Abstract

The growing demand for sustainable, high-performance, and structurally reliable construction materials has intensified research on natural fibre-reinforced composites (NFCs). Among these, hemp stands out due to its high cellulose content, low density, excellent tensile strength, and renewability, making it a promising reinforcement for cementitious and other inorganic matrices, including lime- and geopolymer-based systems. This review focuses exclusively on structural and civil engineering applications, while polymer-based composites are mentioned only for comparative context regarding adhesion and durability. A comprehensive bibliometric and technical analysis was conducted to evaluate the effectiveness of hemp fibre treatment methods in improving fibre–matrix adhesion, mechanical performance, and long-term durability. A systematic search covering major scientific databases from 2014 to 2024 identified global research trends, key treatment techniques, and their performance outcomes. Both chemical (alkaline, silane, acetylation, alkyl ketene dimer—AKD) and physical (plasma, ozone) modification strategies were critically assessed for adhesion, mechanical strength, hydrophobicity, and resistance to environmental cycling. Quantitative results indicate that combined alkaline–AKD treatments produce the most consistent improvement, increasing compressive strength by approximately 30% and flexural strength by up to 25% compared with untreated composites. Physical surface treatments were also found to enhance roughness and interfacial bonding without degrading fibre integrity. Unlike previous reviews that address natural fibres in general, this article specifically targets hemp fibre treatments for inorganic matrices, correlating modification mechanisms with the structural performance indicators relevant to civil engineering. By integrating bibliometric mapping of research evolution, keyword networks, and technological gaps, this review provides a quantitative and engineering-oriented synthesis that highlights its original contribution to sustainable and resilient construction materials. The findings emphasise the need for standardised testing protocols and performance-based evaluations to enable the broader structural application of hemp-based composites in modern construction.

1. Introduction

The global interest in natural fibre-reinforced composites (NFCs) is growing due to their environmental and mechanical advantages, including biodegradability, low cost, low density, and high stiffness. Among the wide range of natural fibres, hemp stands out as a valuable source of high-quality cellulose due to its excellent tensile strength and fibre length, offering great potential for structural and civil engineering applications. However, conventional preparation methods, such as mercerisation, can damage the cellulose structure, thereby reducing fibre quality. To address this challenge, various pretreatment techniques, such as plasma, ozone, alkaline, silane, acetylation, and alkyl ketene dimer (AKD) treatments, have been developed to selectively remove non-cellulosic components while preserving fibre integrity. These treatments optimise the surface characteristics of the fibres, improving adhesion with cementitious and geopolymeric matrices, reducing moisture absorption, and enhancing the long-term durability of structural composites [1,2,3].

Recent studies show that fibre treatment enhances adhesion in cementitious and mortar-based composites, resulting in improved durability, reduced thermal conductivity, and enhanced mechanical behaviour [4,5]. Chemical agents such as sodium hydroxide (NaOH), calcium hydroxide (Ca(OH)2), and ethylenediaminetetraacetic acid (EDTA) have been widely used to modify fibre surfaces and increase adhesion to structural binders, particularly in fibre-reinforced mortars and concretes. However, results are highly dependent on treatment conditions such as temperature, immersion time, and solution concentration [6,7]. If not properly controlled, these parameters may impair adhesion or even degrade the fibre structure. Plant-based fibres such as hemp are particularly vulnerable to degradation in alkaline environments due to their porous structure and high-water absorption, which can lead to inadequate fibre–matrix bonding, microcracking and loss of strength in the mortar matrix [8,9,10].

To mitigate these effects, strategies have included the use of chemical agents to remove surface impurities and increase roughness, as well as the application of hydrophobic coatings to reduce water affinity [11]. While improved adhesion generally enhances the mechanical performance of hemp-based structural composites, high NaOH concentrations may cause fibre damage, underscoring the importance of optimising treatment conditions [6,8,9,11].

Given the growing number of studies on treated hemp fibres in cementitious composites, there is a clear need for a systematic review to consolidate current knowledge and provide guidance for future research. This study, therefore, presents a bibliometric and technical review of hemp fibre treatment methods, focusing on their ability to improve fibre–matrix adhesion and mechanical performance for structural applications in cementitious, lime-based, and geopolymeric composites. The specific objectives are: (i) to analyse the evolution of hemp research fibre-reinforced mortars and concretes (HFRM/HFRC) from 2014 to 2024; (ii) to perform a global bibliometric analysis of publication trends, keywords, and leading contributors; (iii) to summarise the mechanical, physical, and microstructural properties of hemp-based structural composites; and (iv) to compare the efficiency of different chemical and physical treatment methods applied to hemp fibres. By addressing existing knowledge gaps and identifying promising treatment strategies, this work aims to contribute to the advancement of sustainable and high-performance construction materials.

Unlike previous review articles that broadly discuss natural fibres in both polymeric and mineral matrices, the present study is exclusively focused on inorganic systems, including cementitious, lime-based, and geopolymeric composites. Although a few polymeric hemp composites are mentioned for comparative purposes (e.g., adhesion behaviour or hydrophilicity contrast), all mechanical data, effect sizes, and bibliometric analyses presented in this review refer exclusively to inorganic matrices.

2. Hemp Fibres and Their Relevance in Construction

Hemp, an ancient plant from the Cannabaceae family, originates from Asia and is among the earliest domesticated crops in human history. Hemp artefacts such as woven fabrics have been discovered in graves dating back to 8000 B.C. In China, records indicate its cultivation around 4500 years ago for fibre, seed, and oil production, while in Ancient Egypt, fabrics made from hemp were found in the tomb of Pharaoh Akhenaten (c. 1200 B.C.). Between the 16th and 18th centuries, hemp became an essential fibre crop in Europe, Russia, and North America [12,13].

Today, the adoption of eco-friendly hemp materials in construction aims to reduce carbon dioxide (CO2) emissions by using them as carbon sinks through photosynthesis. Although challenges such as enzymatic hydrolysis resistance remain, industrial hemp shows great promise for bioplastic production. Cannabis sativa L., a bast fibre plant, is characterised by a high cellulose content (60–80%), low lignin fraction (2–10%), and a favourable strength-to-weight ratio. The fibre, extracted from the plant’s outer bark, consists of long elementary cells bundled together by lignin and pectin. Its rapid growth cycle, minimal agricultural input, and substantial carbon sequestration capacity make it an environmentally efficient raw material. These intrinsic properties justify its growing use as reinforcement in cementitious and geopolymeric matrices [12,14,15,16].

Recent studies have concentrated on addressing processing and durability issues, while various industries are investigating hemp-derived products for their versatility and sustainability benefits. The woody core (hurds) and shorter tangled fibres produced as by-products of hemp processing can be used in lower-grade materials such as insulation panels, fibreboards, and erosion-control mats. When combined with lime, the fibrous core creates lightweight, thermally efficient concretes [17,18].

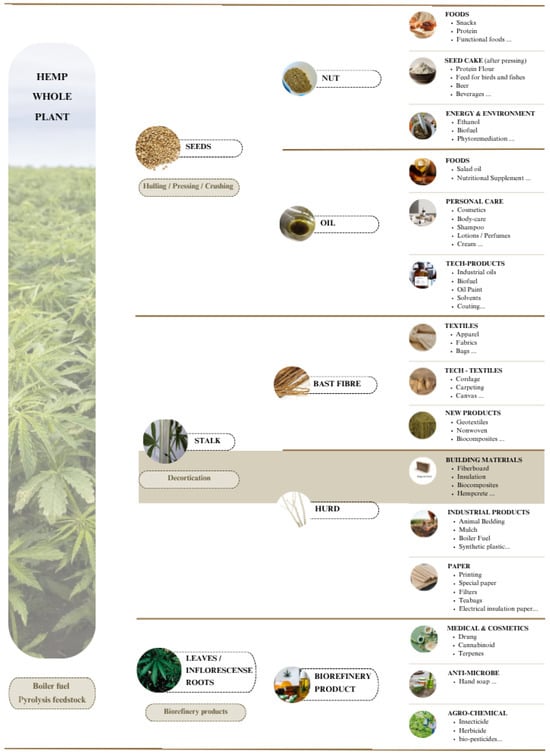

In structural materials, hemp’s application extends to lightweight concrete, fibre-reinforced mortars, and prefabricated building blocks, insulation panels, and geopolymeric composites. This review aims to identify fibre-treatment methods that improve fibre–matrix adhesion and mechanical performance in such structural systems [13]. Figure 1 illustrates the full utilisation chain of the hemp plant, with the construction-related applications highlighted in beige. This visual distinction emphasises the position and relevance of building materials within the broader industrial context of hemp-based products.

Hemp has gained substantial prominence in the construction industry, with hemp concrete emerging as a viable alternative to conventional materials. This bio-composite demonstrates excellent thermal and acoustic insulation properties while remaining lightweight and durable [19,20]. Its applications range from wall panels and roof components to more complex prefabricated structures. This wide industrial versatility underscores hemp’s potential as a sustainable and multifunctional crop capable of meeting construction demands while promoting greener agricultural practices [21,22]. The growing use of eco-friendly hemp-based materials in construction and other sectors highlights a broader move towards sustainability. Despite ongoing technical challenges, hemp remains a viable and promising alternative capable of driving significant progress towards a low-carbon, circular economy that benefits both society and the environment.

Figure 1.

General applications of hemp and emphasis (in beige) on construction and structural materials derived from different parts of the plant [2,13,14,17,22,23,24,25,26,27,28,29,30].

2.1. Hemp Production in the EU

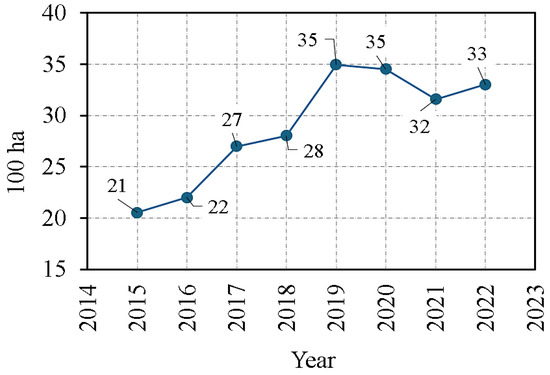

Hemp (Cannabis sativa L.) has been cultivated for millennia for textiles, oil, and other products, but its recent role as a sustainable industrial crop has gained prominence in construction. Unlike many traditional fibres, hemp grows rapidly, requires minimal pesticides and fertilisers, and acts as a carbon sink through photosynthesis. In Europe (Figure 2), cultivated area expanded from about 20,500 ha in 2015 to over 33,000 ha in 2022, with production rising from 97,000 to 179,000 tons, led by France, Germany, and the Netherlands [31,32,33,34].

Figure 2.

Graph of the EU land area used for hemp cultivation, adapted from [34].

This growth reflects the material’s versatility, combining environmental benefits with mechanical performance suitable for construction applications [13,22]. Today, hemp is increasingly used in bio-based composites, hempcrete, and insulation products, supporting circular economy strategies and contributing to low-carbon, disaster-resilient building materials.

2.2. Morphology and Composition

The classification of natural hemp fibres (Cannabis sativa L.) is substantially influenced by their chemical composition and mechanical properties. Under various agronomic and genetic conditions, the hemp plant can reach heights of up to 6 m, exhibiting a high cellulose content, a moderate amount of lignin, and high tensile strength [35]. Table 1 presents the structural classification of hemp fibres as identified in different studies.

Table 1.

Hemp Fibre Classification (Vegetal Fibre—Cannabis Sativa L—Cannabaceae—Bast).

Hemp (Cannabis sativa L.) has a diameter ranging from 25 to 600 µm and a height that can vary between 2 and 6 m. The density of hemp fibre is between 1.4 and 1.6 g/cm3. Additionally, hemp exhibits a regain of 8% to 12%, where regain refers to the amount of moisture absorbed by a material relative to its dry weight, a crucial factor for the quality and processing of textile fibres. The variation in the physical properties of hemp, such as diameter, height, density, and regain, is significant for determining its applicability in different industrial sectors. Controlling these characteristics is essential to optimise the quality and efficiency in the processing of hemp fibres. The hemp stem is primarily composed of two parts: the outer fibre (bark) and the woody core. The bark includes the epidermis, which protects against damage and water loss; the cortex, which stores nutrients; and the phloem, which transports sugars produced in the leaves. The woody core contains the cambium, responsible for secondary growth, and the xylem, which transports water and minerals and provides structural support. Each component plays an essential role in the growth, nutrition, and support of hemp, influencing the physical and mechanical properties of the fibres. Based on this, in Table 2, the measurements of each part of the stem [35,40] have been summarised.

Table 2.

Hemp plant bast components and measurements.

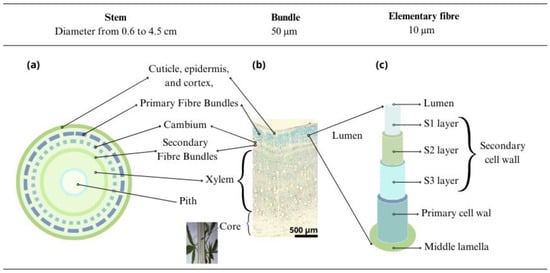

Hemp fibres are characterised by the complexity of their cross-section and specific surface morphology (Figure 3). The cross-section of hemp fibres is complex, and their surface morphology is specific, consisting of composites of hollow cellulose fibrils bound together by a matrix of lignin and hemicelluloses. The cell wall is not homogeneous and includes a thin primary wall and a secondary wall composed of three layers, with the middle layer determining the mechanical properties. The primary fibrils, approximately 5 nm in diameter, are organised into microfibrils of 20–40 nm decorated with hemicelluloses, forming the structural network. Lignin is deposited in the network either as isolated patches, increasing rigidity, or as a continuous matrix, replacing the hemicelluloses and acting as a coupling agent, thereby enhancing the rigidity of the cellulose/hemicellulose composite [18]. Cannabis sativa L. is a source of two types of natural fibres: long and fibrous bast fibres, and short-core woody fibres, known as hurds or shives, which have a granular shape. Figure 3 of the hemp stem illustrates the bark, secondary bast fibres, and woody core [35].

Figure 3.

Hemp fibre structure: (a) cross-section of hemp fibre stem, (b) cross-section morphology of the hemp fibre bundle, and (c) schematic depiction of hemp elementary fibre [2,30,35,42,43].

Hemp fibres exhibit a complex and heterogeneous structure, characterised as a composite composed of three main parts: middle lamella, primary, secondary, and tertiary cell walls, surrounding a central lumen. The middle lamella, rich in pectin and lignin, binds bast fibres into cohesive bundles. The primary cell wall displays cellulose fibrils dispersed in a matrix of hemicelluloses, lignin, and proteins. The secondary cell wall, composed of three layers of cellulose fibrils with different axial orientations, is bound by hemicelluloses. Primary fibres range in length from 5 to 55 mm, while secondary fibres are shorter, approximately 2 mm. The cell walls of bast fibres are significantly thicker than those of woody fibres. In contrast, hurds, which are chemically similar to wood, are considered less valuable [44,45,46].

Microscopic examinations of hemp stem cross-sections reveal that approximately 70–80% of the stem is composed of lignocellulosic tissues arranged in a porous structure. The outer regions are rich in bast fibres with high cellulose and pectin content, while the inner woody core shows higher lignin concentration. Under cytochemical staining, lignified areas exhibit intense colouration, confirming the presence and distribution of lignin within the stem’s vascular bundles and middle lamella [47].

Vegetable fibres such as hemp display complex interactions with water that depend on environmental conditions. Normally, there is continuous moisture exchange, with water retained in the cell walls and vapour occupying the lumen. When fibres are submerged, significant absorption occurs within the cell wall due to diffusion and adsorption processes. This leads to partial separation of bast fibre bundles caused by pectin leaching, often enhanced by microbial enzymatic activity. Electron microscopy studies have shown that immersion and washing remove surface impurities, increase roughness, and expose cellulose microfibrils, modifications that improve fibre–matrix adhesion in composite applications [17].

Hemp, as a member of the bast fibres, has a predominantly cellulose composition (over 75%) and a low amount of lignin (less than 10–12% compared to wood) [17]. This chemical composition strongly influences the fibre’s behaviour, particularly its high water-absorption capacity and chemical reactivity. The abundance of hydroxyl groups in cellulose promotes a strong affinity for water molecules, contributing to the hygroscopic nature of hemp. These same chemical characteristics also make the fibre reactive toward various treatments, which can be harnessed to optimise performance and durability in industrial and construction applications.

The processing of hemp fibres is a complex procedure involving several stages, starting with retting for fibre separation, followed by drying and baling. Hemp fibres are classified into two main categories, bast and hurds, each presenting specific structural characteristics [13,45,46]. Hemp fibres derived from plants have a lignocellulosic nature, being composed of cellulose, hemicelluloses, lignin, pectin and waxy substances. Cellulose is considered the main structural component of these fibres, giving them strength, rigidity and structural stability. The chemical structure of cellulose is characterised by the presence of three hydroxyl groups (OH), which are crucial to the properties of hemp fibres [48]. The chemical composition of hemp fibres, including cellulose, hemicelluloses, lignin, pectin, and wax, is detailed in Table 3, collecting data from different sources.

Table 3.

Chemical composition of hemp fibre.

The main constituents of hemp fibres, as summarised in Table 3, are predominantly crystalline cellulose, which constitutes 55–80% of the fibre mass and is primarily responsible for the tensile strength and stiffness of composites. Hemicellulose, present at 8–22%, contributes to fibre flexibility, but also increases hydrophilicity, which can affect moisture absorption and dimensional stability in the final composite. Lignin accounts for 2–12% of the fibre and provides additional rigidity; however, it can influence durability in alkaline environments, such as those found in cementitious matrices. Minor components, including pectin and waxes (<5%), play a role in fibre–matrix adhesion, impacting the overall mechanical performance of the composite. Hemp fibres also exhibit a moisture regain of 8–12%, which affects both dimensional stability and long-term durability. The ash content of hemp fibres is reported to be approximately 0.8% [35,55]. Variations in the composition of cellulose, hemicellulose, and lignin across different studies are attributed to factors such as planting region, harvest time, and processing methods, highlighting the importance of fibre source and treatment on composite performance, as reported in Table 3 and discussed by Salentijn et al. [22].

Furthermore, harvesting methods and post-harvest handling affect fibre integrity and chemical composition. The complex interaction of these factors results in variations in hemp fibre chemical component levels. Hemp fibres can be modified to enhance interfacial bonding by adding chemical coupling agents and compatibilisers to the polymer matrix. This addition improves the reactivity and wetting of reinforcement fibres, resulting in superior composite performance. Hemp fibre treatments can be classified as biological, physical, or chemical, with specific objectives: (i) removal of unwanted fibre components; (ii) increase in fibre surface roughness; (iii) separation of individual fibres from their bundles; (iv) modification of the fibre surface chemical composition; (v) reduction in hydrophilicity [44].

Following initial treatments, hemp fibres can be processed to achieve nanoscale dimensions using mechanical methods, including high-pressure homogenization, microfluidisation, grinding, refining, high-intensity ultrasonication, and cryo-crushing [56,57]. Each treatment is selected based on the desired properties of the final product, ensuring the optimisation of hemp fibres meets the specific requirements of various advanced applications (i.e., construction materials, textiles and biocomposites).

2.3. Mechanical Properties Analysis of Hemp Fibres

Hemp fibre, rich in crystalline cellulose microfibrils, exhibits a multicellular cell wall with distinct sublayers, impacting its strength and stiffness properties. Its microfibrillar orientation close to the fibre axis provides a high Young’s modulus and tensile strength compared to other natural fibres [35]. As shown in Table 4, hemp fibres’ mechanical properties include tensile strength, Young’s modulus, and elongation at break, indicating their suitability for various industrial applications.

Table 4.

Mechanical properties of hemp fibres.

Among the main mechanical strength properties presented in the above Table 4, it can be observed that tensile strength varies from 270 to 1100 MPa, Young’s modulus from 23.5 to 90 GPa, Specific Young’s modulus from 20 to 50 GPa/gcm3, and elongation/failure strain from 1% to 4.0%. The analysis of hemp fibres’ mechanical properties demonstrates their significant potential for different industrial applications. Their high tensile strength and stiffness, combined with moderate elongation capability, made hemp fibres a versatile and robust option for composites and other advanced engineering materials. The variations observed in studies reflect the importance of optimising cultivation and processing conditions to maximise hemp fibres’ mechanical performance.

2.4. Comparative Analysis of Hemp with Other Natural Fibres

To provide context for the advantages and disadvantages of hemp, the discussion was also comparative with other naturally occurring fibres that are widely used: flax, jute, and sisal [30,54,62,63,64]. The key parameters in construction applications, such as chemical composition, density, tensile strength, and durability, are highlighted in Table 5 [8,54,64,65].

Hemp fibres have a relatively high cellulose content (55–72%) and an average lignin content (6–8%), resulting in an excellent stiffness/toughness ratio [4,65,66,67]. Flax fibres contain more cellulose (62, 1–85%) and less lignin, with higher tensile strength (up to 1500 MPa), but entail higher processing costs [9,11,19,54,64]. Jute fibres, which have lower cellulose content (45–71.5%) and higher lignin levels (12–26%), are less resistant to water and alkaline conditions, limiting their use in cement matrices [37,62,64,66,68].

Table 5.

Comparative properties of hemp, flax, jute, and sisal fibres (adapted from [54,69,70,71]).

Table 5.

Comparative properties of hemp, flax, jute, and sisal fibres (adapted from [54,69,70,71]).

| Property | Hemp | Flax | Jute | Sisal |

|---|---|---|---|---|

| Cellulose (% wt.) | 55–72 | 65–85 | 60–70 | 65–72 |

| Hemicellulose (% wt.) | 10–20 | 12–18 | 12–14 | 10–14 |

| Lignin (% wt.) | 6–8 | 2–3 | 12–14 | 9–11 |

| Density (g/cm3) | 1.48–1.50 | 1.50 | 1.30–1.45 | 1.33–1.50 |

| Tensile strength (MPa) | 350–900 | 500–1500 | 250–400 | 400–700 |

| Elastic modulus (GPa) | 30–70 | 50–70 | 10–30 | 9–20 |

| Moisture absorption (%) | 8–12 | 7–10 | 12–13 | 11–12 |

| Durability in alkaline matrix | Moderate | Low–moderate | Low | Low–moderate |

| Relative cost | Medium | Medium–high | Low | Low |

Sisal fibres exhibit high tensile strength (363–800 MPa) and cellulose content (~60–78%), but, due to a rougher morphology and lower resistance to alkalis, some structural applications are restricted [2,9,19,54,65,69,72].

From an economic perspective, jute and sisal are affordable and readily available in the tropics [54,69], whereas hemp and flax are increasingly cultivated in Europe and North America as sustainable local supply sources [34,37]. When used in engineering, hemp offers good mechanical efficiency, potential durability, and an attractive cost profile, especially when chemical or physical treatments that enhance fibre–matrix adhesion are applied [4,30,37].

3. Procedures for Adhesion Improvement of Hemp Fibres in Composites

The main limitation of hemp fibres that are used as reinforcements in hydrophobic polymer matrices is their hydrophilic nature, which compromises their compatibility with the matrix and ultimately limits their applicability [39,41,73]. The arrangement of cellulose microfibrils in an alternating pattern of crystalline and amorphous zones within each cell wall layer directly impacts the macroscopic mechanical properties of the fibres [74,75]. Crystalline regions are more compact and ordered than amorphous regions, making them less accessible to chemical agents. Conversely, hydroxyl groups (–OH) in the amorphous segments of cellulose, hemicellulose, and lignin are relatively free and readily react with other chemical reagents [35,42,50].

As a result, amorphous regions absorb atmospheric moisture, imparting a hydrophilic character to the hemp fibre surface. Under tensile load, stress concentration points develop at the junctions of moisture-laden cellulose microfibrils in the amorphous regions, initiating microcracks that lead to final fibre failure. Moreover, the hydrophilic nature impedes interfacial interaction between the fibre surface and the polymer matrix, resulting in delamination and reduced mechanical properties of the composites. This issue can be mitigated through fibre surface modification with appropriate treatments. Surface treatment reduces—OH groups by substituting them with other chemical moieties and adjusts the proportions of crystalline cellulose, hemicellulose, and lignin within the fibres, directly impacting fibre strength [76,77,78].

Surface modification prevents hydroxyl group reactivity with water and enhances compatibility between hemp fibre and the polymer matrix, thereby improving the composite’s properties. The modification of the surface of natural fibres is an essential method for improving fibre-matrix adhesion, thereby enhancing the composite properties. Additionally, these treatments are effective in removing impurities such as ashes, waxes, and sugars, which can impede the hardening of the fibres, improve adhesion, increase crystallinity, and consequently, mechanical strength, as well as enhance the durability of the fibres [79,80,81,82].

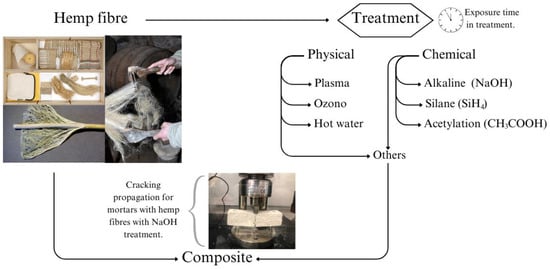

In natural fibre-reinforced polymer composites, the interface and its properties significantly influence the interfacial bonding between the fibre and matrix, and, consequently, the resulting properties. The interaction mechanism at the interface is complex, considering factors such as interface thickness, surface energies, and wetting phenomena. Surface modification of fibres to enhance compatibility with the polymer matrix can be achieved through two approaches: (i) chemical methods and (ii) physical methods [35]. Figure 4 presents an overview of hemp fibre treatments for use in composites.

Figure 4.

Natural fibres treatment schematic [37,82,83,84].

Enhancing the adhesion of natural fibres, such as hemp, with inorganic materials like cement and mortar is essential for developing durable and high-performance composites. In this section, various methods to treat hemp fibres to improve their compatibility with inorganic matrices are analysed properly. Chemical treatments, such as alkali solutions, and physical treatments are analysed for their effectiveness in modifying the surface properties of hemp fibres [85,86,87]. The impact of these treatments on the resulting composites’ mechanical strength and durability properties is evaluated, highlighting advancements in sustainable construction materials through the integration of natural fibres. Hemp fibres hold immense potential as reinforcement materials in polymer matrices; however, their hydrophilic nature restricts their applicability due to incompatibility with hydrophobic matrices and susceptibility to microcracking. Surface modification of hemp fibres is crucial to improve compatibility and enhance composite properties. Chemical and physical treatment methods can mitigate hydrophobicity and optimise fibre structural composition. The following section will delve into a detailed discussion of these surface modification methods, identifying effective treatments and their applications.

3.1. Chemical Methods

The numerous hydroxyl groups present in cellulose, hemicellulose, and lignin make natural fibres susceptible to chemical modifications. These modifications can activate these groups or introduce new chemical fractions, resulting in improved mechanical and chemical interlocking with polymer matrices [35,48]. The main challenge of natural fibre composites arises from the hydrophilic nature of the fibres and the hydrophobic nature of the polymer matrices. This inherent incompatibility between the two phases results in a weakened interfacial bond. Chemical treatments on reinforcement fibres can reduce their hydrophilic tendency, thus improving compatibility with the matrix. Various research activities have been conducted to enhance the adhesion properties of fibres with the matrix through chemical treatments [88,89].

A schematic overview of various chemical treatment methods for hemp fibres is presented in the study of Deshmukh [35], which highlights commonly used treatments such as (i) alkali treatment, (ii) acetylation, (iii) silane treatment, (iv) graft copolymerization, (v) benzoylation, (vi) potassium permanganate, (vii) maleated coupling agents, (viii) epoxidation and (ix) isocyanation. Among the various chemical treatments reported in the literature, alkaline treatment, silane treatment, maleic anhydride coupling, acetylation, and graft polymerisation are highlighted as the most common and promising methods for modifying natural fibres to enhance adhesion in cementitious composites [90]. Natural fibres offer several advantages, such as renewable cultivation, high specific tensile strength, and cost-effectiveness.

However, they also have drawbacks, including biodegradation, moisture absorption, and organic impurities. The closed matrix (cement) in natural fibres can inhibit typical biodegradation processes, which are mainly activated by moisture, oxygen, and UV radiation. Additionally, the waxy coating on the surface of natural fibres can retard biodegradation and reduce interfacial bonding between the fibre and the cement matrix. During the treatment process, wax, oil, and undesirable substances are removed, allowing for better adhesion between natural fibres and cementitious binders [91].

One of the most effective and widely used methods is chemical treatment with alkaline solutions, such as soluble hydroxide or soluble silicate, at appropriate concentrations [92,93]. Alkaline and silane treatments are among the most common surface modification methods used on natural fibre fillers before their incorporation into biocomposites [94,95]. Among the various chemical treatments reported in the literature, alkaline treatment (NaOH) and silane treatment (SiH4) stand out as the most common and promising methods for modifying hemp fibres to improve adhesion in cementitious composites. According to the above-introduced chemical procedures, this study explores three of the most useful chemical treatments for composite compounds, i.e., (i) alkaline treatment (NaOH); (ii) silane treatment (SiH4) and (iii) acetylation treatment (CH3COOH).

3.1.1. Alkaline Treatment (NaOH)

Alkalization is one of the most studied chemical treatments, involving the immersion of lignocellulosic fibres in an alkaline solution. This process removes lignin, pectin, waxes, and natural oils that coat the outer surface of the fibre cell walls [96]. The use of sodium hydroxide (NaOH) in different concentrations has been shown to improve the tensile strength, flexural strength, and stiffness of natural fibre composites [87]. Among the various modification processes, alkaline treatment, also known as mercerisation, stands out as one of the most economical and effective methods for altering the complex cellulose structure [91,97,98].

The structural and chemical effects of alkalisation on hemp fibres have been verified using Fourier-transform infrared (FT-IR) spectroscopy, which reveals clear evidence of compositional changes. The disappearance of absorption peaks near 1730 cm−1 indicates the removal of pectin and waxes, while reductions in bands around 2920 cm−1, 1317 cm−1, and 1250 cm−1 correspond to the partial removal of cellulose, hemicellulose, and lignin at higher NaOH concentrations. These spectral variations confirm the efficiency of the alkaline process in eliminating non-cellulosic compounds and improving fibre purity. Complementary contact-angle analyses show a significant reduction in surface hydrophobicity, demonstrating that NaOH effectively removes oily substances and waxes from the fibre surface [90].

NaOH reacts with hydroxyl groups in the amorphous regions of cellulose, disrupting hydrogen bonds and partially depolymerising the structure, which exposes shorter crystallites and increases fibre surface roughness. These changes reduce hydrophilicity and improve compatibility with polymeric and cementitious matrices [83,88]. In practice, fibres are typically immersed in approximately 6% w/w NaOH solution (1.6 M) for 48 h to remove impurities, followed by rinsing with fresh water to neutralise alkalinity and drying at 60 °C to ensure dimensional stability [85].

Microscopic examinations corroborate these findings, showing that untreated hemp fibres possess smooth surfaces covered by waxes and impurities that limit adhesion to cementitious binders. After alkalisation, these layers are removed, and the surface becomes rougher and more fibrillated, exposing cellulose microfibrils. This morphological transformation enhances the mechanical anchoring of fibres within the composite matrix, promoting improved stress transfer and interfacial bonding [90].

The effectiveness of the alkaline treatment depends strongly on process parameters such as NaOH concentration, immersion time, and temperature. Experimental results demonstrate that optimal treatment with 4–6% NaOH increases tensile strength up to 1064 MPa and Young’s modulus up to 65 GPa, compared to 591 MPa and 38 GPa for untreated fibres [35,54,99]. However, excessively high concentrations (e.g., 18%) can cause over-delignification and fibril disorientation, resulting in reduced strength and brittleness [90,100,101,102,103].

In cementitious systems, alkaline pre-treatment facilitates chemical bonding between fibres and the matrix by removing amorphous hemicellulose and lignin, thereby exposing a higher density of reactive hydroxyl groups on the cellulose surface. These hydroxyls interact with calcium silicate hydrate (C–S–H) phases through Ca2+–O− ionic linkages and hydrogen bonding, enhancing the densification of the interfacial transition zone (ITZ) and improving load transfer efficiency [85,104,105]. The increased roughness and wettability of the treated fibres further promote mechanical interlocking and reduce interfacial porosity.

Overall, NaOH treatment at optimal concentrations (5–6%) significantly improves fibre–matrix adhesion, leading to composites with superior strength, stiffness, and durability [90,106,107]. This enhancement in mechanical and interfacial behaviour confirms that controlled alkaline modification is a key step for integrating hemp fibres effectively into sustainable cementitious and geopolymeric composites.

3.1.2. Silane Treatment (SiH4)

Silane coupling agents are widely used to coat fibre micropores, reducing hydroxyl groups and enhancing fibre–matrix interfacial bonding. The hydrolysable alkoxy portion of silane forms silanols in the presence of moisture, which then react with the hydroxyl groups on the fibre surface, creating stable covalent bonds. This mechanism prevents fibre swelling and significantly strengthens the interface with the cementitious matrix [55,108].

The surface treatment of natural fibres with silane involves applying a diluted solution of the agent, which hydrolyses to form silanols. These silanols undergo condensation, reacting on one side with hydroxyl groups on the fibre surface to form cellulose–O–Si bonds and, on the other side, with functional groups in the matrix, generating a siloxane bridge. This dual linkage improves stress transfer and stabilises mechanical performance under load [35,109]. The most commonly used silane coupling agents for hemp fibres are trialkoxysilanes functionalised with amino, mercapto, glycidoxy, vinyl, or methacryloxy groups [110,111,112]. The selection of suitable organic functionality is critical for optimising natural fibre composite (NFC) performance, as demonstrated in several studies [113,114,115,116,117].

Due to their unique reactivity, silane coupling agents have been employed for decades as key surface modifiers in coatings, paints, and composite formulations [55]. Treating hemp fibres with silane agents enhances the mechanical properties and thermal stability of the composites by forming stable covalent bonds between fibre and matrix. This treatment also reduces fibre moisture absorption, preventing swelling and improving overall adhesion. Selecting the appropriate silane type is, therefore, essential for achieving optimal performance in engineering applications.

In cementitious matrices, silane coupling agents form covalent bonds with both the fibre surface (via –OH groups) and the hydration products through silanol condensation, generating Si–O–Si linkages. This dual reactivity strengthens the interfacial transition zone (ITZ) and reduces surface hydrophilicity, limiting capillary water ingress. Consequently, silane-treated fibres enhance microstructural continuity and delay interfacial microcrack propagation under flexural loading [94,112,117,118].

3.1.3. Acetylation Treatment (CH3COOH)

The acetylation of natural fibre-reinforced composites (NFRCs) is a well-established esterification process that plasticises cellulose fibres, reduces hydrophilicity, and improves the dimensional stability of the composites [39]. This treatment substitutes hydrophilic hydroxyl groups (–OH) with acetyl groups (–O–COCH3), thereby decreasing moisture absorption and increasing durability [109,119]. The modification also alters the fibre surface morphology by removing hydroxyl groups from non-cellulosic components, which, despite slightly reducing crystallinity, enhances fibre–matrix adhesion and mechanical performance (tensile, flexural, and compressive strength) [35].

Acetylation is primarily performed to reduce fibre hygroscopicity, improve dimensional stability, and prevent environmental degradation. The reaction typically involves acetic anhydride, maleic anhydride, or vinyl acetate at elevated temperatures, with or without catalysts such as potassium carbonate, acids, or pyridine [68,88,93]. However, acids like acetic or maleic acid are less preferred due to their lower esterification efficiency [55]. In addition to mechanical improvements, acetylation enhances thermal stability and water resistance, contributing to the overall durability of natural fibre composites [35,120].

At the microscopic level, acetylation replaces cellulose hydroxyl groups with acetyl moieties, reducing polarity and water sorption capacity. In inorganic matrices, this modification decreases the fibre’s affinity for free water, leading to a denser and more stable ITZ with reduced capillary porosity. The reduced swelling and shrinkage of fibres during wet–dry cycles further enhance durability and adhesion retention over time [71,120,121,122,123].

In addition to acetylation, several studies have demonstrated the effectiveness of hydrophobising agents such as Alkyl Ketene Dimer (AKD) in improving fibre–matrix compatibility and long-term durability [37,124,125]. A detailed discussion of AKD mechanisms and performance is presented in the following subsection.

3.1.4. Alkyl Ketene Dimer (AKD) Treatment

Alkyl Ketene Dimer (AKD) is a hydrophobising agent originally used in the paper industry that has recently been adopted to improve water resistance and mechanical performance in natural fibre-reinforced cementitious composites. The reaction mechanism involves the esterification of cellulose hydroxyl groups on the fibre surface, forming β-keto ester linkages that create a long-chain hydrophobic layer. This covalent bonding decreases surface polarity and reduces capillary water sorption [124,125].

The reaction proceeds through a four-membered ketene intermediate (R–CH=C=O), which reacts with surface hydroxyls to yield β-keto esters (R–CH2–CH2–CO–O–Cellulose). The efficiency of this process depends on fibre accessibility and residual moisture. Optimal AKD dosages range between 0.5 and 2.0% on weight of fibre (owf), ensuring sufficient coverage without forming discontinuous or waxy layers that could impair fibre–matrix bonding [37,125].

AKD exhibits moderate stability in alkaline environments, maintaining structural integrity up to pH 12.5, typical of hydrated cement pore solutions. Beyond this level, partial hydrolysis of β-keto ester bonds may occur, reducing hydrophobicity [124]. Nevertheless, after 28 days of immersion in Ca(OH)2 solution, AKD-treated fibres retain significantly higher contact angles than untreated ones, confirming the persistence of surface modification [126,127].

In durability terms, AKD-treated fibres maintain approximately 80–85% of their initial hydrophobicity and 75–80% of flexural strength gains after 20 wet–dry cycles, compared to only 40–50% retention in uncoated or alkali-only treated fibres. This improved performance results from reduced water uptake, limited swelling, and the stability of β-keto ester bonds under cyclic moisture exposure. The hydrophobic barrier delays microcrack formation and enhances ITZ integrity in cementitious composites [37,125,128,129].

Thus, AKD treatment provides a synergistic effect when combined with prior alkaline activation: the alkali step increases fibre roughness and exposes reactive hydroxyl groups, while AKD grafting imparts long-term hydrophobicity and dimensional stability. This combination consistently produces 28–34% increases in compressive strength and 24–28% in flexural strength for hemp fibre cementitious composites, establishing AKD as one of the most promising modifiers for sustainable, bio-based construction materials.

3.2. Physical Methods

Physical treatment of natural fibres is important for producing reinforced composites, aiming to improve compatibility between the fibres and matrices. This process serves two main functions: (i) separating fibre bundles into individual filaments and (ii) modifying the fibres for use in composites [35]. To improve the digestibility of lignocellulosic materials, many physical procedures have been applied, including mechanical grinding (e.g., shredding, grinding, or milling) and radiation (e.g., gamma rays, electron beams, or microwaves) [130].

Fibre bundle separation can be achieved using physical methods such as steam explosion and thermo-mechanical processes, which fragment lignocellulosic material into basic components like cellulose, amorphous lignin, and hemicellulose. These processes produce individual fibres with increased strength and rigidity, and enhanced surface hydrophobicity, thus improving compatibility with the polymer matrix [131]. Natural fibres are noted for their low density due to their hollow tubular structure (lumen). In contrast, commonly used synthetic fibres, such as glass and carbon fibres, have densities of 2.4 g/cm3 and 1.90 g/cm3, respectively, making them significantly denser than even the densest natural fibres. Therefore, natural fibres are particularly suited for lightweight applications in aerospace, maritime, automotive, and construction industries [132,133,134].

Fibre modification can be achieved using physical techniques such as thermal treatment, corona discharge, plasma, ultraviolet (UV) exposure, and fibre beating, which alter the surface properties of the fibres without significantly changing their chemical composition. These treatments, including corona discharge and plasma, increase the surface energy of cellulose fibres, enhancing their compatibility with the matrix. UV treatment increases fibre surface polarity, improving wettability and greater composite strength. Specifically, for hemp fibres, these physical treatments also aid in the separation of individual filaments using techniques such as fibre beating, thermal treatment, and steam explosion [35,130,135].

Although physical treatments do not extensively alter the chemical composition of the fibres, the interface between the fibres and the matrix is improved through increased mechanical bonding. This is particularly important for exploiting the potential of natural fibres as reinforcement in composites, as the aspect ratio (ratio of fibre length to diameter) and the degree of cellulose crystallinity are critical for reinforcement efficiency [135,136,137,138,139].

Studies on specific treatments for hemp fibres, such as Dielectric Barrier Discharge (DBD), show that this technique alters surface chemistry and increases roughness, resulting in improved wettability and adhesion without compromising the physical-mechanical properties of the fibres [140]. Similarly, combined treatments, such as hydrothermal followed by UV or gamma radiation exposure, have been shown to cause structural rearrangement in the fibres, affecting crystallinity and, consequently, physical and mechanical properties [141].

Despite advancements in physical treatments for hemp fibres, significant challenges remain. More detailed studies on process control and optimisation are needed to better understand fibre behaviour during physical treatments and enhance their interfacial properties, increasing compatibility with matrices. In this context, physical treatments selected for further analysis include plasma treatment (cold plasma and corona treatment) and ozone treatment.

3.2.1. Plasma Treatment

Plasma treatment is an effective technique for cationising and introducing functional groups onto natural fibres without significantly affecting their bulk properties [142]. This process etches the fibre surface, increasing roughness and thereby improving compatibility with the matrix [48]. It is widely used to remove surface contaminants while enhancing properties such as wettability, dyeability, and flammability. Moreover, plasma exposure increases surface roughness, which promotes mechanical interlocking and fibre–matrix adhesion. During this process, free radicals are generated and react with surrounding gases, modifying the fibre’s hydrophilic or hydrophobic characteristics [121].

Plasma is a substantially ionised medium composed of highly excited atomic, molecular, ionic, and radical entities containing free electrons and photons. It is produced by passing an electric field between two electrodes with gas in between, either under atmospheric pressure or in a vacuum. The resulting plasma characteristics depend on the gas type, electrical power, and electrode configuration. Plasma treatment is therefore considered an electrical discharge process involving ions, electrons, and UV or vacuum-UV radiation [121,143].

Studies by Pejić et al. [140] demonstrated that plasma treatment at atmospheric pressure significantly modifies the morphology of raw hemp fibres composed of cellulose, hemicellulose, and lignin. The process produces visible surface etching, increased roughness, and partial fibrillation, particularly in samples exposed to higher discharge frequencies. Microscopic analyses revealed the formation of short fibrils on the fibre surface and an enhanced texture, confirming the physical alteration caused by ion bombardment. These modifications result in a larger specific surface area and improved adhesion potential when fibres are incorporated into cementitious or polymeric matrices.

Spectroscopic analyses (ATR-FTIR) further showed that this fibrillation is associated with the removal of hemicelluloses due to ion bombardment and surface-layer etching. The spectra revealed changes in hydroxyl (–OH) group absorption and a decrease in characteristic peaks for cellulose and hemicellulose, accompanied by increased intensity of lignin-related bands. This indicates partial degradation of hemicelluloses and exposure of the underlying lignin structures on the fibre surface [140,144,145].

Two main plasma treatment methods are commonly used for hemp fibres: cold plasma and corona discharge. Both rely on the reaction of ionised gases with the fibre surface, but differ in operating conditions. Cold plasma is generated by high-frequency microwaves under low-pressure or atmospheric environments, while corona plasma operates using low-frequency alternating current at atmospheric pressure [131,142].

Corona treatment activates the fibre surface by controlled oxidation, improving compatibility with hydrophobic matrices and increasing tensile strength and Young’s modulus of hemp/polypropylene (PP) composites by up to 30%. Enhanced adhesion is attributed to mechanical anchoring and increased surface energy. Optimal exposure times are short, typically around 5 min, to achieve maximum strength; longer treatments may cause excessive degradation [35,136].

Plasma treatment, including corona discharge, alters the surface energy of natural fibres, enhancing their compatibility with surrounding matrices. The key distinction is that plasma treatment allows for the precise control of parameters such as gas type, flow rate, and pressure, while corona treatment relies on high-voltage discharge at atmospheric conditions. For hemp fibres, the selective application of low-temperature plasma at atmospheric pressure substantially increases wettability, surface polarity, and dye uptake capacity. However, prolonged plasma exposure can lead to dehydration and structural damage, resulting in reduced tensile strength, Young’s modulus, and elongation at break due to partial microfibrillar degradation [20,35,140,144,146,147].

Both plasma and corona discharges promote surface oxidation and micro-etching without altering the bulk structure of the fibres. The incorporation of polar functional groups (–C=O, –COOH) enhances chemical compatibility with calcium-rich hydrates, favouring secondary bonding with calcium silicate hydrate (C–S–H) and calcium–alumino–silicate hydrate (C–A–S–H) phases. These modifications increase surface energy, improve wettability, and strengthen mechanical interlocking at the fibre–cement interface, leading to interfacial transition zone (ITZ) densification and more homogeneous stress distribution within cementitious composites [20,79,140,147].

3.2.2. Ozone Treatment

Ozone treatment exposes natural fibres to O3 gas, an allotrope of oxygen with strong oxidising properties [142]. This method is energy-efficient, safe, and eco-friendly because it operates at lower temperatures, decomposes back into oxygen, leaving no harmful residues, eliminates the need for harsh chemicals, reduces environmental pollution and chemical waste and enhances matrix adherence [130,148].

The experimental setup for corona treatment involves high-frequency discharges between electrodes, leading to ionisation in the surrounding atmosphere and the production of plasma, visible as a blue emission. In the space between the electrodes, high-velocity electrons bombard the substrate, disrupting molecular bonds on its surface [121]. Ozone, atomic oxygen, and oxygen-free radicals produced by a corona discharge cause surface oxidation of materials. These oxidants react with free radicals on the material’s surface to generate oxidising groups like hydroxyl, carboxyl, carbonyl, or ester groups [121,143].

The presence of polar groups on the material increases surface energy, enhancing wettability and adhesive bonding between cellulose fibres and the polymer matrix. Corona treatment is highly effective as a pre-treatment in the textile industry, particularly for removing surface contaminants and improving bonding with the matrix. However, its limited penetration depth makes it most suitable for short fibres and less effective on yarns due to restricted penetration. Despite this, corona treatment offers significant advantages over traditional plasma treatments, including low cost, low energy consumption, and suitability for large-scale industrial production [143].

Ozone oxidation introduces carbonyl and carboxyl groups on the cellulose backbone, enhancing fibre polarity and potential bonding sites for calcium ions. This controlled oxidation favours physical and chemical adhesion with hydration products, leading to a denser ITZ and lower water permeability. However, excessive ozone exposure may induce chain scission and weaken bonding sites, confirming the importance of balancing oxidation level and fibre integrity [28,149].

Analysis of physical treatments for natural fibres indicates that techniques such as separation, plasma, corona, and ozone are crucial for improving compatibility with matrices. Plasma and corona discharge increase surface energy and adhesion, though prolonged treatment may degrade fibres. Ozone enhances adhesion by removing lignin and increasing roughness. The choice and optimisation of treatments are very useful to maximise the effectiveness of reinforced composites.

3.3. Comparative Summary of Fibre Treatments

To provide a comprehensive overview of the different chemical and physical modification strategies discussed above, this subsection presents a comparative summary of their typical effective parameters, observed failure modes, and resulting changes in mechanical performance [65,115,143].

The data in Table 6 consolidate information reported by multiple authors for alkaline [11], silane [115], acetylation [120], plasma [79], and ozone treatments [140], covering the most frequently used ranges of concentration, pH, temperature, duration, and process intensity. Where quantitative data were available, the corresponding property variations (Δ%) relative to untreated fibres are indicated, together with characteristic degradation or over-treatment phenomena.

Table 6.

Typical processing parameters, failure modes, and property variations for hemp fibre treatments.

As shown in Table 6, each treatment exhibits an optimal operating window that maximises fibre–matrix adhesion while avoiding structural degradation. Alkaline pre-treatment followed by AKD functionalisation tends to provide the highest overall strength gains (≈30%), attributed to improved surface roughness and compatibility with cementitious pore solutions [37,125].

Conversely, plasma and ozone methods are highly effective for rapid surface activation with minimal chemical waste, making them promising for eco-efficient industrial applications [140]. This comparative summary highlights the trade-off between treatment aggressiveness and mechanical enhancement, guiding the selection of modification routes for specific cementitious and geopolymeric matrices.

4. Hemp in Composites for Civil Constructions

Building activities have substantially increased CO2 emissions into the atmosphere worldwide. The use of local, recycled, residual, and biodegradable materials in buildings can assist in minimising carbon emissions. In this view, natural fibres are commonly used in construction materials to improve mechanical and insulating qualities [69,96,152,153,154,155]. They are commonly used in cement composites for structural and non-structural elements, particularly in developing countries, for unreinforced slabs and panels, owing to their accessibility and low cost [156,157].

These fibres help reduce multiple cracking and enhance tensile and flexural performance, as demonstrated for chemically treated flax, sisal, and hemp, which can endure alkaline environments and promote faster autogenous repair during wet–dry cycles. However, this self-healing capacity is limited to micro-cracks [157,158,159,160,161]. Experimental investigations by Nguyễn, Momoh and Sanah [129,162,163] showed that concrete reinforced with natural fibres and cement-based additives strengthens faster for small cracks.

Matrix legend:

For clarity, all performance results and effect sizes are grouped according to the binder matrix type.

LH = Lime–hemp composites (hempcrete);

OPC = Ordinary Portland cement composites;

BC = Blended cements (OPC + pozzolanic additions such as fly ash or slag);

GP = Geopolymer matrices.

Effect sizes (Δ%) are presented within each matrix family to avoid cross-system bias.

Natural fibres have been used to replace synthetic and metallic fibres in a wide range of construction applications, including soil stabilisation, cement reinforcement, thermal insulation, wall panels, and roofing tiles [80,153,154,162,164,165,166,167]. Furthermore, their addition enhances vibration absorption and impact resistance, encouraging use in bridges and seismically resilient structures. Natural fibres can also substitute glass fibres in the automotive and furniture sectors [162,167].

Concrete, the second most used material worldwide, contributes to around 5% of global CO2 emissions [168]. Despite its high compressive strength, it exhibits low tensile strength, leading to cracking and steel-reinforcement corrosion that shortens service life [96]. Natural fibres, as sustainable substitutes for steel, improve flexural strength, impact resistance, and crack control [157,169,170,171].

However, durability in highly alkaline environments remains a challenge. The use of pozzolanic additions (silica fume, fly ash, slag) can reduce alkalinity and mitigate fibre degradation [169,172]. Overall, natural fibres enhance tensile and flexural strength, ductility, and stiffness while reducing density and crack formation [169,173].

According to studies [37,96,117,129,155,174,175], a variety of natural fibres have been employed in different concrete systems, including hemp, coconut, jute, sisal, and pineapple. Hemp fibres, in particular, combine low carbon footprint, low density, and good thermal-acoustic insulation [96,155].

To evaluate the effect of natural fibres on concrete, parameters such as workability and density must be assessed. The inclusion of fibres typically decreases these properties, particularly as fibre content and length increase. To minimise this effect, fibres may be pre-saturated before mixing, chemical additives may be introduced, and optimised mixing techniques can be adopted [104,162,166,173].

Beyond mechanical properties, the incorporation of hemp fibres also significantly influences the rheological behaviour of cementitious and lime-based mixes. A general decrease in slump and flow diameter is observed as fibre fraction and aspect ratio increase. Reported losses in the slump range from 10 to 25% for 0.5% fibre volume and up to 35–50% for 1.5–2.0% fibre content, depending on fibre length (10–40 mm) and surface treatment [92,147,176]. In lime–hemp composites, the drop in flow spread can reach ≈40% due to high water absorption and capillary suction of untreated fibres [28,149].

To mitigate this loss of workability, two main strategies are reported: (i) pre-saturation of fibres, restoring up to 80–90% of baseline slump, and (ii) polycarboxylate-based superplasticisers, which maintain adequate flow even at fibre volumes up to 2% without compromising strength [65,177,178]. These measures compensate for reduced fluidity and promote uniform fibre dispersion and matrix homogeneity.

The optimisation of workability and mixing procedures has enabled the development of diverse hemp-based building materials with distinct functional purposes. There are three main hemp-based construction products: lime–hemp concrete (LHC), hemp wool, and fibre-panel insulation. The building sector, responsible for a large share of GHG emissions, has been actively seeking carbon-sequestering materials [34,179,180,181].

Lime–Hemp Composites (LH)

Lime–hemp composites exhibit low intrinsic compressive strength (0.4–2.0 MPa) due to high porosity and limited pozzolanic reactivity. Alkaline + AKD or silane treatments improve fibre–matrix adhesion, resulting in +20–30% compressive and +15–25% flexural strength gains [16,28,149]. These enhancements are attributed to improved carbonation and ITZ densification around the fibre surface.

OPC and Blended Cements (OPC/BC)

In Portland and blended cement systems, high alkalinity favours stronger fibre–matrix reactions. Combined NaOH + AKD treatments yield +28–34% compressive and +24–28% flexural gains, consistent with enhanced C–S–H bond formation [64,68,80,86,104]. Blended cements containing 20–30% fly ash or slag achieve slightly lower strengths, but exhibit ≈80% retention after wet–dry cycles, indicating improved durability.

Geopolymer Matrices (GP)

Geopolymer matrices dominated by N–A–S–H gel respond best to oxidation-based surface treatments. Plasma or ozone activation results in +10–20% flexural strength improvement and 25–40% reduction in capillary sorption, whereas excessive alkalinity from untreated fibres may hinder geopolymerisation [61,100,103,182,183].

By clearly distinguishing binder families (LH, OPC/BC, GP), the comparative analysis shows that treatment efficiency depends not only on fibre chemistry, but also on matrix alkalinity, hydration mechanism, and ITZ development. The overall effect of fibre-surface modification consistently improves interfacial bonding and long-term durability across all matrix types.

Hemp as a component in cementitious composites offers several benefits for sustainable construction. Firstly, hemp fibres enhance thermal insulation, reducing energy consumption for heating and cooling. Additionally, their light weight lowers the overall density of building materials, facilitating easier and less resource-intensive construction. The incorporation of hemp also improves strength and durability, resulting in longer-lasting structures. Moreover, hemp is a renewable resource that sequesters CO2 during growth, thereby lowering the carbon footprint of construction projects. Furthermore, hemp fibres aid moisture regulation within composites, reducing mould risk and improving indoor air quality. Finally, using hemp in building materials helps reduce agricultural waste and promotes the circular use of bio-resources.

Lime–hemp concrete (Hempcrete) is unique in that it stores more CO2 than it emits during manufacture and retains this carbon throughout the building life cycle, with sequestration values reaching up to 300 kg CO2 per m3 [149,184]. This lightweight composite provides both thermal insulation and long-term carbon storage, supporting the transition toward zero-emission buildings. By improving tensile, flexural, and compressive strength as well as overall durability and toughness, hemp fibres create lighter, more efficient, and resilient composites. Therefore, the inclusion of hemp in cementitious systems not only enhances technical performance, but also reinforces global sustainability objectives and net-zero-emission building targets.

5. Bibliometric Analysis

To identify recent studies on hemp fibre treatments for improving adhesion in civil composites, a systematic bibliometric analysis was conducted following established procedures [185,186]. The method comprised three main steps: (i) selection of the bibliographic portfolio, (ii) evaluation of the most relevant studies, and (iii) mapping of co-authorship, citations, and research keywords (Figure 5). Data were collected from Web of Science, Dimensions, Lens.org, and ScienceDirect, covering the period 2014–2024. Only works focused on cementitious, lime, or geopolymeric matrices were retained, while polymer-based studies were excluded except for comparative reference.

Figure 5.

Map of the literature review related to this research.

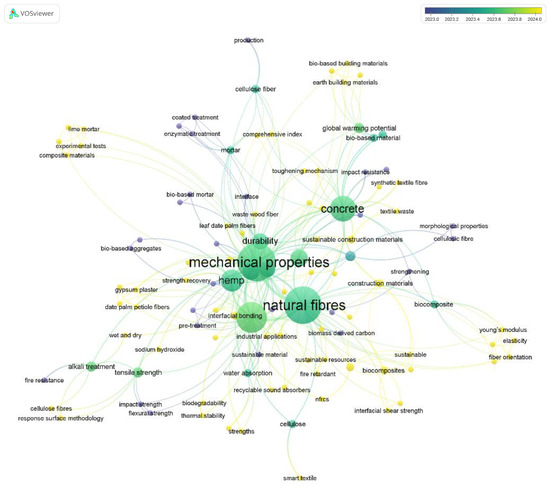

After removing duplicates and screening by title, abstract, and full text, 130 relevant articles were identified, from which 38 core studies were selected for detailed analysis. The bibliometric mapping and keyword co-occurrence were generated using VOSviewer (version 1.6.20) [187,188,189], which enabled the visualisation of citation and collaboration networks, similar to those adopted by Anike et al. [190] and Jin et al. [177]. Table 7 summarises the number of papers retrieved from each database, while Figure 6 illustrates the co-occurrence map of the most frequent keywords.

Table 7.

Results of database filtering (2014–2024).

Figure 6.

Bibliometric flow of keywords produced by VOSviewer 1.6.20.

The analysis highlighted the main keywords associated with the research domain, including mechanical properties, natural fibres, reinforced composites, durability, and surface treatment, confirming that the literature has progressively focused on improving fibre–matrix adhesion for sustainable construction materials. The keyword distribution and citation frequency are presented in Table 8, showing the dominance of studies addressing performance and sustainability metrics.

Table 8.

Results of initial keyword filtering.

Overall, the bibliometric results reveal a consolidated and growing research field led mainly by European and Asian institutions. The consistent appearance of keywords related to mechanical performance, durability, and sustainability underscores the engineering relevance of hemp composites. Furthermore, few studies combine chemical and physical fibre-treatment techniques, indicating a gap for future multidisciplinary research on high-performance and low-carbon construction materials.

5.1. Experimental Trends Identified Using the Bibliometric Portfolio

The summary provided in Appendix A offers a comprehensive overview of the treatments applied to hemp fibres to enhance adhesion to the matrix, analysing the optimal performance of the mechanical properties of the presented composites. Out of the initial 1005 articles, eight studies were selected for inclusion in the analysis.

Song et al. [37] investigated the chemical modification of hemp fibres using alkyl ketene dimer (AKD) following alkaline pre-treatment and defibration. The resulting composites, with 1% fibre content, exhibited a compressive strength of 52.5 MPa and a flexural strength of 8 MPa after 28 days, showing improvements of 28% and 24% compared to untreated composites. Similarly, Dhasindrakrishna et al. [105] explored alkaline treatment (1.63 M NaOH for one hour), achieving optimised compressive and flexural strengths in alkaline-activated cement foam composites.

Maichin et al. [85] compared the performance of Portland cement (OPC) and geopolymer (GP) composites. While alkaline-treated fibres improved OPC performance by 18%, untreated fibres performed better in GP systems due to a self-treatment effect from the alkaline activation process. Suwan et al. [90] confirmed this finding, noting a ~6% increase in flexural strength in treated GP composites.

Song et al. [191] further combined acetone and AKD modifications, achieving compressive and flexural strengths of 53.32 MPa and 8.13 MPa, respectively.

Candamano et al. [192] reported similar improvements through silane treatment, increasing compressive strength from 38 MPa to 45 MPa and flexural strength from 6 MPa to 7.5 MPa. Ghosn et al. [193] and Poletanovic et al. [150] highlighted the influence of fibre concentration, aggregate type, and NaOH levels on mechanical durability under environmental cycles.

Collectively, these findings confirm that alkaline pre-treatment followed by AKD modification provides the most consistent improvement across cementitious systems, achieving increases of up to 34% in compressive strength and 28% in flexural strength [37,125,191]. This combination improves fibre–matrix adhesion and is identified as the most effective strategy for maximising composite performance.

5.2. Implications and Connection to Metrics-Based Analysis

The reviewed literature demonstrates that treatment parameters, particularly NaOH concentration, treatment duration, and additive combinations, play a decisive role in composite optimisation. In OPC systems, excessive alkalinity may damage fibres, whereas in GP composites, the inherent alkalinity often eliminates the need for additional chemical treatment [85,90,101,102].

These insights establish the foundation for the metrics-based evaluation presented in Section 6, which quantitatively assesses the impact, influence, and journal distribution of the most significant studies and authors within the field. Together, the bibliometric and metrics-based analyses provide a comprehensive framework for mapping research trends and identifying opportunities for innovation in hemp fibre–reinforced cementitious composites.

6. Metrics-Based Method in Structural Engineering

Building upon the bibliometric analysis presented in Section 5, a metrics-based evaluation was conducted to assess the impact, quality, and thematic relevance of research on hemp fibre-reinforced cementitious composites. The selection of the most representative studies considered journal impact factors, citation frequency, and the recurrence of key research topics, allowing for a quantitative overview of the scientific relevance of the field.

The analysis also examined how these metrics correlate with experimental approaches and research outcomes, especially concerning the effects of drying and rewetting cycles, chemical surface treatments, and durability enhancement in fibre–matrix systems [27]. This quantitative framework supports the identification of emerging topics and methodological trends directly influencing the performance of civil composites.

To ensure robustness and reproducibility, data were extracted from Web of Science, ScienceDirect, and Dimensions, following the same procedures outlined in Section 5. The search strategy included the combined keywords “hemp”, “cement composite”, “chemical treatment”, and “physical treatment”, restricted to the period 2020–2024. Research topics were carefully selected for their relevance to civil engineering, focusing on studies that addressed mechanical improvement, interfacial adhesion, and long-term durability of the composites.

6.1. Journal Distribution and Impact Analysis

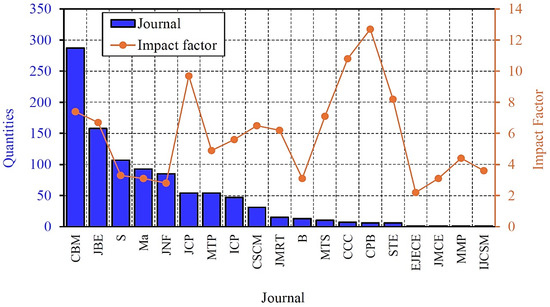

Appendix A presents an overview of studies addressing fibre treatments and their influence on adhesion and mechanical strength. From the initial screening, 977 publications were identified, of which only those directly relevant to civil applications were retained. Figure 7 illustrates the distribution of these publications by journal and impact factor, while Table 9 lists the acronyms and corresponding titles of the principal peer-reviewed journals contributing to this research field.

Figure 7.

Journal with corresponding impact factors and the number of publications concerning the keywords.

Table 9.

Acronym of the main international peer-reviewed journal.

6.2. Identified Research Patterns

After selecting articles on chemical and physical treatments of hemp fibre-reinforced cementitious composites, an additional targeted analysis was performed to identify works involving Alkaline Treatment (NaOH), Silane Treatment (SiH4), Acetylation (CH3COOH), and AKD (Alkyl Ketene Dimer), as well as self-treatment effects arising from alkaline activation. Despite a growing number of publications, no studies were found that simultaneously investigated all these treatments within a unified experimental framework.

Hemp fibres are recognised as a viable alternative for composite reinforcement, owing to their low density, renewability, and satisfactory mechanical strength. However, weak interfacial adhesion, fibre delamination, and tensile fracture remain significant challenges that limit composite performance [194]. Various chemical treatment strategies have been explored to mitigate these drawbacks.

Liu et al. [195] reported that fungal retting slightly reduced fibre tensile strength while enhancing dispersion and bonding with the cement matrix. Treatments with acetic anhydride, sodium hydroxide, silane, and maleic anhydride resulted in higher Young’s modulus and improved tensile behaviour of treated fibres compared to untreated ones [196,197]. Poletanovic et al. [198] observed that fibre incorporation (8–60 mm in diameter) reduced mortar density by approximately 5% and increased water absorption by 20% at 1% fibre content. These findings highlight the trade-off between improved flexibility and increased porosity. Other works [197,199,200] further investigated the influence of hemp fibres on mechanical and durability properties, confirming that optimised treatment parameters are crucial for enhanced performance.

6.3. Correlation Between Bibliometric and Performance Indicators

The results demonstrate that studies addressing alkaline and chemical modifications consistently report mechanical performance gains. Improvements in compressive strength (up to 30%) and flexural strength (20–25%) are typically achieved when hemp fibres are subjected to alkaline pre-treatment followed by AKD modification [37,85,90,191,192]. However, cross-study comparisons are limited due to variations in parameters such as NaOH concentration, fibre size, and curing conditions [85,90].

In contrast, in geopolymer composites (GP), the matrix’s intrinsic alkalinity promotes a self-treatment effect, which enhances fibre–matrix compatibility, even without additional chemical treatment [150,193]. This phenomenon, combined with the use of silane or acetylation agents, contributes to improved interfacial bonding, reduced porosity, and increased overall durability [37,192].

Overall, the metrics-based approach provides a structured framework linking bibliometric trends to quantifiable research impact. The concentration of highly cited studies published in journals such as Construction and Building Materials, Cement and Concrete Composites, and Sustainability underscores the consolidation of hemp composites as a growing research domain relevant to sustainable construction. These insights provide the basis for establishing standardised metrics to evaluate performance, durability, and environmental efficiency in future studies of natural fibre-reinforced composites.

7. Challenges and Future Perspectives

The potential of natural fibres for structural applications is increasingly recognised, with hemp emerging as one of the most promising reinforcements due to its high strength-to-weight ratio, low density, and renewable nature. However, several challenges remain before hemp fibre-reinforced composites can be fully integrated into mainstream civil engineering practice. Current research highlights critical concerns related to water absorption, mechanical performance, durability, and long-term sustainability [73,77,97].

The effectiveness of hemp-based cementitious composites largely depends on the fibre–matrix interface, which governs stress transfer, crack propagation, and overall structural integrity. Improving this interface requires a deeper understanding of interfacial chemistry, bonding mechanisms, and the microstructural effects of fibre treatments. Future investigations should prioritise the development of surface modifiers, including coupling agents, dispersants, and hydrophobic coatings, which are not only effective, but also economically viable and environmentally benign. Moreover, ensuring the reproducibility and scalability of these treatments is crucial for their adoption in industrial-scale production.

A major technical challenge lies in finding the optimal balance between enhancing adhesion and preserving fibre integrity. Excessively aggressive chemical treatments may degrade cellulose and reduce fibre strength, whereas mild treatments can result in insufficient bonding improvement. Consequently, systematic comparative analyses of chemical and physical surface modifications are essential to establish quantitative correlations between treatment conditions, mechanical performance, and cost-effectiveness.

Further research should also address the behaviour of hemp fibre composites under environmental stressors, including wet–dry and freeze–thaw cycles, carbonation, and chemical attack, which are key to evaluating long-term performance in realistic service conditions. Additionally, techno-economic and life-cycle assessments (LCA) must be integrated into future studies to ensure that proposed treatments are both sustainable and economically feasible.

By addressing these challenges through a combination of material science, structural testing, and environmental evaluation, the path toward standardised, high-performance hemp composites can be consolidated, enabling their use in sustainable and disaster-resilient construction.

8. Conclusions

This review presented a comprehensive evaluation of hemp fibres in natural fibre-reinforced composites (NFRCs), focusing primarily on cementitious and geopolymeric matrices. The analysis demonstrated that the mechanical and durability performance of hemp-based composites is strongly influenced by fibre surface modification, which governs interfacial adhesion, stress transfer efficiency, and long-term stability. Improper or excessive treatments can damage the cellulose microstructure, leading to a reduction in composite strength and durability, underscoring the importance of treatment optimisation.

Among chemical approaches, alkaline, silane, and alkyl ketene dimer (AKD) treatments exhibited the most notable improvements in both compressive and flexural strength, as well as enhanced fibre–matrix compatibility. Meanwhile, physical modification techniques, such as plasma and ozone treatments, have shown potential to increase surface roughness and chemical reactivity without compromising fibre integrity. Furthermore, the incorporation of nanoparticles as surface modifiers has emerged as a promising pathway for reducing water absorption and enhancing interfacial adhesion, thus contributing to the development of high-performance and sustainable composites.