Recovery

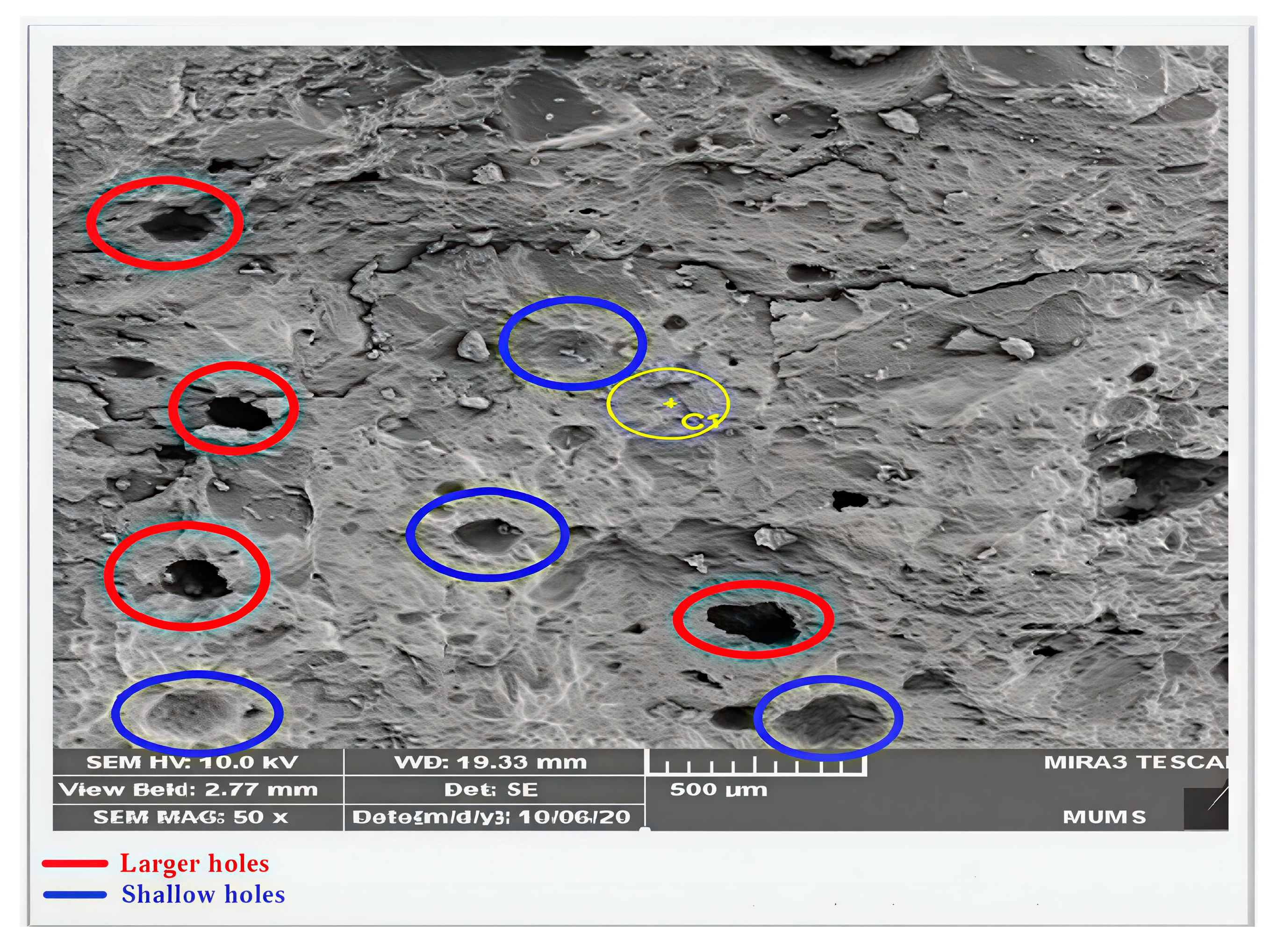

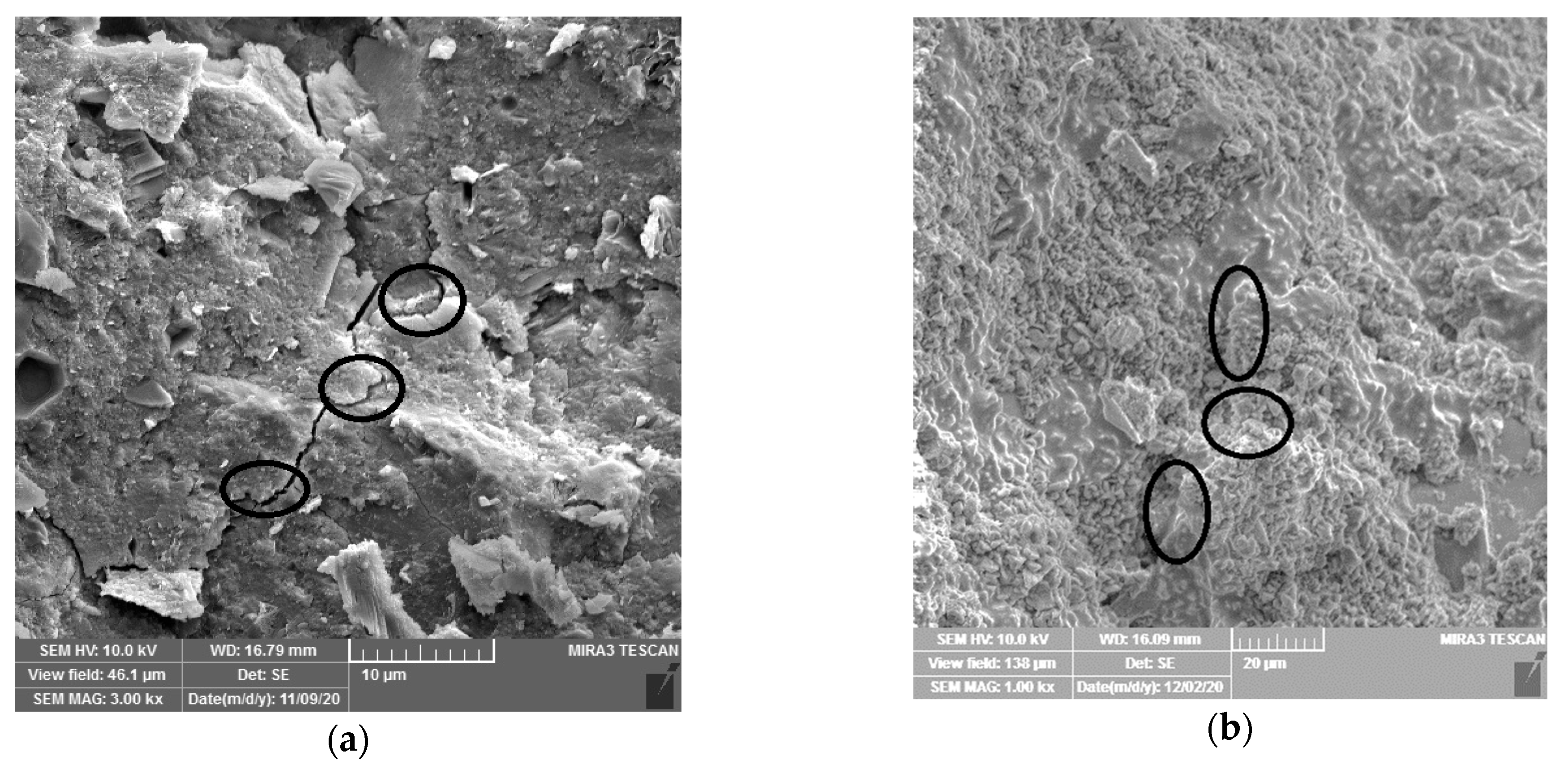

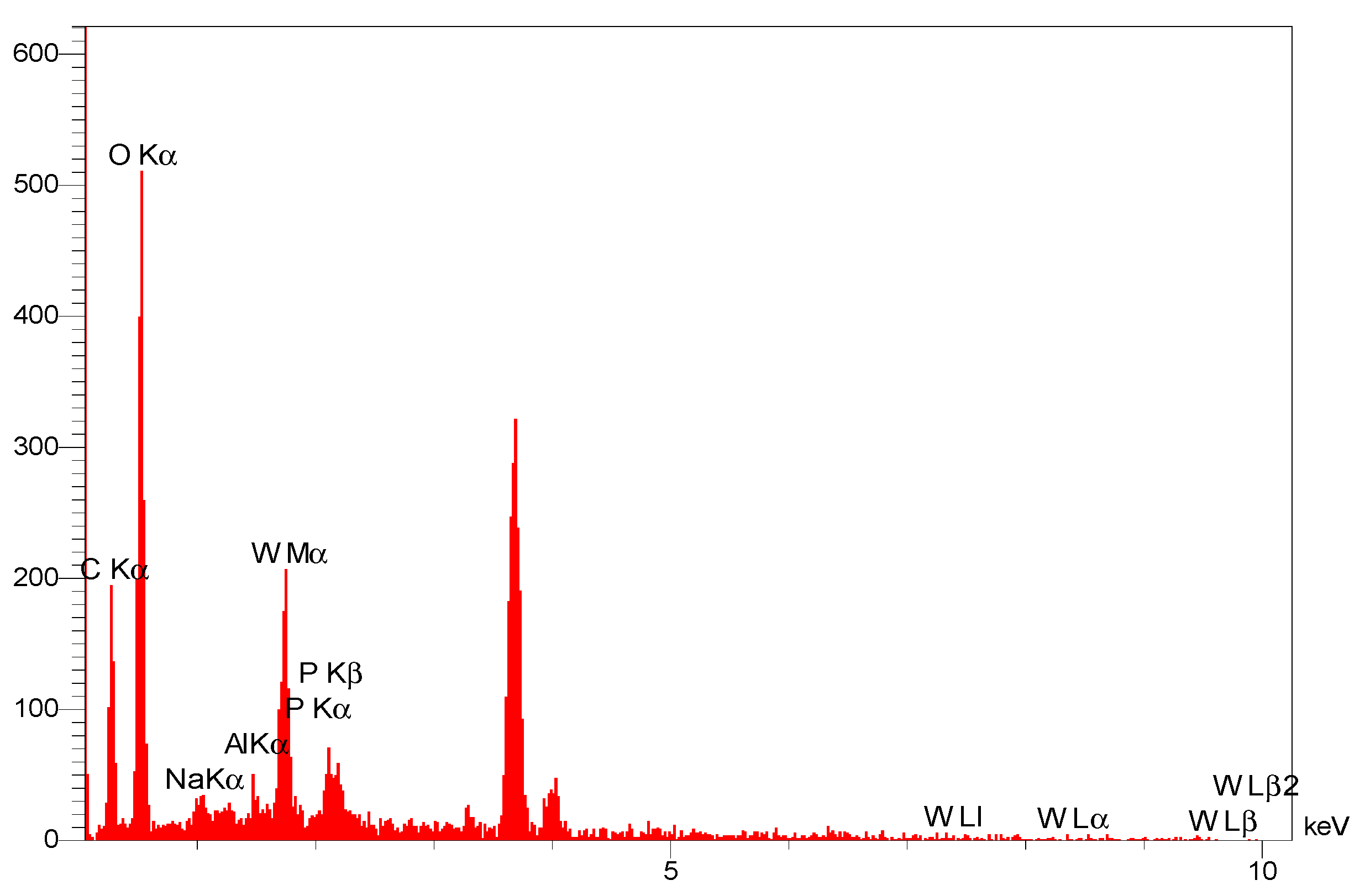

3. Morphology and Composition of Microcapsules

4. Mechanical Properties of Microcapsule-Based Self-Healing Concrete

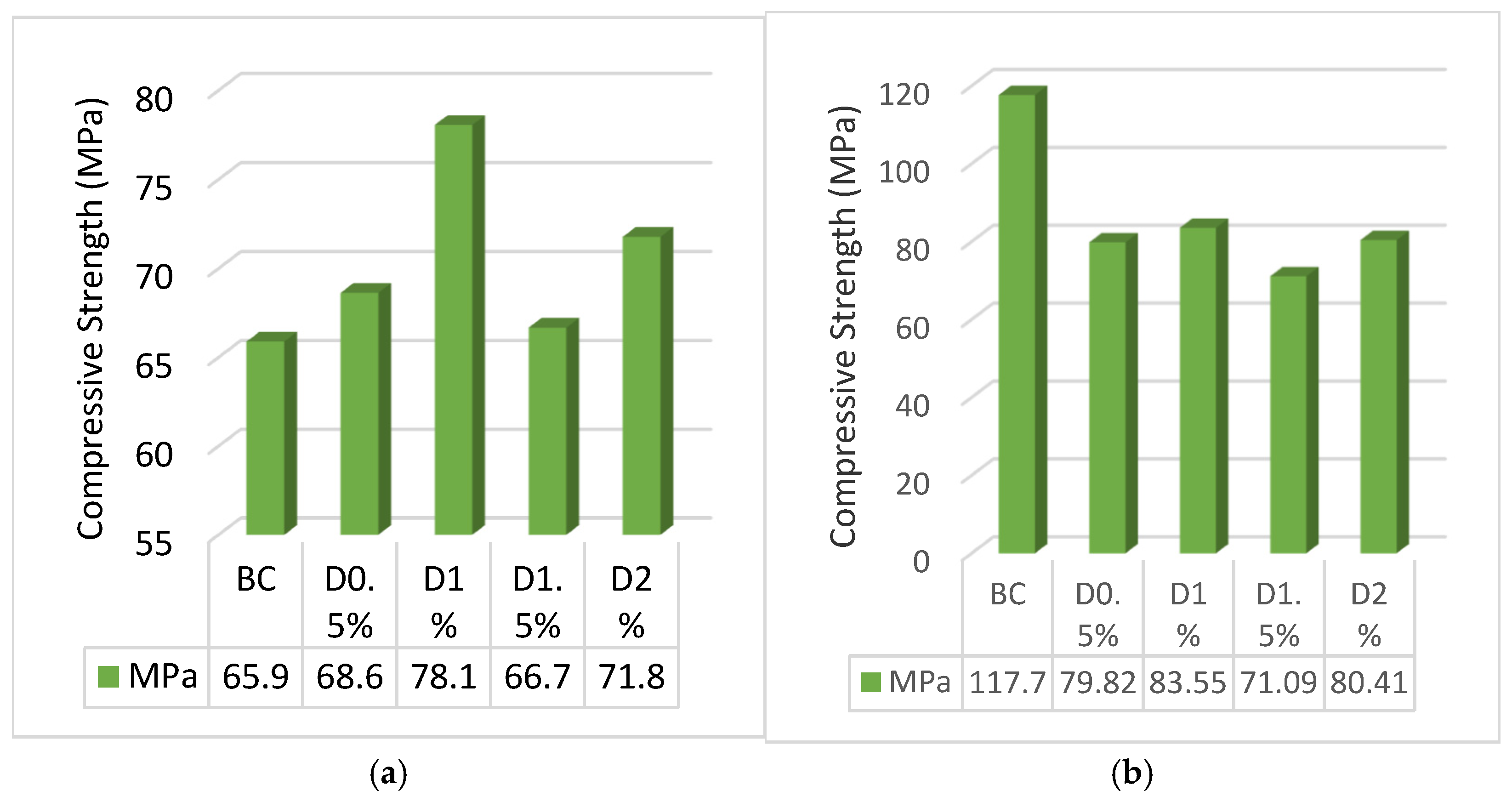

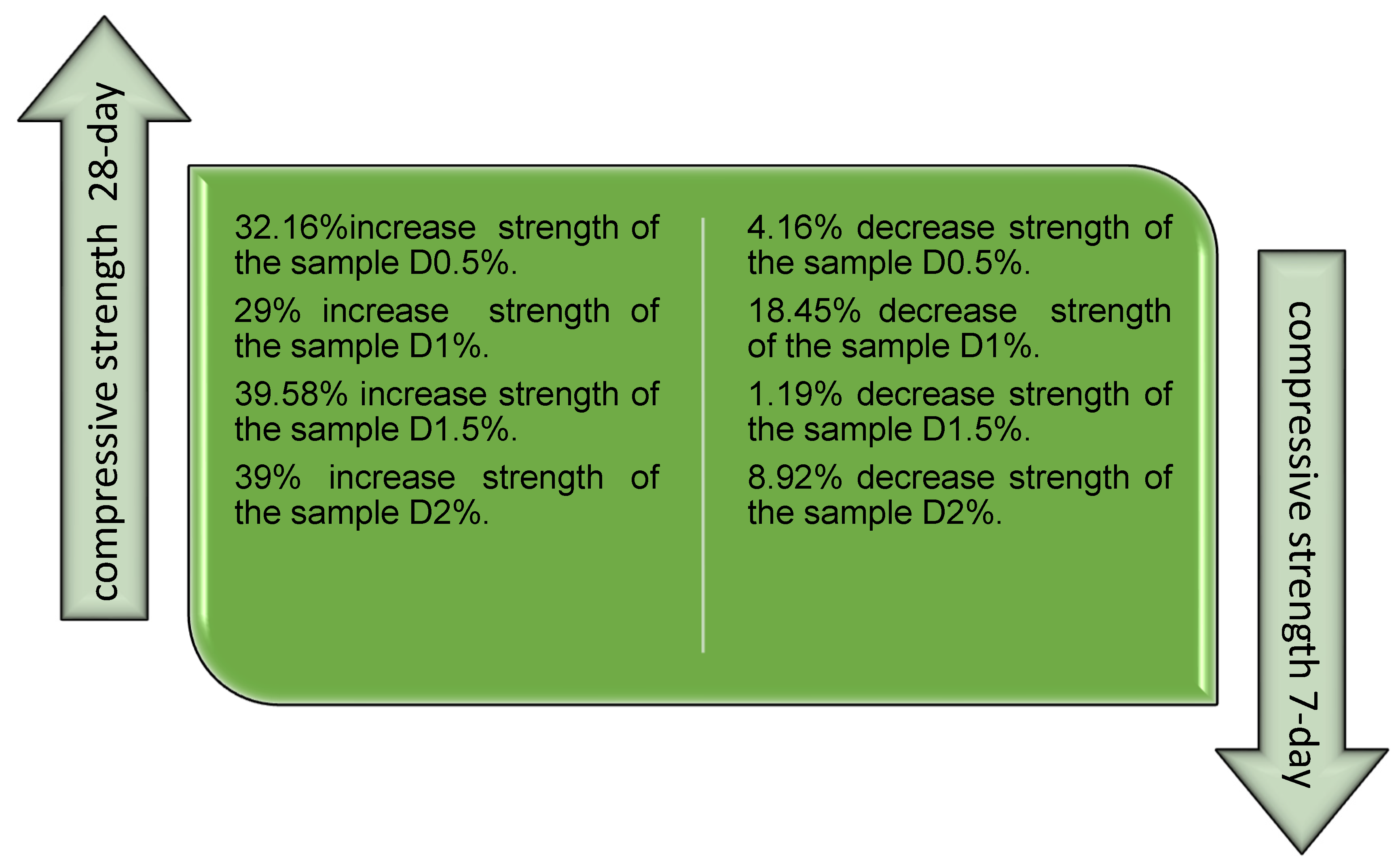

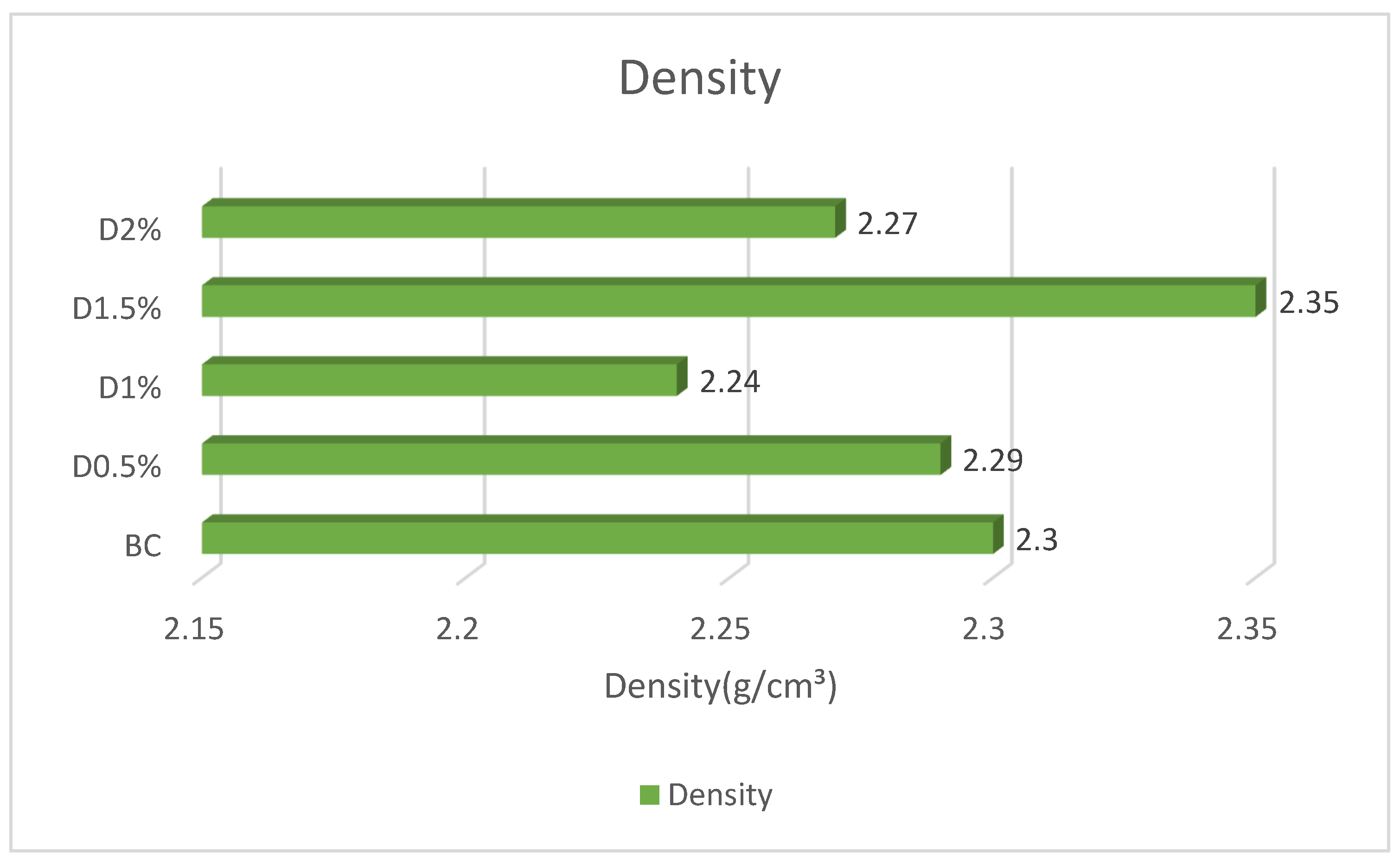

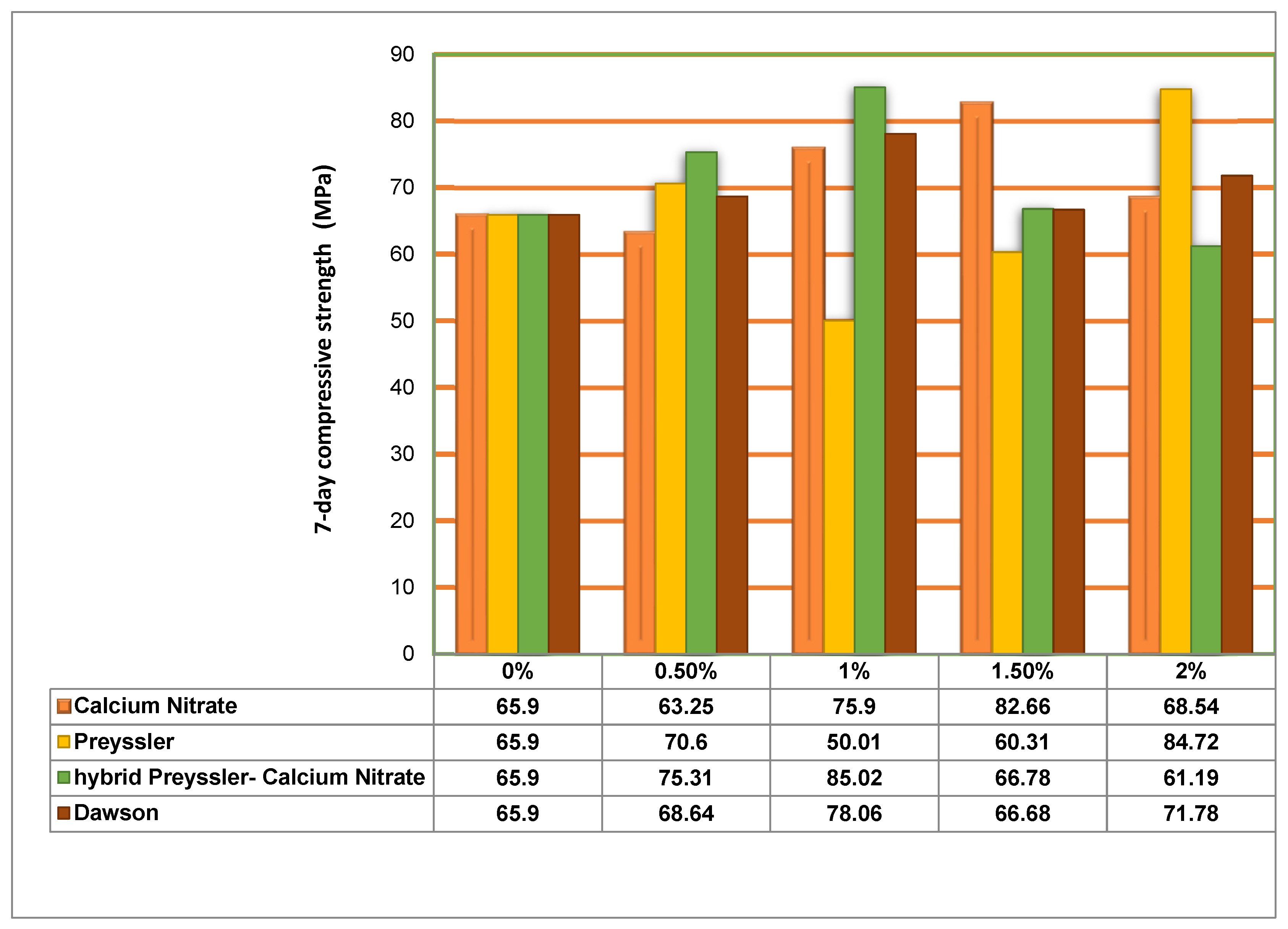

Effects of Microcapsule Content on Compressive Test

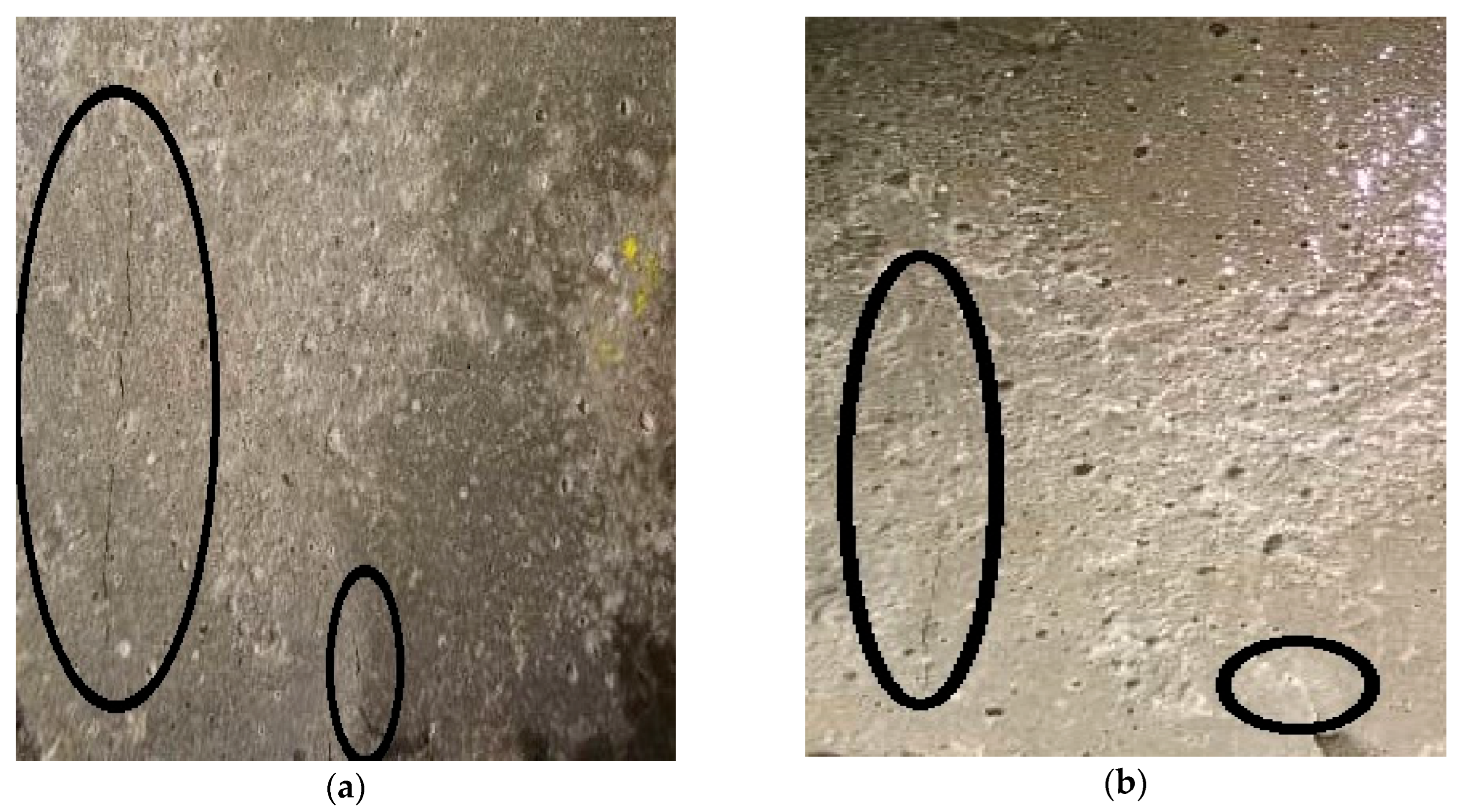

5. Strength Healing Performance of Self-Healing Concrete

Before and After Healing

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Singh, M.; Saini, B.; Chalak, H. Performance and composition analysis of engineered cementitious composite (ECC)—A review. J. Build. Eng. 2019, 26, 100851. [Google Scholar]

- Yıldırım, G.; Keskin, Ö.K.; Keskin, S.B.; Şahmaran, M.; Lachemi, M. A review of intrinsic self-healing capability of engineered cementitious composites: Recovery of transport and mechanical properties. Constr. Build. Mater. 2015, 101, 10–21. [Google Scholar] [CrossRef]

- Yunovich, M.; Thompson, N.G. Corrosion of highway bridges: Economic impact and control methodologies. Concr. Int. 2003, 25, 52–57. [Google Scholar]

- Fernandez, C.A.; Correa, M.; Nguyen, M.-T.; Rod, K.A.; Dai, G.L.; Cosimbescu, L.; Rousseau, R.; Glezakou, V.-A. Progress and challenges in self-healing cementitious materials. J. Mater. Sci. 2021, 56, 201–230. [Google Scholar]

- Patrick, J.F.; Robb, M.J.; Sottos, N.R.; Moore, J.S.; White, S.R. Polymers with autonomous life-cycle control. Nature 2016, 540, 363–370. [Google Scholar] [CrossRef]

- Sidiq, A.; Gravina, R.; Giustozzi, F. Is concrete healing really efficient? A review. Constr. Build. Mater. 2019, 205, 257–273. [Google Scholar] [CrossRef]

- Zhu, Y.; Yang, Y.; Yao, Y. Autogenous self-healing of engineered cementitious composites under freeze–thaw cycles. Constr. Build. Mater. 2012, 34, 522–530. [Google Scholar]

- Han, T.; Wang, X.; Li, D.; Li, D.; Xing, F.; Han, N.; Li, Z. Uniaxial deformation characteristics and mechanical model of microcapsule-based self-healing cementitious composite. Constr. Build. Mater. 2021, 274, 121227. [Google Scholar] [CrossRef]

- Salman, R.T.; Othman, F.M.; Abdul-Hamead, A.A. Experimental investigation of cement encapsulated with different polymers for self-healing applications. Mater. Today Proc. 2021, 42, 1941–1945. [Google Scholar]

- Zhang, H.; Qi, C.; Chen, W.; Li, Q.; Wu, L.; Chen, W. A novel method of self-healing cement paste by using gel microparticles encapsulating phosphate. Constr. Build. Mater. 2021, 279, 122439. [Google Scholar] [CrossRef]

- Han, T.; Wang, X.; Li, D.; Li, D.; Xing, F.; Han, N. Influence of strain rate on mechanical characteristic and pore structure of self-healing cementitious composites with epoxy/urea-formaldehyde microcapsules. Constr. Build. Mater. 2021, 268, 121138. [Google Scholar] [CrossRef]

- White, S.R.; Sottos, N.R.; Geubelle, P.H.; Moore, J.S.; Kessler, M.R.; Sriram, S.; Brown, E.N.; Viswanathan, S. Autonomic healing of polymer composites. Nature 2001, 409, 794–797. [Google Scholar] [CrossRef]

- Beglarigale, A.; Seki, Y.; Demir, N.Y.; Yazıcı, H. Sodium silicate/polyurethane microcapsules used for self-healing in cementitious materials: Monomer optimization, characterization, and fracture behavior. Constr. Build. Mater. 2018, 162, 57–64. [Google Scholar] [CrossRef]

- Wang, X.; Yin, H.; Chen, Z.; Xia, L. Epoxy resin/ethyl cellulose microcapsules prepared by solvent evaporation for repairing microcracks: Particle properties and slow-release performance. Mater. Today Commun. 2020, 22, 100854. [Google Scholar] [CrossRef]

- Lv, L.; Guo, P.; Xing, F.; Han, N. Trigger efficiency enhancement of polymeric microcapsules for self-healing cementitious materials. Constr. Build. Mater. 2020, 235, 117443. [Google Scholar] [CrossRef]

- Li, Y.; Yu, J.; Cao, Z.; Du, W.; Zhang, Y.; Zou, Y. Preparation and characterization of nano-Fe3O4/paraffin encapsulated isocyanate microcapsule by electromagnetic controlled rupture for self-healing cementitious materials. Constr. Build. Mater. 2020, 265, 120703. [Google Scholar] [CrossRef]

- Zhou, G.; Jiang, W.; Li, S.; Liu, R.; Zhang, Q.; Qi, G.; He, Z. Preparation and performance analysis of dopamine hydrochloride functionalized E-51@MPF/SiO2 double-wall microcapsules for microcracks self-healing in cement-based materials. Constr. Build. Mater. 2022, 325, 126622. [Google Scholar]

- Silvestre, J.; Silvestre, N.; De Brito, J. Review on concrete nanotechnology. Eur. J. Environ. Civ. Eng. 2016, 20, 455–485. [Google Scholar] [CrossRef]

- Li, H.; Xiao, H.-g.; Ou, J.-P. A study on mechanical and pressure-sensitive properties of cement mortar with nanophase materials. Cem. Concr. Res. 2004, 34, 435–438. [Google Scholar] [CrossRef]

- Ślosarczyk, A.; Kwiecińska, A.; Pełszyk, E. Influence of selected metal oxides in micro and nanoscale on the mechanical and physical properties of the cement mortars. Procedia Eng. 2017, 172, 1031–1038. [Google Scholar] [CrossRef]

- Pope, M. Heteropoly and Isopoly Oxometalates; Springer: Berlin/Heidelberg, Germany, 1983. [Google Scholar]

- Misono, M. Recent progress in the practical applications of heteropolyacid and perovskite catalysts: Catalytic technology for the sustainable society. Catal. Today 2009, 144, 285–291. [Google Scholar] [CrossRef]

- Ghaemifard, S.; Khosravi, H.; Farash Bamoharram, F.; Ghannadiasl, A. Self-healing concrete using microcapsules containing mineral salts. Int. J. Eng. 2024, 37, 779–793. [Google Scholar] [CrossRef]

- Toohey, K.S.; Sottos, N.R.; Lewis, J.A.; Moore, J.S.; White, S.R. Self-healing materials with microvascular networks. Nat. Mater. 2007, 6, 581–585. [Google Scholar] [CrossRef]

- Hansen, C.J.; Wu, W.; Toohey, K.S.; Sottos, N.R.; White, S.R.; Lewis, J.A. Self-healing materials with interpenetrating microvascular networks. Adv. Mater. 2009, 21, 4143–4147. [Google Scholar] [CrossRef]

- Idumah, C.I.; Nwuzor, I.; Odera, S.R. Recent advancements in self-healing polymeric hydrogels, shape memory, and stretchable materials. Int. J. Polym. Mater. Polym. Biomater. 2021, 70, 941–966. [Google Scholar] [CrossRef]

- Romanelli, G.; Autino, J.C.; Baronetti, G.; Thomas, H.J.M. Efficient deprotection of phenol methoxymethyl ethers using a solid acid catalyst with Wells-Dawson structure. Molecules 2001, 6, 1006–1011. [Google Scholar] [CrossRef]

- García-López, E.I.; Marcì, G.; Krivtsov, I.; Casado Espina, J.; Liotta, L.F.; Serrano, A.J. Local structure of supported Keggin and Wells–Dawson heteropolyacids and its influence on the catalytic activity. J. Phys. Chem. C 2019, 123, 19513–19527. [Google Scholar] [CrossRef]

- Richard, P.; Cheyrezy, M.H. Reactive powder concretes with high ductility and 200–800 MPa compressive strength. SP-144 Concr. Technol. Past Present Future 1994, 144, 507–518. [Google Scholar]

- Jincheng, W.; Sihao, C. Preparation and characterization of microcapsules containing capsaicin. J. Appl. Polym. Sci. 2010, 116, 2234–2241. [Google Scholar] [CrossRef]

| Materials | Amount in kg/m3 |

|---|---|

| Cement (kg) | 840 |

| Water (kg) | 200 |

| Silica sand (kg) | 1104 |

| Admixture1 (Superplasticizer polycarboxylate-based product) | 42 |

| Admixture2 (Microcapsule concentration 1 (%)) | 0.5, 1, 1.5 and 2% |

| Micro-silica (kg) | 202 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khosravi, H.; Ghaemifard, S.; Movahedi Rad, M. Mechanical Properties of Self-Healing Concrete with Dawson Microcapsule. Buildings 2025, 15, 4292. https://doi.org/10.3390/buildings15234292

Khosravi H, Ghaemifard S, Movahedi Rad M. Mechanical Properties of Self-Healing Concrete with Dawson Microcapsule. Buildings. 2025; 15(23):4292. https://doi.org/10.3390/buildings15234292

Chicago/Turabian StyleKhosravi, Hossein, Saeedeh Ghaemifard, and Majid Movahedi Rad. 2025. "Mechanical Properties of Self-Healing Concrete with Dawson Microcapsule" Buildings 15, no. 23: 4292. https://doi.org/10.3390/buildings15234292

APA StyleKhosravi, H., Ghaemifard, S., & Movahedi Rad, M. (2025). Mechanical Properties of Self-Healing Concrete with Dawson Microcapsule. Buildings, 15(23), 4292. https://doi.org/10.3390/buildings15234292