Physical Modeling of a Novel Rigid Bottom Wall to Mitigate the Damage of Shallow Tunnels in Normal Faults

Abstract

1. Introduction

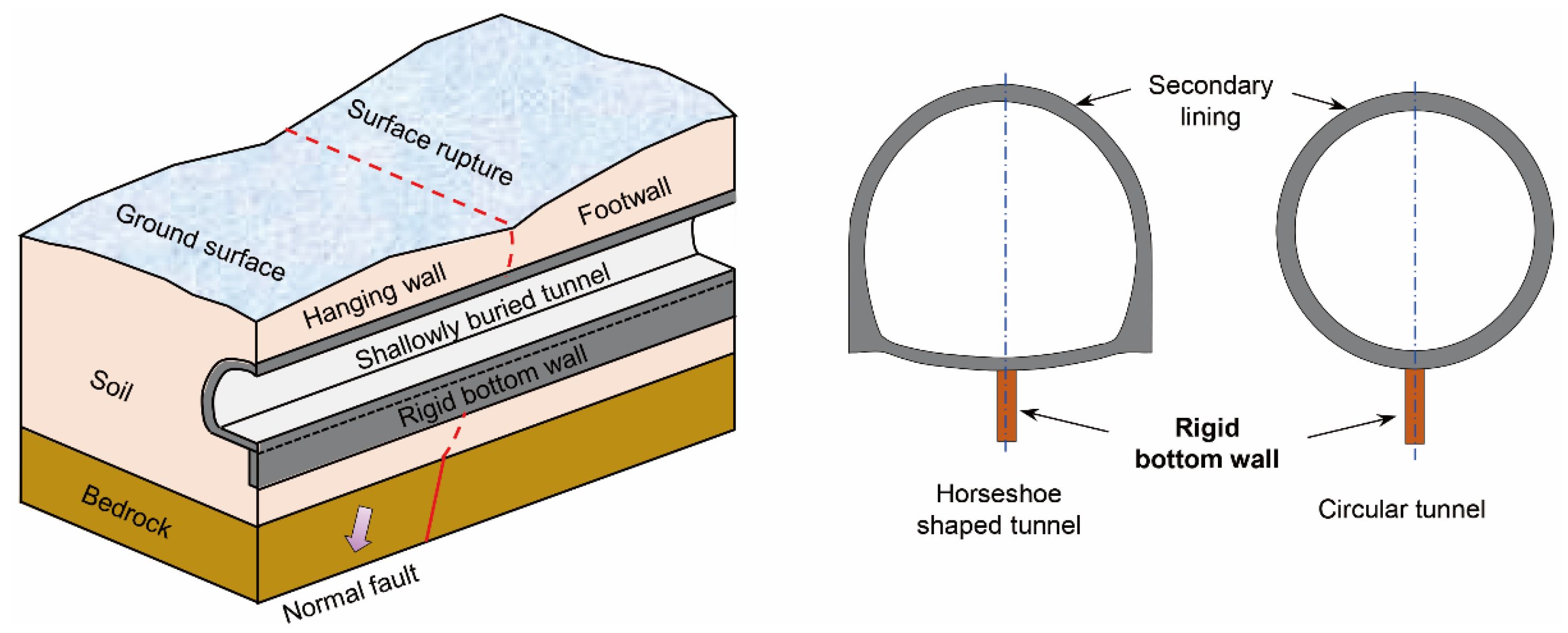

2. A Novel Rigid Bottom Wall

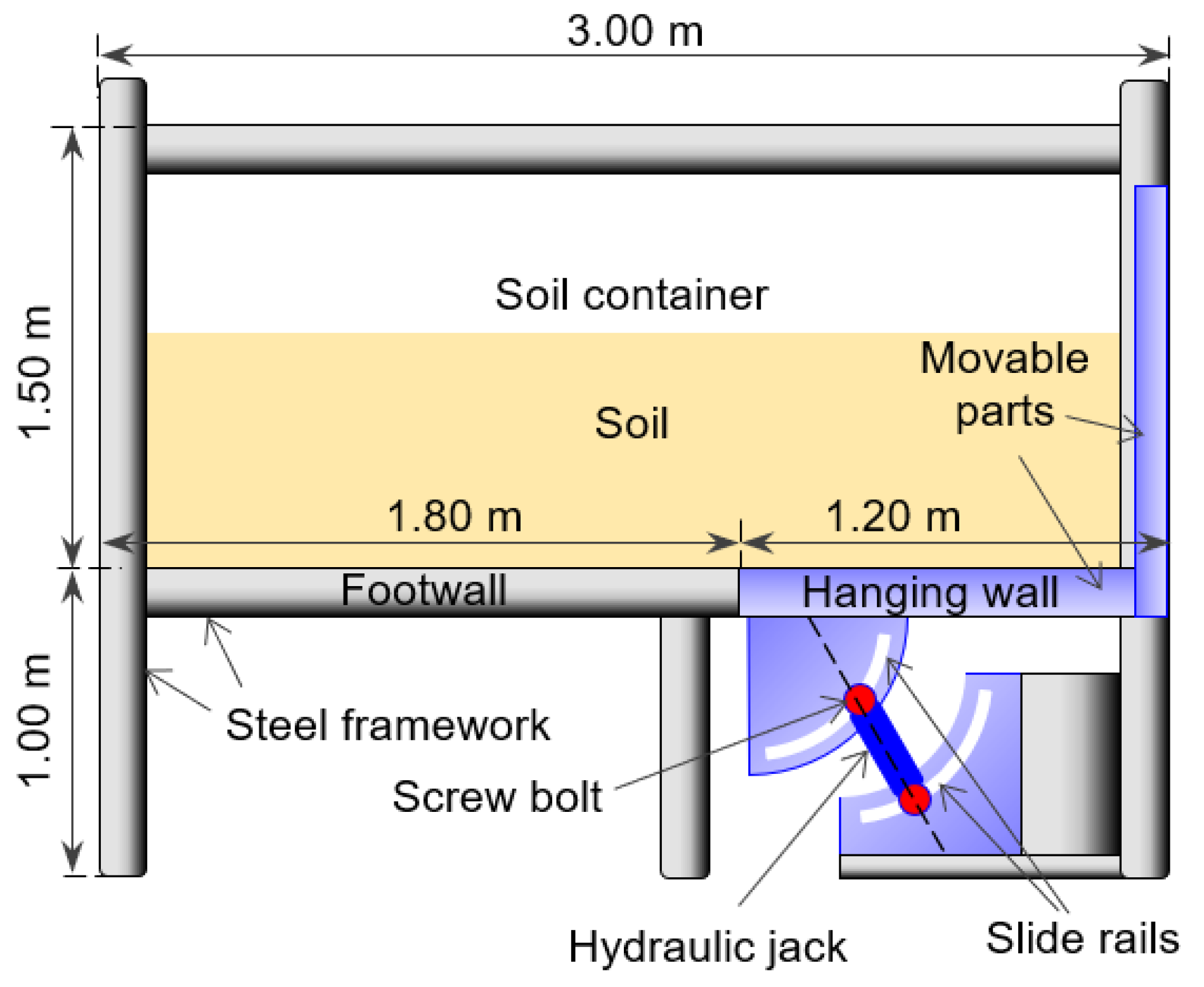

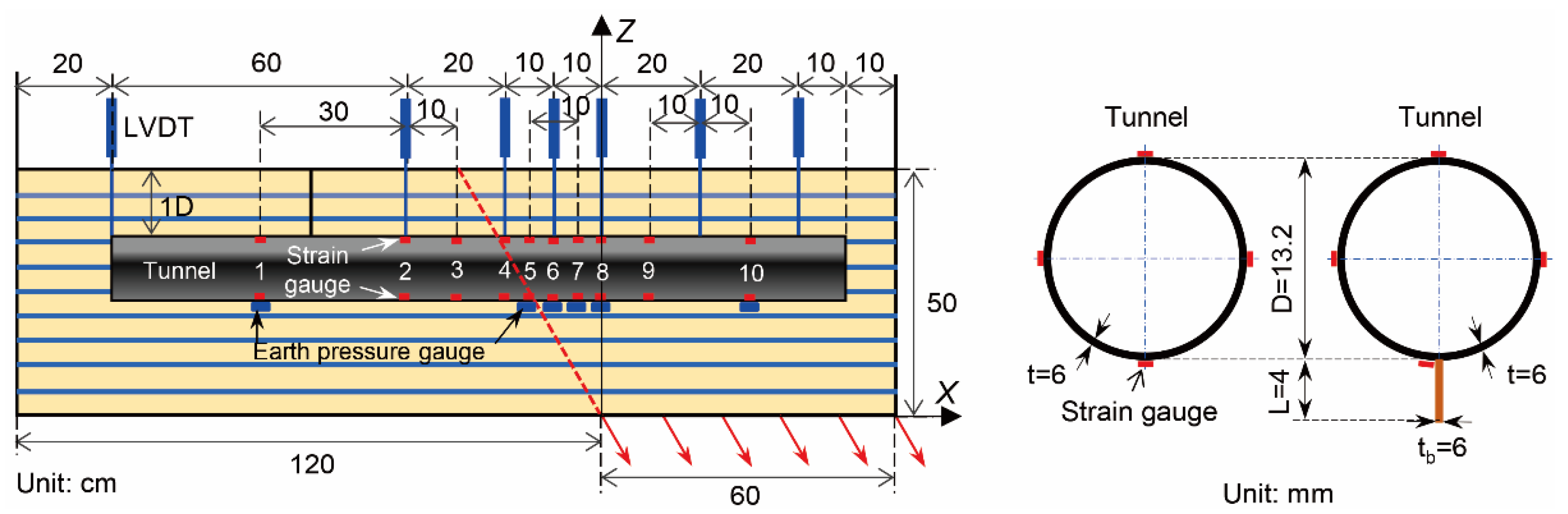

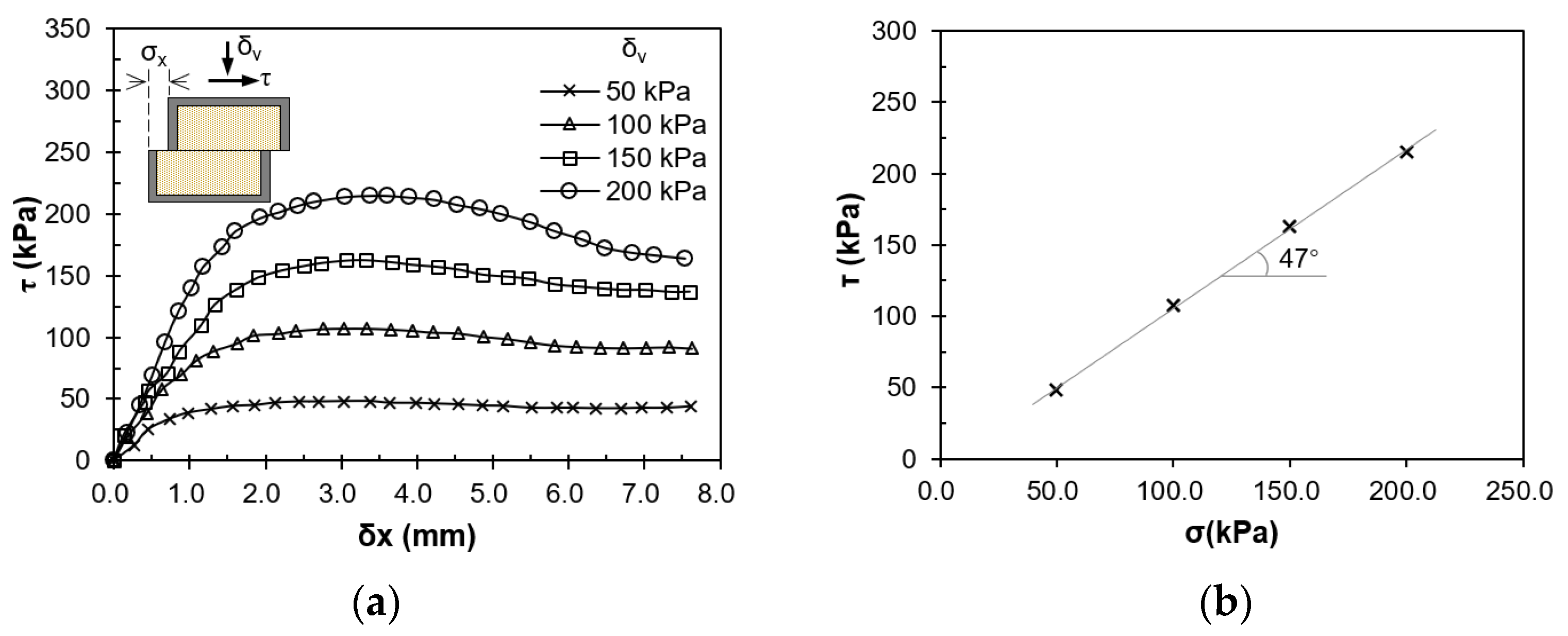

3. Physical Modeling

4. Results and Discussions

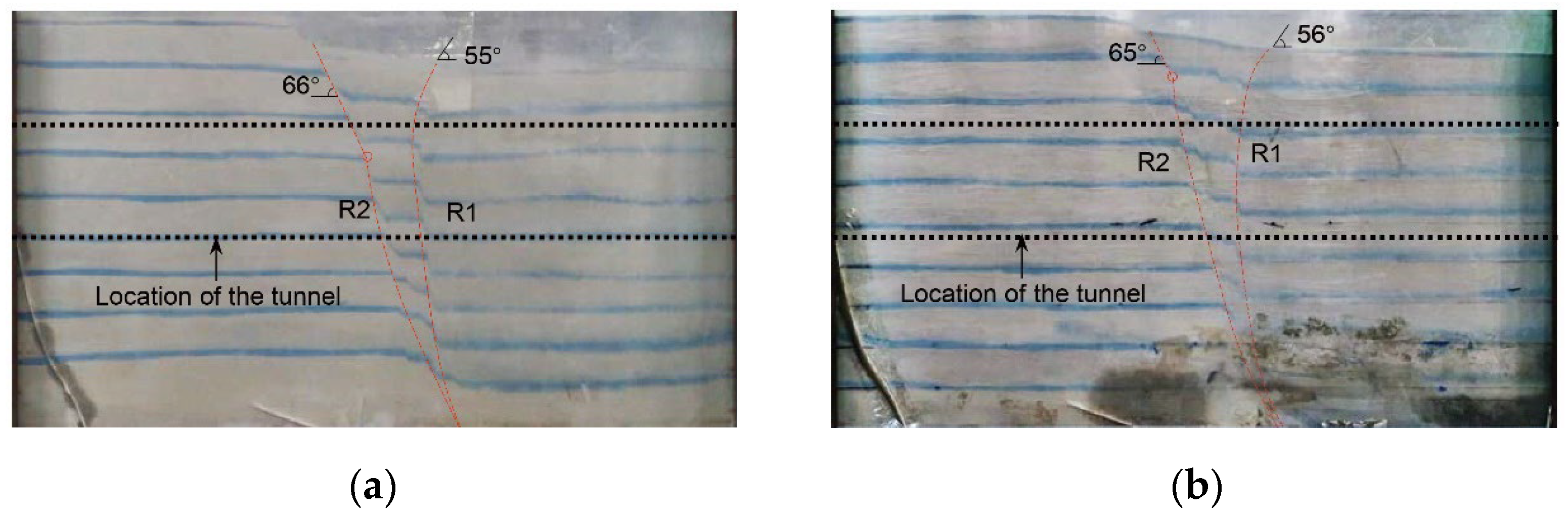

4.1. Fault Rupture Propagation

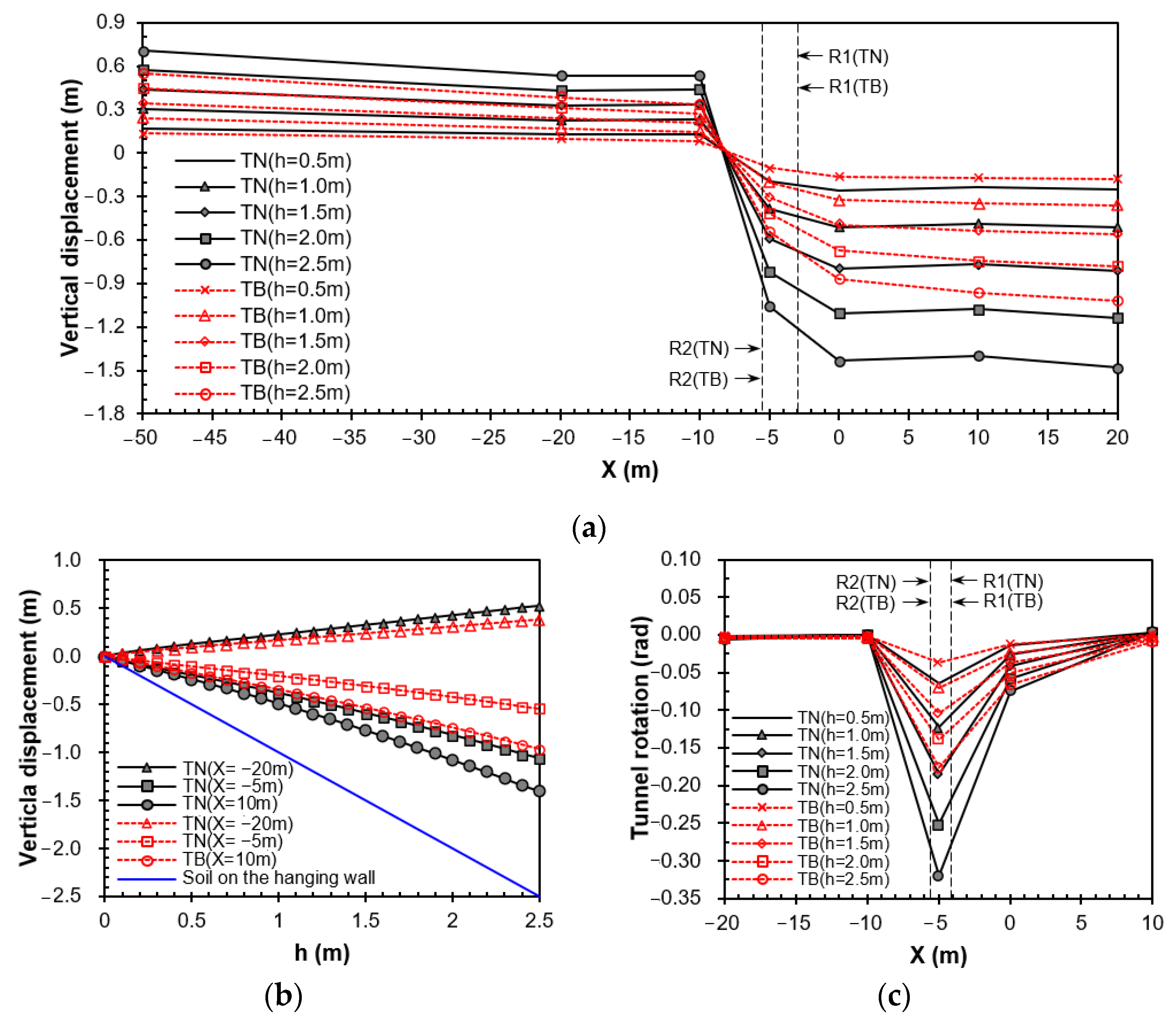

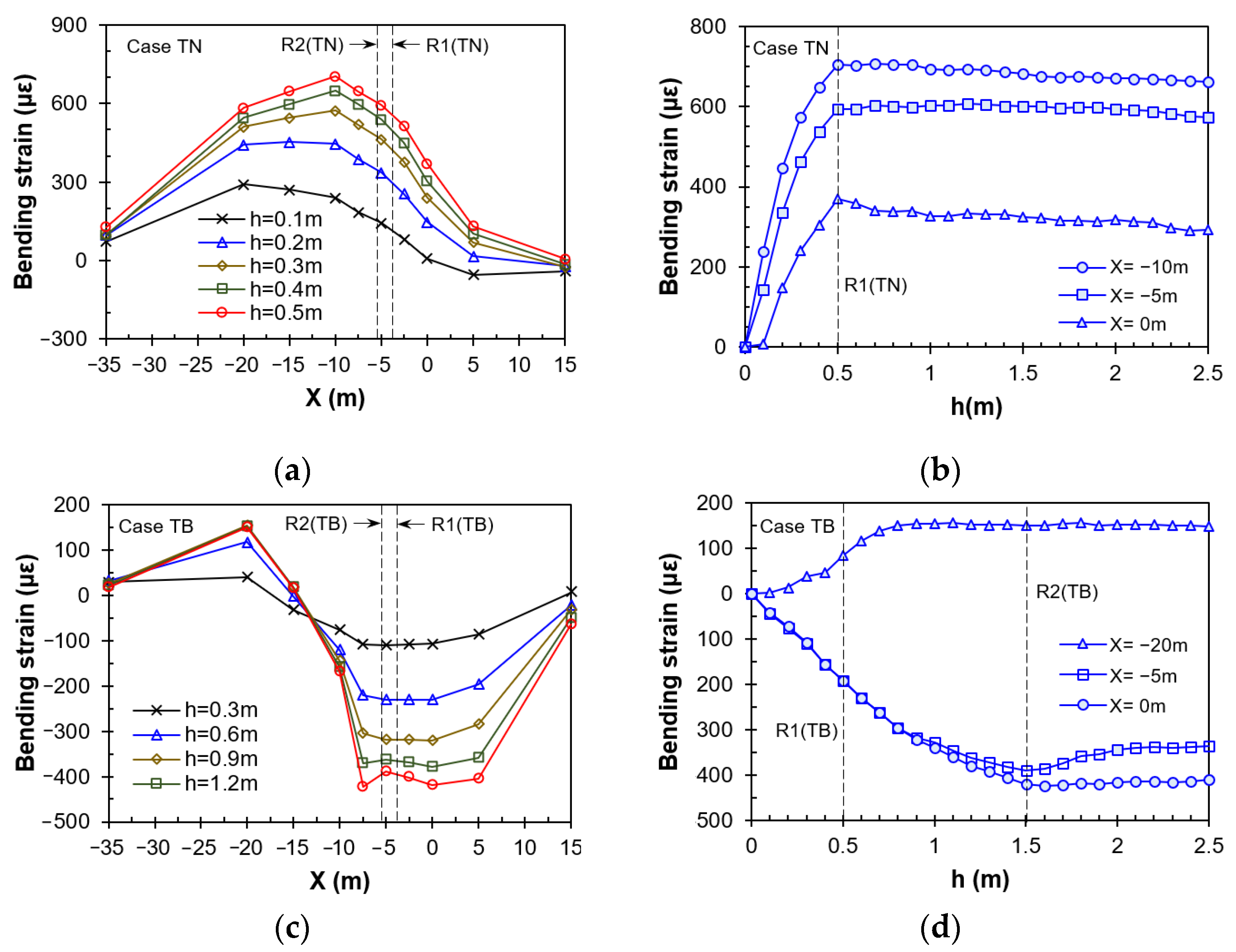

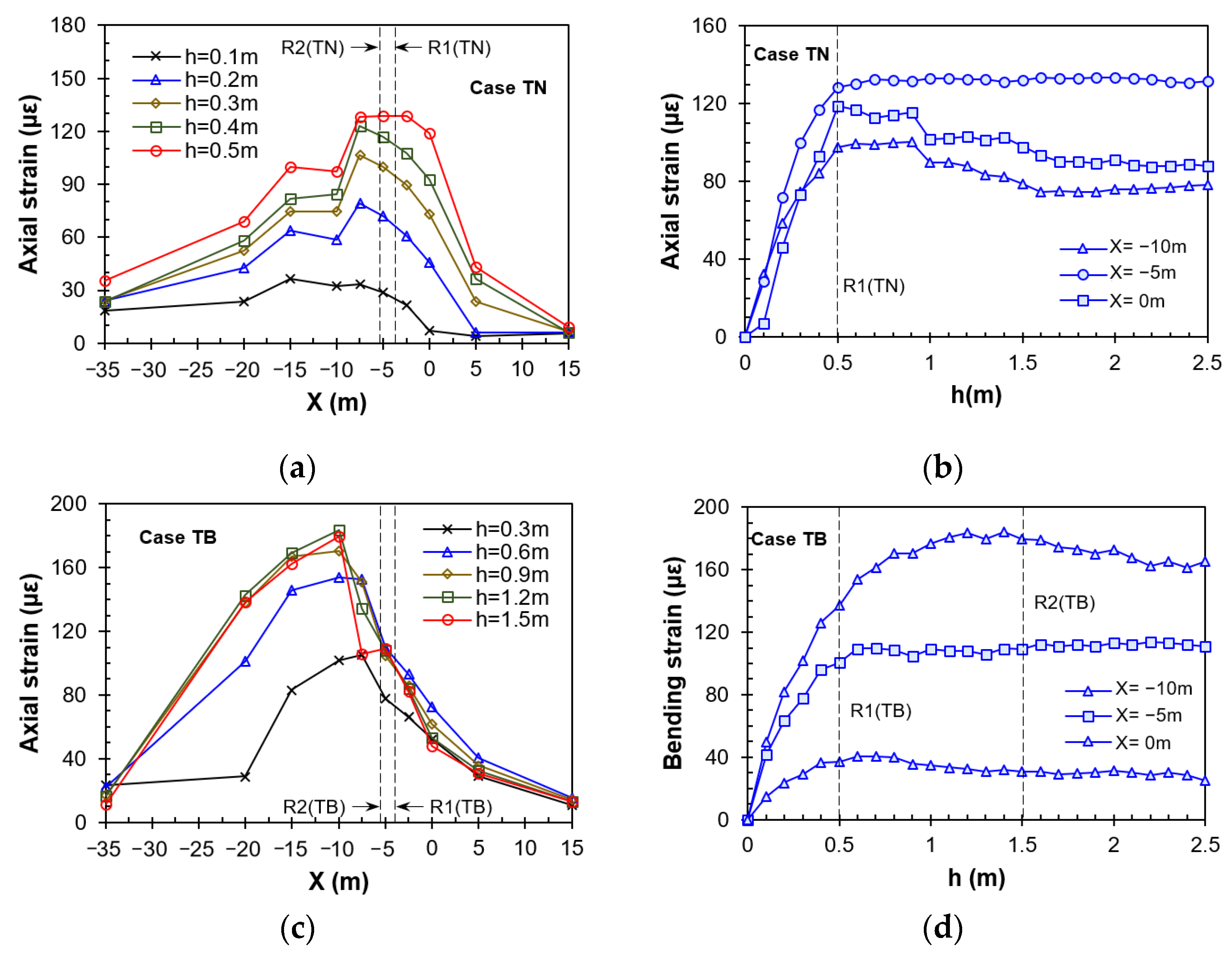

4.2. Tunnel Behaviors

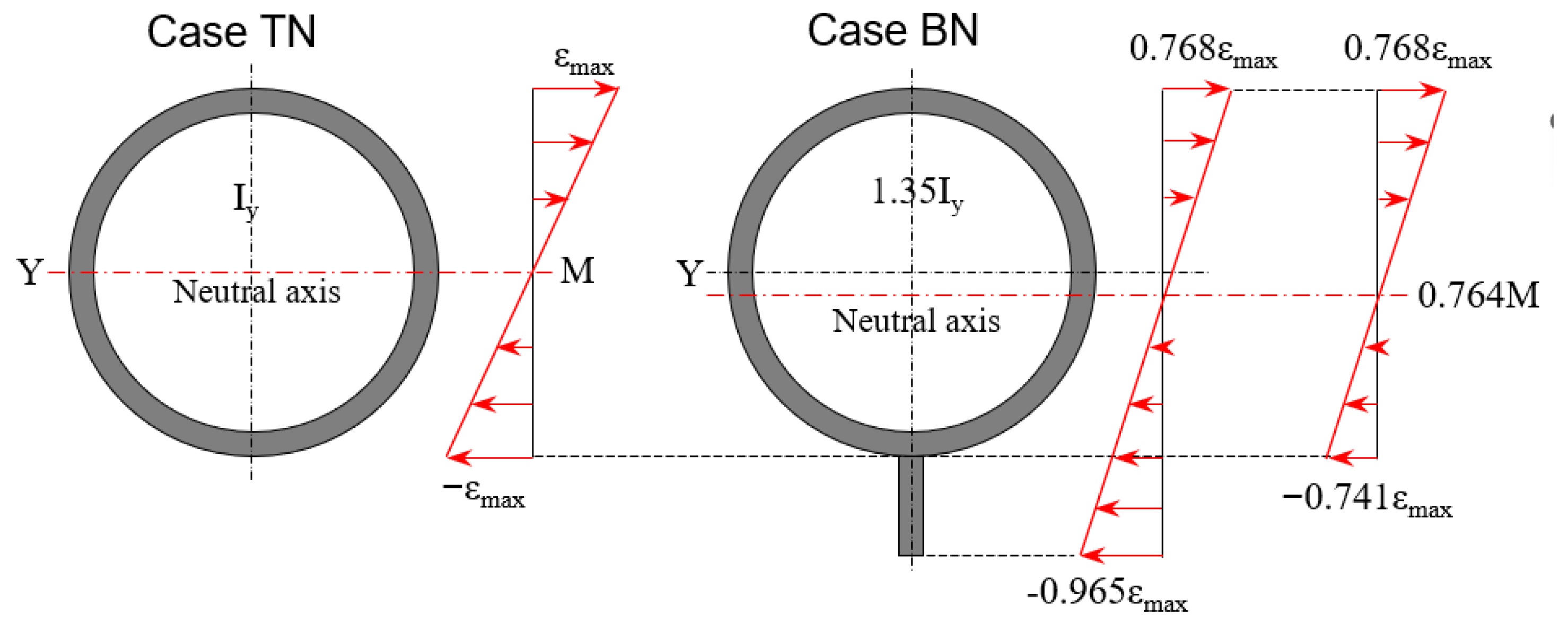

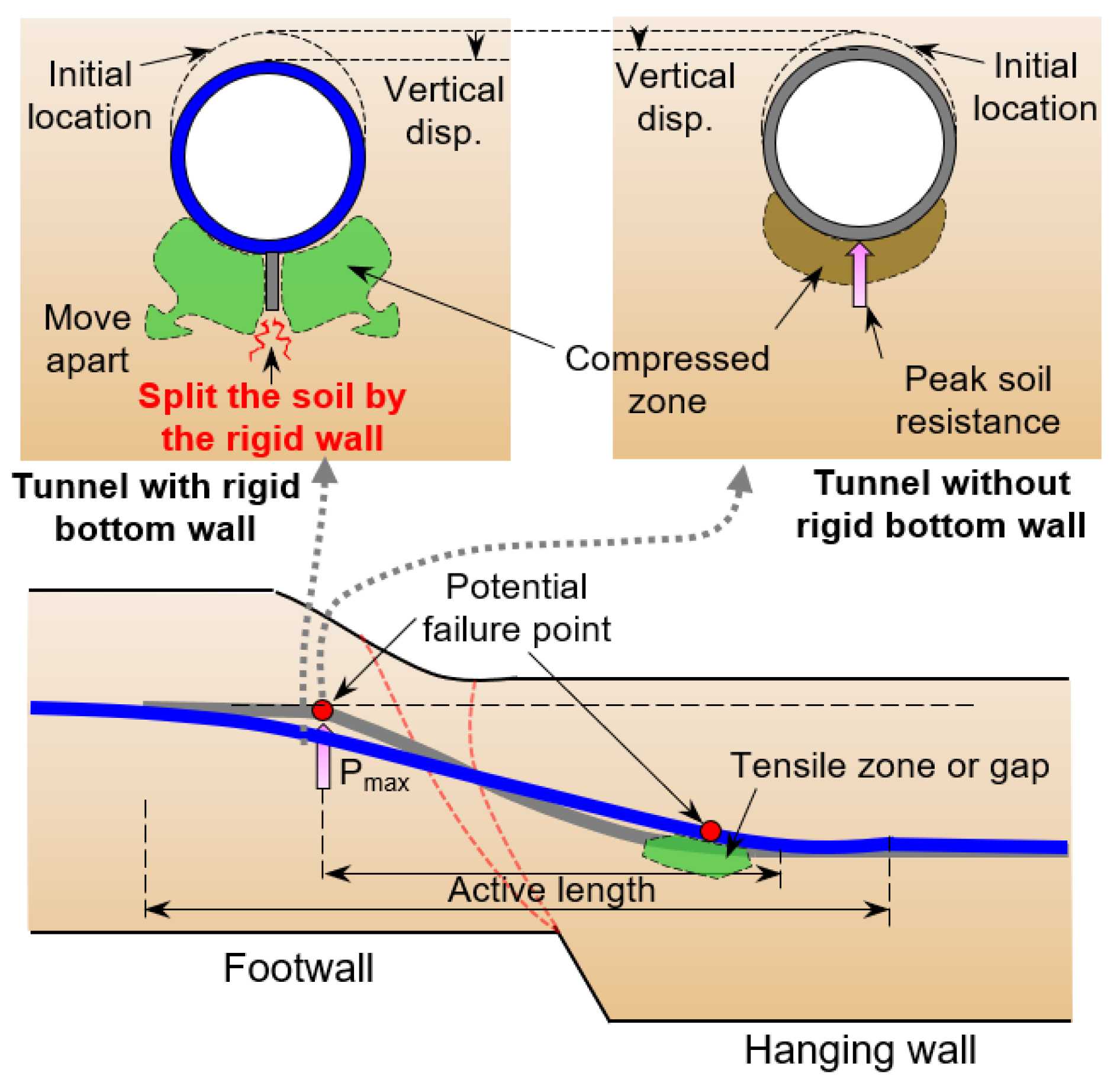

4.3. Possible Mechanisms

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, W.L.; Wang, T.T.; Su, J.J.; Lin, C.H.; Seng, C.R.; Huang, T.H. Assessment of Damage in Mountain Tunnels Due to the Taiwan Chi-Chi Earthquake. Tunn. Undergr. Space Technol. 2001, 16, 133–150. [Google Scholar] [CrossRef]

- Anastasopoulos, I.; Gazetas, G. Analysis of Cut-and-Cover Tunnels against Large Tectonic Deformation. Bull. Earthq. Eng. 2010, 8, 283–307. [Google Scholar] [CrossRef]

- Yao, C.; Duan, J.; Liu, Y.; He, C.; Liu, Y.; Yang, W.; Yan, Q.; Luo, W. Tunnels Crossing Active Faults: A Review of Case Histories and Modeling Methods. Tunn. Undergr. Space Technol. 2026, 168, 107086. [Google Scholar] [CrossRef]

- Huang, S.; Xin, C.; Song, D.; Feng, W.; Liu, X.; Wang, E.; Xu, T.; Xiong, X. Resilience Assessment of the Seismic Damage Mechanism of the Daliang High-Speed Railway Tunnel in the 2022 Menyuan Earthquake (Mw 6.7) in China. Transp. Geotech. 2024, 49, 101417. [Google Scholar] [CrossRef]

- Chen, P.; Geng, P.; Chen, J.; Gu, W. The Seismic Damage Mechanism of Daliang Tunnel by Fault Dislocation during the 2022 Menyuan Ms6.9 Earthquake Based on Unidirectional Velocity Pulse Input. Eng. Fail. Anal. 2023, 145, 107047. [Google Scholar] [CrossRef]

- Tao, L.; Wang, Z.; Shi, C.; Zhang, H. Investigation of the Longitudinal Mechanical Response of Pipeline or Tunnel under Reverse Fault Dislocation. Rock Mech. Rock Eng. 2023, 56, 6237–6259. [Google Scholar] [CrossRef]

- Zhang, X.; Yu, L.; Wang, M.; Yang, H. Mechanical Response and Failure Characteristics of Tunnels Subjected to Reverse Faulting with Nonuniform Displacement: Theoretical and Numerical Investigation. Eng. Fail. Anal. 2024, 156, 107809. [Google Scholar] [CrossRef]

- Zhang, S.; Li, Z.; Bu, R.; Shen, M. Nonlinear Structural Responses of the Buried Oval Steel Pipelines Crossing Strike-Slip Faults. Structures 2024, 69, 107366. [Google Scholar] [CrossRef]

- Gao, J.; Wang, Q.; Wang, R.; Yang, J.; Yang, Y. Model Test Study on the Deformation and Failure Characteristics of Mountain Tunnel under a Strike-Slip Fault Dislocation. Structures 2024, 60, 105903. [Google Scholar] [CrossRef]

- Schaumann, M.; Gamba, D.; Garcia Morales, H.; Corsini, R.; Guinchard, M.; Scislo, L.; Wenninger, J. The Effect of Ground Motion on the LHC and HL-LHC Beam Orbit. Nucl. Instrum. Methods Phys. Res. A 2023, 1055, 168495. [Google Scholar] [CrossRef]

- Ji, Y.; Chen, Y.; Hofmann, H.; Zhang, Y.; Zang, A.; Zimmermann, G. The Role of Temperature-enhanced Fault Closure in Promoting Postinjection Pressure Diffusion and Seismicity in Enhanced Geothermal Systems. Deep. Undergr. Sci. Eng. 2023, 2, 394–405. [Google Scholar] [CrossRef]

- Han, X.; Li, W. Numerical Analysis on the Structure Type and Mechanical Response of Tunnel Crossing Active Reverse Fault. Geofluids 2021, 5513042. [Google Scholar] [CrossRef]

- Zaheri, M.; Ranjbarnia, M.; Dias, D.; Oreste, P. Performance of Segmental and Shotcrete Linings in Shallow Tunnels Crossing a Transverse Strike-Slip Faulting. Transp. Geotech. 2020, 23, 100333. [Google Scholar] [CrossRef]

- Shen, Y.S.; Wang, Z.Z.; Yu, J.; Zhang, X.; Gao, B. Shaking Table Test on Flexible Joints of Mountain Tunnels Passing through Normal Fault. Tunn. Undergr. Space Technol. 2020, 98, 103299. [Google Scholar] [CrossRef]

- Shi, X.; Feng, X.; Shi, T. Novel Corrugated Tube–Rubber–Concrete Flexible Joint for Lining Water Conveyance Tunnels Crossing Reverse Faults: Numerical Analysis of Dislocation Resistance Performance. Tunn. Undergr. Space Technol. 2024, 144, 105556. [Google Scholar] [CrossRef]

- Zhang, J.; Cui, Z.; Sheng, Q.; Zhao, W.; Song, L. Experimental Study on the Effect of Flexible Joints of a Deep-Buried Tunnel across an Active Fault under High in-Situ Stress Conditions. Undergr. Space 2024, 19, 189–207. [Google Scholar] [CrossRef]

- Baziar, M.H.; Nabizadeh, A.; Jung Lee, C.; Yi Hung, W. Centrifuge Modeling of Interaction between Reverse Faulting and Tunnel. Soil Dyn. Earthq. Eng. 2014, 65, 151–164. [Google Scholar] [CrossRef]

- Nabizadeh, A.; Mojtahedi, A.S. Centrifuge Modeling of Normal Faulting and Underground Tunnel in Sandy Soil Deposit. Soils Rocks 2021, 44, e2021059520. [Google Scholar] [CrossRef]

- Cividini, A.; Gioda, G.; Petrini, V. Finite Element Evaluation of the Effects of Faulting on a Shallow Tunnel in Alluvial Soil. Acta Geotech. 2010, 5, 113–120. [Google Scholar] [CrossRef]

- Aghamolaei, M.; Saeedi Azizkandi, A.; Khorashadizadeh, M. Evaluation of the Mechanical Response of Tunnel Lining Induced by Reverse Faulting Using Numerical Simulations. Int. J. Civil. Eng. 2023, 21, 1739–1750. [Google Scholar] [CrossRef]

- Wu, X.; Nie, C.; Li, D.; Qiu, F.; Tang, Y. Structural Response of a Prefabricated Utility Tunnel Subject to a Reverse Fault. Buildings 2022, 12, 1086. [Google Scholar] [CrossRef]

- Mehrabi, R.; Baziar, M.H.; Nabizadeh, A.; Hung, W.Y. Discrete-Element Modelling of Underground Tunnel Response to Reverse Fault Rupture in Sand. Proc. Inst. Civil. Eng.–Geotech. Eng. 2021, 176, 356–368. [Google Scholar] [CrossRef]

- Ghadimi Chermahini, A.; Tahghighi, H. Numerical Finite Element Analysis of Underground Tunnel Crossing an Active Reverse Fault: A Case Study on the Sabzkouh Segmental Tunnel. Geomech. Geoengin. 2019, 14, 155–166. [Google Scholar] [CrossRef]

- Baziar, M.H.; Nabizadeh, A.; Mehrabi, R.; Lee, C.J.; Hung, W.Y. Evaluation of Underground Tunnel Response to Reverse Fault Rupture Using Numerical Approach. Soil Dyn. Earthq. Eng. 2016, 83, 1–17. [Google Scholar] [CrossRef]

- Yao, C.; Yan, Q.; Sun, M.; Zhang, J.; He, C. Analysis of a Novel Subway Station Structure to Mitigate Damages Induced by Normal Faulting. Soil Dyn. Earthq. Eng. 2020, 136, 106246. [Google Scholar] [CrossRef]

- Yao, C.; Yan, Q.; Sun, M.; Dong, W.; Guo, D. Rigid Diaphragm Wall with a Relief Shelf to Mitigate the Deformations of Soil and Shallow Foundations Subjected to Normal Faulting. Soil Dyn. Earthq. Eng. 2020, 137, 106264. [Google Scholar] [CrossRef]

- Yao, C.; Luo, W.; Zhang, Y.; He, C.; Li, Y.; Yang, W.; Liu, Y.; Yuan, R. Inclined Rigid Sliding Walls to Protect Tunnels Subjected to Reverse Faulting. Comput. Geotech. 2023, 164, 105824. [Google Scholar] [CrossRef]

- Yao, C.; Luo, W.; Zhang, Y.; He, C.; Yang, W.; Zhang, J.; Yan, Q. A Novel Structural System to Protect Pipe-Jacking Tunnel Subjected to Normal Faulting: Physical Modeling. Tunn. Undergr. Space Technol. 2025, 157, 106349. [Google Scholar] [CrossRef]

- Yao, C.; Zhang, Y.; He, C.; Kang, X.; Yang, W.; Geng, P.; Wang, T. An Anti-Rotation Shelf to Mitigate the Rotation of Shield Tunnels Subjected to Normal Faulting. Comput. Geotech. 2023, 156, 105297. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, M.; Li, Z.; Yu, L.; Yang, H. Mechanical Response of Tunnels Crossing Active Fault Zones under Normal or Reverse Faulting: A Refined Nonlinear Analytical Approximate Solution. Comput. Geotech. 2024, 167, 106028. [Google Scholar] [CrossRef]

- Wang, Z.; Zhong, Z.; Zhao, M.; Du, X.; Huang, J.; Wang, H. Experimental Study on Mechanical Behavior and Countermeasures of Mountain Tunnels under Strike-Slip Fault Movement. Undergr. Space 2025, 21, 1–21. [Google Scholar] [CrossRef]

- Ba, Z.; Wang, Y.; Li, D. Numerical Investigation on Seismic Damage of Tunnels Subjected to Fault Dislocation Using the FDM-DEM Approach. Comput. Geotech. 2025, 182, 107169. [Google Scholar] [CrossRef]

- Cheng, T.; Yao, C.; Duan, J.; He, C.; Xu, H.; Yang, W.; Yan, Q. Prediction of Active Length of Pipes and Tunnels under Normal Faulting with XGBoost Integrating a Complexity-Performance Balanced Optimization Approach. Comput. Geotech. 2025, 179, 107048. [Google Scholar] [CrossRef]

- Melissianos, V.E.; Lignos, X.A.; Bachas, K.K.; Gantes, C.J. Experimental Investigation of Pipes with Flexible Joints under Fault Rupture. J. Constr. Steel Res. 2017, 128, 633–648. [Google Scholar] [CrossRef]

- Kaya, E.S.; Uckan, E.; Taciroglu, E. Damage Mitigation of Fault-Crossing Elbowed Water Transmission Pipes Using Flexible Joints. Soil Dyn. Earthq. Eng. 2026, 200, 109845. [Google Scholar] [CrossRef]

- Rojhani, M.; Moradi, M.; Derakhshani, A. Innovative Mitigation Method for Buried Pipelines Crossing Faults. Earthq. Eng. Eng. Vib. 2022, 21, 1089–1101. [Google Scholar] [CrossRef]

- Rasouli, H.; Fatahi, B. Geofoam Blocks to Protect Buried Pipelines Subjected to Strike-Slip Fault Rupture. Geotext. Geomembr. 2020, 48, 257–274. [Google Scholar] [CrossRef]

- Wang, T.; Geng, P.; Li, P.; Wang, Q.; Wang, L. Deformation and Failure of Overburden Soil Subjected to Normal Fault Dislocation and Its Impact on Tunnel. Eng. Fail. Anal. 2022, 142, 106747. [Google Scholar] [CrossRef]

- Bolton, M.D. The Strength and Dilatancy of Sands. Géotechnique 1986, 36, 65–78. [Google Scholar] [CrossRef]

- Jardine, R.J.; Potts, D.M.; Fourie, A.B.; Burland, J.B. Studies of the Influence of Non-Linear Stress–Strain Characteristics in Soil–Structure Interaction. Géotechnique 1986, 36, 377–396. [Google Scholar] [CrossRef]

- Cole, D.A.; Lade, P.V. Influence Zones in Alluvium Over Dip-Slip Faults. J. Geotech. Eng. 1984, 110, 599–615. [Google Scholar] [CrossRef]

- Lade, P.V.; Cole, D.A.; Cummings, D. Multiple Failure Surfaces Over Dip-Slip Faults. J. Geotech. Eng. 1984, 110, 616–627. [Google Scholar] [CrossRef]

- Stone, K.J.L.; Wood, D.M. Effects of Dilatancy and Particle Size Observed in Model Tests on Sand. Soils Found. 1992, 32, 43–57. [Google Scholar] [CrossRef]

- Yao, C.; Takemura, J.; Ma, G.; Dai, C.; An, Z. Effect of Boundary Friction on Revere Fault Rupture Propagation in Centrifuge Tests. Soil Dyn. Earthq. Eng. 2021, 147, 106811. [Google Scholar] [CrossRef]

- Yao, C.; Takemura, J.; Zhang, J. Centrifuge Modeling of Single Pile-Shallow Foundation Interaction in Reverse Fault. Soil Dyn. Earthq. Eng. 2021, 141, 106538. [Google Scholar] [CrossRef]

- Kiani, M.; Akhlaghi, T.; Ghalandarzadeh, A. Experimental Modeling of Segmental Shallow Tunnels in Alluvial Affected by Normal Faults. Tunn. Undergr. Space Technol. 2016, 51, 108–119. [Google Scholar] [CrossRef]

- Cai, Q.P.; Peng, J.M.; Ng, C.W.W.; Shi, J.W.; Chen, X.X. Centrifuge and Numerical Modelling of Tunnel Intersected by Normal Fault Rupture in Sand. Comput. Geotech. 2019, 111, 137–146. [Google Scholar] [CrossRef]

- Rostami, H.; Osouli, A.; Kumar, S. Experimental Modeling of Far-Field Effects in Buried Pipelines Subjected to Reverse Faulting. Soil Dyn. Earthq. Eng. 2023, 164, 107561. [Google Scholar] [CrossRef]

- Ha, D.; Abdoun, T.H.; O’Rourke, M.J.; Symans, M.D.; O’Rourke, T.D.; Palmer, M.C.; Stewart, H.E. Buried High-Density Polyethylene Pipelines Subjected to Normal and Strike-Slip Faulting—A Centrifuge Investigation. Can. Geotech. J. 2008, 45, 1733–1742. [Google Scholar] [CrossRef]

- Moradi, M.; Rojhani, M.; Galandarzadeh, A.; Takada, S. Centrifuge Modeling of Buried Continuous Pipelines Subjected to Normal Faulting. Earthq. Eng. Eng. Vib. 2013, 12, 155–164. [Google Scholar] [CrossRef]

- Saiyar, M.; Ni, P.; Take, W.A.; Moore, I.D. Response of Pipelines of Differing Flexural Stiffness to Normal Faulting. Géotechnique 2016, 66, 275–286. [Google Scholar] [CrossRef]

- Yao, C.; He, C.; Huang, X.; Takemura, J.; Yang, W.; An, Z. Response of a Continuous Pipeline in Sand Subjected to Normal Faulting. Transp. Geotech. 2022, 36, 100824. [Google Scholar] [CrossRef]

- Li, H.; Li, X.; Liu, H. Deformation and Failure Mechanism of Metro Shield Tunnel Subjected to Buried Fault Dislocation. Eng. Fail. Anal. 2023, 153, 107551. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, Y.; Wei, R.; Yin, C.; Zhang, H. The Damage Mode and Forced Response Characteristics of Articulated Lining Structure: A Case Study of Metro Tunnel under a Reverse Fault Action. Tunn. Undergr. Space Technol. 2023, 140, 105246. [Google Scholar] [CrossRef]

- Tsatsis, A.; Loli, M.; Gazetas, G. Pipeline in Dense Sand Subjected to Tectonic Deformation from Normal or Reverse Faulting. Soil Dyn. Earthq. Eng. 2019, 127, 105780. [Google Scholar] [CrossRef]

- Sabagh, M.; Ghalandarzadeh, A. Centrifugal Modeling of Continuous Shallow Tunnels at Active Normal Faults Intersection. Transp. Geotech. 2020, 22, 100325. [Google Scholar] [CrossRef]

| Conditions | Measures | Structures | References |

|---|---|---|---|

| Structures paralleling the fault planes | Diaphragm wall | Subway station | [25,26] |

| Inclined sliding wall | Tunnel | [27] | |

| Anti-rotation shelf | Tunnel | [28,29] | |

| Structures crossing faults | flexible joints | Tunnel or pipe | [34,35] |

| low-density gravel with high porosity | Pipe | [36] | |

| geofoam blocks | Pipe | [37] | |

| pumice with high porosity | Pipe | [36] |

| Scale | Outer Diameter, D | Inner Diameter, d | Thickness, t | Height of Wall, L | Thickness of the Wall, tb | Unit Weight, γ | Young’s Modulus, E | Yielding Stress, σy |

|---|---|---|---|---|---|---|---|---|

| Model | 132 mm | 120 mm | 6 mm | 40 mm | 6 mm | 1.2 kN/m3 | 2.46 GPa | 50 MPa |

| Prototype | 3.30 m | 3.00 m | 0.15 m | 1.00 m | 0.15 m | 25 kN/m3 | 34.5 GPa | 59 MPa |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yao, C.; Liu, Y.; Zhang, Y.; Liu, S.; Yang, W.; Guo, D. Physical Modeling of a Novel Rigid Bottom Wall to Mitigate the Damage of Shallow Tunnels in Normal Faults. Buildings 2025, 15, 4156. https://doi.org/10.3390/buildings15224156

Yao C, Liu Y, Zhang Y, Liu S, Yang W, Guo D. Physical Modeling of a Novel Rigid Bottom Wall to Mitigate the Damage of Shallow Tunnels in Normal Faults. Buildings. 2025; 15(22):4156. https://doi.org/10.3390/buildings15224156

Chicago/Turabian StyleYao, Chaofan, Yulin Liu, Yifei Zhang, Suyuan Liu, Wenbo Yang, and Deping Guo. 2025. "Physical Modeling of a Novel Rigid Bottom Wall to Mitigate the Damage of Shallow Tunnels in Normal Faults" Buildings 15, no. 22: 4156. https://doi.org/10.3390/buildings15224156

APA StyleYao, C., Liu, Y., Zhang, Y., Liu, S., Yang, W., & Guo, D. (2025). Physical Modeling of a Novel Rigid Bottom Wall to Mitigate the Damage of Shallow Tunnels in Normal Faults. Buildings, 15(22), 4156. https://doi.org/10.3390/buildings15224156