Deep Learning-Based Safety Early-Warning Model for Deep Foundation Pit Construction with Extra-Long Weir Construction Method—A Case Study of the Jinji Lake Tunnel

Abstract

1. Introduction

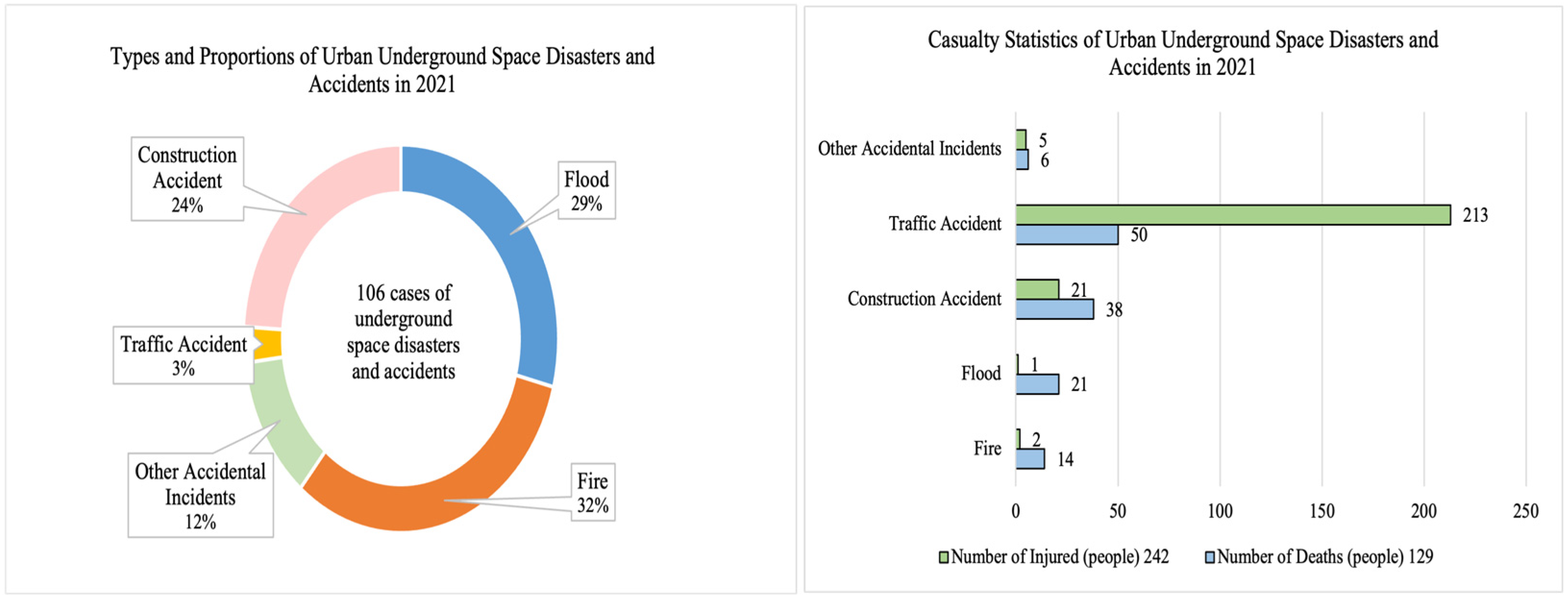

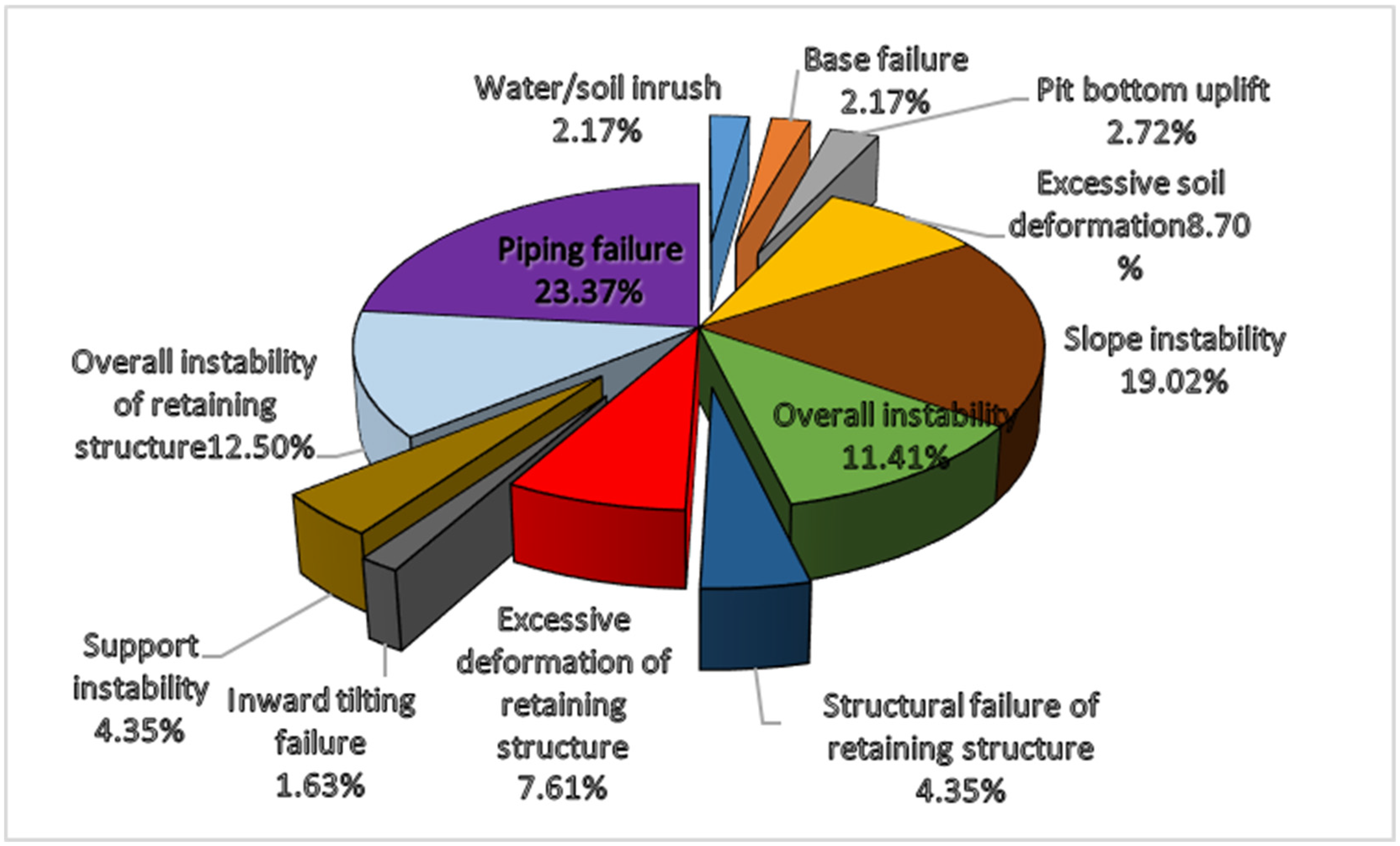

1.1. Background

1.2. Scientific and Practical Significance

2. Literature Review

2.1. Current Research Status

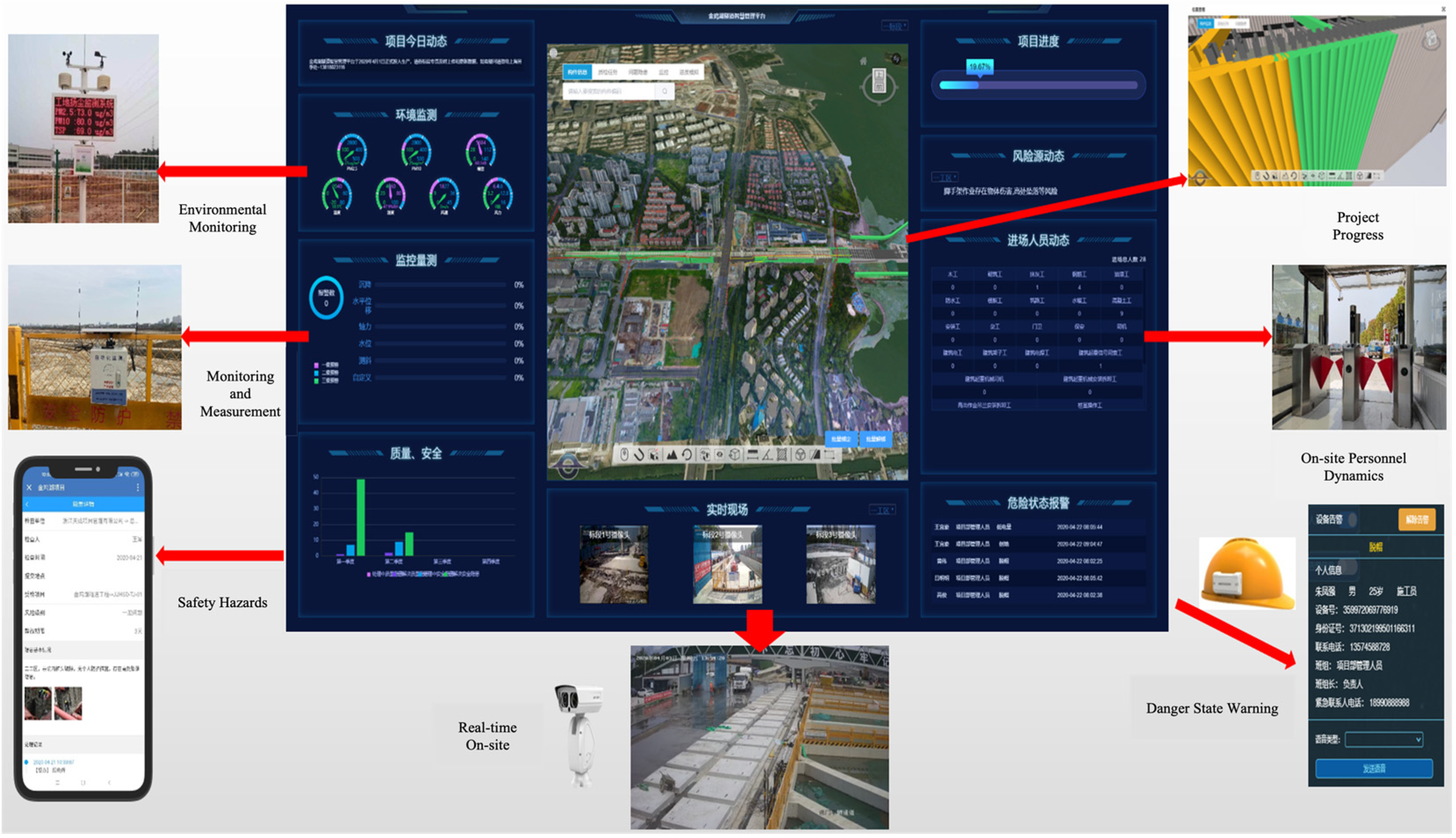

2.2. Current Practice Status

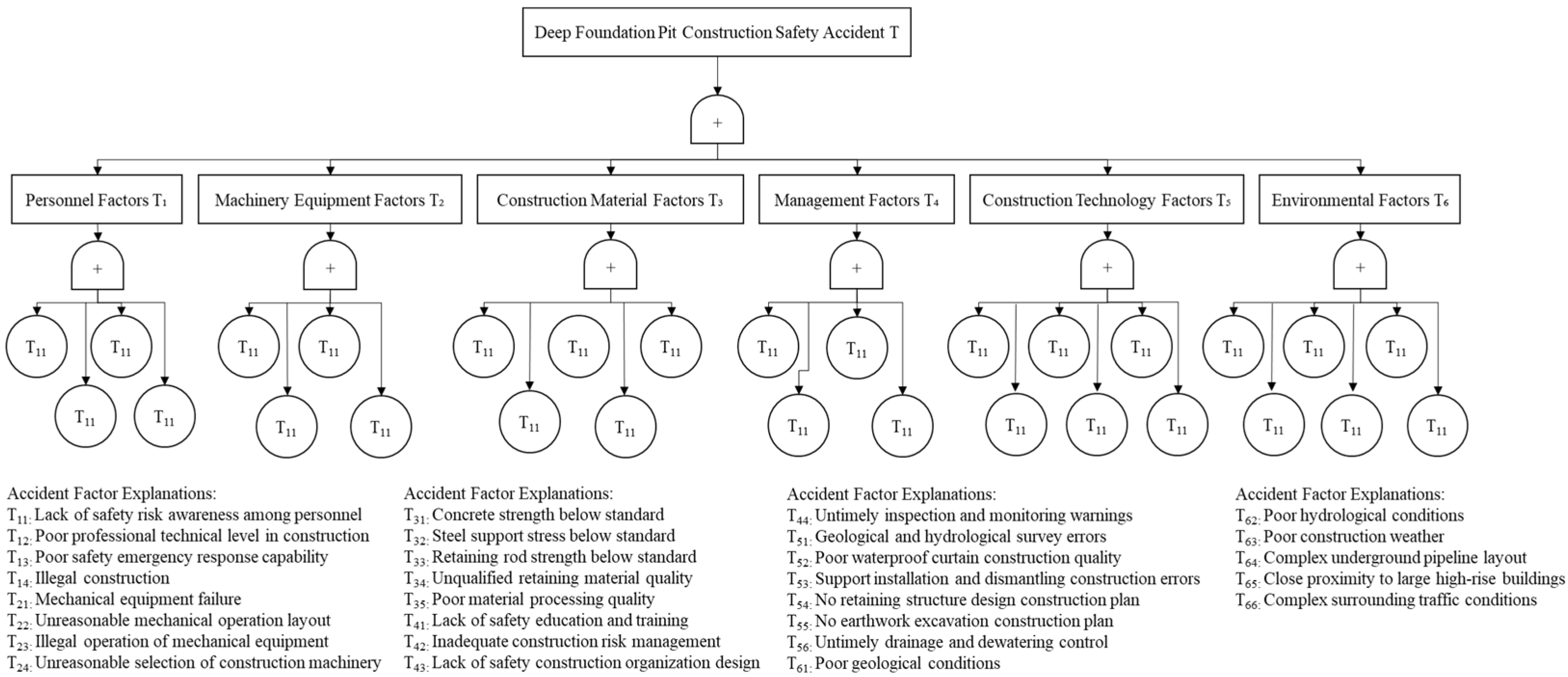

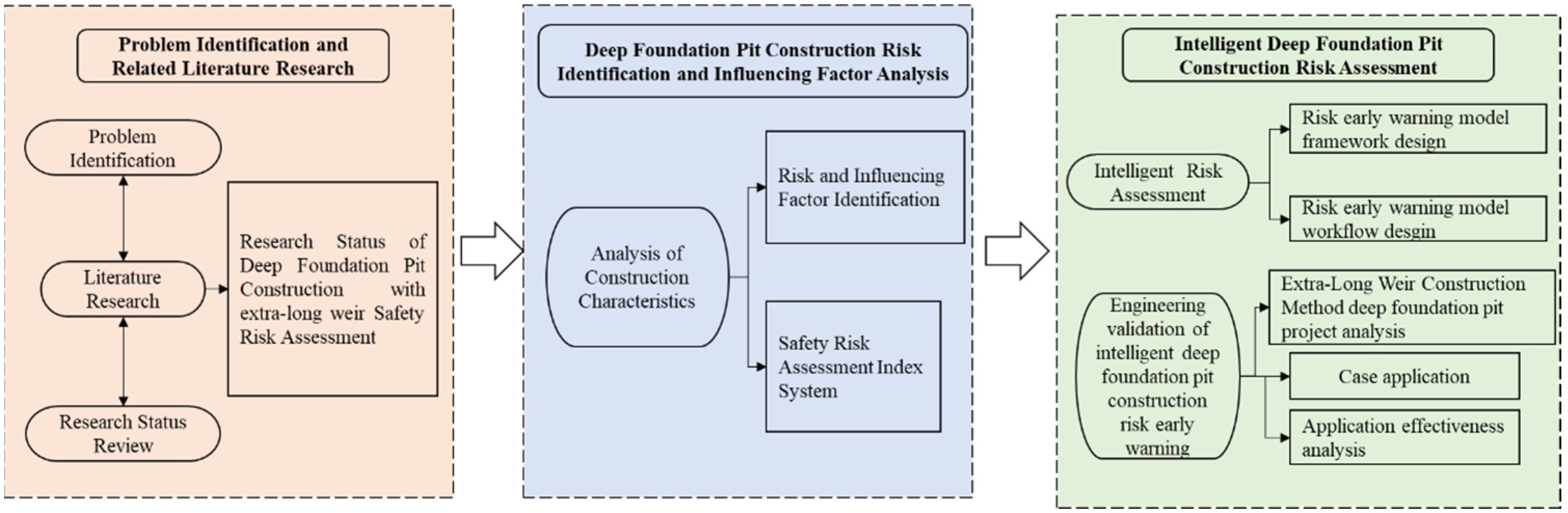

3. Materials and Methods

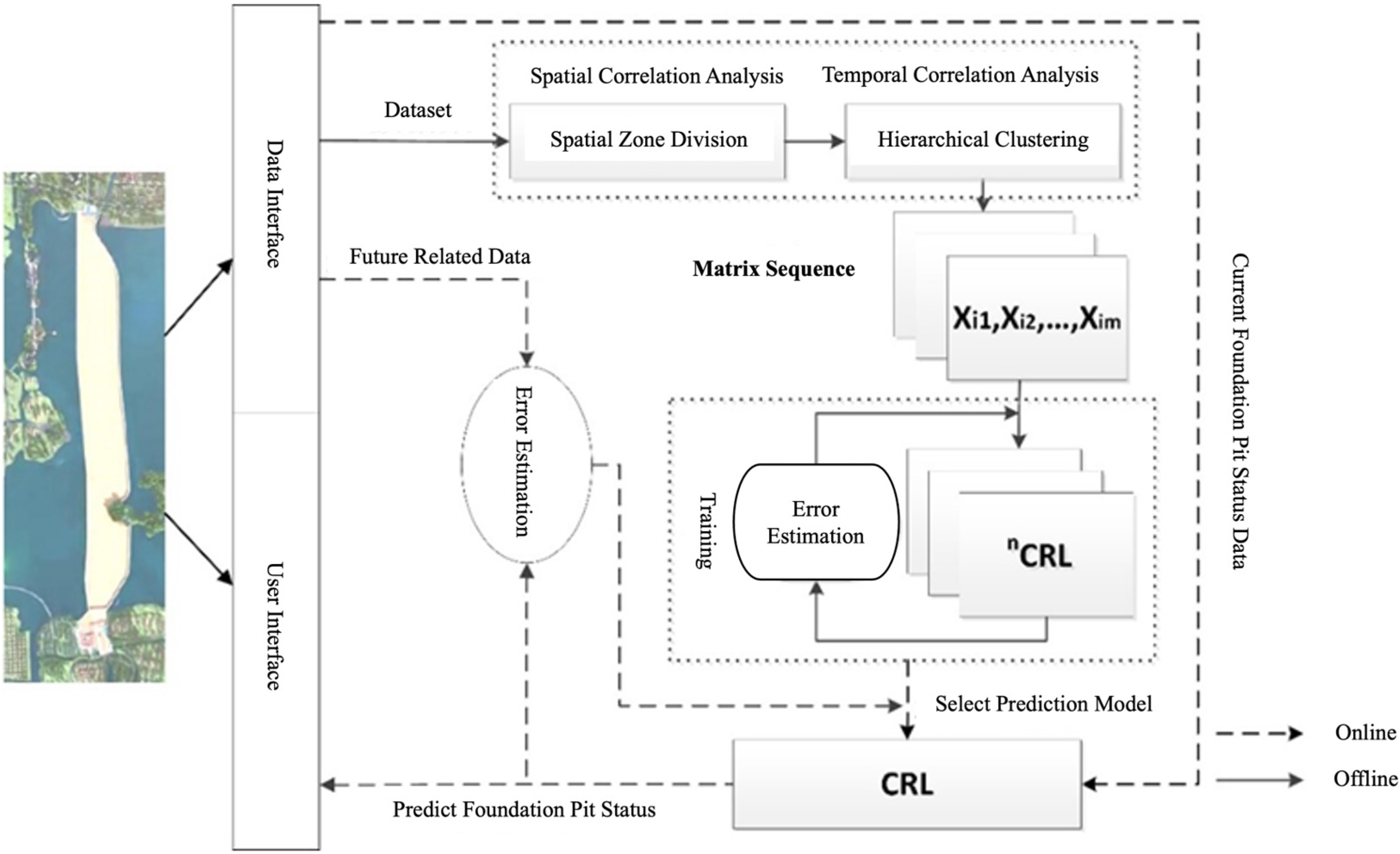

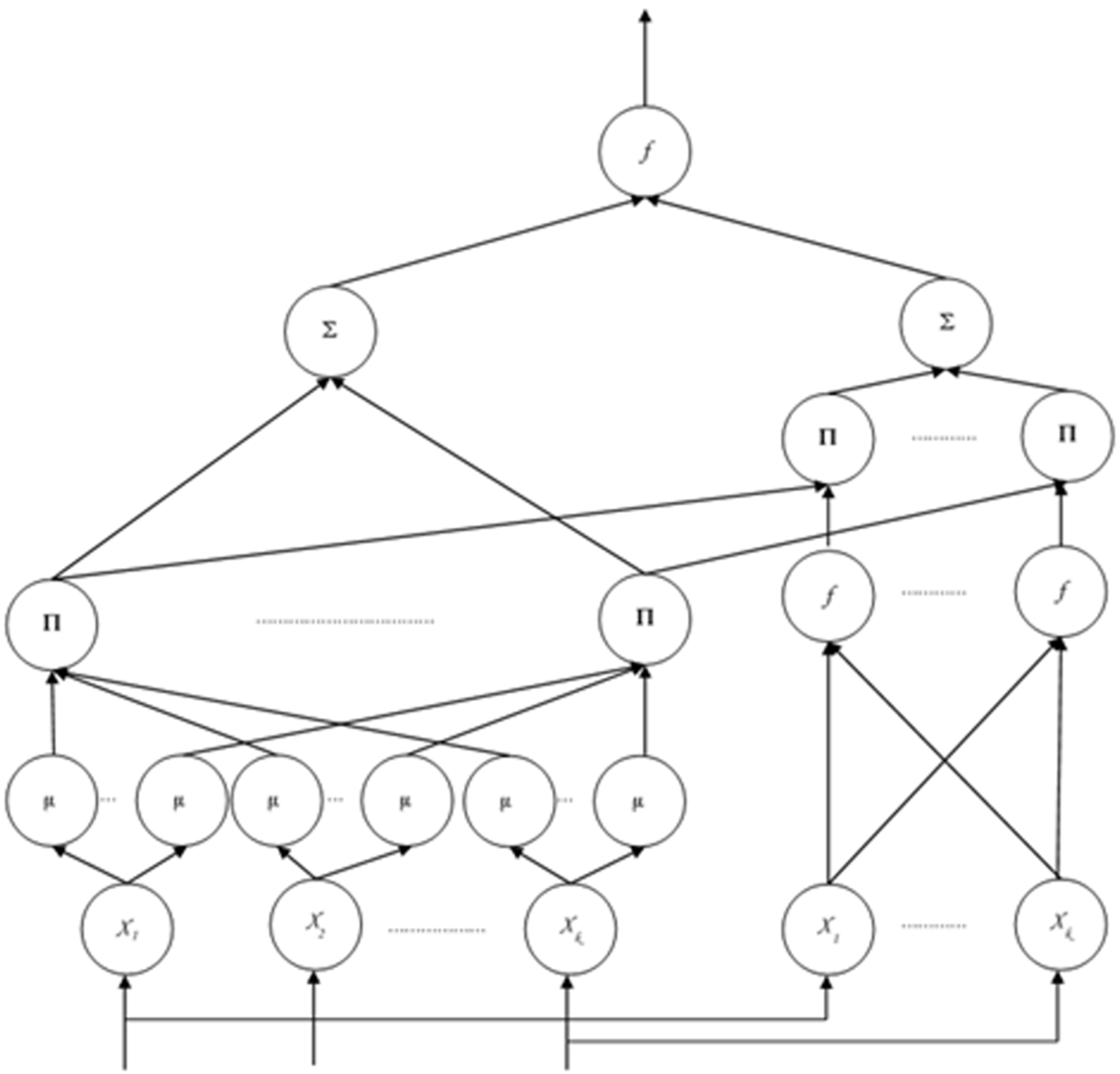

3.1. Research Methodology

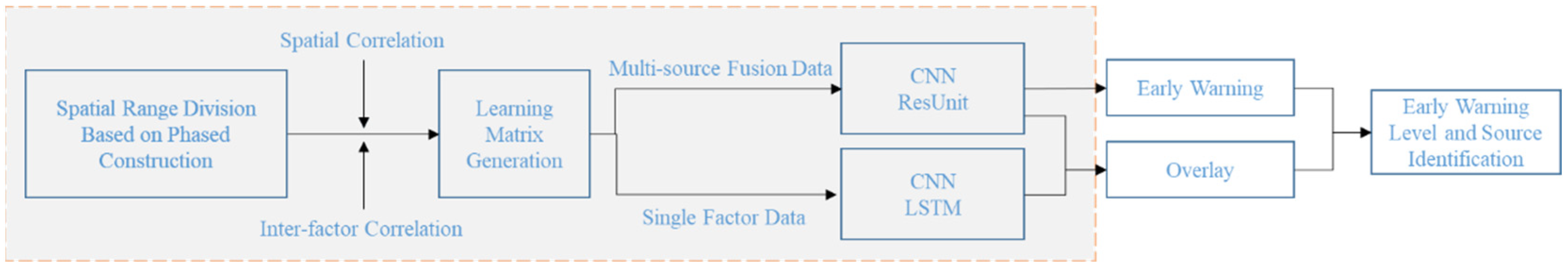

3.2. Framework of Early-Warning Model

| Algorithm 1: 3DM-DLM Training Algorithm |

| Input: Historical observations: {X0, ⋯, Xn−1}; Lengths of time, day, week sequences: Lt, Ld, Lw; Output: learned 3DM-DLM model // construct training instances D ← Ø For all available time interval t () do St = (Xt−1, ⋯, Xt−(Lt−1), Xt−Lt ) Sd = (Xt−d, ⋯, Xt−(Ld−1)*d), Xt−Ld) Sw = (Xt−w, ⋯, Xt−(Lw−1)*w), Xt−Lw) // Xt is the target at the time t Put an training instance ({St, Sd, Sw}, X(t)) into D // train the model Initialize all learnable parameters in 3DM-DLM Repeat Find by minimizing the Equation (1) Until stopping criteria is met |

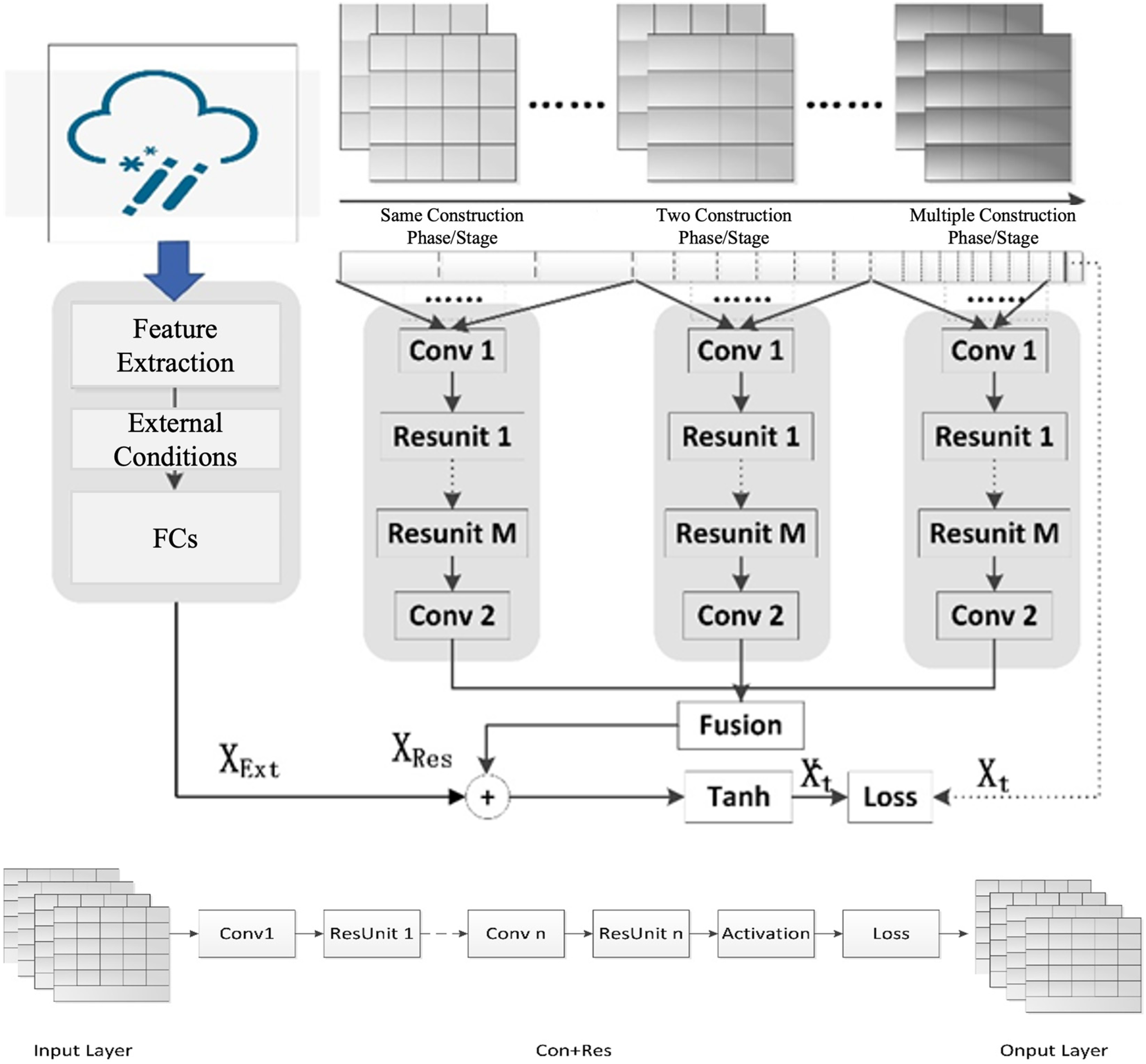

3.2.1. CNN

3.2.2. ResUnit

| Input |

| |- Convolution |

| |- Batch Normalization |

| |- Activation |

| |- Convolution |

| |- Batch Normalization |

| |- Add (with Input) |

| |- Activation |

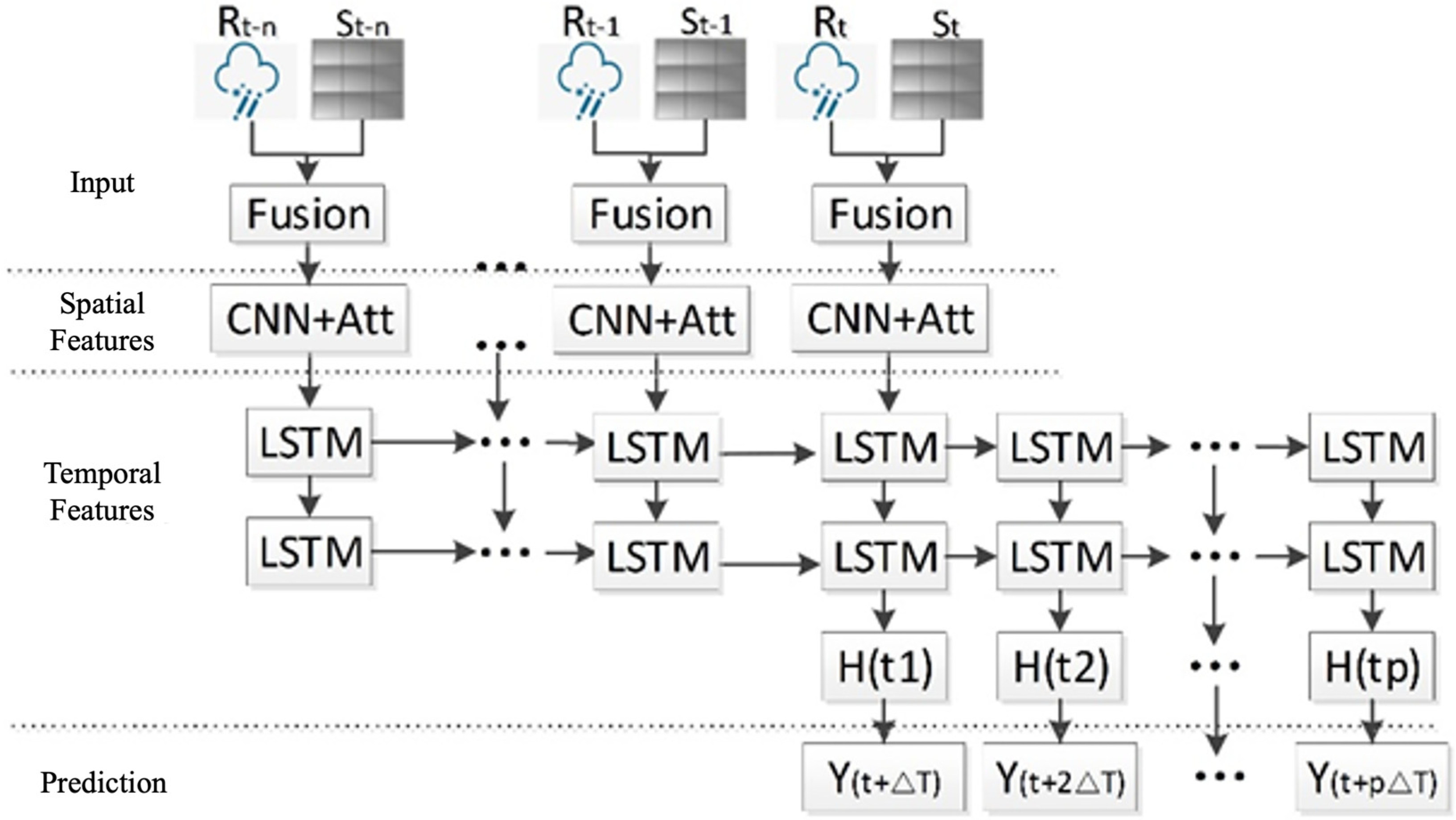

3.2.3. LSTM

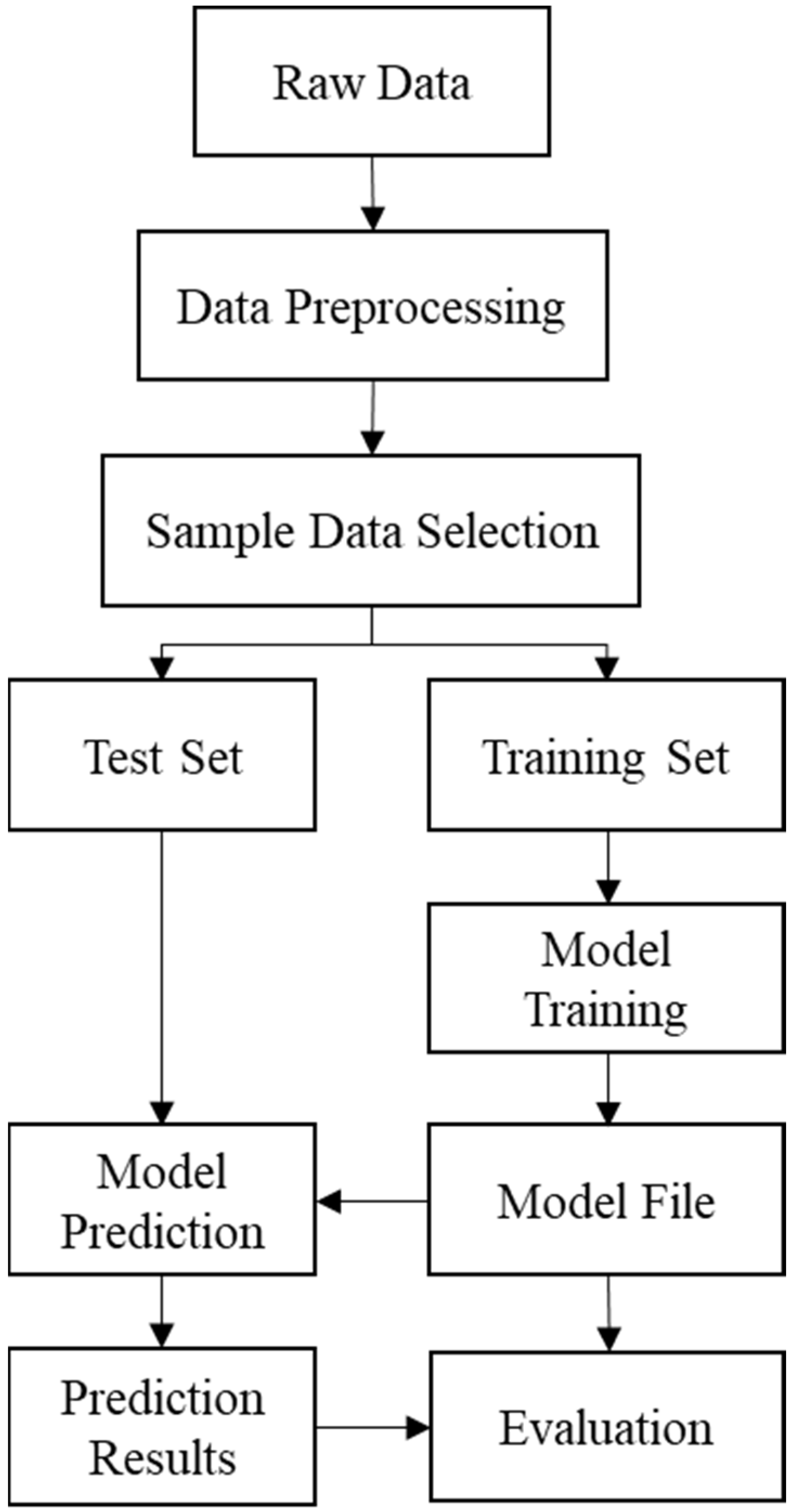

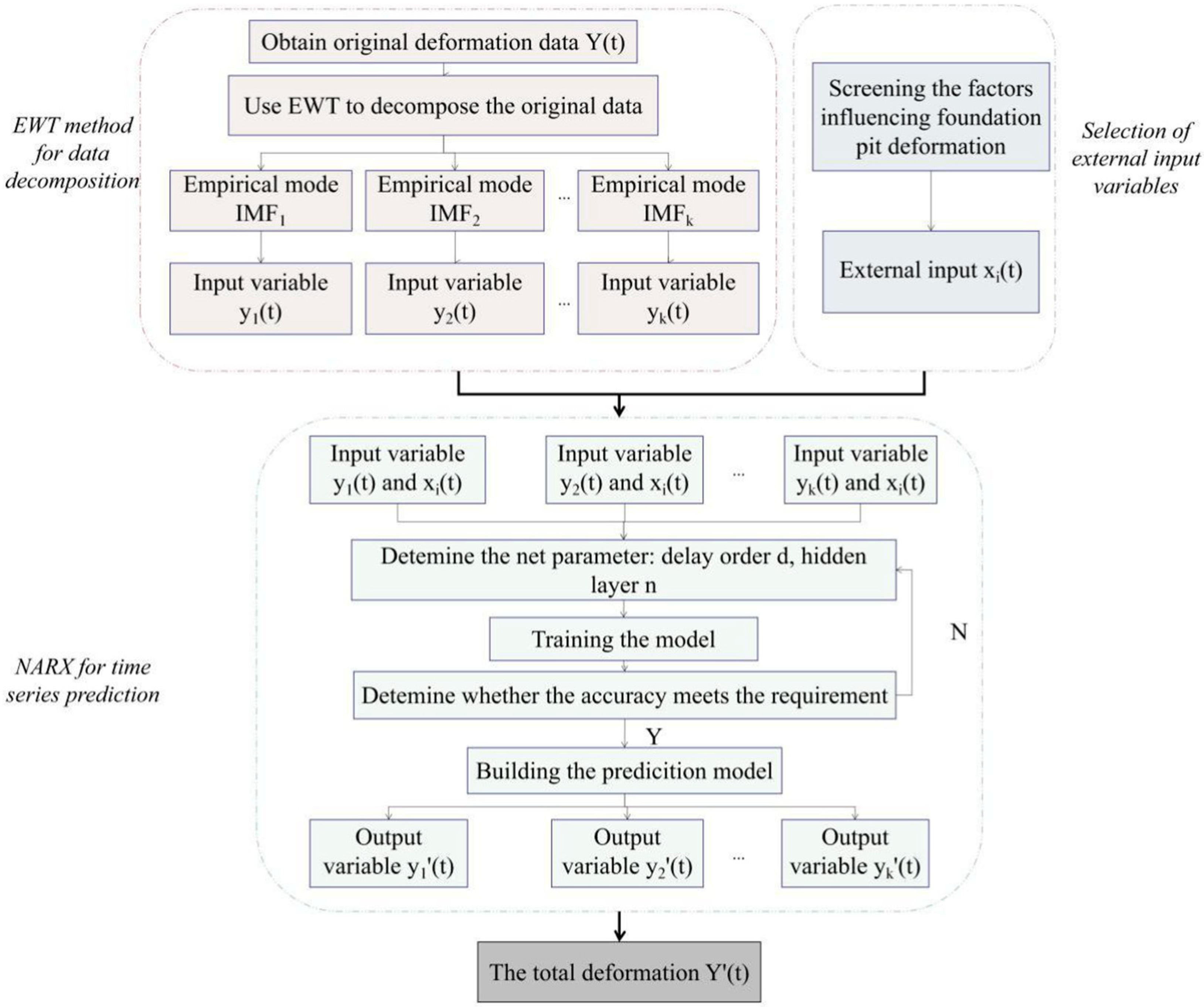

3.3. Workflow of Early-Warning Model

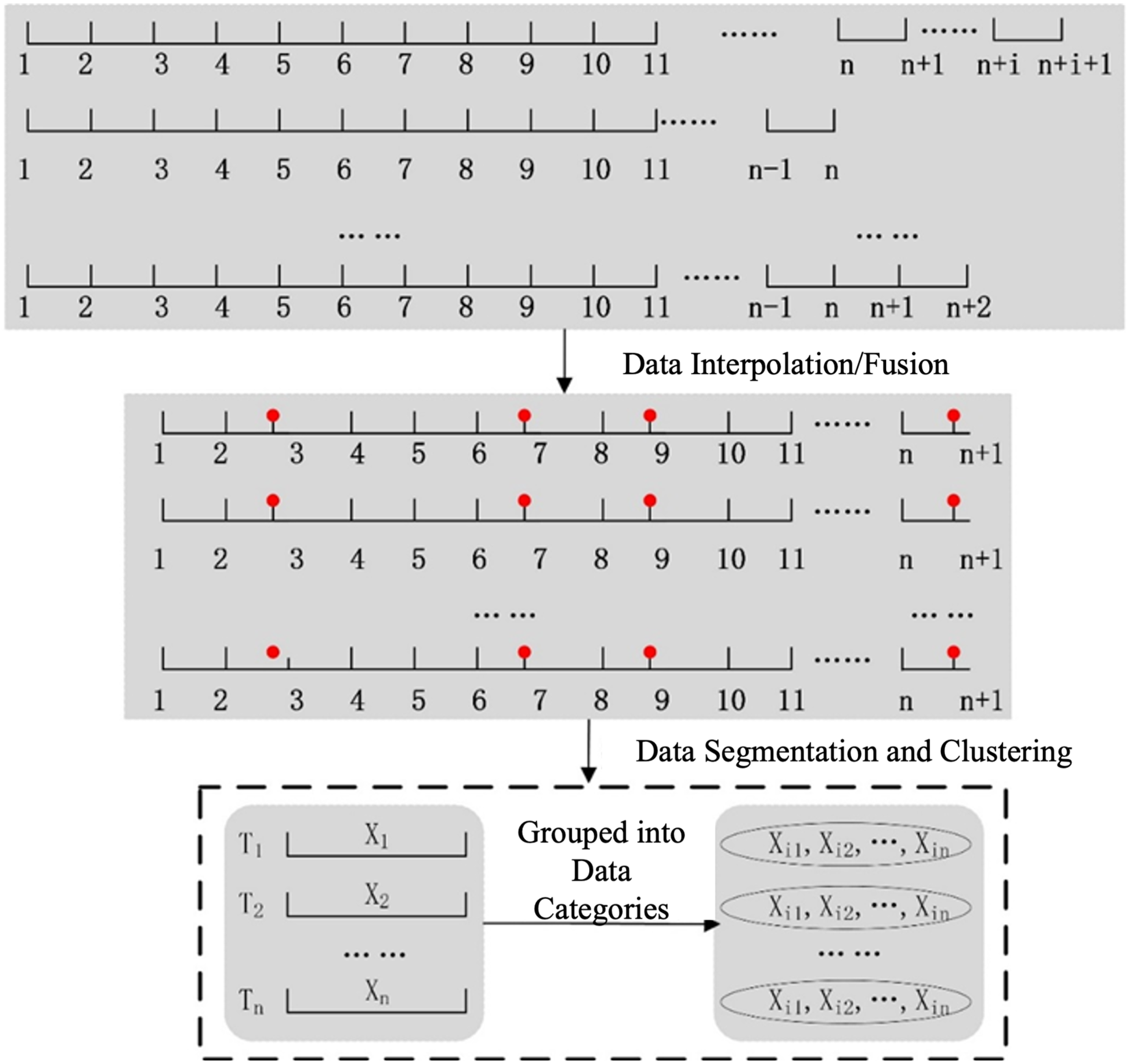

3.3.1. Data Preprocessing

- (1)

- Feature Standardization

- (2)

- Outlier Processing

(xi − x0)(xi − x1)…(xi − xi − 1)(xi − xi + 1)…(xi − xn)

- (3)

- Data Balancing

- (4)

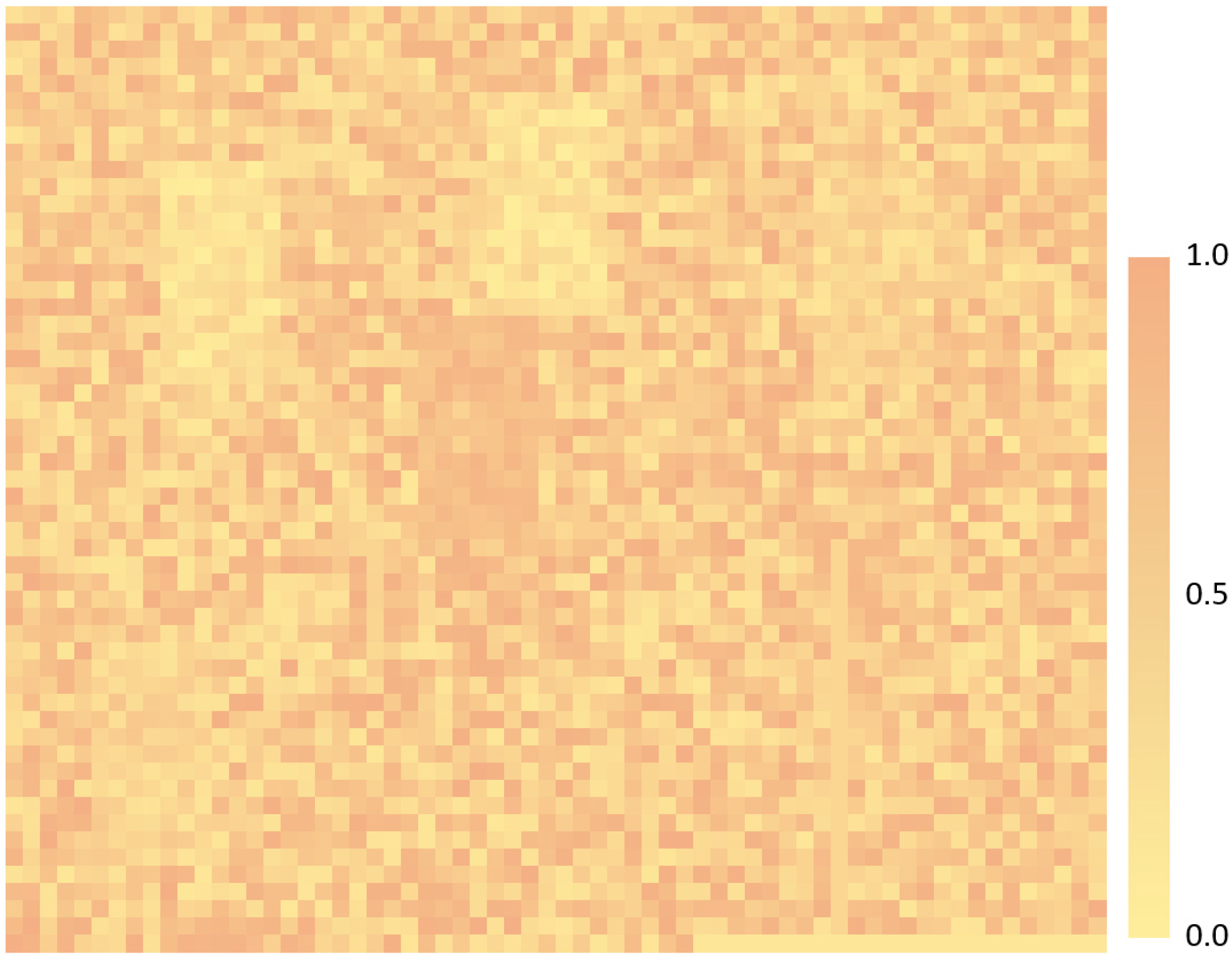

- Data Clustering

- (5)

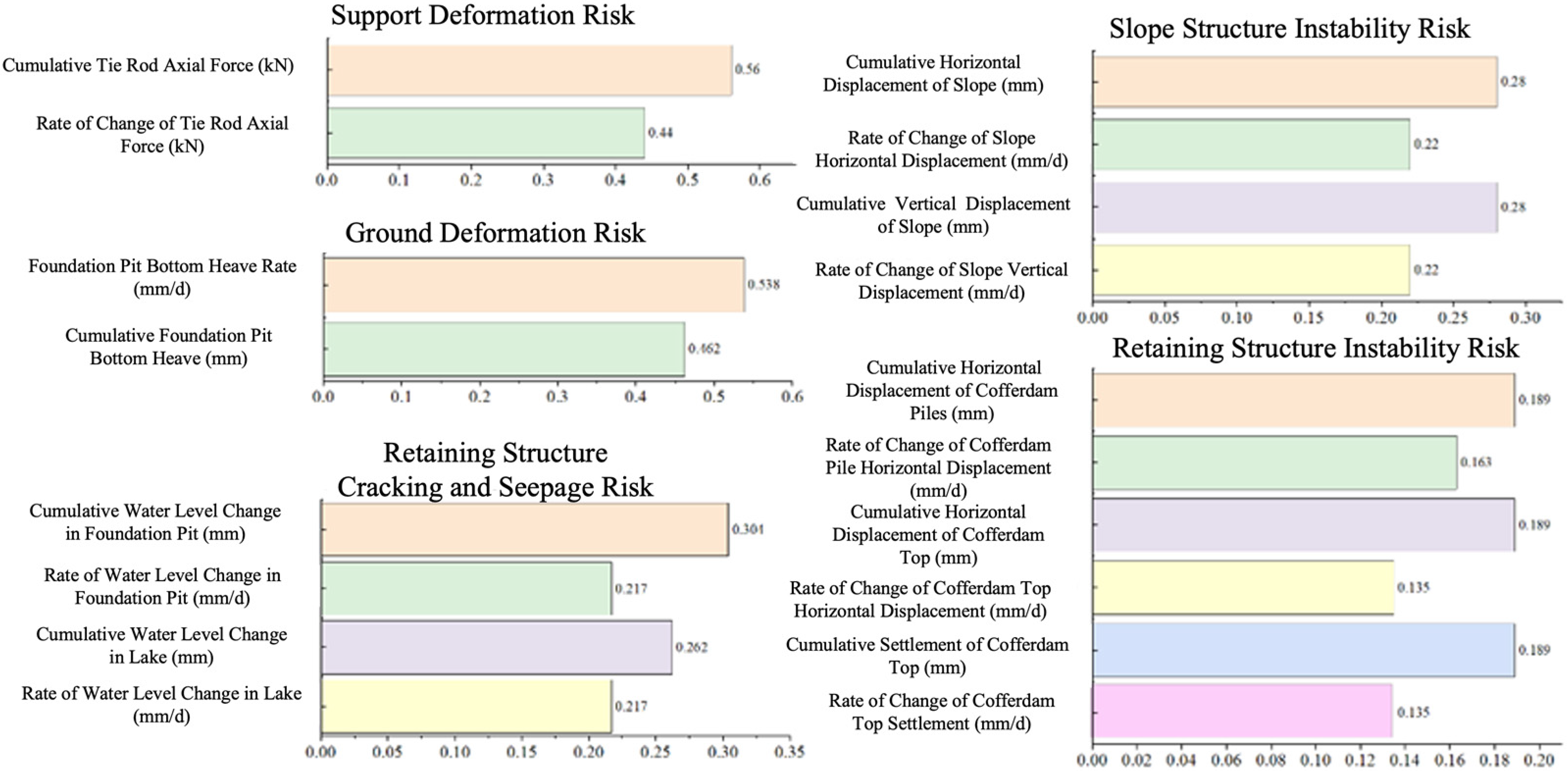

- Feature Weight Acquisition

- (6)

- Data Fusion

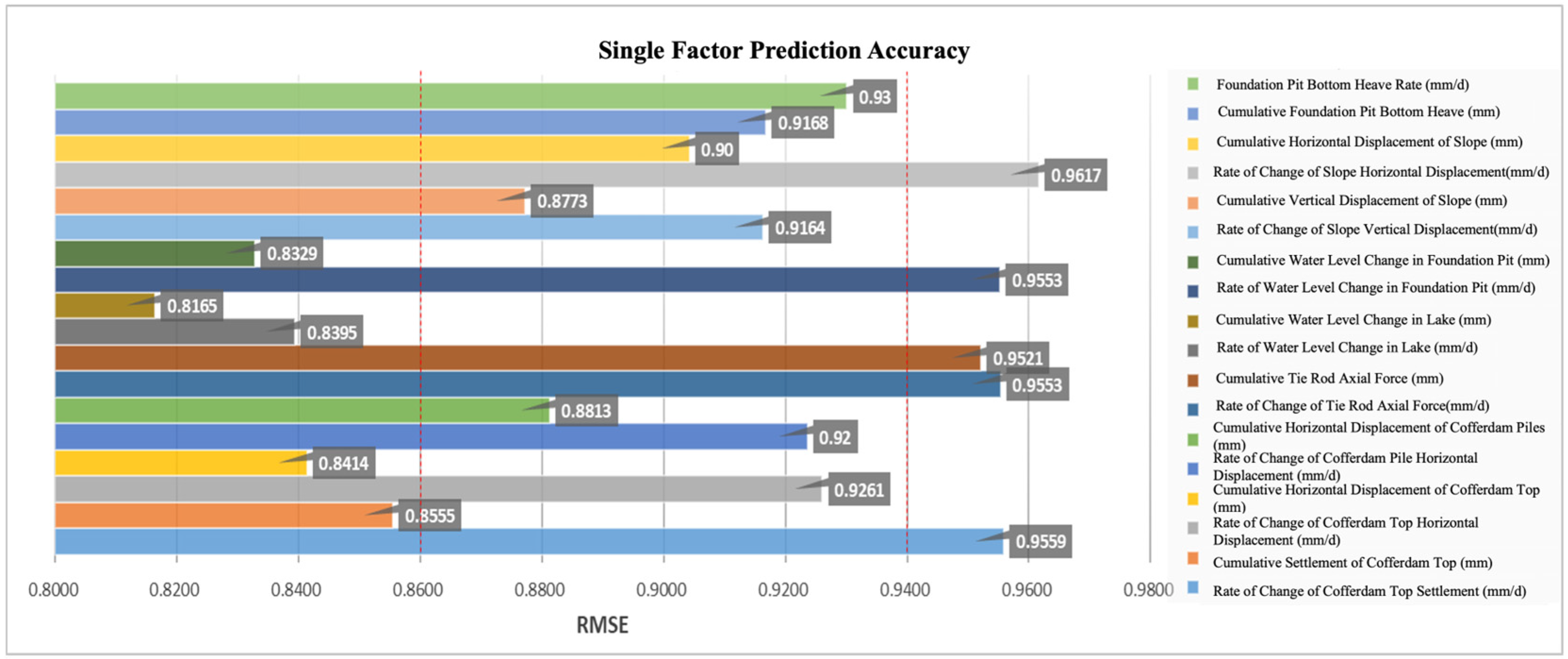

3.3.2. Data Selection

4. Case Application and Verification

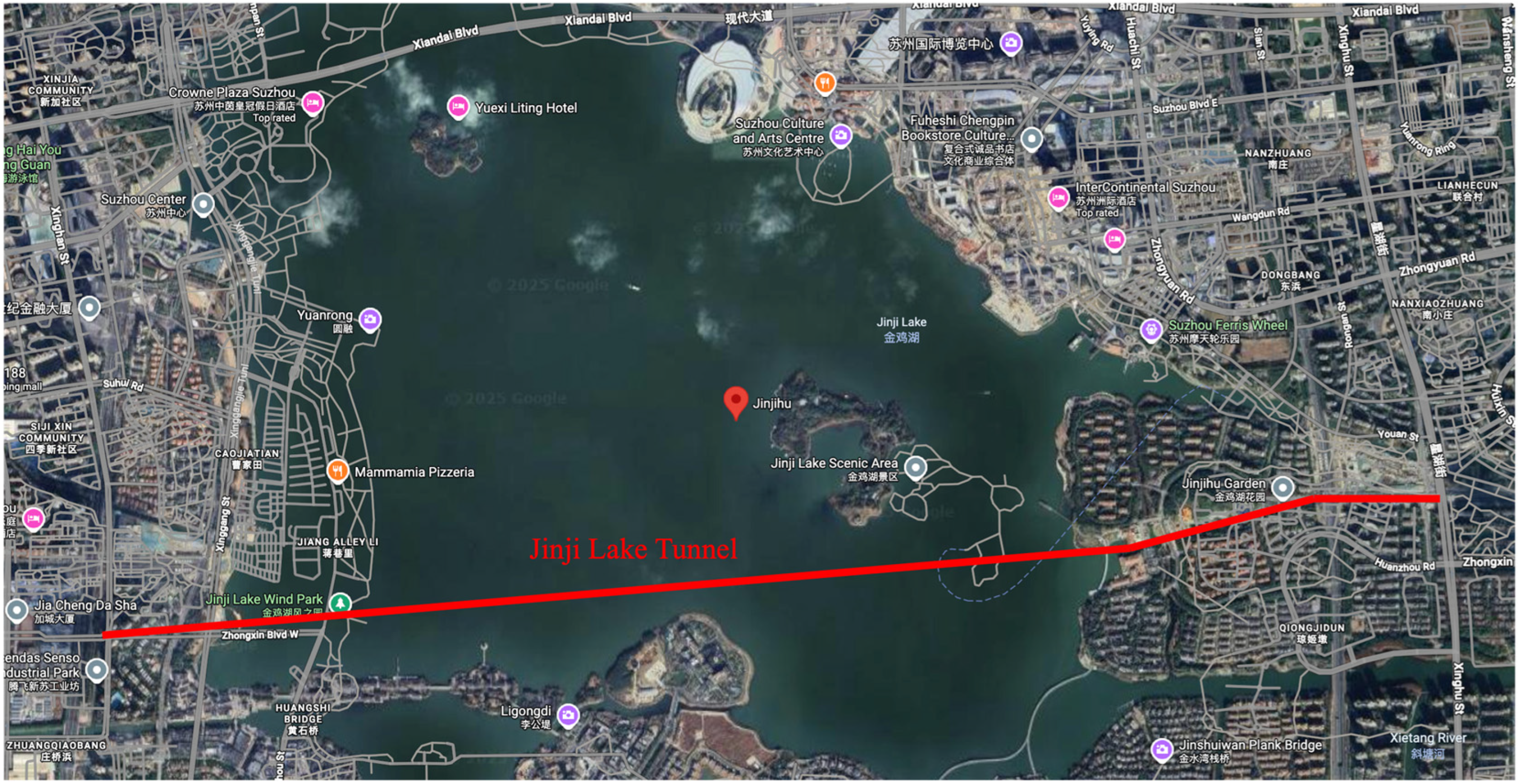

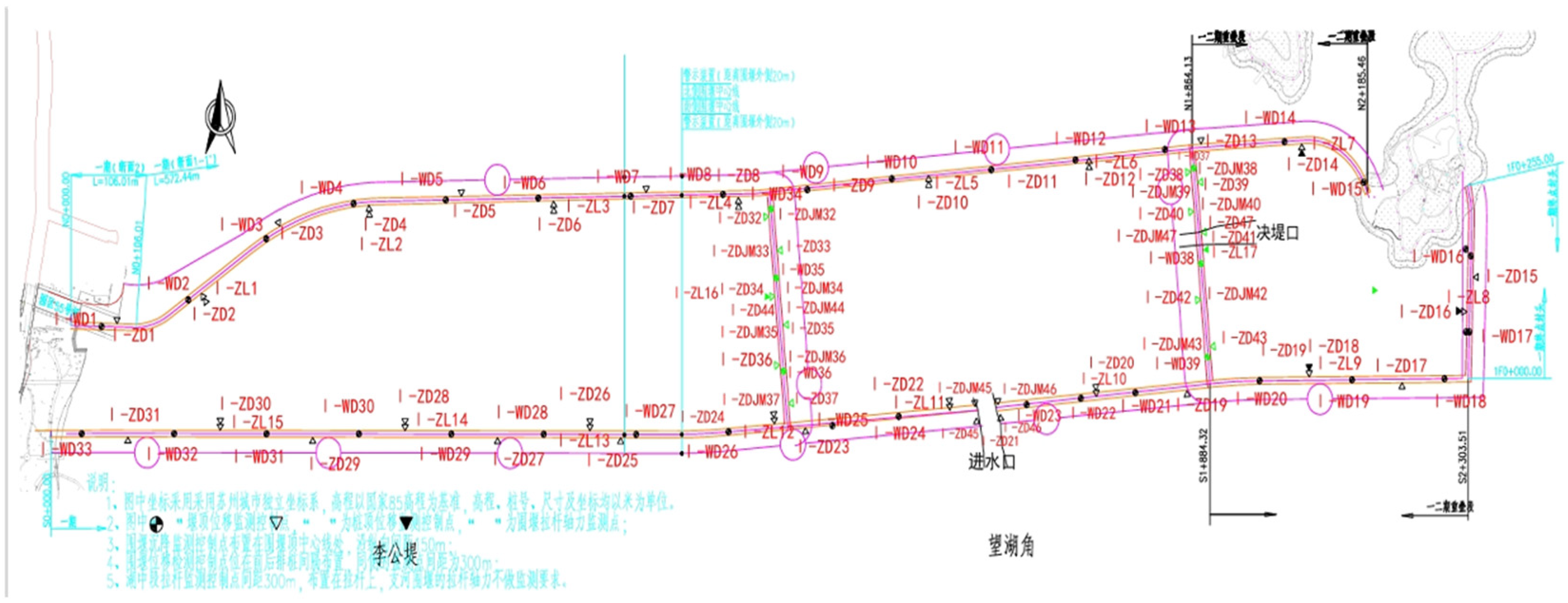

4.1. Case Background

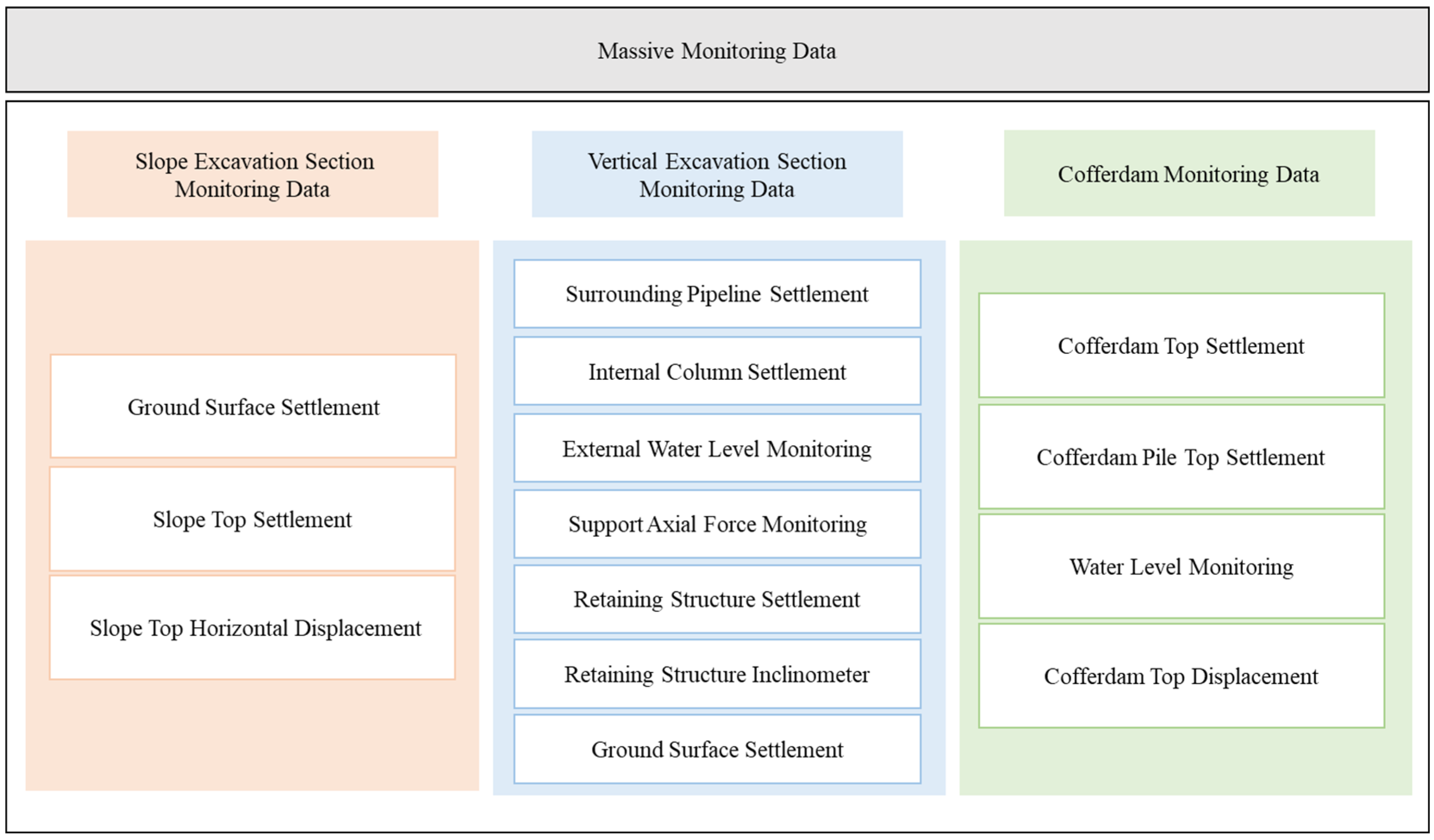

4.2. Data Overview

4.2.1. Experimental Data Collection

4.2.2. Collected Data Processing

4.3. Basic Methods and Evaluation Indicators

4.4. Prediction Process

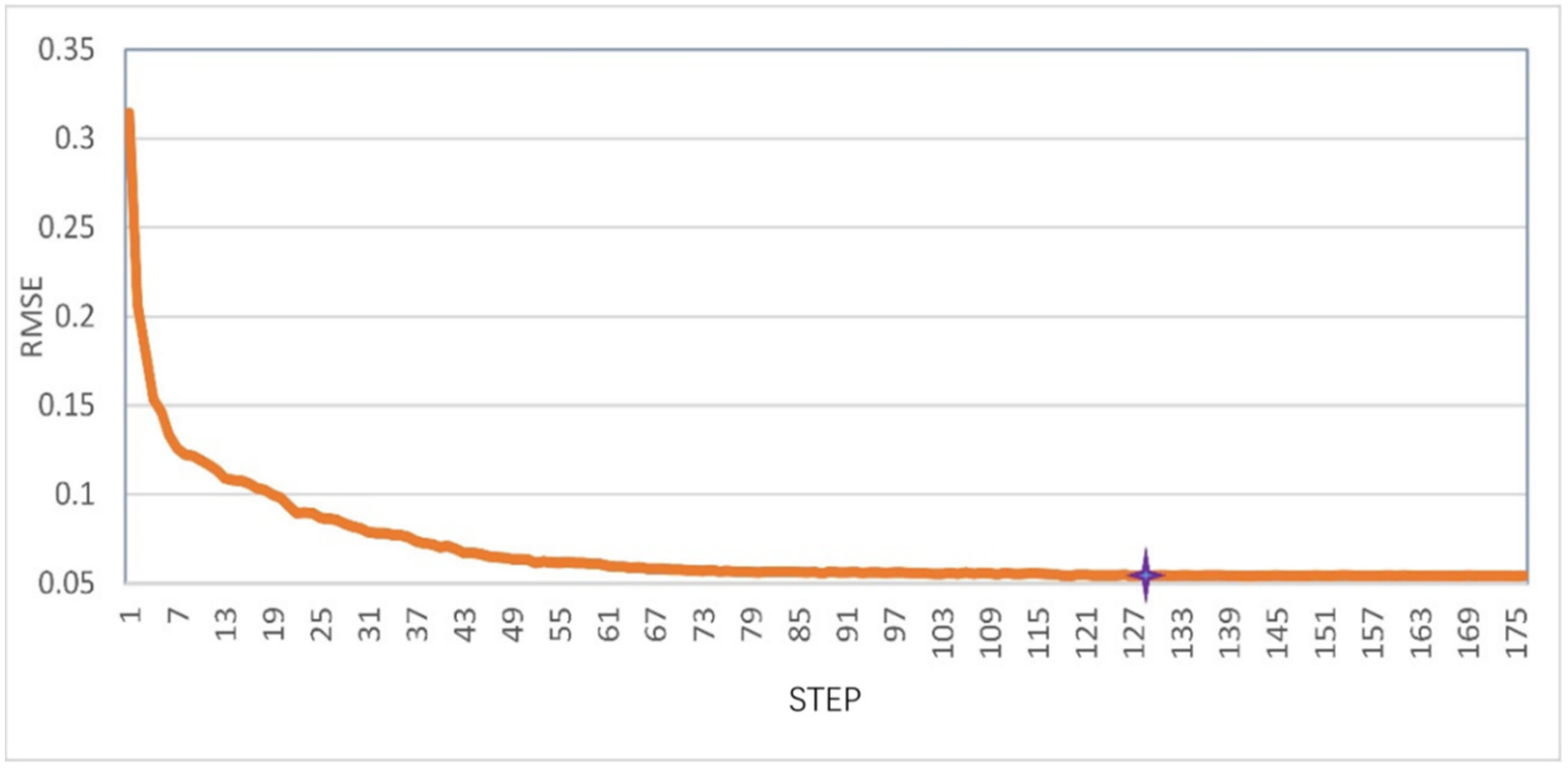

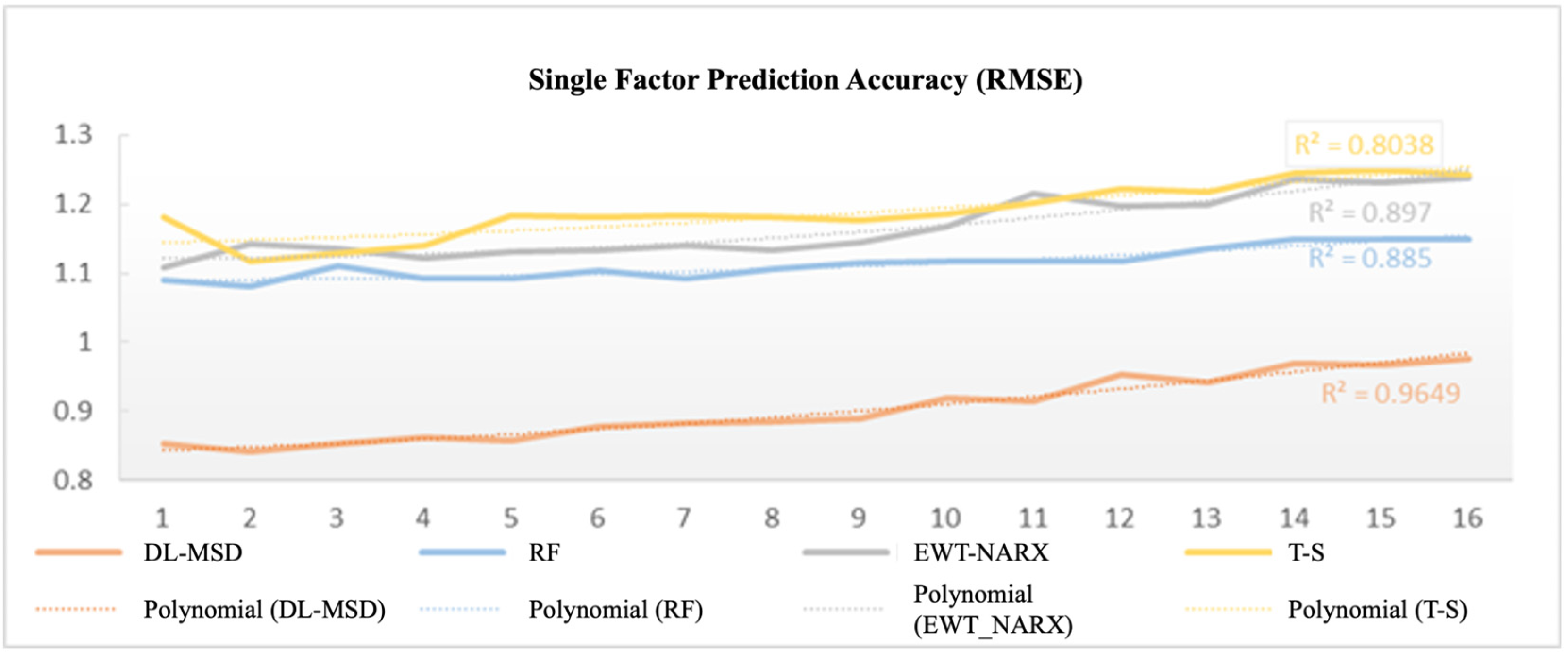

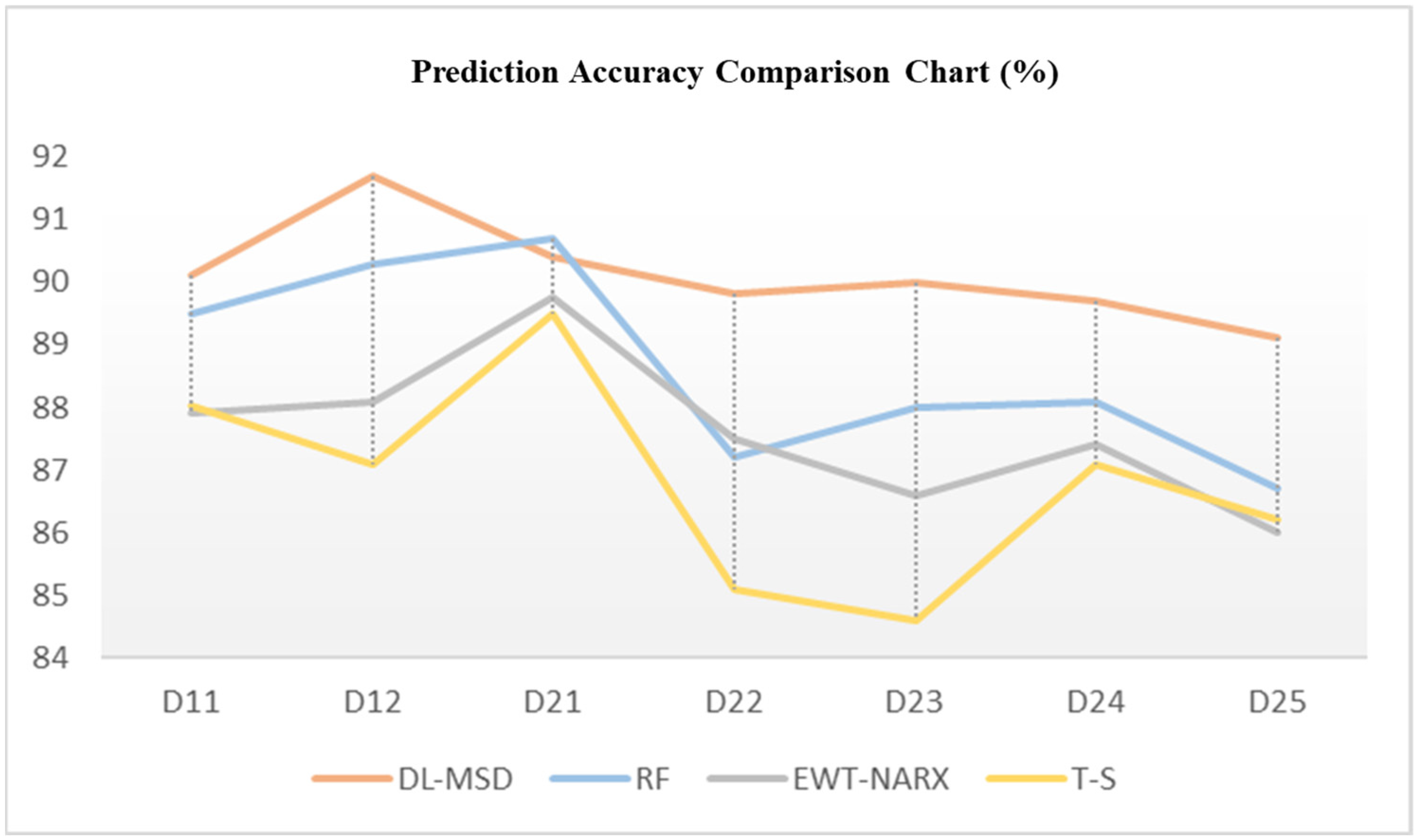

4.5. Verification Results

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ye, F.; Qin, N.; Liang, X.; Ouyang, A.; Qin, Z.; Su, E. Analyses of the defects in highway tunnels in China. Tunn. Undergr. Space Technol. 2021, 107, 103658. [Google Scholar] [CrossRef]

- Chinese Society for Rock Mechanics & Engineering. Sus-Society for Underground Space of CSRME. Available online: http://www.csueus.com (accessed on 13 September 2025).

- Xiao, Y.; Liu, X.; He, X.; Zheng, C.; Bai, Q.; Zhang, Y. Case Study on the Mutual Influence of Simultaneous Construction of Adjacent Deep Foundation Pit with Cover-Excavation Reverse Method. Adv. Civ. Eng. 2024, 2024, 5197973. [Google Scholar] [CrossRef]

- Yingxia, Y.; Han, J.; Gu, H.; Yang, Y. Dynamic Optimization of Construction Time-Cost for Deep and Large Foundation Pit Based on BIM Technology and Genetic Algorithm. Appl. Sci. 2023, 13, 10716. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, X. Early Warning Model Construction for Deformation Monitoring and Management of Deep Foundation Pit Project Combined with Artificial Intelligence. Int. J. Adv. Comput. Sci. Appl. 2025, 16, 621–622. [Google Scholar] [CrossRef]

- Gayarre, F.L.; González-Nicieza, C.; Alvarez-Fernández, M.I.; Álvarez-Vigil, A. Forensic analysis of a pile foundation failure. Eng. Fail. Anal. 2010, 17, 486–497. [Google Scholar] [CrossRef]

- Hung, M.; Fabian, C. Problems in Deep Foundation Construction in Taiwan. J. Perform. Constr. Facil. 1990, 4, 259–270. [Google Scholar] [CrossRef]

- Zhang, G.; Wu, D. Analysis of foundation pit accidents due to expansive soil in Hefei district. In Proceedings of the 3rd International Conference on Civil Engineering and Transportation (ICCET 2013), Kunming, China, 14–15 December 2013. [Google Scholar]

- Zhang, X.; Zhang, Q.; Wang, C.; Wang, Y. Monitoring analysis and safety evaluation of deep foundation pit under complex conditions. In Proceedings of the 4th International Conference on Civil Engineering, Architecture and Building Materials (CEABM), Haikou, China, 24–25 May 2014. [Google Scholar]

- Qian, Q.; Lin, P. Safety risk management of underground engineering in China: Progress, challenges and strategies. J. Rock. Mech. Geotechical Eng. 2016, 8, 423–442. [Google Scholar] [CrossRef]

- Zhou, H.; Zhang, H. Risk assessment methodology for a deep foundation pit construction project in Shanghai, China. J. Constr. Eng. Manag.-ASCE 2011, 137, 1185–1194. [Google Scholar] [CrossRef]

- Wang, C.; Lu, Y.; Dai, Y.; Wu, H.; Ma, Z. In-situ 4D CT analysis of microcrack evolution in carbonated fiber-reinforced recycled aggregate concrete. Cem. Concr. Compos. 2025, 163, 106161. [Google Scholar] [CrossRef]

- Wang, C.; Du, Z.; Zhang, Y.; Li, L.; Ma, Z. Meso-structural insights into post-peak behaviors of micro steel fiber-reinforced recycled aggregate concrete using in-situ 4D CT and DVC techniques. J. Build. Eng. 2025, 100, 111674. [Google Scholar] [CrossRef]

- Wang, C.; Yuan, J.; Zhang, Y.; Wu, H.; Ma, Z. Advanced in-situ 4D CT reconstruction for exploring fiber distribution effects on the mechanical behaviors and interface optimization of carbonated high-toughness recycled aggregate concrete. Constr. Build. Mater. 2025, 473, 140941. [Google Scholar] [CrossRef]

- Wang, C.; Guo, J.; Wang, X.; Zhang, Y.; Ma, Z. Dynamic mechanical properties and damage constitutive model of high-toughness recycled aggregate concrete under high strain rate impact loads. J. Build. Eng. 2025, 106, 112589. [Google Scholar] [CrossRef]

- Wang, C.; Zhao, W.; Dai, Y.; Wu, H.; Ma, Z. Exploring the energy dissipation mechanism and toughness quantitative model for high-toughness recycled concrete subjected to dynamic impact loading. J. Build. Eng. 2025, 108, 112809. [Google Scholar] [CrossRef]

- Tian, W.; Meng, J.; Zhong, X.; Tan, X. Intelligent Early Warning System for Construction Safety of Excavations Adjacent to Existing Metro Tunnels. Adv. Civ. Eng. 2021, 2021, 8833473. [Google Scholar] [CrossRef]

- Hu, H.; He, J.; Liu, P.; Zhu, C. Identification and evaluation of deep foundation pit construction risks based on Grey-DEMATEL-Fuzzy comprehensive evaluation method. PLoS ONE 2024, 19, e0304095. [Google Scholar]

- Pan, Y.; Zhou, X.; Chen, J.; Hong, Y. Temporal-spatial-fusion-based risk assessment on the adjacent building during deep excavation. Inf. Fusion. 2025, 114, 102653. [Google Scholar] [CrossRef]

- Mana, A.; Clough, G. Prediction of Movements for Braced Cuts in Clay. J. Geotechical Eng. Div. 1981, 107, 759–777. [Google Scholar] [CrossRef]

- Ou, C.-Y.; Hsieh, P.-G.; Chiou, D.-C. Characteristics of ground surface settlement during excavation. Can. Geotech. J. 1993, 30, 758–767. [Google Scholar] [CrossRef]

- Wu, B.; Wei, Y.; Meng, G.; Xu, S.; Wang, Q.; Cao, D.; Zhao, C. Multi-Source Monitoring Data Fusion Comprehensive Evaluation Method for the Safety Status of Deep Foundation Pit. Sustainability 2023, 15, 11809. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, F.; Wang, Y.; Zhang, Y.; Sun, Z.; Zhang, M. Prediction of retaining structure deformation of ultra-deep foundation pit by empirical mode decomposition with recurrent neural networks. Environ. Earth Sci. 2023, 82, 553. [Google Scholar] [CrossRef]

- Zhang, Y.; Xing, X.; Antwi-Afari, M.F. A hybrid approach for optimizing deep excavation safety measures based on Bayesian network and design structure matrix. Adv. Eng. Inform. 2023, 58, 102223. [Google Scholar] [CrossRef]

- Zhou, C.; Ding, L. Safety barrier warning system for underground construction sites using Internet-of-Things technologies. Autom. Constr. 2017, 83, 372–389. [Google Scholar] [CrossRef]

- Zhou, C.; Ding, L.; Zhou, Y.; Luo, H. Topological mapping and assessment of multiple settlement time series in deep excavation: A complex network perspective Author links open overlay panel. Adv. Eng. Inform. 2018, 36, 1–19. [Google Scholar] [CrossRef]

- Wu, J.; Peng, L.; Li, J.; Zhou, X.; Zhong, J.; Wang, C.; Sun, J. Rapid safety monitoring and analysis of foundation pit construction using unmanned aerial vehicle images. Autom. Consruction 2021, 128, 103706. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, C.; Ding, L.; Sekula, P.; Love, P.; Zhou, C. Combining association rules mining with complex networks to monitor coupled risks. Reliab. Eng. Syst. Saf. 2019, 186, 194–208. [Google Scholar] [CrossRef]

- Xu, Y.; Zhao, Y.; Jiang, Q.; Sun, J.; Tian, C.; Jiang, W. Machine-Learning-Based Deformation Prediction Method for Deep Foundation-Pit Enclosure Structure. Appl. Sci. 2024, 14, 1273. [Google Scholar] [CrossRef]

- Huang, J.; Jian, X.; Ren, H. Research on Safety Risk Evaluation System for Seepage in Ship Lock Foundation Pit Engineering. Buildings 2024, 14, 2972. [Google Scholar] [CrossRef]

- Sheikh, M.R.; Nakata, Y.; Shitano, M.; Kaneko, M. Rainfall-induced unstable slope monitoring and early warning through tilt sensors. Soils Found. 2021, 61, 1033–1053. [Google Scholar] [CrossRef]

- Jiang, J.; Liu, G.; Ou, X. Risk Assessment of Constructing Deep Foundation Pits for Metro Stations Based on Fuzzy Evidence Reasoning and Two-tuple Linguistic Analytic Network Process. Shock. Vib. 2022, 2022, 2650627. [Google Scholar] [CrossRef]

- He, S.; Song, D.; Mitri, H.; He, X.; Chen, J.; Li, Z.; Xue, Y.; Chen, T. Integrated rockburst early warning model based on fuzzy comprehensive evaluation method. Int. J. Rock. Mech. Min. Sci. 2021, 142, 104767. [Google Scholar] [CrossRef]

- Guo, Y.; Li, C.; Yan, M.; Ma, R.; Bi, W. Research on Deformation Safety Risk Warning of Super-Large and Ultra-Deep Foundation Pits Based on Long Short-Term Memory. Buildings 2024, 14, 1464. [Google Scholar] [CrossRef]

- Wang, X.; Xu, Z.; Sun, Y.; Zheng, J.; Zhang, C.; Duan, Z. Construction of multi-factor identification model for real-time monitoring and early warning of mine water inrush. Int. J. Min. Sci. Technol. 2021, 31, 853–866. [Google Scholar] [CrossRef]

- Bahrami, M.; Roghani, B.; Gratl, T.F.; Rokstad, M.M. A deep dive into green infrastructure failures using fault tree analysis. Water Res. 2024, 257, 121676. [Google Scholar] [CrossRef]

- Ji, S.; Yang, M.; Yu, K. 3D convolutional neural networks for human action recognition. IEEE Trans. Pattern Anal. Mach. Intell. 2013, 35, 221–231. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Zheng, Y.; Qi, D. Deep spatio-temporal residual networks for citywide crowd flows prediction. In Proceedings of the 31st AAAI Conference on Artificial Intelligence, San Franciso, CA, USA, 4–9 February 2017. [Google Scholar]

- Rui, F.; Zuo, Z.; Li, F. Using LSTM and GRU neural network methods for traffic flow prediction. In Proceedings of the Youth Academic Conference of Chinese Association of Automation, Hefei, China, 19–21 May 2017. [Google Scholar]

- Wang, R.; Zhang, L.; Lu, X. Crop Evaluation System Optimization: Attributte Weights Determination Based on Rough Sets Theory. Math. Probl. Eng. 2017, 2017, 6781671. [Google Scholar] [CrossRef]

- Chao, L.; Zhang, K.; Li, Z.; Zhu, Y.; Wang, J.; Yu, Z. Geographically weighted regression based methods for merging satellite and gauge precipitation. J. Hydrol. 2018, 558, 275–289. [Google Scholar] [CrossRef]

- Wei, T.; Song, P.; Chen, Y.; Xu, H.; Jin, C.; Choy, L.K.S.K.T. Short-Term Intensity Prediction of Tropical Cyclones Based on Multi-Source Data Fusion with Adaptive Weight Learning. Remote Sens. 2024, 16, 984. [Google Scholar]

- Wang, J.; Jiang, Z.; Li, F.; Chen, W. The prediction of water level based on support vector machine under construction condition of steel sheet pile cofferdam. Concurr. Comput. Pract. Exp. 2020, 33, e6003. [Google Scholar] [CrossRef]

- Lan, B.; Wang, Y.; Wang, W. Review of the Double-Row Pile Supporting Structure and Its Force and Deformation Characteristics. Appl. Sci. 2023, 13, 7715. [Google Scholar] [CrossRef]

- Zhang, J. Finite Element Analysis of Ultra-deep Foundation Pit Covered Top-Down Excavation Based on PLAXIS. Earth Environ. Sci. 2019, 300, 022158. [Google Scholar] [CrossRef]

- Xiao, B.; Li, P. Load Regularity Analysis on Spatial Load Forecasting of Urban Power System. Power Syst. Technol. 2009, 33, 113–119. [Google Scholar]

- Ma, Q.; Liu, S.; Fan, X. A time series prediction model of foundation pit deformation based on empirical wavelet transform and NARX network. Mathematics 2020, 8, 1535. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, S.; Zhou, C.; Luo, H. Intelligent Approach Based on Random Forest for Safety Risk Prediction of Deep Foundation Pit in Subway Stations. J. Comput. Civ. Eng. 2018, 33, 05018004. [Google Scholar] [CrossRef]

- Zhu, H.; Yan, J.; Liang, W. Challenges and Development Prospects of Ultra-Long and Ultra-Deep Mountain Tunnels. Engineering 2019, 5, 384–392. [Google Scholar] [CrossRef]

- Fathi, F.; Kariminejad, N.; Boali, A.; Shamsi, S.; Shafaie, V.; Rad, M.; Pourghasemi, H. Assessment of soil erosion patterns in Maharloo watershed using remote sensing techniques and early warning signals. J. Arid Environ. 2026, 232, 105496. [Google Scholar] [CrossRef]

| Target Layer | Criteria Layer | Indicator Layer |

|---|---|---|

| Deep Foundation Pit Construction Risk Assessment Index System T | Personnel Factors T1 | T11 Personnel safety risk awareness T12 Personnel professional technical level T13 Personnel safety emergency response capability T14 Construction compliance with standards and specifications |

| Machinery and Equipment Factors T2 | T21 Machinery and equipment maintenance measures T22 Machinery and equipment operation arrangement, and command T23 Machinery and equipment operation compliance T24 Rationality of machinery and equipment selection | |

| Construction Material Factors T3 | T31 Concrete strength T32 Steel support stress T33 Anchor rod strength and quality T34 Retaining wall material quality compliance T35 Material processing quality control | |

| Management FactorsT4 | T41 Safety and civilized construction education and training T42 Construction safety risk management measures T43 Safe construction organization design scheme T44 Inspection, monitoring, and early-warning control measures | |

| Construction Technology Factors T5 | T51 Geological and hydrological survey analysis T52 Foundation pit waterproof curtain design and construction T53 Foundation pit support installation and dismantling design and construction T54 Foundation pit retaining structure design and construction T55 Foundation pit earthwork excavation construction T56 Drainage and dewatering construction control measures | |

| Environmental Factors T6 | T61 Soil layer geological conditions T62 Underground hydrological conditions T63 Construction climate conditions T64 Underground pipeline burial situation T65 Location and size of surrounding buildings T66 Surrounding road traffic conditions |

| Tomek Links | SMOTE |

|---|---|

| From imbleam.under_sampling import TomekLinks | From imblearn.over_sampling import SMOTE |

| Tl = TomekLinks(return_indices = Ture, atio = majority) | Smote = SMOTE(ratio = minority) |

| X_tl, y_tl, id_tl = tl.fit_sample(X,y) | X_sm, y_sm = smote.fit_sample(X,y) |

| Sample | Impact Factors | Level of Risk | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | …… | Cn | ||

| 1 | 0.66 | 0.94 | 0.71 | 0.30 | 0.67 | 0.09 | 0.05 | 0.31 | 0.86 | III | |

| No | Monitoring Items | Monitoring Scope | Measuring Point Sections and Spacing | Remarks |

|---|---|---|---|---|

| 1 | Foundation pit interior and exterior observation | Ground outside pit, building strata soil description, support piles, internal supports | Conducted at any time | Including surrounding ground cracks, collapse, seepage, overloading, etc. |

| 2 | Surface settlement around foundation pit | Surrounding area within twice the excavation depth | Midpoints of long and short sides, with spacing within 20–50 m range | No less than 3 monitoring points on each side |

| 3 | Wall top displacement | Top ring beam of wall | Midpoints of long and short sides, with spacing within 20 m range | No less than 3 monitoring points on each side |

| 4 | Groundwater | Around foundation pit | Outside pit: midpoints of long and short sides, with spacing within 20–50 m range; inside pit: preferably arranged at the center and peripheral corners of foundation pit | |

| 5 | Wall deformation | Full height of wall | Midpoints of long and short sides, with spacing within 20–50 m range; vertical spacing 1 m | No less than 3 monitoring points on each side |

| 6 | Support axial force | End or middle of supports | Within <15 m range from midpoints of long and short sides | No less than 3 internal force monitoring points for each support layer |

| 7 | Pipeline monitoring | Around foundation pit | Pipeline monitoring points should have planar spacing of 15–25 m, extending beyond pit edge by 1 times the excavation range | No less than 3 monitoring points for each pipeline |

| 8 | Important buildings (structures) | Both sides of foundation pit | Corner points and midpoints of buildings (structures), with peripheral arrangement spacing no greater than 10 m | No less than 3 monitoring points on each side of building |

| 9 | Intermediate support pile columns | Vertical displacement | One measuring point for each intermediate support |

| Monitoring Time/Day | Actual Value | Level III Warning Value | Level II Warning Value | Level I Warning Value | ||||

|---|---|---|---|---|---|---|---|---|

| Daily Variable | Cumulative Variable | Daily Variable | Cumulative Variable | Daily Variable | Cumulative Variable | Daily Variable | Cumulative Variable | |

| 11 | −0.20 | 13.20 | 2.4 mm/d | 24 mm | 2.7 mm/d | 27 mm | 3.0 mm/d | 30 mm |

| 12 | −0.70 | 12.50 | ||||||

| 13 | −2.80 | 11.90 | ||||||

| 14 | −2.50 | 9.40 | ||||||

| 15 | −0.10 | 9.30 | ||||||

| 16 | 0.20 | 9.50 | ||||||

| 17 | 0.10 | 9.60 | ||||||

| 18 | 0.20 | 9.80 | ||||||

| Monitoring Time/Day | Actual Value | Level III Warning Value | Level II Warning Value | Level I Warning Value | ||||

|---|---|---|---|---|---|---|---|---|

| Daily Variable | Cumulative Variable | Daily Variable | Cumulative Variable | Daily Variable | Cumulative Variable | Daily Variable | Cumulative Variable | |

| 69 | −0.10 | 26.40 | 3.2 mm/d | 36 mm | 3.6 mm/d | 40.5 mm | 4.0 mm/d | 45 mm |

| 70 | −0.40 | 26.80 | ||||||

| 71 | −0.10 | 26.20 | ||||||

| 72 | −0.50 | 26.20 | ||||||

| 73 | 4.00 | 30.20 | ||||||

| 74 | 3.50 | 33.70 | ||||||

| 75 | 3.10 | 36.90 | ||||||

| 76 | 0.20 | 24.40 | ||||||

| 77 | −0.20 | 24.20 | ||||||

| Monitoring Time/Day | Actual Value | Level III Warning Value | Level II Warning Value | Level I Warning Value | ||||

|---|---|---|---|---|---|---|---|---|

| Daily Variable | Cumulative Variable | Daily Variable | Cumulative Variable | Daily Variable | Cumulative Variable | Daily Variable | Cumulative Variable | |

| 236 | −0.17 | 12.19 | 2.4 mm/d | 28 mm | 2.7 mm/d | 31.5 mm | 3.0 mm/d | 35 mm |

| 237 | −0.27 | 11.92 | ||||||

| 238 | 0.27 | 12.19 | ||||||

| 239 | 0.36 | 12.55 | ||||||

| 240 | 1.43 | 13.98 | ||||||

| 241 | 0.57 | 14.55 | ||||||

| 242 | 1.42 | 15.97 | ||||||

| 243 | 2.88 | 18.85 | ||||||

| 244 | 0.08 | 18.93 | ||||||

| Dataset | Cofferdam Deformation (D11) | Foundation Pit Deformation (D12) |

|---|---|---|

| Data Sample | 258 | 234 |

| Type of Accident | Ground Deformation (D21) | Support Deformation (D22) | Retaining Structure Cracking and Seepage (D23) | Slope Structure Instability (D24) | Cofferdam Structure Instability (D25) |

|---|---|---|---|---|---|

| Sample | 216 | 223 | 258 | 257 | 271 |

| Sample | Impact Factors | Risk Level | |||||

|---|---|---|---|---|---|---|---|

| C1 | C2 | C3 | C4 | C5 | C6 | ||

| 1 | 0.85 | 0.52 | 0.84 | 0.95 | 0.47 | 0.30 | I |

| 2 | 0.69 | 0.78 | 0.46 | 0.03 | 0.38 | 0.92 | IV |

| 3 | 0.66 | 0.38 | 0.88 | 0.19 | 0.60 | 0.07 | II |

| 4 | 0.72 | 0.73 | 0.97 | 0.91 | 0.14 | 0.61 | III |

| 5 | 0.25 | 0.85 | 0.60 | 0.30 | 0.73 | 0.28 | V |

| 6 | 0.70 | 0.60 | 0.99 | 0.94 | 0.94 | 0.36 | II |

| 7 | 0.95 | 0.97 | 0.47 | 0.75 | 0.00 | 0.10 | V |

| 8 | 0.15 | 0.76 | 0.27 | 0.98 | 0.38 | 0.29 | IV |

| 9 | 0.28 | 0.03 | 0.80 | 0.90 | 0.52 | 0.33 | III |

| 10 | 0.81 | 0.29 | 0.70 | 0.35 | 0.69 | 0.69 | V |

| 11 | 0.43 | 0.99 | 0.04 | 0.72 | 0.90 | 0.47 | IV |

| 12 | 0.14 | 0.28 | 0.88 | 0.18 | 0.68 | 0.76 | II |

| 13 | 0.13 | 0.20 | 0.23 | 0.71 | 0.75 | 0.07 | III |

| 14 | 0.68 | 0.28 | 0.77 | 0.14 | 0.71 | 0.22 | V |

| 15 | 0.61 | 0.54 | 0.75 | 0.70 | 0.54 | 0.15 | II |

| System | Configuration |

|---|---|

| Local Computer | Intel Core i7-8565-U, 64-bit OS, 16.0 GB RAM |

| Google Collaboratory | Python 3 Google Compute Engine backend (TPU) |

| IBM Watson Studio | 4 vCPU and 16 GB RAM, Default Python 3.6 S |

| Dataset | Learning Time | Std. | Prediction Time | Std. |

|---|---|---|---|---|

| D11 | 378.37 | 0.01 | 31.28 | 0.01 |

| D12 | 429.23 | 0.01 | 33.02 | 0.01 |

| D21 | 458.33 | 0.02 | 34.06 | 0.02 |

| D22 | 440.28 | 0.02 | 34.73 | 0.04 |

| D23 | 466.86 | 0.02 | 36.42 | 0.01 |

| D24 | 496.36 | 0.02 | 38.42 | 0.03 |

| D25 | 487.34 | 0.02 | 34.50 | 0.02 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, F.; Zheng, M.; Yu, J.; Ding, X.; Xiahou, X.; Li, Q. Deep Learning-Based Safety Early-Warning Model for Deep Foundation Pit Construction with Extra-Long Weir Construction Method—A Case Study of the Jinji Lake Tunnel. Buildings 2025, 15, 4270. https://doi.org/10.3390/buildings15234270

Li F, Zheng M, Yu J, Ding X, Xiahou X, Li Q. Deep Learning-Based Safety Early-Warning Model for Deep Foundation Pit Construction with Extra-Long Weir Construction Method—A Case Study of the Jinji Lake Tunnel. Buildings. 2025; 15(23):4270. https://doi.org/10.3390/buildings15234270

Chicago/Turabian StyleLi, Funing, Min Zheng, Jiaxin Yu, Xingyuan Ding, Xiaer Xiahou, and Qiming Li. 2025. "Deep Learning-Based Safety Early-Warning Model for Deep Foundation Pit Construction with Extra-Long Weir Construction Method—A Case Study of the Jinji Lake Tunnel" Buildings 15, no. 23: 4270. https://doi.org/10.3390/buildings15234270

APA StyleLi, F., Zheng, M., Yu, J., Ding, X., Xiahou, X., & Li, Q. (2025). Deep Learning-Based Safety Early-Warning Model for Deep Foundation Pit Construction with Extra-Long Weir Construction Method—A Case Study of the Jinji Lake Tunnel. Buildings, 15(23), 4270. https://doi.org/10.3390/buildings15234270