A Comparative Analysis of Prefabricated and Traditional Construction of a Rail Transit Equipment Room Piping System Under a Mountainous Area: A Case Study of Chongqing Rail Transit

Abstract

1. Introduction

1.1. Background

1.2. Overview of Pipeline System Prefabrication Mode

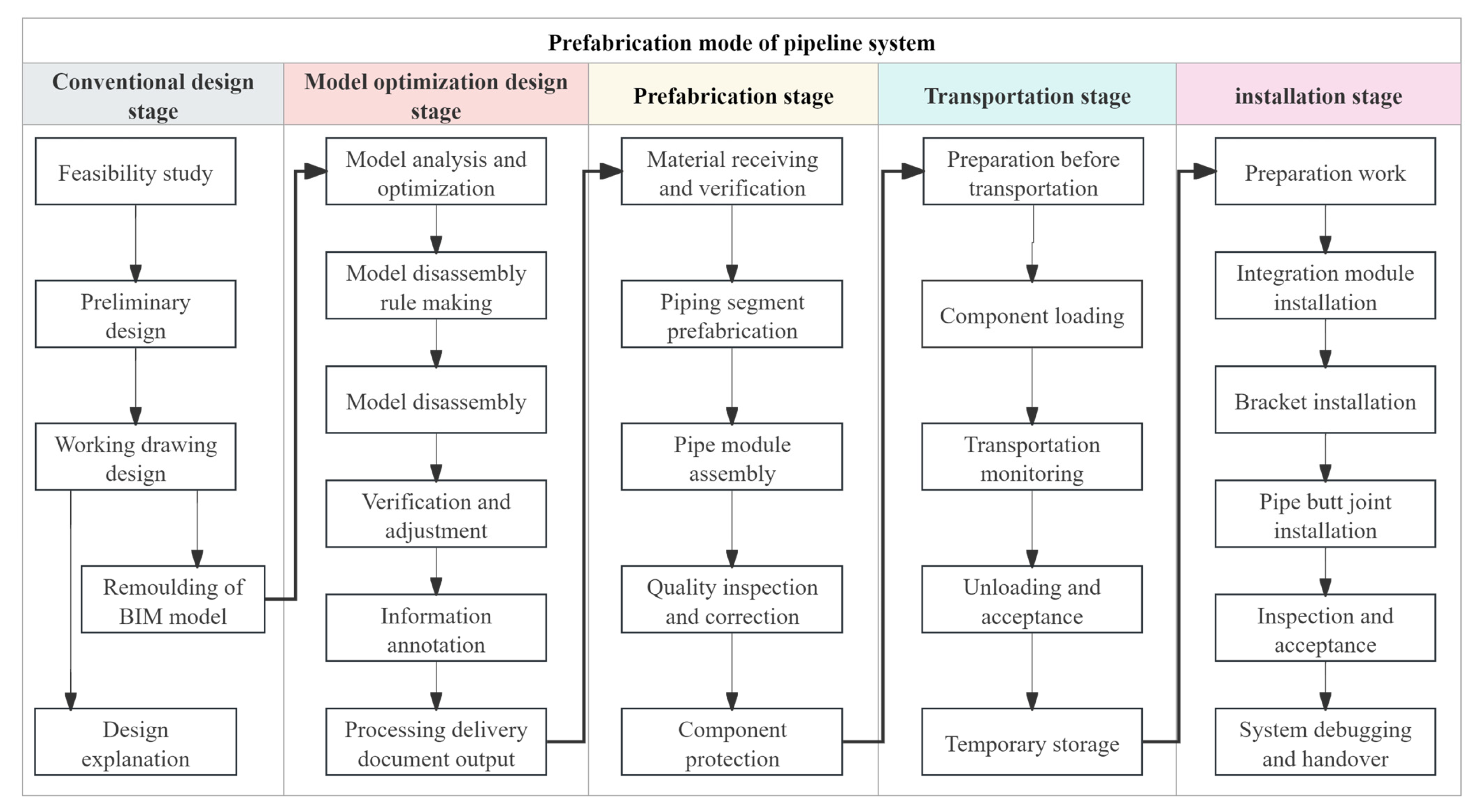

1.2.1. Prefabrication Mode

1.2.2. Application of Prefabricated Mode

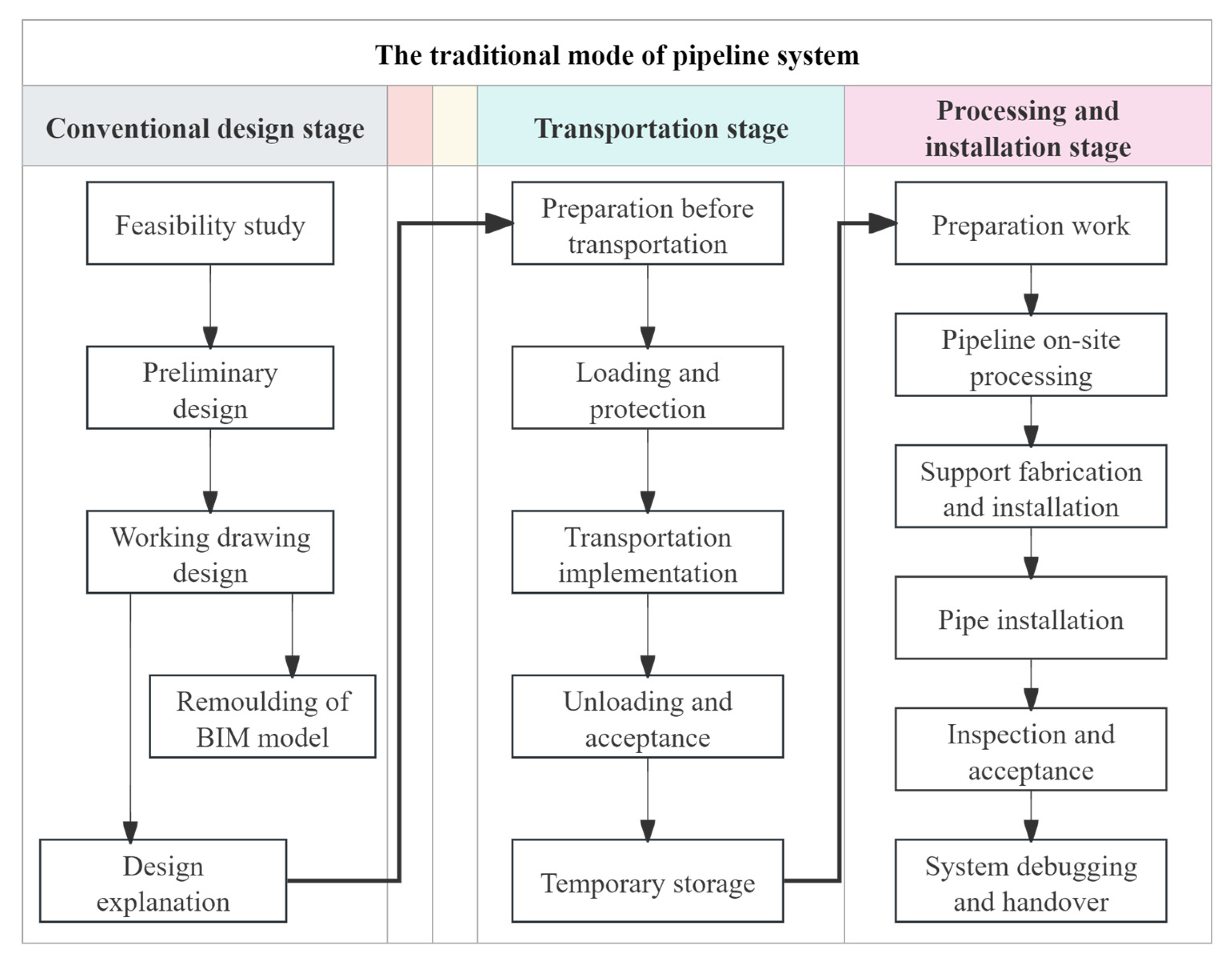

1.2.3. Overview of Pipeline System Construction

1.2.4. Summary

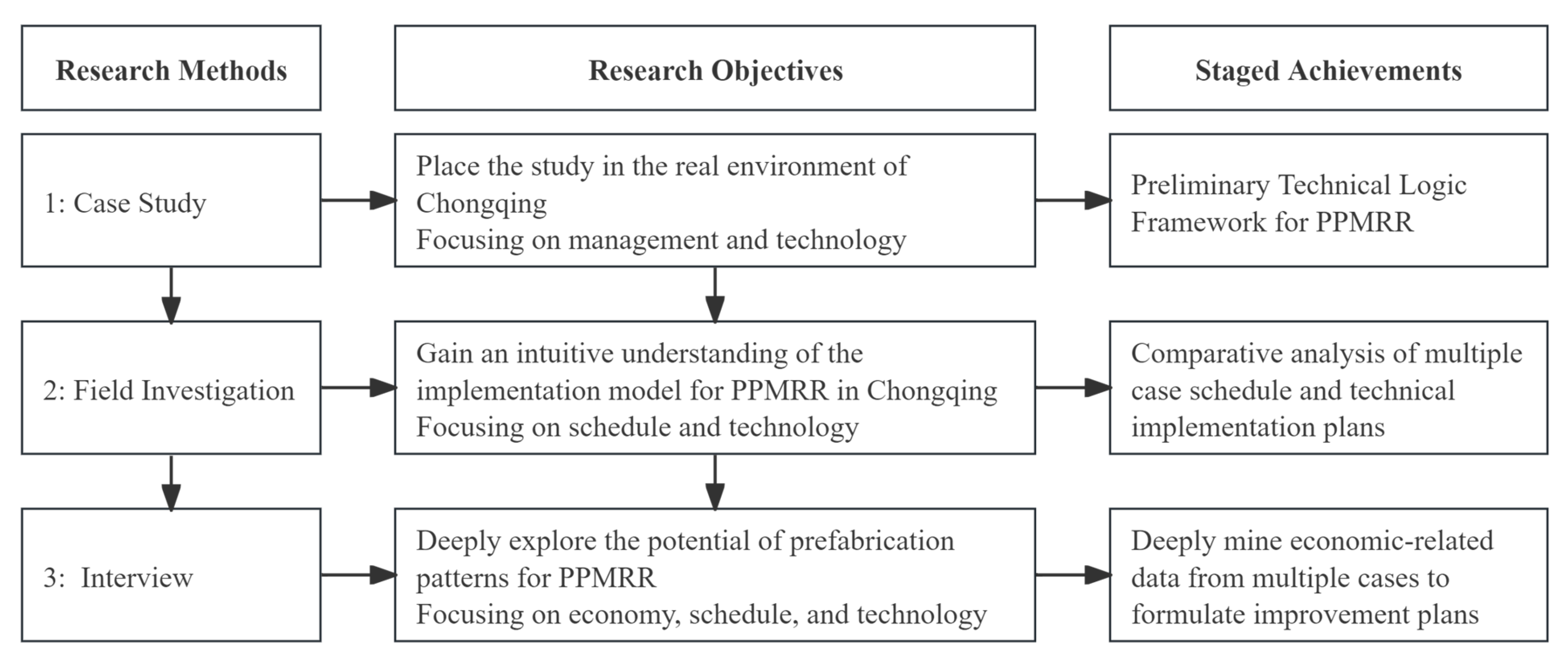

2. Research Methods

2.1. Case Study

2.2. Site Visit

2.3. Interview

3. Analysis and Discussion of Typical Case Studies

3.1. Overview of Typical Cases of Chongqing Rail Transit

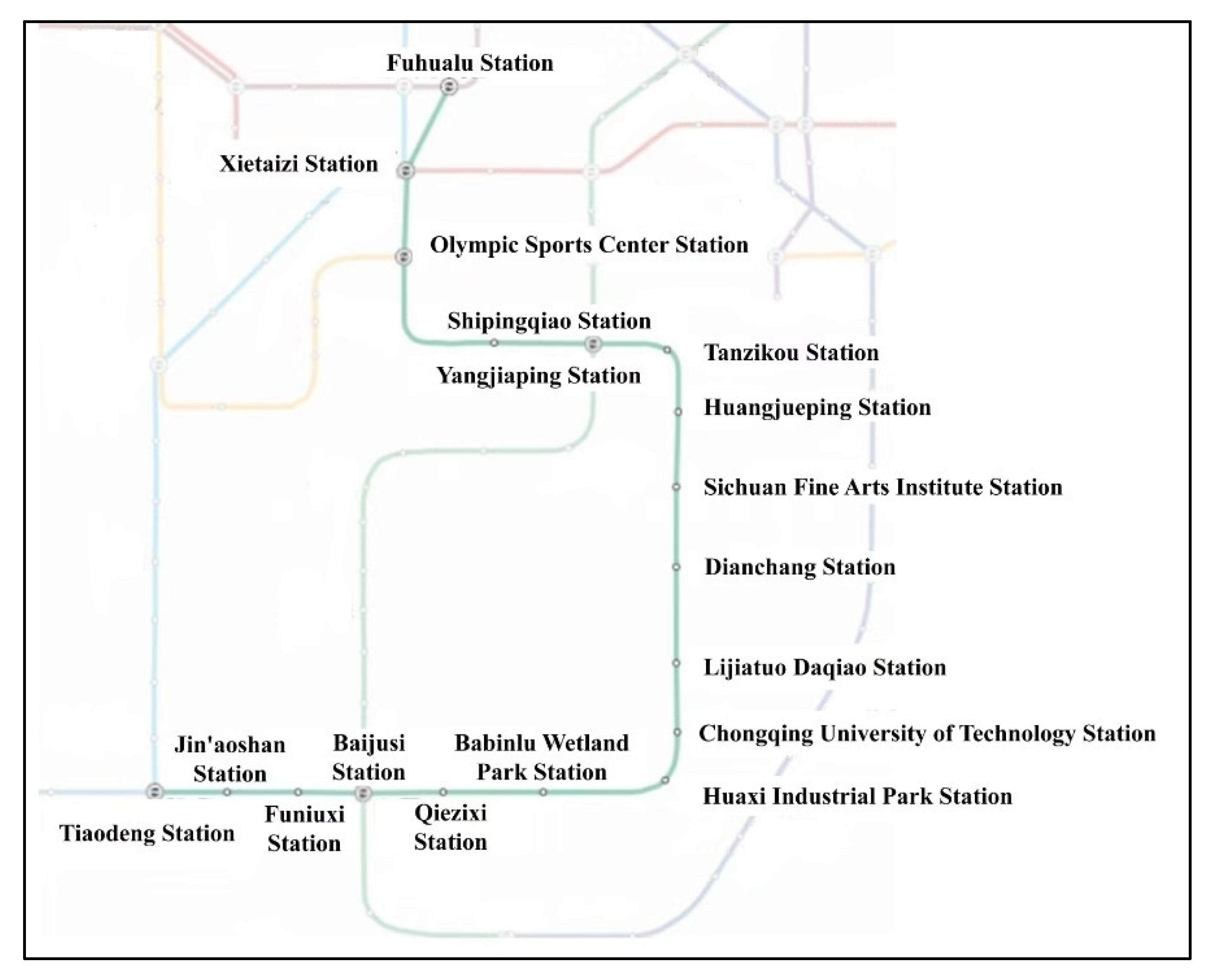

3.1.1. Chongqing Rail Transit Line 18 Project

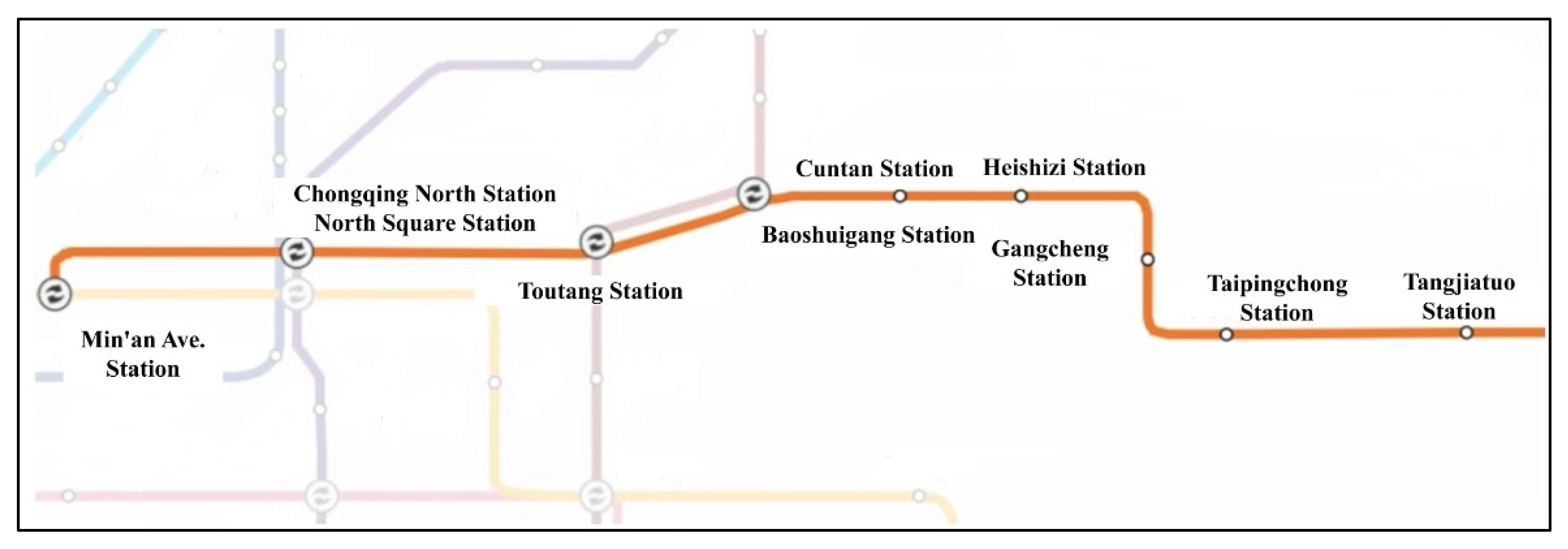

3.1.2. Chongqing Rail Transit Line 4 Project

3.2. Comparative Analysis of the Implementation Methods of Pipeline System Between Equipment Pipelines

3.2.1. Progress Dimension Comparison

3.2.2. Comparison of Technical Dimensions

3.2.3. Economic Dimension Comparison

4. Discussion

4.1. Design Model Optimization

4.2. Information Chain and Collaborative Management Between Stages

4.3. The Supporting Professional Level of Prefabricated Mode

4.4. Limitations of This Study

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Correspondence Stage of Respondents | Core Research Direction | Semi-Structured Interview Questions |

|---|---|---|

| Design Phase (including BIM model optimization) |

1. Interdisciplinary collaboration and optimized disassembly;

2. Model-field precision matching; 3. Economic control in the modeling stage; | 1. Does the prefabrication mode impose limitations in your construction drawing design? If yes, what are they? 2. When optimizing the BIM model, what are the high-frequency difficulties and solutions of cross-disciplinary coordination? What are the standards and difficulties of pipe disassembly? 3. How do you align the fineness of the pipeline model between the platform equipment with the on-site accuracy? Has there ever been a case of rework due to precision deviation? If yes, can you share cases and improvements? 4. What are the main costs of the BIM phase? How much cost savings can be achieved through model optimization? |

| Pipeline Prefabrication Phase | 1. Prefabrication Process Bottlenecks and Precision Control; 2. Prefabrication Phase Cost Optimization; | 1. From prefabrication drawing review to component delivery, what is the most critical bottleneck process in the entire workflow? How would you recommend optimizing it? 2. Where do the main precision challenges lie in pipeline processing? If discrepancies between components and the BIM model are identified during re-inspection, how would you resolve them? 3. What proportion of total costs do raw materials account for in the prefabrication phase? What level of cost optimization could be achieved through procurement improvements and waste reduction? Is the current labor allocation appropriately aligned with the prefabrication schedule? |

| Prefabricated Component Transportation Phase | 1. Transportation-Warehousing Coordination and Risk Management; 2. Economic Optimization of Transportation and Warehousing; | 1. What specific transportation plan would you develop for prefabricated components (e.g., securing methods, route selection)? How would you mitigate risks such as impact damage? How should conflicts between transportation and on-site construction (e.g., storage area arrangements, hoisting operations) be coordinated? 2. Which factors significantly influence transportation costs (e.g., vehicle rental, reinforcement materials)? To what extent can transportation expenses be reduced through route optimization and shipment consolidation? How do storage methods impact component damage rates and the efficiency of secondary transportation? |

| On-site Prefabricated Installation and Construction Phase | 1. Model-On-site Matching and Rework Prevention; 2. Installation Process Optimization; 3. Installation Phase Cost Control and Management; | 1. When discrepancies are identified between BIM models and field conditions (e.g., structural dimensional deviations), how would you address them? What impact would such discrepancies have on installation efficiency? How are common rework issues identified during acceptance inspections (e.g., interface leakage) correlated with construction techniques and worker operations? 2. What are the key technical challenges in component assembly (e.g., flange sealing, pipeline slope control)? What specific improvements in construction techniques would you recommend? 3. What are the respective proportions of labor and equipment costs during the installation phase? To what extent could costs be reduced through shift scheduling optimization and equipment idle time reduction? |

| Post On-site Construction Acceptance | 1. Labor and Schedule Profiles: Prefabricated vs. Conventional Modes; 2. Comparative Evaluation of Full-Life-Cycle Economics; | 1. When comparing prefabricated installation with the conventional mode, what are the fundamental differences in personnel allocation (specialization of labor, skill requirements) and overall project timeline? What are the underlying reasons? How do these differences impact labor costs? 2. In which specific phases (design → prefabrication → transportation → installation → maintenance) are the most significant differences in full lifecycle costs manifested between the two modes? At what stage do the cost advantages of the prefabricated mode (such as maintenance savings) typically become apparent? 3. What is the return on investment for the upfront additional investments in the prefabricated mode (e.g., BIM software, prefabrication equipment)? What factors primarily support its economic advantages (e.g., benefits from shortened project durations)? |

References

- Shahtaheri, Y.; Rausch, C.; West, J.; Haas, C.; Nahangi, M. Managing risk in modular construction using dimensional and geometric tolerance strategies. Autom. Constr. 2017, 83, 303–315. [Google Scholar] [CrossRef]

- Jang, S.; Lee, G. Process, productivity, and economic analyses of BIM–based multi-trade prefabrication—A case study. Autom. Constr. 2018, 89, 86–98. [Google Scholar] [CrossRef]

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Guiding Opinions on Promoting the Collaborative Development of Intelligent Construction and Building Industrialization; Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2020. Available online: http://www.gov.cn/zhengce/zhengceku/2020-07/28/content_5530762.htm (accessed on 28 May 2025).

- Hu, R.; Chen, K.; Fang, W.; Zheng, L.; Xu, J. The technology-environment relationship revisited: Evidence from the impact of prefabrication on reducing construction waste. J. Clean. Prod. 2022, 341, 130883. [Google Scholar] [CrossRef]

- Liu, W. Practice of Prefabricated Mechanical and Electrical Installation in Urban Rail Transit. Build. Constr. 2021, 43, 2360–2363. [Google Scholar]

- Dong, C.; Wang, H.; Zhang, H.; Zhang, M.; Guan, J.; Zhang, Z.; Lin, Q.; Zuo, Z. Research on Fine Scheduling and Assembly Planning of Modular Integrated Building: A Case Study of the Baguang International Hotel Project. Buildings 2022, 12, 1892. [Google Scholar] [CrossRef]

- Baek, S.; Won, J.; Jang, S. Economic Integrated Structural Framing for BIM-Based Prefabricated Mechanical, Electrical, and Plumbing Racks. Appl. Sci. 2023, 13, 3677. [Google Scholar] [CrossRef]

- Banihashemi, S.; Tabadkani, A.; Hosseini, M.R. Integration of parametric design into modular coordination: A construction waste reduction workflow. Autom. Constr. 2018, 88, 1–12. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Fung, I.W.H.; Sing, M.C.P.; Ogunlana, S.O. Best practice of prefabrication implementation in the Hong Kong public and private sectors. J. Clean. Prod. 2015, 109, 216–231. [Google Scholar] [CrossRef]

- Sweis, G.; Sweis, R.; Hammad, A.; Shboul, A. Delays in construction projects: The case of Jordan. Int. J. Proj. Manag. 2008, 26, 665–674. [Google Scholar] [CrossRef]

- Li, Z.; Shen, G.Q.; Xue, X. Critical review of the research on the management of prefabricated construction. Habitat Int. 2014, 43, 240–249. [Google Scholar] [CrossRef]

- Zhang, W.; Lee, M.W.; Jaillon, L.; Poon, C.S. The hindrance to using prefabrication in Hong Kong’s building industry. J. Clean. Prod. 2018, 204, 70–81. [Google Scholar] [CrossRef]

- Li, X.; Li, Z.; Wu, G. Modular and Offsite Construction of Piping: Current Barriers and Route. Appl. Sci. 2017, 7, 547. [Google Scholar] [CrossRef]

- Khanzode, A.; Fischer, M.A.; Reed, D.A. Benefits and lessons learned of implementing building virtual design and construction (VDC) technologies for coordination of mechanical, electrical, and plumbing (MEP) systems on a large healthcare project. J. Inf. Technol. Constr. 2008, 13, 324–342. [Google Scholar]

- Zhang, Y.; Bai, X.; Dong, D.; Liu, C.; Li, B. Modular installation technology of MEP pipelines on the standard floor of super high-rise buildings. Installation 2019, 9, 53–56. [Google Scholar]

- Zhu, X.; Gao, Y. Discussion on modular design and construction of hospital data center computer room. Chin. J. Health Inf. Manag. 2022, 19, 551–555. [Google Scholar]

- Tommelein, I.D.; Gholami, S. Root causes of clashes in building information models. In Proceedings of the 20th Annual Conference of the International Group for Lean Construction, San Diego, CA, USA, 18–20 July 2012; pp. 1–10. [Google Scholar]

- Korman, T.M.; Simonian, L.; Speidel, E. Using Building Information Modeling to Improve the Mechanical, Electrical, and Plumbing Coordination Process for Buildings. J. Inf. Technol. Constr. 2008, 13, 1–10. [Google Scholar]

- Riley, D.R.; Varadan, P.; James, J.S.; Thomas, H.R. Benefit-Cost Metrics for Design Coordination of Mechanical, Electrical, and Plumbing Systems in Multistory Buildings. J. Constr. Eng. Manag. 2005, 131, 877–889. [Google Scholar] [CrossRef]

- Korman, T.M.; Fischer, M.A.; Tatum, C.B. Knowledge and Reasoning for MEP Coordination. J. Constr. Eng. Manag. 2003, 129, 627–634. [Google Scholar] [CrossRef]

- Yu, Y.; Zhang, J.; Yin, K. Application of modular MEP production and processing equipment in engineering. Installation 2022, 23, 23–25. [Google Scholar]

- Liu, S.; Zhang, N.; Chen, G.; Chen, H. Application of pipeline modular prefabrication and Prefabricated construction in large refrigeration room. Construction 2022, 44, 367–370. [Google Scholar]

- Bataglin, F.S.; Viana, D.D.; Formoso, C.T.; Bulhões, I.R. Model for planning and controlling the delivery and assembly of engineer-to-order prefabricated building systems: Exploring synergies between Lean and BIM. Can. J. Civ. Eng. 2020, 47, 165–177. [Google Scholar] [CrossRef]

- Said, H. Modeling and likelihood prediction of prefabrication feasibility for electrical construction firms. J. Constr. Eng. Manag. 2016, 142, 04015071. [Google Scholar] [CrossRef]

- Samarasinghe, T.; Gunaratna, M.M.M.P.; Feng, H.; Weerasuriya, T.U.; Yigitcanlar, T. Dependency Structure Matrix and Hierarchical Clustering based algorithm for optimum module identification in MEP systems. Autom. Constr. 2019, 104, 153–178. [Google Scholar] [CrossRef]

- Safa, M.; Shahi, A.; Nahangi, M.; Haas, C.; Noori, H. Automating measurement process to improve quality management for piping fabrication. Structures 2015, 3, 71–80. [Google Scholar] [CrossRef]

- Pan, Z.; Yang, R.; Yang, Z.; Liu, D.; Zhang, Y. Recovering building information model from 2D drawings for mechanical, electrical and plumbing systems of ageing buildings. Autom. Constr. 2023, 152, 104914. [Google Scholar] [CrossRef]

- Valkonen, T.; Alhava, O.; Viitanen, J.; Seppänen, O. Why do some projects prefabricate MEP while others do not? Lean Constr. J. 2025, 2025, 96–124. [Google Scholar] [CrossRef]

- Yan, G.; Liu, S.; Wang, H.; Ma, G.; Wang, L. A review of life cycle construction process and cutting-edge technology in prefabricated MEP installation engineering. Buildings 2024, 14, 630. [Google Scholar] [CrossRef]

- Antillón, E.I.; Morris, M.R.; Gregor, W. A value-based cost-benefit analysis of prefabrication processes in the healthcare sector: A case study. In Proceedings of the 22nd Annual Conference of the International Group for Lean Construction, Oslo, Norway, 25–27 June 2014; pp. 995–1006. [Google Scholar]

- McGraw Hill Construction. Prefabrication and Modularization: Increasing Productivity in the Construction Industry; McGraw Hill: New York, NY, USA, 2011; Available online: https://www.smacna.org/docs/default-source/resource-documents/prefabrication-modularization-in-the-construction-industry-smr-2011r.pdf?sfvrsn=e3b09a24_1 (accessed on 7 January 2025).

- Jaillon, L.; Poon, C.S. Sustainable construction aspects of using prefabrication in dense urban environment: A Hong Kong case study. Constr. Manag. Econ. 2008, 26, 953–966. [Google Scholar] [CrossRef]

- Yin, R.K. Case Study Research and Applications: Design and Methods, 6th ed.; SAGE Publications: Singapore, 2018. [Google Scholar]

- DBJ50/T-514-2025; Application Technical Standard of ASSEMBLED comprehensive Support and Hanger. Chongqing Housing and Urban-Rural Construction Committee: Chongqing, China, 2025.

| Rail Transit Line | Typical Platform | Platform Type | The Stage of Construction | Construction Pattern |

|---|---|---|---|---|

| Line 4 | Baoshuigang Station | underground station | Operation Phase | Conventional |

| Line 5 | Zhongliangshan Station | elevated station | Operational Phase | Conventional |

| Line 18 | Shipingqiao Station Aoti Zhongxin Station | underground station | Model Design Optimization Phase | Prefabricated |

| Prefabricated Component Fabrication Phase | ||||

| On-site Construction Phase | ||||

| Line 17 | All 10 stations | —— | Construction Document Development Phase | Prefabricated |

| NO. | Role | Corresponding to the Core Construction Stage | Relevant Work Experience (Years) |

|---|---|---|---|

| 1 | MEP General Head of Rail Transit Design Institute | Design Phase | 10 |

| 2 | MEP Designer of Rail Transit Design Institute | Design Phase | 8 |

| 3 | MEP Designer of Rail Transit Design Institute | Design Phase | 10 |

| 4 | MEP Modeling Engineer of Rail Transit Design Institute | Design Phase | 8 |

| 5 | Prefabrication plant person in charge | Pipeline Prefabrication Phase | 7 |

| 6 | Prefabrication plant employees | Pipeline Prefabrication Phase | 5 |

| 7 | The person in charge of the prefabricated component transportation fleet is a part-time driver | Prefabricated Component Transportation Phase | 5 |

| 8 | The person in charge of the on-site prefabricated construction team | On-site Prefabricated Installation Phase | 10 |

| 9 | Prefabricated construction team workers on site | On-site Prefabricated Installation Phase | 6 |

| 10 | Project leader of the rail transit construction unit | All Phases | 8 |

| 11 | Project leader of the rail transit construction unit | On-site Prefabricated Installation Phase | 12 |

| 12 | Scholars and management experts from local universities | All Phases | 15 |

| Comparative Stage | Key Indicators | Prefabricated Mode (Line 18) | Conventional Mode (Line 4) | Quantitative Difference Analysis |

|---|---|---|---|---|

| Design Optimization Phase | Total cycle | Shiping Bridge Station 97 days Chuanmei Station 112 days | 6 months of conventional design | Add 3–4 months to optimization cycle |

| Model disassembly cycle | Shipingqiao station 28 days Chuanmei station 31 days | Not this stage | —— | |

| Prefabricated drawing cycle | Shipingqiao station 20 days Chuanmei station 28 days | Not this stage | —— | |

| Prefabrication Processing Phase | Total cycle | Shipingqiao station 25 days Chuanmei station 33 days | On-site processing + acceptance for 42 days | 17.5–37.5% shorter cycle time |

| Core production cycle | Both stations are 18 days | On-site processing for 35 days | 49% shorter cycle time | |

| Transportation Phase | Effective period | Shipingqiao station 2 days Chuanmei station 1 day | Raw material transportation cycle 15 days | Cycle time shortened by more than 80% |

| On-site Installation Phase | Total cycle | Shipingqiao station 18 days Chuanmei station 23 days | Total cycle 60 days | 62–70% shorter cycle time |

| Core Process Cycle | Precast splicing 7 days | On-site cutting + welding + installation 45 days | 84% shorter cycle time |

| Comparison Category | Key Indicators | Prefabricated Mode (Line 18) | Traditional Mode (Line 4) | Quantitative Analysis of Differences |

|---|---|---|---|---|

| Design technique | BIM application depth | Identify 19 interference problems in advance. | Only BIM turnover | Prefabrication “active control” Traditional “on-site exposure problem” |

| Process technology | Component rework rate | Shipingqiao station 3.2% Chuanmei station 4.5% | 18.7% | Rework rate decreased by 71.7–81.3%. |

| Transportation technology | Component damage rate | Shipingqiao station 1.8% Chuanmei station 2.1% | 9.3% | Damage rate decreased by 77.4–81.7%. |

| Mounting technique | Debugging period | 2 days | >5 days | Reduces debugging cycle by 60% |

| Phase of the Cycles | Cost Terms | Prefabricated Mode (Line 18) | Traditional Mode (Line 4) | Cost Differential |

|---|---|---|---|---|

| Short-term construction phase | 1. Model Optimization and Drawing Production Fees | 2.00 | (without BIM optimization) | +2.00 |

| 2. Material Procurement Costs | 80.00 (contains 5% factory loss) | 65.00 (contains 15% processing loss) | +15.00 | |

| 3. Prefabrication Labor Costs | 2.00 (25 days × 4 people/day × CNY 200) | 25.20 (traditional on-site processing 60 days × 12 people/day × CNY 350) | −20.26 | |

| 4. On-site Construction Labor Costs | 2.94 (14 days × 6 people/day × CNY 350) | |||

| 5. Transportation and Equipment Rental Expenses | 20.00 (transport 120,000 + equipment lease 80,000) | 10.00 (transportation 35,000 + equipment rental 65,000) | +10.00 | |

| 6. Rework Costs | 2.00 | 5.00 | −3.00 | |

| Subtotal: Construction Phase | 108.94 | 105.20 | 3.74 | |

| Long-term Operation and Maintenance Phase | 1. Average Annual Leakage Maintenance Costs | 1.50 (prefabricated annual average maintenance costs: CNY 1–2 million) | 5.00 (traditional annual maintenance costs: CNY 4–6 million) | −3.50 |

| 2. 30-Year Total Maintenance Cost | 45.00 | 150.00 | −105 | |

| 3. End-of-Life Pipeline Replacement Costs | 54.47 (initial construction 50% cost) | 84.16 (initial construction 80% cost) | −29.69 | |

| Total 30-Year Cost | — | 208.41 | 339.36 | −130.95 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, C.; He, B.; Li, G.; Wang, J.; Ou, Y.; Luo, Q.; Chen, H.; Zhong, K.; Liu, Z.; Zhou, Y. A Comparative Analysis of Prefabricated and Traditional Construction of a Rail Transit Equipment Room Piping System Under a Mountainous Area: A Case Study of Chongqing Rail Transit. Buildings 2025, 15, 4267. https://doi.org/10.3390/buildings15234267

Wang C, He B, Li G, Wang J, Ou Y, Luo Q, Chen H, Zhong K, Liu Z, Zhou Y. A Comparative Analysis of Prefabricated and Traditional Construction of a Rail Transit Equipment Room Piping System Under a Mountainous Area: A Case Study of Chongqing Rail Transit. Buildings. 2025; 15(23):4267. https://doi.org/10.3390/buildings15234267

Chicago/Turabian StyleWang, Chun, Bo He, Gang Li, Jun Wang, Yangpeng Ou, Qing Luo, Haiqing Chen, Kun Zhong, Zhaojin Liu, and Yijun Zhou. 2025. "A Comparative Analysis of Prefabricated and Traditional Construction of a Rail Transit Equipment Room Piping System Under a Mountainous Area: A Case Study of Chongqing Rail Transit" Buildings 15, no. 23: 4267. https://doi.org/10.3390/buildings15234267

APA StyleWang, C., He, B., Li, G., Wang, J., Ou, Y., Luo, Q., Chen, H., Zhong, K., Liu, Z., & Zhou, Y. (2025). A Comparative Analysis of Prefabricated and Traditional Construction of a Rail Transit Equipment Room Piping System Under a Mountainous Area: A Case Study of Chongqing Rail Transit. Buildings, 15(23), 4267. https://doi.org/10.3390/buildings15234267